Heated build chamber 3d printer

Open, and enclosed passive/active chamber 3D printers

All plastics, when extruded at high temperature, undergo a shrinkage during cooling which can be between 0.3 % and 4 %. This shrinkage can cause deformations, if the cooling is not smooth and homogeneous, giving rise to problems such as warping, delamination of layers or dimensional deformations of the part.

|

Material |

% of contraction during cooling |

|---|---|

|

PLA |

0.3 - 0.5 |

|

PETG |

0.2 - 1.0 |

|

Nylon 12 |

0.7 - 2.0 |

|

Nylon 6-6 |

0. |

|

ABS |

0.7 - 1.6 |

|

ASA |

0.4 - 0.7 |

|

PP |

1.0 - 3.0 |

|

HIPS |

0.2 - 0.8 |

|

PC/ABS |

0.5 - 0.7 |

|

Fibre-reinforced nylon |

0.5 - 1.0 |

|

PEEK |

1.2 - 1.5 |

|

Fibre-reinforced PEEK |

0.5 - 0.8 |

|

PVDF |

2.0 - 4.0 |

Table 1.

Percentage shrinkage of various plastics used in FFF 3D printing. Source: SpecialChem.com

Percentage shrinkage of various plastics used in FFF 3D printing. Source: SpecialChem.comTo avoid this problem, the temperature around the part should ideally be slightly lower than the material's glass transition temperature (Tg) throughout the printing process, and should be slowly reduced to room temperature after printing.

|

Material |

Tg (ºC) |

Printing temperature (ºC) |

|---|---|---|

|

PLA |

40 - 60 |

190 - 215 |

|

PETG |

75 - 85 |

220 - 260 |

|

Nylon 12 |

55 - 65 |

260 - 290 |

|

Nylon 6-6 |

75 - 85 |

255 - 280 |

|

ABS |

90 -100 |

220 - 240 |

|

ASA |

90 - 100 |

240 - 260 |

|

HIPS |

80 - 90 |

210 - 240 |

|

PC/ABS |

100 - 150 |

270 - 285 |

|

PEEK |

140 -160 |

380 - 400 |

|

PEI |

190 - 210 |

350 - 400 |

Table 2: Tg and printing temperature of various filaments.

Source: Filament2print

Source: Filament2printThose materials that suffer low shrinkage rates (less than 0.5%) do not require heating the part environment, as the shrinkage effects are practically negligible, so they can be printed perfectly well on open 3D printers, even large parts. These materials are mainly PLA and most PETg filaments (but not other copolyesters such as PET or CPE), as well as their derivatives.

It is possible to print materials with higher shrinkage percentages on open printers, however this possibility is limited to small parts, so with this type of materials it is advisable to use closed printers or printers with an active heated chamber.

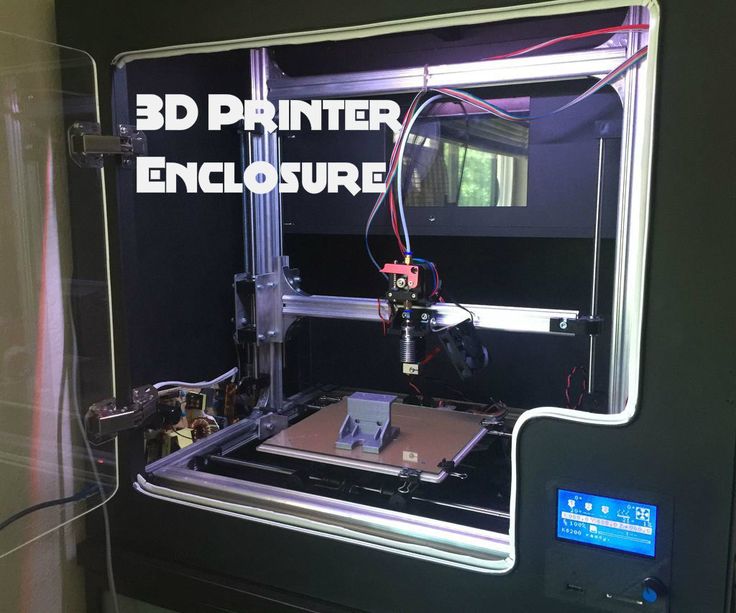

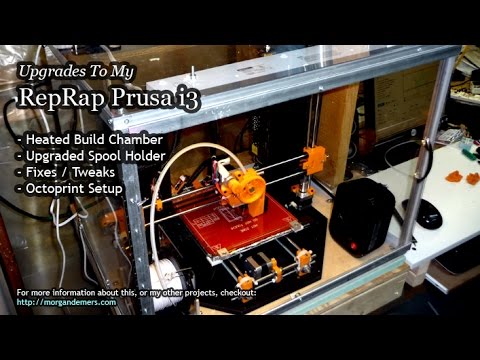

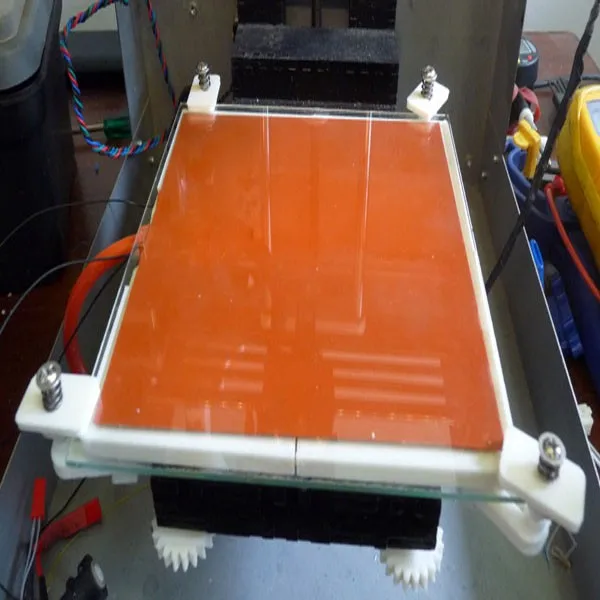

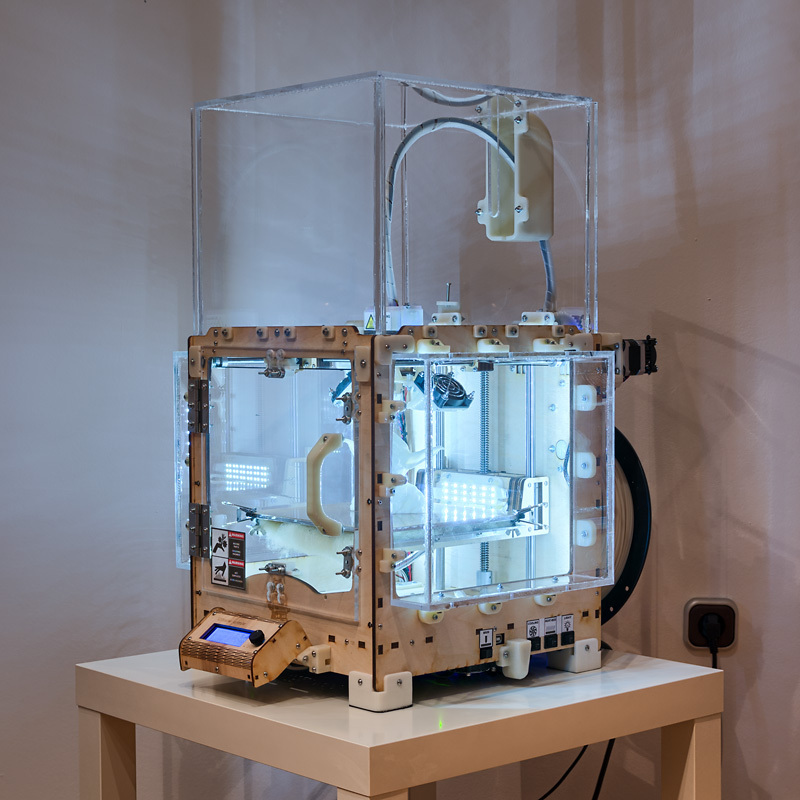

Image 1: An open 3D printer. Source: Prusa3D

Open printers are mainly recommended for printing PLA, PETg and flexible filaments.

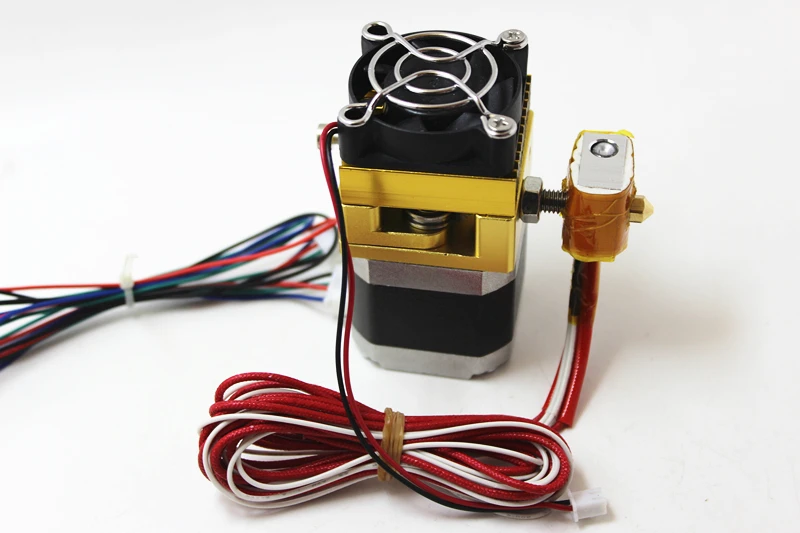

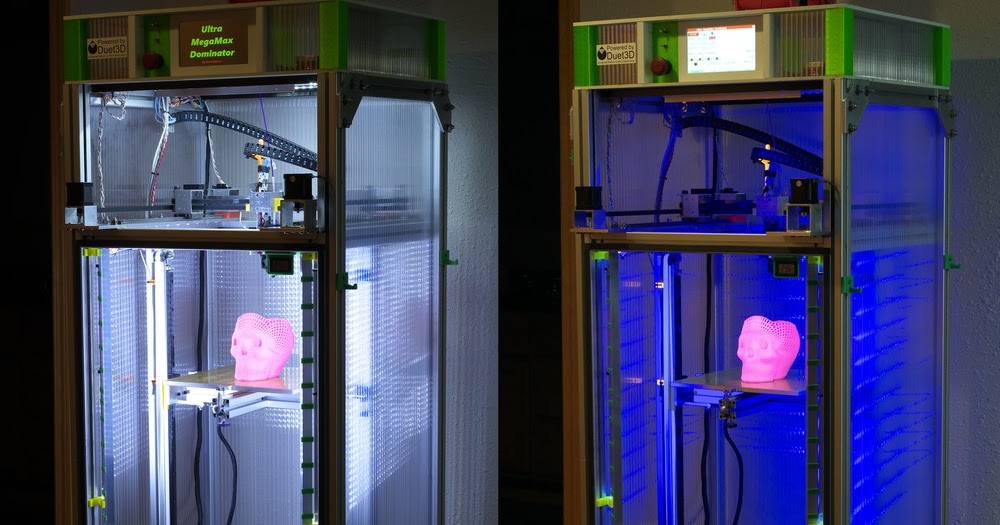

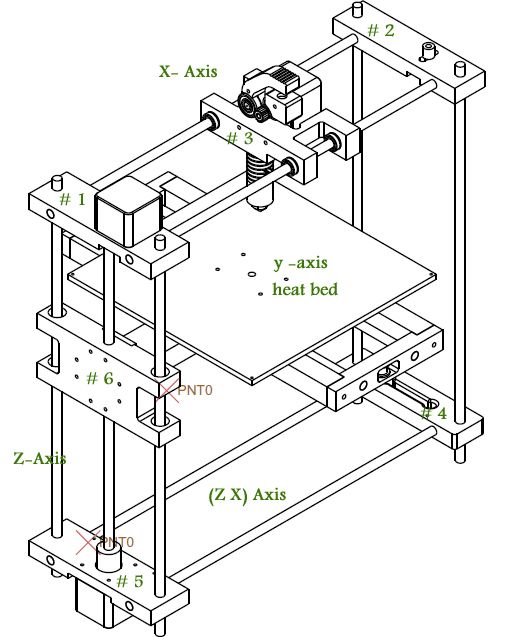

Closed printers or printers with a passive heated chamber

Closed printers are those whose printing area is completely enclosed. Some manufacturers use the term passive heated chamber, as they tend to accumulate the heat generated by the printing platform.

Some manufacturers use the term passive heated chamber, as they tend to accumulate the heat generated by the printing platform.

The internal temperature that these printers can reach varies greatly from one printer to another depending on the material they are made of, their volume, the temperature of the printing platform, the quality of the insulation and the temperature of the room where they are located. In general, the best quality printers are capable of providing temperatures between 45°C and 65°C at best.

Although these temperatures are not very high, they are close to the Tg of materials such as Nylon, ABS or ASA, making them easier to print and allowing the production of larger parts. Although these types of printers substantially improve the printing of these types of materials, they can fail with large volume parts. These printers are recommended for printing small to medium sized parts in PETg, ABS, ASA, Nylon or HIPS.

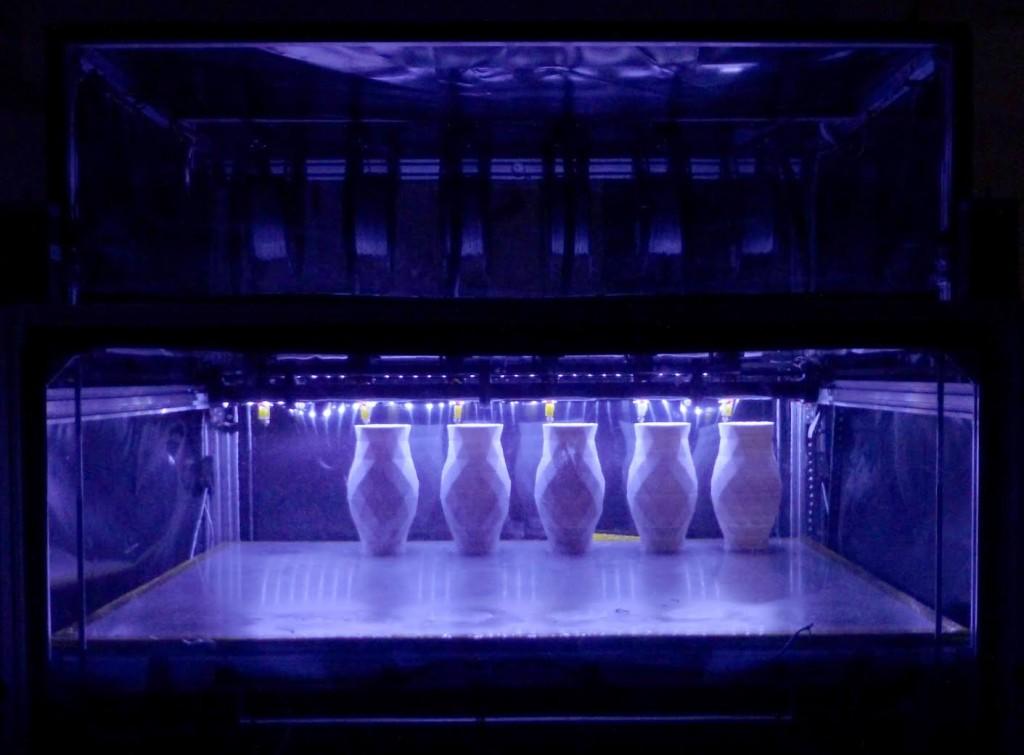

Image 2: A 3D printer with a passive heated chamber. Source: Raise3D

In general, it is not advisable to use PLA in this type of printers when they are completely closed, as the heat generated can exceed the Tg of the filament, causing it to soften inside the hotend and cause a jam.

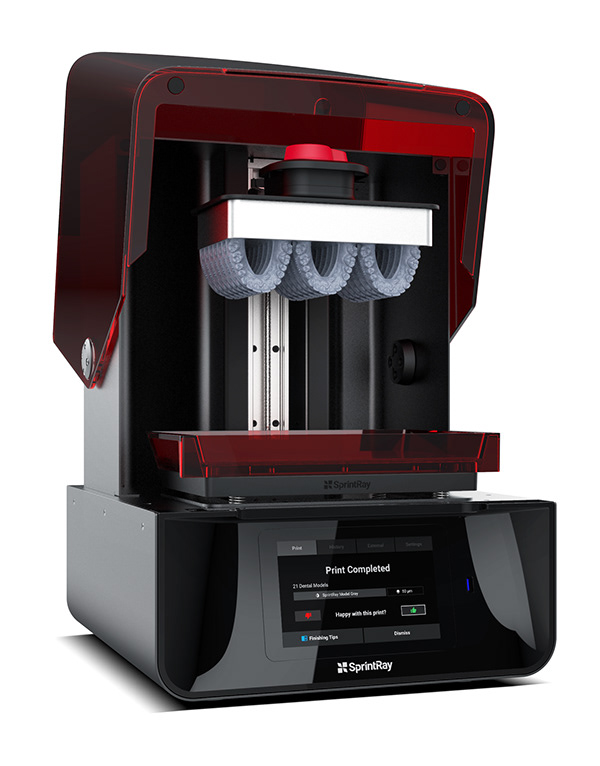

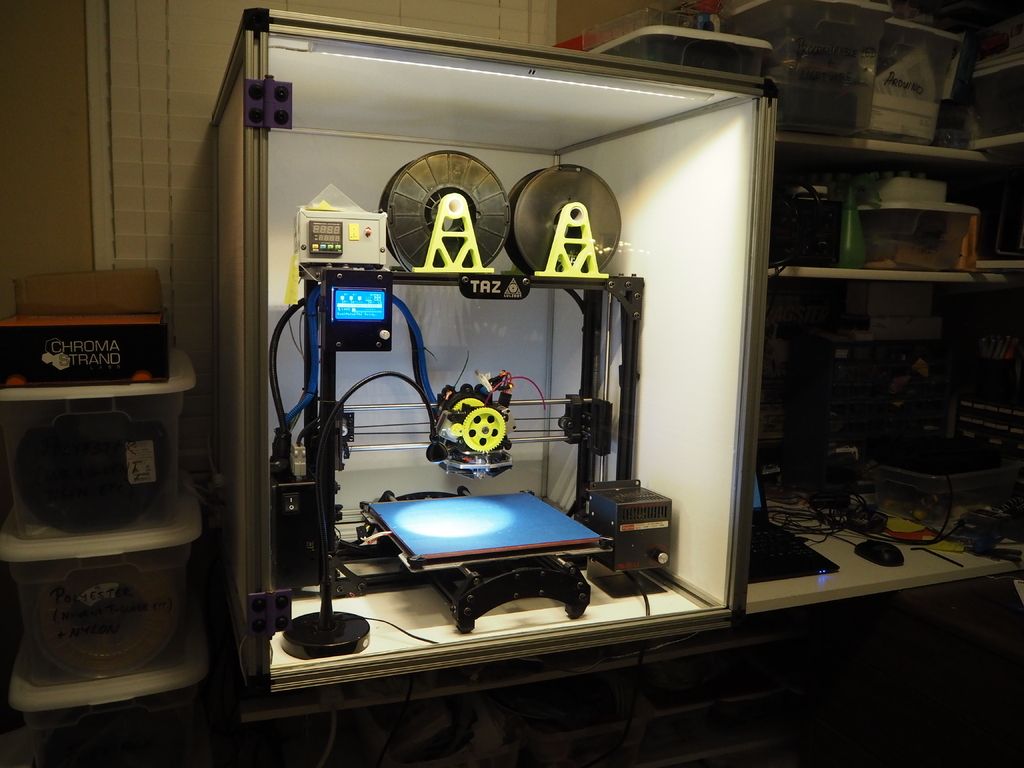

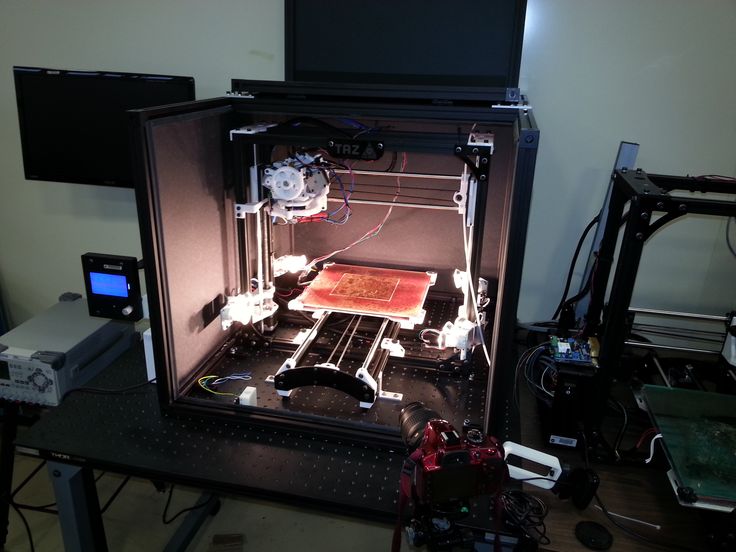

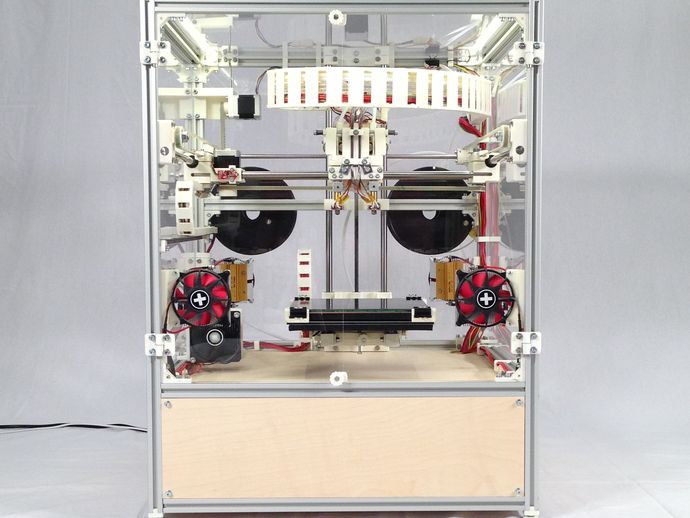

Closed printers with an active heated chamber

These are 3D printers capable of controlling the temperature inside the chamber. They are usually more complex and cost more than the previous ones. They also incorporate high temperature hotends (400 ºC - 500 ºC) and liquid cooling systems.

There are two types: high temperature and low temperature.

Low-temperature heated chamber

Low-temperature active heated chamber printers typically allow controlled maximum temperatures of between 80 ºC and 120 ºC. These printers are designed for the production of high quality, large ASA, ABS, Nylon or PC parts.

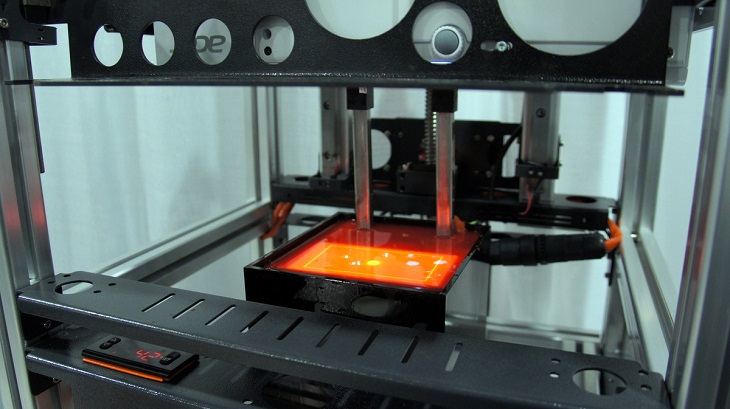

Image 3: A 3D printer with a low-temperature heated chamber. Source: 3ntr

Although these types of 3D printers are sometimes advertised as compatible with PEEK, they are not usually compatible with all types of PEEK, only with some low-temperature PEKK, and always limited to small parts.

These types of 3D printers are ideal for producing ABS, ASA, Nylon and PC parts that require good dimensional stability and low deformations, making them the best option when producing technical parts or functional components with these materials.

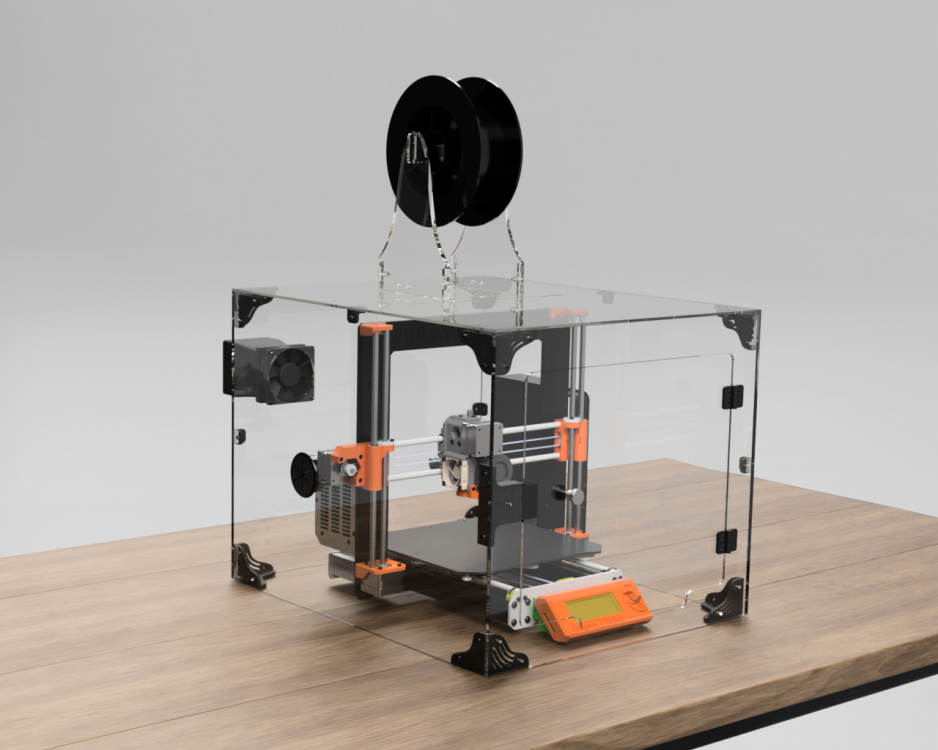

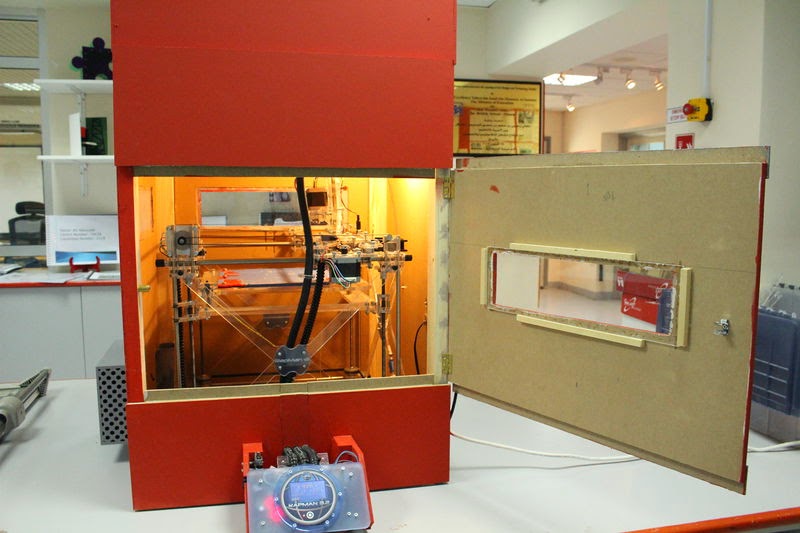

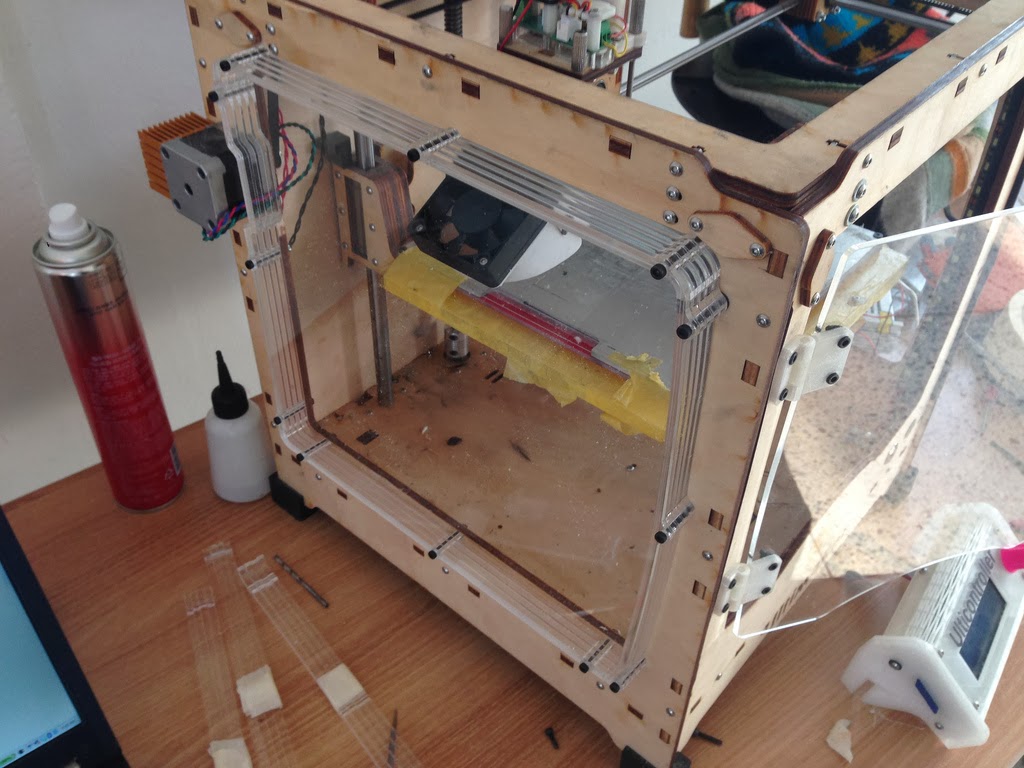

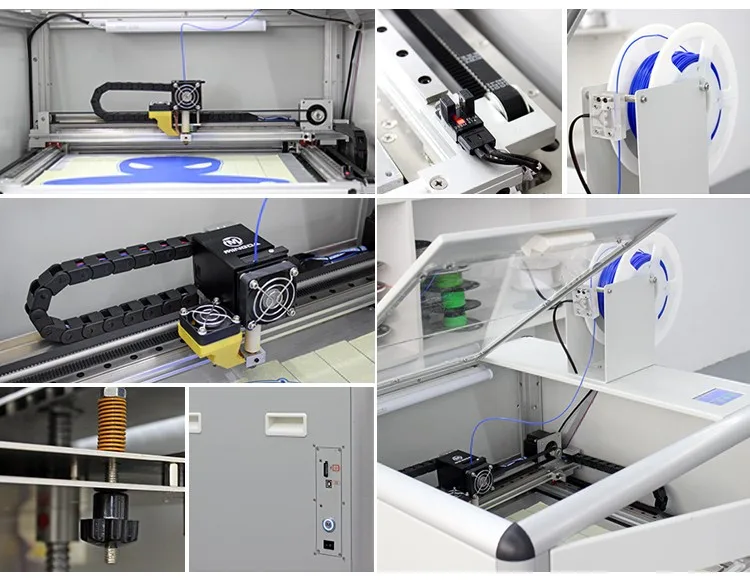

High temperature heated chamber

In general, they allow temperatures in the range of 160 ºC - 180 ºC to be controlled. These printers are specifically designed for the production of parts in PEEK, PEKK and PEI, so it is not common to use other types of materials. This equipment is expensive and requires specialized and trained personnel for its use.

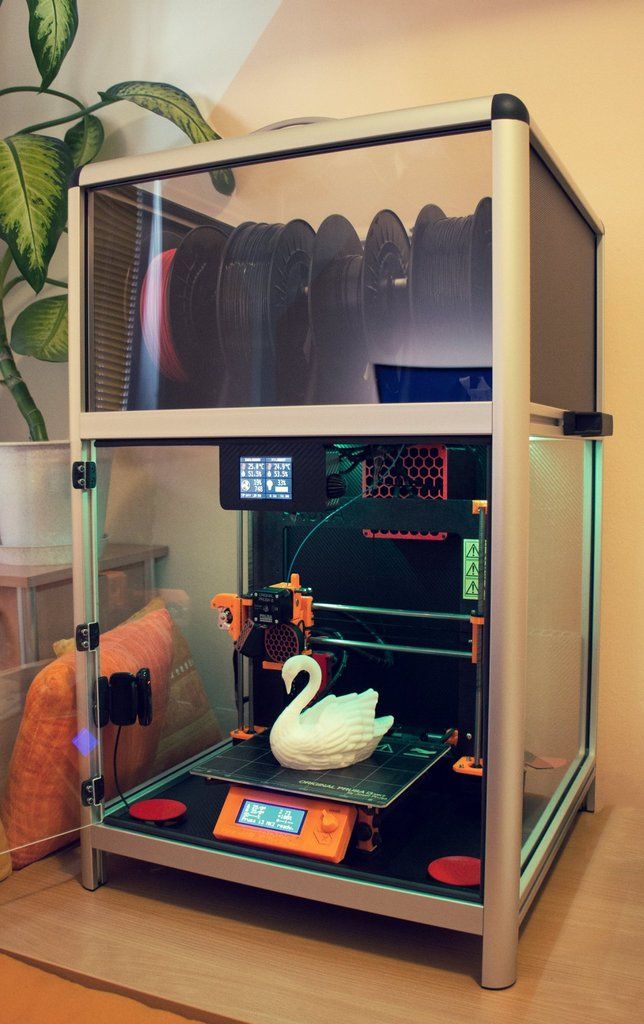

Image 4: A 3D printer with a high temperature heated chamber.

Source Dynamical3D

Source Dynamical3DWhen selecting a type of printer, it is very important to determine beforehand what type of parts and materials will be used.

This guide discusses the concepts in a general way and does not focus on a specific make or model, although they may be mentioned at some point. There may be important differences in calibration or adjustment procedures between different makes and models, so it is recommended that the manufacturer's manual be consulted before reading this guide.

Subscribe to our monthly newsletter and you will receive every month in your email the latest news and tips on 3D printing.

* By registering you accept our privacy policy.

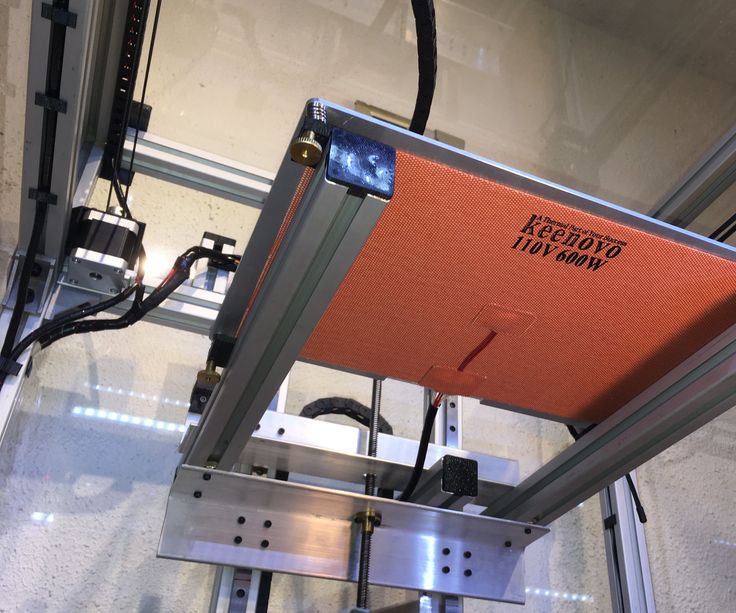

Best Heaters for 3D Printer Enclosure Heating

3D Insider is ad supported and earns money from clicks, commissions from sales, and other ways.

When 3D printing with challenging filaments like ABS and Nylon, you want to make sure that there is as little heat loss as possible. The usual solution to this is to use a 3D printer enclosure to envelop the heat and reduce the rate of heat loss to the environment. However, this may not be enough. If you live in a cold region, the heat loss even with an enclosure may still not be acceptable.

The usual solution to this is to use a 3D printer enclosure to envelop the heat and reduce the rate of heat loss to the environment. However, this may not be enough. If you live in a cold region, the heat loss even with an enclosure may still not be acceptable.

An enclosure heater is a way to provide active heating inside the enclosure. This is quite unconventional, so what’s the best equipment for this method?

Why use a 3D printer enclosure heater?

To preface this entire discussion, it’s worth mentioning that using active heating inside an enclosure is not something that is commonly done. This means that you’re not likely to find equipment that is specifically designed for this purpose. Instead, there will be a healthy amount of DIY involved.

Why go all the bother of building an enclosure with active heating? As with any heating solution, the ultimate goal is to prevent warping or improve layer adhesion. This is important when dealing with notoriously difficult filaments like ABS, Polycarbonate, or Nylon.

Normally, using an enclosure with a heated bed is enough to address any heating-related issues. More problems can come up if you’re trying a print a particularly tall model. If the heated bed is the primary source of heat, it tends to dissipate rapidly the farther away from the bed the layers are. This often leads to layer delamination and warping in the upper parts of a model.

The goal of an enclosure heater is to make sure that the temperature is constant at every point inside the enclosure. This eliminates the issue of heat localization and avoids problems in 3D printing large or tall objects.

The best heaters to use for enclosure heating

There isn’t really a single product that is specially designed as a heated for a 3D printer enclosure. Instead, we will have to make do with makeshift solutions.

The first order of business is a thermocouple for temperature monitoring. In case you go for an electronic heat source, it would be best to get an integrated temperature controller and thermocouple such as this module from Docooler. Not only does it provide a temperature readout but it can also regulate the output of a digitally controlled heat source.

Not only does it provide a temperature readout but it can also regulate the output of a digitally controlled heat source.

As for the actual heat source, here are some options to consider:

Light bulb

The cheapest and simplest option is a standard halogen light bulb. Make sure to get a light bulb that is compatible with a dimmer to allow for temperature control.

Take note that a light bulb isn’t exactly designed to generate heat. It would have to be positioned close to the print to make any difference. If your build chamber is small, then a light bulb would be perfectly viable.

The great thing about light bulbs being so inexpensive is that you can use several of them at the same time. Having problems with a “cold spot” in your print chamber? Then point another light bulb on that particular spot.

IR heating lamp

A step up from a halogen light bulb, an IR heating lamp was actually meant to give off copious amounts of heat. Typically used for spas, chicken coops, and reptile pet tanks, IR heating can keep a large space warm even in winter. They also aren’t expensive – this pair of heat flood light bulbs from the KOR brand cost less than $20.

They also aren’t expensive – this pair of heat flood light bulbs from the KOR brand cost less than $20.

The advantage of an IR heating lamp is that a single lamp is usually enough to provide heat even to a large build chamber. Just take note that the heat can get very intense near the lamp itself, so keep it away from any parts that can easily burn or melt. Using two IR lamps is also a possible option when printing in winter or if you have a very large printing chamber.

Hairdryer

This is an option for those who aren’t keen on buying an additional accessory for 3D printing. Since most households already have a hairdryer, then you might as well give this approach a shot.

To use a hairdryer for enclosure heating, simply cut a hole in your enclosure and stick the outlet of the hairdryer inside. Depending on your hairdryer, there should be some way to regulate its output, even if it’s just a low or high setting. This lack of adjustment is the major limitation of using a hairdryer, aside from the fact that they aren’t exactly built to run for several hours on end.

PTC fan air heater

A PTC (positive temperature coefficient) fan heater is a fan that is specifically designed to blow hot air into a small space. This is perfect for a 3D printer enclosure as the forced convection naturally encourages even heating at all points in the chamber. It also generates heat faster than a bulb or heating lamp.

This 12V PTC fan air heater from Mumusuki is a convenient option as it is already pre-wired for connection to a temperature controller like the one we have linked to above. This combination should help you maintain a constant temperature inside the chamber without having to readjust the position and intensity of the heat source periodically.

Portable space heater

If you use a portable space heater for your car, then the same device can also be used to maintain heat inside a 3D printer enclosure. This compact heater from Honeywell would be a very good option.

Compared to a PTC fan, a commercial space heater isn’t pre-wired for connection to a temperature controller. Instead, you’ll have to take it apart and look for the wires that regulate its heat output. The benefit of the Honeywell space heater is that it comes in a ceramic case that protects its internal components from getting damaged because of the heat.

Instead, you’ll have to take it apart and look for the wires that regulate its heat output. The benefit of the Honeywell space heater is that it comes in a ceramic case that protects its internal components from getting damaged because of the heat.

A few tips on maintaining enclosure temperature

Not all filaments need a heated chamber

If you’re printing with PLA or ABS, then you really don’t need to bother with a heated enclosure. In fact, you can get by without an enclosure at all!

Just as important as using a heated enclosure is hitting the proper temperature for the filament you’re working with. The smallest bit of added heat helps, even if you can’t hit the target temperature. Going over the recommended temperature for your filament would be a bigger problem, as your prints might start drooping ever so slowly.

Consider insulating your enclosure

Most 3D printer enclosures, particularly DIY ones, are made of clear material on all sides. While this is great for keeping an eye on your print, you don’t really need a 360-degree view of your project as it is printing.

While this is great for keeping an eye on your print, you don’t really need a 360-degree view of your project as it is printing.

Instead, consider adding a layer of insulation on a few sides of the enclosure. This will further minimize heat loss and reduce the power needed to maintain the temperature of your print chamber Make sure to use insulation material that’s fireproof, such as ceramic fiber.

Don’t blow cold air into a warm enclosure

When a 3D printer is enclosed, there needs to be a way for the air to vent out to remove any toxic fumes or microplastic particles. This means that you need to draw in air from the environment to maintain the pressure of the chamber. The problem is that you could be drawing in cold air, which is as good as not having an enclosure at all.

A good option is to build a mechanism that filters the hot vented air and recirculates it back into the print chamber. This means that you’ll also be blowing hot air back into the chamber, making it a lot easier to maintain the internal temperature.

Keep your printer’s electronics outside the heated enclosure

If you’re designing your own 3D printer enclosure, do it in a way that keeps your printer’s electronics outside the heated area. This includes your printer’s control boards and, more importantly, its power supply. Take note that the power supply already generates its own heat – it probably does not help to make it any hotter.

As a general rule, your printer’s control boards and power supply should not be exposed to temperatures exceeding 50 °C. Doing so makes them a lot more prone to breaking down prematurely.

Final thoughts

Providing active heating to an enclosed chamber is already quite extreme as far as 3D printing techniques go. It’s a measure that we would only recommend if you’ve already tried all the usual solutions to warping and delamination. It’s still a valid approach, though, especially if you’re working on an exceptionally large model.

The biggest issue with heated enclosures is that it requires quite a bit of DIY work. You’ll have to rely on makeshift solutions using heating lamps or space heaters. Even if you can’t get the heating to work perfectly, this is what you need to keep in mind – every little bit of added heat helps.

You’ll have to rely on makeshift solutions using heating lamps or space heaters. Even if you can’t get the heating to work perfectly, this is what you need to keep in mind – every little bit of added heat helps.

Warning; 3D printers should never be left unattended. They can pose a firesafety hazard.

Overview of high-temperature 3D printers with Formnext 2017 Today, we note the significantly increased number of 3D printers since last year for working with high-temperature engineering plastics, starting with polycarbonate and further to polyamides, Ultem, PEEK, PPSU and composites based on them.

These materials are used in the aerospace industry, the chemical industry, and medicine, where properties such as low weight, high temperature resistance, mechanical strength, chemical inertness, and biocompatibility are in demand. We wrote more about engineering filaments and their application here.

Differences between industrial 3D printers

To work with engineering plastics, the printer must have a high-temperature extruder. There are two classes of equipment here. Junior - up to 300 ° C, this is enough for modifications of ABS, polycarbonate and polyamides. Senior - above 300 ° C. For PEEK or Ultem you need about 400.

There are two classes of equipment here. Junior - up to 300 ° C, this is enough for modifications of ABS, polycarbonate and polyamides. Senior - above 300 ° C. For PEEK or Ultem you need about 400.

Extruder is not everything. A heated platform or vacuum table is a must to keep the part in place. And printing should take place in a working chamber isolated from the outside world, maintaining a predetermined temperature. Failure to comply with the mode leads to deformation or violation of the integrity of the printed object.

So, let's look at the patterns we've seen.

Intamsys

The Chinese manufacturer offers four models of 3D printers. The basic Funmat and Funmat Pro work with common plastics, from PLA to nylon, and composites. Funmat HT and Funmat Pro HT are already capable of printing in PEEK, Ultem and PPSU.

Intamsys FUNMAT, FUNMAT HT

- Working chamber: 260 x 260 x 260 mm;

- layer thickness: from 50 microns;

- nozzle diameter: 0.

4mm;

4mm; - FUNMAT: extruder up to 280°C, bed up to 150°C;

- FUNMAT HT: extruder up to 450°C, bed up to 160°C.

Compact printers with a closed working chamber, in the HT version it is equipped with heating, maximum temperature 90 °C.

Intamsys FUNMAT PRO, FUNMAT PRO HT

- Working chamber: 450 x 450 x 600 mm;

- layer thickness: from 50 microns;

- nozzle diameter: 0.4mm;

- FUNMAT PRO: extruder up to 280°C, bed up to 150°C, chamber up to 60°C;

- FUNMAT PRO HT: extruder up to 450°C, bed up to 160°C, chamber up to 120°C.

Industrial printers for printing large parts with high-temperature plastics, equipped with a heated working chamber.

ROBOZE

One of the leading companies producing high-temperature 3D printers, we wrote more about it here. Offers three printers for engineering filaments. Roboze One is the basic model for common plastics - from PLA to polyamide inclusive. Roboze One +400 - with a high-temperature extruder, Roboze Argo 500 - a large installation, with a working chamber of 500 x 500 x 500 mm. Roboze printers are interesting in the rejection of drive belts and the use of a rack-and-pinion transmission to move the print head.

Roboze One is the basic model for common plastics - from PLA to polyamide inclusive. Roboze One +400 - with a high-temperature extruder, Roboze Argo 500 - a large installation, with a working chamber of 500 x 500 x 500 mm. Roboze printers are interesting in the rejection of drive belts and the use of a rack-and-pinion transmission to move the print head.

Roboze One +400

- Working chamber: 200 x 200 x 200 mm;

- extruder temperature: up to 400 °C;

- layer thickness: from 50 µm.

The printer is designed with an emphasis on reliability, all parts of the extruder are made of metal.

Roboze Argo 500

- Working chamber: 500 x 500 x 500 mm;

- layer thickness: from 50 microns;

- extruder temperature: up to 550 °C;

- chamber temperature: up to 180 °C.

The older Roboze model has a vacuum table to hold the part. Compartments for filament are equipped with heating. When one coil runs out, the machine automatically switches to the next one.

Compartments for filament are equipped with heating. When one coil runs out, the machine automatically switches to the next one.

VSHAPER

A Polish manufacturer whose product range includes high-temperature printers for medical applications and five-axis 3D printing machines.

VSHAPER 270 Med

- Working chamber: 270 x 270 x 200 mm;

- extruder temperature: up to 450 °C;

- layer thickness: from 50 µm.

A medical-grade printer with an antibacterial coating on the build chamber and a built-in UV sterilizer that sterilizes every layer as it prints. The main purpose is the printing of implants and additional equipment for surgical operations.

VSHAPER 5-Axis Machine

- Working area: cylinder 300 mm in diameter and 300 mm high;

- automatic change of hotends;

- heated working chamber;

- the ability to print one model with several materials.

The five-axis design allows complex shapes to be printed without supports. The ability to print one model with several materials with different properties allows you to create parts that are complex in composition, for example, with an inner core made of a stronger material, or with a coating or inserts made of flexible. For the convenience of printing with different materials, the platform is also optimized - it is divided into cells that can be set to different heating temperatures.

The printer is already available for pre-order, and shipments will begin, according to the manufacturer, from January 2019.

3DGENCE INDUSTRY F340

- Working chamber: 260 x 340 x 340 mm;

- layer thickness: from 150 microns;

- chamber temperature: up to 85 ˚C;

- extruder temperature: up to 500 ˚C.

The printer can be equipped with one of three printing modules. Standard - up to 265 ˚C, medium - up to 350 ˚C, high temperature - up to 500 ˚C. Printed modules - with two hotends, for the main and auxiliary materials. Among other interesting features, we note the preheating of the plastic and the coil mass sensor.

Standard - up to 265 ˚C, medium - up to 350 ˚C, high temperature - up to 500 ˚C. Printed modules - with two hotends, for the main and auxiliary materials. Among other interesting features, we note the preheating of the plastic and the coil mass sensor.

Apium

Apium Additive Technologies GmbH is a German manufacturer of small printers for high temperature PEEK, Ultem and PPSU filaments and composites. Apium is translated from Latin as "celery". For products, support for printing with metal-filled filaments is declared for further baking.

Apium P155

- Working chamber: 155 x 155 x 155 mm;

- extruder temperature: up to 520 °C;

- table temperature: up to 160 °C;

- layer thickness: from 100 µm.

Desktop high temperature printer with a small printable area. It is the heir to the Indmatec HPP 155. Apium also offers a slightly larger model - P220, with a print area of 200 x 160 x 160 mm.

GEWO 3D

The German manufacturer offers one high-temperature printer, with a very serious margin for the heating temperature of the printing platform and the working chamber.

GEWO HTP 260

- Working chamber: 350 x 150 x 165 mm;

- layer thickness: from 20 microns;

- extruder temperature: up to 450 °C;

- table temperature: up to 270 °C;

- chamber temperature: up to 260 °C.

Prints with all common engineering plastics, equipped with two extruders. Possibility of installation of a spindle for machining of a detail is provided.

MiniFactory Innovator 2

- Working chamber: 300 x 160 x 160 mm;

- layer thickness: from 30 µm.

Finnish dual extruder printer, the manufacturer focuses on PEEK printing. Other engineering plastics such as ABS, polycarbonate or Ultem are also supported.

Omni3D Factory 2.0

- Working chamber: 500 x 500 x 500 mm;

- layer thickness: from 140 microns;

- extruder temperature: up to 360 °C;

- table temperature: up to 130 °C;

- chamber temperature: up to 70 °C.

An industrial printer from Poland is equipped with two extruders and can print large parts from ABS, polycarbonate, polyamide and composites based on them.

DynamicalTools DT600

- Working chamber: 600 x 450 x 450 mm;

- layer thickness: from 140 microns;

- extruder temperature: up to 500 °C;

- table temperature: up to 150 °C.

The Spanish printer with two independent printheads, in addition to normal printing, supports printing modes for two identical or mirror parts at the same time. Works with all high temperature filaments up to PEEK, Ultem, PPSU. Equipped with systems for heating plastic and automatic change of coils.

Equipped with systems for heating plastic and automatic change of coils.

HAGE3D 140L

- Working chamber: 700 x 500 x 400 mm;

- layer thickness: from 50 microns;

- extruder temperature: up to 450 °C;

- chamber temperature: up to 85 °C.

Austrian industrial machine that supports most engineering filaments and composites. Heated working chamber, three-zone heating table.

AIM3D

The company offers a complex of equipment for the manufacture of metal objects. At the first stage, the part is printed on a 3D printer, at the second stage it is placed in an oven, where the binder plastic burns out and the metal filler is sintered.

AIM3D ExAM 255

- Working chamber: 255 x 255 x 255 mm;

- layer thickness from: 20 µm;

- table temperature: up to 120 °C.

The printer does not work with filament, but with granules. This allows the use of raw materials for FDM printing, which are usually used in MIM installations, Metal Injection Molding. You can also print with plastic pellets, which is usually cheaper than using filament.

This allows the use of raw materials for FDM printing, which are usually used in MIM installations, Metal Injection Molding. You can also print with plastic pellets, which is usually cheaper than using filament.

AIM3D ExSO 90

- workpiece diameter, up to: 90 mm;

- 6-sided heated;

- isolation and collection of fumes generated during sintering;

- temperature: up to 1350 °C.

Furnace for high-temperature sintering of parts printed on AIM3D ExAM 255 in an inert gas atmosphere.

How to purchase an industrial 3D printer

Looking for an industrial 3D printer? Top 3D Shop is the official representative of most of the manufacturers mentioned in the review, we are ready to supply equipment, commissioning, training and maintenance.

We have made a comparison table for these machines, with technical nuances - print and camera temperatures, materials used, number of extruders and estimated cost.

Prices for 3D printers that print with high temperature plastics, as for industrial equipment, often depend on the manufacturer's very flexible pricing policy.

The price may vary from delivery to delivery, depending on many factors, and some manufacturers are categorically against the publication of final prices in the public domain, therefore we do not indicate prices in the article, but we provide a table on request.

For more information and assistance in choosing an industrial high-temperature 3D printer, please contact Top 3D Shop.

Want more exciting news from the world of 3D technology?

Follow us on social. networks:

F2 Pro industrial 3D printer

F2 printing technology

Ultra-fast heating of

extruders in 3 seconds, quick change system for cartridges with nozzles of different diameters

Chamber

Unique system for providing the required temperature environment with high uniformity of heating of the entire chamber

Own electronics and intuitive interface developed by the company

F2 innovations

•Industrial FDM/FFF 3D printer, own production

F2 innovations.

• Printer for printing large and non-standard products.

| Order now |

| Get detailed specifications |

F2 Pro breaks new ground in FDM/FFF 3D printing technology.

It's faster, more powerful, smarter, and most importantly, bigger.

F2 Pro is an industrial 3D printer ideal for printing large-sized and non-standard products (print area 1000*600*1000 mm).

Two high-temperature extruders (up to 550°C) allow you to print not only standard polymers (ABS, PLA, PP, etc.), engineering polymers (ASA, PC, ABS+CF, etc.), but also high-temperature polymers such as PEEK, PEKK, Ultem, PEEK+CF, etc.

F2 printing technology provides ultra-fast heating of the extruder to operating temperature in 3 seconds, the accuracy of maintaining the melt temperature up to 3 ° C, and the quick change system for cartridges with nozzles of different diameters makes the printing process simple and fast.

To store the filament, the printer has independent heated (up to 70°C) cells for two spools weighing up to 5 kg.

F2 Printing Technology

We developed FDM/FFF 3D printing technology to open up new possibilities for additive technologies in any industry, making 3D printing of any materials fast and high-quality for each manufacturer.

| Read more |

F2 Printing Technology

We developed FDM/FFF 3D printing technology to open up new possibilities for additive technologies in any industry, making 3D printing with any materials fast and high-quality for each manufacturer.

| More details |

Nozzle size

0.15 - 1 mm0003 (optionally up to 160 ° C)

Press area

1000*1000*1000 mm

Heated Platform

Heated up to 140 ° C with

vehicles (optionally up to 160 ° C)

USER UNTERFACE

own electronics and intuitive interface

extruders

two high temperature (up to 550°C)

nozzle diameter

0. 15 - 1 mm

15 - 1 mm

print chamber

Heating up to 80 ° C with convection of

(optionally up to 160 ° C)

Press area

1000*600*1000 mm

Platform

Heated up to 140 ° C with

( optional up to 160°C)

User Interface

own electronics and intuitive interface

Extruders

two high temperature (up to 550°C)

Order

User Interface

Proprietary electronics and intuitive interface

Minimal training is required to operate the printer, by looking at the interface you will immediately understand how to operate it.

User Interface

Proprietary electronics and intuitive interface

Minimal training is required to operate the printer, by looking at the interface you will immediately understand how to operate it.

Print chamber

80°C convection chamber

(optional up to 160°C)

Forced convection of the chamber and uniform heating allows printing large parts with high interlayer adhesion.

Parts will not delaminate or deform.

Print chamber

80°C heated chamber with convection

(optional up to 160°C)

Forced convection of the chamber and even heating allows printing large parts with high interlayer adhesion.

Parts will not delaminate or deform.

Extruders

Two high-temperature extruders allow you to print the full range of available materials

F2 printing technology provides an ultra-fast extruder heating to operating temperature in 3 seconds with high melt temperature accuracy.

Extruders

Two high-temperature extruders allow you to print the full range of available materials

F2 printing technology provides ultra-fast extruder heating to operating temperature in 3 seconds with high melt temperature accuracy.

Built-in filters

Built-in air filtration system traps all unwanted particles

When heated, some plastics can release harmful substances, such as vapors from styrene derivatives, hydrocyanic acid, acetaldehyde.

Built-in high temperature filters not only block harmful particles but also odors.

Built-in filters

Built-in air filtration system traps all unwanted particles

When heated, some plastics can release harmful substances, such as vapors from styrene derivatives, hydrocyanic acid, acetaldehyde.

Built-in high temperature filters not only block harmful particles but also odors.

Print Platform

Quick Change Print Platform

heated to 140°C (optional up to 160°C)

Quick Release Print Platform makes printing quick and easy.

This avoids damage to larger models and allows the printer to be used almost without interruption between print runs.

Print Platform

Quick Change Print Platform

heated to 140°C (optional up to 160°C)

Quick Release Print Platform makes printing quick and easy.

This avoids damage to larger models and allows the printer to be used almost without interruption between print runs.