Start up 3d printing companies

20 Emerging 3D Printing Startups (2022)

You may also like:

- 6 Product Development Trends

- 20 Thriving Robotics Startups

- 40 Growing AI Companies & Startups

Heading into 2022, the global market for 3D printing is projected to be worth $17.4 billion.

And is forecasted to grow more than 26% over the next 2 years.

On top of that, the 3D printing market is expected to grow at a CAGR of over 18% into 2025.

All things considered, it’s safe to say that the growth of this industry isn’t slowing down anytime soon, especially with new ventures launching every year. We’ve gathered the best 3D printing startups you should follow in 2022.

1. Relativity Space

5-year search growth: 1325%

Search growth status: Exploding

Year founded: 2015

Location: Long Beach, CA

Funding: $1. 3B (Secondary Market)

What they do: Relativity Space is an aerospace startup that designs and manufactures 3D printed autonomous rockets. The company claims that their rockets can be designed and launched in a matter of days, as opposed to years. In 2019, Relativity Space made it to Fast Company’s list of most innovative companies (space sector).

2. Mighty Buildings

5-year search growth: 1050%

Search growth status: Peaked

Year founded: 2017

Location: Oakland, CA

Funding: $101.8M (Series B)

What they do: Mighty Buildings is a modular construction technology company that builds 3D printed homes. They do this by leveraging 3D printed panels and prefab technology. The company has completed about a dozen projects so far.

3. nTopology

5-year search growth: 1328%

Search growth status: Exploding

Year founded: 2015

Location: New York, NY

Funding: $135. 2M (Series D)

2M (Series D)

What they do: A software company, nTopology creates tools for design, engineering, and simulation. Their software solutions are designed to support and make the fabrication/3D printing processes smoother. nTopology’s solutions have been used to create +2,200 parts so far.

4. Multiply Labs

5-year search growth: -70%

Search growth status: Peaked

Year founded: 2016

Location: San Francisco, CA

Funding: $22.7M (Series A)

What they do: Combining pharma with robotics, Multiply Labs creates 3D printed personalized capsules. Each capsule contains multiple products that are released at different times in the human body. It is estimated that the company currently earns $5M in annual revenue.

5. Additive Industries

5-year search growth: -80%

Search growth status: Peaked

Year founded: 2012

Location: Eindhoven, Netherlands

Funding: $24. 3M (Series Unknown)

3M (Series Unknown)

What they do: Additive Industries specializes in offering metal additive manufacturing solutions to industrial markets. Specifically, they offer 3D metal printers and supporting services to aerospace, automotive, energy, and high-tech companies. In 2019, Additive Industries was shortlisted for the 3D Printing Industry Awards in the “Enterprise 3D Printer (Metals)” category.

6. VELO3D

5-year search growth: 1266%

Search growth status: Exploding

Year founded: 2014

Location: Campbell, CA

Funding: $205.1M (Post-IPO Equity)

What they do: A digital manufacturing company, VELO3D offers 3D metal printers and custom-printed components. Their platform is designed to provide end-to-end AM solutions for manufacturing problems. VELO3D made it to the Fast Company’s list of the most innovative manufacturing companies in 2021.

7. Fast Radius

5-year search growth: 189%

Search growth status: Regular

Year founded: 2017

Location: Chicago, IL

Funding: $167.8M (Post-IPO Equity)

What they do: Fast Radius is a 3D printing startup that provides production and logistics assistance to manufacturing companies. They do this by offering on-demand manufacturing services, additive technology, and a cloud-based virtual warehouse. Fast Radius has served around 1.8K customers so far.

8. Mixed Dimensions

5-year search growth: 69%

Search growth status: Regular

Year founded: 2009

Location: San Mateo, CA

Funding: $7.5M (Seed)

What they do: Mixed Dimensions is a 3D printing startup that transforms digital products into physical objects. They sculpt 3D collectibles of virtual characters and objects from video games. According to their website, Mixed Dimensions has partnered with some of the leading gaming and technology companies, including CCP Games, Cryptic, and Daz 3D.

They sculpt 3D collectibles of virtual characters and objects from video games. According to their website, Mixed Dimensions has partnered with some of the leading gaming and technology companies, including CCP Games, Cryptic, and Daz 3D.

9. Formlabs

5-year search growth: -16%

Search growth status: Regular

Year founded: 2011

Location: Somerville, MA

Funding: $253.7M (Series E)

What they do: A hardware manufacturer, Formlabs builds and sells accessible 3D printers. They also offer material used for 3D printing, along with supporting software. Formlabs says that their users have printed over 40 million parts so far.

10. Fictiv

5-year search growth: 90%

Search growth status: Regular

Year founded: 2013

Location: San Francisco, CA

Funding: $192. 6M (Series E)

6M (Series E)

What they do: A fabrication service, Fictiv offers custom on-demand manufacturing. They provide an online platform where their customers can upload 2D/3D files, receive a quote, and track the progress of the manufacturing process. Fictiv claims that they currently have over 250 manufacturing partners worldwide.

11. Markforged

5-year search growth: 45%

Search growth status: Regular

Year founded: 2013

Location: Watertown, MA

Funding: $346.8M (Post-IPO Equity)

What they do: Markforged is a hardware company that offers industrial-grade additive manufacturing solutions. Specifically, they offer 3D printers, materials, and software. Markforged claims that their 3D printers are used by the world’s top 9 manufacturing companies.

12. Xometry

5-year search growth: 488%

Search growth status: Exploding

Year founded: 2013

Location: Gaithersburg, MD

Funding: $197. 2M (Series E)

2M (Series E)

What they do: Xometry is an online marketplace where customers can find suppliers for custom 3D components and prototypes. In addition to 3D printing, users can also find suppliers for CNC machining, injection molding, and more. Xometry says that they currently have 4,000+ manufacturing partners in their network.

13. Glowforge

5-year search growth: 516%

Search growth status: Peaked

Year founded: 2014

Location: Seattle, WA

Funding: $113.2M (Series E)

What they do: Glowforge manufactures consumer-grade 3D laser printers. Their printers use subtractive manufacturing to print objects with different materials. Last year, Glowforge earned $28 million in pre-order sales.

14. 9T Labs

5-year search growth: 5600%

Search growth status: Regular

Year founded: 2018

Location: Zurich, Switzerland

Funding: $22. 5M (Series A)

5M (Series A)

What they do: 9T Labs offers 3D printing solutions focused on carbon composites. Their solutions, which consist of both hardware and software, are designed to help their customers produce carbon composites in high volumes. According to their website, they are trusted by the leading manufacturing organizations, including ESA BIC Switzerland, Ansys, and ETH Zurich.

15. 3YOURMIND

5-year search growth: -27%

Search growth status: Peaked

Year founded: 2014

Location: Berlin, Germany

Funding: $32.9M (Series A)

What they do: A software company, 3YOURMIND offers a suite of additive manufacturing solutions. Their software suite is designed to automate the additive manufacturing workflows of companies. According to their website, 3YOURMIND is used by the leading companies in the AM industry.

16. NEXA3D

5-year search growth: 733%

Search growth status: Exploding

Year founded: 2014

Location: Ventura, CA

Funding: $95M (Series Unknown)

What they do: NEXA3D is a manufacturing company that builds polymer 3D printers and supportive software. The company has aimed to make its products accessible to businesses of all sizes. NEXA3D claims that their solutions can deliver a 20X productivity gain.

The company has aimed to make its products accessible to businesses of all sizes. NEXA3D claims that their solutions can deliver a 20X productivity gain.

17. Equispheres

5-year search growth: -100%

Search growth status: Peaked

Year founded: 2015

Location: Ottawa, Canada

Funding: $26.6M (Grant)

What they do: A materials science company, Equispheres offers additive manufacturing products. Specifically, they manufacture metal powders that the company claims have superior mechanical properties. In 2019, Equispheres received $8M in cleantech funding from BDC.

18. Arevo

5-year search growth: -100%

Search growth status: Peaked

Year founded: 2013

Location: Milpitas, CA

Funding: $69.5M (Series Unknown)

What they do: Arevo is a manufacturing company that develops 3D printed components for end-use. They do this by offering software solutions, carbon fiber material, and hardware designed for mass production. In 2019, Arevo won the startup prize at JEC World.

They do this by offering software solutions, carbon fiber material, and hardware designed for mass production. In 2019, Arevo won the startup prize at JEC World.

19. Dyndrite

5-year search growth: 0%

Search growth status: Peaked

Year founded: 2016

Location: Seattle, WA

Funding: $13M (Series A)

What they do: Dyndrite offers digital manufacturing software solutions. Their core platform, called “Dyndrite Accelerated Computation Engine,” supports the creation of software and hardware used in additive manufacturing. The startup was selected as one of the “Best Small Companies to Work For” by Built In Seattle in 2020.

20. 3DEO

5-year search growth: -58%

Search growth status: Peaked

Year founded: 2016

Location: Gardena, CA

Funding: $33. 8M (Series Unknown)

8M (Series Unknown)

What they do: A 3D printing technology company, 3DEO builds and supplies metal components. They also offer a cloud-based manufacturing platform designed to manage the entire development process. Last year, 3DEO announced that they shipped 150,000 production parts for end-use applications.

conclusion

And that wraps up our list of 3D printing startups.

As additive manufacturing and prefab technologies become necessities, the industry for 3D printing products and services is set to see continued growth in the years to come.

19 Startups in the 3D Printing Industry

Updated:

March 26, 2022

|

UnicornsStartupsFailed StartupsAccelerators & Incubators

Ad

Mention helps you take charge of your social media workflow, thanks to their suite of powerful social monitoring and scheduling features. Check out their free guide, to help take your first steps into designing a workflow that works for you.

Countless 3D Printing startups are being launched every day.

Many fail because they did not learn from the success of other companies who've managed to rise above.

We just published this list of 19 well-known and fast-growing 3D Printing companies that impressed investors.

1) Formlabs

Formlabs creates easy-to-use 3D fabrication tools for producing complex figures.

Details of the startup:

- Country: United States

- City: Somerville

- Started in: 2011

- Founders: David Cranor, Maxim Lobovsky, Natan Linder

- Number of employees: 501-1000

- Funding amount: $253,699,968

- Number of funding rounds: 9

- Number of investors: 24

You can find their website here.

2) Mighty Buildings

Mighty Buildings is a company that creates 3D printing technologies and an automated platform to help clients afford housing.

Details of the startup:

- Country: United States

- City: Oakland

- Started in: 2017

- Founders: Alexey Dubov, Dmitry Starodubtsev, Sam Ruben, Slava Solonitsyn

- Number of employees: 51-100

- Funding amount: $101,823,024

- Number of funding rounds: 7

- Number of investors: 28

You can find their website here.

3) Markforged

Markforged is a manufacturing startup that has developed a novel 3D printing technology for creating products made of Continuous Carbon Fiber.

Details of the startup:

- Country: United States

- City: Watertown

- Started in: 2013

- Founders: David Benhaim, Gregory Mark

- Number of employees: 251-500

- Funding amount: $136,800,000

- Number of funding rounds: 5

- Number of investors: 7

You can find their website here.

4) Xometry

Customers can access a network of machine shops and custom manufacturers through Xometry's online marketplace.

Details of the startup:

- Country: United States

- City: Gaithersburg

- Started in: 2013

- Founders: Laurence Zuriff, Randy Altschuler

- Number of employees: 251-500

- Funding amount: $197,200,000

- Number of funding rounds: 8

- Number of investors: 13

You can find their website here.

5) ICON

ICON is a construction technology business that is revolutionizing homebuilding with 3D robotics, software, and sophisticated materials.

Details of the startup:

- Country: United States

- City: Austin

- Started in: 2017

- Founders: Alex LeRoux, Evan Loomis, Jason Ballard

- Number of employees: 51-100

- Funding amount: $59,499,997

- Number of funding rounds: 5

- Number of investors: 22

You can find their website here.

6) Local Motors

Local Motors is an American automaker that designs and manufactures safe and accessible mobility solutions for small towns.

Details of the startup:

- Country: United States

- City: Chandler

- Started in: 2007

- Founders: Damien Declercq, John B. Rogers, Mark Smith

- Number of employees: 251-500

- Funding amount: $15,250,000

- Number of funding rounds: 5

- Number of investors: 5

You can find their website here.

Ad

Mention helps you take charge of your social media workflow, thanks to their suite of powerful social monitoring and scheduling features. Check out their free guide, to help take your first steps into designing a workflow that works for you.

7) ThreeKit

ThreeKit is a 3D product configuration and visualization platform that helps businesses develop and manage stunning images at scale.

Details of the startup:

- Country: United States

- City: Chicago

- Started in: 2005

- Founders: Ben Houston

- Number of employees: 101-250

- Funding amount: $30,000,000

- Number of funding rounds: 2

- Number of investors: 3

You can find their website here.

8) NEXA3D

Professionals and organizations of all sizes may now afford ultrafast industrial-grade Stereolithography 3D printers thanks to NEXA3D.

Details of the startup:

- Country: United States

- City: Ventura

- Started in: 2014

- Founders: Andrea Denaro, Avi Reichental, Gianni Zitelli, Luciano Tringali

- Number of employees: 11-50

- Funding amount: $94,999,999

- Number of funding rounds: 5

- Number of investors: 3

You can find their website here.

9) Hubs

Hubs is a web-based manufacturing platform that connects engineers to a global network of manufacturing partners on demand.

Details of the startup:

- Country: The Netherlands

- City: Amsterdam

- Started in: 2013

- Founders: Bram de Zwart, Brian Garret, Filemon Schöffer

- Number of employees: 101-250

- Funding amount: $31,499,998

- Number of funding rounds: 4

- Number of investors: 8

You can find their website here.

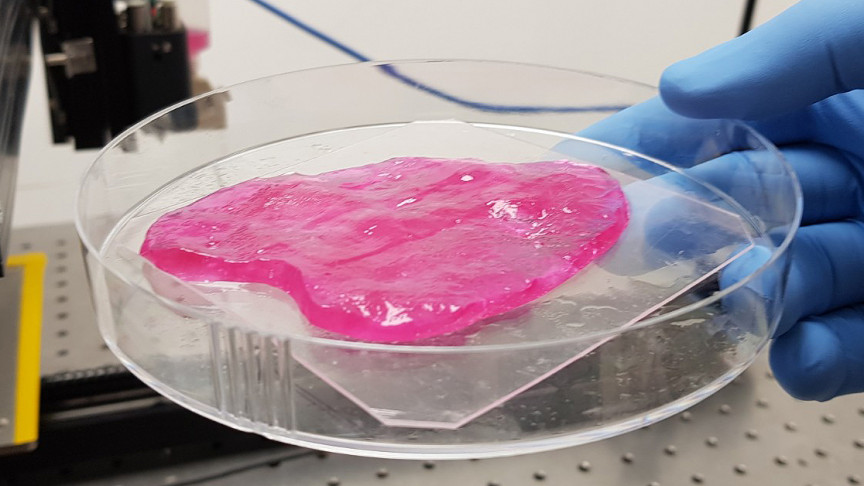

10) Brinter

Brinter is a cutting-edge modular 3D bioprinter designed for global markets.

Details of the startup:

- Country: Finland

- City: Turku

- Started in: 2018

- Founders: Piira Marko, Tomi Kalpio

- Number of employees: 1-10

- Funding amount: € 1,200,000

- Number of funding rounds: 1

- Number of investors: 1

You can find their website here.

11) 3YOURMIND

Industry 4.0 automation software to handle part selection, ordering, and production workflows for additive manufacturing.

Details of the startup:

- Country: Germany

- City: Berlin

- Started in: 2014

- Founders: Aleksander Ciszek, Stephan Kuehr

- Number of employees: 51-100

- Funding amount: $32,859,690

- Number of funding rounds: 6

- Number of investors: 10

You can find their website here.

12) CGTrader

CGTrader is the world's leading provider of high-quality 3D content for e-commerce, gaming, virtual reality, entertainment, and 3D printing.

Details of the startup:

- Country: Lithuania

- City: Vilnius

- Started in: 2012

- Founders: Dalia Lasaite, Marius Kalytis

- Number of employees: 51-100

- Funding amount: $12,112,321

- Number of funding rounds: 4

- Number of investors: 5

You can find their website here.

The All-In-One Newsletter for Startup Founders

Every week, I’ll send you Failory’s latest interviews and articles and 3 curated resources for founders. Join +20,000 other startup founders!

13) angelalign

Angelalign is a global provider of invisible orthodontic technology, as well as manufacture and sales of invisible orthodontics.

Details of the startup:

- Country: China

- City: Shanghai

- Started in: 2010

- Number of employees: 251-500

- Funding amount: $23,600,000

- Number of funding rounds: 2

- Number of investors: 2

You can find their website here.

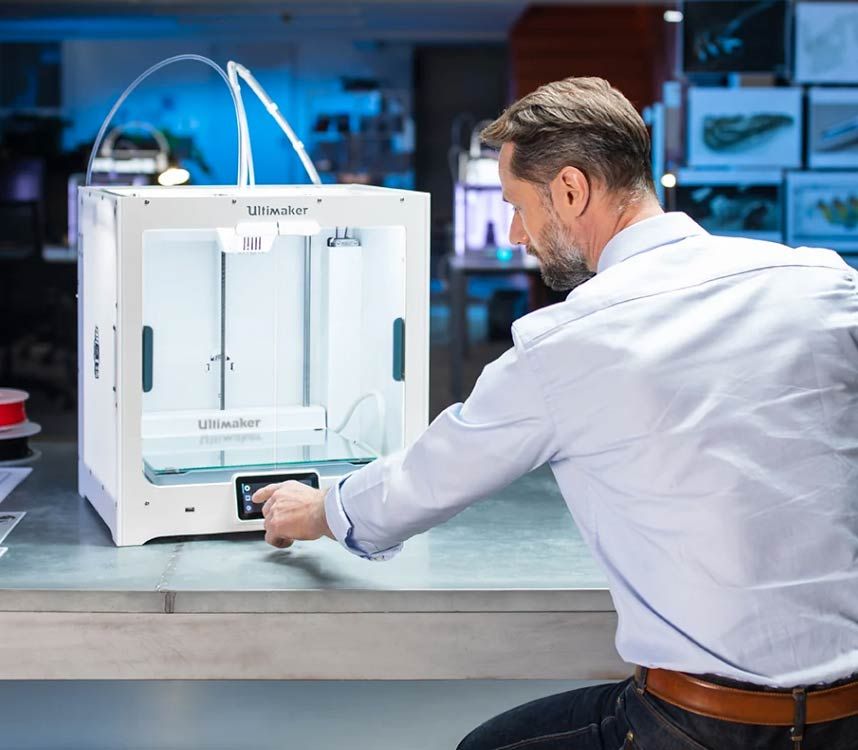

14) Ultimaker

Since May 2011, when Ultimaker began shipping its first Ultimaker 3D printers, the business has occupied a key place in the 3D printing industry.

Details of the startup:

- Country: The Netherlands

- City: Geldermalsen

- Started in: 2010

- Founders: Erik de Bruijn, Martijn Elserman, Siert Wijnia

- Number of employees: 251-500

- Funding amount: € 15,000,000

- Number of funding rounds: 2

- Number of investors: 2

You can find their website here.

15) Shapr3D

Shapr3D is bringing CAD into the twenty-first century.

Details of the startup:

- Country: Hungary

- City: Budapest

- Started in: 2015

- Founders: István Csanády

- Number of employees: 51-100

- Funding amount: $7,300,000

- Number of funding rounds: 4

- Number of investors: 6

You can find their website here.

16) Volumental

For product customization, a cloud-based platform leveraging 3D is used.

Details of the startup:

- Country: Sweden

- City: Stockholm

- Started in: 2012

- Founders: Alper Aydemir, Caroline Walerud, Miroslav Kobetski, Rasmus Göransson

- Number of employees: 11-50

- Funding amount: $4,458,029

- Number of funding rounds: 4

- Number of investors: 7

You can find their website here.

17) LuxCreo

LuxCreo is a company that specializes in 3D printing.

Details of the startup:

- Country: China

- City: Beijing

- Started in: 2017

- Founders: Zhifeng Yao

- Number of employees: 101-250

- Funding amount: $37,442,027

- Number of funding rounds: 2

- Number of investors: 4

You can find their website here.

18) HeyGears

Digital 3D Printing Application Service Provider with a Global Reach

Details of the startup:

- Country: China

- City: Guangzhou

- Started in: 2015

- Founders: Heyuan Huang, Peiyan Gui

- Number of employees: 251-500

- Funding amount: $106,925,987

- Number of funding rounds: 2

- Number of investors: 5

You can find their website here.

19) Snapmaker

Snapmaker is composed entirely of metal, resulting in a high-quality and dependable 3D printing experience.

Details of the startup:

- Country: China

- City: Guangdong

- Started in: 2016

- Founders: Daniel Chen

- Number of employees: 1-10

- Funding amount: $4,269,000

- Number of funding rounds: 2

- Number of investors: 1

You can find their website here.

No items found.

No items found.

Industry

10 reasons to contact the prototyping center

Analytics and business

Rapid prototyping

Experts recommend

Author: Andrey Kombarov

Author: Andrey Kombarov

1. Supply chain management | 2. Large selection of materials | 3. Variety of colors and finishes | 4. Large format 3D printing | 5. Professional quality parts | 6. Cost reduction | 7. Save time | 8. Scalability | 9. Expert advice and assistance | 10. Services of professional designers

The 3D printing services business is growing faster than ever. This happens because more and more people are striving to realize their ideas by means of additive technologies. Many solo enthusiasts, research groups, and manufacturing companies are not interested in investing in 3D printers, but prefer to go to a prototyping center first.

This happens because more and more people are striving to realize their ideas by means of additive technologies. Many solo enthusiasts, research groups, and manufacturing companies are not interested in investing in 3D printers, but prefer to go to a prototyping center first.

Today, 3D printing services are based mainly on working with professional clients. Of course, orders are also carried out for individuals, but most of the market is the B2B segment.

Even if you have access to a 3D printer, sometimes it's better to hire an outside contractor. Let's say you need a part in a material or color you don't have, and you'd rather not buy the whole lot. It is much wiser to order the missing part, and not to purchase all the equipment and inventory that may not be needed in the future.

We will look at ten reasons why additive manufacturing using a service can be more profitable.

Do you have projects that you would like to realize using 3D printing, 3D scanning or 3D modeling? Order a service from our company!

Leave a request

1.

Supply chain management

Supply chain management Additive technologies have been improved over the years, and today they allow the production of both prototypes and final parts, especially when solving certain problems.

In general, the development and manufacture of a particular part can be expensive due to high tooling costs. 3D printing is an extremely flexible technology. Manufacture of many different products and refinement of their designs is no longer a complex problem, which makes additive manufacturing a reliable solution to problems with the active use of redesign.

Outsourcing 3D printing jobs saves costs and lead times © Leo Gregurić via All3DP

Today, many research groups and companies rely on 3D printing services as a supply chain. It is extremely useful for them to be able to easily create and deliver custom parts.

2. Large selection of materials

One of the strong selling points for 3D services is the variety of consumables (and technologies) on offer. Thanks to the constant introduction of innovations in this area, service providers are able to work with the latest developments, especially large companies.

Thanks to the constant introduction of innovations in this area, service providers are able to work with the latest developments, especially large companies.

Prototyping centers offer, as a rule, the three most popular additive technologies: FDM, SLA and SLS. Accordingly, polymer filaments or granules, photopolymer resin and plastic powders are used as consumables.

A wide range of options gives the customer the opportunity to obtain the material that is required for a particular project, based on mechanical and chemical properties and aesthetic requirements.

The variety of materials is practical not only for professional needs. The Professional 3D Services Center will also offer simple materials that may not be available to a private person. Buying a certain material and printing a product from it on your own can be more expensive than simply ordering the manufacture of a single part from this material.

iQB Technologies experts recommend an article: 9 products that are more profitable to make on a photopolymer 3D printer

3.

Variety of colors and finishes

Variety of colors and finishes With such a wide range of materials available, 3D printing service customers are not limited in their choice of colors and finishes. Creating the perfect combination for a specific task has never been easier.

Colors

FDM filaments (PLA, ABS, PETG, and others) are typically offered in a wide range of colors. The plastic granules from which the thread is made are easily dyed.

More advanced combinations of plastics in the form of filaments, such as polymer composites or nylon, are difficult to dye and their color range is not as rich.

With regard to SLA technology, various colors are available for photopolymers. True, there are not as many of them as for PLA. Methods like SLS use industrial grade nylon powder, which comes in white, black, or some color in between. This is also due to the difficulty of coloring.

Technology available for full-color 3D printing © Hubs

There are full-color 3D printers that are ideal for creating visually appealing prototypes and teaching models, such as anatomy and geography. Given the high cost of professional machines, the ability to use technology that is not otherwise available through a 3D printing service is of great importance to the end user.

Given the high cost of professional machines, the ability to use technology that is not otherwise available through a 3D printing service is of great importance to the end user.

Finish

The surfaces of products created on a 3D printer can be subjected to various post-processing methods. Details are processed until the layers are completely indistinguishable and, as a result, look as if they were not printed at all.

But this is only the beginning. Processing can include sanding, polishing, galvanizing and painting, and many other finishes. Not every 3D printing material is suitable for all post-processing methods, and the service provider should explain this point to you when ordering.

In addition to the huge selection of options, one of the biggest benefits of ordering a finishing service is quality and convenience. Post-processing can take a lot of time, and entrusting the work to professionals, you will be sure of a high-quality and reliable result.

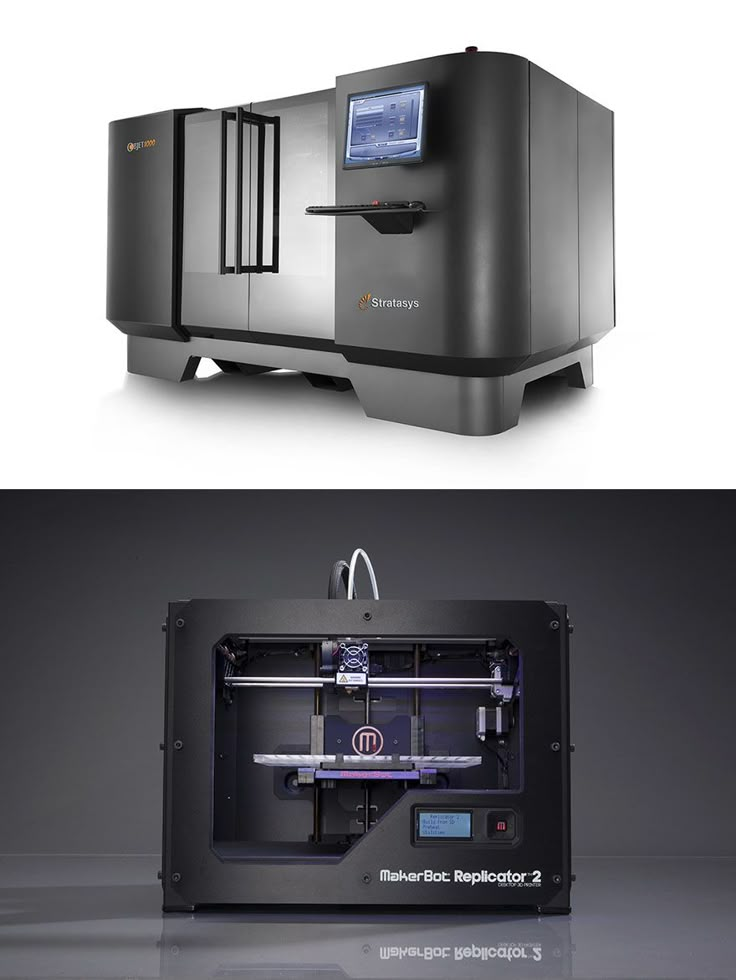

4. Large Format 3D Printing

Sometimes you may need a large printer © WASP Team via Youtube

An additive manufacturing services company typically operates multiple 3D printers to meet high demand (and meet deadlines) and various other requests. This provides a number of advantages, among them - the flexibility of product sizes.

Sometimes splitting a large part into multiple sub-elements is not the best solution, so an additive setup with a large build platform is needed. An individual or company often does not have access to large 3D printers, while many 3D service providers do.

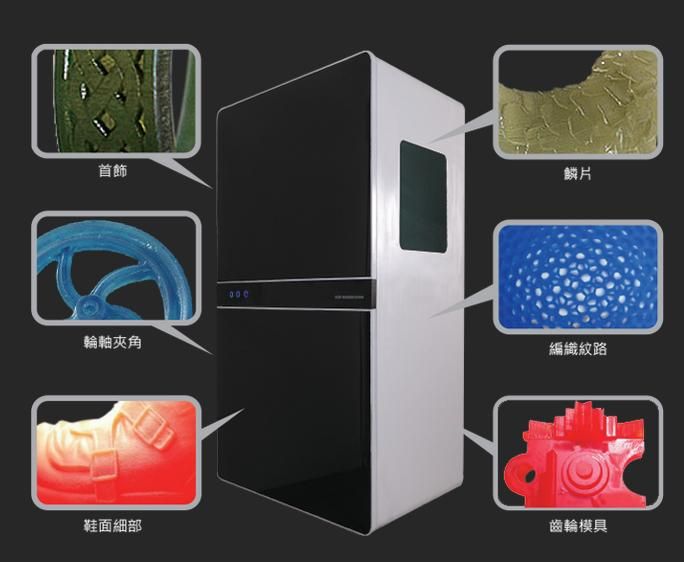

5. Professional quality parts

3D printers are becoming more reliable, and even the most affordable technology is showing impressive accuracy. However, many products (say, jewelry) require more precise workmanship or tighter tolerances to ensure perfect compatibility (for example, functional units). The professional results offered by the 3D printing service guarantee consistently high-quality workmanship in terms of precision and finish.

Professional machines are more reliable in terms of repeatability. This is an important factor to consider when printing a large number of parts that require constant and tight tolerances.

But not only machines determine the final result. The people who work with 3D printers make a significant contribution to the production of professional quality parts. They have the knowledge and experience to advise you on how to best prepare your model, select the most suitable material, and finally create the final part.

A high-quality prototype created on an industrial SLA printer at the TWIZE Prototyping Center © TWIZE

6. Cost reduction

If you need to make something on a 3D printer, there are two options: either buy equipment and print the parts yourself, or order printing and receive finished products. Using a 3D printing service can save you money.

When a business is considering launching its own additive manufacturing, outsourcing through a service provider first makes sense. This will allow an individual or company to access 3D printing technologies while avoiding the cost of equipment, materials and maintenance. Once you understand that 3D printing meets the needs of your business, this may be the right time to start thinking about buying equipment.

This will allow an individual or company to access 3D printing technologies while avoiding the cost of equipment, materials and maintenance. Once you understand that 3D printing meets the needs of your business, this may be the right time to start thinking about buying equipment.

There are other scenarios as well. Some businesses can save money in the prototyping phase by having them 3D printed before putting the final version into production through another process such as injection molding.

However, outsourcing a project can save a lot of money until a “tipping point” is reached, at which point the cost of acquiring the equipment becomes a worthy investment.

Considering starting a 3D services business?

We share our experience in the article 3D printing as a business: the most profitable concepts of the RP Center

We will consult and select ready-made solutions. Contact us!

7.

Save time

Save time When ordering 3D printing from a service provider, you don't have to worry about printer setup and maintenance. In fact, you make a payment and get the parts you need. Everything is done on a turnkey basis, and you don't have to think about all the additional costs associated with setting up, maintaining and operating the equipment.

3D printing of some parts may require time that you do not have © Leo Gregurić via All3DP

And even if you have printers, they may not be enough to print a large number of products in a short time. Since prototyping centers usually have a large stock of equipment, large batches can be produced very quickly.

Of course, the order may take a long time, so choose the service wisely. But the turnaround time for an order (printing from standard media with standard post-processing) may well be shorter than the total time it takes to set up, maintain, and operate the related equipment. For many, this alone is enough to apply for a service to a contractor.

In addition, the production of an object on a 3D printer takes hours or days - this requires control, which not everyone can do.

8. Scalability

Since the advent of 3D printing, it has been described in the mainstream media as a slow process. What is usually meant is that additive manufacturing cannot compete with traditional methods such as injection molding when it comes to high volume production.

There is some truth in this, but it is important to understand that 3D printing is a very effective process in certain circumstances. When you need to produce large batches of the same parts, this is not the best option, but 3D printers are more than capable of producing in small and medium volumes.

This is especially beneficial when we are dealing with individual designs or iterations, that is, when classical methods involve much more time and money.

For this reason, 3D printing services in particular can provide scalable manufacturing solutions that meet the needs of even medium volume production. Small-scale production is possible in a garage or a small office, something larger is hardly imaginable, and this is where the use of a 3D printing service makes sense.

Small-scale production is possible in a garage or a small office, something larger is hardly imaginable, and this is where the use of a 3D printing service makes sense.

3D service providers can deliver scalable solutions © BMW Group

9. Expert advice and assistance

As already mentioned, 3D printing services are available to a large number of different customers. These can be both individuals who want to print a cartoon character figurine on a 3D printer, and world-famous corporations seeking to optimize their workflows. In any case, consultation is an important factor that can help close the deal.

The additive manufacturing experts at the 3D Services Center can help customers determine the right course of action before launching a project. Working with the client on the specific needs of his project, he is explained the available options.

Identifying the exact applications for 3D printing as well as discussing technical issues and specifics (such as what material is best for the purpose) are all part of the consulting service. Sometimes good preparation based on consultation can save money as the project progresses. For large projects, this is certainly an important advantage.

Sometimes good preparation based on consultation can save money as the project progresses. For large projects, this is certainly an important advantage.

10. Professional design services

Most 3D service companies expect you to already have a 3D model ready to print. Often this is the case, but some clients still need additional help. In cases where the customer needs to develop a part from scratch and he does not have 3D modeling experience, a service with the involvement of full-time professional designers will come in handy.

Moreover, not all 3D models are ideal for 3D printing in production. In these cases, the advice (or adjustments) from the AM specialist is really helpful. It may not be useful to all customers, but for new customers it will be a nice bonus.

Author of the material: Leo Gregorich. Source: all3dp.com

Article published on 04/28/2022, updated on 08/01/2022

The 3D printing market continues to grow: trends, prospects, business strategies

The future of additive manufacturing begins with understanding the goals and expectations of 3D printing users around the world. This was the reason for the launch of an ambitious research project by the French company Sculpteo - the annual State of 3D Printing report. Today it is one of the most authoritative and comprehensive sources of information about the real situation and prospects of the industry.

This was the reason for the launch of an ambitious research project by the French company Sculpteo - the annual State of 3D Printing report. Today it is one of the most authoritative and comprehensive sources of information about the real situation and prospects of the industry.

This year, 1600 respondents from 71 countries took part in the Sculpteo survey. According to the report, a growing number of companies are realizing the possibilities of additive manufacturing, increasing investments and demonstrating undeniable confidence in the future of professional use of 3D printing.

This resource provides a complete overview of the world of additive manufacturing and will help you develop the right business strategy.

Additive Manufacturing Trends

Materials

- New and accessible materials.

- Improving the quality and stability of budget additive technologies.

- Improving post-processing technologies to obtain parts with the highest quality surface.

- 3D printing from multiple materials at once.

Environmental sustainability

- Biodegradable materials and materials of biological origin.

- On-demand and on-site production to reduce transport and environmental costs.

- Application of 3D printing for solving problems of renewable energy and energy efficiency.

Technology Development

- Improving the usability of software and printers

- Mass Production: Printing and 3D Scanning Speed

- Generative design

Availability

- Reducing the cost of 3D printers and materials (metals, photopolymers).

- Low post-processing costs.

- Sharing projects and tools.

Applications of 3D printing

The possibilities of 3D printing are growing every day, and with them the scope of its application is expanding. Gradually, companies begin to feel more confident in relation to 3D technologies. 68% of respondents are looking to use additive manufacturing to solve a wider range of problems, and 44% are going to introduce new 3D printing technologies. Most professionals outsource SLS and Jet Fusion printing and metal 3D printing so that they do not need to maintain their own equipment, and this will encourage them to test new technologies.

68% of respondents are looking to use additive manufacturing to solve a wider range of problems, and 44% are going to introduce new 3D printing technologies. Most professionals outsource SLS and Jet Fusion printing and metal 3D printing so that they do not need to maintain their own equipment, and this will encourage them to test new technologies.

So what are the most popular 3D printing and post-processing technologies? Let's find out!

Once again, the volume of production using 3D printing continues to grow. We are seeing this growth in research and development and education, which is in line with the increased demand for new materials and technologies in the market.

The use of photopolymers is increasing through both internal and external services, while for metal 3D printing, most users outsource.

Design, testing and prototyping continue to be the main challenges of 3D printing.

Consistency and quality control remain a major concern for users seeking to scale up the use of 3D printing.

Most users are using SLS, Jet Fusion, and Metal 3D Printing through outsourcing without purchasing hardware.

3D printing users are interested in exploring new applications, technologies and materials.

Typically, 3D printing is used in conjunction with traditional manufacturing methods such as laser cutting, CNC machining, and injection molding.

A look at additive technologies

What do respondents think about 3D printing technologies? In this section, we will look at the main benefits of 3D printing for users and their companies. How exactly does it optimize production processes?

66% of respondents use 3D printing to create parts with complex geometries. Survey participants cite the reduction in iterations, lead times and costs as the most important benefits of this technology.

In this section, we also look at the future of the additive industry and the factors driving its growth and business adoption. What needs to be done to accelerate the adoption of 3D technologies? Now we'll find out.

What needs to be done to accelerate the adoption of 3D technologies? Now we'll find out.

As technology and materials become more accessible, the cost savings of 3D printing become clear to more and more users. Many also cite time savings due to reduced iterations and lead times as a benefit.

Set-up costs and lack of knowledge are seen as the main limiting factors for the adoption of 3D printing.

The role of 3D printing in business and manufacturing continues to grow.

More than 55% of the industry needs new materials and reliable technologies.

Business Strategies for 3D Printing

Additive manufacturing is a huge competitive advantage. With some significant benefits of 3D printing, such as reduced lead times and speed of innovation, the vast majority of respondents view 3D printing as a significant improvement for their business.

As far as money is concerned, investments in additive technologies are growing every year. Most of these users will increase their investments in 2020! It can also be seen that the vast majority of those surveyed have been using 3D printing for several years and plan to invest more in this technology in the near future. The business world believes in the promise of additive manufacturing.

Most of these users will increase their investments in 2020! It can also be seen that the vast majority of those surveyed have been using 3D printing for several years and plan to invest more in this technology in the near future. The business world believes in the promise of additive manufacturing.

Let's see how 3D printing becomes a real asset for companies, helping them develop their business strategy!

63% see a significant or dramatic impact on sales. Reduced lead times and speed of innovation are the most important success metrics for 3D printing.

Nearly 60% cite 3D printing as one of their strengths compared to the competition.

65% of companies plan to increase their investment in 3D printing in 2020.

The integration of 3D printing into manufacturing processes continues to increase, with 74% actively using 3D printing in their companies.

Overview of the 3D printing industry over the past 6 years

The Sculpteo report offers a look at the analysis of the state of the 3D printing industry for each year since 2015. How has the use of 3D printing evolved over the period 2015-2020? Let's look at the answers of the latest polls.

How has the use of 3D printing evolved over the period 2015-2020? Let's look at the answers of the latest polls.

Large-scale production using 3D printing continues to spread, becoming as commonplace as prototyping and testing.

Accelerating development and offering customized products and limited editions remains a major challenge for companies using 3D printing.

The market share of photopolymers continues to increase, showing significant growth over the past two years.

Key takeaways

1. Lack of stability is the Achilles' heel of 3D printing

In order for additive manufacturing to become an integral part of any production, it is necessary to develop equipment and materials that provide high stability.

- 51% say they use 3D printing mostly for quality control purposes.

- 62% believe the 3D printing industry needs more robust technology to grow.

2. 3D printing is gaining ground in certain industries

Many industries are starting to increase their use of 3D printing as it plays an increasingly important role in their manufacturing processes. Users are constantly deepening their knowledge and experience in the application of additive technologies.

Users are constantly deepening their knowledge and experience in the application of additive technologies.

- 80% have been using 3D printing in their companies for over 2 years.

- 33% expect up to a 50% increase in investment this year, which is a more conservative estimate than in previous years.

3. 3D printing may be considered unprofitable

For wider use of additive technologies, the cost of manufactured parts must be reduced - this will attract more industries and sectors.

- More than 50% order SLS, Jet Fusion, SLM/DMLS and Binder Jetting outsourced to offset equipment and service costs.

- 59% indicate that the cost of organizing production is a limiting factor for the adoption of 3D printing.

4. Changing perceptions: from prototyping to full-fledged manufacturing technology

Despite the increasing use of 3D printing in manufacturing, its benefits are still clear only for prototyping and small-scale production.