Make 3d printing projects

3D Printing Projects - Instructables

Marblevator, "The Ferris Wheel at the Pumpkin Patch" by gzumwalt in 3D Printing

2 8 723

WINTURER: a Portable NP-F Battery Charger Wind Turbine by adriancubas in 3D Printing

11 2.4K

Screwdriver Wallmount Custom 3D Printed by F1nnsp1n in 3D Printing

129

Copic Marker Pen Classic "Pen Holder Organizer" by SundaeCreations in 3D Printing

172

Window Repairs Using Fusion 360 Saved Me Over $300 by DanPro in Repair

1 203

Crayon Pen by jorik. dammann in 3D Printing

8 328

3d-Printed Generator by 1970sWizard in 3D Printing

11 1.0K

3D Printed Wigglegram Lens (Sony E-mount / APSC) by scealux in 3D Printing

25 2.9K

Craft Room Rotating Crayon Holder by mammothcreations in Art

Runner Up 10 420

Metal Notebook Cover With 3D Printed Hinge by Constance N Variables in 3D Printing

1 243

Antique Phonograph Spring Motor Restoration Using 3D Printed Parts by RobertD171 in 3D Printing

2 428

Magnetic Toolholder by Max Siebenschläfer in 3D Printing

5 368

Learn How to Make a 3D Printed RC Tank From Scratch!!! by aaditya03 in 3D Printing

Second Prize 12 639

Cement Mixer Machine Tinkercad 3d Design by Creativity Buzz in 3D Printing

6 249

Animated, 3D Printed, Clothespin Characters by EdgertonCenter in 3D Printing

First Prize 7 528

3D Printed Star Wars Door Handle by JPGrox in 3D Printing

3 152

Infinity Stone Watch by alan0001 in Costumes & Cosplay

1 233

Star Wars Deathstar Signage by Muhammad FasyaD in 3D Printing

3 135

3D Printed Tardis With Sound and Fading Lights by Calebs in 3D Printing

8 226

3d Model Animal Cell for the Classroom by lamichhanebis in Science

176

Build Your Own Quadruped Robot Using Tinkercad by PJ2000 in 3D Printing

12 423

Tens'EGG'rity - Halloween - 3D Printed by seabirdhh in Decorating

47 7. 7K

7K

Automatic Power Off Your 3D Printer With Octoprint by dawidma in 3D Printing

7 313

3d Printed 'cork' Bottle Stopper by mrsmerwin in 3D Printing

Runner Up 2 182

Faux Barbed Wire Choker and Bracelet - Flexible 3D Print by Penolopy Bulnick in 3D Printing

1 58 4.7K

INNER WALL SPEED Effects on OUTSIDE PRINT QUALITY (Close-Up COMPARISON) by diyperspective in 3D Printing

5 434

How to Design the Best Wind Farm Blade in Tinkercad - a STEM Challenge & Lesson Plan for Teachers by MyStemKits in Math

45 7. 1K

1K

Blastoise Humidifier by Muhammad FasyaD in 3D Printing

First Prize 34 1.5K

Easy Build Heat Set Insert Press by Maker-Mike in 3D Printing

21 1.1K

Forged Fabric Parts!!?.. With 3D Printed Compression Molds by JGJMatt in 3D Printing

Runner Up 106 5.1K

3D Printed Good Habits Tracker by Ondřej Beneš in 3D Printing

9 674

Life Sized Talking BMO From Adventure Time (that's Also an Octoprint Server!) by katzcreates in 3D Printing

Grand Prize 114 9. 6K

6K

3D PRINT a STEAM TRAIN 🚂 With Live Camera Streaming and Wifi Controls by DIY Machines in 3D Printing

First Prize 258 39K

Cut 3D Print Times in Half With Negative Volume Printing by MechanicalMashup in 3D Printing

13 1.2K

Are Expensive Nozzles OVERRATED? by diyperspective in 3D Printing

12 15K

Maze Cube by aswd1234567891011 in 3D Printing

2 234

A 3D Printed Slinky Machine by gzumwalt in 3D Printing

2 16 834

3D Printed Mouse - Vaxee Outset AX Inspired - Ajazz I305 Internals by MechaMouse in 3D Printing

Runner Up 8 664

Creating a Hot Air Ballon Using Tinkercad by sarahcath in 3D Design

9 2. 0K

0K

Marblevator, Golf by gzumwalt in 3D Printing

Judges Prize 2 34 2.7K

Furkan`s Cheap MicroAlgae Filter by furkanguzel161 in 3D Printing

Runner Up 7 640

Make an Ostrich Egg Lamp by alatorre in Reuse

Second Prize 40 6.9K

Egg Topper -Tinkercad basics by sigritom in 3D Printing

First Prize 1 36 3. 3K

3K

3d Printed Braille Business Card (Double Sided) by LakerMakersClub in 3D Printing

6 240

Making Life-size Todo 360! (Cad Bane's Droid - Star Wars) by 3Demon-3Dprint in 3D Printing

16 916

How to Clean 3D Printer Nozzle by Burning Off the Plastic by Maker-Mike in 3D Printing

9 526

Blade Runner 2049 Joi Emanator by MatterWiz in Costumes & Cosplay

Runner Up 8 1. 1K

1K

Fume Extractor by Arnov Sharma in 3D Printing

24 1.6K

Replace Power Button on the BIQU Magician 3D Printer by andymenon in 3D Printing

1 301

3D Print-It-Yourself Workshop Vacuum Extension Handle by DwarMeji in 3D Printing

4 190

Teaching With TinkerCAD - 3D Printed Keyrings by Faisal A in 3D Printing

26 1. 2K

2K

Ultimate (On a Budget) Home Vacuum by Icelandian in 3D Printing

Runner Up 48 5.7K

Tim's Hybrid Harmonic Drive by Palingenesis in 3D Printing

13 1.2K

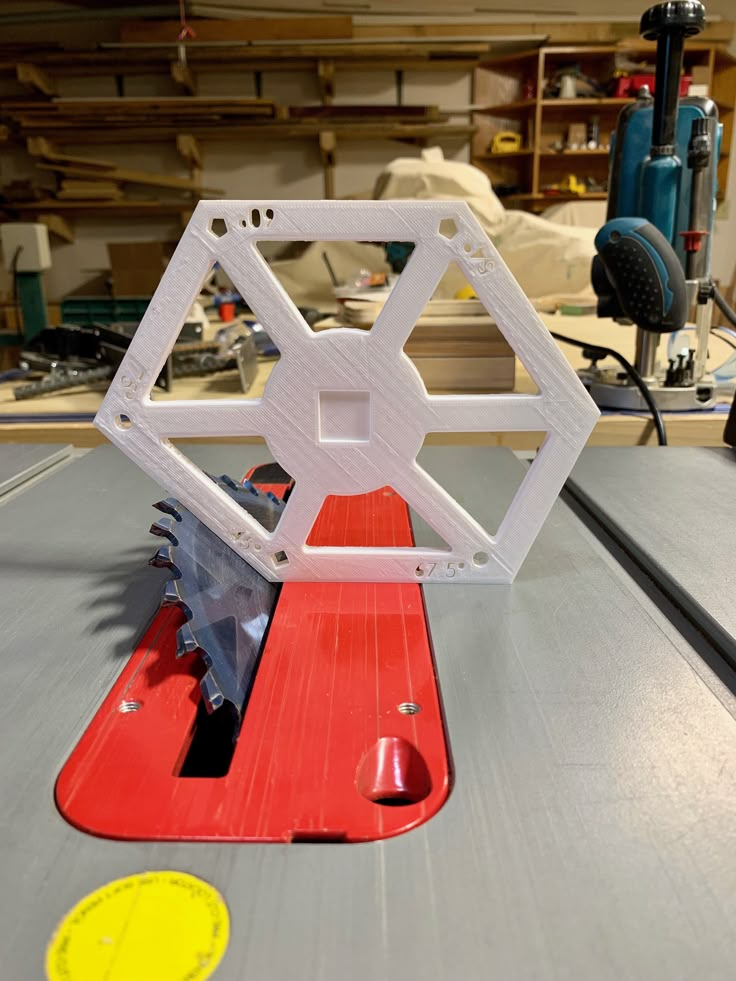

3D Printed Multi-Angle Drill Guide by Kartik_Nanduri in 3D Printing

102 6.9K

Model Paint Shaker by Muhammad FasyaD in 3D Printing

Runner Up 48 3. 4K

4K

Slidee: Non-motorized Automatic Camera Slider by Shivam Dehinwal in 3D Printing

Second Prize 104 6.2K

Jurassic Park Gate Remote Control by Muhammad FasyaD in 3D Printing

Judges Prize 35 4.4K

Creating and Using Shapes in Tinkercad by sarahcath in 3D Printing

6 429

Yidimu Falcon Pro Display Replacement Hack by andymid2001. 3d in 3D Printing

3d in 3D Printing

1 183

3D Printer FAN PWM NOISE 100% Elimination by diyperspective in 3D Printing

8 1.4K

3D Printing & Imaging DIY Projects for Makers

Over the years there have been a few troubling stories of house fires caused by 3D printers with electrical problems. When you think about it, this makes sense doesn’t it? You’ve got an electrical heater that is being pushed to over 200 degrees celcius, a bunch of moving parts, and the possibility of a glob […]

Continue Reading

One of the biggest complaints of 3D printing in the home is that it can’t do shiny metal prints, unless of course you have some super expensive metal printer. However, as Hen3drik shows us, there is a way to take a normal print from your typical resin based MSLA machine and make it look fully […]

However, as Hen3drik shows us, there is a way to take a normal print from your typical resin based MSLA machine and make it look fully […]

Continue Reading

For the first time since 2019, East Coast RepRap Festival (ERRF) was held in-person in Bel Air, Maryland. A total of about 1600 attendees, including over 60 corporate sponsors and almost 50 exhibitors filled the APFCU Arena at Harford Community College. The event was a mix of business-to-business dealmaking, hobbyist showcase, and some wide-eyed kids […]

Continue Reading

FlashForge has launched its newest 3D printer tailored towards consumer and education audiences. Touted as a beginner friendly 3D printer that also fits the needs of true 3D printing heads, FlashForge Artemis is a FDM 3D printer that provides excellent reliability and print quality, with many features to make it a true workhorse. Nearly a […]

Touted as a beginner friendly 3D printer that also fits the needs of true 3D printing heads, FlashForge Artemis is a FDM 3D printer that provides excellent reliability and print quality, with many features to make it a true workhorse. Nearly a […]

Continue Reading

with Joan Horvath and Rich Cameron Author/Educators Joan Horvath and Rich Cameron join me to talk about their new book, Make: Calculus, which take a different approach to teaching and learning calculus. This book, like their previous book, Make: Geometry, relies on creating visual models created with Legos or 3D printers to teach Calculus concepts […]

Continue Reading

Ian Charnas got a question stuck in his head. Is it possible to perfectly split an Oreo cookie by twisting it? That seems simple enough. we’ve all tried it at some point, gripping the two cookie halves in each hand and twisting to get at the creamy goodness. It never quite splits evenly does it? […]

Is it possible to perfectly split an Oreo cookie by twisting it? That seems simple enough. we’ve all tried it at some point, gripping the two cookie halves in each hand and twisting to get at the creamy goodness. It never quite splits evenly does it? […]

Continue Reading

Manufacturer: Mingda URL: http://www.3dmingdaofficial.com Price: $599 Features The Mingda Magician Pro is aiming at the people who want to print large things with decent features, without spending the money for a massive 3D Printer. At roughly $600, this printer won’t be competing directly with the most budget minded (like it’s smaller sibling the Mingda magician X does), but […]

Continue Reading

When you buy through links on our site, we may earn an affiliate commission.

Our websites use cookies to improve your browsing experience. Some of these are essential for the basic functionalities of our websites. In addition, we use third-party cookies to help us analyze and understand usage. These will be stored in your browser only with your consent and you have the option to opt-out. Your choice here will be recorded for all Make.co Websites.

Allow Non-Necessary Cookies Allow Non-Necessary Cookies

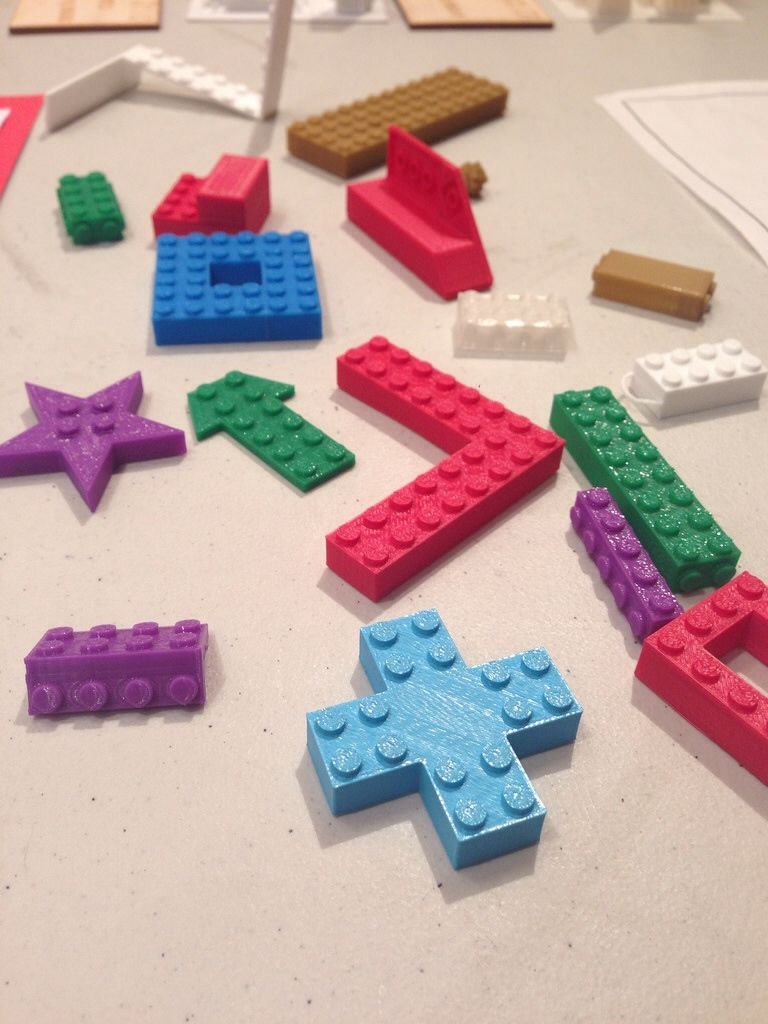

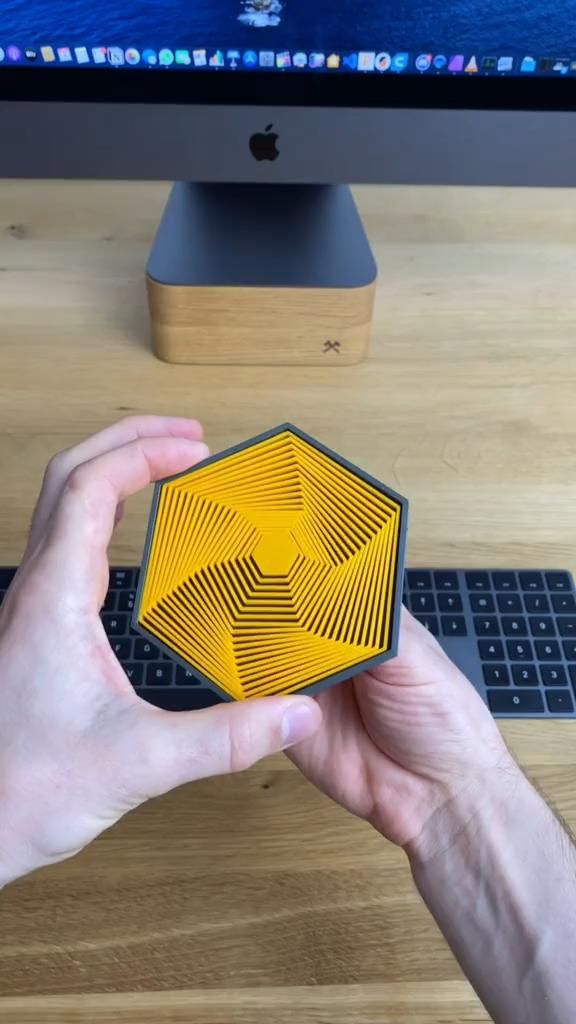

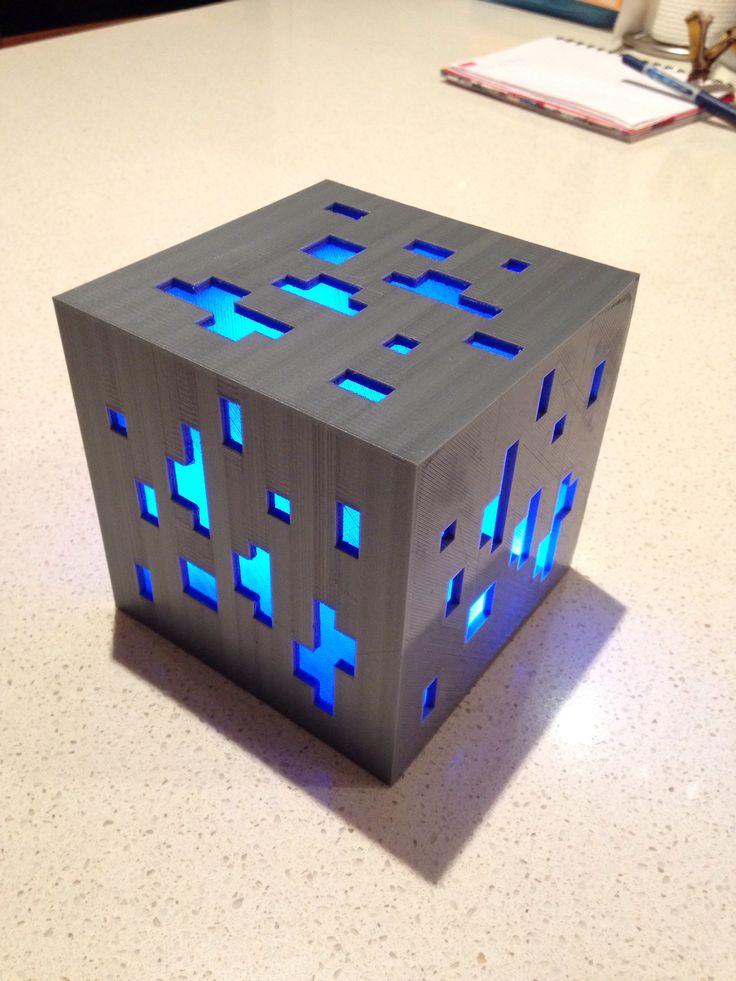

Cool 3D projects using 3D printing

3D printing

Subscribe to the author

Subscribe

Don't want

12

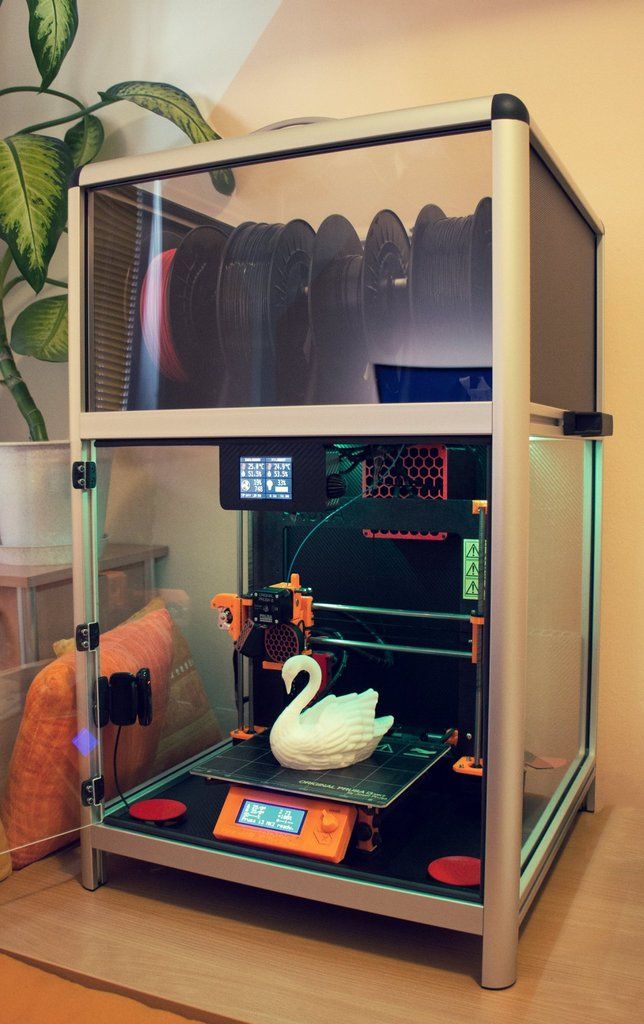

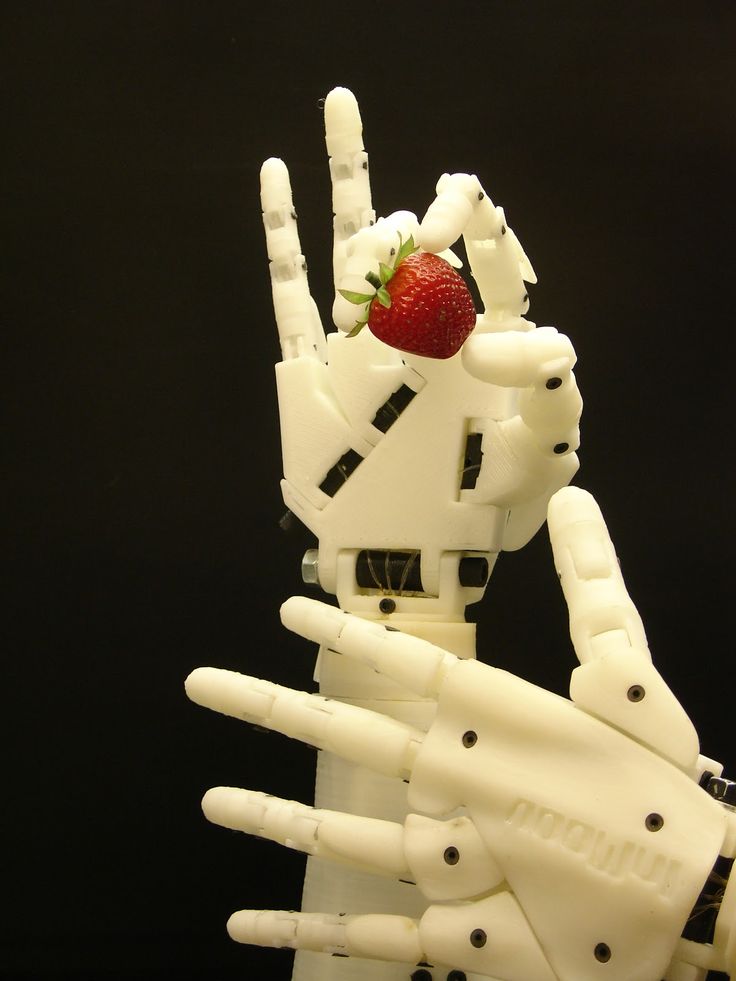

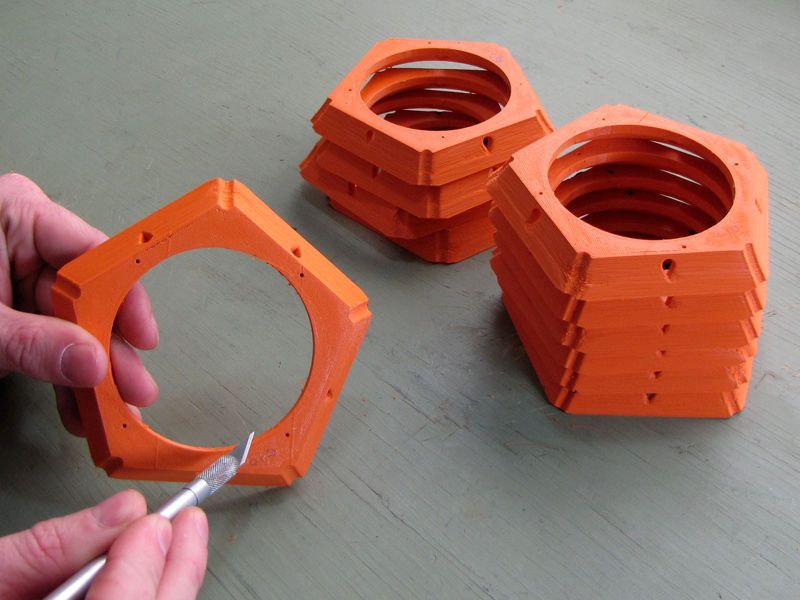

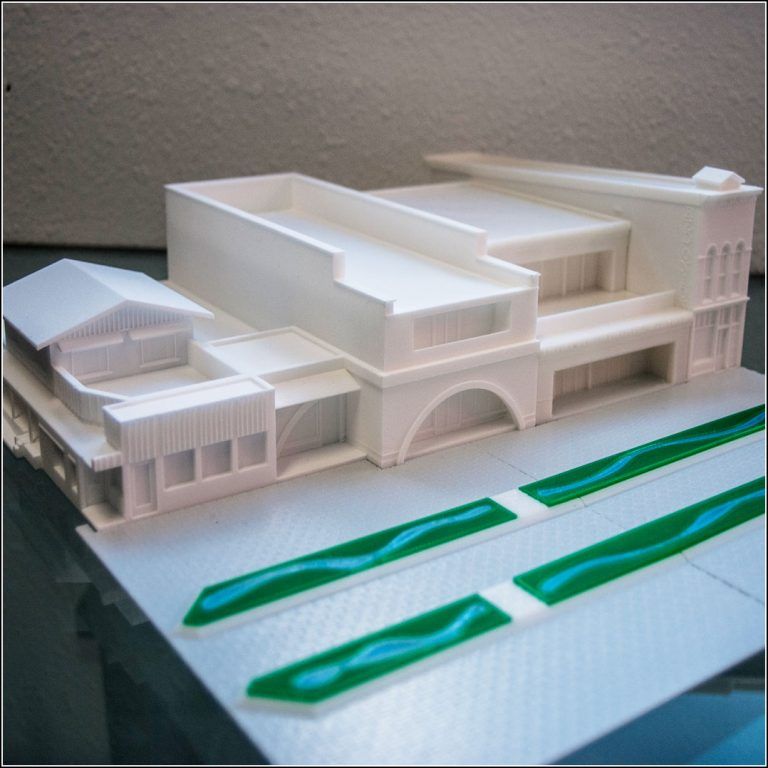

Chapter 1. Background. In this article I will talk about why you need a 3D printer at home and what you can do with it. And you can make and print on a 3D printer any part, both plastic and rubber. but the secret of success lies in the fact that it is not enough to have a 3D printer, but you also need to be able to model parts and properly prepare them for the printing process. Anyone can afford to buy a printer, or you can assemble it yourself. But it takes time to learn how to model. A lot of my projects required the manufacture of non-standard parts, which is why the idea of buying a 3D printer was born.

Anyone can afford to buy a printer, or you can assemble it yourself. But it takes time to learn how to model. A lot of my projects required the manufacture of non-standard parts, which is why the idea of buying a 3D printer was born.

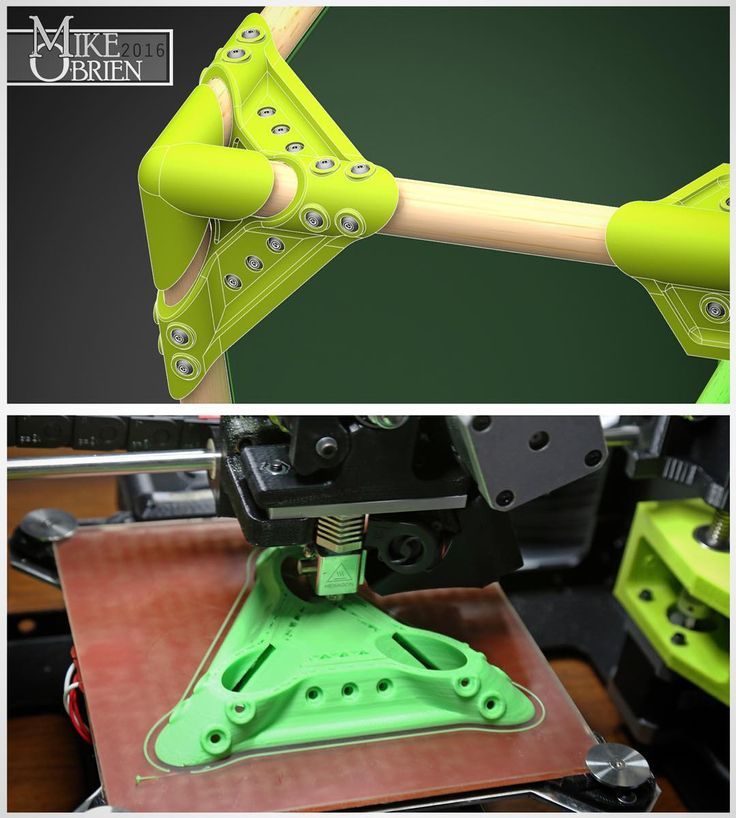

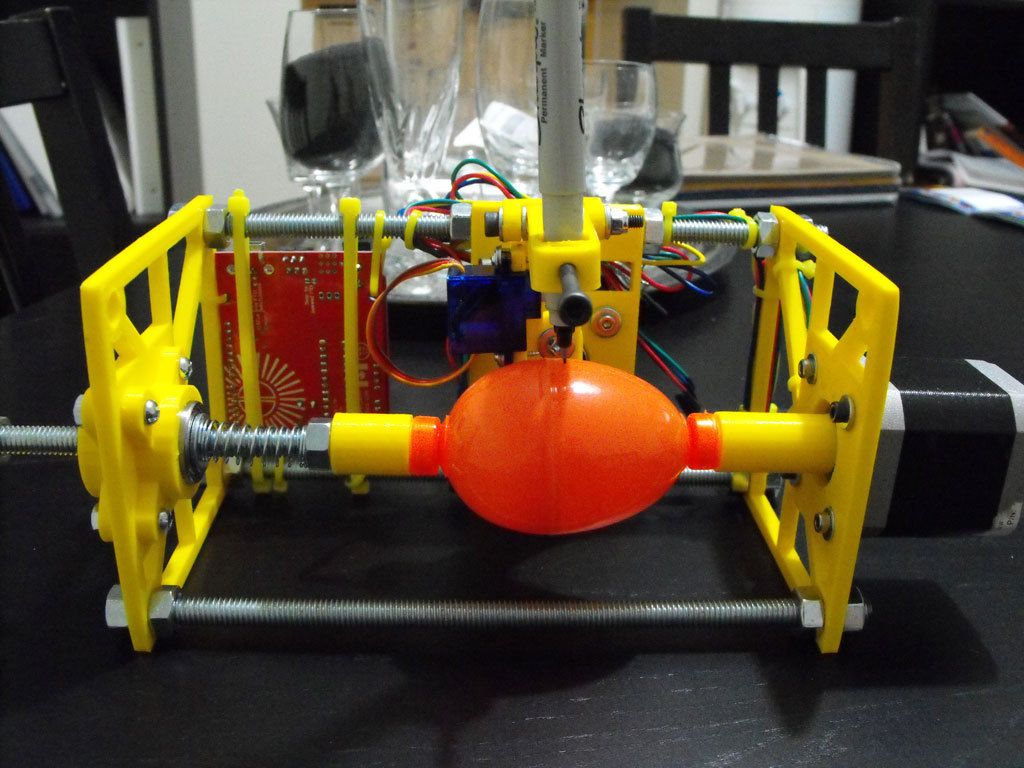

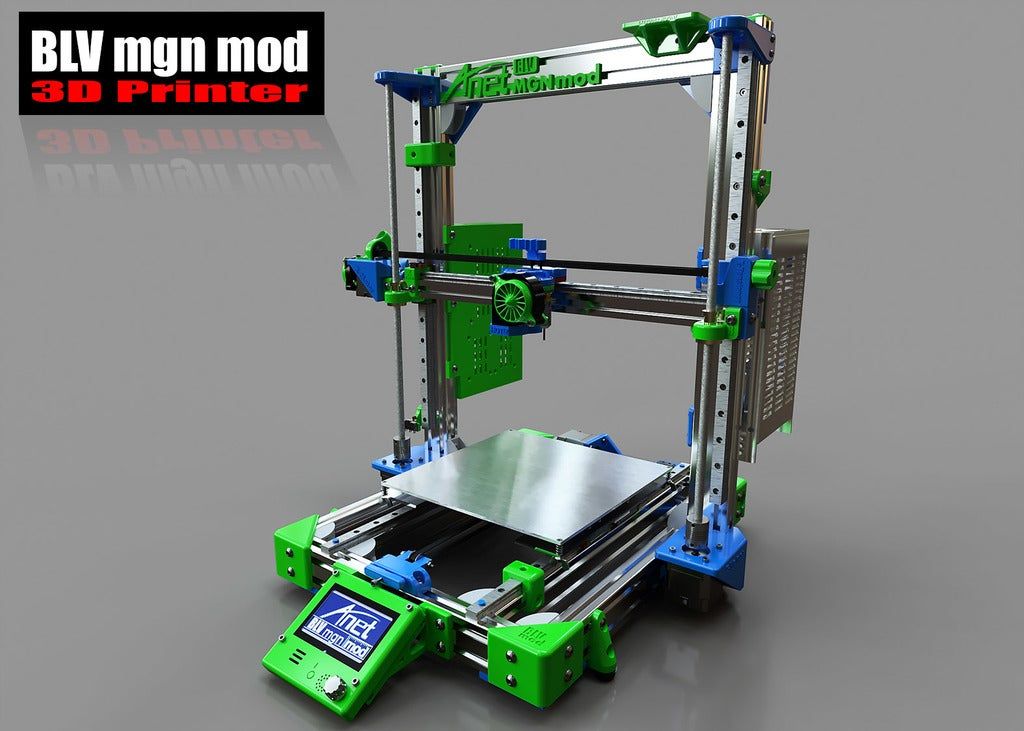

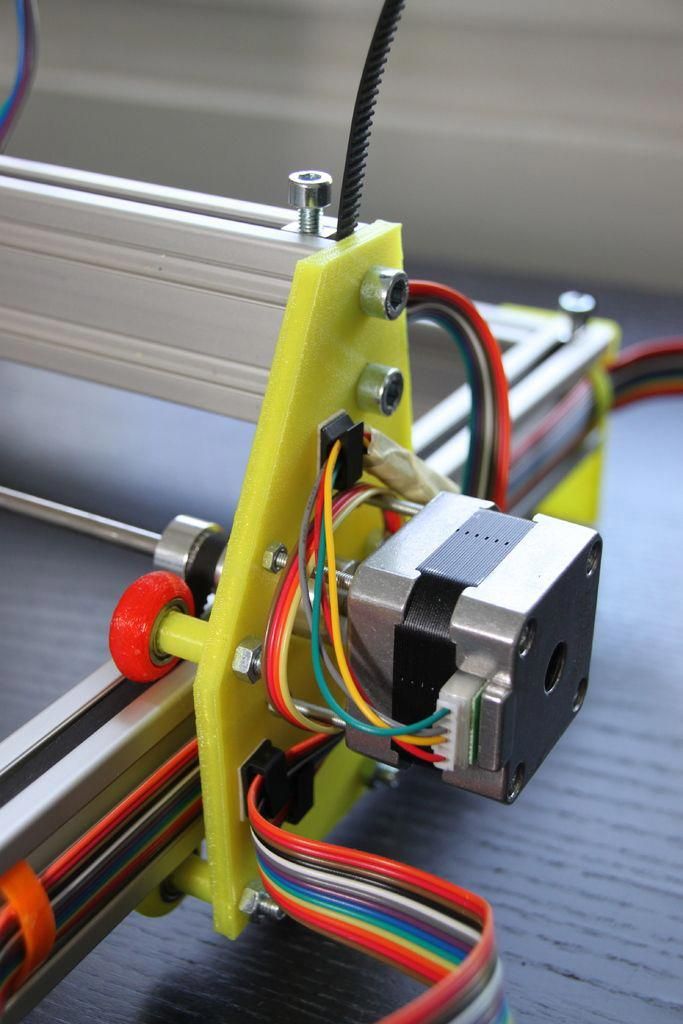

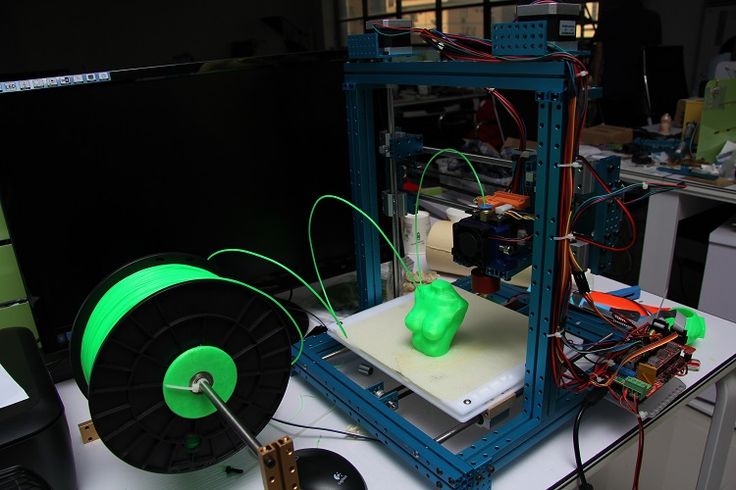

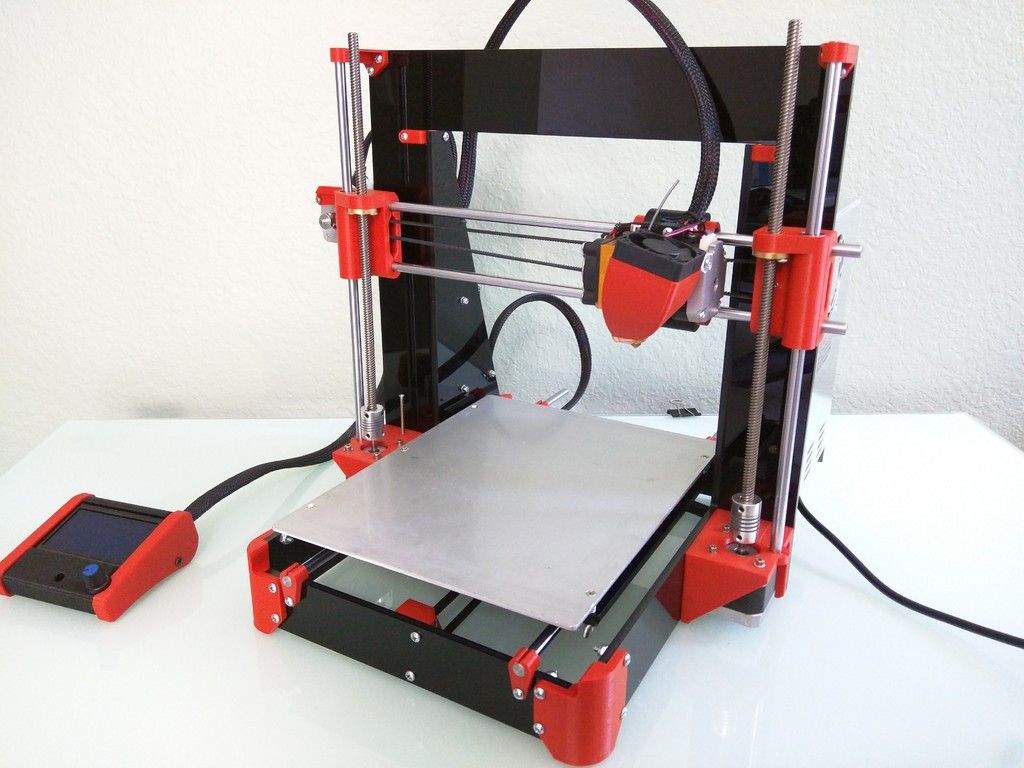

Chapter 2. Exploring the world of 3D printing and technology. My first printer was Anet A8. And like all beginner 3D printers, the first thing I started printing was upgrades for it.

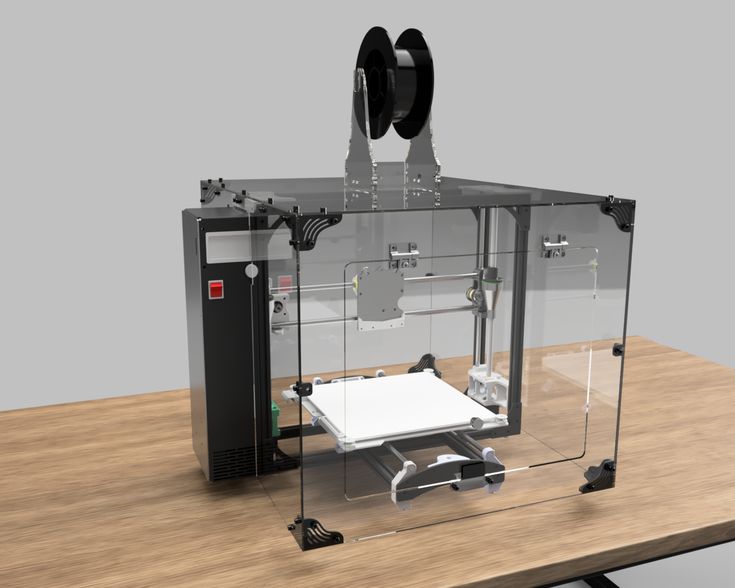

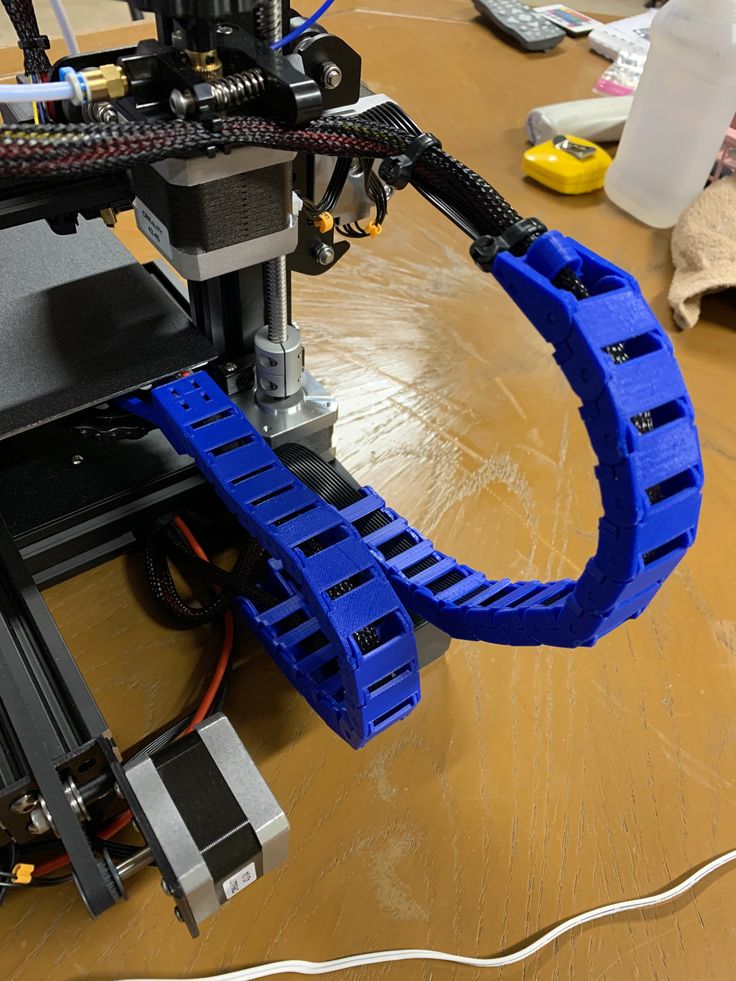

Since stock printers from the budget segment, in my opinion, it is necessary to refine them so that they give more or less good results in printing. I described in detail about all my improvements on the site, who are interested can familiarize themselves with and apply for their Anet (https://3dtoday.ru/blogs/alexforward/konkurscrealityv). The printer turned out to be very functional and gave rise to a new printer with CORE XY kinematics. The printer turned out to be of decent quality and produced a good print result. And most importantly, it was more compact, had its own heat chamber, direct extruder, and the print speed on it was faster. This project is also described in detail by me https://3dtoday.ru/blogs/alexforward/klassnyi-3d-printer-po-tipu-core-xy-iz-orgtexniki-konkurscreality

This project is also described in detail by me https://3dtoday.ru/blogs/alexforward/klassnyi-3d-printer-po-tipu-core-xy-iz-orgtexniki-konkurscreality

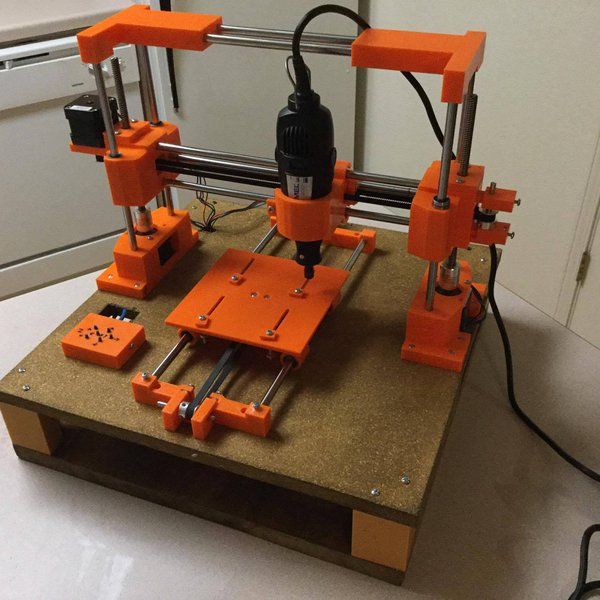

But these were all finished projects modeled by other people, I just took the best and brought it to life. More serious projects already required the study of 3D modeling programs.

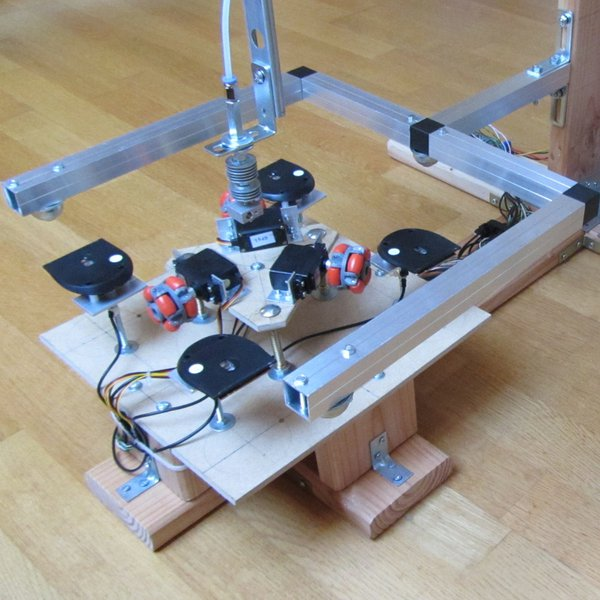

Chapter 3. Program selection and training . To study 3D modeling, I chose Compass 3D from Ascon. I think one of the best programs, since it is used by the majority, Compass is actively used in industry and enterprises, many free study lessons. But the most important factor, my brother, who works as a design engineer at the factory, can easily fix jambs when creating a model or suggest how best to do it. By the way, the program is easy to study on your own and does not require basic skills. I learned it from scratch, having no idea about 3D modeling at all. My first completed projects using Compass 3D and 3D printing were the creation of fittings (legs, handles, plastic dowels, etc. ), electronics cases, radio-controlled models.

), electronics cases, radio-controlled models.

Toys and accessories.

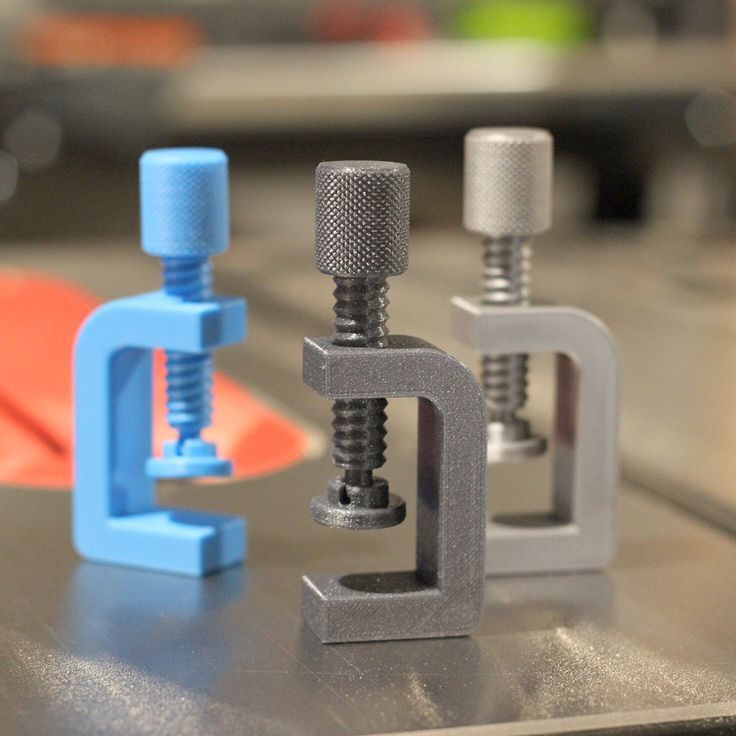

Tool. I will give an example of my template for installing handles and locks for interior doors. This template is my own developed copy of the existing model on the Internet. In terms of money, the template cost me almost 10 times cheaper than it is sold on the Internet.

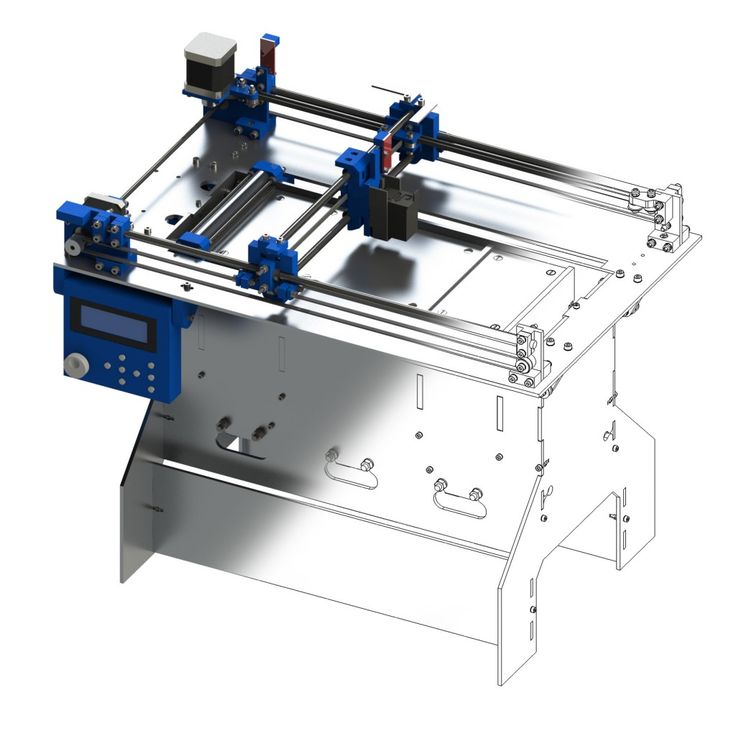

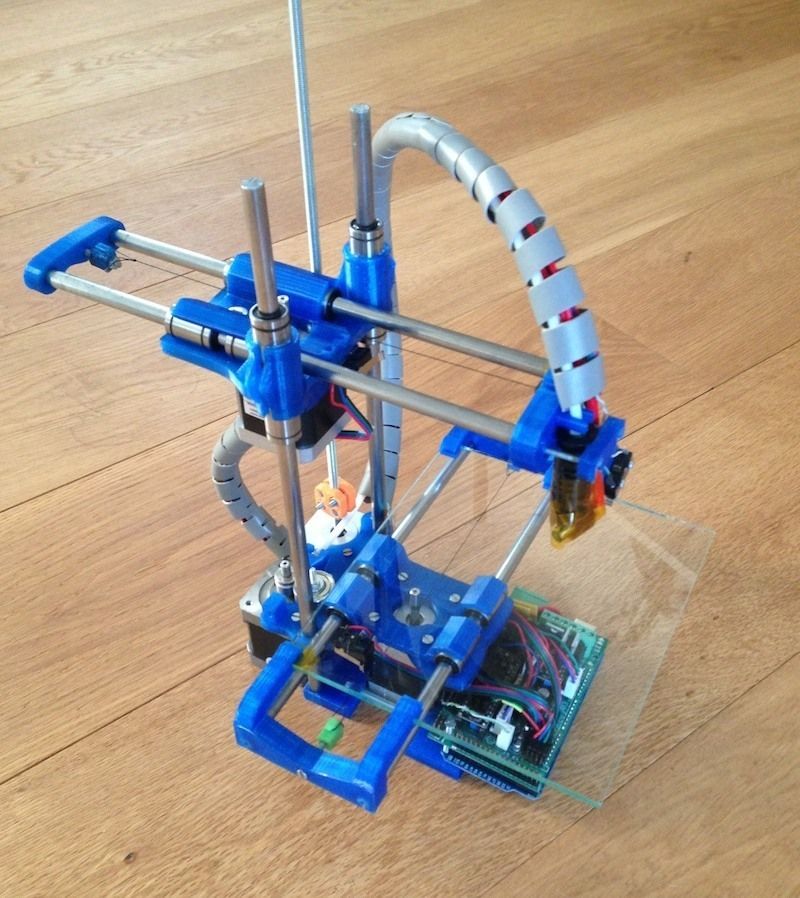

But in order to create a part consisting of several parts, and print everything the first time, so that everything fits together, Compass 3D has a wonderful assembly function for this. In it, in fact, you can check whether the parts fit together and immediately make changes and corrections to the model. According to this principle, I implemented projects for the modernization and upgrade of my friends' 3D printers.

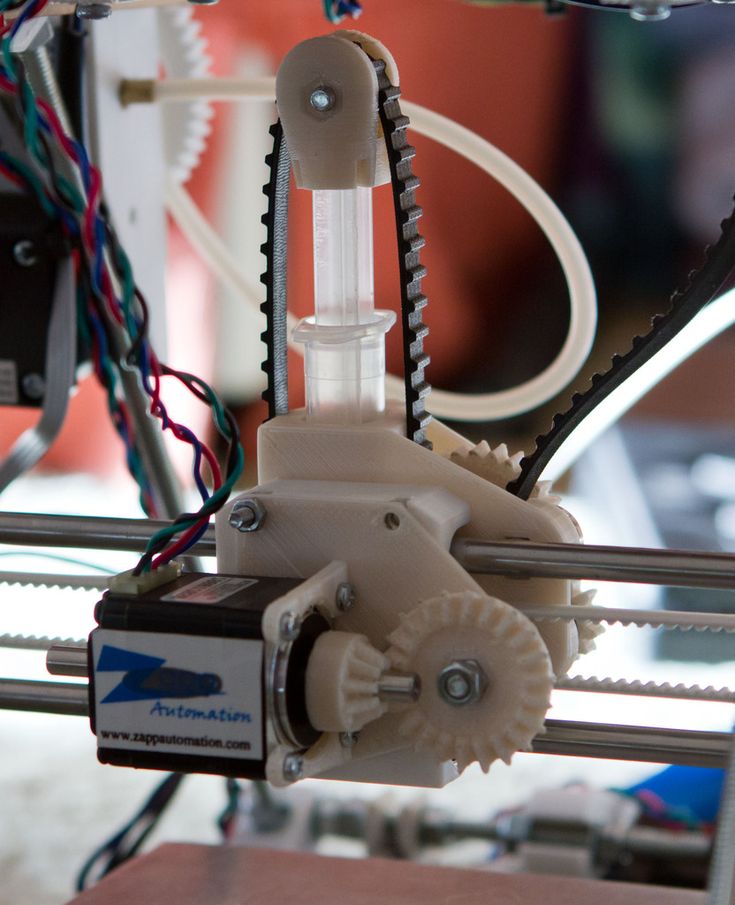

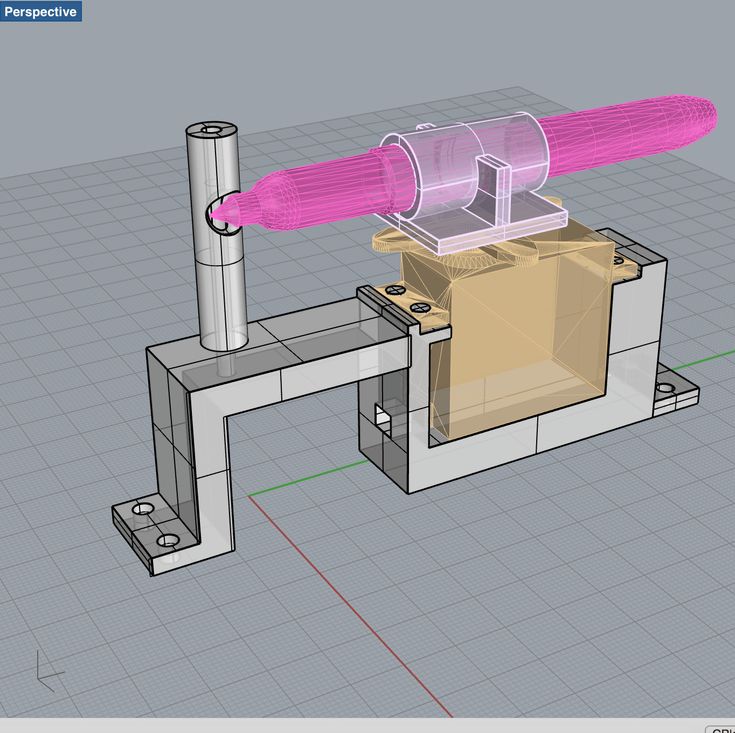

JGAurora print carriage upgrade. First, 3D models were made separately. Then, with the help of the assembly, they were brought to mind and adjusted to each other. The carriage became lighter, there was an adjustment of the tension of the belts along the axis, better blowing of the parts and, most importantly, the installation of an E3D V6 hotend.

Full upgrade of Anycubic I3 Mega. But in this project, half of the details were borrowed from other users.

Before

Now

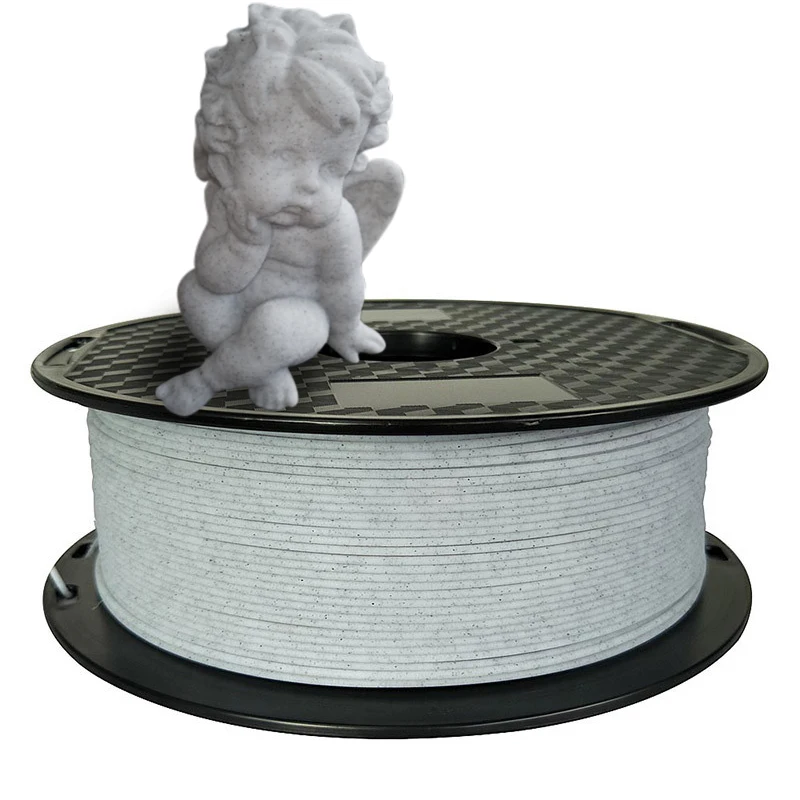

This is just a part of my work. In fact, a huge number of parts and spare parts were printed. Not always everything worked out the first time, especially printing with ABS plastic was hard to master. I mostly print ABS as it is the cheapest material and is easily machined. Yes, it has many disadvantages, but for my purposes, ABS is the best material.

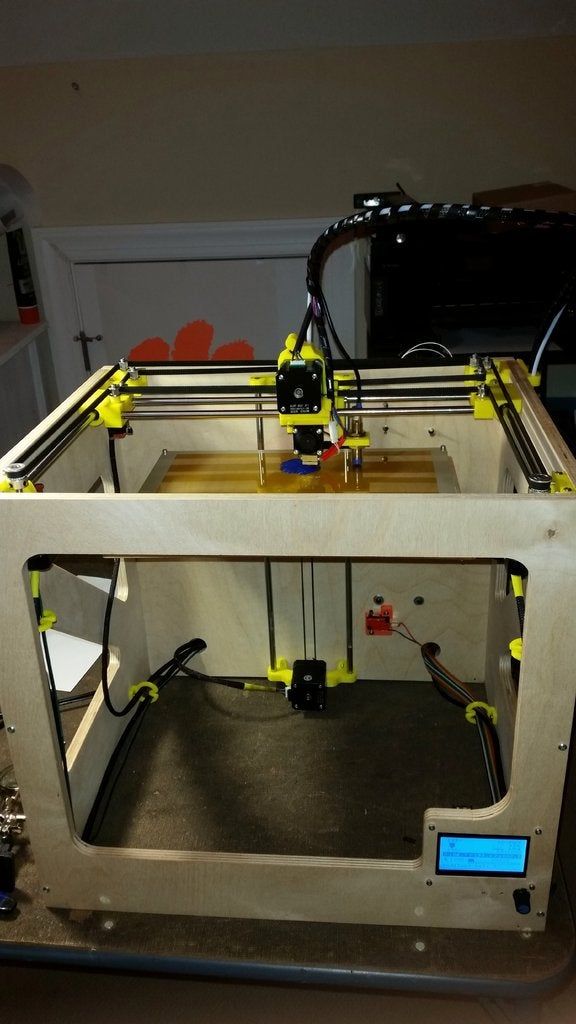

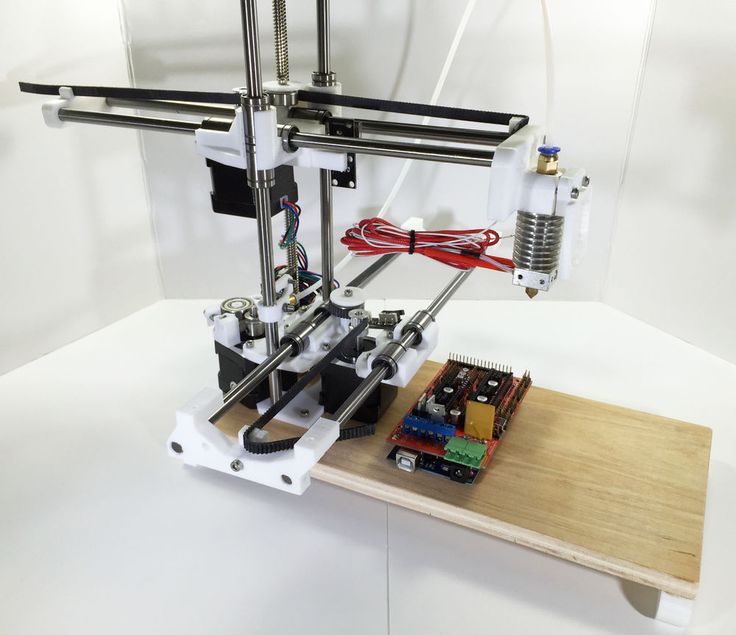

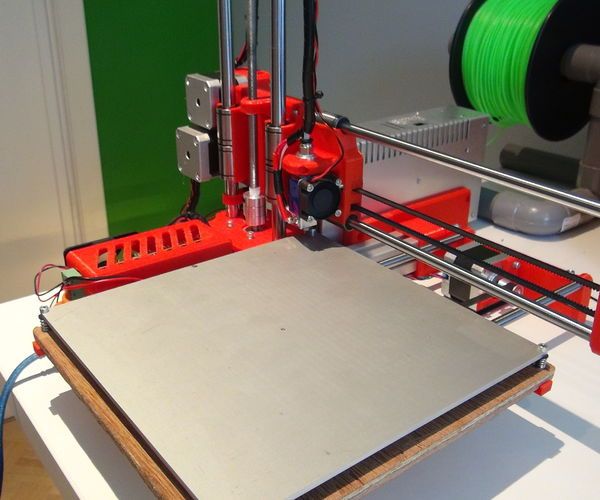

Chapter 4. Summing up. Having received basic knowledge of 3D printing and modeling, I decided to assemble a 3D printer for my purposes, so that it would be an indispensable assistant and meet the following requirements:

1. Printing with ABS plastic - need a hot table and closed case

2. E3D V6 hotend - for fast repair and availability of spare parts at low prices

3. Good print quality and printing speed - fast production of parts

4. Compact - takes up little space on the desktop

Compact - takes up little space on the desktop

5. The printer must be popular with users - a large number of upgrades and the availability of information on maintenance and repair.

Ultimaker Original proved to be ideal for these requirements. This printer has all the files for its creation and refinement in the public domain, produces excellent print quality at high speeds.

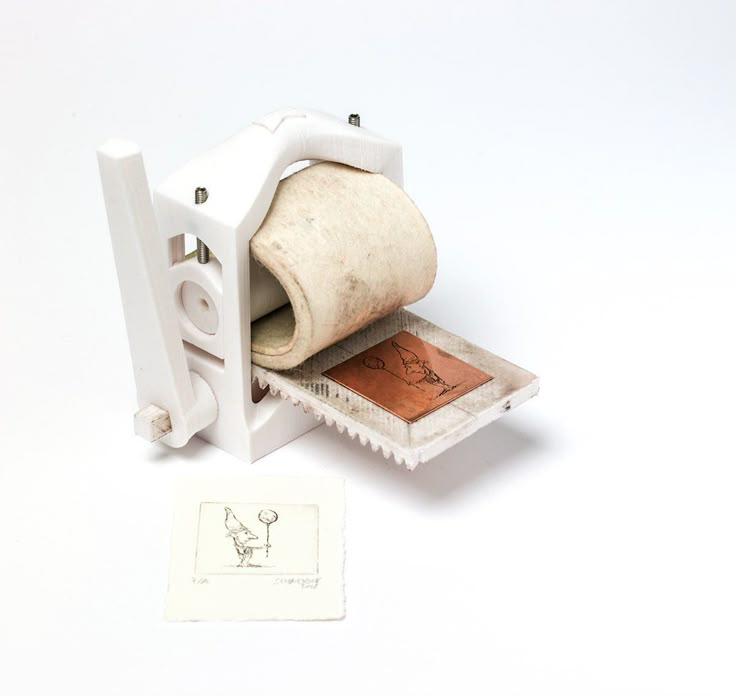

To make an airtight chamber from a draft, I developed drawings for the doors and the hood of the printer, since I could not find these parts, and I made a box for tools. As a result, the printer takes up minimal space on the table. Someone will say that it is easier to buy a new one. I do not argue with this, but my goal was to minimize the cost of building a 3D printer, which is several times cheaper than the original. At the moment, Ultimaker is already hard at work creating my next projects. At the moment, a machine for sharpening knives and scissors has already been developed, it is waiting for its implementation.

And plans to build a CNC router and laser engraver from a structural profile for home use with a small area. These tools will significantly expand the scope of modeling and product creation.

3Didea

Subscribe to the author

Subscribe

Don't want

12

Programs for modeling and printing on a 3D printer

Contents

-

- 3 Programs for 3D modeling

- types of files for 3D printing

- Free programs

- Paid programs for 3D modeling

- Programs for cutting 3D models (slisers)

- Free sluds 9009

- To summarize

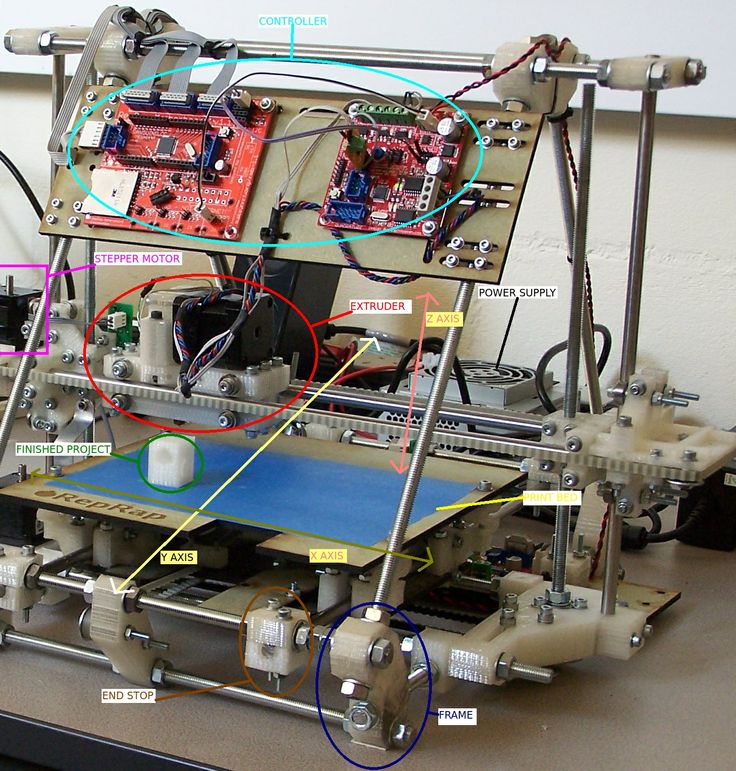

The whole cycle of creating a part on a 3D printer can be fit into three stages: Creating / finding a model, cutting a model in a slicer, printing on a 3D printer. Each stage is tied to its own program. Models are created in special programs, then in the slicer the model is “cut” into steps that the printer will sequentially execute. The resulting list of steps (commands) is either placed on a memory card and run from the printer itself, or sent to the printer via a wired/wireless connection. As a result of all these actions, we get the product. Therefore, looking for a “3D printer program” is wrong: you need to look for a modeling program and a slicer.

The resulting list of steps (commands) is either placed on a memory card and run from the printer itself, or sent to the printer via a wired/wireless connection. As a result of all these actions, we get the product. Therefore, looking for a “3D printer program” is wrong: you need to look for a modeling program and a slicer.

3D modeling software

Programs for 3D modeling are divided into two large groups:

Obviously, when creating a drawing, an engineer needs precise tools: a ruler, pencil, compass, etc. But the artist needs more free tools: brushes, pastels, palettes and others. Programs are divided according to the same principle: in engineering programs, there are all the tools that allow you to accurately specify the characteristics of each element of the part, and in art programs, tools are created to give smoother forms so that the model looks as natural as possible. Of course, in art programs it is possible to model technical products, but this is comparable to drawing a drawing with pastel: it is inconvenient, difficult and inaccurate. Therefore, it is very important to determine why you need a simulation program.

Therefore, it is very important to determine why you need a simulation program.

Tip: It is best to learn one or two programs at a professional level, as this will allow you to create complex models. But you should also know the basics in other programs, since a large circle of knowledge allows you to more flexibly choose the approach to creating models.

File types for 3D printing

To begin with, it is worth understanding what types of files are involved in the manufacturing process of the part. The first step is to create a model. It can be saved in the format of the program itself (for example, KOMPAS-3D files have the .m3d extension, while 3ds Max has the .MAX file extension). Such files can only be opened in the programs in which they were created. But we need a universal format - STL. All programs can save models in this format. It stores the polygons that create the model.

All files are divided into 3 categories:

-

Files that store polygonal information (STL, OBJ, etc.

). They are analogues of a raster image. It is possible to increase the quality of 3D models in this format only by smoothing, but in this case small details will be lost, and the file weight will increase greatly.

). They are analogues of a raster image. It is possible to increase the quality of 3D models in this format only by smoothing, but in this case small details will be lost, and the file weight will increase greatly. -

Files that store the steps for creating a part (STEP, STP, etc.). Here you can draw an analogy with vector images. Each element is specified either using simple dot connections (for example, as in a cube or pyramid), or using formulas (any curved, rounded objects). Models in this format can be scaled without loss of quality, while maintaining a relatively small file size.

-

Utility files that store steps for a 3D printer (GCODE, GCOD). These files store the commands that the printer executes and, in some cases, comments (for example, with what settings the model was cut). Some slicers can simulate the movements of the printer, thereby rendering the model, but it is impossible to convert a file from this format to a full-fledged model.

Be careful! If you are not sure that the GCODE file is intended for your printer, then you should not print it, because the print area for each printer is different. On third-party firmware there is no limit on the maximum travel distance, some third-party software commands may lead to incorrect operation of the control board. If the printer tries to move the print head out of the printable area many times, then it can harm itself!

If the files are in the same category, then they can be easily converted from one format to another with almost no data loss. The formats indicated in brackets are a kind of “transits”. For example, Inventor has its own file format - itp, and Fusion 360 has its own - f3d. But if you save the file in Inventor in the generic STEP format, you can open it in any engineering program and then save it in that program's format.

Free programs

Usually, free programs are either limited in functionality or created by enthusiasts, which is why they have a very crooked interface and a lot of errors. But their functionality is enough to create simple models, and in some cases, such programs can completely replace paid software.

Tinkercad

In essence, this is not even a program, but a website, that is, it does not need to be installed on a computer and it opens from any device that has Internet access. But this is its main disadvantage - without Internet access, you will not be able to download any model for yourself, because each project is initially saved in the cloud. You also need to register to use this site. Initially, the site was created for children, so each tool is intuitive. The program is suitable for modeling simple products: gaskets, bushings, adapters, covers, boxes, etc.

Pros:

Cons:

-

Inability to work without the Internet

-

Each individual project needs to be downloaded

-

Limited number of tools

FreeCAD

This program is designed to create technical products: fasteners, bushings, hinges and more. Since this is an open source project, it is distributed free of charge. At the same time, it has all the necessary functionality for opening and editing files with the .step extension - a universal format for all engineering programs. It is also worth noting the ability to add addons - special subroutines that allow you to perform any actions in a fully automatic mode. For example, there is an addon that makes it easier to create various gears. In this program, you can create more complex products: mechanisms, gearboxes, hinges, etc.

Since this is an open source project, it is distributed free of charge. At the same time, it has all the necessary functionality for opening and editing files with the .step extension - a universal format for all engineering programs. It is also worth noting the ability to add addons - special subroutines that allow you to perform any actions in a fully automatic mode. For example, there is an addon that makes it easier to create various gears. In this program, you can create more complex products: mechanisms, gearboxes, hinges, etc.

Pros:

Cons:

OpenSCAD

This CAD is closer to programming languages than to modeling: each object or any action is specified as a code. This allows you to create universal models. For example, a coin sorter: once you write the “model code”, you can create a huge number of variants of this model for different countries, changing just a few parameters. This program, like the previous one, is an open source project, as a result of which it is regularly updated.

Pros:

-

Works on weak PCs

-

Ease of creating universal models

-

Easy to learn if you have programming experience

Cons:

-

No Russian interface

-

Is a programming language

-

Difficult to create curvilinear geometry

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Anycubic |

Free shipping

Add to compare

Product added to compare Go

| Manufacturer | Phrozen |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Raise3D |

Free shipping

Add to compare

Product added to compare Go

| Manufacturer | Anycubic |

Meshmixer

Art program for entry-level 3D modeling. There are simple tools for processing STL files and functions for recovering “broken” files. Using Meshmixer, you can conveniently cut the model into several parts, as it is possible to set the size of the print area of your printer. And one of the most useful tools is the installation of tree supports. This function has already appeared in many slicers, but it is in meshmixer that they can be flexibly configured and installed manually. Despite the many tools, this program is rather auxiliary, as there are more suitable programs for creating a model from scratch.

There are simple tools for processing STL files and functions for recovering “broken” files. Using Meshmixer, you can conveniently cut the model into several parts, as it is possible to set the size of the print area of your printer. And one of the most useful tools is the installation of tree supports. This function has already appeared in many slicers, but it is in meshmixer that they can be flexibly configured and installed manually. Despite the many tools, this program is rather auxiliary, as there are more suitable programs for creating a model from scratch.

Pros:

Cons:

-

Limited functionality for creating 3D models

-

Lack of Russian interface

-

Some operations require a powerful PC

Blender

A completely free program with huge possibilities not only for creating models, but also for animation, rendering, simulations and much more. It is mainly used by multipliers, but due to the large number of extensions, this program covers a huge range of tasks. At first glance, Blender may seem too complicated, but everyone can master the basic functionality. Also worth noting are constant updates that improve performance and add new tools. A large community of people working in this program and developing it will help with the solution of many problems.

It is mainly used by multipliers, but due to the large number of extensions, this program covers a huge range of tasks. At first glance, Blender may seem too complicated, but everyone can master the basic functionality. Also worth noting are constant updates that improve performance and add new tools. A large community of people working in this program and developing it will help with the solution of many problems.

Paid 3D modeling software

This category includes programs for professionals and enterprises, as well as their simplified versions for home use. Many companies have begun releasing a product at a low cost for home use, although initially the designs were intended only for enterprises and were priced accordingly. The common advantage of these programs is great functionality and constant support. For example, Autodesk Inventor was first released back in 1999 and is updated annually. Next, we will look at the most popular of them.

Fusion 360

The new product from Autodesk tried to combine several tasks at once: modeling, simulation and rendering. In many ways, it adopted the functionality of the previously mentioned Inventor, but supplemented it with a simple interface: many tools are similar to those that can be used in the previously mentioned Tinkercad. You can also edit STL files in it, albeit with a limited set of tools.

In many ways, it adopted the functionality of the previously mentioned Inventor, but supplemented it with a simple interface: many tools are similar to those that can be used in the previously mentioned Tinkercad. You can also edit STL files in it, albeit with a limited set of tools.

The main feature of this program is cloud data processing, such as simulations and renders. At the same time, almost all functions can be performed offline using the power of a PC. To process tasks in the cloud, you need to buy additional tokens, but when creating models, they are not necessary. It is worth considering that despite the presence of a native file format (f3d), all files are initially stored on Autodesk servers, and then they can be saved to your computer.

There is a version for schools and universities, but obtaining such a license requires the educational institution to register and issue you a personal license.

Pros:

Cons:

Price: from 7,123₽ to 25,721₽ for 1 year

Netfabb

The program is designed to prepare the model before slicing. In many ways, it is similar to meshmixer, but it does not have the tools to create a model from scratch. Merging several models in STL format can be called a distinctive function, but the most important tool is the “repair” of models. That is why everyone should install this program, even if you have another model editor or model repair built into the slicer. Also in Netfabb it is very convenient to cut the model into several parts for printing separately. At the moment, the Netfabb functionality is built into Fusion 360 and is not officially available separately, but can be found on third-party resources as a separate program.

In many ways, it is similar to meshmixer, but it does not have the tools to create a model from scratch. Merging several models in STL format can be called a distinctive function, but the most important tool is the “repair” of models. That is why everyone should install this program, even if you have another model editor or model repair built into the slicer. Also in Netfabb it is very convenient to cut the model into several parts for printing separately. At the moment, the Netfabb functionality is built into Fusion 360 and is not officially available separately, but can be found on third-party resources as a separate program.

Pros:

-

Great functionality for repairing the model

-

Convenient cutting into pieces

-

Easy to learn all the necessary tools

Cons:

Price: from 18 024₽ for 1 month

KOMPAS-3D

A professional program created by Russian developers for Russian enterprises. It has a huge functionality, but at the same time, each function has a description, and the main tools have explanatory animations, a huge database of standards and GOSTs is built in. The program is free for all students and does not require verification of documents. There is also a paid version of KOMPAS-3D HOME, which, although intended only for home use, retains all the functionality of the “professional” version. Because of this, and also because of the low price, this CAD system is the best choice as the first professional program for creating complex 3D models.

It has a huge functionality, but at the same time, each function has a description, and the main tools have explanatory animations, a huge database of standards and GOSTs is built in. The program is free for all students and does not require verification of documents. There is also a paid version of KOMPAS-3D HOME, which, although intended only for home use, retains all the functionality of the “professional” version. Because of this, and also because of the low price, this CAD system is the best choice as the first professional program for creating complex 3D models.

Pros:

-

Completely Russian interface

-

A large number of tools

-

Availability of a free student version

-

Very low price

Cons:

Price: from 1 490₽ for 1 year

SolidWorks

One of the oldest programs on the market that has become a standard. If you learn how to work in SolidWorks, then you can work in any CAD. It has a relatively simple interface, an average number of tools that are enough even for professionals, but since the program is designed for production, many functions will only interfere with work. It should be noted that this program is available in Russian, and this is one of the reasons for the prevalence of this program in Russia.

If you learn how to work in SolidWorks, then you can work in any CAD. It has a relatively simple interface, an average number of tools that are enough even for professionals, but since the program is designed for production, many functions will only interfere with work. It should be noted that this program is available in Russian, and this is one of the reasons for the prevalence of this program in Russia.

Pros:

-

Easy to learn

-

The presence of the Russian interface

-

Large community of people using SolidWorks

-

Widespread in Russia

Cons:

Price: from 8,431₽ to 292,560₽ for 1 year

Inventor

The main program at many enterprises, but due to the simplicity of the interface and the presence of the Russian language, it is easy to learn. In many ways, it is similar to SolidWorks, both in functionality and in purpose. The main distinguishing feature of this program is a large number of high-quality video tutorials and text courses. It is studied at many universities both around the world and in Russia.

The main distinguishing feature of this program is a large number of high-quality video tutorials and text courses. It is studied at many universities both around the world and in Russia.

Pros:

-

Prevalence among the Russian community

-

Lots of learning materials

-

Intuitive interface

-

Availability of student version

Cons:

Price: from 106 860₽ for 1 year

SelfCAD

It is the simplest program for technical modeling. As easy to learn as Tinkercad, but not for kids, but for professional 3D printing. This program is not CAD, so there is no editing history, which allows, for example, to change sketches without entering edit mode.

You can download this program for free, but this version will have limited functionality. There are also paid versions with monthly payment or a one-time purchase forever. Only paid versions have a simple slicer, but its functionality is extremely limited.

Only paid versions have a simple slicer, but its functionality is extremely limited.

Pros:

Cons:

-

Small functionality

-

Big cost

Price: from 1160₽ ($14.99) for 1 month

3ds Max

The program is designed to create 3D models and render images. It has great functionality, but it is extremely difficult to learn due to the lack of the Russian language and a complex interface. This is due to the fact that 3ds Max was originally developed for 3D animation and video game studios. It was to create a simple and free analogue that the previously mentioned Blender was created. Due to the above reasons, this program is not suitable for creating 3D models for subsequent printing on a 3D printer, but nothing prevents you from doing this.

Pros:

Cons:

Price: from 9 791₽ for 1 month

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Phrozen |

Free Shipping

Add to Compare

Product added to comparison Go

| Manufacturer | Anycubic |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | PICASO 3D |

Free Shipping

Add to Compare

Product added to compare Go

| Manufacturer | Phrozen |

3D cutting software (slicers)

Having any model in STL format, you cannot immediately place it in the printer and start printing, because the printer only executes commands, and these commands form a slicer. According to the etymology of the word, one can understand that the program cuts the model into layers, or rather into separate commands. But the number of cutting options for one model is almost endless. In this regard, a large number of programs have appeared that allow you to fully customize the operation of the slicer, or rather, how it will split the model into separate commands. The slicer itself consists of two parts: the core and the shell. The slicer core performs slicing based on the specified parameters, and the shell allows you to set these parameters and visually evaluate the slicing result before sending the model to print. In addition, many slicers have built-in functionality for direct access to the printer, which allows you to manually control the printer and carry out its settings and diagnostics. Next, we will consider the most popular slicers, which have their positive and negative sides.

According to the etymology of the word, one can understand that the program cuts the model into layers, or rather into separate commands. But the number of cutting options for one model is almost endless. In this regard, a large number of programs have appeared that allow you to fully customize the operation of the slicer, or rather, how it will split the model into separate commands. The slicer itself consists of two parts: the core and the shell. The slicer core performs slicing based on the specified parameters, and the shell allows you to set these parameters and visually evaluate the slicing result before sending the model to print. In addition, many slicers have built-in functionality for direct access to the printer, which allows you to manually control the printer and carry out its settings and diagnostics. Next, we will consider the most popular slicers, which have their positive and negative sides.

Free slicers

The availability of free slicers is due to the fact that without them the printer becomes a useless machine that can only heat coffee and play a melody with the help of motors. Therefore, many companies that create 3D printers supply slicers with them, while laying them out in the public domain. Often these are large companies such as Ultimaker, CraftUnique, Prusa, etc.

Therefore, many companies that create 3D printers supply slicers with them, while laying them out in the public domain. Often these are large companies such as Ultimaker, CraftUnique, Prusa, etc.

Ultimaker Cura

It was originally created only for Ultimaker 3D printers, but soon became an open-source project. Now in its library of profiles you can find a huge number of printers from various manufacturers. Uses its own core Cura, which has many settings and functions: tree support, wireframe printing, color printing, etc.

Frequent updates bring innovations and even more profiles for various 3D printers. It is a standard choice for beginners, as it has two control modes: simple and professional. Recently, support for add-ons has appeared that allows you to save backup copies of settings, repair the model directly in the slicer, integrate various programs for 3D modeling, and much more.

It is also possible to control the printer by sending commands directly from the computer. But there is no feedback from the printer, apart from receiving information about the temperature of the nozzle and table.

But there is no feedback from the printer, apart from receiving information about the temperature of the nozzle and table.

Pros:

Cons:

Prusa Slic3r

Sometimes you can find other names: Slic3r Prusa Edition or Slic3r PE. Prusa decided not to reinvent the wheel, and took the open-source Slic3r project, partially reworked it and began to actively develop it. Like Cura, Prusa Slic3r has many printer profiles, but Prusa's printer profiles are the most optimized. The core of the slicer of our own design, while the number of settings is less than that of the same Cura.

A distinctive feature is the flexible adjustment of the layer thickness and the support of a special extruder capable of printing 5 different plastics at once (again, produced by Prusa). The program will be extremely useful for people who have more than one 3D printer: all settings are divided into 3 tabs, each of which can be saved to separate profiles. But the printer control console disappeared completely, only the send button for printing via wire remained. In general, this program will be a reliable and convenient slicer, especially if you have a large number of printers.

But the printer control console disappeared completely, only the send button for printing via wire remained. In general, this program will be a reliable and convenient slicer, especially if you have a large number of printers.

Pros:

Cons:

Repetier

This slicer was created more for remote control of the printer, but it can also cut models. One of the few programs where you can choose the slicing core: Cura, Sic3r, Prusa Slic3r. The number of settings for the slicing itself is extremely small, but they are enough to cut the test cube.

The most important plus of this slicer is the huge functionality for managing and configuring the printer. It is worth noting the convenient interface for sending commands, as well as customizable temperature graphs. This is extremely useful, for example, when tuning the PID or checking the movement of the axes. Even if you choose a different slicer, this program is handy to have in order to 3D print using GCODE from another slicer.

Pros:

Cons:

MatterControl 2.0

One of the few programs that combine functions for editing stl files and a slicer. You won't be able to create any serious model, but you can add text or cut out part of the model. The slicer has not so many settings, but they are enough for a beginner 3D printer. This slicer can be useful if you need to make art products with minor changes. Supports saving to the cloud.

Pros:

Cons:

3DprinterOS

This software is designed to remotely manage printers from anywhere in the world. All that is needed is to connect the printer to the computer and install this program on it. From now on, all printer management occurs through the web interface. In it, you can remotely change the model, cut it and put it on print. It is also possible to connect a camera and observe the printing process. There are very few slicing settings, some will not even be enough to calibrate the printer, not to mention serious printing.

Carefully! It is not recommended to leave the printer unattended, especially if it is no longer new: at any time there may be a risk of fire due to wiring or mechanical problems.

Pros:

-

Simple interface

-

Start printing from anywhere in the world

-

Ability to monitor printing

-

Availability of tools for editing the model

Cons:

IceSL

It is a combination of OpenSCAD with its “modeling language” and slicer. In addition, models can be edited using a “brush”, like the one in Meshmixer. It has many small pluses that are not found in other slicers, but it is not suitable for everyday use due to an inconvenient interface and a small number of slicer functions. This program can be described in one phrase: interesting, but not recommended.

Pros:

Cons:

Octoprint

In many ways it is similar to 3DprinterOS, but is an open source project, as a result of which it has many additions. Designed for home use. It is the most popular way to remotely control a printer, and the user community is constantly growing. Therefore, it will be very easy to transfer your printer to remote control due to the large number of lessons and articles. The program itself does not have a slicer, but direct export of files from Slic3r is supported, which is already good in itself. Just like Repetier, it has an excellent printer management and monitoring console. But, unlike the aforementioned analogue, most of the functions will have to be configured manually.

Designed for home use. It is the most popular way to remotely control a printer, and the user community is constantly growing. Therefore, it will be very easy to transfer your printer to remote control due to the large number of lessons and articles. The program itself does not have a slicer, but direct export of files from Slic3r is supported, which is already good in itself. Just like Repetier, it has an excellent printer management and monitoring console. But, unlike the aforementioned analogue, most of the functions will have to be configured manually.

Pros:

-

Large user base

-

Lots of tutorial articles

-

Ability to create a video broadcast of the printing process

Cons:

Paid Slicers

At the moment, many paid slicers are no longer used, as free ones have either caught up or overtaken them. But some of them are still unique.

Simplify3D

One of the first thundered paid slicers. At the time of its introduction, it was the most advanced due to the ability to change the print settings for one model at different layer heights and the functionality of printing with more than one extruder. But at the moment it has been replaced by Cura and Prusa Slic3r. Nevertheless, the convenience of setting up print settings and their number still remain the main advantage of this slicer. Also worth noting is the excellent printer management interface, second only to Repetier host.

Another difference is the ability to manually install supports and a large number of filling patterns. Viewing models also has several features: changing the way models are displayed, viewing in section, displaying normals to planes.

Pros:

-

Lots of print options

-

Convenient printer management interface

-

Manual installation of supports

-

Changing print settings at different heights

-

Easy print setup with two extruders

Cons:

Price: from 11499₽ ($149)

Read also: A detailed review of 3D printing slicers: Ultimaker Cura, Simplify3D, IdeaMaker, UP Studio, FlashPrint

Astroprint

Many believe that this particular software is a direct competitor to 3DPrinterOS. The most important difference is user friendliness, achieved through a user-friendly interface and easy installation. The program is based on Octoprint, essentially providing only a server, a modified interface and several add-ons that allow you to fully manage the printing process while away from the printer - from finding a model, to cutting and printing. At the same time, the program positions itself as a serious business solution, so the company also provides special PCs and management consoles that make it easy to connect the printer to the system. A trial plan is available where only 2 printers can be connected, but all basic features will be available.

The most important difference is user friendliness, achieved through a user-friendly interface and easy installation. The program is based on Octoprint, essentially providing only a server, a modified interface and several add-ons that allow you to fully manage the printing process while away from the printer - from finding a model, to cutting and printing. At the same time, the program positions itself as a serious business solution, so the company also provides special PCs and management consoles that make it easy to connect the printer to the system. A trial plan is available where only 2 printers can be connected, but all basic features will be available.

Pros:

-

Easy connection and setup

-

Trial Availability

-

Interface specially designed for mobile devices

Cons:

Price: from 765₽ ($9.90) for 1 month

KISSlicer

This slicer is another representative of programs that failed to keep up with the times. Previously, its functionality was a cut above the rest, but now the same Cura has all the same settings as KISSlicer, and also adds its own. Of the useful in this program, we can note the function of joint viewing of GCODE and model.

Previously, its functionality was a cut above the rest, but now the same Cura has all the same settings as KISSlicer, and also adds its own. Of the useful in this program, we can note the function of joint viewing of GCODE and model.

There were two versions: free and PRO. The only significant difference between them is that the paid version has support for printing in multiple colors. At the moment the project is dead, even the main site does not work, but the program can still be found on third-party sources.

Pros:

Cons:

Price: from 3240₽ ($42)

Summing up

After considering all the popular programs, we can highlight the clear favorites:

For beginners in 3D printing, Tinkercad is the best 3D modeling software because it combines simplicity with the necessary functionality. The best programs for professional-level 3D modeling are KOMPAS-3D, Fusion 360 and Blender, due to the huge number of tools and a large community that makes it easy to find lessons and guides.