3D printer air scrubber

Best Air Purifiers for 3D Printers [With HEPA and Carbon Filters]

If you’re a 3D printer enthusiast, then you’re probably well aware of the pollutants that are emitted when printing. In this article, we’ll be discussing the best air purifiers for 3D printers, with both HEPA and carbon air filters.

Printing in a well-ventilated room is always advisable, but if you want to take things one step further, an air purifier is a great way to eliminate any harmful emissions from your 3D printer.

Which Air Filters Work for 3D Printers?

There are three types of filters that are effective at trapping particles emitted by 3D printers: HEPA, carbon air filters, and PECO filters.

HEPA Filters

Airborne contaminants come in many forms, from large particles that are easily visible to the naked eye to smaller microparticles that can only be seen with a microscope. During the printing process, 3D printers release a fine mist of ink particles into the air, known as ultrafine particles, or UFPs. These particles are small enough to bypass the body’s natural defenses and enter the bloodstream, where they can cause respiratory problems, heart disease, and cancer.

HEPA filters are designed to trap particles as small as 0.3 microns in size, which means they are effective at capturing most UFPs. However, True HEPA filters are even more effective, with the ability to trap 99.9 percent of particles as small as 0.1 microns. This makes True HEPA filters the best option for reducing exposure to UFPs emitted during the 3D printing process. You can also find out if HEPA air filters remove asbestos from the air by checking our article here.

Carbon Air Filters

A carbon air filter is a type of air filter that uses activated charcoal to trap pollutants. Carbon filters are effective at trapping a range of pollutants, including volatile organic compounds (VOCs), which are released when plastic is heated during 3D printing. VOCs can be dangerous to your health, so it’s important to remove them from the air you breathe.

But, while carbon air filters are good at removing VOCs and odors, they are not as effective at trapping UFPs. This is because the pores in activated charcoal are too large to capture such small particles. Moreover, carbon air filters need to be replaced more frequently than other types of air filters, as they lose their efficiency over time.

PECO Filters

There are many dangers that come with 3D printing, chief among them the release of toxic fumes into the air. But a new technology promises to change all that, and it’s called photoelectrochemical oxidation (PECO).

PECO filters out both particles and VOCs from the air, permanently destroying any toxins. What’s more, PECO can destroy carbon-based particulates, which is what most plastic molecules are made of. In other words, PECO filters are the best way to keep your air clean and safe when 3D printing.

Read Also: Do Air Purifiers Release EMF Radiation?

Best Air Purifiers for 3D Printer Pollution

Now that we know which air filters are effective at trapping 3D printer emissions, let’s take a look at the best air purifiers for 3D printers.

1. Molekule Air Purifier with PECO Technology

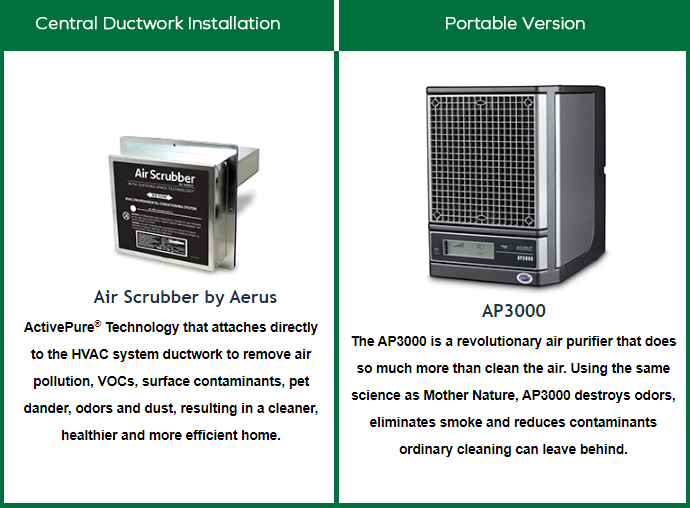

The Molekule air purifier is a top-of-the-line device that is perfect for larger rooms up to 600 square feet. It features an easy-to-control touch-screen interface, and it also can be remotely controlled by phone.

This air purifier has three fan speeds that you can choose from to customize your purification needs. It is also very quiet, only 41 decibels at the lowest speed. Additionally, it can be easily carried and placed anywhere in the room.

The best feature of the Molekule air purifier is the PECO technology. This doesn’t just collect 3D printing pollutants, it destroys them at a molecular level. There is also an indicator to track the replacement schedule for your PECO filter.

Check out this 3D printer air purifier on Amazon.

2. Medify Air Purifier with h23 True HEPA Filter

The Medify air purifier is designed with a sleek touch screen operation panel that allows you to choose from 3 fan speeds and a 0-8 hour timer. The lowest setting operates virtually silent, making it ideal for nighttime use. It also has a sleep mode, which completely dims the unit’s panel lights.

The lowest setting operates virtually silent, making it ideal for nighttime use. It also has a sleep mode, which completely dims the unit’s panel lights.

Perfect for spaces up to 1,000 square feet, this air purifier will remove 99.9% of harmful particles including allergens, dust, contaminants, and more down to 0.1 microns in size using HEPA h23 filtration technology. The activated carbon filter removes VOCs and burning plastic odors that come from 3D printing.

The Medify air purifier has a child lock feature, making it great for both kids and pets. It also comes with a filter replacement indicator to let you know when it’s time to replace the filters.

You can check and buy this HEPA air purifier for 3D printers here.

3. Levoit Air Purifier with a True HEPA and Carbon Filter

The Levoit air purifier has a CADR of 466 m³/h and delivers fresh air in rooms as large as 1,150 square feet in just 30 minutes. It is equipped with a 3-stage filtration system: h23 True HEPA filter, activated carbon filter, and nylon pre-filter. Therefore, it can remove 99.97% of particles, including resin 3D printer fumes.

Therefore, it can remove 99.97% of particles, including resin 3D printer fumes.

This air purifier has a rated power of 49W, making it a low-cost option that doesn’t consume a lot of energy. Additionally, it is whisper-quiet with noise levels as low as 25dB in sleep mode.

It’s also easy to use, with a timer that can be set for 1-12 hours and a filter replacement indicator. The air purifier is safe and trustworthy with a Levoit professional customer support team.

Click here to see the Levoit air purifier on Amazon.

4. ELEGOO Mini Air Purifier for Resin 3D Printers

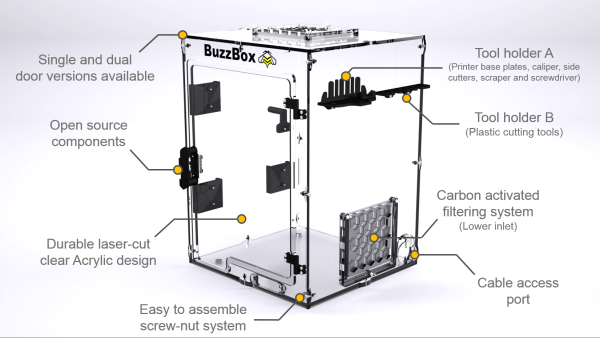

The ELEGOO mini air purifier not only matches ELEGOO Mars series printers, but is also compatible with other types of 3D printers, such as LCD, DLP, and MSLA resin 3D printers. It works by absorbing and filtering out the resin odor before it is circulated throughout the printer.

This small and affordable air purifier comes with one activated carbon block that can be used for 3 to 6 months and can be replaced as needed. The 2000mAh battery allows the purifier to work continuously for at least 24 hours once fully charged. The only downside is that the charcoal packs are difficult to find.

The 2000mAh battery allows the purifier to work continuously for at least 24 hours once fully charged. The only downside is that the charcoal packs are difficult to find.

See this product on Amazon.

In conclusion, the best air purifier for a 3D printer is one that has both HEPA and carbon air filters. This will ensure that any harmful pollutants are removed from the air, making it safer for you to breathe.

We also recommend trying the Molekule air purifier with PECO technology, which is specially designed to break down and remove UFPs and VOCs.

Nevermore Is What You Get When Engineers Design Air Filters For 3D Printers

- by: Donald Papp

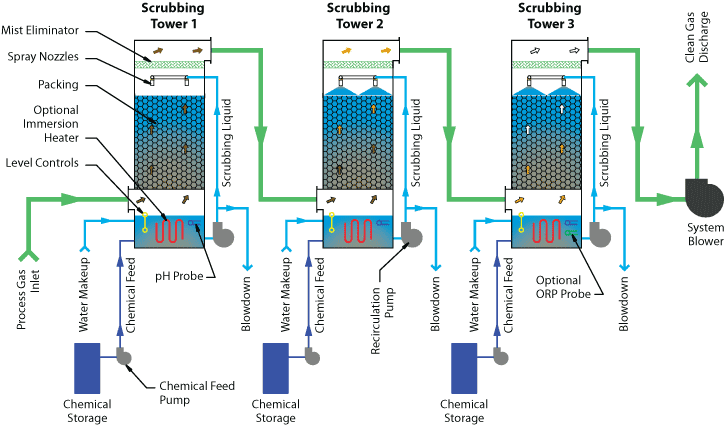

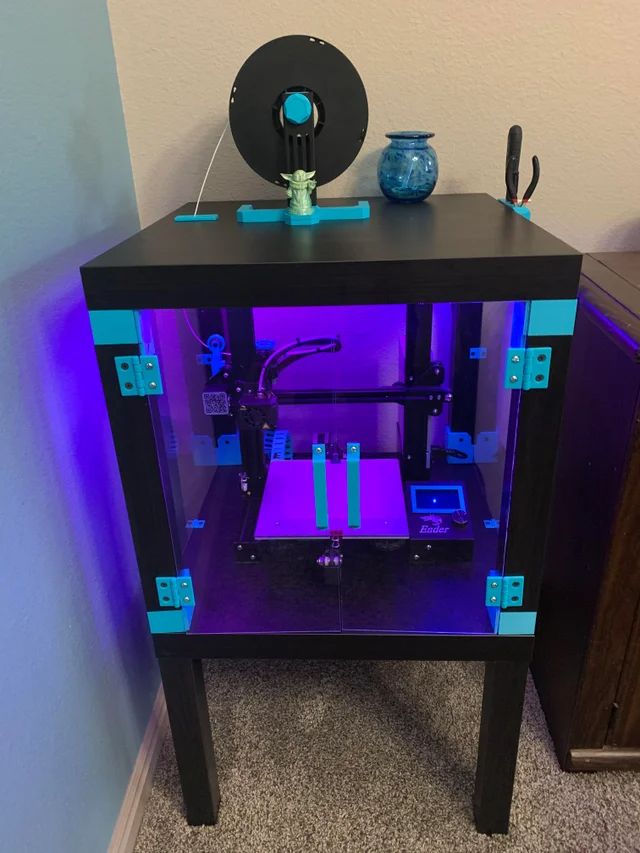

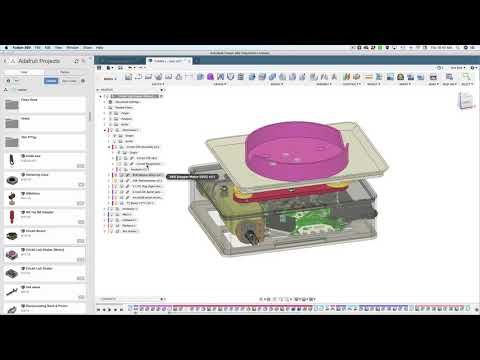

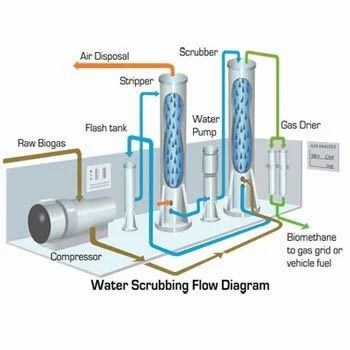

What happens when an air filter for 3D printers gets designed by engineers with a passion for function, a refusal to compromise, and a desire to do without bad smells or fumes? You get the Nevermore, a design for a recirculating active-carbon filtration system to deal with VOCs (volatile organic compounds) from 3D printing.

The Nevermore Micro (and larger Nevermore Max) were originally intended to complement the Voron 3D printer design, but are made such that they can be used with just about anything else. These filters use 3D-printable parts, and are designed to be easily filled (and refilled) using bulk-activated carbon instead of some kind of proprietary pre-packed filter like most commercial offerings. The Voron project is all about a printer without compromises, and the Nevermore comes from that same design ethos.

A Nevermore filter sits inside the build chamber, and works by recirculating air inside while passing it through the activated carbon. The idea is that by concentrating on dealing with the problem at the source inside a relatively small build chamber, one doesn’t need a lot of airflow. A small recirculating air filter can do the job efficiently, though for best results, the build chamber should be as sealed as possible.

One interesting caution is that it seems not all activated carbon is the same, and it is absolutely crucial to use only acid-free, steam-activated (not acid-washed) carbon in a recirculating filter like the Nevermore. There are horrifying photos of oxidized metal surfaces resulting from using acid-residue carbon, some of which took only minutes to occur. Thankfully, there are pointers to trusted sources for the known-good stuff.

It’s known that 3D printing results in chemical and particle emissions. These differ significantly depending on both material and type of printer, but it’s enough of an issue to warrant attention. One deals with particulates with something like a HEPA filter, but VOCs require a carbon filter. This is where the Nevermore comes in. Active carbon filters will wear out simply from exposure to the air, so if one is serious about cleaning VOCs when printing, it is definitely worth looking into bulk carbon with a design like the Nevermore.

Air pollution in 3D printing

Main page

Articles

Smoke from a 3D printer

Smoke from a 3D printer

Introduction How does a printer pollute the air How does a BOFA filter

What is 3D printing

3D printing is also known as additive manufacturing. This means that the product is created by adding material in layers. The process is controlled by a coordinate XYZ robot with digital control. Printers work with plastic or metal. The material is fed to the deposition point in the form of wire or powder. The printer is melting the material. Then it connects to the previously applied base.

This means that the product is created by adding material in layers. The process is controlled by a coordinate XYZ robot with digital control. Printers work with plastic or metal. The material is fed to the deposition point in the form of wire or powder. The printer is melting the material. Then it connects to the previously applied base.

A 3D printer will produce objects of complex shape. This favorably distinguishes the additive process from the subtractive one, when excess is removed from a large piece of material. Machining, laser processing, soldering or welding generate more contamination. And a lot of material is wasted. 3D printing does not consume a lot of extra material. It appears to be a clean process, but it still pollutes the air.

Anyone using 3D printing needs to be aware of the health risks. The 3D printer seems safe. But it can generate toxic fumes and hazardous substance particles. Technological processes that transform the material pollute the air in the workplace. This applies to cutting, engraving, thermal decomposition in a laser machine, soldering with a toxic flux, etc. Molten metals and polymers are no exception.

This applies to cutting, engraving, thermal decomposition in a laser machine, soldering with a toxic flux, etc. Molten metals and polymers are no exception.

Why is a 3D printer dangerous?

Ultrafine particles

Heating a substance causes the release of solid particles, droplets and vapors. They may be harmful if inhaled.

European scientists are gradually revealing the dangers of 3D printing to health. According to the 3D Printer Emissions Report , plastic melting releases small nanoparticles of material into the air. They cannot be seen without special equipment. But that doesn't mean they are safe.

PLA plastic nanoparticles are used in pharmaceuticals as a means of delivering drugs to various organs, including the brain. Cosmetics use the same effect. Ultrafine particles penetrate the skin. By themselves, PLA particles are not toxic. But no one knows about the consequences of accumulation in human organs. Nanoparticles condense into relatively large formations. It is known for certain about the harmfulness of soot nanoparticles from automobile exhausts . They are associated with degenerative brain diseases, such as Alzheimer's disease.

Nanoparticles condense into relatively large formations. It is known for certain about the harmfulness of soot nanoparticles from automobile exhausts . They are associated with degenerative brain diseases, such as Alzheimer's disease.

ABS plastic is toxic when melted. Nanoscopic ABS particles are just as toxic. These particles are very small. During inhalation, they enter the brain through the olfactory nerve. They spread throughout the body through the bloodstream. Most organs can get rid of them naturally, but the brain and lungs become clogged for a long time.

In fact, particles as small as 10-200nm easily enter the bloodstream through the lungs. Their toxic action differs from the original substance in the usual shapes and sizes. According to study by the Italian Institute of Health and Consumer Protection nanoparticles are deposited in the lungs in greater quantities than e-cigarette smoke.

Gases or vapors

Molten ABS gives off a particularly unpleasant odor. Other plastics including nylon, HIPS and HDPE emit the same toxic fumes but have less odor.

Other plastics including nylon, HIPS and HDPE emit the same toxic fumes but have less odor.

Polymer materials can vaporize some of their constituents. Dioctyl phthalate is often added to them for flexibility and mold resistance. During high heat or laser treatment, benzene is released in hazardous quantities. And while working with PVC, HCl aerosol condenses in the air.

The high temperature in the area of the printer head causes the air to expand. Vapors quickly spread in the work area along with plastic particles. Thermal degradation products of polymers are shown in the diagram below.

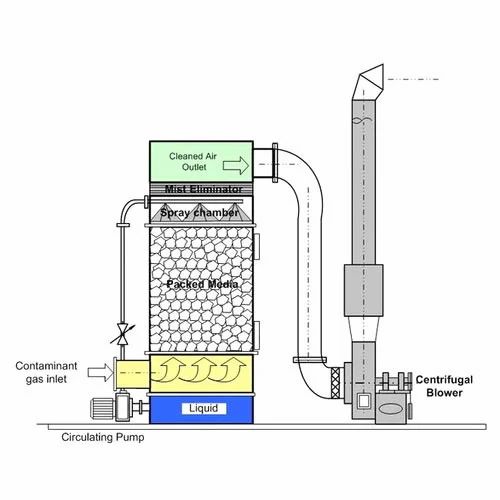

How does BOFA work?

A smoke extractor is an extractor hood with filters placed in one device. She got her name at the time when she removed the smoke of a soldering iron or a laser engraver. But these same devices with special filters are also suitable for a three-dimensional printer. The smoke extractor block for the printer is not much different from the soldering block.

3D printing is sensitive to changes in air temperature. Therefore, he is afraid of drafts. If you are using a small open printer, then the polluted air can be removed with a conventional smoke extractor. In order not to disturb the climate in the printer, select the minimum air suction speed.

If your 3D printer model is closed, there is a protective cover, then you can install a cleaning curtain. During operation, while the printer window is closed, it can be turned off. But it will clean the outgoing air when you open the box to take out the finished product.

If your printer is large and completely enclosed, then it will most likely have built-in pipes for connecting the hood. They can be connected to a smoke extractor with large filters. It can operate continuously or turn on at the command of the printer. The fume extractor captures dirty air and returns it back to the printer so as not to change the air temperature during the printing process.

3-stage filtration

A complete smoke extractor is equipped with three filters. The first is the pre-filter. It does not let in coarse dust, so as not to clog the main fine filter with it. The fine filter is HEPA. Particles of all sizes, including aerosols and nanoparticles, settle on its fibers. The gas filter completes the cleaning. It consists of densely packed activated carbon granules with interlayers of fiberglass. Activated carbon traps VOCs and nanoparticles that HEPA missed.

Smoke extractor against exhaust

The cheapest way to remove smoke is a duct fan and air ducts. The emission of polluted air through the window is prohibited by SanPin standards. And the smoke extractor has advantages.

- Good air purification from all kinds of solid particles and aerosols

- There will be no odors from melted plastic or metal in the room

- You will be sure that your health will not suffer

- The microclimate in the 3D printing machine will be stable

- Supply ventilation with heating or air conditioning is not needed, as for the extract through the window

Eliminate the harmful agent

The hood with filters will solve the problems with harmful emissions from 3D printing with polymers and metal powder. Without proper filtration, ultrafine particles cause skin and eye irritation. Nanoparticles accumulate in internal organs and lead to systemic disorders, heart and vascular diseases, and Alzheimer's disease. The smoke extractor is suitable for household and professional models of printers. Extractor hood with filter, recirculation and airflow adjustment minimally affects the air temperature inside the printer. BOFA will take care of you and the world we live in.

Without proper filtration, ultrafine particles cause skin and eye irritation. Nanoparticles accumulate in internal organs and lead to systemic disorders, heart and vascular diseases, and Alzheimer's disease. The smoke extractor is suitable for household and professional models of printers. Extractor hood with filter, recirculation and airflow adjustment minimally affects the air temperature inside the printer. BOFA will take care of you and the world we live in.

Smoke extractor catalog PDF

You can familiarize yourself with the models on our website in the section Smoke detectors for 3D printers

During business hours, a showroom or showroom is open in our office. Popular BOFA smoke extractors are on display here.

Watch our video

Visit our YouTube channel where you can get a closer look at the manual editing methods we offer: www.youtube.com/user/ARGUSXvideo

How I made a humidifier using a 3D printer / Sudo Null IT News

Initially, an ultrasonic humidifier was purchased to humidify the air in the apartment. But after a while they began to notice a white coating on furniture and other surfaces - the salts contained in the water. The question arose about replacing the ultrasonic humidifier with some other one. We decided to try to make it ourselves.

But after a while they began to notice a white coating on furniture and other surfaces - the salts contained in the water. The question arose about replacing the ultrasonic humidifier with some other one. We decided to try to make it ourselves.

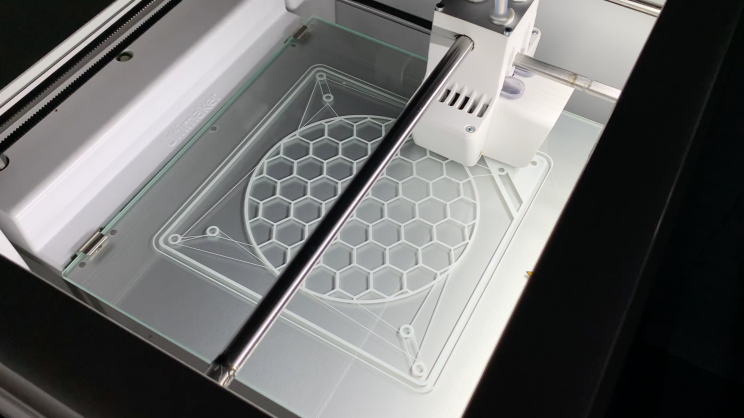

There was no exact project, and the first set of 29 evaporator discs was printed sector-by-sector, the width of which was the size of a nightstand.

In the future, it was planned to order an aquarium made of fiberglass for the base of the structure. It took several days to print four sectors intermittently: the net print time for one sector is 19 hours, about 1.7 kg of plastic was used. During the printing of one sector, there was a power outage, I had to print the rest separately. The sectors were later connected to each other with a soldering iron. The set consists of 28 disks with a thickness of about a millimeter and a radius of 14.5 cm on one axis, plus a gear with a thickness of 2 mm and 74 teeth.

A plastic container was used as a water container.

A hole was cut through almost the entire area in its lid so that only a couple of centimeters remained along the perimeter. The second similar container went to increase the height of the device: about half of its height was cut off from it and planted with hot glue on the lid of the first one upside down. Its bottom became the lid of the humidifier, a hole was cut in the wall for the exit of moist air, and holes for air inlet were cut at the top, as well as a mechanism that ensured the rotation of the disks. The plastic of the container is fragile, the knife is tight and can break off abruptly, it might be better to melt the necessary holes with a soldering iron.

The disks themselves are suspended on the walls of the lower container using such brackets with cutouts that allow you to quickly remove and install the rotating part.

Such a suspension is good because water can be poured above the axis of the discs so that it lasts longer. Lubrication is not applied. The rims and all the orange parts are made from PLA, the rest are white ABS.

The rims and all the orange parts are made from PLA, the rest are white ABS.

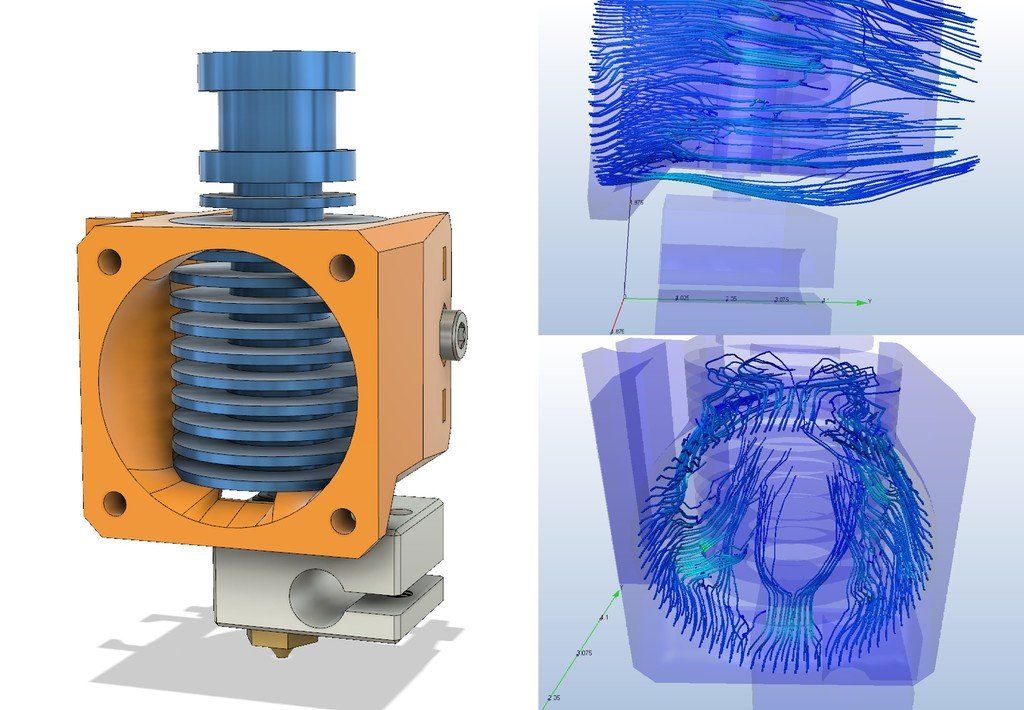

In the inside of the humidifier cover, two gears are installed on the same axis with a gear ratio of approximately 1:4, with teeth that differ significantly in size: very small (there are already 178 of them) receive rotation from the gearbox located on top of the cover, and large ones (in total 9) transmit rotation to the disks.

The gearbox located on the cover was used factory (taken from an old scanner) in view of the low noise that the experimental samples printed on the printer could not achieve. As a silent engine, a fan from a computer case with broken blades was used, a roller from an old tape recorder was glued to it. Such an engine has one drawback: it cannot spin up on its own, you have to push it after turning it on. A rubber belt transfers the rotation from the former fan to a large roller, which in turn rotates the gears of the gearbox. Air is blown by two low voltage fans to reduce noise.