Tevo 3d printer review

TEVO Tarantula Review 2022 - Is This 3D Printer Worth The Money?

3.4

See Price

Choosing a budget 3D printer is tough. If you’re new to the hobby, you might not know which specifications are important, and which are only mentioned to draw your attention away from other things. The good news is that you don’t have to spend hours on research: we’ve done it for you.

Today, we’re looking at a popular entry-level printer, the TEVO Tarantula. We’ll be highlighting this model’s strengths and weaknesses in the hopes of giving you all the information you’ll need to decide if the Tarantula is right for you. Without further ado, let’s begin.

| Filament Diameter | 1.75mm |

| Extruders | 1 |

| Supported Materials | PLA, ABS, PETG, PVA, Exotics |

| Connectivity | USB, SD Card |

| Printing Speed | 150mm/s |

| Build Volume | 7. |

Table of ContentsShow

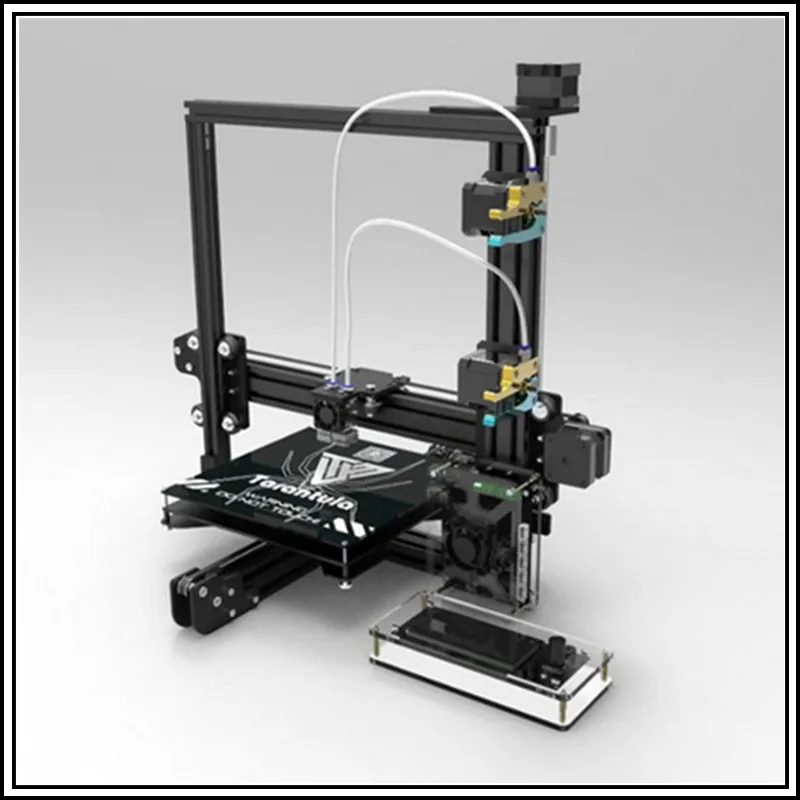

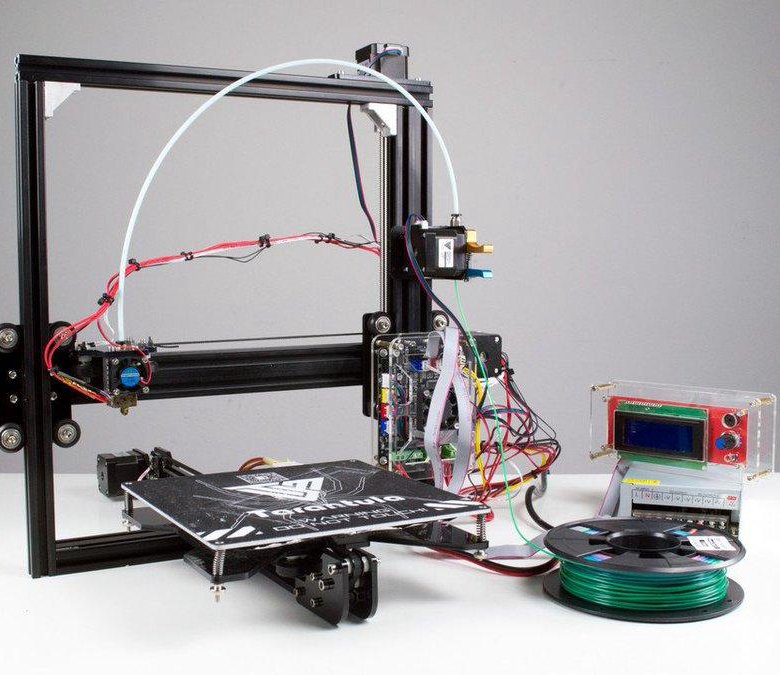

Design

First of all, you should know that this printer has to be assembled from parts. Still, the construction is fairly straightforward, if a little time-consuming. When it’s complete, you’ll notice that the build area is pretty big for a printer in this price range. Simply, that’s never a bad thing.

On the other hand, there are a few structural complaints. The frame is a little flimsy and prone to wobbling during prints, the print bed is absurdly sticky, and the bed-leveling mechanism isn’t as stable as we’d like. Still, these issues can be solved with a bit of preparation, so they’re not total deal-breakers.

Because the entire unit is so open and accessible, there’s a lot of scope for modifications. Some of these (like additional support brackets) can actually help offset some of the issues we discussed earlier, although really, you shouldn’t have to. You can even add WiFi support to complement the USB and SD card interfaces if you’d like.

Printing

Due to the lack of a cooling fan, it’s hard to print with anything other than PLA at first. The temperature is just too inconsistent. However, once you add a fan, it’s possible to create decent models at reasonable speeds. Make no mistake: this is not a pro-level printer, but it’ll do fine for around the home or office.

The Tarantula does have layer integration going for it though. You can print as finely as 50 microns, at which point the layers are barely perceptible, assuming you’ve set the printer up properly. However, it can be difficult to achieve a perfect print since the Tarantula is prone to spool tangles, heating issues, and sticking.

Initially, we were impressed by the range of materials that this printer could handle. That said, there are just too many variables to look after, at least initially. We’d recommend sticking with the basic filaments until you get a feel for this model’s quirks.

Features

As far as functionality goes, this is a pretty bare-bones printer. There’s a small screen so you can control prints when not connected to a PC, but that’s about it. Indeed, the features that get people excited online seem to be the ones they’ve added personally.

There’s a small screen so you can control prints when not connected to a PC, but that’s about it. Indeed, the features that get people excited online seem to be the ones they’ve added personally.

At the very least, there is a heated print bed. In theory, this should help keep your prints in place, but in practice, it can be extremely difficult to remove them once completed. If you like to tinker, this may be a good long-term project, but if you just want something that works consistently, the Tarantula probably won’t cut it.

There is one saving grace: the build volume is larger than you’d usually find on an entry-level printer. That said, whether you’ll get any advantage from this is unclear, given how often the Tarantula encounters problems.

Cost

It’s true that the TEVO Tarantula is one of the least expensive 3D printers on the market. You can pick one up for around $200, and its running costs are fairly low too, thanks to its ability to use third-party materials. However, what you save in cash, you pay for with your time.

However, what you save in cash, you pay for with your time.

Remember that you’ll have to build this printer from a kit, a process that can take days if you’re inexperienced. Additionally, some users have reported their kits to arrive without essential components, or with parts that don’t fit. As such, be prepared to spend a couple more days waiting for replacements to arrive.

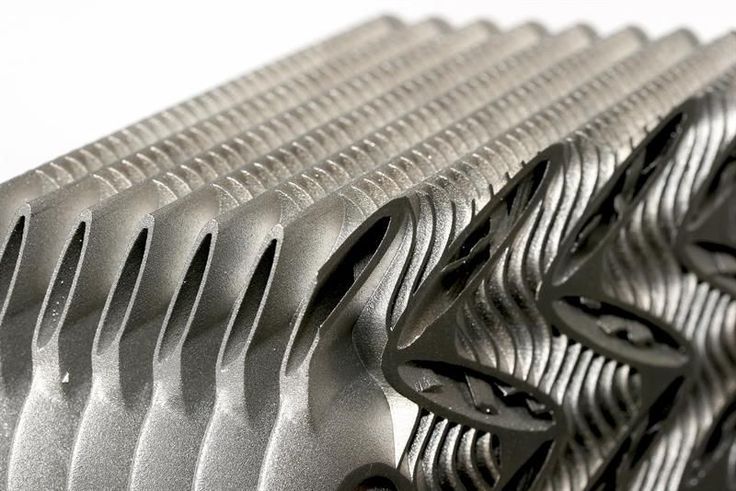

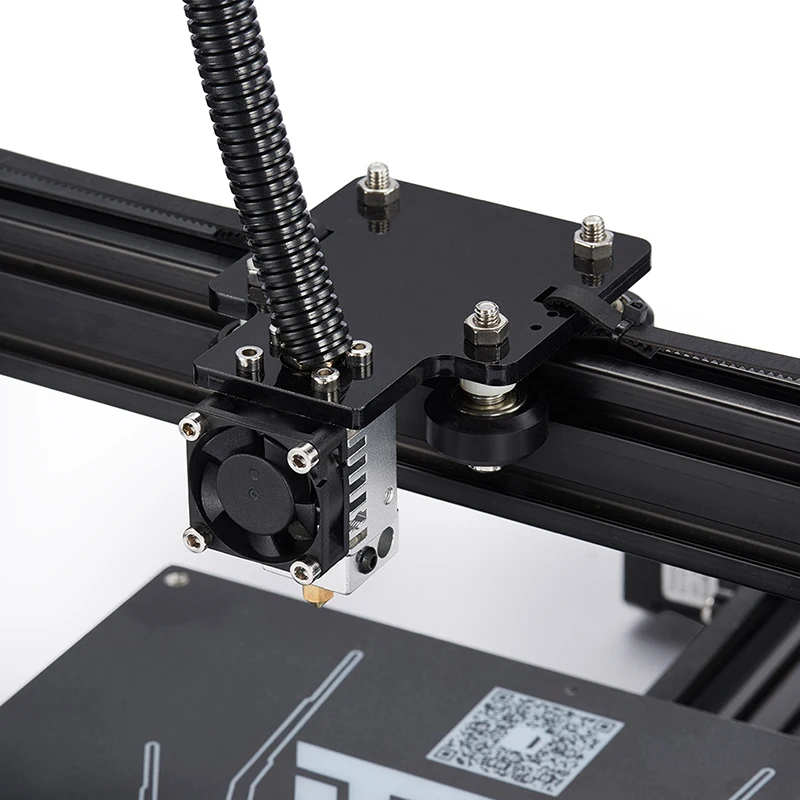

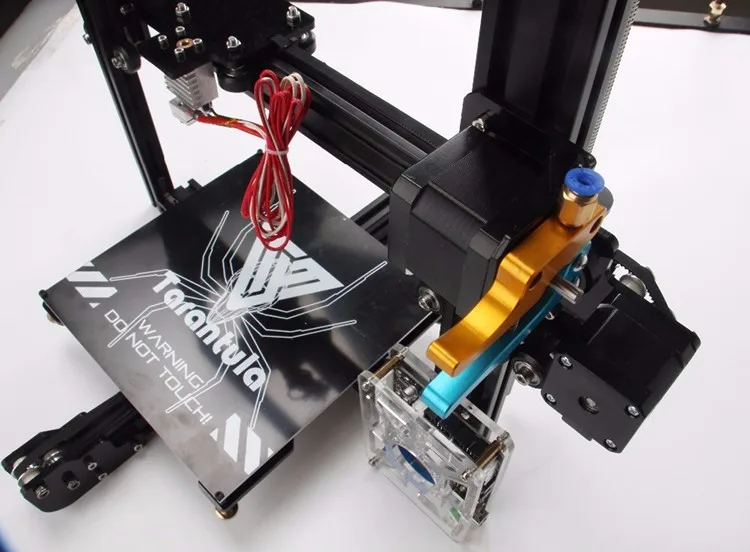

It’s also worth noting that this isn’t a simple product to make. Its design is deceptively simple, but take a look at the image above. That’s a blown-up diagram of how the extruder fits onto the arm and we count no less than 15 components, all of which have to be quality checked and attached.

Support

The Tarantula support page can be described as basic, at best. It consists entirely of a ridiculously complex construction guide for the printer. There are firmware updates (hosted on Dropbox, of all places) on a separate page, but no troubleshooting guides, tutorials, or anything approaching a professional-level support system.

If you’re completely stuck, you can contact TEVO via email, a support form, or (sigh) Facebook Messenger. The site is primarily written in broken English, so you’ll probably have to resort to forums or YouTube videos to better understand how to fix a given problem.

This is quite simply one of the least professional websites we’ve ever seen. It’s a real shame since $200 is still a lot of money, and customers deserve to be given some kind of after-purchase support. TEVO’s iterative design practices mean that much of the helpful information out there becomes more outdated each time they release an upgrade, too, so you might well end up having to fix problems on your own.

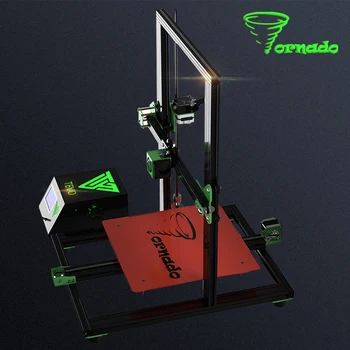

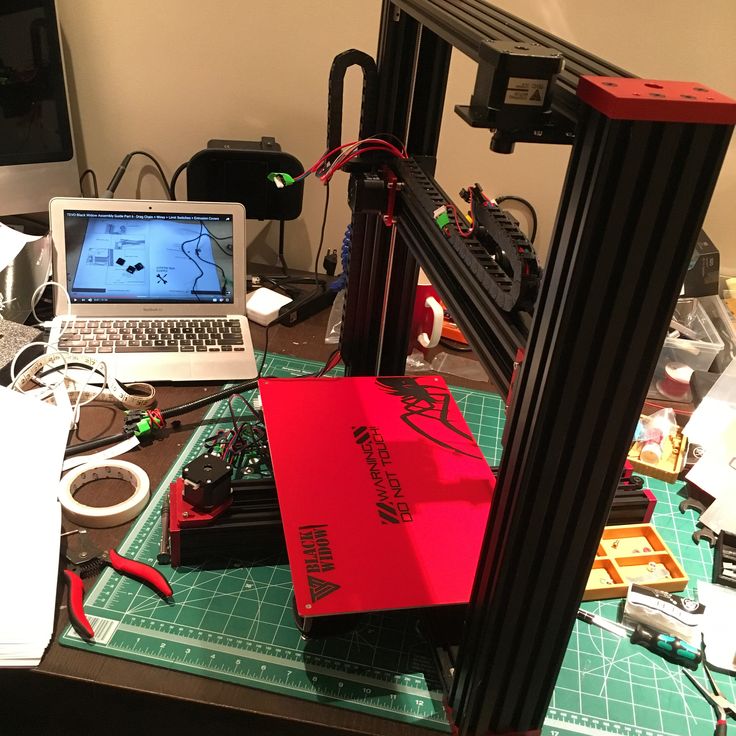

Tevo Tornado - Our complete review - 3D Print

3D Printers reviews

Posted on Author easy3dhome Comment(0)

Post Views: 236

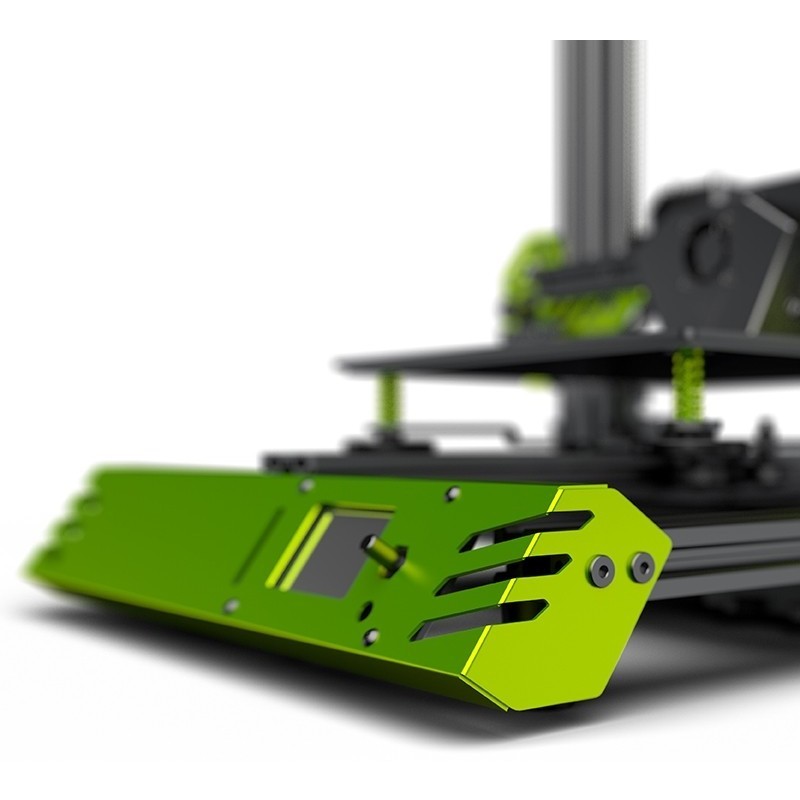

This Tevo Tornado is the carbon paper copy of the most popular Creality CR-10, it is an economical 3D printer with a very generous printing volume. For many 3D printing enthusiasts on a tight budget, the Chinese 3D printer manufacturer TEVO has become a viable option. This is because it offers an excellent range of affordable FDM machines and has become very popular.

For many 3D printing enthusiasts on a tight budget, the Chinese 3D printer manufacturer TEVO has become a viable option. This is because it offers an excellent range of affordable FDM machines and has become very popular.

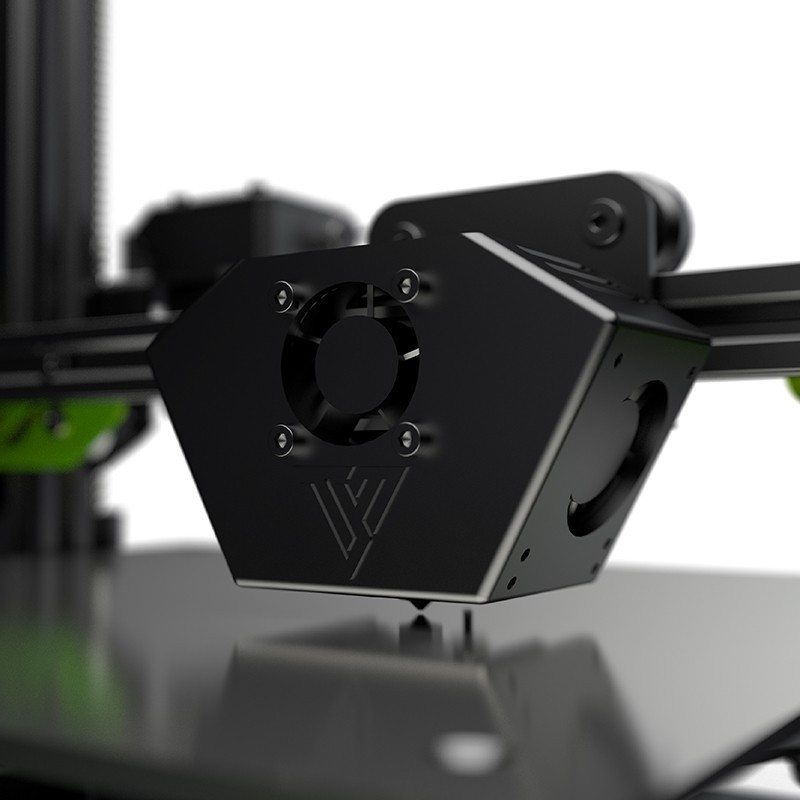

One of the latest printers from TEVO is the Tornado, a sturdy 3D printer with aluminium frame, Titan bowden extruder and other interesting features.

This 3D printer is constantly compared to the popular Creality CR-10, which makes sense considering that the two share the same design. However, there are some obvious differences between TEVO Tornado and Creality CR-10.

Before we go into the review, let’s take a look at the features of this machine:

- min. Level resolution: 50 micron

- Extruder: Full Metal similar E3D Titan

- Positioning accuracy: Z 0.004 mm, XY 0.012 mm

- Max. extruder temperature: 260°C

- Temperature of the heating plate: 60-110 ° C

- Power Requirements: 220 V, 250 W, 50 Hz, 0.

89 A

89 A - Compatibility: Windows, Linux, Mac

TEVO TORNADO: Features

In general, the most interesting feature of the TEVO 3D Tornado 3d printer is the size of 300 X 300 X 400 mm, which for about 298 €. seems a bargain. When combined with a minimum thickness of 50 microns and a (stated) print speed of 150 mm/s this 3D printer seems a valid purchase option.

The 3D TEVO Tornado printer is almost completely assembled and arrives at your house divided into 2 pieces, which are joined by tightening a few screws. The Tornado will be ready for printing in less than an hour, even if you are not exactly familiar with assembly. The best will be able to see it up and running in less than 20 minutes.

Differences and similarities with CR-10

At first glance, TEVO’s Tornado 3D printer looks like a clone of the popular Creality CR-10 (and in many ways, it’s identical). However, there are some features that separate these two machines.

However, there are some features that separate these two machines.

One of the biggest differences is that the Tevo Tornado is equipped with a Titan extruder (clone of the original, produced by E3D). This high-end accessory is commonly used to upgrade low-cost 3D printers. Tevo has chosen to include it with the stock kit. With the Titan extruder, the 3D printer should be able to process a wide range of filaments, including PLA, ABS, PETG, exotic, TPU and others.

Can find here our guides to filaments: https://www.easy3dhome.com/category/3d-filament/

Another distinctive feature of this 3D printer is the 220 volt heated bed, which allows the printing area to be heated to high temperatures in less than a minute.

As another side of the coin, some people in the 3D printing community say that Creality CR-10 (in the CR-10S version) offers better quality electronics and a wider support group.

Last but not least, the Tornado tends to be a little cheaper than the CR-10, but not by much. Prices for both of these 3D printers seem to vary simultaneously, but the Tevo usually always costs €20-30 less.

TEVO Tornado: Cons

Some owners of TEVO Tornado 3D printers have reported on the Italian Facebook group of Tevo printers the 2 problems that this printer presents. The first of the problems that has been raised by the 3D printing community is the “salmon skin” effect on the surface of 3D prints. As the name suggests, the 3D printer produces objects with a strange striped pattern, reminiscent of salmon meat. This is due to the 32 microstep drivers used for the electronics of this printer (16 drivers do not have this problem).

Other users claim to have some problems with the quality of the SD cards provided by Tevo.

When we find problems we are also used to looking for a solution. For the “salmon skin” effect we can add Smoother. These smoother are small electronic boards that in addition to eliminating the salmon skin effect will also make better prints. They can be found anywhere and cost a small amount of money. On Amazon you will receive them in a few days for less than 5 euros. Not even to say even replace SD card is obviously quite simple, if you encounter problems. In fact, in this case you can also switch to using a Wifi SD card, to transfer the Gcode to the printer without even getting up from the chair!

For the “salmon skin” effect we can add Smoother. These smoother are small electronic boards that in addition to eliminating the salmon skin effect will also make better prints. They can be found anywhere and cost a small amount of money. On Amazon you will receive them in a few days for less than 5 euros. Not even to say even replace SD card is obviously quite simple, if you encounter problems. In fact, in this case you can also switch to using a Wifi SD card, to transfer the Gcode to the printer without even getting up from the chair!

TEVO Tornado: Pro

After the cons, we have to go on to analyze the PROs. TEVO Tornado is an open source 3D printer. This makes it much easier to make upgrades and changes to achieve superior print quality. Unlike Creality, changing the firmware is very easy. Build quality is definitely a bargain for price quality. As already mentioned also the fact of being born with the extruder Titan stock gives you a good advantage over the competition. Last but not least, the Tevo printers also have a good appeal. They can build printers that are also pleasing to the eye, and this tornado is no less impressive.

Last but not least, the Tevo printers also have a good appeal. They can build printers that are also pleasing to the eye, and this tornado is no less impressive.

Where to buy this 3D printer?

You can buy this 3D Printer at GearBest and Amazon. Gearbest offers this printer. When you buy it from Geabest, you can be sure that you won’t have to pay customs duties of around €50, and you’ll receive it at home within 15 days.

If you think you can’t last 15 days and are willing to spend almost twice as much then you can also buy it at Amazon!

If you have found this review useful, please LIKE on Easy 3D Home Facebook’s page to receive updates on all the news of the Blog! You can find more 3D Printers reviews at 3D Printer section!

Like this:

Like Loading...

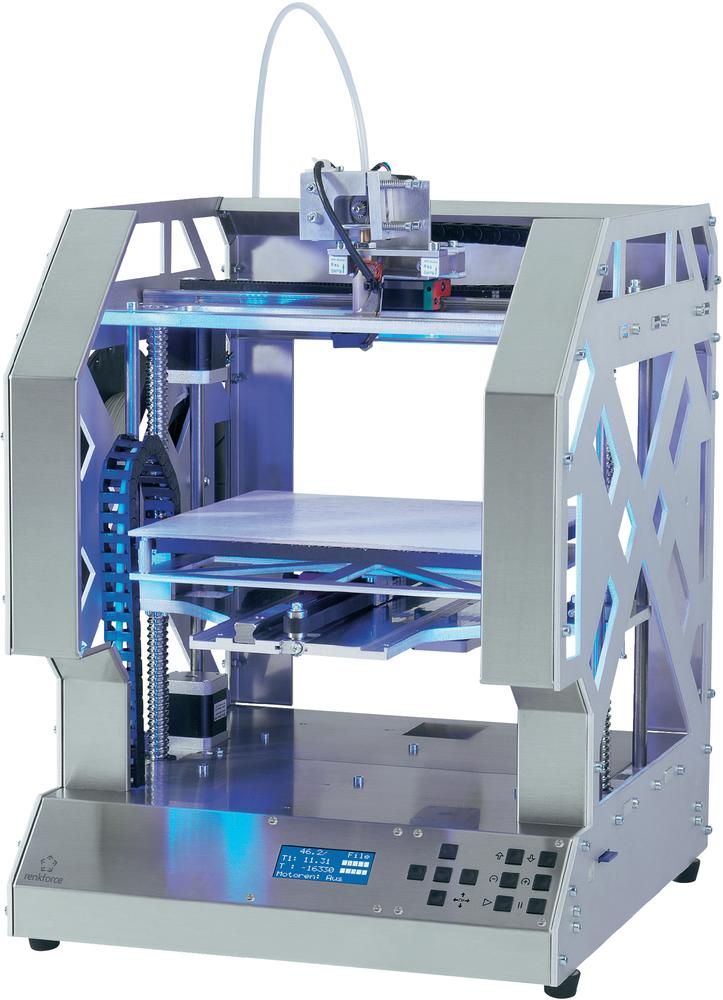

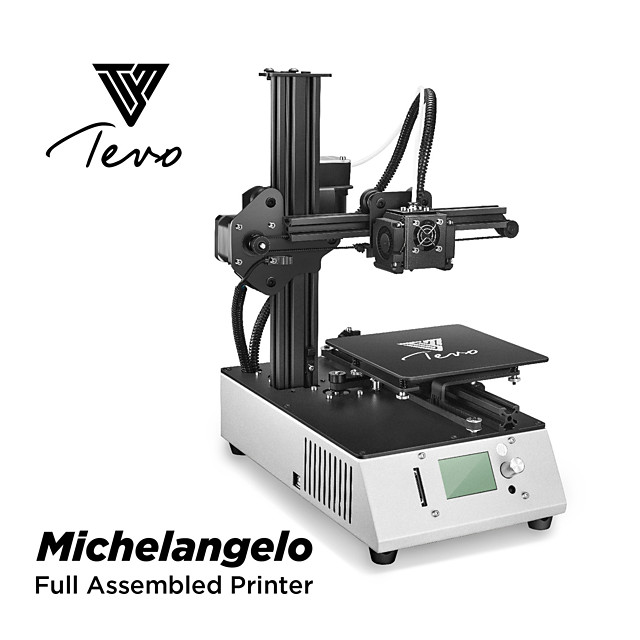

Overview of TEVO Nereus 3D Printer Features

Overview of TEVO Nereus 3D Printer Features

TEVO Nereus is a budget friendly touch screen 3D printer that understands Wi-Fi and boasts a significant working volume of 320×320×400mm . Let's study.

Let's study.

Over the past few years, the FDM 3D printing market has been undergoing a significant transformation: low-cost machines continue to become more advanced, not very expensive. Chinese manufacturer TEVO has always been at the forefront of the budget market and has consistently released affordable 3D printers with flashy names (eg TEVO Flash, TEVO Tornado, TEVO Tarantula, etc.) and color options.

The company kicked off 2019 with a big bang, rolling out the new TEVO Nereus at the end of the holidays. And it turned out to be perhaps the most feature-rich of the entire extensive line of 3D printers.

As far as we can tell, Nereus is the next step in the evolution of TEVO. This FDM printer has received features that previous models did not have. Named after the ancient Greek sea god Nereus, TEBO Nereus could really make a big splash and upset the budget 3D printing market. But is there anything that radically sets this printer apart from the Creality Ender 3 imitations that have flooded the budget market?

To understand this, you need to look at the features and understand the characteristics.

Features

In fact, if we looked at TEVO Nereus one-sidedly, we would be tempted to say that, in fact, this is the same Flash, only in profile. Like most TEVO 3D printers, Nereus has a minimalist open frame made of simple aluminum profiles, but if TEVO Flash has a metallic red base, reminiscent of the popular superheroes of the same name (there were several different Flashes), then TEVO Nereus shifted the gamma towards road orange.

But the Chinese did not limit themselves to one color. To start with, TEVO Nereus has an impressive working volume of 320 x 320 x 400mm, larger than TEVO Flash and TEVO Tornado.

TEVO Nereus also includes features that have become standard on new desktop 3D printers, such as filament detection and print resume. There is also a touch screen mounted on the side of the printer base, new to the TEVO family.

TEVO Nereus table with heating and magnets

Another important feature of TEVO Nereus is the Wi-Fi interface, which allows you to use a mobile application to launch and monitor printing. This solution is usually supported by more expensive devices, but TEVO decided to play it safe and offer it to the masses.

This solution is usually supported by more expensive devices, but TEVO decided to play it safe and offer it to the masses.

It's important to note that we haven't tested the TEVO Nereus 3D printer and its TEVO mobile app, so we don't know how it all works. Still, the features mentioned may herald the golden age of budget 3D printers, when dual extrusion and Wi-Fi are no longer considered exotic.

Specifications

And the main thing.

| Manufacturer | TEVO |

| Brand | Tevo |

| Model | Nereus |

| Print Precision | 0.1 mm |

| Frame | aluminum profile |

| Platform base | aluminum profile |

| Nozzle | single |

| Nozzle diameter | 0.4 mm |

| Nozzle temperature | 180...240℃ |

| Displacement | 320 × 320 × 400 mm |

| Layer thickness | 0. 1-0.36 mm 1-0.36 mm |

| Memory card for offline printing | TF |

| LCD screen | available |

| Print speed | up to 150 mm/s |

| Platform temperature | 0...80℃ |

| Materials | ABS, PLA, HIPS, flexible, wood |

| Filament cross section | 1.75 mm |

| Interface language | English |

| Model support function | have |

| XY positioning accuracy | 0.05 mm |

| Voltage | 100/240V |

| Package type | assembled |

| Voltage range | 100-240V, max 600W |

| Interface | SD card |

DIMENSIONS AND WEIGHTS

| Net weight | 13 kg |

| Gross weight | 13. 5 kg 5 kg |

| Machine dimensions | 53.70 x 58.70 x 62.40 cm / 21.14 x 23.11 x 24.57 inches |

| Package dimensions | 55.00 × 63.00 × 28.00 cm / 21.65 × 24.8 × 11.02 inches |

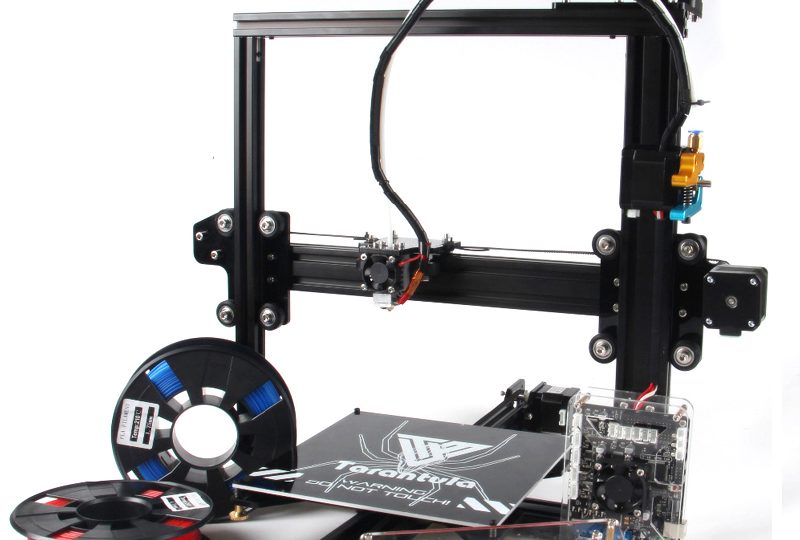

Tevo Tarantula - honest review

Hi all!

I’ll note right away that with this review I don’t want to push anyone to buy this 3D printer, on the contrary, its disadvantages will be discussed here more than its advantages. Today, instead of it, there are more worthy options.

Today 3D printing is quite a fast-growing modern direction. And I wanted to say so, to try, feel, evaluate what a miracle of technology is - a 3D printer.

I didn’t have the task of printing to order, but, without a doubt, it was clear that for an electronics engineer, home-made and techie, a 3D printer is like an indispensable tool in the implementation of any of their ideas, an assistant in the household, and just a device for interesting hobby. Therefore, I considered budget options in aliexpress, from pryushka-like ones, such as anets, but chose another one, relying on customer reviews.

Therefore, I considered budget options in aliexpress, from pryushka-like ones, such as anets, but chose another one, relying on customer reviews.

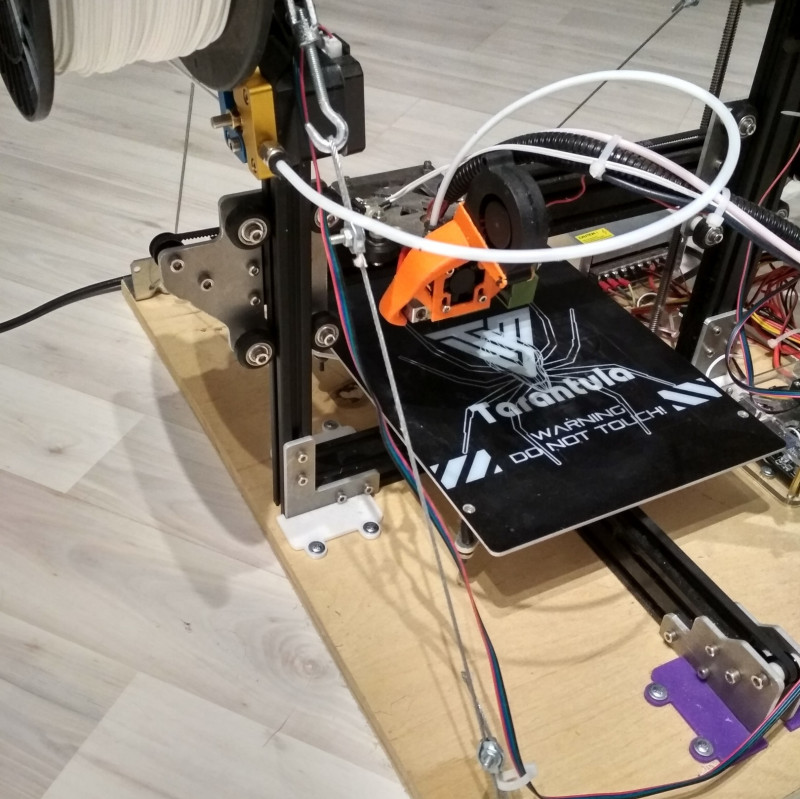

And was ordered to, such a beast, Tevo Tarantula.

At the time of choice, there was just a sale on Ali. And taking into account the use of fat coupons and the seller's discount, it cost me only 9700 rubles, somewhere around $ 150 (at that time), not bad at all, given the cost without a discount of more than 13 thousand.

The printer was sold with delivery from Russia, and it was lucky that it was just in stock in the Russian warehouse, usually they are usually not available, so the seller offers to ship from China, but of course more expensive. Sent from somewhere in the Russian warehouses in the east, delivery took 3 weeks.

To be honest, when choosing, I didn’t understand either the kinematics of 3D printers, or the reliability of the implemented mechanics in this or that model, in general, I was generally a layman in this matter)) but now, a year later, I have something to say about it.

Characteristics, briefly:

Print area 200x200x200, although it will decrease to 180 along the Z axis when the wiring harness is fixed on the X carriage. if you change the extruder.

Drain nozzle diameter 0.4. The maximum print speed is 100mm s, the recommended 60. But with proper assembly and slicing settings, its cruising speed is 80mm.s.

The printer comes well packaged. All elements were tightly folded, as it were, in layers using dense spongy material; nothing dangles or breaks inside.

The kit additionally included two coils of filament, two hundred grams each.

As a gift, the Chinese put a branded extruder TEVO TITAN, which we will definitely test in work. Consumables and small parts are arranged in bags with numbering for assembly according to the instructions.

I won't go into assembly details. In the reviews, they complain about the instructions, although I assembled everything according to it without any problems, spending two evenings on it, it took 6 hours in total. I think that techies with hands from where they need to should have no problems at all, but an ordinary user can have big problems , it's still that puzzle.

In the reviews, they complain about the instructions, although I assembled everything according to it without any problems, spending two evenings on it, it took 6 hours in total. I think that techies with hands from where they need to should have no problems at all, but an ordinary user can have big problems , it's still that puzzle.

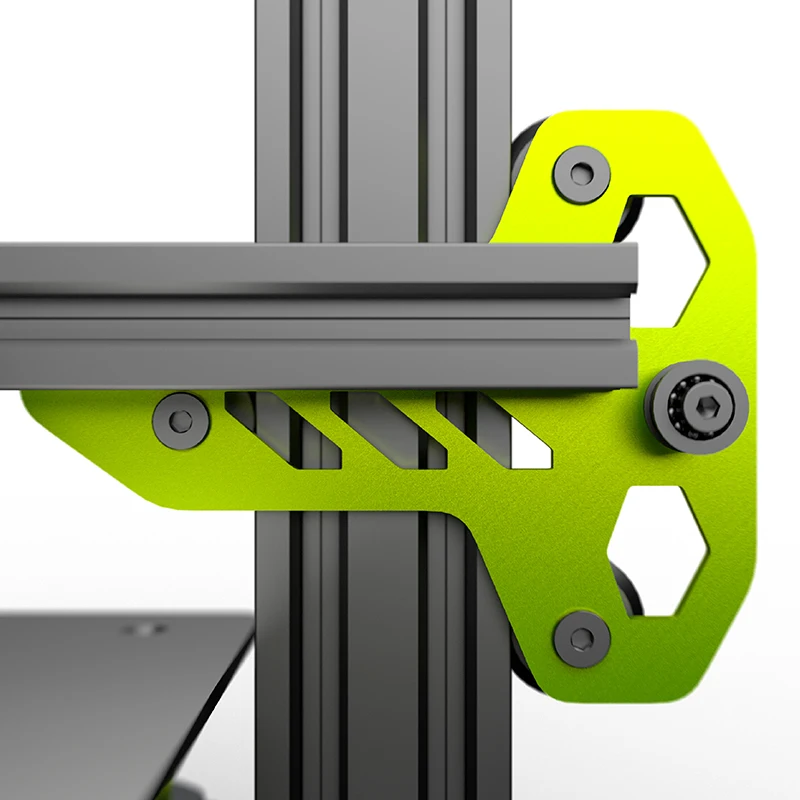

Frame

The frame of the printer consists of 20x20 and 20x40 sections of an anodized b-slot structural profile, which are fastened with internal steel, applied aluminum and applied acrylic corners, as if forming a perimeter for the X and Z axes. And for the Y axis, between the two cuts of the 2040 profile, which form the lower crossbar, the profile for the Y axis is attached longitudinally. And it is at this attachment point that I want to highlight the first problem of this printer.

Firstly, during assembly, a slight distortion of the lower two halves relative to the X-axis plane is formed, this is either due to a slightly curved profile cutting, or due to the peculiarity of fastening with internal corners.

This problem can be solved by first printing out a set of brackets and fixing the printer to a furniture panel of suitable dimensions.

I initially saved on the filament and fixed it on the galvanized furniture corners, slightly trimming them. Later I redid it, already on printed brackets. If the frame is not fixed at all, well, let's say if it were even, because of its ease the printer prints the fill, the walls can generally crawl away from vibrations)) so there is no way without a 'board'.

Still, there are problems with the frame even after fastening to a rigid base due to such an economical implementation of the drygost. Namely, the Z axis bends at an angle relative to the Y axis, this is hardly noticeable if you apply force to the upper crossbar of the frame, you can see a displacement of only 2-3 mm. Jambs because of this appear when printing tall objects.

I plan to remake the lower part of the frame as in Tevo Tornado. There will be a 2040 profile frame in the lower part, to which the upper part will be attached with connecting plates and corners. Maybe the electrician can be hidden under the table.

There will be a 2040 profile frame in the lower part, to which the upper part will be attached with connecting plates and corners. Maybe the electrician can be hidden under the table.

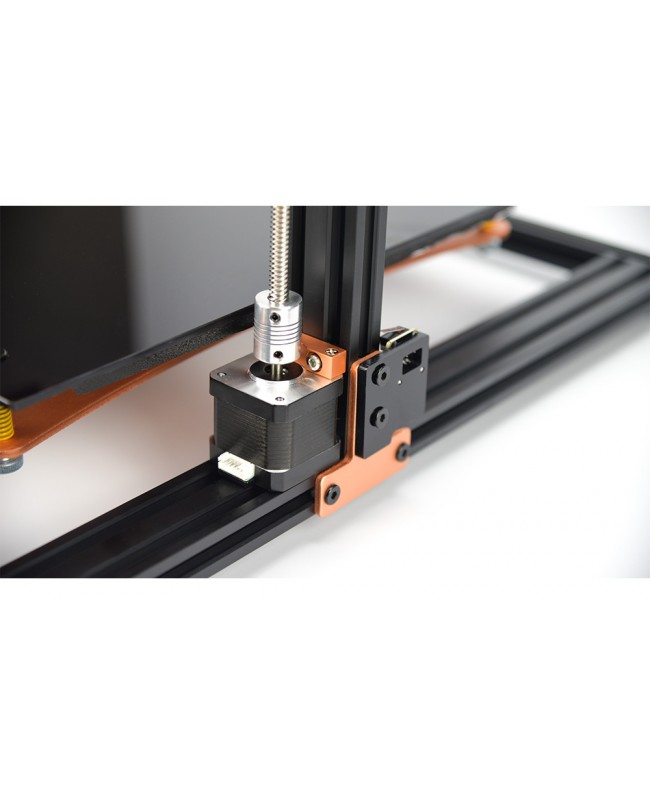

Kinematics and mechanics

The kinematics from the pryusha, the classic dry-table, the Bowden extruder are used in the tarantula. The movements of all axes are realized on rollers, consisting of bearings and holders dressed on them made of wear-resistant POM plastic. There are 4 rollers on each carriage, two of which have eccentric nuts for adjusting the gripping force on both sides of the profile. This is the most practical and simple mechanics of cheap solutions, certainly better than studs. I will not ascribe rails in comparison, since they are already used in a different price segment of 3D printers, although it can be noted that they are noisy. The rollers are very cheap and easy to change, they are quiet and can be adjusted. But they also have downsides. Such mechanics take up more space. At the expense of the difference in weight - I did not compare, I assume that it is heavier than the studs, but the rail is lighter. They can not be overtightened, they will wear out quickly. However, any mechanic wears out.

Such mechanics take up more space. At the expense of the difference in weight - I did not compare, I assume that it is heavier than the studs, but the rail is lighter. They can not be overtightened, they will wear out quickly. However, any mechanic wears out.

In the tarantula all carriages are made of acrylic and this is his second problem.

First. The fact is that, because of acrylic, you can get there already during assembly, since this material is too caustic, it cannot be overtightened, it can crack, fortunately I was lucky with this.

Second. Acrylic plays already with little effort, if in more detail, it is expressed as follows:

Well, if I didn’t notice a special jamb on the X axis, although there is not a big skew with the force on the X carriage, this is played by the acrylic plates of the carriages on the Z axis and X (carriage X - bends especially noticeably if you apply force to the hot end) and this is nothing at all compared to two other problems, namely:

The Z-axis motor is mounted on an acrylic bracket to the upper transverse profile and it does not walk vertically so weakly, there is no rigid fixation to the frame!

Thirdly, it's a joint of tarantula joints, it's a Y-carriage. The implementation of the acrylic table fastening is nothing at all. Due to the large area of the carriage, the table, sorry for the expression, dangles like something in an ice hole. I also read in the reviews that, due to the heating of the carriage, the table takes away .. At least they would have made a stamped steel carriage here, maybe ... of this, shoals appear as a print.

The implementation of the acrylic table fastening is nothing at all. Due to the large area of the carriage, the table, sorry for the expression, dangles like something in an ice hole. I also read in the reviews that, due to the heating of the carriage, the table takes away .. At least they would have made a stamped steel carriage here, maybe ... of this, shoals appear as a print.

But here it begs, dude, what did you want for this money?

To solve all the problems associated with acrylic parts, I ordered a set of aluminum carriages, in the future we will see how their replacement will affect the quality and speed of printing.

Okay, let's move on..

The X and Y axes are driven by a 6mm wide GT2 belt. It should be noted that here the Chinese saved on pulleys, they are plastic, but with bearings, they don’t seem to hit, okay. Thanks, at least on the engines, the drive pulleys are aluminum. There are no belt tensioners.

The Z axis is driven by a T8 screw with a 2mm stroke, i.e. one revolution of the Z screw moves 2mm. For this, Tevo is definitely a plus, there are printers with 8mm screws, and this affects the print quality, not much - but it does. The declared accuracy of movement along the axes, XY-12 microns Z-40 microns. I plan to hang the Z axis on two shafts and try to switch from a Bowden extruder to direct.

Electrics

All electrics are powered by a power supply unit with active cooling at 12V, 300W, well, yes, what, a 12-volt PSU is more budgetary)) I didn’t observe his work, well, except that I printed it out and installed such a noise reduction:

and filled the cooler with grease, but this must be done on all Chinese fans.

Everything is controlled by the MKS Gen L V0.1 board with A4988 plug-in drivers. On the Internet, I found complaints about this board, there were cases of burning the mosfet on the table, and for some it sins with an unstable reading of the temperature from the hotend thermocouple. I checked the temperature - it reads stably, probably lucky:

I checked the temperature - it reads stably, probably lucky:

and the table was powered through a module on a powerful mosfet with a radiator and the MKS stopped heating up!

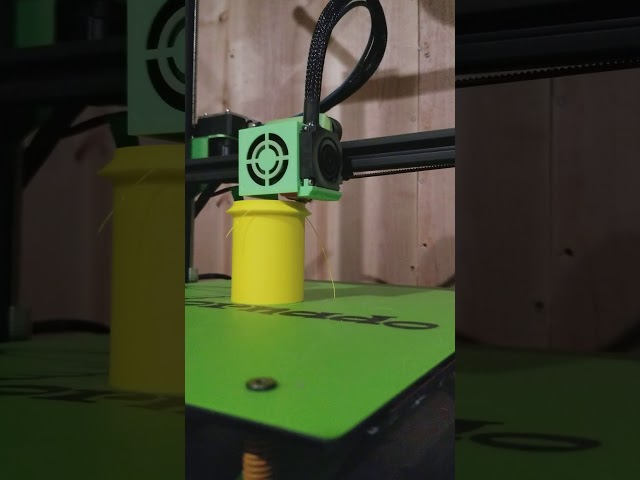

9I flashed 0006 MKS-ku almost immediately after assembly on Merlin, maybe there were problems with temperature on the native firmware, but I did not notice this. The transition to Merlin is due to the lack of the necessary functionality on the native firmware, but this is a separate issue ... they wedged someone...Installed hot end MK8 with a square radiator. Works without problems. Once cleaned from the cork, when the tube was not fully stuck during assembly. The kit does not provide a fan for cooling the extrusion, so the first thing I printed out was this:

but it turned out to be ineffective due to the use of a conventional 40x40 cooler with a fan. Later I printed this one, for a 50x15 impeller.

There are many options on thingiverse, but anything with 40x40 coolers is ineffective, and airflow must be from at least two points. The board has a connector for automatic control of the cooling fan.

The board has a connector for automatic control of the cooling fan.

Heated table here 130W, Teflon coated. Rather, it’s probably some kind of not Teflon, but plastic, which can withstand 150 degrees. At the first touch of the nozzle, pits appear, so I tore off this coating and cleaned it of glue, and then the glass ... clothespins ... classic))

I liked that the table has a connector, and if necessary, it can be turned off, the harness for the table can be completely removed to repair it, because the wires are not eternal!

Electricity in the tarantula is not organized at all. I do not like how stupidly implemented the mounting of the control board with the display. A kind of ala version of the terminator. The fan blowing the board blows on the table. There is nowhere to attach the display, I found such a case on thingiverse and printed it out.

There are even two different housings, for the MKS and the display, and they can be fixed together. I transferred the boards to it and somehow it still became more fun. I really liked the implementation of cooling in it, these are two 40x40 coolers that cool the MKS with a through flow from both sides.

I transferred the boards to it and somehow it still became more fun. I really liked the implementation of cooling in it, these are two 40x40 coolers that cool the MKS with a through flow from both sides.

For laying the bundles, I used a special mounting spiral tape with a diameter of 10 mm. Well, I love order, there's nothing to be done.

You can find the tape in electrical stores or order it in aliexpress.

The corrugation from the kit also came in handy, although it is already very rigid, the main thing is to fix it well on the X carriage, the tourniquet bends more in this place. It is also better to remove the X-axis motor wire into a spiral and also secure it well with ties, otherwise it will bend and break at the motor connector.

With the alteration of the lower part of the frame, it is planned to remove all the electrics under the table, let's see what happens.

Conclusions

What can we say about the printer in general. The low cost of any equipment is always due to certain problems. In the case of Tevo Tarantula, I see three problems, these are: the use of cheap material, acrylic, in the production of parts, saving on profiles - and this, the frame has been simplified so much that it is problematic to use it without fixing the printer to a hard surface. Well, the third problem is the assembly of the printer, which few people may find pleasant.

The low cost of any equipment is always due to certain problems. In the case of Tevo Tarantula, I see three problems, these are: the use of cheap material, acrylic, in the production of parts, saving on profiles - and this, the frame has been simplified so much that it is problematic to use it without fixing the printer to a hard surface. Well, the third problem is the assembly of the printer, which few people may find pleasant.

But along with this, it is clear that the Tevo company adds nice changes to the package.

Over time, the tarantula began to be equipped with an anodized profile. To strengthen the frame, added internal overhead corners. The control board is usually the latest version at the time of sale. The power supply was previously 250W, now it is equipped with a 300-watt one. The heated table became not with a soldered cable, but with a connector.

Who knows, maybe over time there will be changes in the design, or at least the Y carriage will be changed.