Stratasys uprint se plus 3d printer price

3D Printer Shootout - $600 Printrbot vs. $20,000 uPrint SE Plus

browse by category or date

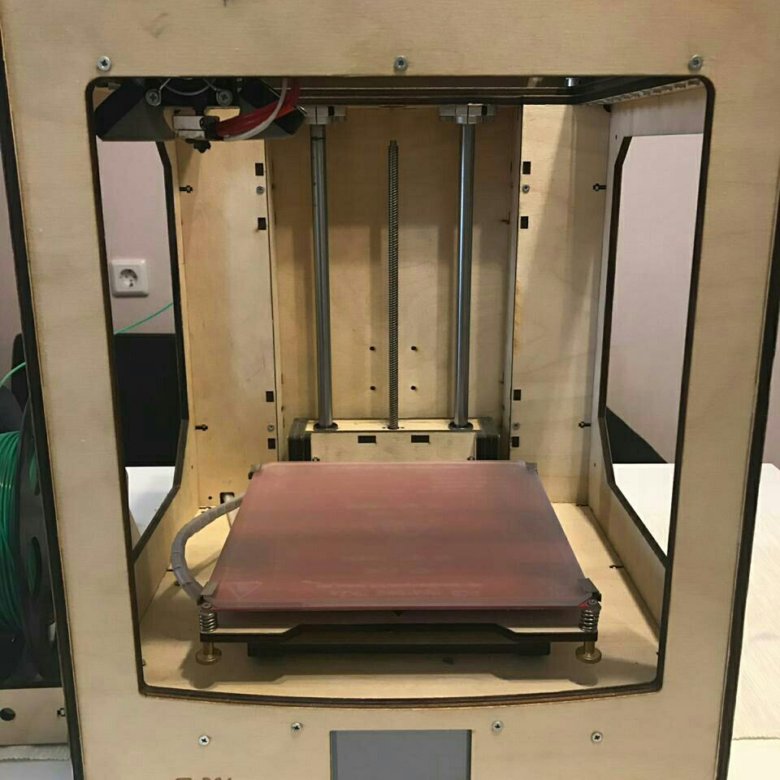

February 06, 2015 Posted in 3D PrintingFirst, let's level set with a disclaimer. I am a smart enough person but a total beginner at 3D printing. I've been 3D printing for about two weeks using a Printrbot Simple Metal from Amazon that I got for US$599. Other than Amazon affiliate links (buy from my links and you buy me tacos!) I don't have ANY relationship with Printrbot or anyone in the 3D Printing space. I'm unaffiliated. This "shootout" is an interesting experience. I'm sure I did something wrong, or perhaps my partner in crime on this experiment, Brandon Potter, missed a step. Who knows? But this is how it went down.

Brandon saw that I was doing some 3D printing and mentioned they had a <$22,000 3D printer at his work and what did I think about doing a comparison? I had been having trouble printing with success, ruining at least 2 out of 3 prints, but recently got my Printrbot dialed in nicely. '

Here's my investment so far both in time and money.

- Printrbot Simple Metal from Amazon that I got for US$599

- Raspberry Pi and Raspberry Camera to watch my prints and do time-lapse videos with Octoprint. Figure $60.

- A spool of RioRand 1.75mm PLA Filament in Black for $28.

- Digital Calipers for measuring stuff. $20.

- And a number of printed parts to improve my 3D printer's performance including:

- Raspberry Pi mount and camera holder

- Printrbot Simple Metal filament spool holder

- Feet for the Printrbot (plus little rubber feet-bits)

- Uline brand blue tape. Works WAY WAY better than other blue tapes. This made a HUGE difference. $15

So I'm into it for $722 and my time. I did NOT use a Heated Bed for my Printrbot Simple Metal but I am told it's a great upgrade.

Here's Brandon's company's outlay in his words:

- uPrint SE Pro Printer and Dissolving Bath – about $22,000

- 1 Spool of Model Material (Black) – $205.

00 (produces 42 cubic inches of printing)

00 (produces 42 cubic inches of printing) - 1 Spool of Support Material – $200.00 (42 cubic inches worth)

- Box of Build Plates – $125.00 for 24 (you need one for each print, so it costs about $5.20/each)

- Soluble Concentrate – $149.00 for 12 bottles (dissolves support material, aka fancy drain-O)

- Warranty Support – $2,000/year – because it does break from time to time.

- Brandon says - Add a little bit of shipping, and for a mere $25K you’re ready to print your very own coffee cup.

We decided to print a coffee cup. I don't plan on drinking from it because who knows if the plastic will leech off, but it seemed like an interesting and common object. As a 3D model it has some nice curves, the handle overhang is a small challenge and it's something we can easily compare.

I printed one on my Printrbot and Brandon printed one on their Stratasys uPrint SE Pro. Then Brandon mailed me his cup and I'm sitting here holding them both in my hands.

Here is a timelapse video of my cup printing. My 0.2mm print took about 7 hours and this video is 90 seconds. I used Octoprint and the Raspberry Pi to create the video.

I downloaded the Coffee Cup model from Thingiverse as an STL 3D model. I ran the STL model through the Microsoft 3D Printing NetFabb online service to make sure the model was watertight. Then I loaded the result directly into Repetier and used Cura to slice the model into individual instructions for the printer. I made one adjustment to the slicing settings, telling it to make a "support structure" when it sees an overhang over 30 degrees. I was concerned about the cup's handle. Other than that one settings change which resulted in the support being added (which is easily pulled off after the print) it was a "printing as is." Brandon's model also used a support structure to print the cup and keep the handle stable so we decided this was pretty typical. He also printed on his pro printer with no changes.

He also printed on his pro printer with no changes.

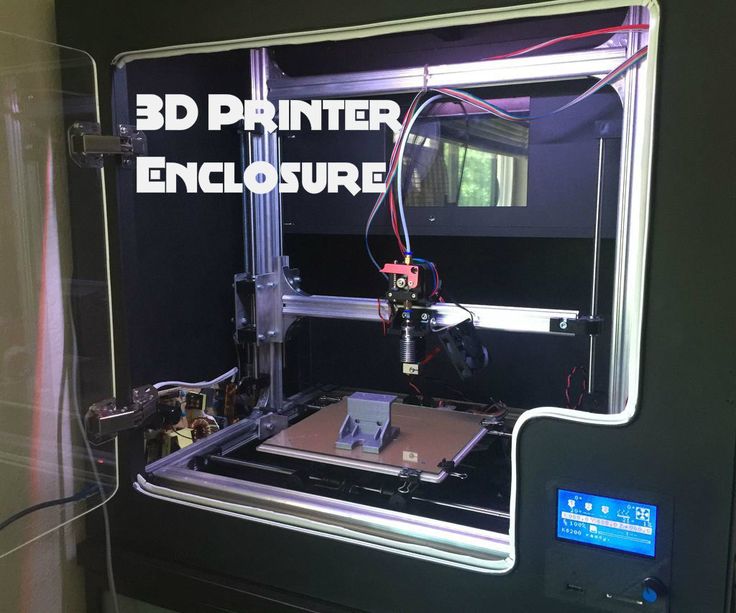

Here is a picture of my setup. There's my printer on the right with some stuff I've made and my box of tools/crap on the left. You can see the spool, the printer (the red lipstick looking thing is where the hot plastic comes out), the Raspberry Pi and the tape that I print on. I can print objects up to 6 inches on a side, so a big 6 inch cube. If I paid more money I could get the 10 inch model, but so far for my hobbies I'm happy with that size. I can break things up and assemble them with acetone or bolts if I want to make larger models. One fellow 3D-printed a whole full-sized motorcycle with a small printer and assembled the parts.

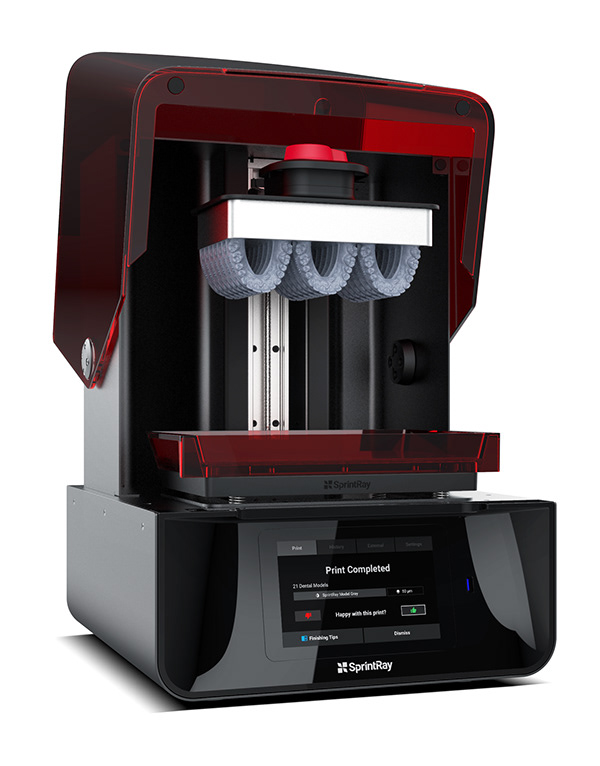

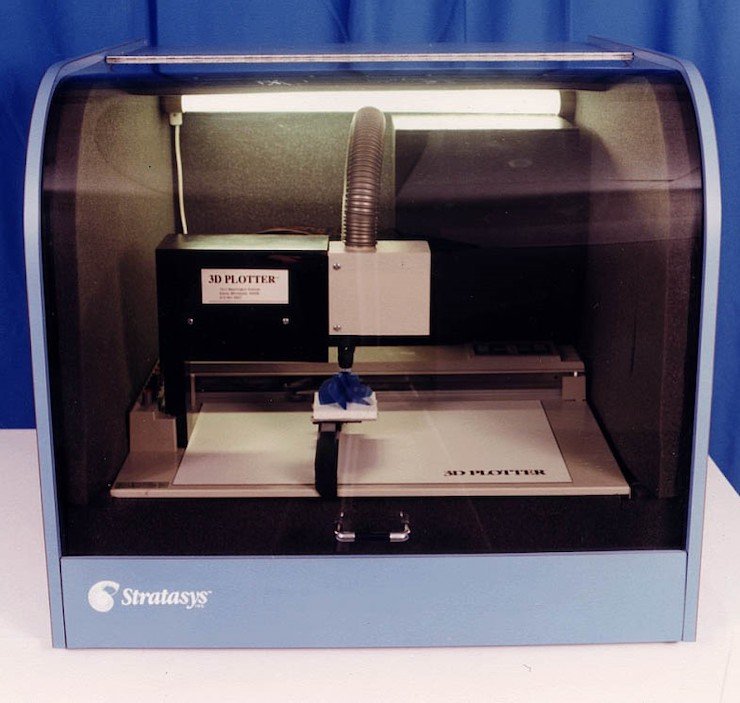

Here is Brandon's printer. Again, $600 vs. $25000.

By the way, is this a silly comparison? Perhaps. But no more than a Tesla vs. a Challenger Hellcat. Actually, I think my printer is a Geo Metro. But I get great mileage!

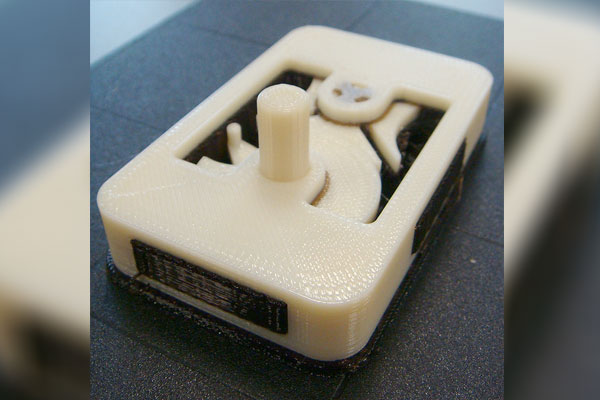

Ok, here's the prints. Feel free to click to zoom in to make your decision. Which cup came from which printer?

Which cup came from which printer?

Here's slightly larger pics. Note I am not/have not moved the cups side to side. Left/right is consistent for this photo series.

Which is which?

The $599 Printrbot Simple Model printing at 0.2mm is on the left. The $20k uPrint SE Plus printing at 0.1mm is on the right.

The uPrint's base was messed up somehow. A bad start perhaps, but unfortunate as it's supposed to just work since Brandon used the one-time-use custom bases that the uPrint comes with. He also used the dissolving bath to take the white support structure off. You can see some of the white still there, perhaps it wasn't in long enough. My print had supports but I just pulled them off with my hands. Of course, if you have an intricate print with small parts that's not always possible. This is a very simple object, to be clear. It's not interlocking gears or something.

Here's the uPrint cup. Brandon said it took 8 hours and 22 minutes.

Here's the Printrbot's cup. Note the "Z scar" (an artifact from the printer moving up the Z-Axis) on the print? On my print it ended up by the handle, but on Brandon's it ended up on the side of the cup, marring the print, in my opinion.

What's the takeaway? If we assume that I have a totally dialed-in well calibrated super cheap consumer/hobbyist 3D Printer and that Brandon has a $20k professional 3D Printer that's maybe got some calibration issues, they seem very comparable.

However, in real one-time costs my cup cost me 21.02 meters of filament, costing me perhaps $2 maybe a little more if you count the few pieces of tape. For Brandon and his Pro printer, in direct costs, he used $23.62 in model material, $2.06 in support material, and $5.20 build plate, for a total of $30.88 for this cup.

Naysayers will say that this isn't a great model to have chosen. Clearly my little Printrbot Simple Metal can only make things of a certain size, but it's clearly fair to say that it's a surprisingly competent printer when it's calibrated well. Additionally, if I were a 3D modeling shop with a Pro printer, I think I would definitely pick up a few sub-$1000 printers for basic stuff as the big printers may be costing you money. If I was a small business I would really do my homework before buying a pro printer that claims to be problem- and maintenance-free. Go read Brandon Potter's account of his "pro print" and compare notes!

Additionally, if I were a 3D modeling shop with a Pro printer, I think I would definitely pick up a few sub-$1000 printers for basic stuff as the big printers may be costing you money. If I was a small business I would really do my homework before buying a pro printer that claims to be problem- and maintenance-free. Go read Brandon Potter's account of his "pro print" and compare notes!

NOTE: This post is intended in no way to talk up Printrbot nor to talk down Stratasys. It's a simple one time anecdote as it happened, using a simple model.

What do you think, Dear Reader?

Sponsor: Big thanks to Infragistics for sponsoring the feed this week! Responsive web design on any browser, any platform and any device with Infragistics jQuery/HTML5 Controls. Get super-charged performance with the world’s fastest HTML5 Grid – Download for free now!

About Scott

Scott Hanselman is a former professor, former Chief Architect in finance, now speaker, consultant, father, diabetic, and Microsoft employee. He is a failed stand-up comic, a cornrower, and a book author.

He is a failed stand-up comic, a cornrower, and a book author.

About Newsletter

Hosting By

Disclaimer: The opinions expressed herein are my own personal opinions and do not represent my employer's view in any way.

Podcast

- Hanselminutes

- This Developer's Life

- Ratchet & The Geek

Speaking

- Speaking/Videos

- Presentations Tips

Books

- ASP.NET 4.5

- ASP.NET MVC 4

- Relationship Hacks

© Copyright 2022, Scott Hanselman. Design by @jzy, Powered by .NET 6.0.8 and deployed from commit 5c6a80 via build 20220310.1

uPrint SE 3D Printer Review 2022

4.2

See Price

A compact printer with all the precision and quality of printers three times its size? Here’s our take on the uPrint SE 3D printer.

| Printing Area | 203 mm x 152 mm x 152 mm |

| Layer Resolution | 254 Microns |

| Supported Filament | ABS (ABSplus) and dissolvable support materials |

| Extruders | 2 |

| Software | CatalystEX |

Table of ContentsShow

Design & Features

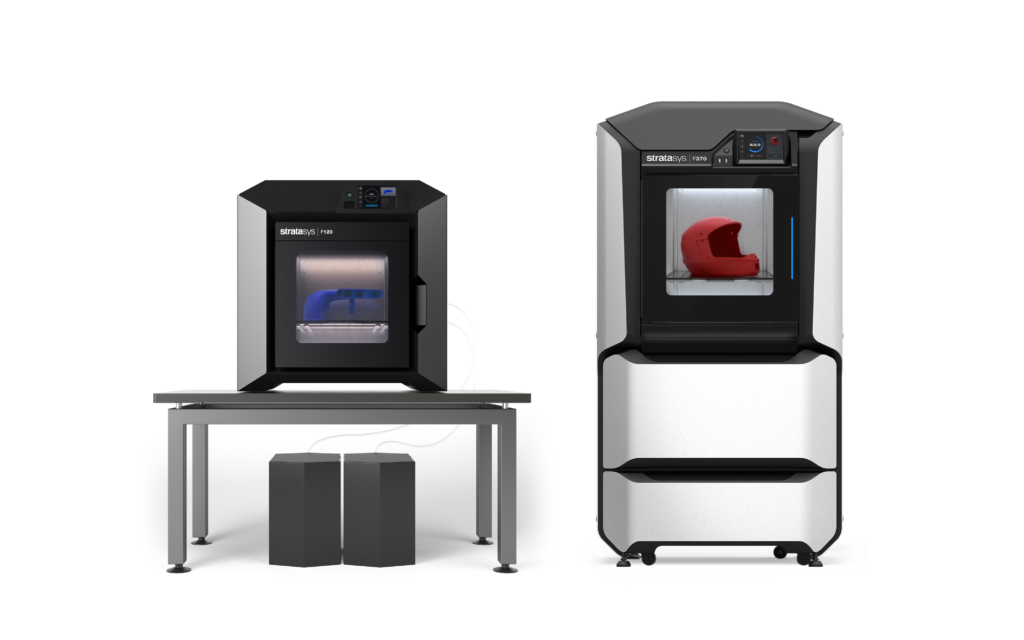

With the uPrint SE, Stratasys has taken all its industrial-scale printing know-how, then miniaturized it into a form factor fit for the desktop or home office. We have here a relatively diminutive device that is more akin to a coffee maker or large microwave than the fridge-sized units usually shipped from the company’s depots. The footprint measures in at only 635 mm x 660 mm x 787 mm weighing in at a comparatively light 76 kg.

We have here a relatively diminutive device that is more akin to a coffee maker or large microwave than the fridge-sized units usually shipped from the company’s depots. The footprint measures in at only 635 mm x 660 mm x 787 mm weighing in at a comparatively light 76 kg.

Aesthetically, it borrows heavily from the Stratasys tradition with a thick off-white and gray acrylic outer shell supported by a CNC-milled steel frame on the inside. Stratasys isn’t known for making particularly visually enticing products, and as such, the uPrint SE follows suit with a functional, unembellished look.

The build chamber is fully enclosed (with an internal light activated during printing) and accessed via a hinged, heavyset door fitted with a see-through plexiglass window — the door locks during printing for additional security. Two retractable materials bays sit below the chamber and are used to store both filament and support material. Stratasys also sells additional material bays to expand and effectively double the material capacity of the printer. These sit on top of the existing row when installed.

These sit on top of the existing row when installed.

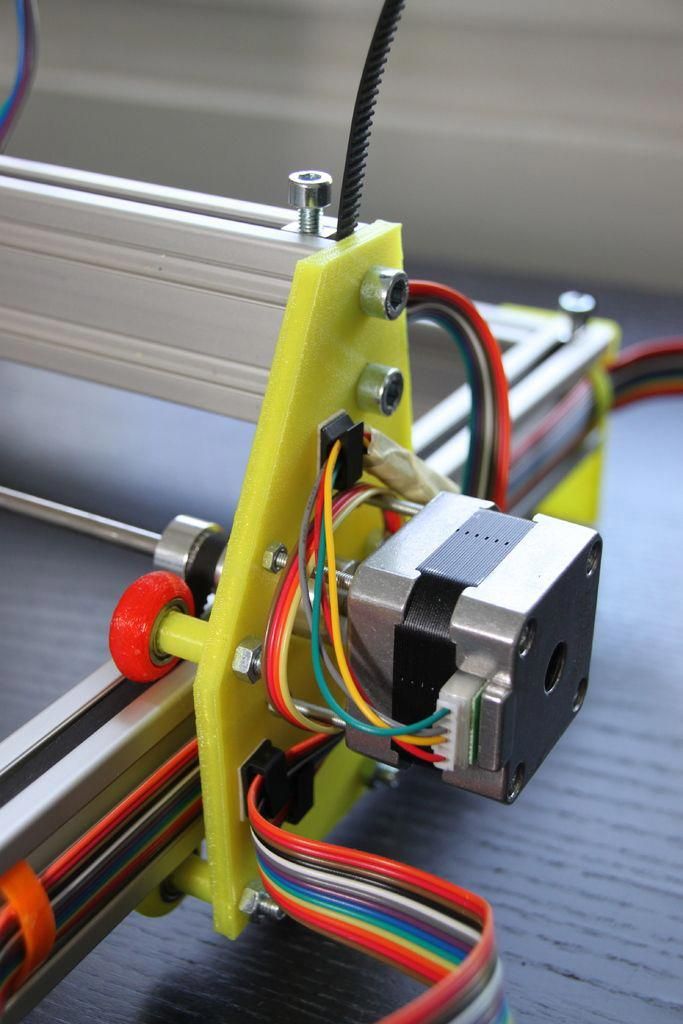

Internally, the uPrint SE is based on Stratasys’ long-standing FDM technology powered by belted servo stepper motors running on all three axes along lead screws and guide rods. The build platform, or platen as Stratasys has coined it, support one-time use modeling bases or beds and provides a build volume of 203 mm x 152 mm x 152 mm for the standard uPrint SE or 203 mm x 203 mm x 152 mm for the larger, but internally identical uPrint SE Plus model.

Every new print needs a new modeling base. If not replaced, the printer is prone to calibration errors, and extrusion issues reflected in sub-par quality finished prints. Costs invariably stack up, but given that the uPrint SE is designed as a compact solution for professional R&D and manufacturing setups, the expenses remain comparatively marginal.

Two direct drive extruders sit inside the uPrint SE; one tasked with extruding filament, and the other exclusively used to deposit support materials. Layer thickness is locked in at 254 microns for a happy middle ground between precision prints and rougher sketch modeling. Minimum wall thickness is 914 microns. An extruder tip wiping assembly also sits alongside the extruders and is designed to remove filament build up on the tips/tip shields and deposit debris in a removable purge bucket.

Layer thickness is locked in at 254 microns for a happy middle ground between precision prints and rougher sketch modeling. Minimum wall thickness is 914 microns. An extruder tip wiping assembly also sits alongside the extruders and is designed to remove filament build up on the tips/tip shields and deposit debris in a removable purge bucket.

The uPrint SE is solely geared towards ABS thermoplastic and specifically Stratasys’ proprietary ABSplus material. ABSplus is available in ivory, white, blue, fluorescent yellow, black, red, nectarine, olive green, and gray.

ABSplus is marketed as being admirably stronger than classic ABS with a higher tensile strength, more heat resistance, and better impact toughness. The material ships in bespoke plastic cartridges that sit in the material bay below the uPrint SE. The same applies to the support material that is exclusively available from Stratasys. Third-party ABS is not supported.

A standalone WaveWash Support Cleaning System is available alongside the uPrint SE. As the name suggests, it is used to remove support structures from finished models by bathing them in a solution made up of part water, part EcoWorks Cleaning Agent.

As the name suggests, it is used to remove support structures from finished models by bathing them in a solution made up of part water, part EcoWorks Cleaning Agent.

The front top left of the printer features a backlit multi-line LCD, four single line displays, and a keypad to navigate a variety of menus that manage material loading/unloading, material levels, print triggering, printing status, setup, and maintenance options.

In what is a pretty standard move for a Stratasys product, connectivity is limited to Ethernet, which should suit most professional setups with multiple PCs being able to access the printer through a local network.

The uPrint SE uses CatalystEX software to convert CAD files in STL former into a sliced model readable by the printer. The software is fairly basic but is both reliable and easy to use with an almost point and click simplicity bolstered by scale, resize, orientation, position, infill, support, and rotation options. CatalystEX is compatible with Windows only.

Packaging & Assembly

The uPrint SE is a fully assembled device, and installation is limited to fitting a modeling base via a set of clips onto the platform and loading the ABSplus/support material into the cartridge bays. The bays do most of the heavy lifting by grabbing onto the filament end and feeding it to the extruder and as such no time is wasted toiling away forcing the filament through the tubing as is too often the case with 3D printers.

The printer comes well packaged in a range of protective materials. The package includes the uPrint SE alongside an ethernet cable, crossover cable, a tip replacement kit (support tip, model tip, eight tip shields, and four tip wipe assemblies), WaveWash Support Cleaning System, ABSplus spool, CatalystEX installation CD, 1/8 inch T-Handle wrench, 7/64 inch T-Handle wrench, system software installation CD, user guide CD, support material spool, needle nose pliers, 10 magnifier loupes, cutters, wire brush, gloves, and power cord.

Printing

The uPrint SE is capable of rendering all manner of elaborate, geometrically challenging models time and time again. We tested over 30 prints to see how far this model could go and we only faced one single clogging issue, which the system picked up automatically and provided instructions on how to proceed. We didn’t even have to start the printing process from scratch as the uPrint SE simply paused the print and picked up where it left off.

The results were smooth, intricate prints with next to no blemishes or issues. The support system works incredibly well allowing for some seriously complex overhangs, and the cleaning bin system did a great job of producing near-perfect post-production prints.

The focus purely on ABS is limiting, but given how well the uPrint SE handles the material, we can forgive this specialization. The chamber environment is ideally suited for ABS, and we encountered no warping issues nor problems with sustaining adequate temperatures.

Support

The uPrint SE has a one year warranty alongside Stratasys’ renowned customer service. Stratasys also offers a free comprehensive recycling scheme for both spent cartridges and excess ABS filament.

Verdict

With the uPrint SE, Stratasys have succeeded in morphing their large scale industrial grade printers into a much more manageable size. It’s compact, reliable, and just as performance oriented as other models from the company.

The precision of the prints means it is ideally suited to proof of concept models, functional testing, prototyping, product mockups, and marketing tool production along with more classic design functions.

The price tag does mean it is only reserved for commercial use, but within that very space remains accessible. The ongoing cost of sourcing ABSplus and modeling bases direct from Stratasys needs to be taken into account.

3D printer Stratasys Uprint Se Plus

Professional 3D printer

for printing ABS-plastic

Main characteristics

FDM

Print technology

203 x 202 9000

Working volume in mm mm mm mm

ABSPLUS- 430

Model Material

25cc

Capacity per Hour

Sealed Heated Chamber

Ensures high print quality and repeatability.

100% material coverage

You choose the pattern coverage, quality and strength.

9 material colors

Model material available in 9 different colors to choose from.

Soluble Support

Allows you to print designs with complex geometries.

Patented platform

Heated platform ensures accurate and fast printing.

Powerful software

Simple and reliable software makes preparation and printing easy.

Need more information?

Leave a phone number - and we will contact you at a convenient time

Engineering Material

uPrint SE Plus works with durable industrial grade ABSPlus-p430 thermoplastic. It has the status of production grade and has stable characteristics. This material has proven itself in various industries, it is 40% stronger than conventional ABS and is highly amenable to post-processing.

Even the most complex objects can be printed from ABSPlus

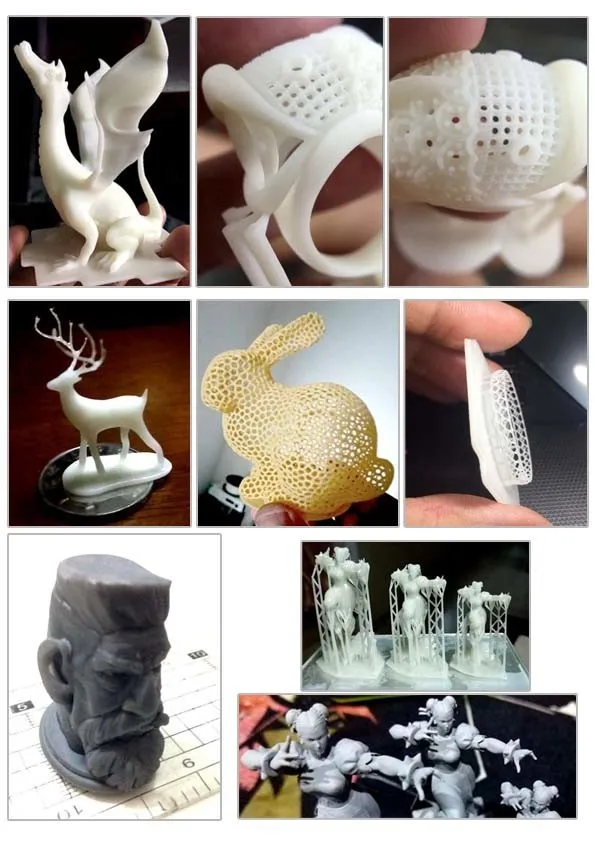

CAD models and products printed from them

Exact reproduction of the CAD model

You get an object that repeats 99% of the computer model you have developed. Printing accuracy minimizes the number of printing iterations required. This sets uPrint SE Plus apart from custom printers that do not guarantee exact repetition of CAD data.

Printing accuracy minimizes the number of printing iterations required. This sets uPrint SE Plus apart from custom printers that do not guarantee exact repetition of CAD data.

Industrial assembly

uPrint SE Plus is factory assembled from durable industrial components. Every part of the 3D printer is tested, which ensures a long service life of the equipment even under high workload.

uPrint SE Plus is assembled from the best components at the Stratasys factory

| Warranty and service Another important advantage of uPrint SE Plus is a full manufacturer's warranty and quality service from Globatek.3D. - Delivery to any city in Russia |

Where uPrint SE Plus is used

Manufacturing

Manufacturing tooling, prototypes, finished products.

Education

Assistance in the implementation of student projects, research.

Services

Custom printing of various plastic items.

Case Studies

GoEngineer makes custom plastic parts with uPrint SE Plus. For example, parts for engines with the required characteristics.

Leading universities in Russia With its help, students of technical specialties get the opportunity to quickly produce plastic components for their projects. According to university teachers, 3D printing allows future designers and developers to gain deeper knowledge. Now they can get working prototypes of their projects quickly and cheaply. The portfolio of operating devices has a positive effect on the employment of graduates.

What owners say about uPrint

The print consistency of uPrint SE Plus is amazing. We can be sure that if we send 10 parts for printing, all 10 will be the same.

We can be sure that if we send 10 parts for printing, all 10 will be the same.

Konstantin Podberezkin

Head of the Development Department of Pribor-NKR LLC

Our students load the printer to the fullest! There is a queue of projects that need to be printed. The prices for consumables are not the most democratic, but we are used to it.

Alexey Filantyev

Vice-Rector of the Regional University

For us, the main value of this 3D printer is the predictable result. No "dancing with a tambourine" and complicated settings. Send it to print - get the exact result. The material is familiar to every engineer who works with plastics.

Anton Prokofiev

Design Engineer

Want to see what uPrint can do?

Come to the demo room

You can personally see how the uPrint SE Plus 3D printer works in the Globatek.3D showroom.

Request a test print

We will print your part on uPrint SE Plus so you can evaluate the material properties and build quality on a specific project.

Get information

For more information about uPrint SE Plus features, usage examples, material consumption, please contact Globatek.3D consultants.

Want to see uPrint SE Plus in action for yourself? Come to our demo hall in Moscow!

Call +7 495 646-15-33

| Enroll |

How much does uPrint SE Plus cost?

Package Contents:

- Stratsys uPrint SE Plus 3D Printer

- P430XL Cartridge (Main Material, 688cc)

- SR-30XL Cartridge (Support, 688cc)

- Build Platform (24pcs) )

- CatalystEX Software

Get Quote

Package Includes:

- Stratsys uPrint SE Plus 9 3D Printer0003 - P430XL Cartridge (Main Material, 688cc)

- SR-30XL Cartridge (Support, 688cc)

- Build Platform (24 pcs)

- CatalystEX Software

Request a Quote

In Stock !

The 3D printer is in stock in Moscow and is ready for shipment the next day.

We will deliver and install

We will deliver to any city in Russia by a reliable transport company. Globatek.3D engineer will install and set up a 3D printer.

Warranty

uPrint SE Plus 1 year warranty. Repair, diagnostics, replacement of parts during this period - free of charge.

Consumables

Only with uPrint SE Plus you can buy a set of consumables at a special price

- P430XL Cartridge (Ivory, 688 cc)

- P430XL Cartridge (Black, 688 cc)

- SR Cartridge -30XL (Support, 688cc)

- uPrint SE Plus Replacement Pads (24 pcs)

- Eco-works Support Thinner (24 pcs)

Quote

Enter your contact details and we will prepare a detailed quote for you

Need a detailed consultation?

Call +7 495 646-15-33 and Globatek.3D specialists will answer all your questions.

| Back to 3D printer catalog0254 © CJSC Group Companies Globate 2010–2017 +7 495 646-15-33 9000 9000 3D 3D printer UPRINT SE PLUS manufacturer Stratasys Ltd - reviews of the owners of the 3D printer, description, characteristics, photos, printed models on the 3D printer uPrint SE PlusBrief characteristics: Printing technology: Fused deposition modeling (FDM / FFF) Construction area, mm: 203x203x152 Material for printing: ABS plastic, All Specs uPrint SE Plus 3D Printer Description The uPrint SE Plus 3D printer uses Fused Deposition Modeling (FDM) technology to create models in true ABSplus thermoplastic for strength, stability and jewelry accuracy of models and functional prototypes. About the uPrint SE Plus printerAdditional consumable drawers increase continuous printing time, allowing you to achieve peak productivity even when you're out of the office. The uPrint SE Plus 3D Printing Kit is everything you need to start 3D modeling uPrint SE Plus 3D Printer Initial batch of materials and bases CatalystEX Software WaveWash 9 Auxiliary Material Cleaning System0004uPrint SE Plus Owner ArticlesMore Featured 3D PrintersAnet A8 1458 articles 1717 owners Anet A8 3D printer is a budget 3D printer from China. |

With nine available colors, realistic prototypes and marketing models can be created. Use them to evaluate form, fit and function at all stages, from ergonomic design to manufacturing, right from your desktop. Two layer thicknesses allow you to print your 3D model up to 30% faster or at higher resolution. Can be equipped with one or two compartments for consumables.

With nine available colors, realistic prototypes and marketing models can be created. Use them to evaluate form, fit and function at all stages, from ergonomic design to manufacturing, right from your desktop. Two layer thicknesses allow you to print your 3D model up to 30% faster or at higher resolution. Can be equipped with one or two compartments for consumables.