3D printing sculpteo

3D Printing Materials: Plastic, Resin, Metal

With 75+ combinations of 3D printing materials and finishings, we guarantee the highest professional quality from each of our state-of-the-art 3D printers and printing techniques.

- ISO 9001

- Fast Turnaround

- Secure File Upload

3D Printing

Selective Laser Sintering

HP Jet Fusion

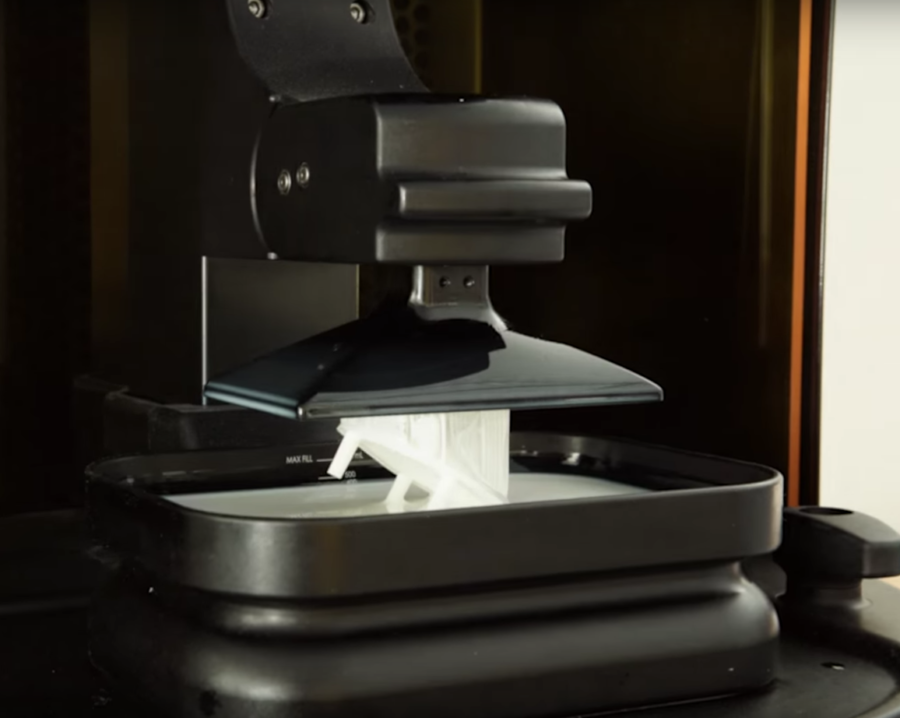

Stereolithography

DLP / LCD

Polyjet

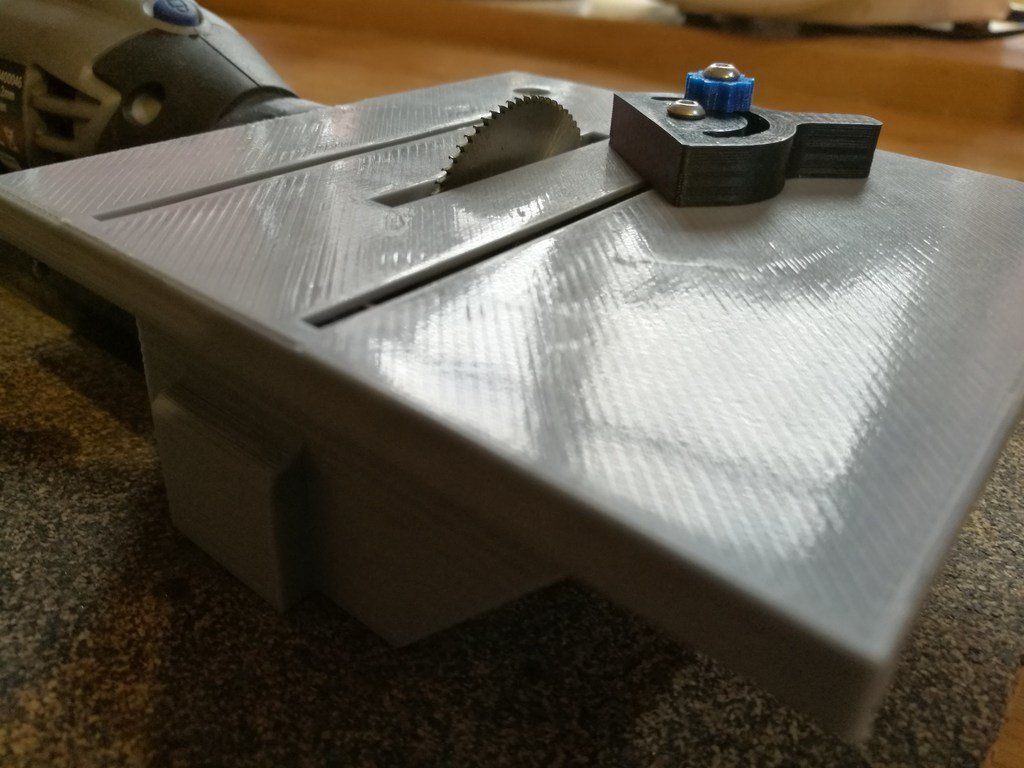

Fused Deposition Modeling

DMLS / SLM

Metal Filament

Binder Jetting

Wax Casting

Laser Cutting / Engraving

Laser Sintering / Powder bed technology

Polymer powder

For prototyping and production

Lead times: 2 - 15 days

- Laser Sintering / Powder bed technology

- Polymer powder

- For prototyping and production

- Lead times: 2 - 15 days

Multi-agent printing / Powder bed technology

Polymer powder

For prototyping and production

Lead times: 2 - 15 days

- Laser Sintering / Powder bed technology

- Polymer powder

- For prototyping and production

- Lead times: 2 - 15 days

Photochemical process curing liquid resin

Photopolymer resins

For prototyping

Lead times: 1 - 15 days*

- Photochemical process curing liquid resin

- Photopolymer resins

- For prototyping

- Lead times: 1 - 15 days*

* With this technology, we offer a 24H Express option. Orders passed before 15:30 (GMT + 1) will be ready for pick up or shipping by 11:00 am (GMT + 1) the following day.

Photochemical process curing liquid resin

Photopolymer resins

For prototyping and production

Lead times: 5 - 15 days

- Photochemical process curing liquid resin

- Photopolymer resins

- For prototyping and production

- Lead times: 5 - 15 days

Jet layers of curable liquid photopolymer

Photopolymer resins

For prototyping and production

Lead times: 2 - 15 days

- Jet layers of curable liquid photopolymer

- Photopolymer resins

- For prototyping and production

- Lead times: 5 - 15 days

Design

Verowhite

Polyjet Technology

Design

VeroClear

Polyjet Technology

Photochemical process curing liquid resin

Photopolymer resins

For prototyping and production

Lead times: 2 - 15 days

- Photochemical process curing liquid resin

- Photopolymer resins

- For prototyping and production

- Lead times: 5 - 15 days

3D Printing Materials

Performance

Rigid Polyurethane

Carbon DLS Technology

Deposits melted filament layer by layer

Polymer filament

For prototyping and production

Lead times: 5 - 15 days

- Deposits melted filament layer by layer

- Polymer filament

- For prototyping and production

- Lead times: 5 - 15 days

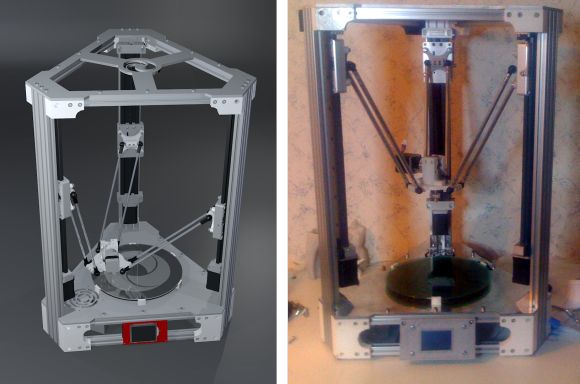

Laser Sintering / Powder bed technology

For prototyping and production

Lead times: 15 - 25 days

- Laser Sintering / Powder bed technology

- Metal

- For production

- Lead times: 15 - 25 days

Metal Filament

Deposits melted filament layer by layer

For prototyping and production

Lead times: 15 - 25 days

- Deposits melted filament layer by layer

- Metal

- For prototyping and production

- Lead times: 15 - 25 days

Binding agent / Bed powder technology

For production

Lead times: 15 - 25 days

- Binding agent / Bed powder technology

- Metal

- For production

- Lead times: 15 - 25 days

Binding agent / Bed powder technology

For production

Lead times: 15 - 25 days

- Binding agent / Bed powder technology

- Metal

- For production

- Lead times: 15 - 25 days

Laser cutting / engraving

For prototyping and production

Lead times: 5 - 25 days

- Laser cutting/ Powder bed technology

- For prototyping and production

- Lead times: 5 - 25 days

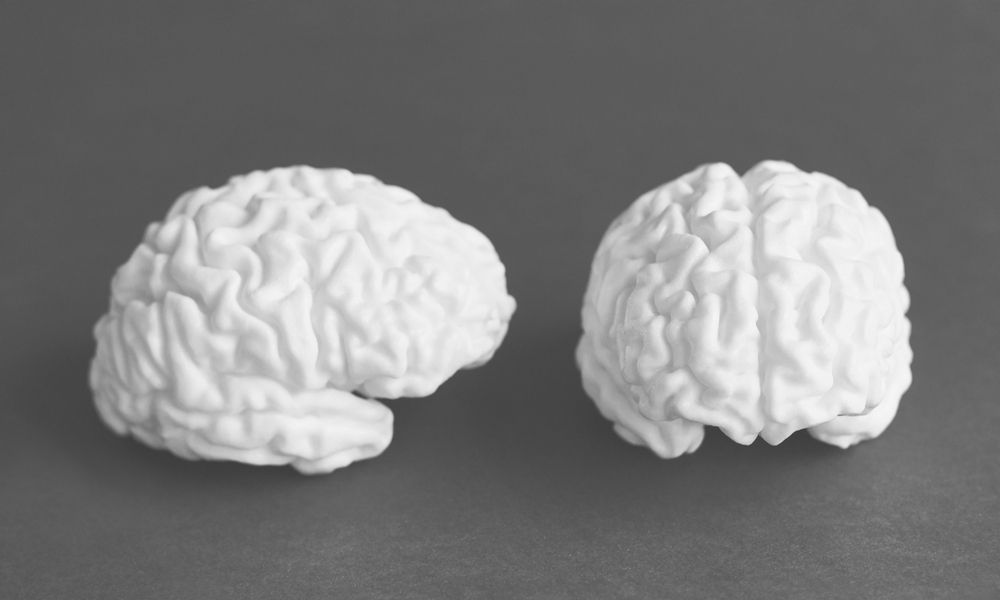

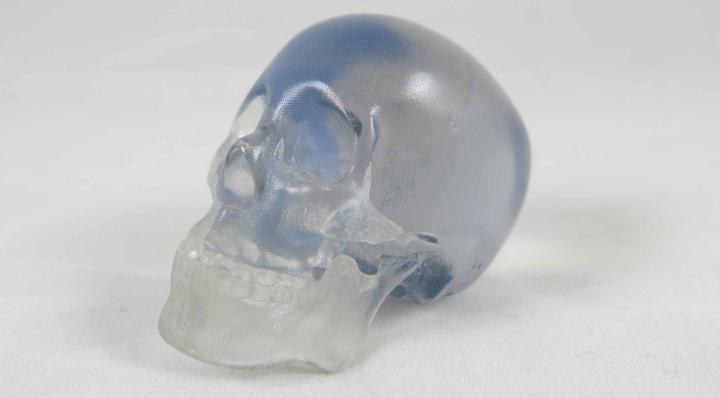

3D printing materials

There are many different 3D printing materials on the market. We at Sculpteo offer many of them for your printing job. The right material is essential for the perfect outcome of your 3D-printed object. Every material has different properties and possibilities. Filaments for example are great for applications such as tools or prosthetics. The most common filaments are ABS, PETG, Nylon, and PLA.

We at Sculpteo offer many of them for your printing job. The right material is essential for the perfect outcome of your 3D-printed object. Every material has different properties and possibilities. Filaments for example are great for applications such as tools or prosthetics. The most common filaments are ABS, PETG, Nylon, and PLA.

Even if it sounds like magic, it is also possible to print metal objects. The process is very similar to a filament printing process, but after the object is printed it has to be debinded and sintered. The metal portfolio is not yet as broad as the filament one, but there are options available still.

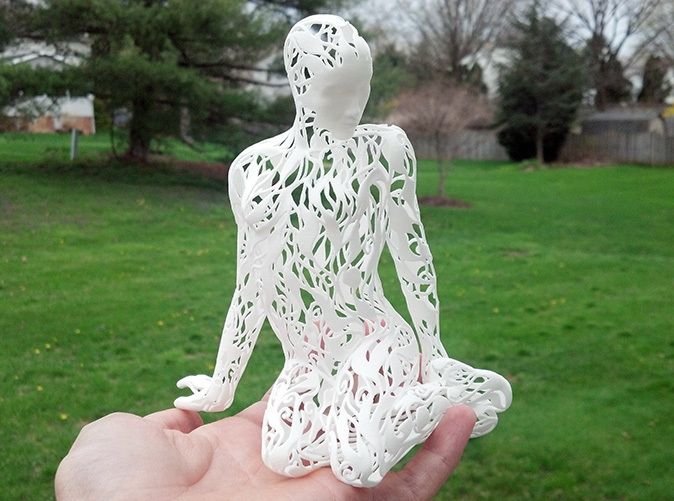

It is also possible to print an object out of resin photopolymer material. These materials are liquid that is hardened by a laser within the printing process. Resins are often the chosen material when it comes to concept or functional models.

Get Your Free Guide!

500 +

Parts printed per day

1000 +

Happy customers each year

0 +

Technologies and finishes

0 +

Industrial 3D Printers

Join the brands that trust us!

Sculpteo was the partner we needed for producing Tundra, being able to 3D print parts made it possible to create a customizable drone. Our partnership with Sculpteo was an essential part in the creation of this machine.

Our partnership with Sculpteo was an essential part in the creation of this machine.

Alexandre Labesse Hexadrone CEO

3D printing gives us the ability to get our parts quickly, compared to other manufacturing techniques. We can also manufacture complex parts with a finished appearance, which could not be machined. We have been working with Sculpteo since 2014 and the quality keeps improving. Our contacts with the team are regular in order to find the best compromises regarding our needs.

Nicolas RigauxMechanical engineer at Microfilms

At the small scale of the cargo projects we run, 3D printing is the only economical production method for the geometries we need. Using Sculpteo’s service allows us to produce a much more professional quality product than we could achieve in-house, at a much lower time investment.

Jürg GermannHead of Engineering at WeRobotics

We are always looking for performance for our robots, and this fundamentally involves reducing the weight of the various fittings linked to the robots such as their grippers. 3D printing is a solution for us to combine performance, rigidity and mass of these assemblies. We have been working with Sculpteo for 4 years, the quality of the prints has always been very satisfactory and the proximity of our account manager allows us to save time and improve our performance in the realization of our projects.

3D printing is a solution for us to combine performance, rigidity and mass of these assemblies. We have been working with Sculpteo for 4 years, the quality of the prints has always been very satisfactory and the proximity of our account manager allows us to save time and improve our performance in the realization of our projects.

Anthony MOUTEAU Designer / SAS I.D.E.C

3D printing is an opportunity to easily reproduce the structure of a robot. More and more robots are being produced thanks to 3D printing. Additive manufacturing is a long-term trend for the robotic market, just as it is for aeronautic and automobile businesses

Jérôme LAPLACEDirector, Génération Robots / HumaRobotics

Previous

Next

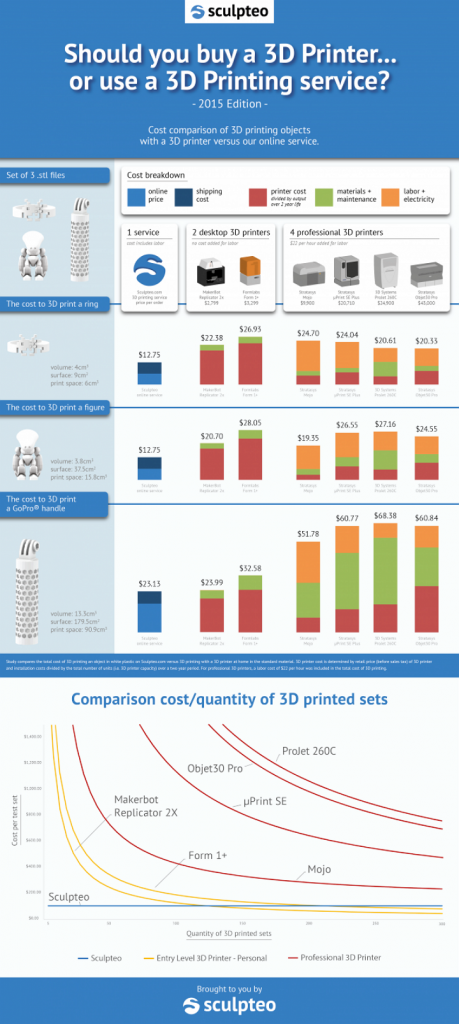

Try out Sculpteo's online 3D printing service

With +10 years of expertise in additive manufacturing for production and prototyping, Sculpteo brings +75 materials and finishes to develop your most ambitious projects. Our online 3D printing service provides professional 3D printing with rigorous quality control.

Our online 3D printing service provides professional 3D printing with rigorous quality control.

Create a free account and upload your 3D files, select your material, technology, and post-processing options, and order online.

We’ll take care of the rest in our industrial ISO 9001 factory.

3D Printing Blog: Tutorials, News, Trends and Resources

Discover the new benefits of Ultrasint® PA11 with Sculpteo!

Posted By Stephany Vaussanvin on Dec 8, 2022

Nylon PA12 is one of the most extensively used engineering thermoplastic materials for additive prototypes and end-use product manufacturing. However, as companies and clients demand cleaner, more sustainable materials, PA11 quickly becomes the mater...

Read MoreThe State of 3D Printing 2022 is now available!

Posted By Stephany Vaussanvin on Nov 24, 2022

The 8th edition of The State of 3D Printing is here! Every year we survey professional 3D printing users from around the world to follow the adoption of additive manufacturing by nearly every industry to capture the evolution and potential for growth. ..

..

Meet Sculpteo’s Project Manager: Lucie Pertuisel

Posted By Stephany Vaussanvin on Oct 24, 2022

Hello, I’m Lucie Pertuisel. I’m a project manager in charge of continuous improvement in production. I have been in the company for 4 years! What is your job and mission at Sculpteo? I started at Sculpteo as Deputy Production Manager, immersing my...

Read MoreForward AM Award Winner for 2022!

Posted By Stephany Vaussanvin on Oct 18, 2022

The Forward AM award is an award to celebrate startups and Additive Manufacturing. The Finals happened on Monday, October 10th, 2022, in Barcelona and online with a series of talks and startup pitches discussing high-potential applications for Additi...

Read MoreATHOS climbing shoes are the perfect fit thanks to HP Multi Jet Fusion technology

Posted By Lucie Gaget on Oct 3, 2022

Among all the diverse applications of additive manufacturing, footwear, and more specifically, sports footwear, has significant advantages. The Spanish start-up ATHOS understood the potential of 3D printing and how HP Multi Jet Fusion 3D printing tec...

The Spanish start-up ATHOS understood the potential of 3D printing and how HP Multi Jet Fusion 3D printing tec...

Discover Citroën and BASF’s collaboration: oli, an innovative concept car

Posted By Lucie Gaget on Sep 29, 2022

A collaboration between Citroën and BASF gave life to a fully electric concept car. An innovative project is pushing the limits by rethinking the design and the different components of the vehicle, proving that simplicity can go with enhanced functio...

Read MoreGet to know our CEO, Alexandre D’Orsetti!

Posted By Stephany Vaussanvin on Sep 19, 2022

Alexandre d’Orsetti is Managing Director of Sculpteo, where he ran the design studio for six years. He is an industrial designer who graduated from ENSCI-Les Ateliers. He is passionate about the formal and technical potential of additive manufacturin...

Read More3D printing and spare parts: Discussion on the environmental benefits

Posted By Stephany Vaussanvin on Sep 9, 2022

Companies increasingly take responsibility for facing environmental challenges by moving towards more sustainable production solutions. Among them, the production of spare parts, especially with 3D printing, is increasingly used. An economic asset fo...

Among them, the production of spare parts, especially with 3D printing, is increasingly used. An economic asset fo...

Interview with the Head of Sculpteo Studio Manon Le Moal-Joubel

Posted By Stephany Vaussanvin on Aug 23, 2022

We wanted to highlight our different teams at Sculpteo for you to get to know us better! This month we interviewed the Head of the Studio Design team Manon Le Moal-Joubel, an industrial designer specializing in industrial engineering. With these two ...

Read MoreSculpteo hosts an open house for clients to see and visit the new HP factory!

Posted By Stephany Vaussanvin on Jul 11, 2022

To collaborate more with customers and share our entire production process and capabilities, Sculpteo and HP held an open house for 30 clients and prospective clients to visit Sculpteo’s HP factory in Villejuif. Participants saw the high-quality manu...

Read MoreSculpteo has a new CEO Alexandre d’Orsetti!

Posted By Stephany Vaussanvin on Jul 5, 2022

Alexandre d’Orsetti takes over from Clement Moreau, who co-founded and led Sculpteo for over 13 years. Alexandre has a unique history at Sculpteo; after directing the design studio for six years, he is now the Managing Director of Sculpteo. Alexandre...

Alexandre has a unique history at Sculpteo; after directing the design studio for six years, he is now the Managing Director of Sculpteo. Alexandre...

Bernay Automation relies on Additive Manufacturing to streamline their production process quickly and efficiently

Posted By Stephany Vaussanvin on Jun 23, 2022

To mass-customize their vibrating bowls in a quick and cost-effective way, Bernay Automation turned to the innovative power of 3D printing and Sculpteo’s reliable online manufacturing services. By adopting additive manufacturing technology into its p...

Read MorePage 1 of 14412345678910...2030405060708090100110...»144

Discover more about 3D printing and digital manufacturing with our blog

Sculpteo is a digital manufacturing service that provides both a 3D printing and a laser cutting service. We decided to add a blog to our website back when the company was created. The overall goal is keep you updated on all the latest news and trends of the digital manufacturing in general and 3D printing in particular. On our blog you’ll find information on the 3D printers, on 3D modeling with detailed tutorials, comparisons between the technologies, events and even discounts.

On our blog you’ll find information on the 3D printers, on 3D modeling with detailed tutorials, comparisons between the technologies, events and even discounts.

Unique custom-made 3D sculptures at Sprint 3D

We have repeatedly said that we print miniature figures of people on a 3D printer, but did not mention another relevant service - the creation of copies of architectural monuments . Fixing it! So, what is this service, for what purpose can such 3D sculptures be made, and what opportunities does modern 3D printing open up? Let's talk about this!

Like a souvenir, only better! nine0014

Perhaps the first association that arises when looking at the miniature 3D sculptures is exactly souvenirs. In fact this is not true. Yes, souvenir shops in many cities have similar products - local miniature sights. But! Firstly, these are not copies, but only souvenirs that approximately repeat the shape and style of an architectural monument. Secondly, they differ little from each other, because they are created on the conveyor. No originality or authenticity. And the quality is usually below average. nine0007

Secondly, they differ little from each other, because they are created on the conveyor. No originality or authenticity. And the quality is usually below average. nine0007

Copies of architectural monuments are copies. We create the most detailed products with the most precise proportions. Every detail, every element - all this is taken into account and reproduced with maximum accuracy. As a result, it seems to you that you are holding in your hands an ideally accurate, just a greatly reduced copy of an architectural object.

See how we work

We mainly make sculptures according to photo . The client provides us with several pictures of an architectural object (or we take them on the Internet), we create 3D models of monuments , approve them and send them to print. But in some cases, the work is much more difficult.

For example, we advise you to familiarize yourself with how we created the figurine for the "Person of the Year" award in Orenburg , where the main decoration was a miniature stele "Kind Angel of the World". The real stele is located in the city itself, has a height of 3 meters, and the pedestal itself is 6 meters. In short, we had to use drones to create high-resolution images, shoot from all angles, and only after that create a three-dimensional model. nine0007

The real stele is located in the city itself, has a height of 3 meters, and the pedestal itself is 6 meters. In short, we had to use drones to create high-resolution images, shoot from all angles, and only after that create a three-dimensional model. nine0007

This is to say that the approach to creating sculptures on the 3D printer in Sprint 3D is really complex. Our copies of architectural monuments are true works of art. Albeit in miniature.

Copies of architectural monuments as gifts and not only

3D sculptures are primarily an association with the city, its architecture and sights. Accordingly, the first option for using such products is as an exclusive souvenir. We can organize the printing of such miniatures in the quantity you need. And you decide how to dispose of them in the future - sell, donate, etc.

There are many options for using copies of architectural monuments:

- a gift to guests of the city;

- elements of the award: goblet, figurine, etc.

;

; - present to a business colleague and much more.

Do you have a favorite attraction in the city? Or some monument from another city or country impressed you a lot and you want to keep a reminder of it for yourself? Just a few days - and we will create such a figure for you. nine0007

We are repeatedly contacted by representatives of universities, architectural bureaus and museums who need to make miniatures of city sights or, in the case of architects, small copies of structures, monuments, and other objects created by them.

Original compositions with miniature monuments

At Sprint 3D you can order not only copies of architectural monuments separately, but also entire compositions. For example, a human figurine next to an architectural monument. To do this, you need to provide several pictures of the person whose figure you want to make. We will model all the elements of the composition, approve with you and print. nine0007

nine0007

Printing compositions greatly expands the possibilities of using copies of architectural monuments. There are a lot of options, and almost all of them we are ready to implement for you!

Order a copy of architectural monuments now

Discuss the details of the future order with the manager and provide us with a photo of the architectural object that needs to be recreated in miniature. The more shots and angles, the easier it will be for us to create a model and the more accurate it will be. If an architectural object is popular and there are many photos of it on the Web, we will select the appropriate ones ourselves. nine0007

When the desired photos are available, we will discuss the dimensions and features of the future product. We will create a three-dimensional model, approve it with you, make adjustments if necessary and send the layout to print. You will receive your order in just 7-10 business days. And if necessary, we will perform urgent printing - no more than a week.

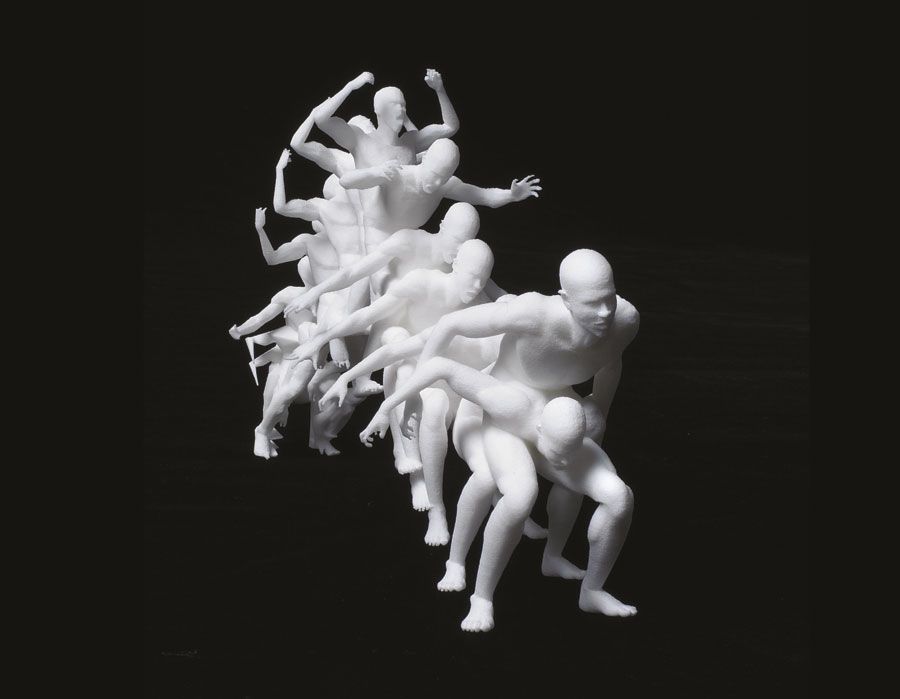

3D printing of life figures and park sculptures. Large sizes

Modern technologies have opened up new possibilities in the implementation of ideas in the field of design. We are talking about growth figures and sculptures of various purposes. If earlier the figures were made of papier-mâché and left much to be desired or were created by artists, but cost simply fabulous sums, like those produced in factories by casting or stamping, now everything has become much simpler and much better in terms of quality. 3D printing allows you to quickly, efficiently and cheaply produce figures of any size and complexity. nine0007

So what options does 3D printing open up for us?

Life-size Figures

Life-size figure is a figure of some real or fictional character made in full height and in volume. These figures are very realistic.

Everyone has seen the figures and is well acquainted with them. You come across them at various promotions, they can be seen in amusement parks, theme parks, in cafes and restaurants, in shops and shopping centers, at exhibition sites. They allow you to create a mood, attract attention, which is extremely important from the point of view of advertising! nine0007

They allow you to create a mood, attract attention, which is extremely important from the point of view of advertising! nine0007

There is a place for a full-length figure in the interior, especially if it is a favorite hero or character. And both at home and in the office.

Life figures can be made by 3D printing, and this approach has many advantages:

- durability and practicality - the figures are printed from plastic, which is not affected by moisture and temperatures;

- the ability to print figures of any size;

- the ability to accurately implement an idea of any degree of complexity with the highest detail; nine0072

- high degree of realism;

- light weight - figures can be easily transported and moved;

- the shortest production time.

At 3D Service you can order 3D printing of life figures of any size. You can provide your file with a layout or entrust the creation of a 3D model to our specialists. All details must be agreed with the customer before printing. Our employees are also ready to paint the figure professionally. It can be monochrome painting, metallic or full color version. We guarantee high quality workmanship and affordable prices! nine0007

All details must be agreed with the customer before printing. Our employees are also ready to paint the figure professionally. It can be monochrome painting, metallic or full color version. We guarantee high quality workmanship and affordable prices! nine0007

Park sculptures

Landscape design is not complete without various sculptures. They are made from different materials. Even in private gardens, small figurines appear to set the mood. As a rule, these are small ceramic products of standard production, that is, they do not carry a complex and extraordinary semantic load and are not unique.

Do you want to use unique park sculptures for your landscape? There is such an opportunity, and it will cost inexpensively, and the execution time will be very short. nine0007

3D printing allows you to create unique park sculptures. With this, you can create entire storylines, such as an Alice in Wonderland-themed theme park or a landscape in the style of a hobbit village. All this is possible thanks to 3D printing.

All this is possible thanks to 3D printing.

3D printed park sculptures have many advantages:

- the highest resistance to negative environmental influences;

- reasonable price;

- the shortest terms of execution; nine0072

- realistic and accurate implementation of tasks of any complexity;

- originality and exclusivity;

- low weight products, which guarantees ease of transportation and mobility;

- no restrictions on size, detail, etc.;

- durability.

At 3Dservices you can order 3D printing of garden and park sculptures at a bargain price. You can provide us with a ready-made layout or we will create a unique 3D layout for you with mandatory approval before sending it to print. We can not only print park sculptures of fairy-tale characters, but also monuments, plaques, arches, any elements of small architectural forms (arches, columns, etc.) Products can be painted in colors according to your idea, made in monochrome or metal .