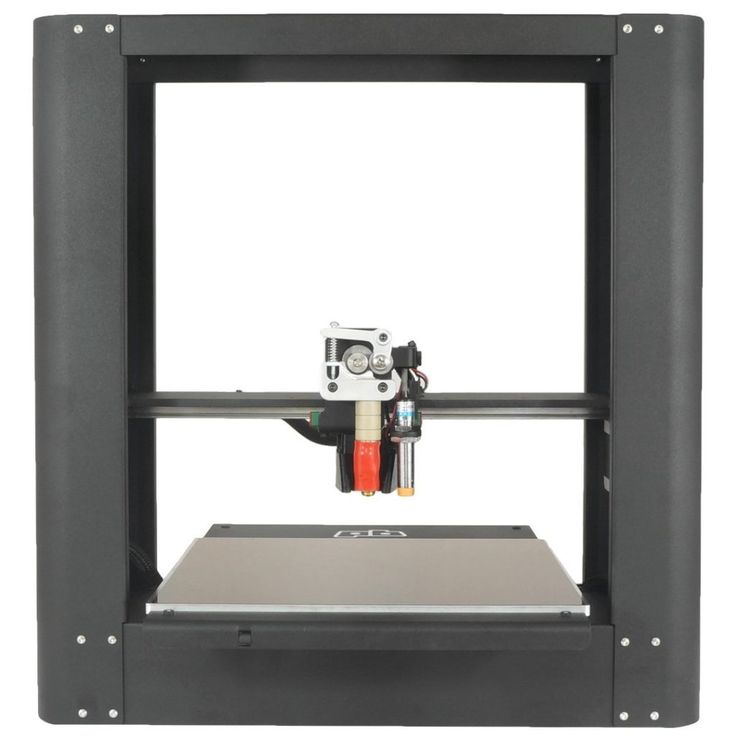

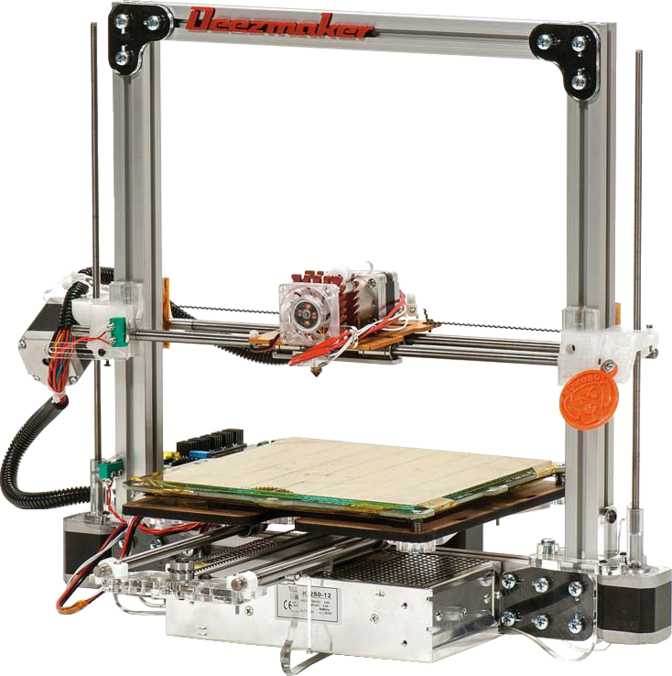

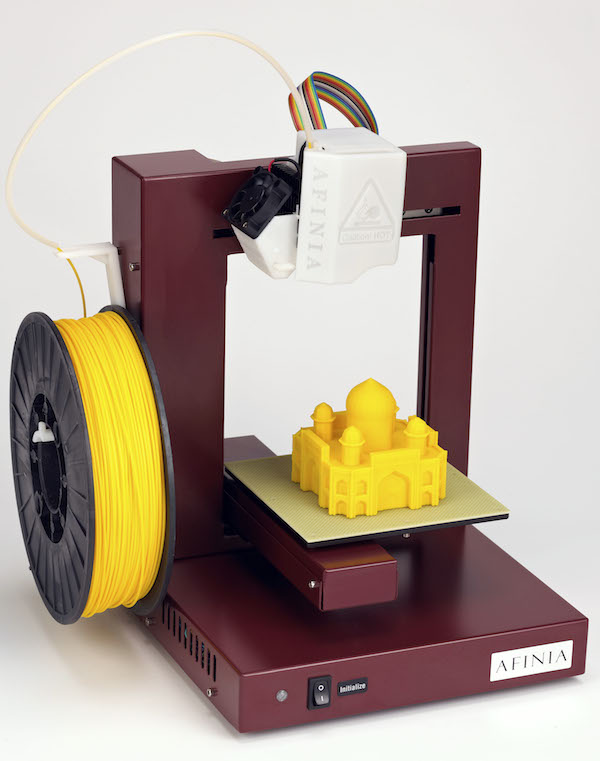

Fablicator 3d printer

MX - Fablicator

- Products

- FM1

- MX

- SX

Multi-Color Mode

Print with two different colors.

Makes prints look stunning and enables a high level of artistic creativity

Support Material Mode

Creates supports using a dissolvable or easy to remove support material

Great for complex parts not designed specifically for 3D Printing

Copy Mode

Each head prints a copy of a part

simultaneously

Perfect for producing a large quantity of simple parts quickly

Single Extruder Mode

Only use one extruder to print

a single material part.

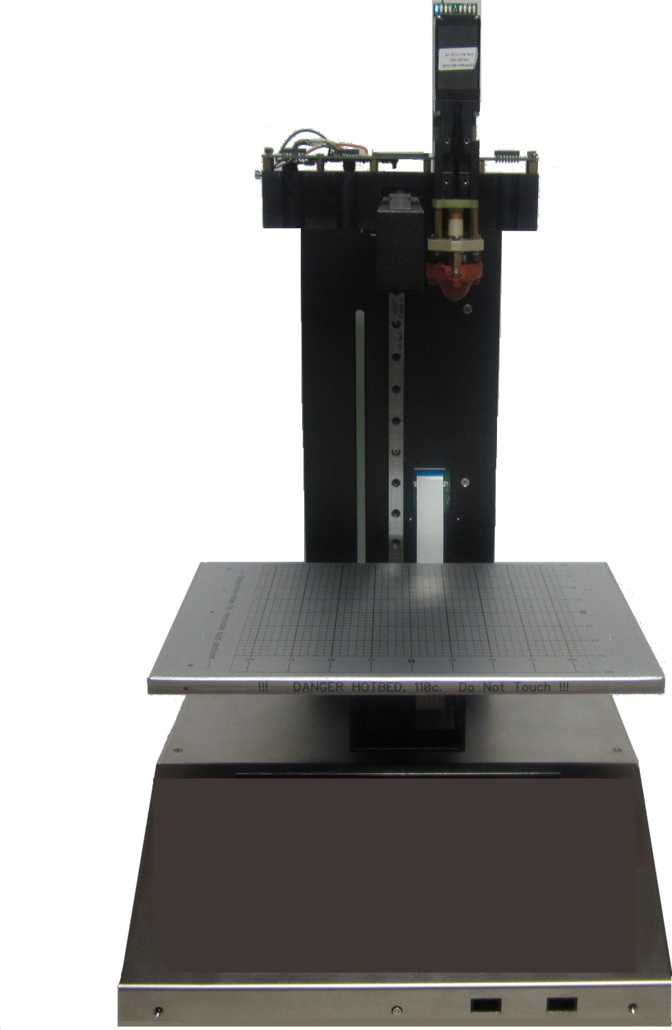

Largest build area and extremely simple settings selection.

Larger than a sheet of paper

Multi-Color Mode

Support Material Mode

Copy Mode (each half)

Single Material Mode

13 x 8.5 x 9.5

13 x 8.5 x 9.5

7 x 8.5 x 9.5

13. 5 x 8.5 x 9.5

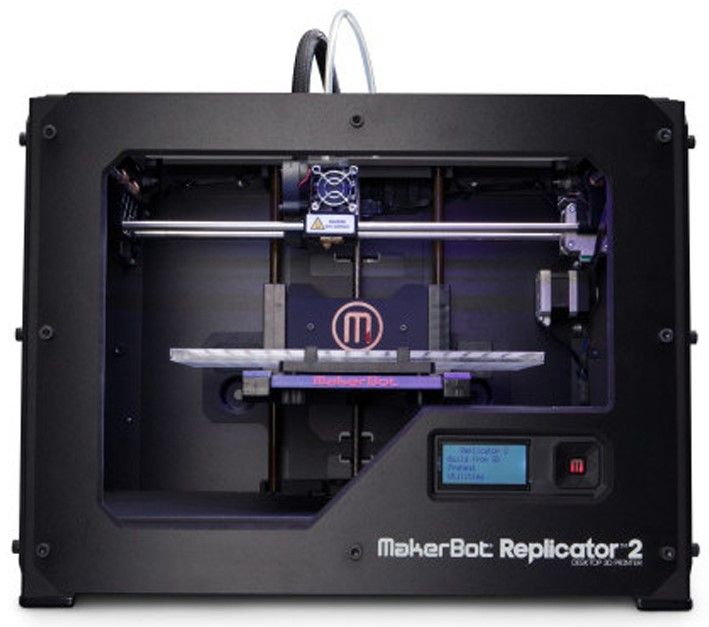

Design and Print from one place

Can run SolidWorks, Inventor, Blender, TinkerCAD, or any other CAD program directly from the printer.

Interface with the printer directly using a monitor, keyboard and mouse.

Low maintenance and user replaceable parts

Easily replace components should

the unexpected happen

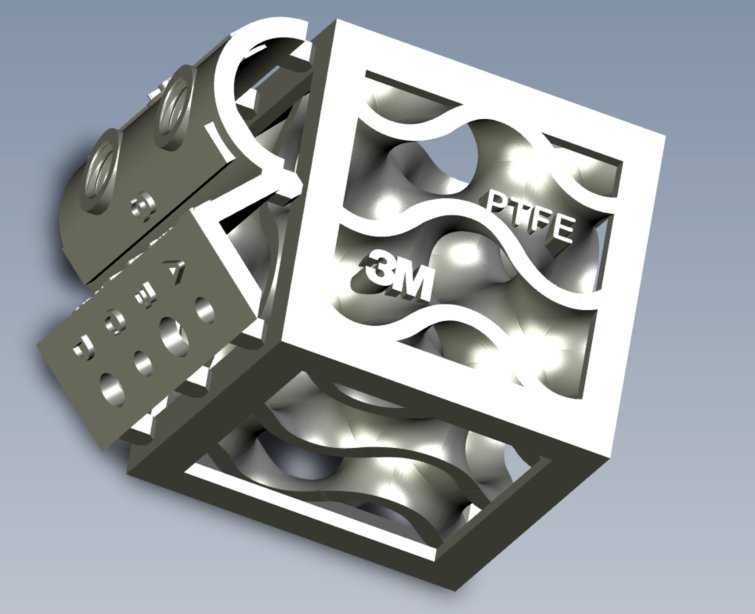

No plastic parts, No leaks

Built around a stainless steel core press fit onto an aluminum heater block and heat sink

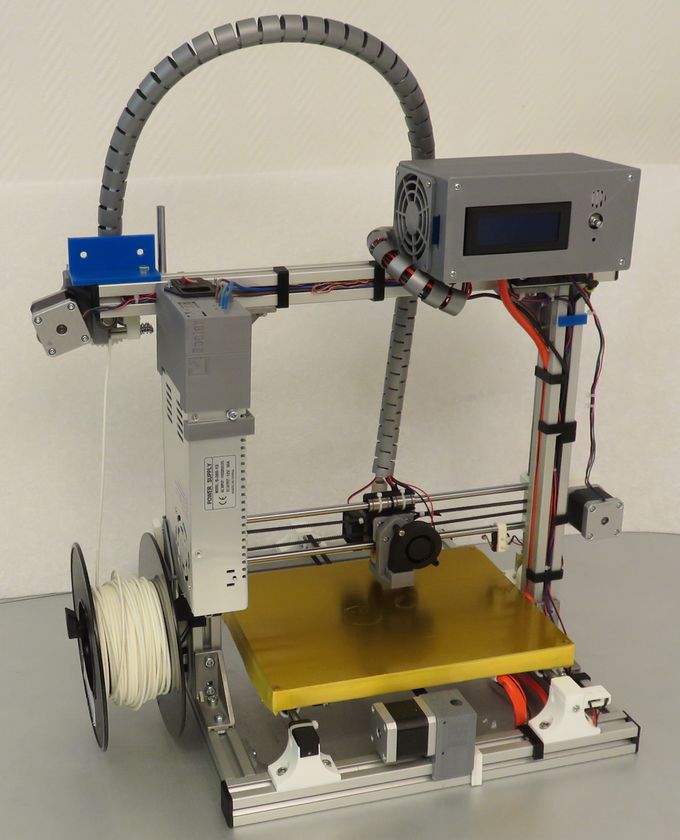

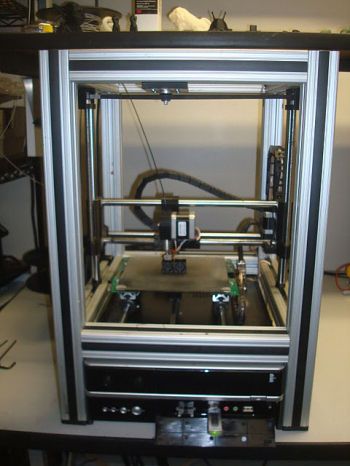

Industrial aluminum frame

40mm aluminum extrusions and 12mm linear rails for reliability and precision

| ABS | PLA |

| PET | PVA |

| SemiFlex TPE | PLA-PHA |

| Anti-Static PET | HIPS |

No proprietary filament

The variety of available filament is ever expanding, and we don’t want to limit innovation by only allowing our own filament to be used.

More than 12 colors of ABS, PLA, and PET are available directly from Fablicator.

Parts adhere well while printing and remove easily

Exceptional flatness, and holds calibration between prints.

Resists solvents and scratches. Evenly heated.

Parts print directly on the surface with a primer, no tape or rafts needed.

Our facilities are located in Allentown, Pennsylvania

Printing

Printer Type

FFF (Fused Filament Fabrication)

Number of Extruders

Dual Independent

Maximum Build Size

13.5 L x 8.5 W x 9.5in H in

[343 L x 216 W x 241 H mm]

Maximum Build Volume

1090in³ [ 17.8 Liter]

Filament Diameter

1.75mm

Usable Materials

ABS

PLA

PLA-PHA

PET

Semiflex TPU

Antistatic ABS

Antistatic PET

Woodfill

HIPS

Nozzle

.35mm

Stainless Steel Core

Workspace Illumination

LED

Size and Weight

Printer Dimensions

With filament

31.5 L x 18 W x 23 H in

[800 L x 457 W x 584 H ] mm

Without Filament

23. 125 L x 18 W x 23 H

125 L x 18 W x 23 H

[588 L x 457 W x 584 H mm]

Shipping Weight

78lb [31kg]

Printer Weight

65lbs [30kg]

Mechanical

Frame

4040 Aluminum Extrusion

12mm linear rails

Build Surface

Chemically strengthened and textured glass

Calibration

Factory calibrated

Mechanical Precision

0.00035in [10micron] or better

Integrated Computer

Software

Windows 10 64 bit PRO

SolidWorks, Inventor, and TinkerCAD capable

Hardware

Intel Core i5 6500

16gb ram

240gb SSD

650W power supply

Dual front USB ports

Printing Software

Slicing

KISSlicer 64 bit

Interface:

Fablicator Interface

File type

.STL, G-Code

File import

USB, WiFi, Ethernet

Electrical

Power

Power

100-240V

6A max, 2A typical

FAQs - Fablicator

Is support handled by a human being?

Every support request, either through e-mail or phone call, is handled by a Fablicator staff member. We do not outsource our support overseas.

We do not outsource our support overseas.

Does using a Fablicator require a lot of technical expertise?

Our fully integrated 3D printing workstation is a relatively easy machine to learn. As with any new technology, there is a learning curve, and using the manual to get started will help immensely. 3D printing is not magic, and requires a willingness to learn the capabilities and limitations of the process.

Why buy a Fablicator vs an inexpensive chinese printer?

• We design our machines to be robust and reliable. Our very first machines are still producing parts after many thousands of hours of print time.

• Unlike the vast majority of chinese machines, we provide excellent, personal technical support when you have a problem.

• Our machines are made in the USA, and many components are made by local businesses.

• The part quality and strength produced by our machines is exceptional. Just compare our sample parts to those produced on other machines. It’s easy to skew ‘quality’ numbers on the internet, the proof is in the parts.

It’s easy to skew ‘quality’ numbers on the internet, the proof is in the parts.

Are Fablicator printers plug-and play?

Yes, all of our printers are already integrated with computers with all drivers and software pre-installed. You can go from .stl to part without installing anything.

Will I need to make a lot of adjustments to my printer to make good quality parts?

No, the included KISSlicer software contains pre-configured profiles which yield excellent quality parts from day one. Additionally, each machine comes calibrated from the factory, and only in rare cases will the bed level need to be adjusted at all.

How do I compare quality between 3D printers?

Many companies will tout theoretical resolution and fine layer heights. Unfortunately, these metrics are in most cases exaggerated and somewhat useless. The surface quality of parts produced depends heavily on a factors which can’t be easily distilled into a few advertized values. The only good way we’ve found is to take a look at the parts produced.

How fast is the Fablicator compared to other 3D printers?

Pretty fast. (200mm/s moves and up to 75mm/s print speeds.) However, speed depends heavily on acceleration and extrusion rate. We’ve seen lots of machines advertized with print speeds of 300-400mm/s, but accelerations so low they will never reach those speeds in reality. We think the best comparison here is to have a part printed, and compare the total print time.

What programs can I use to design parts to print?

Any program which will output a non-intersecting watertight .stl mesh will work. This includes most solid modelling programs. The ones we see most commonly used are:

•Solidworks

•Inventor (free for .edu)

•Fusion 360 (free for .edu)

•TinkerCAD (free)

•Blender (free)

Where can I get parts to print without having to design them myself?

In addition to the included sample .stl files shipped with the printer, there are a number of online websites which have files available to download. The most common ones we see are:

The most common ones we see are:

•Thingiverse

•YouMagine

•GrabCAD

What materials can the Fablicator print?

•PLA

•PET

•Woodfill PLA

•Brass/Copper Fill PLA

•PLA/PHA

•SemiFlex

•ABS

•HIPS

•AntiStatic PET

•AntiStatic ABS

•Nylon (must use different bed primer, and some work much better than others)

Is there a warranty in case something breaks on the Fablicator?

Yes, the Fablicator comes with a 1 year warranty, and extended warranties are also available.

What operating system will the Fablicator software work with?

The fablicator has all software built in to the Windows 64bit PC. No other PC is required.

Does the Fablicator require maintenance?

The fablicator requires some minor periodic maintenance, such as keeping the printer fans clear of dust and debris, cleaning off buildup at the nozzle tip, and lubricating the lead screws.

Where do I buy filament for my Fablicator

We recommend purchasing material from Fablicator as we source our filament through high-quality suppliers. However, you may use filament which is not from us, but we suggest only buying from well known reputable sources. Good quality filament is critical to the proper operation of the Fablicator 3D printers.

However, you may use filament which is not from us, but we suggest only buying from well known reputable sources. Good quality filament is critical to the proper operation of the Fablicator 3D printers.

The new industry standard on your desk

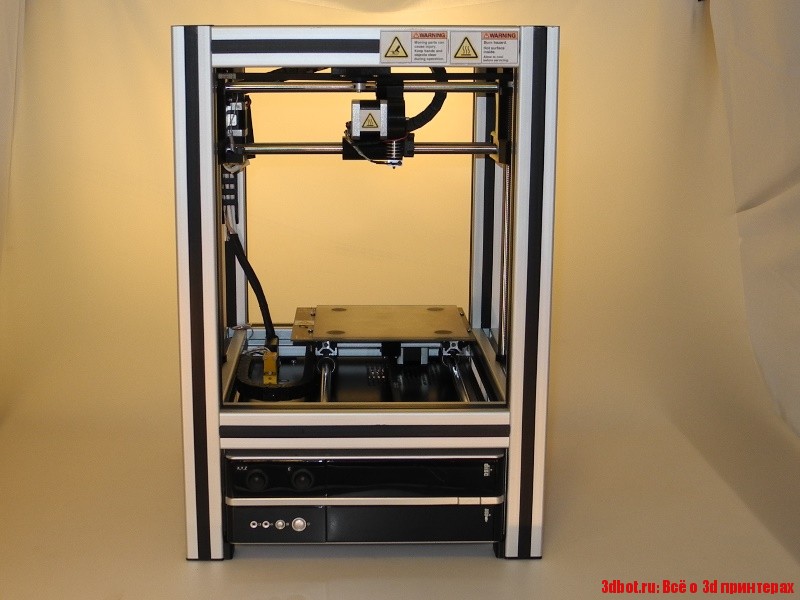

Designer X PRO Designer X PRO is a printer with a new core, with a new idea and many advanced solutions, created by PICASO 3D engineers to complete complex tasks.

You no longer have to choose between speed and quality. Save time

and be sure of the result.

Fastest 2-material printing *

There is nothing more valuable than time, save it with the advanced JetSwitch.

180 mm

Model height

0.1 mm

Layer height

Time sprouted between materials

5 seconds

without Jetswitch

secondswithout Jetswitch 9000,000,000 seconds

without jetswitch

without jetswitch

20 seconds

Without JetSwitch

15 seconds

Time spent on

switching, hours

2. 5

5

5

7.5

12.50005

17.5

Total print time

Models, hours

22

25.5

27

32

37

Savings with Jetswitch : 15 hours

A quality revolution

Newly designed print head with precision switching up to 1 µm*, frame construction, precision mechanics and next generation hardware platform make your prints look amazing.

Be sure of the result

The key to success is the ability to timely and equally perform tasks accurately. For your confidence in the result, we supplemented the printer control systems that will not only be monitor the status of the printer, but also inform you about its status*.

Serviceability

Less calibration, more printing.

Don't waste your time.

50 seconds

Calibration of working platform

5 seconds

Automatic calibration

nozzle height

5. 5 minutes

5 minutes

Calibration

Nozzle Offsets

Print with your favorite materials

Thanks to the new directional plastic feed system in the print head and a wide range of operating temperatures mechanical components, Designer X PRO allows you to use wide range of materials.

410 ° C

Maximum operating temperature of the extruder

150 ° C

Working platform maximum operating temperature

3D network

Built-in networking features let you connect all your Designer X PRO in a single interface updated POLYGON X. No matter how many You never had printers, now you can easily You can manage the work of each of them. Small batch production planning and printing prefabricated models has never been so convenient.

Connection interfaces

Ethernet

The new heart of the printer

New hardware platform Designer X PRO, built on a 32-bit processor with a core ARM CORTEX M4, made it possible to create a completely new concept of printer operation. More reliable faster, quieter, more precise.

More reliable faster, quieter, more precise.

Noise level

55 dBa

Pitch division

1\256

Core based processor

ARM Cortex M4 168Mhz

Technical specification

Print technology

FUSED FILAMENT FABRICATION [FFF]

Material change technology

Jetswitch ™

Extruders

2

201 x 201 x 210 mm

Print speed

up to 100 cm3/h

Nozzle diameter

0.3mm

Print resolution

10-250 microns (nozzle 0.3mm)

Positioning accuracy

XY: 11 microns; Z: 1.25 micron

Plastic thread diameter

1.75 ± 0.1 mm

Software

Picaso 3D Polygonx ™

The maximum print temperature

410 ° C

The maximum table temperature

150 ° C 9000

Ambient operating temperature

15 ° - 32 ° C

Storage temperature

0 ° - 32 ° C

Physical measurements

Printer size

49. 2x 39 x 43 cm

2x 39 x 43 cm

Packaging size

9000 x 54 x 70 cmWeight (packed/unpacked)

22.5 kg/15.6

Electricity

Mains operation

220V±15% 50Hz,(option 110V±15% 690Hz)

5

Maximum power input 400W

Interfaces

USB, Ethernet, USB Flash [included]

Hardware platform

Shacha division

1: 256 step

Noise level

55 dBA

Mechanics

aluminum

22 Steel

Print platform

Aluminium, glass

Guide rails

XY: rail (steel), Z: cylindrical (steel)

Media

Base material

ABS, FORMAX, PLA, ULTRAN 630, ULTRAN 6130, ASA, ABS/PC, PET, PC, FRICTION, CAST, RELAX, ETERNAL, FLEX, RUBBER, SEALANT, PETG, AEROTEX, CERAMO, WAX, SBS, SBS PRO, PROTOTYPER SOFT, PRO-FLEX, TOTAL PRO, NYLON and others

Soluble support material

PVA, HIPS

Software

Software

PICASO 3D Polygon X™

plg

Operating system

Windows XP and later

Replacement car

For the duration of the repair, you

are provided with a

replacement printer **

2 year warranty!

We give a full

product warranty

Distributor network

Warranty service at any

distributor throughout Russia

Order Designer X PRO

Order

Designer X

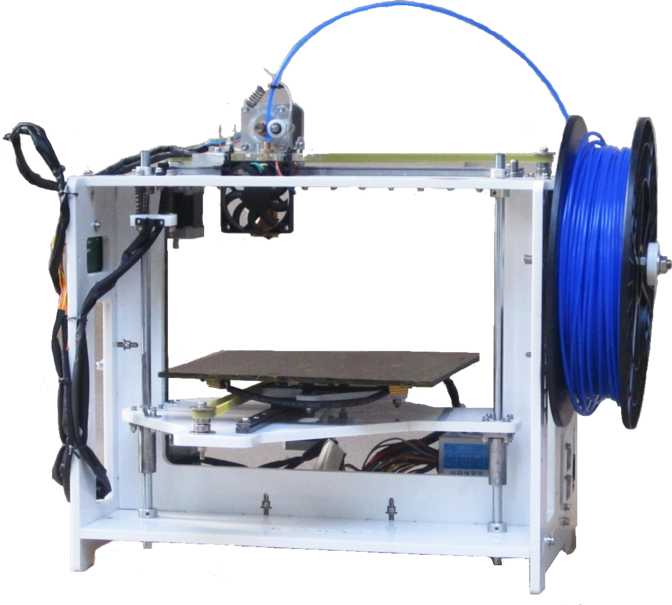

Designer X Designer X is a high-performance professional-grade 3D printer, a tool for realizing any ideas.

The new printer combines the reliability of the legendary PICASO 3D Designer with the quality and stability of the new X platform. Designer X is always ready to go. The highest resolution (layer from 0.01 mm) and print productivity (up to 100 cm 3 / hour) make this printer unique.

Everything under control

Clogged nozzle, tangled plastic, uneven diameter, or broken bar will no longer ruin the model. Encoder system Flow Control is watching printing condition, ensuring stable results.

The Designer X encoder averages three measurements per second* (*at speed 60 mm/s, layer 0.2 mm)

This allows you to almost instantly pause printing ("Pause" mode) and automatically start the algorithm for solving the problem. If the abnormal situation is not resolved, the printer will wait for user intervention.

Plastic Feed Control

Detection of clogged or slipped plastic. Some blockages can be cleared automatically by the printer. The print result is saved (Pause mode), it can be continued after cleaning the nozzle or replacing it.

The print result is saved (Pause mode), it can be continued after cleaning the nozzle or replacing it.

Plastic Presence Detection

Detects the end or breakage of plastic when printing. The print result is saved and can be continued after replacing the filament spool.

Print Surface Inspection

Detects part slip or surface artifacts that could damage the part (or the printer itself). The printer goes into "Pause" mode, saving time and material.

Heatsink temperature control

The maximum heatsink temperature is set in the profile of each plastic. If the sensor detects that the temperature is too high, the printer pauses, turns off the heating elements, and waits for the print head to cool down to operating temperature. This helps protect the printer from clogged nozzles and overheating.

Built-in plastic dryer

Printing can now be resumed even if there is a power outage. The printer will “remember” where printing stopped and will offer to resume it from the current moment. The only thing that is required of you is to make sure that during the downtime the part has not come unstuck from the printing platform.

The only thing that is required of you is to make sure that during the downtime the part has not come unstuck from the printing platform.

Profile system

This system allows you to prepare a print job without reference to a specific material. ABS, PLA, Ultran or any other thermoplastic - the material is selected on the printer screen right before printing.

Alert system

Visual alert (with different backlight colors) for printer problems. A transparent understanding of the state of the device allows you to respond in a timely manner in case of any difficulties. Time is money.

First Layer Print Control

Automatic adjustment of the first layer print pressure based on the media.

Networking

Ability to manage all printers simultaneously from one computer over a network. Combining all X-line printers into one ecosystem.

Self-diagnosis

The printer performs self-diagnostics and detects possible problems.

Quality in detail

The quality of Designer X printing is our pride. Precision mechanics and X hardware platform help to achieve the highest results.

Precision mechanics and X hardware platform help to achieve the highest results.

The minimum print layer is 10 microns. It is 10 times thinner than a human hair.

1

Double-ended plastic feeder

Double-sided plastic feeder ensures maximum retention of the plastic in the feed gears. This reduces the chance of the gears breaking off the plastic in the event of a sharp increase in the thread pulling force.

2

Flow Control encoder sensor system

Consistent quality printing - synergy of various factors. Encoder system Flow Control - a set of executable algorithms and hardware solutions for detecting and correcting problems during the printing process

3

Plastic feed guide

This assembly ensures the stability of the printer with flexible materials

4

Heat sink temperature sensor

Heatsink temperature sensor allows to control and prevent overheating of the printhead in advance

5

Plastic preload system

If necessary, allows you to adjust the plastic pressure system force in case of using very specific materials

6

take advantage of the capabilities of a single nozzle printer and print without support for parts with overhangs

6

Dual part blower system

Allows you to get the most out of a single nozzle printer and print without support for parts with overhangs

7

Multiple nozzle options

In addition to standard nozzles (0. 3 mm), Designer X0.2 can print with nozzles , 0.5 and 0.8 mm, as well as steel (for carbon-filled composites). For different tasks - different nozzles

3 mm), Designer X0.2 can print with nozzles , 0.5 and 0.8 mm, as well as steel (for carbon-filled composites). For different tasks - different nozzles

Do you think you can print with any materials? And there is!

A new directional plastic feed system in the print head and a wide operating temperature range of mechanical components - that's what allows Designer X to work with a wide range of materials.

Print with any filament, including high melting engineering thermoplastics.

Another distinctive feature of the X platform is the Profile System. You no longer need to prepare a job for each plastic: the material is selected when printing is started on the printer.

Would you like to change temperature, cooling or other filament related parameters? No problem - you can do it both through Polygon X and on the 3D printer itself.

Printing with any materials is easy!

ESUN

PICASO 3D

REC

Filamentarno

Air flow control

The correct distribution of air flows is ensured by a system of two powerful and silent fans. They create the necessary microclimate for each specific material, which allows printing complex-shaped parts with high quality and stability.

They create the necessary microclimate for each specific material, which allows printing complex-shaped parts with high quality and stability.

PICASO 3D Ecosystem

Built-in networking features allow you to connect any number of your X-Line printers in a single interface to the updated POLYGON X.

Now you can easily manage the operation of each network printer from one PC.

Connection interfaces

Ethernet

Easy to manage with Polygon X

The new Polygon X will be equally convenient for both beginners and more advanced users. The ability to generate executable code in a few clicks is available in the quick mode, and for those who like experiments and their own settings, an advanced task preparation mode is available.

Create the history of the industry with Designer X

Industry

Aviation Building

Instrumentation

Robotics

Jewelry

Architecture, Design

Business

Medicine

9000Data sheet

Printing

Printing Technology

Fused Filament Fabrication [FFF]

Press area

201 x 210 mm 210 mm

Press speed

to 100 cm 3 /h

Minimum layer thickness

10 micron

Plastic thread diameter

1. 75 ± 0.1 mm mm mm mm mm

75 ± 0.1 mm mm mm mm mm

Nozzle diameter

0.3 mm / (0.2-0.8 mm)

Media location

Inside the printer body

Maximum print temperature

410 °C

Maximum table temperature

150 ° C

System

Main systems

Plastic supply control

Monitoring the presence of plastic

Monitoring the first layer

Built -in system

Printer Auto Diagnostics

Mechanics

Outer Case

Aluminum [Composite]

Frame

Steel

Print platform

aluminum, glass

Directors (ShVP)

steel

Physical characteristics / 15.6 kg

Electricity

Mains operation

220V±15% 50Hz

(option 110V±15% 60Hz)

Maximum input power

400W

Interfaces

USB [USB Flash included], Ethernet

Media

ABS, PLA, HIPS, PVA, ULTRAN 630, ULTRAN 6130, ASA, ABS/PC, PET, PC, FRICTION, CAST, RELAX, ETERNAL, FLEX, RUBBER, SEALANT, PETG, AEROTEX, CERAMO, WAX, SBS, SBS PRO, PROTOTYPER SOFT, PRO-FLEX, TOTAL PRO, NYLON, PEEK and others

Software

Software

PICASO 3D Polygon X ™

File types

*.