Sugar printer 3d

A DIY 3D Sugar Printer

Inspiration / 3D printing in 2006

In the spring of 2006, we attended the very first Maker Faire, which was held in San Mateo California. We exhibited our very own Interactive LED Dining Table project there, and got hooked on all things Maker Faire. Amongst the things that we saw there were incredible 3D printed metal mathematical sculptures by Bathsheba Grossman. We had never seen anything like them. We came away from Maker Faire with a solid idea for next year: to make our own 3D printer.

At the time, 3D printing wasn’t in the mainstream consciousness the way that it is today. Even the term “3D printing” itself had a different meaning — it was a trademarked phrase that referred to one particular fabrication process. At least, it was supposed to. In practice, “3D printing” is such a good and practical term for all the different kinds of additive manufacturing processes that it stuck, and now encompasses everything from traditional stereolithography to direct metal printing. But in 2006, you were more likely to hear someone talk about “rapid prototyping” or occasionally “solid freeform fabrication.” For example, RepRap was already around, but you wouldn’t have found the phrase “3D printer” on its home page.

Commercial 3D printers (from Stratasys, Z Corp., and others) were on the market, but starting at around $20k, they were simply unattainable on a hobby budget. There were just a few DIY-oriented 3D printing kits around as well (e.g., RepRap and Fab@Home), but they were still mostly in the $1-3k range.

For our own project, we wanted something that would let us fabricate big 3D models. Most of the homebrew 3D printers at the time were extruders (“fused deposition modeling” machines), making tiny, precise plastic models. While that can be scaled up, a secondary concern was the cost of the special filaments that they used, which were not in wide distribution and ranged in price up to several dollars per cubic inch. If we wanted to make big models, it would be nice to be able to use easily available, lower-cost media.

A separate question is about which fabrication technology to use. Each has its own challenges: UV-curing resins are messy, lasers can be expensive and potentially dangerous, plastic fumes are smelly, inkjet heads are hard to control, and extruders can’t make overhanging parts very well. And all of it was expensive and a patent minefield, which would both be concerns if we ever did make a kit version of our project.

Of the choices, the powder-bed methods − used in selective laser sintering and in systems that printed binders with inkjet heads − seemed the cleanest and most capable. A great choice, so long as the difficulties with the print media, lasers, and/or print heads could be solved.

Just add sugar, just add heat.

If you think about it for a moment, sugar is a particularly good print medium because it’s easy to obtain, low in cost, kid friendly, water soluble, non-hazardous, non-toxic, non-intimidating, rigid despite having a low melting point, and potentially suitable for making objects for lost sugar (like lost wax) investment casting.

It is also possible to make interesting food with this technology.

To melt and fuse the sugar, we used a modified hot air rework (soldering) station. An equivalent could be made by using just its replacement air heating element (500 W, $10) with a $5 aquarium air pump. Of course, it also needs a housing and a control system that can provide a the chosen amount of power to the heating element. We have seen that the element can be driven directly from 120 V, with duty cycle controlled by an inexpensive digital relay. The heater element is hardly new technology; it’s the baby sister of the one in your hair dryer. None the less, it’s well designed and quite suitable for this application.

One detail to consider: Most hot air sources are designed for a relatively high air flow rate. But, for our purpose — blowing hot air at sugar not to move it but just to melt it — getting better performance means that we want high heat but very flow air flow rate. In a hair dryer (or hot air rework station handpiece), it’s the air flowing through that cools the unit and makes it safe to use. When you turn down the air flow rate, you have to make sure that your heater doesn’t melt or otherwise self destruct.

When you turn down the air flow rate, you have to make sure that your heater doesn’t melt or otherwise self destruct.

Building the CandyFab 4000

Like other 3D printers, ours works by stacking layers of 2D images. We begin with a flat bed of sugar and “print” a 2D design into it by selectively fusing the sugar. The bed is then lowered slightly, a new layer of sugar is added, and the next 2D image is printed, fusing with the layer below. This process is repeated to build up the three-dimensional image. Our machine makes the vertical translation possible by providing a large, five-sided wooden box with a floor that can move up and down on drawer slides.

The X and Y axis motion control systems were based on belt drives and quadrature-encoded motors recycled from old HP plotters, while the Z axis is based on a modified automotive jack. This isn’t necessarily the best way to do things, but it was cost effective. The overall project budget was about $500.

Custom closed-loop, high-power drive electronics were designed to power each of the three axes and accept position commands, using standard hobby servo PWM control code. The X and Y axes each had their own hand-wired board with an ATmega168 microcontroller, reading the quadrature outputs from the motor, and PWM “analog” output, to a linear power amplifier that drove each motor. Computer control and interface were provide through a MAKE Controller, an ARM based I/O board that was popular at the time.

The X and Y axes each had their own hand-wired board with an ATmega168 microcontroller, reading the quadrature outputs from the motor, and PWM “analog” output, to a linear power amplifier that drove each motor. Computer control and interface were provide through a MAKE Controller, an ARM based I/O board that was popular at the time.

We designed the frame of the machine in Sketchup and built it in our garage from plywood and lumber. It doesn’t take high-tech tools to do stuff like this. We used the tools that we had: a power drill and a drill press, a jigsaw, and a hand sander.

Form follows function: The wooden base was sized to fit the particular HP pen plotters that we had disassembled, and the center part was designed to support the giant piston, and the one-ton servo motor that raises and lowers it.

Atop the wood sits a flexible canvas liner. It lines the piston to prevent sugar from leaking out in strange places and assists in recovering unused media.

After the liner, the X and Y stages are added. The Y-axis belt-drive system is mounted, on one end, to a linear bearing that slides along a steel rail. That bearing is pushed by the belt-driven carriage on the X axis, through a rubber band low-cost flexible rubber coupling. The other end of the Y-axis belt-drive system is supported by a free-rolling rubber wheel from the hardware store.

You can read more about the build process in this blog post and in our main announcement about the CandyFab 4000. See more pictures in this flickr set.

Finally, CNC Toast

The hot air gun is mounted to the belt-driven carriage on the Y axis of the printer. In final testing, we needed to test the performance of the XY stage and of the hot air gun. That’s quite easy to do by simply moving the Z stage out of the way.

The intermediate result was surprisingly fun: a genuine CNC toaster!

3D Printing with the CandyFab 4000

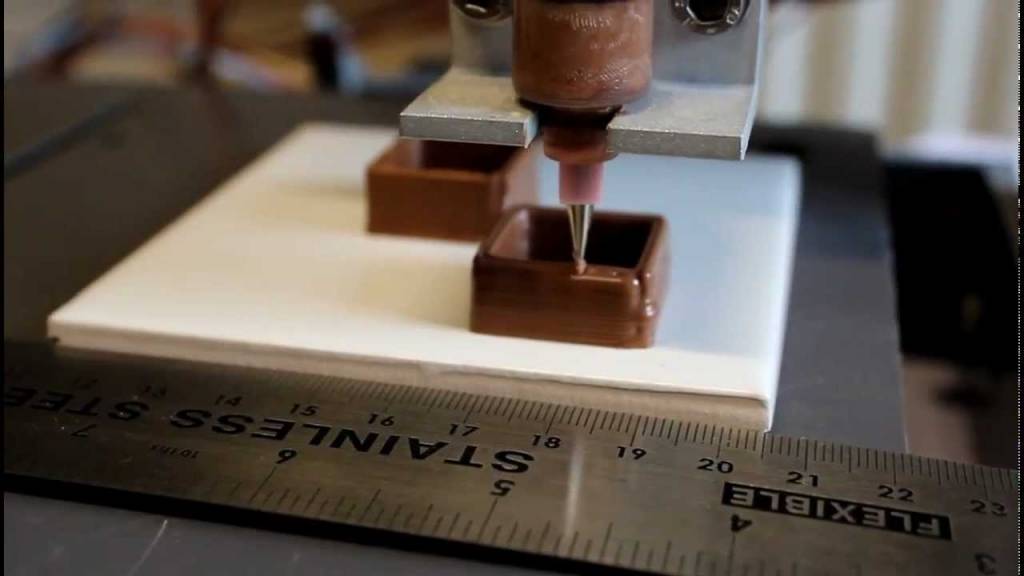

The printing process begins by drawing a thin line with the heater element, fusing the sugar together. The width of the line drawn in these first tests was about 3 mm, and defined our minimum feature size. For each pixel that we want to fuse, we hold the hot air gun over that point for a period of time, typically between one and three seconds, depending on air temperature settings and the thickness of the layer that we want to fuse.

The width of the line drawn in these first tests was about 3 mm, and defined our minimum feature size. For each pixel that we want to fuse, we hold the hot air gun over that point for a period of time, typically between one and three seconds, depending on air temperature settings and the thickness of the layer that we want to fuse.

At each stage of the print, there is some exposed, fused sugar. It has a glassy surface of amorphous sugar. The top layer is about 1/8 of an inch (3 mm) thick and is uniformly colored a light golden brown– caramelized in the melt process. Spots that appear darker overlap (or partially overlap)– and are fused to– the layers below them, because we are looking into a deeper layer of colored sugar.

Because the hot air gun blows air continuously, it leaves a shallow trail of disturbed (but not melted) sugar wherever it goes − even between areas that it melts. Excess fusion was not an issue so long as “rapid moves” between areas to be fused were actually rapid.

This toroidal coil sculpture was one of the first objects that we made with the CandyFab. It is already big, but to give you a sense of scale, four of these could be fabricated simultaneously within the printable volume.

The CandyFab 4000 had a maximum printable volume of 24 x 13.5 x 9 inches (61 x 34 x 23 cm)– 2916 cubic inches, or 1.7 cubic feet. Beyond just lowering the media cost of a given fabricated object, using a low-cost medium can be leveraged to make large-volume printing both practical and economical. Filling the bed of the CandyFab 4000 takes a little more than 100 pounds of sugar, which costs about $37 retail. For comparison, the fine nylon powders used by high quality SLS (selective laser sintering materials) tend to cost upwards of $25 per pound. Even accounting for its lower density, filling the bed with nylon powder would still cost about $700.

If you look closely, you can see the pixelated nature of our fabricated object. The bulk of the material is solid, glassy, lightly caramelized sugar. It feels and acts very much like regular glass. It smells great. The outside surface is covered by loosely attached sintered sugar (white), and can be removed or smoothed over by hand.

It feels and acts very much like regular glass. It smells great. The outside surface is covered by loosely attached sintered sugar (white), and can be removed or smoothed over by hand.

A giant model of a wood screw, and a modest dodecahedron.

When printing the early layers of the wood screw, just the edges of the threads are visible. It’s a philips-head screw, so the broad cross sections where you only see a single slot must be just above or just below the center of the model. When it finishes printing, the bed raises in order to allow the humans to extract the model. Even after raising the piston up, some digging is still required to get the last ten pounds of sugar off the top. For reference, the print media cost for the giant screw model is under one dollar.

In 3D printing, it is practical to make complex shapes that cannot be efficiently manufactured by traditional subtractive processes, where material is cut away from a block to make an object. Consider a chain of connected links. While skilled whittlers can indeed carve a chain out of a single piece of wood, it’s a labor intensive process that requires accessing the part from many different angles. In contrast, in an additive process it is no more difficult to make a connected chain than it is to make any other shape. To prove the point, we constructed this chain of 12 links– using about a pound of sugar per link.

Consider a chain of connected links. While skilled whittlers can indeed carve a chain out of a single piece of wood, it’s a labor intensive process that requires accessing the part from many different angles. In contrast, in an additive process it is no more difficult to make a connected chain than it is to make any other shape. To prove the point, we constructed this chain of 12 links– using about a pound of sugar per link.

When we first start to build up the chain, we are only printing the lowest part of the six chain links that are vertically oriented; it’s hard to see from the pattern of melted sugar alone how this will turn into a chain. In the middle section of the chain, where we are printing parts of all twelve links, it is a little more obvious.

One thing to note is that the loose “horizontal” links are suspended by the loose print medium (sugar) in the print bed. This is in contrast to some other fabrication technologies which require a separate support matrix to be built alongside the actual desired object.

An array of fat, low-resolution dodecahedrons, printed as giveaways and test objects. (Question: Can you smooth the surface by warming the pieces in the oven? Answer: no.) Wider beams made them less likely to break upon handling, and we could turn up the heat and speed when precision was less critical.

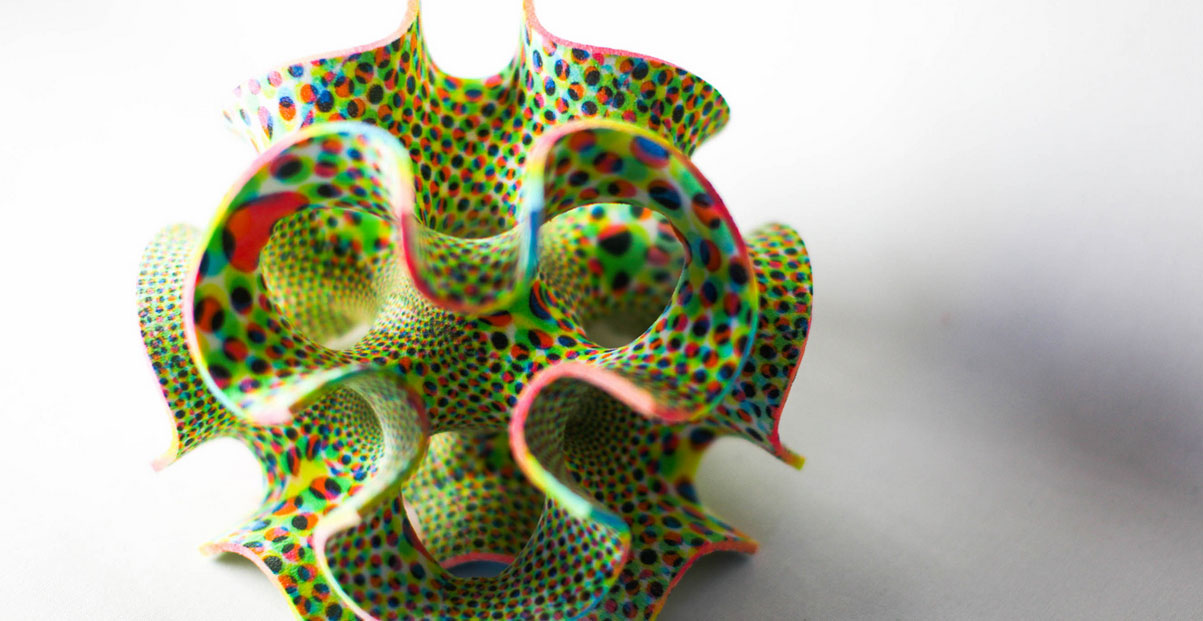

The sculpture Soliton by Bathsheba Grossman (model used by kind permission).

A ¾ twist mobius strip with a square cross section and windows cut at regular intervals in all of the sides. Even though it’s hollow, it still weights nearly eight pounds— that’s a lot of sugar.

It was at about this stage that we brought the CandyFab 4000 to the 2007 Bay Area Maker Faire, where it was a hit indeed. There were four 3D printers there that year: The CandyFab, a $20k Stratasys Dimension, Fab@Home, and a couple of avid hackers making excellent progress with a hot glue gun and XYZ stage. Some pictures at the event: 1, 2, 3, 4.

Improving precision

CandyFab Heater versions 2.0 and 2.1 were based around commercially available sealed heating elements: a beautifully made 24V, 50 W ceramic element made by Hakko (model A1321) and a standard 55W cartridge heater. Both had their pros and cons. Around the heating element, we wrapped several windings of 1/8″ OD soft copper refrigeration tubing and a bundle of high-temperature insulation. Copper is not actually a good choice for the tubing here, since it oxidizes rapidly with high temperature air flow, and these heater assemblies had a very short life. Pro-tip: Use stainless steel tubing for hot air.

Other considerations aside, this heater gave us the precision and control to take CandyFab to the next level.

Same model, much finer quality. Our estimate was that the effective pixel size was reduced from about 1/5″ (5 mm) to about 1/16″ (1.6 mm).

This was starting to get interesting. Now we could make a tiny chain of movable links of sugar.

We had also by this point audited all of the materials in the sugar and air paths to make sure that everything was genuinely food safe. The new resolution was also a big advantage: Nobody wants to eat a pound of sugar, but we could at least print simple decorations for a birthday cake.

We also began to experiment with printing plastic, using a hybrid method with plastic pellets resting on a bed of sugar. Upside: More permanent. Downside: Doesn’t smell as nice. We made a trefoil knot and a fruit bowl from HDPE pellets this way. (The dark dots are green colored HDPE pellets.)

While the CandyFab 4000 worked well enough, it was built from surplus junk. Thus, in a word, it was unmanufacturable. And so we got to work, spending the next year on a version that we could actually make more of.

The CandyFab 5000 was a complete design departure from the CF4k, using new off-the-shelf parts wherever possible. Additionally, effort was made to use components and materials that are accepted for use with food where possible and/or necessary.

Photo credit: Scott Beale / Laughing Squid.

The structural design was based on 1/2″ plywood, cut to shape with a CNC router.

The piston walls were constructed of high-temperature UHMW polyethylene and the piston floor was topped with a gum-rubber surface that made a tight seal against the four walls. The build volume was 8.5″ x 11″ x 17″.

The motion control systems in the three axes were based on beefy stepping motors and timing belts. The Z axis was driven by a single stepping motor, driving a double-sided timing belt that turns four acme screws to lift the piston. The X axis, which moved the Main Carriage, or Gantry, that includes the whole Y axis, was driven by dual acme lead screws on either side of the machine, which are in turn driven by a single timing belt from a stepping motor. The Heater Carriage, which held the heating element, was attached directly to the a timing belt driven by a smaller stepping motor. The Heater Carriage position was constrained by two linear shafts.

As part of the design, we also built a new third-generation heater that had a stainless steel housing and nozzle. And, we reworked the electronics from being a handwired mess into something almost elegant. The platform was called “Zuccherino” for the italian term meaning “sugar cube” (in the idiomatic sense). The name is meant to be suggestive of both the modular nature of the CandyFab control electronics platform, and the fact that it works with sugar. As an Arduino derivative, its name is also reminiscent of the name Arduino and those of its clones, while minimizing abuse of the Italian language.

The Zuccherino platform is a series of small semi-independent microcontroller-based circuit boards, in several different flavors. Each type of Zuccherino board is dedicated to a single control function and sports the necessary hardware to carry out that single task. For example, the “Zuccherino Stepper Board” controls a single stepper motor.

In a working setup there is exactly one Zuccherino Master Board (that serves as the computer interface) and any number of additional Zuccherino boards of other flavors. For example, a minimal CandyFab setup might use five Zuccherino boards: One Master Board, three Zuccherino Stepper Boards to control the three cartesian axes, and one Zuccherino (solid state) Relay Board that controls the heater. We also developed a servo motor controller board that (like those on the CF4k) could control a DC motor equipped with a quadrature encoder.

For example, a minimal CandyFab setup might use five Zuccherino boards: One Master Board, three Zuccherino Stepper Boards to control the three cartesian axes, and one Zuccherino (solid state) Relay Board that controls the heater. We also developed a servo motor controller board that (like those on the CF4k) could control a DC motor equipped with a quadrature encoder.

There were a lot of promising things about the CandyFab 5000, its mechanics, and its control system. Unfortunately, our CNC manufacturing plan hit a wall. (The wall was human in nature, not technical. See the Epilogue for more discussion.) For the sake of manufacturability, we ended up making the decision to start over again from scratch, this time with a design that could be fabricated on a laser cutter.

We had already spent nearly a year on the CF5k, and it didn’t make sense to continue pouring time and effort into what had suddenly become a dead-end development path. Back to the drawing board we went. The CandyFab 5000 never saw “first melt.”

The CandyFab 5000 never saw “first melt.”

In the spring of 2009, we finished designing and building the third-generation CandyFab, the CandyFab 6000. It came with a spiffy new logo.

Like its predecessor, the CandyFab 6000 was essentially an all-new design using off-the-shelf parts wherever possible. The structural design was based on high-end 6 mm plywood which can be cut to shape with a CO2 laser cutter. Careful planning went into picking components and materials that are accepted for use with food where possible and/or necessary.

Unlike the previous versions of the CandyFab, the CandyFab 6000 was designed as a “benchtop” 3D printer, not as a floor-standing model. The build volume is 8.5″ x 11″ x 7″ deep. Much smaller, but still a respectable 10 liters. (Subsequent models could have been made larger again.)

The motion control systems in the three axes were based on servo motors (DC motors equipped with quadrature motors) and timing belts. The Z axis was driven by a single servo motor that drives a timing belt that turns four 3/8-12 acme screws to lift the piston. The X axis, which moves the Main Carriage, or Gantry, that includes the whole Y axis, was driven by dual timing belts on either side of the machine, which are in turn driven by a single timing belt from a servo motor. The Heater Carriage, which holds the heating element (“oven”), was attached directly to a timing belt driven by a smaller servo motor, and constrained in position by an off-the-shelf dust-resistant linear slide. Most exposed bearings in the CandyFab 6000 design are plain (as opposed to ball) bearings made from dust-resistant high performance composite materials. Sugar is dusty.

The Z axis was driven by a single servo motor that drives a timing belt that turns four 3/8-12 acme screws to lift the piston. The X axis, which moves the Main Carriage, or Gantry, that includes the whole Y axis, was driven by dual timing belts on either side of the machine, which are in turn driven by a single timing belt from a servo motor. The Heater Carriage, which holds the heating element (“oven”), was attached directly to a timing belt driven by a smaller servo motor, and constrained in position by an off-the-shelf dust-resistant linear slide. Most exposed bearings in the CandyFab 6000 design are plain (as opposed to ball) bearings made from dust-resistant high performance composite materials. Sugar is dusty.

A washable cotton “culinary” liner provided a food-safe seal around the edges of the piston. Food-safe UHMW HDPE funnels (gutters) around the edge of the piston can return unused media to a storage tray beneath the unit.

The CF6k still used the same Zuccherino control system designed for the CF5k, with some hacking to make everything work. The Zuccherino modules were master (1), XYZ servo motor drivers (3), and solid-state relays (2), to drive the heater and control the air flow by regulating power to the aquarium air pump.

The Zuccherino modules were master (1), XYZ servo motor drivers (3), and solid-state relays (2), to drive the heater and control the air flow by regulating power to the aquarium air pump.

By the time we started printing with the new machine, it was already producing output as fine as the best we had ever seen on the CandyFab 4000. On the one hand, that was great. On the other, there is a very real sense in which we hadn’t made any progress (other than the shape of the machine!) after spending two more years working so hard on the project.

Photo credit (both): Scott Beale / Laughing Squid.

Windell Oskay and Lenore Edman write about their current projects at Evil Mad Scientist Laboratories.

A DIY 3D Sugar Printer

Inspiration / 3D printing in 2006

In the spring of 2006, we attended the very first Maker Faire, which was held in San Mateo California. We exhibited our very own Interactive LED Dining Table project there, and got hooked on all things Maker Faire. Amongst the things that we saw there were incredible 3D printed metal mathematical sculptures by Bathsheba Grossman. We had never seen anything like them. We came away from Maker Faire with a solid idea for next year: to make our own 3D printer.

Amongst the things that we saw there were incredible 3D printed metal mathematical sculptures by Bathsheba Grossman. We had never seen anything like them. We came away from Maker Faire with a solid idea for next year: to make our own 3D printer.

At the time, 3D printing wasn’t in the mainstream consciousness the way that it is today. Even the term “3D printing” itself had a different meaning — it was a trademarked phrase that referred to one particular fabrication process. At least, it was supposed to. In practice, “3D printing” is such a good and practical term for all the different kinds of additive manufacturing processes that it stuck, and now encompasses everything from traditional stereolithography to direct metal printing. But in 2006, you were more likely to hear someone talk about “rapid prototyping” or occasionally “solid freeform fabrication.” For example, RepRap was already around, but you wouldn’t have found the phrase “3D printer” on its home page.

Commercial 3D printers (from Stratasys, Z Corp. , and others) were on the market, but starting at around $20k, they were simply unattainable on a hobby budget. There were just a few DIY-oriented 3D printing kits around as well (e.g., RepRap and Fab@Home), but they were still mostly in the $1-3k range.

, and others) were on the market, but starting at around $20k, they were simply unattainable on a hobby budget. There were just a few DIY-oriented 3D printing kits around as well (e.g., RepRap and Fab@Home), but they were still mostly in the $1-3k range.

For our own project, we wanted something that would let us fabricate big 3D models. Most of the homebrew 3D printers at the time were extruders (“fused deposition modeling” machines), making tiny, precise plastic models. While that can be scaled up, a secondary concern was the cost of the special filaments that they used, which were not in wide distribution and ranged in price up to several dollars per cubic inch. If we wanted to make big models, it would be nice to be able to use easily available, lower-cost media.

A separate question is about which fabrication technology to use. Each has its own challenges: UV-curing resins are messy, lasers can be expensive and potentially dangerous, plastic fumes are smelly, inkjet heads are hard to control, and extruders can’t make overhanging parts very well. And all of it was expensive and a patent minefield, which would both be concerns if we ever did make a kit version of our project.

And all of it was expensive and a patent minefield, which would both be concerns if we ever did make a kit version of our project.

Of the choices, the powder-bed methods − used in selective laser sintering and in systems that printed binders with inkjet heads − seemed the cleanest and most capable. A great choice, so long as the difficulties with the print media, lasers, and/or print heads could be solved.

Just add sugar, just add heat.

If you think about it for a moment, sugar is a particularly good print medium because it’s easy to obtain, low in cost, kid friendly, water soluble, non-hazardous, non-toxic, non-intimidating, rigid despite having a low melting point, and potentially suitable for making objects for lost sugar (like lost wax) investment casting.

It is also possible to make interesting food with this technology.

To melt and fuse the sugar, we used a modified hot air rework (soldering) station. An equivalent could be made by using just its replacement air heating element (500 W, $10) with a $5 aquarium air pump. Of course, it also needs a housing and a control system that can provide a the chosen amount of power to the heating element. We have seen that the element can be driven directly from 120 V, with duty cycle controlled by an inexpensive digital relay. The heater element is hardly new technology; it’s the baby sister of the one in your hair dryer. None the less, it’s well designed and quite suitable for this application.

Of course, it also needs a housing and a control system that can provide a the chosen amount of power to the heating element. We have seen that the element can be driven directly from 120 V, with duty cycle controlled by an inexpensive digital relay. The heater element is hardly new technology; it’s the baby sister of the one in your hair dryer. None the less, it’s well designed and quite suitable for this application.

One detail to consider: Most hot air sources are designed for a relatively high air flow rate. But, for our purpose — blowing hot air at sugar not to move it but just to melt it — getting better performance means that we want high heat but very flow air flow rate. In a hair dryer (or hot air rework station handpiece), it’s the air flowing through that cools the unit and makes it safe to use. When you turn down the air flow rate, you have to make sure that your heater doesn’t melt or otherwise self destruct.

Building the CandyFab 4000

Like other 3D printers, ours works by stacking layers of 2D images. We begin with a flat bed of sugar and “print” a 2D design into it by selectively fusing the sugar. The bed is then lowered slightly, a new layer of sugar is added, and the next 2D image is printed, fusing with the layer below. This process is repeated to build up the three-dimensional image. Our machine makes the vertical translation possible by providing a large, five-sided wooden box with a floor that can move up and down on drawer slides.

We begin with a flat bed of sugar and “print” a 2D design into it by selectively fusing the sugar. The bed is then lowered slightly, a new layer of sugar is added, and the next 2D image is printed, fusing with the layer below. This process is repeated to build up the three-dimensional image. Our machine makes the vertical translation possible by providing a large, five-sided wooden box with a floor that can move up and down on drawer slides.

The X and Y axis motion control systems were based on belt drives and quadrature-encoded motors recycled from old HP plotters, while the Z axis is based on a modified automotive jack. This isn’t necessarily the best way to do things, but it was cost effective. The overall project budget was about $500.

Custom closed-loop, high-power drive electronics were designed to power each of the three axes and accept position commands, using standard hobby servo PWM control code. The X and Y axes each had their own hand-wired board with an ATmega168 microcontroller, reading the quadrature outputs from the motor, and PWM “analog” output, to a linear power amplifier that drove each motor. Computer control and interface were provide through a MAKE Controller, an ARM based I/O board that was popular at the time.

Computer control and interface were provide through a MAKE Controller, an ARM based I/O board that was popular at the time.

We designed the frame of the machine in Sketchup and built it in our garage from plywood and lumber. It doesn’t take high-tech tools to do stuff like this. We used the tools that we had: a power drill and a drill press, a jigsaw, and a hand sander.

Form follows function: The wooden base was sized to fit the particular HP pen plotters that we had disassembled, and the center part was designed to support the giant piston, and the one-ton servo motor that raises and lowers it.

Atop the wood sits a flexible canvas liner. It lines the piston to prevent sugar from leaking out in strange places and assists in recovering unused media.

After the liner, the X and Y stages are added. The Y-axis belt-drive system is mounted, on one end, to a linear bearing that slides along a steel rail. That bearing is pushed by the belt-driven carriage on the X axis, through a rubber band low-cost flexible rubber coupling. The other end of the Y-axis belt-drive system is supported by a free-rolling rubber wheel from the hardware store.

The other end of the Y-axis belt-drive system is supported by a free-rolling rubber wheel from the hardware store.

You can read more about the build process in this blog post and in our main announcement about the CandyFab 4000. See more pictures in this flickr set.

Finally, CNC Toast

The hot air gun is mounted to the belt-driven carriage on the Y axis of the printer. In final testing, we needed to test the performance of the XY stage and of the hot air gun. That’s quite easy to do by simply moving the Z stage out of the way.

The intermediate result was surprisingly fun: a genuine CNC toaster!

3D Printing with the CandyFab 4000

The printing process begins by drawing a thin line with the heater element, fusing the sugar together. The width of the line drawn in these first tests was about 3 mm, and defined our minimum feature size. For each pixel that we want to fuse, we hold the hot air gun over that point for a period of time, typically between one and three seconds, depending on air temperature settings and the thickness of the layer that we want to fuse.

At each stage of the print, there is some exposed, fused sugar. It has a glassy surface of amorphous sugar. The top layer is about 1/8 of an inch (3 mm) thick and is uniformly colored a light golden brown– caramelized in the melt process. Spots that appear darker overlap (or partially overlap)– and are fused to– the layers below them, because we are looking into a deeper layer of colored sugar.

Because the hot air gun blows air continuously, it leaves a shallow trail of disturbed (but not melted) sugar wherever it goes − even between areas that it melts. Excess fusion was not an issue so long as “rapid moves” between areas to be fused were actually rapid.

This toroidal coil sculpture was one of the first objects that we made with the CandyFab. It is already big, but to give you a sense of scale, four of these could be fabricated simultaneously within the printable volume.

The CandyFab 4000 had a maximum printable volume of 24 x 13.5 x 9 inches (61 x 34 x 23 cm)– 2916 cubic inches, or 1. 7 cubic feet. Beyond just lowering the media cost of a given fabricated object, using a low-cost medium can be leveraged to make large-volume printing both practical and economical. Filling the bed of the CandyFab 4000 takes a little more than 100 pounds of sugar, which costs about $37 retail. For comparison, the fine nylon powders used by high quality SLS (selective laser sintering materials) tend to cost upwards of $25 per pound. Even accounting for its lower density, filling the bed with nylon powder would still cost about $700.

7 cubic feet. Beyond just lowering the media cost of a given fabricated object, using a low-cost medium can be leveraged to make large-volume printing both practical and economical. Filling the bed of the CandyFab 4000 takes a little more than 100 pounds of sugar, which costs about $37 retail. For comparison, the fine nylon powders used by high quality SLS (selective laser sintering materials) tend to cost upwards of $25 per pound. Even accounting for its lower density, filling the bed with nylon powder would still cost about $700.

If you look closely, you can see the pixelated nature of our fabricated object. The bulk of the material is solid, glassy, lightly caramelized sugar. It feels and acts very much like regular glass. It smells great. The outside surface is covered by loosely attached sintered sugar (white), and can be removed or smoothed over by hand.

A giant model of a wood screw, and a modest dodecahedron.

When printing the early layers of the wood screw, just the edges of the threads are visible. It’s a philips-head screw, so the broad cross sections where you only see a single slot must be just above or just below the center of the model. When it finishes printing, the bed raises in order to allow the humans to extract the model. Even after raising the piston up, some digging is still required to get the last ten pounds of sugar off the top. For reference, the print media cost for the giant screw model is under one dollar.

It’s a philips-head screw, so the broad cross sections where you only see a single slot must be just above or just below the center of the model. When it finishes printing, the bed raises in order to allow the humans to extract the model. Even after raising the piston up, some digging is still required to get the last ten pounds of sugar off the top. For reference, the print media cost for the giant screw model is under one dollar.

In 3D printing, it is practical to make complex shapes that cannot be efficiently manufactured by traditional subtractive processes, where material is cut away from a block to make an object. Consider a chain of connected links. While skilled whittlers can indeed carve a chain out of a single piece of wood, it’s a labor intensive process that requires accessing the part from many different angles. In contrast, in an additive process it is no more difficult to make a connected chain than it is to make any other shape. To prove the point, we constructed this chain of 12 links– using about a pound of sugar per link.

When we first start to build up the chain, we are only printing the lowest part of the six chain links that are vertically oriented; it’s hard to see from the pattern of melted sugar alone how this will turn into a chain. In the middle section of the chain, where we are printing parts of all twelve links, it is a little more obvious.

One thing to note is that the loose “horizontal” links are suspended by the loose print medium (sugar) in the print bed. This is in contrast to some other fabrication technologies which require a separate support matrix to be built alongside the actual desired object.

An array of fat, low-resolution dodecahedrons, printed as giveaways and test objects. (Question: Can you smooth the surface by warming the pieces in the oven? Answer: no.) Wider beams made them less likely to break upon handling, and we could turn up the heat and speed when precision was less critical.

The sculpture Soliton by Bathsheba Grossman (model used by kind permission).

A ¾ twist mobius strip with a square cross section and windows cut at regular intervals in all of the sides. Even though it’s hollow, it still weights nearly eight pounds— that’s a lot of sugar.

It was at about this stage that we brought the CandyFab 4000 to the 2007 Bay Area Maker Faire, where it was a hit indeed. There were four 3D printers there that year: The CandyFab, a $20k Stratasys Dimension, Fab@Home, and a couple of avid hackers making excellent progress with a hot glue gun and XYZ stage. Some pictures at the event: 1, 2, 3, 4.

Improving precision

CandyFab Heater versions 2.0 and 2.1 were based around commercially available sealed heating elements: a beautifully made 24V, 50 W ceramic element made by Hakko (model A1321) and a standard 55W cartridge heater. Both had their pros and cons. Around the heating element, we wrapped several windings of 1/8″ OD soft copper refrigeration tubing and a bundle of high-temperature insulation. Copper is not actually a good choice for the tubing here, since it oxidizes rapidly with high temperature air flow, and these heater assemblies had a very short life. Pro-tip: Use stainless steel tubing for hot air.

Copper is not actually a good choice for the tubing here, since it oxidizes rapidly with high temperature air flow, and these heater assemblies had a very short life. Pro-tip: Use stainless steel tubing for hot air.

Other considerations aside, this heater gave us the precision and control to take CandyFab to the next level.

Same model, much finer quality. Our estimate was that the effective pixel size was reduced from about 1/5″ (5 mm) to about 1/16″ (1.6 mm).

This was starting to get interesting. Now we could make a tiny chain of movable links of sugar.

We had also by this point audited all of the materials in the sugar and air paths to make sure that everything was genuinely food safe. The new resolution was also a big advantage: Nobody wants to eat a pound of sugar, but we could at least print simple decorations for a birthday cake.

We also began to experiment with printing plastic, using a hybrid method with plastic pellets resting on a bed of sugar. Upside: More permanent. Downside: Doesn’t smell as nice. We made a trefoil knot and a fruit bowl from HDPE pellets this way. (The dark dots are green colored HDPE pellets.)

Upside: More permanent. Downside: Doesn’t smell as nice. We made a trefoil knot and a fruit bowl from HDPE pellets this way. (The dark dots are green colored HDPE pellets.)

While the CandyFab 4000 worked well enough, it was built from surplus junk. Thus, in a word, it was unmanufacturable. And so we got to work, spending the next year on a version that we could actually make more of.

The CandyFab 5000 was a complete design departure from the CF4k, using new off-the-shelf parts wherever possible. Additionally, effort was made to use components and materials that are accepted for use with food where possible and/or necessary.

Photo credit: Scott Beale / Laughing Squid.

The structural design was based on 1/2″ plywood, cut to shape with a CNC router.

The piston walls were constructed of high-temperature UHMW polyethylene and the piston floor was topped with a gum-rubber surface that made a tight seal against the four walls. The build volume was 8.5″ x 11″ x 17″.

The build volume was 8.5″ x 11″ x 17″.

The motion control systems in the three axes were based on beefy stepping motors and timing belts. The Z axis was driven by a single stepping motor, driving a double-sided timing belt that turns four acme screws to lift the piston. The X axis, which moved the Main Carriage, or Gantry, that includes the whole Y axis, was driven by dual acme lead screws on either side of the machine, which are in turn driven by a single timing belt from a stepping motor. The Heater Carriage, which held the heating element, was attached directly to the a timing belt driven by a smaller stepping motor. The Heater Carriage position was constrained by two linear shafts.

As part of the design, we also built a new third-generation heater that had a stainless steel housing and nozzle. And, we reworked the electronics from being a handwired mess into something almost elegant. The platform was called “Zuccherino” for the italian term meaning “sugar cube” (in the idiomatic sense). The name is meant to be suggestive of both the modular nature of the CandyFab control electronics platform, and the fact that it works with sugar. As an Arduino derivative, its name is also reminiscent of the name Arduino and those of its clones, while minimizing abuse of the Italian language.

The name is meant to be suggestive of both the modular nature of the CandyFab control electronics platform, and the fact that it works with sugar. As an Arduino derivative, its name is also reminiscent of the name Arduino and those of its clones, while minimizing abuse of the Italian language.

The Zuccherino platform is a series of small semi-independent microcontroller-based circuit boards, in several different flavors. Each type of Zuccherino board is dedicated to a single control function and sports the necessary hardware to carry out that single task. For example, the “Zuccherino Stepper Board” controls a single stepper motor.

In a working setup there is exactly one Zuccherino Master Board (that serves as the computer interface) and any number of additional Zuccherino boards of other flavors. For example, a minimal CandyFab setup might use five Zuccherino boards: One Master Board, three Zuccherino Stepper Boards to control the three cartesian axes, and one Zuccherino (solid state) Relay Board that controls the heater. We also developed a servo motor controller board that (like those on the CF4k) could control a DC motor equipped with a quadrature encoder.

We also developed a servo motor controller board that (like those on the CF4k) could control a DC motor equipped with a quadrature encoder.

There were a lot of promising things about the CandyFab 5000, its mechanics, and its control system. Unfortunately, our CNC manufacturing plan hit a wall. (The wall was human in nature, not technical. See the Epilogue for more discussion.) For the sake of manufacturability, we ended up making the decision to start over again from scratch, this time with a design that could be fabricated on a laser cutter.

We had already spent nearly a year on the CF5k, and it didn’t make sense to continue pouring time and effort into what had suddenly become a dead-end development path. Back to the drawing board we went. The CandyFab 5000 never saw “first melt.”

In the spring of 2009, we finished designing and building the third-generation CandyFab, the CandyFab 6000. It came with a spiffy new logo.

Like its predecessor, the CandyFab 6000 was essentially an all-new design using off-the-shelf parts wherever possible. The structural design was based on high-end 6 mm plywood which can be cut to shape with a CO2 laser cutter. Careful planning went into picking components and materials that are accepted for use with food where possible and/or necessary.

The structural design was based on high-end 6 mm plywood which can be cut to shape with a CO2 laser cutter. Careful planning went into picking components and materials that are accepted for use with food where possible and/or necessary.

Unlike the previous versions of the CandyFab, the CandyFab 6000 was designed as a “benchtop” 3D printer, not as a floor-standing model. The build volume is 8.5″ x 11″ x 7″ deep. Much smaller, but still a respectable 10 liters. (Subsequent models could have been made larger again.)

The motion control systems in the three axes were based on servo motors (DC motors equipped with quadrature motors) and timing belts. The Z axis was driven by a single servo motor that drives a timing belt that turns four 3/8-12 acme screws to lift the piston. The X axis, which moves the Main Carriage, or Gantry, that includes the whole Y axis, was driven by dual timing belts on either side of the machine, which are in turn driven by a single timing belt from a servo motor. The Heater Carriage, which holds the heating element (“oven”), was attached directly to a timing belt driven by a smaller servo motor, and constrained in position by an off-the-shelf dust-resistant linear slide. Most exposed bearings in the CandyFab 6000 design are plain (as opposed to ball) bearings made from dust-resistant high performance composite materials. Sugar is dusty.

The Heater Carriage, which holds the heating element (“oven”), was attached directly to a timing belt driven by a smaller servo motor, and constrained in position by an off-the-shelf dust-resistant linear slide. Most exposed bearings in the CandyFab 6000 design are plain (as opposed to ball) bearings made from dust-resistant high performance composite materials. Sugar is dusty.

A washable cotton “culinary” liner provided a food-safe seal around the edges of the piston. Food-safe UHMW HDPE funnels (gutters) around the edge of the piston can return unused media to a storage tray beneath the unit.

The CF6k still used the same Zuccherino control system designed for the CF5k, with some hacking to make everything work. The Zuccherino modules were master (1), XYZ servo motor drivers (3), and solid-state relays (2), to drive the heater and control the air flow by regulating power to the aquarium air pump.

By the time we started printing with the new machine, it was already producing output as fine as the best we had ever seen on the CandyFab 4000. On the one hand, that was great. On the other, there is a very real sense in which we hadn’t made any progress (other than the shape of the machine!) after spending two more years working so hard on the project.

On the one hand, that was great. On the other, there is a very real sense in which we hadn’t made any progress (other than the shape of the machine!) after spending two more years working so hard on the project.

Photo credit (both): Scott Beale / Laughing Squid.

Windell Oskay and Lenore Edman write about their current projects at Evil Mad Scientist Laboratories.

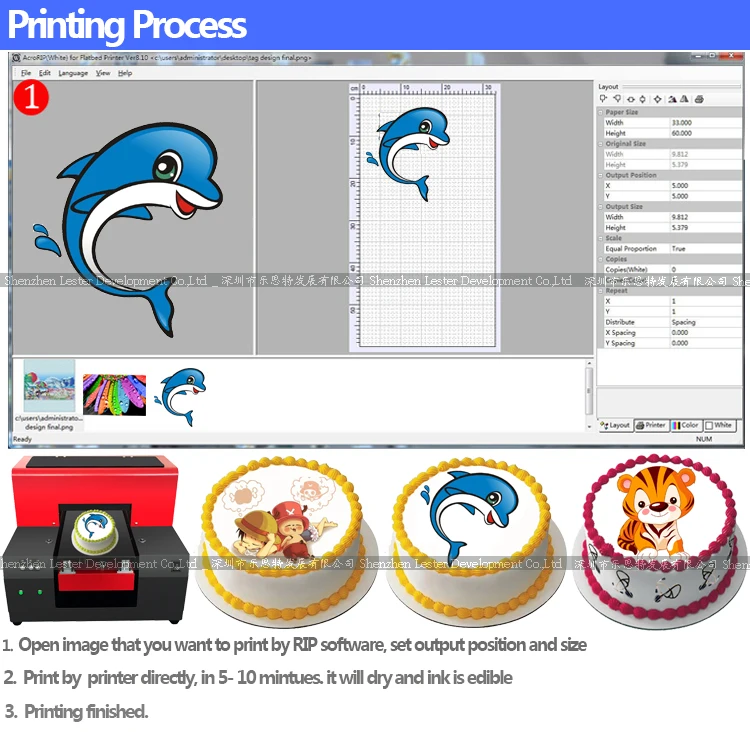

90,000 characteristics, pros and cons of each model07.04.2021

Content

-

- What is a food 3D printer

- Field of use

- used raw materials

- 9000 9000 9000 9000

- Top 10 Best Food Printers: A List of the Most Current Models

- 1. PancakeBot 2.0

- 2. Wiiboox Sweetin

- 3. Choc Creator V2.0 Plus

- 4. Choc Creator V2.0 Plus Food 3D Printer with Cooling Chamber

- 5. byFlow Focus

- 6. Chefjet Pro

- 7. Foodini

- 8. Mmuse – Chocolate 3D Printer Commercial ArtcakesOT7 .

90BOT Printer F5

90BOT Printer F5 - 10. ZMorph VX

- What is a food 3D printer

- Selection guide

- Output

A food printer is a high-tech device that is used to create culinary masterpieces. The decorative design of food products has reached a new level thanks to the use of modern technologies: high-quality and large-format printing is carried out on cakes, waffles, pancakes and even coffee. Here are the top best 3D food printers in different price categories for people who are fond of cooking. nine0003

What is a 3D food printer

The main feature of a food 3D printer is the raw materials used: instead of printing ink, the device is filled with edible ingredients. The database stores a large number of different recipes, and in order to print a dish, you just need to select one of them and activate the printing process. The final product is layered on a work surface or on a plate: it can be baked in the oven or sent to the freezer. nine0003

Application

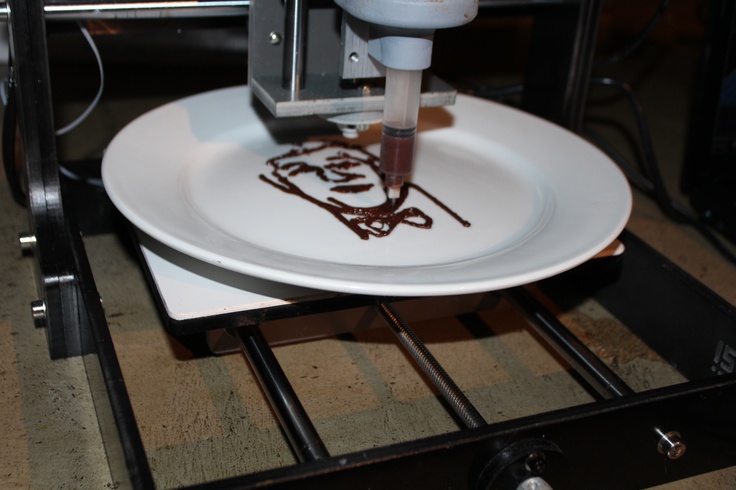

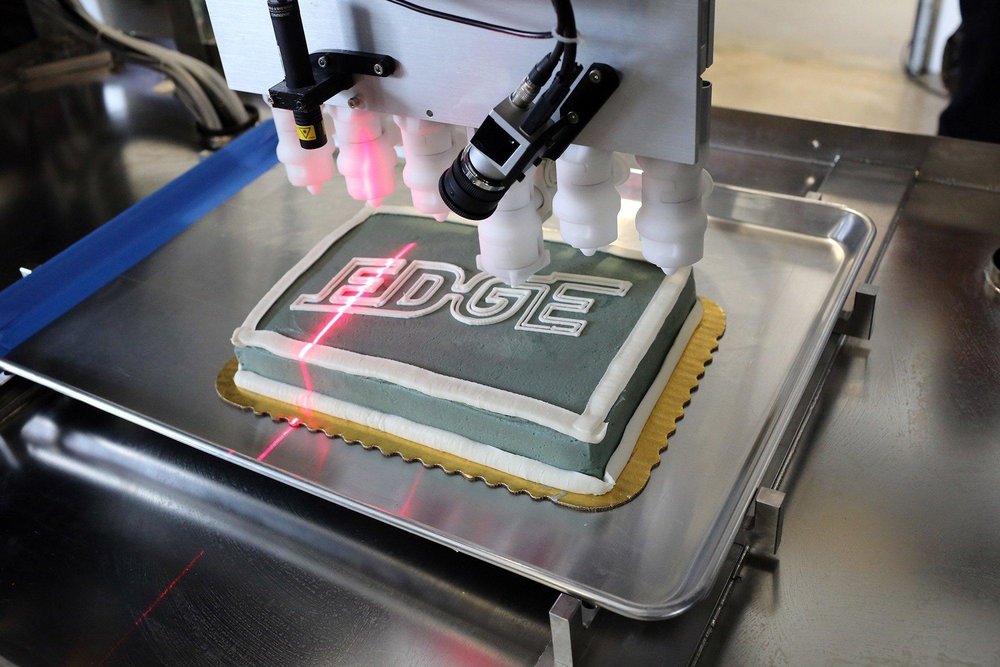

Futuristic 3D Printed Sugar Candy

Cookies printed with icing

Chocolate logos of famous companies

Cream Photo Print

Buying a food 3D printer is worth the owners of coffee houses, author's bakeries and private workshops. The finished product has a unique shape and bright appearance. Food printers are often used to create custom wedding cakes, cartoon character cookies, Christmas gingerbread cookies, and so on. The possibilities of a baker who owns such a device are endless: the main thing is to buy quality products. nine0003

The finished product has a unique shape and bright appearance. Food printers are often used to create custom wedding cakes, cartoon character cookies, Christmas gingerbread cookies, and so on. The possibilities of a baker who owns such a device are endless: the main thing is to buy quality products. nine0003

Raw materials used

The following ingredients are used as raw materials:

-

Chocolate without additives and impurities;

-

Mastic;

-

Sugar;

-

Whipped cottage cheese;

-

Vegetable and fruit pastes; nine0003

-

Fish and meat pates;

-

Flour;

-

Cheese, etc.

The confectionery pattern is applied to sugar, wafer or shock transfer paper. The first type has a sweetish aftertaste and aroma of vanilla. Due to the snow-white surface, no additional coating is required: the drawings look bright and clear. The wafer paper is made from rice flour and does not have a special taste, due to the light shade, the final drawings look less clear. Shock transfer paper is completely transparent and is suitable for transferring a design to a product (for example, a cake). For the packaging of finished products, food-grade plastic for a 3D printer is used. nine0003

The wafer paper is made from rice flour and does not have a special taste, due to the light shade, the final drawings look less clear. Shock transfer paper is completely transparent and is suitable for transferring a design to a product (for example, a cake). For the packaging of finished products, food-grade plastic for a 3D printer is used. nine0003

Interesting! Food printers are involved in waste reduction. Unattractive fruit and confectionery leftovers are used in the preparation of printing mixes. This makes it possible to use the means of production more efficiently.

Types of 3D food printers

Cooking enthusiasts can take advantage of the following food printing devices:

-

Food 3D printers are devices that print dishes whose recipes are listed in a database. The final product is layer-by-layer superimposed on the work surface, and the raw material comes from filled cartridges; nine0003

-

Confectionery printers are used to transfer images onto specialty paper or to design small confectionery products such as candies.

Such printers print an image on pre-prepared paper: rice, wafer or shock transfer;

Such printers print an image on pre-prepared paper: rice, wafer or shock transfer; -

Food plotters transfer the image not to paper, but directly to the finished product. For example, a plotter is used to transfer an image directly onto a cake. nine0003

There are several types of food 3D printers:

-

Extrusion - paint is applied to the surface before the dish is created. The process is controlled by the computer with the loaded image. The system has an extruder that heats the food mixture, and the distribution of raw materials depends on the print head. The raw material is loaded into a syringe placed in the head. This means that in order to combine different shades, you have to periodically stop printing and change the syringe; nine0003

-

A carousel-type food 3D printer also has an extruder, but its main feature is the method of feeding raw materials: the containers rotate around the working surface, the supply and dosage of the material used depends on the recipe specified in the program.

The storage can contain countless recipes, and operation does not cause difficulties even for an inexperienced user.

The storage can contain countless recipes, and operation does not cause difficulties even for an inexperienced user.

Popular brands

Eminent manufacturers offer the best value for money food 3D printer. Quality devices provide accurate printing, high speed, durability, simplicity and ease of use.

Wiibox

This company manufactures 3D printers with high build quality and high productivity. These are universal mechanisms that fill both chocolate paste and mashed potatoes. Numerous positive reviews confirm the high quality of Wiibox products. nine0003

byFlow

The Dutch company byFlow specializes in food printing technology. The pursuit of excellence helps the company open up new horizons: the technique prints products from spinach, meat emulsion and other materials. High build quality, ease of use and durability - all these characteristics are applicable to the products of this company.

Choc Edge

Choc Edge is committed to revolutionizing the world of chocolate making. Numerous experiments and focus on consumer feedback help to create more powerful devices that provide the optimal temperature for preparing and storing chocolate figures.

Numerous experiments and focus on consumer feedback help to create more powerful devices that provide the optimal temperature for preparing and storing chocolate figures.

Attention! Printing dishes helps save time on cooking: instead of culinary worries, the user can simply activate the printing process and get on with other things.

nine0134Free shipping

Add to compare

Item added to compare Go

Manufacturer Choc Edge Available on credit. To checkout, add the product to the cart and follow the instructions Go nine0003

Manufacturer Wiiboox Free Shipping

Add to compare

Item added to compare Go

Manufacturer Choc Edge Top 10 Best Food Printers: List of the Most Current Models

Before you buy a food 3D printer, you need to familiarize yourself with the most popular devices on the world market.

The top is based on ratings and customer reviews. nine0003

1. PancakeBot 2.0

PancakeBot 2.0 is easy to use, which means it's suitable for inexperienced users too. Users can choose from suggested designs in the software, or create their own. Used to print pancakes.

Pros:

Ease of operation;

A wide range of proposed projects; nine0003

High speed.

Cons:

2. Wiiboox Sweetin

Buying a food printer from Wiiboox is worth not only for confectionery lovers, but also for ordinary chefs: the device prints cakes, cookies and even mashed potatoes. The main raw materials can be meat, cheese, chocolate, jam, mashed potatoes, dough and much more. A convenient touch panel helps to set the desired mode of operation, and a stylish appearance complements the interior of any establishment. nine0003

Pros:

Versatility: the ability to print not only sweet dishes, but also side dishes;

Attractive appearance;

High build quality;

Convenient control by touch panel.

nine0173 Cons:

High price.

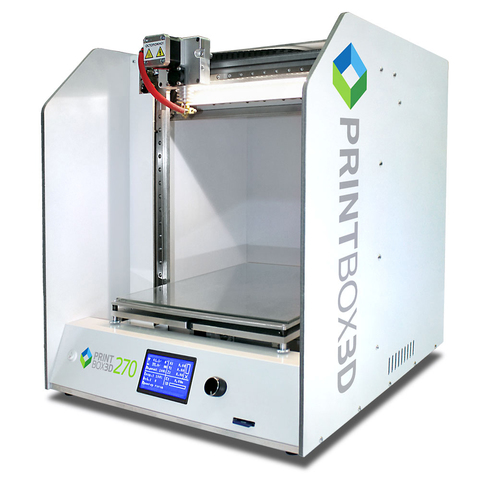

3. Choc Creator V2.0 Plus

When talking about which chocolate 3D printer to buy, it is worth mentioning the numerous advantages of Choc Creator V2.0 Plus. The new model has become more perfect: the developers have worked hard to eliminate the shortcomings of the previous version. The modern model has small dimensions, thanks to which it can be used in any kitchen, and the uniform heating of the syringe ensures high-quality and uninterrupted operation. In practice, the chocolate printer has shown tremendous potential: it prints complex figures from chocolate. nine0003

Pros of :

Attractive appearance;

Uninterrupted work;

Durability;

The ability to create durable and beautiful chocolate figures.

Cons :

4.

Choc Creator V2.0 Plus 3D food printer with cold chamber

The new version of the Choc Creator V2.0 Plus printer is equipped with cooling chambers by popular demand. Users say that maintaining the optimal temperature in the room to preserve the integrity of chocolate figures is too problematic: therefore, the new device cools the raw materials. The price of a food 3D printer with a cooling system is slightly higher than a classic one, but the high performance of the final product justifies any costs. nine0003

Pros of :

Availability of a cooling system for finished products;

High printing precision;

Long service life;

Ease of use: You can turn the fans on and off with the side buttons.

Cons :

High price.

Attention! Confectionery food 3D printers are often used by artists to create edible masterpieces.

This is a unique technology that helps to unleash the creative potential of the chef.

5. byFlow Focus

Food printer from the Dutch company byFlow, which specializes in 3D printing of food. The compact high-tech device is used for the bakery industry, and the cartridges are suitable for the application of any pasty ingredients. nine0003

Pros:

Cons:

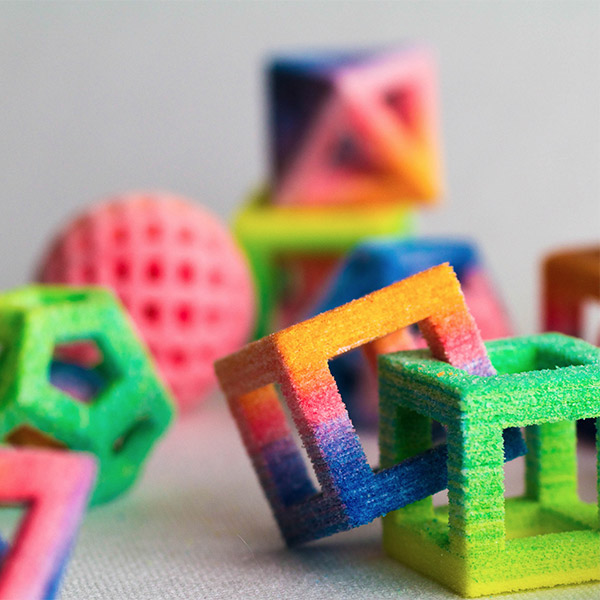

6. Chefjet Pro

Buying a ChefJet Pro food printer is a must for people who dream of making bright and stylish sweets. The device is created on the principle of inkjet printing: sugar-containing powder materials are used instead of paints. The final product is made by powder layering. The printer is suitable for combining different shades and creating gradients. nine0003

Pros:

The ability to create unique flavors;

Neat and bright printing;

Aesthetic appearance of the device.

Cons:

- nine0015

High price.

7. Foodini

The 3D food printer from Foodini works on the principle of a stationary printer, but instead of printing inks, layer-by-layer imposition of edible raw materials is used: dough, cream, chocolate, cream, etc. The device is versatile: the user himself can choose the material, or use ready-made cartridges with products.

Pros:

Practicality; nine0003

High build quality;

Attractive appearance;

Availability of an online platform with unique recipes.

Cons:

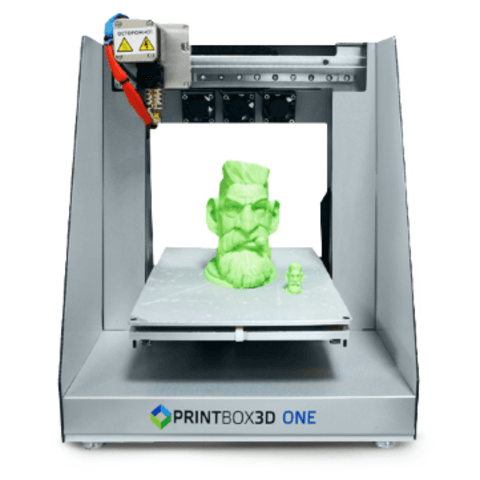

8. Mmuse – Chocolate 3D Printer

The closed MMuse 3D printer is suitable for chocolate printing. Chocolate beans are used as raw materials: they are heated in an extruder and fed to the work surface through the print head.

nine0003

Pros:

Cons:

9. ZBOT Commercial Art Pancakes Printer F5

ZBOT Commercial Art Pancakes Printer F5 3D Printer

A food printer from Chinese manufacturers is used in the process of making pancakes of various shapes. Ease of operation allows the device to be used by children under adult supervision. nine0003

Pros:

Ease of operation;

High build quality;

Affordable cost.

Cons:

10. ZMorph VX

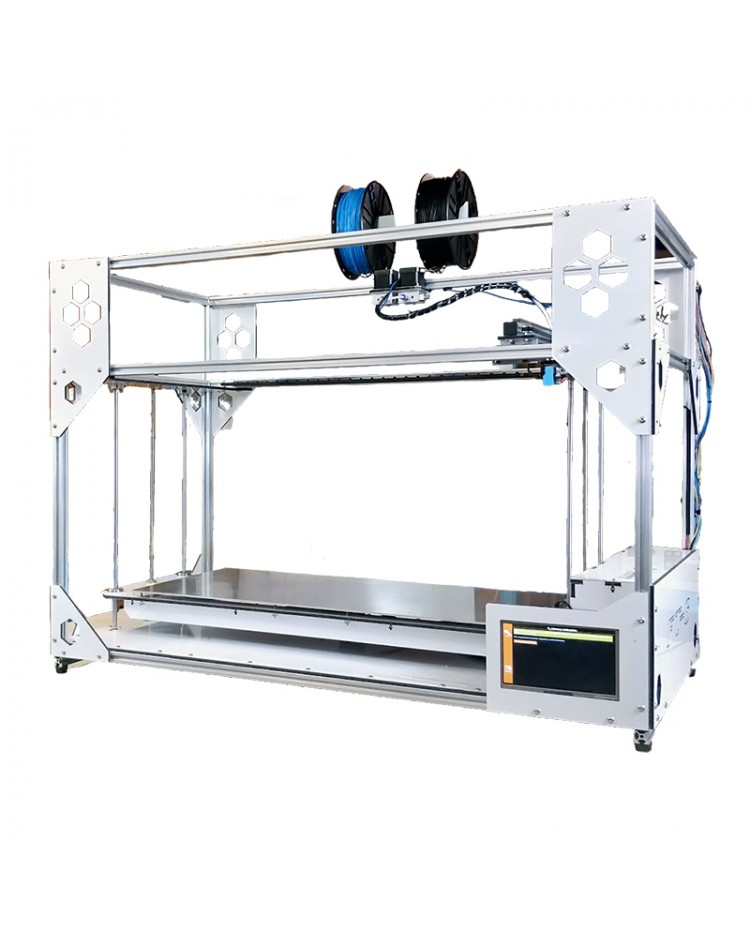

A multifunctional 3D printer capable of printing not only food, but also rubber, ABS plastic, polylactide, PVA, nylon, elastic and metal materials. The product is able to print with chocolate, butter, cookies, icing and other ingredients. In addition, there is a function of engraving and CNC milling. nine0003

Pros:

Cons:

High price.

Selection guide

The modern market offers a wide range of food printers. Before making a purchase, you need to carefully study the characteristics of each model and build on your own preferences. Experts have created several recommendations for choosing: nine0003

In case you want to create realistic images for confectionery 3D printing, pay attention to the diameter of the nozzle: the narrower it is, the more accurate the image will be;

- nine0007

It is better for people living in regions with a warm climate to purchase chocolate 3D printers with a cooling system: such devices ensure that the figurines are kept at the optimum temperature;

The possibility of self-refilling the cartridge is the most practical and economical way to operate the printer;

Print speed is an important consideration for restaurant owners. Large batches of dishes must be produced quickly, and for home use this is not a very strict selection criterion.

Output

In the catalog of our online store, you can choose the best food printers from famous brands to create culinary masterpieces. Explore our range, learn about the characteristics of each printer and make great purchases. nine0003

#Useful

Expert in the field of additive and subtractive technologies, 3D equipment and CNC machines with over 10 years of experience.

Share

all materials

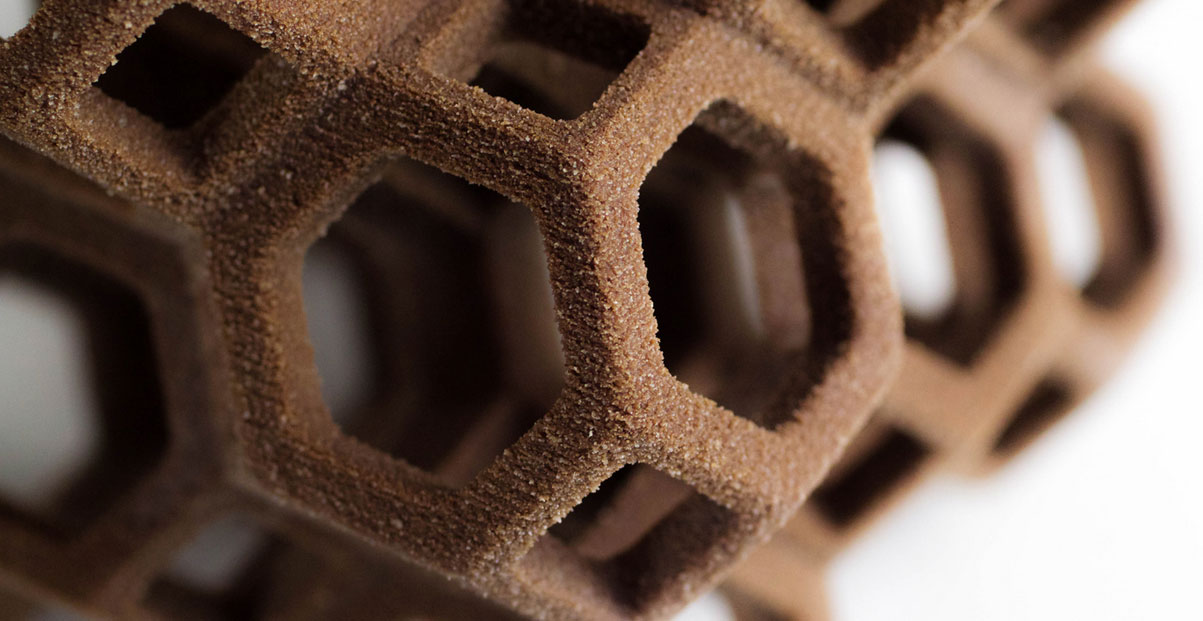

how it works, a review of culinary (confectionery) models and examples of work for cakes and chocolate printing products. Interest in 3D food printing is understandable - every year manufacturers release new models that open up more and more prospects for owners of 3D printers. In the article we will talk about the device of a 3D food printer and what can be done with it. We'll also talk about 3D printing with sugar and chocolate, edible prints on drinks, and even 3D pancakes. Get ready to be amazed - the scale of food printing on 3D printers will amaze even the most sophisticated user.

nine0003

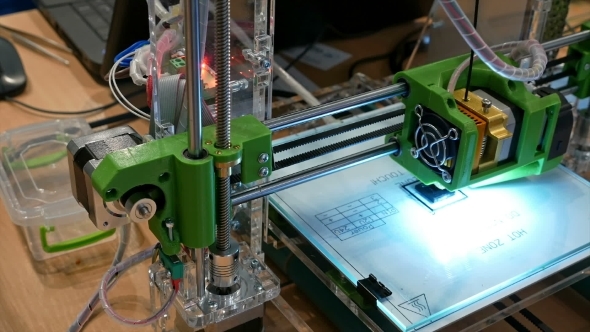

How it works and types of devices

The principle of operation of a 3D food printer is similar to a conventional inkjet printer. The only difference is that instead of simple ink cartridges in a food 3D printer, food coloring cartridges are used. The memory of the device allows you to store many recipes. To print the desired dish, you just need to select the saved recipe and press the button. After the dish is sent to print, the printer will begin to lay out the ingredients in layers on the work surface or directly on the plate. The printed dish can be sent to cool in the refrigerator or baked in the oven. nine0003

Views

Despite the fact that 3D food printing technology is the youngest in the field of 3D modeling, it is dynamically developing and improving in several directions at once. Food 3D printers have significant differences and are divided into several types:

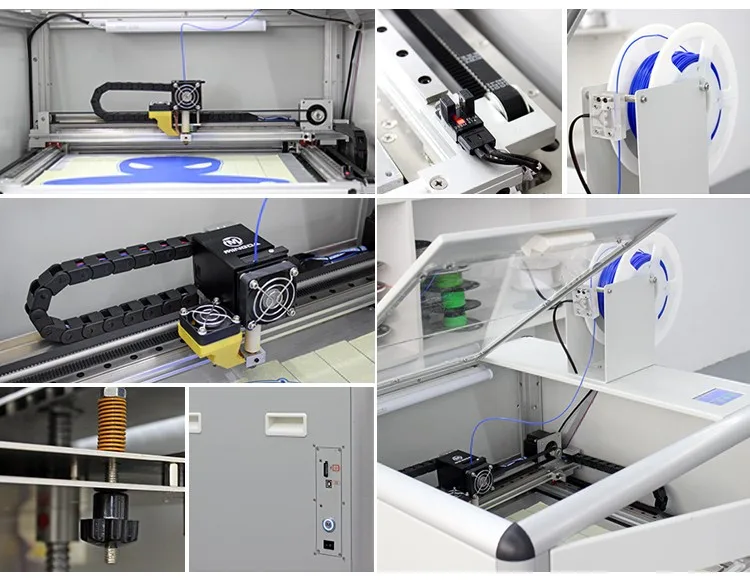

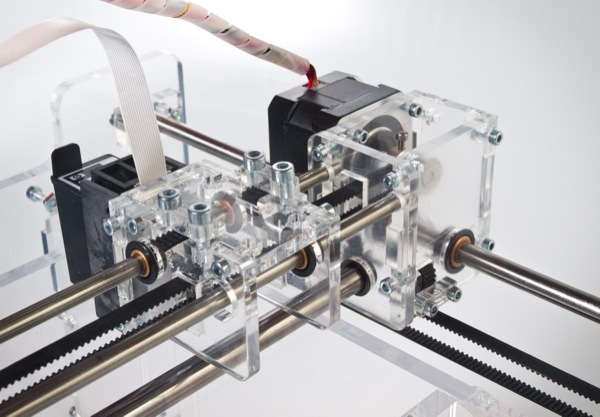

- Food extrusion type 3D printer - this type of device extrudes the edible mass layer by layer onto the work surface until the dish is completely formed.

The operation of the printer is controlled by a computer, on which the three-dimensional model of the object and the recipe are located. The printer itself, like its inkjet counterparts, is very simple - it consists of a table and a print head. The head moves along three coordinate axes, and an extruder is placed inside it to heat the mixture. The extruder is the main element of extrusion type printers. The printing ingredients are filled into a special syringe, which is placed in the print head. A significant disadvantage of this type of device is that the more complex the model in terms of composition and color scheme, the more often you will have to stop printing and replace the syringe. Extrusion-type printers include Chokola 3D - the device allows you to work with chocolate and pasty ingredients. nine0012

Please note! The smaller the diameter of the nozzle through which the raw material is squeezed out, the neater, more accurate and more realistic the printed dish will be.

- 3D food carousel printer - despite the fact that the main working element of this type of printer is an extruder, such devices are called carousels because of the feed mechanism. The carousel 3D printer rotates over the working surface of the container with raw materials, selecting the desired ingredient and squeezing out the dosage of the product indicated in the recipe. Outwardly, the printer really resembles a kind of carousel - containers with products rotate at a slow pace over the table. An almost unlimited number of recipes can be stored in the base of a carousel-type food 3D printer, and special skills are not needed to use it. All that is required from the user is to simply press a button and start printing. The carousel printer independently dispenses raw materials, alternately squeezing out the food mixture from the desired container. Depending on the model of the device, the containers can be from 4 to 16 pieces. Author's product from Martha Stewarts Crafts - the Cricut Cake carousel printer will help you create an original cookie or decoration for a festive cake.

The owner of the printer just needs to press the start button - everything else will be done by Cricut Cake. Included with the device is a large cookbook with ideas for creating real edible works of art. nine0012

What can be done with a 3D food printer?

A wide range of 3D compatible ingredients allows you to create virtually any 3D model - the scale is limited only by the user's imagination. With the help of a food 3D printer, you can create figures of any complexity that will give even a simple cake a designer look.

Three-dimensional models of the bride and groom or any hero of the occasion; mask-cast of chocolate; planes, cars and cartoon characters on cakes for children; voluminous bouquets; edible figurines; original inscriptions and company logos - all this can be printed on a food 3D printer. nine0003

That is why such devices are gaining more and more popularity in hand made confectioneries - exclusive products attract customers and emphasize the professionalism of the creator.

Printing pancakes

If you are not impressed by unusual cake decorations and original edible models, and you think that 3D food printing is just pampering, then especially for you and other connoisseurs of a rational approach, manufacturers have released 3D printers that bake pancakes. The device is a dream of housewives and pancake lovers, it costs more than a pancake maker or an ordinary frying pan, but can even the most modern pancake maker bake pancakes in the shape of a dinosaur, your favorite character or even your own head for breakfast? nine0003

As an example, consider the PancakeBot model, which not only bakes pancakes and pancakes, but also knows how to create shadows and halftones. Thanks to these unique features, 3D images printed on the PancakeBot are as realistic and voluminous as possible. During the printing process, the printer immediately fries the products.

The PancakeBot uses a heated non-stick surface as its working base and computer controlled heat and extruder action.

The model is equipped with one print head, connects to a computer via an SD card or USB cable. The productivity of the printer is 100mm/s. nine0003

Like any device, PancakeBot and other 3D food printers have their advantages and disadvantages.

The main drawback of the design of printers that print pancakes, users consider the inadmissibility of even the slightest lumps in the dough. The fact is that even the smallest lump can clog the nozzles of the device and stall the printing process. The problem is solved simply - just monitor the viscosity of the dough.

The advantages of PancakeBot are highly appreciated by artists and creative personalities - the user can draw absolutely everything that his talent and imagination allow him to draw. nine0003

Indisputable plus - simple ingredients. PancakeBot does not require expensive raw materials - the printer works with a simple pancake dough, the taste of which depends only on the user.

Please note! The manufacturer's website notes that any image can be downloaded to the PancakeBot's SD card, be it pictures downloaded from the Internet or your own photos.

Another benefit of PancakeBot is its availability. The device is relatively inexpensive. nine0003

PancakeBot will suit both private mini-confectioneries and catering chains, as well as simple pancake lovers — unusual pancakes and pancakes will delight children, decorate any holiday and surprise customers.

Sugar printing

Back in 2013, architects Kyle and Liz von Hasseln founded The Sugar Lab and, to the delight of sweet lovers, found a new application for 3D inkjet printing. Using the ChefJet confectionery food 3D printer as an example, we will talk about the production of three-dimensional models from sugar. nine0003

ChefJet applies a thin layer of granulated candy to the work surface and then selectively glues it with water, which is fed through the nozzle of the print head. The ChefJet head follows the contours of a digital model, moving in two dimensions. The printer then applies a new layer of ingredients, repeating the process to form the next layer of the shape.

Food additives and dyes make it possible to create models of various flavors and colors. nine0003

The ChefJet is a little too big for a typical kitchen, but the size of the working area inspires respect and allows you to decorate the average birthday cake.

Even the most inexpensive version of ChefJet has a significant plus - the printer can print mint, vanilla, chocolate, cherry and apple candies and icing. The disadvantage of the basic configuration is the inability to print multi-color sweets.

More advanced version of ChefJet allows you to print different colors of candy and mix flavors. Only one comparative disadvantage overshadows the professional model - the dimensions of the device have increased somewhat. nine0003

Perhaps the main advantage of ChefJet is the ability of the printer to work not only on powdered sugar, but also on caramel and even on chocolate chips.

The use of additive manufacturing allows ChefJet to create highly geometrically accurate sugar models.

Please note! ChefJet can even print hollow sugar products with free-flowing fillings in any flavor. For example, it is quite possible to print an edible rattle - ChefJet accurately prints edges, avoiding sharp corners and unsafe chips. nine0003

The ChefJet 3D Food Printer is designed for professional chefs and confectioners who will operate printers in bakeries, pastry shops and restaurants. Especially for users, the manufacturer plans to complete the devices with software and a digital cookbook. As an example, the manufacturer cites the possibility of printing figurines for wedding cakes.

Perhaps the high cost of ChefJet is the main disadvantage of this printer. However, there is always an opportunity to save money - on the market you can find used devices in good condition at a lower price. nine0003

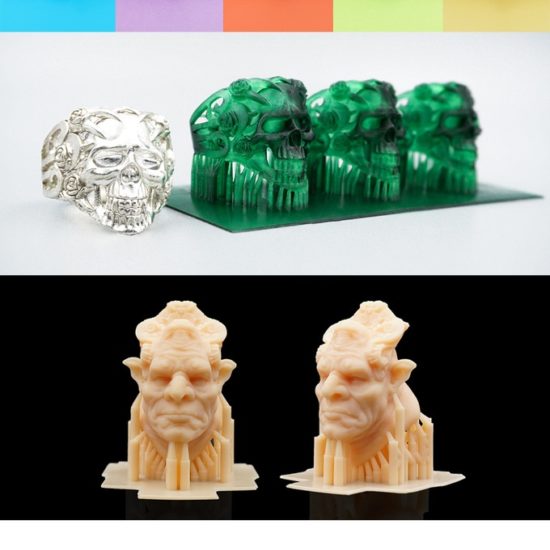

Chocolate printing

Choc Creator 2.0 Plus is the best example of a chocolate printing 3D food printer.

In our opinion, this is one of the most stable working models, affordable and creating real miracles from chocolate.

Choc Creator 2.0 Plus is the perfect assistant for chocolatiers, professional confectioners and just lovers of real Belgian chocolate.

Choc Creator 2.0 Plus was developed taking into account all the disadvantages of the previous version - the creators improved the convenience and technology of work, but did not forget about the design of the device - the new Choc Creator conquers with its compact dimensions, high performance, intuitive interface and unlimited possibilities for working with chocolate . nine0003

A few words about the design - the printer is equipped with a 5-inch touch screen. The start and settings buttons are conveniently located on the screen.

Choc Creator 2.0 Plus will fit both in a professional pastry chef's kitchen and in an apartment - the printer can easily be placed on a bar counter, window sill and any other flat surface.

Another indisputable plus for visuals is the opportunity to observe the process of printing chocolate figures.

Choc Creator 2.0 Plus is a master of chocolate, from miniature cake decorating figures to large chocolate models. nine0003

The manufacturer's concern for its customers deserves special attention, which is felt from the moment you open the box with the printer. First, Choc Creator 2.0 Plus is in assembled condition. Secondly, a small transparent suitcase, complete with the necessary accessories, emphasizes the premium model. Inside the case are:

- stainless steel syringe;

- two nozzles of different diameters;

- special needle for cleaning clogged nozzles; nine0012

- magnets for easy paper fixing;

- 5 loading heads;

- Stylish USB flash drive in gold casing;

- height calibration disc;

- hex.

The manufacturer has not forgotten about the brush for cleaning the syringe, the stylus for the touchscreen and other useful little things that express concern for the buyer.

It would seem that Choc Creator 2.0 Plus is one solid plus, but there is also a relatively small drawback - the printer only works on high-quality raw materials without additives. nine0003

The creators of the printer strongly recommend using only Belgian chocolate with a cocoa content of at least 54.5%.

Choc Creator 2.0 Plus will suit both professional chocolatiers and confectioners, as well as simple connoisseurs of quality chocolate.

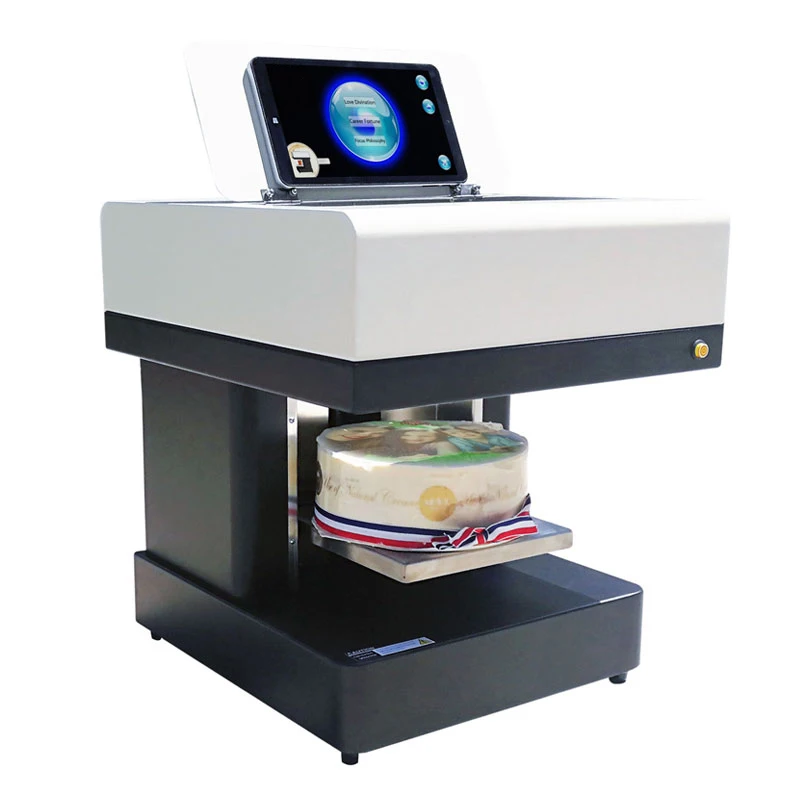

3D printing on drinks

Just a few years ago, only a few baristas could draw a simple pattern on coffee. The process took time, and the result did not always meet the client's expectations. Serious competition for the creative workers of coffee houses and their flowers on the foam was 3D printers. These devices can print anything on any drink, including milkshakes and beer. nine0003

CafeMaker is a 3D inkjet printer that can print images on various types of drinks, and can do it with three food colors at the same time.

The CafeMaker's print speed is 10 seconds/cup, allowing you to design your drinks in seconds.

Important! The CafeMaker doesn't just print on drinks, it can also print on small cream cakes.

An indisputable plus of CafeMaker is its own CupShow application, in which you can select pictures for printing from those saved in the device’s memory, as well as create inscriptions, logos, or even print personal photos.

CafeMaker can print with a single ink or a combination of cyan, red and yellow.

The process of refilling CafeMaker is similar to working with a conventional inkjet printer - dye is slowly poured into the cartridge, and then the finished cartridges are placed inside the device. nine0003

A small drawback of the device lies in its requirements for a cup or glass - containers should not be transparent, their height should not exceed 18 cm, and their diameter should not exceed 11 cm.

restaurant - any client will be happy to receive a cup of coffee, a glass of beer or a cupcake with an original image.

Printing with paste ingredients

Printing with sugar and chocolate is no longer just a fantasy. Now you will not surprise anyone with three-dimensional models from familiar products, so 3D printer manufacturers decided to take a step towards lovers of everything unusual and create devices that print almost any product from various ingredients. nine0003

The Foodini 3D printer will give a confident rebuff to multicookers and other kitchen gadgets - the device can independently print dumplings, prepares the finest Italian pasta, cookies, donuts covered with icing, and even hamburgers.

Up to five different textures can be loaded into the Foodini printer at the same time. Thanks to the nozzles of different diameters, which are supplied with the printer, a wide variety of dishes are suitable for printing.

Unlike its counterparts, Foodini has firmly taken its place in the restaurant business. Of course, not all establishments can afford an expensive unit.

For example, the Foodini printer is used in one of the most popular restaurants in Barcelona, La Enoteca. One of the institution's most unusual dishes is seafood puree, which is almost impossible to decorate by hand so gracefully. nine0003

The print speed of the Foodini printer is 100 mm/s, which is another advantage of the device.

Perhaps the only relative disadvantage of Foodini is its high price, but it is compensated by the increased interest of customers in the dishes produced and, as a result, an increase in the institution's profit. The Foodini printer is ideal for restaurants and other catering establishments that want to emphasize the creative approach of the management and the chef, as well as the high class of the company. nine0003

What kind of raw material is used for printing?

The following ingredients can be used as raw materials for 3D edible printing:

- plain chocolate and chocolate chips;

- food mastic;

- sugar;

- curd mass;

- fish, meat and liver pates;

- cheese;

- vegetable and fruit pastes;

- flour;

- food colors and flavors.

Learn more