How to work with 3d printer

9 Great 3D Printing Jobs

- 3D printing is a technology that creates a three-dimensional object using a computer-aided design (CAD).

- The 3D printing industry is rapidly growing thanks to its ability to create a wide range of versatile products in a fast, cost-effective way.

- For job seekers, the 3D printing industry offers some cool jobs on the cutting edge of the technology.

- This article is for professionals and entrepreneurs who want to work in the 3D printing industry.

President Barack Obama once said 3D printing has the “potential to revolutionize the way we make almost everything.” For that reason, the 3D printing industry was valued at $13.78 billion in 2020. And market research projections suggest it will continue its meteoric growth through 2028 – when it is expected to reach an estimated $59.65 billion.

As the 3D printing industry booms, what does it mean for job seekers? Here are 9 opportunities that will be created or get a boost from 3D printing.

What is 3D printing?

Rather than using ink and paper, a 3D printer uses materials like plastic, metal or ceramic to create a 3D model. By using computer-aided design (CAD) files as digital instructions to create an object, a 3D printer repeatedly covers a work surface with layers of material in precisely the right spots to create a structure from scratch.

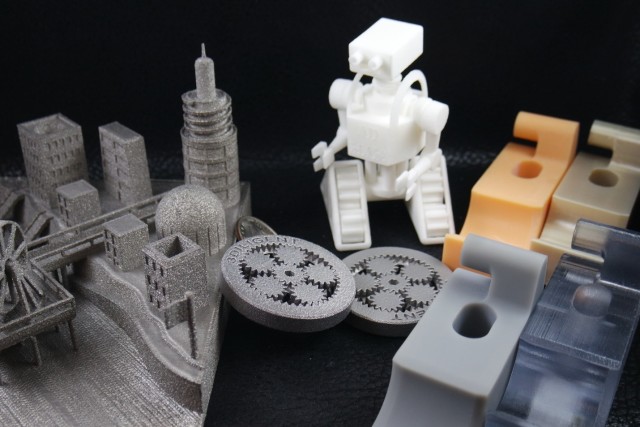

While 3D printing can be used for large-scale structures, 3D printing is most useful in creating smaller, customized parts or prototype components for various uses – including automotive engineering or the medical industry. With the versatility of 3D printing, it’s a field that’s filled with opportunities. Let’s take a look at some of the areas 3D printing is being used today.

3D printing jobs

1. 3D design

3D printing relies heavily on designers who can take a product idea and bring it to life. Thanks to its growth, 3D printing will create jobs for 3D designers at 3D printing firms, in companies as part of creative teams and as freelancers.

3D printers are being used in many design disciplines – such as product design, medical device design, architectural visualization and entertainment design, said Erol Gunduz, a professor at New York University’s School of Continuing and Professional Studies (NYU-SCPS), which offers programs in 3D printing, design and modeling.

To be competitive, job seekers should gain hands-on experience in 3D technologies and stay current on how companies are using 3D printing. For instance, recent graduate student designers and researchers who are familiar with 3D printing methods have the benefit of knowing how to use the technology within their design process, Gunduz explains.

“This gives them a significant advantage when looking for career opportunities within creative fields,” Gunduz said.

Did you know? 3D printers can create replacement parts for the human body, among the many things that 3D printers make.

2. 3D CAD modeling

3D printing would not be possible without CAD experts who have the skills to convert product designs into digital blueprints that the printers need. Along with product designers, there will be a demand for 3D CAD modelers.

Along with product designers, there will be a demand for 3D CAD modelers.

“I see a lot more demand for CAD and 3D modeling jobs on the horizon because of 3D printing,” said Alex English, owner of ProtoParadigm. ProtoParadigm is a 3D printing business that also performs research and development on 3D printing hardware and new printing materials.

Although 3D CAD professionals are also needed to construct models for mass 3D printing, they are especially important for custom products.

“Bespoke manufacturing and custom prototyping both rely on the user’s ability to conceptualize the object they want and accurately create its digital representation,” English said.

Consequently, 3D CAD modeling jobs will require printing-specific modeling skills, such as feature size, geometrical constraints and knowledge of materials, English added.

3. Research and development

3D printing is all the buzz – and not just in the gadget world. Just as the 3D printing industry will require more product designers and CAD modelers, jobs will open up for forward-thinking research and development professionals who understand the intersection of tech and consumer products.

“While 3D visualization technologies have been used in the past within various fields, such as engineering and scientific agendas, many artistic and consumer product industries – such as fashion design and jewelry design – are beginning to take advantage of 3D printing systems,” Gunduz said.

Companies will need people who can find the best way to utilize 3D printing for consumer products at the lowest cost possible.

“The ability to visualize a line of fashion accessories or jewelry designs before committing to working with expensive materials affords an advantage for companies to reduce costs in development cycles,” Gunduz said.

Tip: Is your business experimenting with 3D printing research and development? Consider these tax credits that are available to companies performing cutting-edge research.

4. Biological and scientific modeling

3D printing is not limited to consumer products; it creates many products that promote medical advancement and save lives. It can also create drone and defense equipment, and possibly even space food.

It can also create drone and defense equipment, and possibly even space food.

Accordingly, the 3D printing industry will need more engineers, designers and modelers who have a biomedical or scientific background to further innovate and produce highly advanced 3D-printed products.

“While all manner of designers will be able to print the things they design, there will be a high end to the market – particularly in medical, aerospace, military, and other high-precision or mission-critical applications – for those that better understand the printing technologies and how to design for their strengths and limitations,” English said.

5. Architecture and construction modeling

3D printing will disrupt various industries, particularly those that rely heavily on blueprinting or prototyping. For the construction industry, this paradigm shift will boost the need for 3D modelers that may replace current 2D construction planning solutions.

“In the architecture, engineering and construction industries, 3D printing will redefine the production of construction documents,” said Lira Luis, chief collaboration architect at Atelier Lira Luis LLC, a Chicago-based architecture and design firm.

Instead of 2D CAD modeling on paper, 3D printing can produce true-to-life models to better represent what structures will look like.

“As the 3D printing process becomes more streamlined, it could potentially eliminate the need for construction documents and move directly to printing full-scale mock-ups prior to construction of structures,” Luis said.

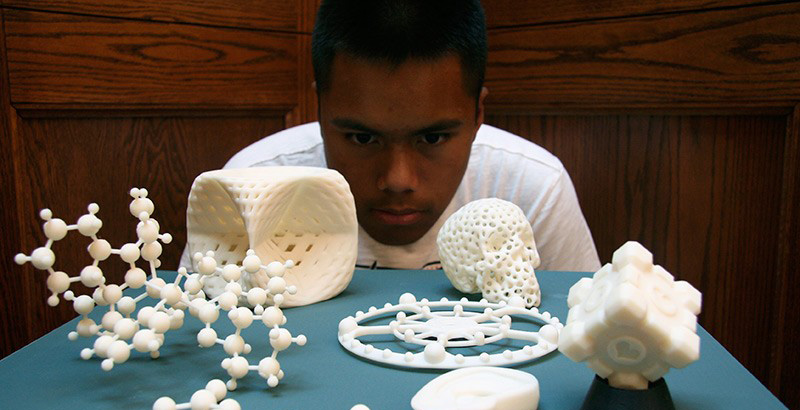

6. Education

What good are these jobs if no one has the qualifications to fill them? To help fill the skills gap, schools are developing – and some have already launched – 3D printing programs at all grade levels. This will open up jobs for educators who can teach the technical and business aspects of 3D printing.

“From an educational perspective, many K-12 schools are looking to 3D printing as a point of exposure for students within the arts as well as scientific areas of study,” Gunduz said. Colleges and universities are also launching 3D printing courses and certificate programs, such as NYU-SCPS’ certificate in 3D printing rapid prototyping.

Teachers will need to have a background in the 3D printing industry. They will also need specific skill sets to teach specialized courses and stay current on the latest trends.

“For educators, having an understanding of 3D modeling and 3D printing techniques will be invaluable, as the culture of fab labs is starting to gain support as an important aspect of education,” Gunduz said. “Teachers with 3D modeling and fabrication experience have a range of opportunities open to them within educational programs looking to incorporate this new technology.”

7. Legal professionals

3D printing is not confined to the tech world. As a creative field, the industry is wide open to legal issues, prompting a need for more lawyers and legal professionals who specialize in intellectual property (IP) rights.

“As 3D printing technologies advance and become more widely accessible, it will be easier for infringers to create, market, and sell products that infringe patents, copyrights, and valuable brands,” said Julie Matthews, partner at Edwards Wildman – an Am Law 100 firm with offices in the U. S., the U.K. and Asia. “As 3D printing technologies advance, new business models will emerge in which consumer products and their component parts can be copied, modified, juxtaposed with others and produced almost anywhere.”

S., the U.K. and Asia. “As 3D printing technologies advance, new business models will emerge in which consumer products and their component parts can be copied, modified, juxtaposed with others and produced almost anywhere.”

As a result, there will be an increased need for IP enforcement actions and lawsuits, as well as expanded services to monitor for infringements, Matthews explained.

Growth areas include IP ownership, scope of rights, licensing, fair use and international rights.

8. Startup companies

Thinking of starting a new business? 3D printing offers opportunities for innovation – not only in creating products, but also for entrepreneurship. 3D printing spans across various technical and design roles, many of which make great business ideas to support companies’ 3D printing needs.

“As 3D printing technologies advance and become readily accessible to home users, undoubtedly, this will lead to new business opportunities for individuals and companies offering onsite and remote 3D printing services, new product and industrial designers, and computer-aided design specialists,” Matthews said.

With 3D printing costing between $1,999 and $3,500, anyone with 3D printing knowledge can start their business.

Tip: Consider a 3D-printing-as-a-service franchise for your new business venture.

9. Administrative roles

3D printing companies don’t run on engineers and technicians alone. As the industry grows, new and established 3D printing companies will need employees to keep their business running smoothly. This includes operations and administrative staff, analysts, finance and sales professionals, and retail employees.

“The businesses that will spring up with new business models centered on 3D printing will also have a need for more common jobs that other businesses need, like marketing, clerical, shipping, etc.,” English said.

These jobs will open up in all types of 3D printing companies, including vendors, manufacturers and retail stores.

Business News Daily editorial staff contributed to the writing and reporting in this article. Source interviews were conducted for a previous version of this article.

Source interviews were conducted for a previous version of this article.

3D Printing: What It Is, How It Works and Examples

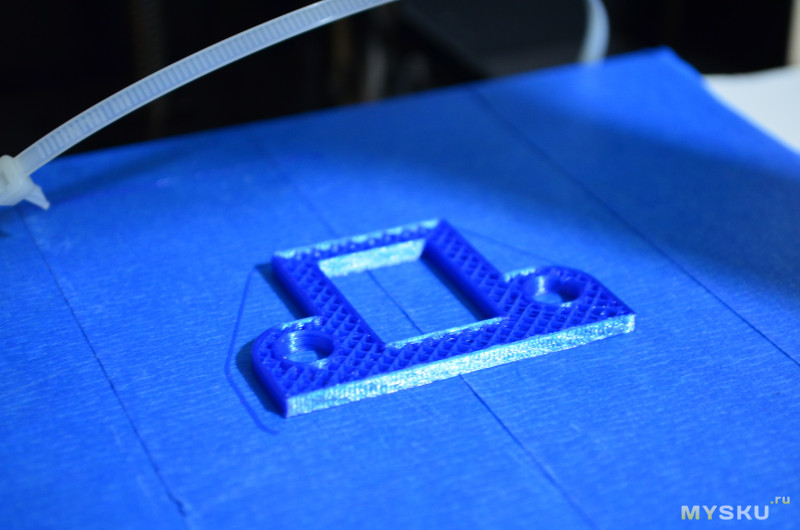

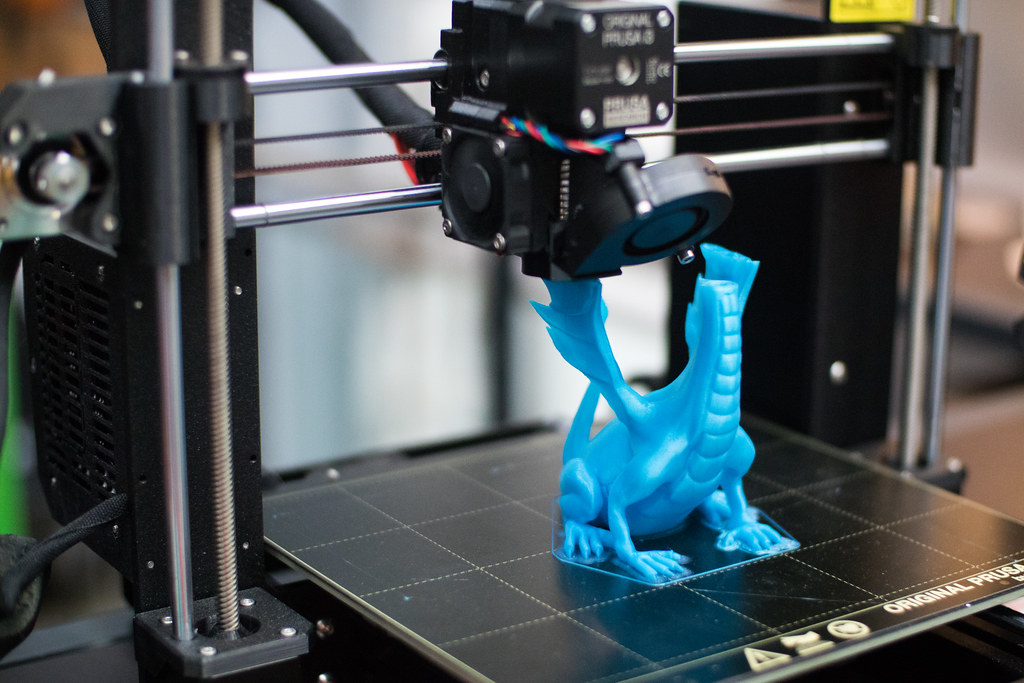

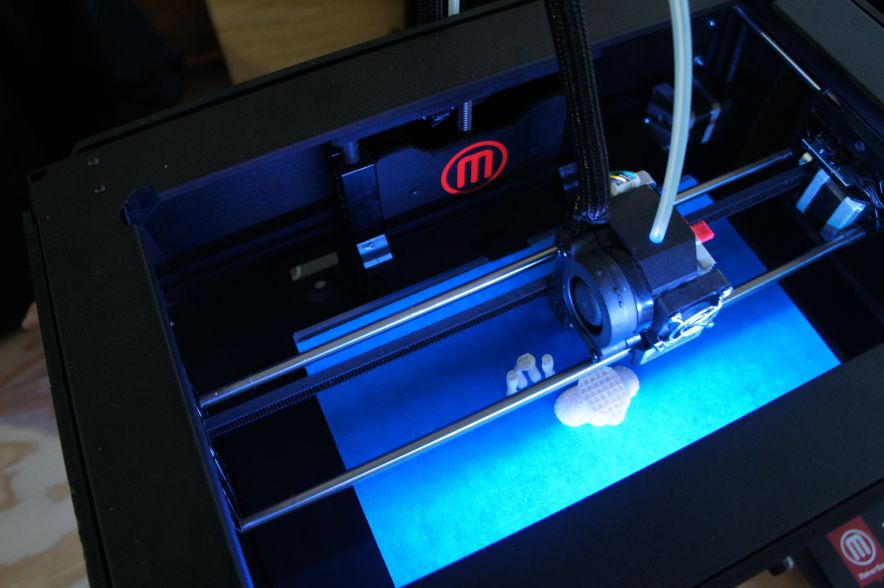

3D printers might seem like they're right out of a science fiction movie, but they're proving to be useful in a variety of industries. | Image: ShutterstockHow Do 3D Printers Work?

3D printing is part of the additive manufacturing family and uses similar methods to a traditional inkjet printer — albeit in 3D. Additive manufacturing describes the process of creating something in layers, adding material continuously until the final design is complete. This term most often refers to molding and 3D printing.

It takes a combination of top-of-the-line software, powder-like materials and precision tools to create a three-dimensional object from scratch. Below are a few of the main steps 3D printers take to bring ideas to life.

How Does a 3D Printer Work?

3D printers are related to additive manufacturing. 3D printers use computer-aided design to understand a design. When a design is ready, a material that can be dispensed through a hot nozzle or precision tool is printed layer by layer to create a three-dimensional object from scratch.

When a design is ready, a material that can be dispensed through a hot nozzle or precision tool is printed layer by layer to create a three-dimensional object from scratch.

3D Modeling Software

The first step of any 3D printing process is 3D modeling. To maximize precision — and because 3D printers can’t magically guess what you want to print — all objects have to be designed in a 3D modeling software. Some designs are too intricate and detailed for traditional manufacturing methods. That’s where CAD software comes in.

Modeling allows printers to customize their product down to the tiniest detail. The 3D modeling software’s ability to allow for precision designs is why 3D printing is being hailed as a true game changer in many industries. This modeling software is especially important to an industry, like dentistry, where labs are using 3D software to design teeth aligners that precisely fit to the individual. It’s also vital to the space industry, where they use the software to design some of the most intricate parts of a rocketship.

3D PRINTERS USE MODELING AND SLICING SOFTWARE TO GUIDE THE PRINTER IN CREATING EACH OBJECT. Video: Digital Trends

Slicing the Model

Once a model is created, it’s time to “slice” it. Since 3D printers cannot conceptualize the concept of three dimensions, like humans, engineers need to slice the model into layers in order for the printer to create the final product.

Slicing software takes scans of each layer of a model and will tell the printer how to move in order to recreate that layer. Slicers also tell 3D printers where to “fill” a model. This fill gives a 3D printed object internal lattices and columns that help shape and strengthen the object. Once the model is sliced, it’s sent off to the 3D printer for the actual printing process.

The 3D Printing Process

When the modeling and slicing of a 3D object is completed, it’s time for the 3D printer to finally take over. The printer acts generally the same as a traditional inkjet printer in the direct 3D printing process, where a nozzle moves back and forth while dispensing a wax or plastic-like polymer layer-by-layer, waiting for that layer to dry, then adding the next level. It essentially adds hundreds or thousands of 2D prints on top of one another to make a three-dimensional object.

The printer acts generally the same as a traditional inkjet printer in the direct 3D printing process, where a nozzle moves back and forth while dispensing a wax or plastic-like polymer layer-by-layer, waiting for that layer to dry, then adding the next level. It essentially adds hundreds or thousands of 2D prints on top of one another to make a three-dimensional object.

3D Printing Materials

There are a variety of different materials that a printer uses in order to recreate an object to the best of its abilities. Here are some examples:

Acrylonitrile Butadiene Styrene (ABS)

Plastic material that is easy to shape and tough to break. The same material that LEGOs are made out of.

Carbon Fiber Filaments

Carbon fiber is used to create objects that need to be strong, but also extremely lightweight.

Conductive Filaments

These printable materials are still in the experimental stage and can be used for printing electric circuits without the need for wires. This is a useful material for wearable technology.

This is a useful material for wearable technology.

Flexible Filaments

Flexible filaments produce prints that are bendable, yet tough. These materials can be used to print anything from wristwatches to phone covers.

Metal Filament

Metal filaments are made of finely ground metals and polymer glue. They can come in steel, brass, bronze and copper in order to get the true look and feel of a metal object.

Wood Filament

These filaments contain finely ground wood powder mixed with polymer glue. These are obviously used to print wooden-looking objects and can look like a lighter or darker wood depending on the temperature of the printer.

The 3D printing process takes anywhere from a few hours for really simple prints, like a box or a ball, to days or weeks for much larger detailed projects, like a full-sized home.

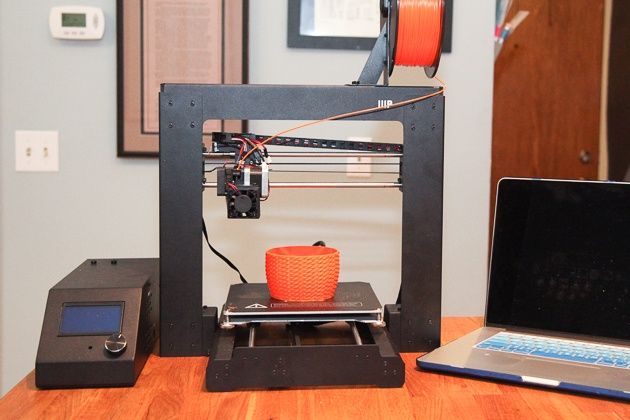

How Much Do 3D Printers Cost?

The cost of 3D printers vary based on the size, specialty and use. The cheapest 3D printers, for entry level hobbyists, typically range from $100 to $500. More advanced models can range between $300 and $5,000. Industrial 3D printers can cost up to $100,000.

More advanced models can range between $300 and $5,000. Industrial 3D printers can cost up to $100,000.

3D Printing Processes and Techniques

here are also different types of 3D printers depending on the size, detail and scope of a project. Each different type of printer will vary slightly on how an object gets printed.

Fused Deposition Modeling (FDM)

FDM is probably the most widely used form of 3D printing. It’s incredibly useful for manufacturing prototypes and models with plastic.

Stereolithography (SLA) Technology

SLA is a fast prototyping printing type that is best suited for printing in intricate detail. The printer uses an ultraviolet laser to craft the objects within hours.

Digital Light Processing (DLP)

DLP is one of the oldest forms of 3D printing. DLP uses lamps to produce prints at higher speeds than SLA printing because the layers dry in seconds.

Continuous Liquid Interface Production (CLIP)

CLIP is amongst the faster processes that use Vat Photopolymerisation. The CLIP process utilizes Digital Light Synthesis technology to project a sequence of UV images across a cross-section of a 3D printed part, resulting in a precisely controlled curing process. The part is then baked in a thermal bath or oven, causing several chemical reactions that allow the part to harden.

The CLIP process utilizes Digital Light Synthesis technology to project a sequence of UV images across a cross-section of a 3D printed part, resulting in a precisely controlled curing process. The part is then baked in a thermal bath or oven, causing several chemical reactions that allow the part to harden.

Material Jetting

Material Jetting applies droplets of material through a small diameter nozzle layer-by-layer to build a platform, which becomes hardened by UV light.

Binder Jetting

Binder Jetting utilizes a powder base material layered evenly along with a liquid binder, which is applied through jet nozzles to act as an adhesive for the powder particles.

Fused Deposition Modeling (FDM)

FDM, also known as Fused Filament Fabrication (FFF), works by unwinding a plastic filament from a spool and flowing through a heated nozzle in horizontal and vertical directions, forming the object immediately as the melted material hardens.

Selective Laser Sintering (SLS)

A form of Powder Bed Fusion, SLS fuses small particles of powder together by use of a high-power laser to create a three-dimensional shape. The laser scans each layer on a powder bed and selectively fuses them, then lowering the powder bed by one thickness and repeating the process through completion.

The laser scans each layer on a powder bed and selectively fuses them, then lowering the powder bed by one thickness and repeating the process through completion.

Multi-Jet Fusion (MJF)

Another form of Powder Bed Fusion, MJF uses a sweeping arm to deposit powder and an inkjet-equipped arm to apply binder selectively on top. Next, a detailing agent is applied around the detailing agent for precision. Finally, thermal energy is applied to cause a chemical reaction. Direct Metal Laser Sintering (DMLS) also utilizes this same process but with metal powder specifically.

Sheet Lamination

Sheet Lamination binds material in sheets through external force and welds them together through layered ultrasonic welding. The sheets are then milled in a CNC machine to form the object’s shape.

Directed Energy Deposition

Directed Energy Deposition is common in the metal industry and operates by a 3D printing apparatus attached to a multi-axis robotic arm with a nozzle for applying metal powder. The powder is applied to a surface and energy source, which then melts the material to form a solid object.

The powder is applied to a surface and energy source, which then melts the material to form a solid object.

instruction how to work from scratch for beginners and dummies, how

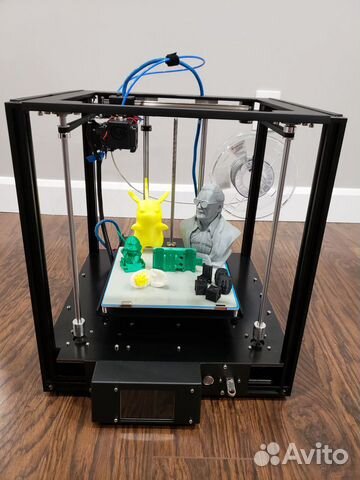

looks likeThree-dimensional printing has become increasingly introduced into our daily lives. Thanks to new technologies, it has become possible to easily print from a small detail to a large building. The range of products is also pleasing - today you can find a lineup that includes both affordable devices and more expensive ones. But how to work with a 3D printer? This is a completely normal question that any beginner will have, it is for this reason that we will try to answer it as simply and accessible as possible. nine0003

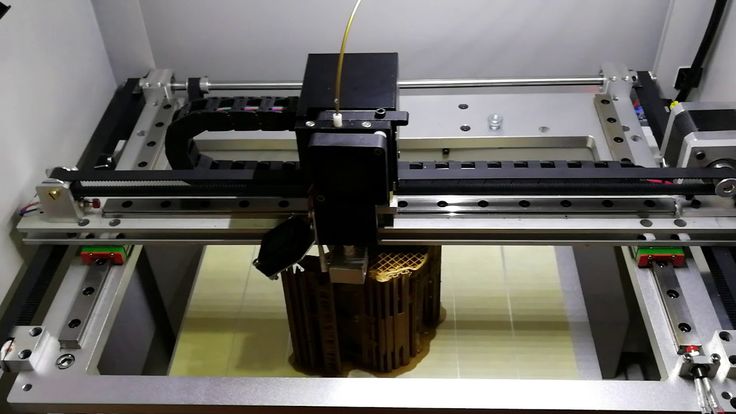

What is a 3D printer and how does it work?

The 3D device consists of the printer itself and a computer that controls all processes. The principle of operation of such a design is to create 3D models by superimposing layers of liquid material. There are a large number of printer models - from large industrial ones to compact ones, but they all have the same principle of operation and component parts:

- Extruder - the print head through which the thread passes.

The head heats the thread to a semi-liquid state and evenly supplies the material to the working surface. nine0010

The head heats the thread to a semi-liquid state and evenly supplies the material to the working surface. nine0010 - Work surface - a printing platform on which a 3D model is formed.

- Motors - mechanisms responsible for the accuracy of movement and speed of printing.

- Sensors are electronic devices that limit moving parts to specified coordinates.

- The frame is the structure that connects all parts of the printer.

How a 3D printer works: features

Work with the aim of building a three-dimensional model begins with a sketch, which is created in a special program. After that, the software independently generates a plan for the movement of the print head and a print sequence. The 3D model is reproduced by strongly heating the plastic and distributing it evenly. nine0003

3D printers are used in many areas. Let's list some of them:

- Architecture - creation of models of buildings.

- Medicine - dental prosthetics, making models of organs for study.

- Construction - production of houses using 3D printing technology.

- Education - a visual aid for learning 3D printing.

- Automotive - creation of tuning parts, prototype layouts and other products.

This is a small list of industries where 3D printing is actively used. Today, almost every entrepreneur and just an enthusiastic person can afford a printer. nine0003

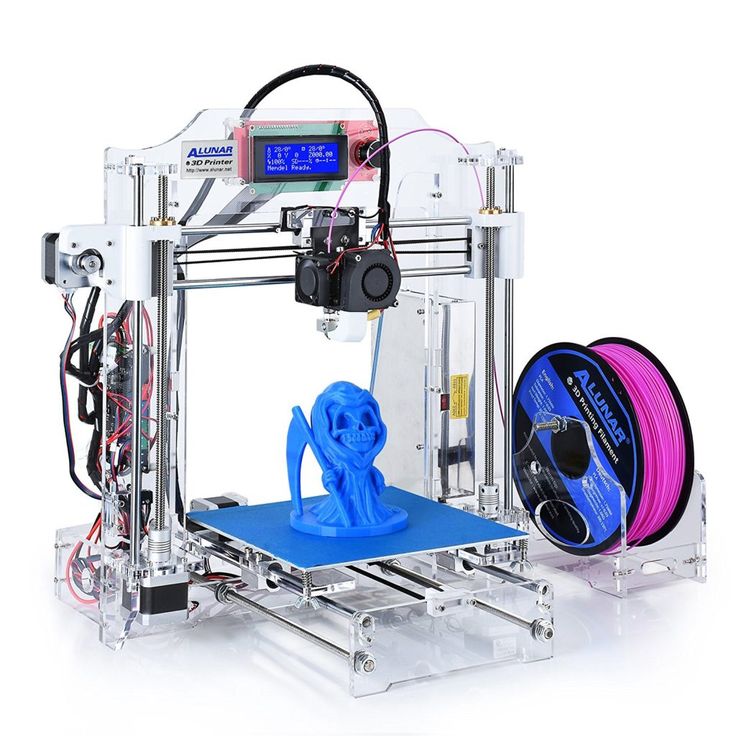

The following printers are distinguished by design features:

- RepRap - self-reproducing printers that can create their own copies.

- DIY-kit - the device comes disassembled with instructions, the assembly of which will take a sufficient amount of time.

- Completed - Models are delivered assembled and ready to use.

- Commercial and Industrial - devices capable of printing metal, concrete, polymers and other materials. nine0010

How to use a 3D printer: tips for beginners, where to start

Mastering the technique of 3D printing is not difficult if you follow the recommendations and tips. Especially for those who plan to learn the basics of 3D modeling, an up-to-date list of questions and detailed answers to them has been prepared.

Especially for those who plan to learn the basics of 3D modeling, an up-to-date list of questions and detailed answers to them has been prepared.

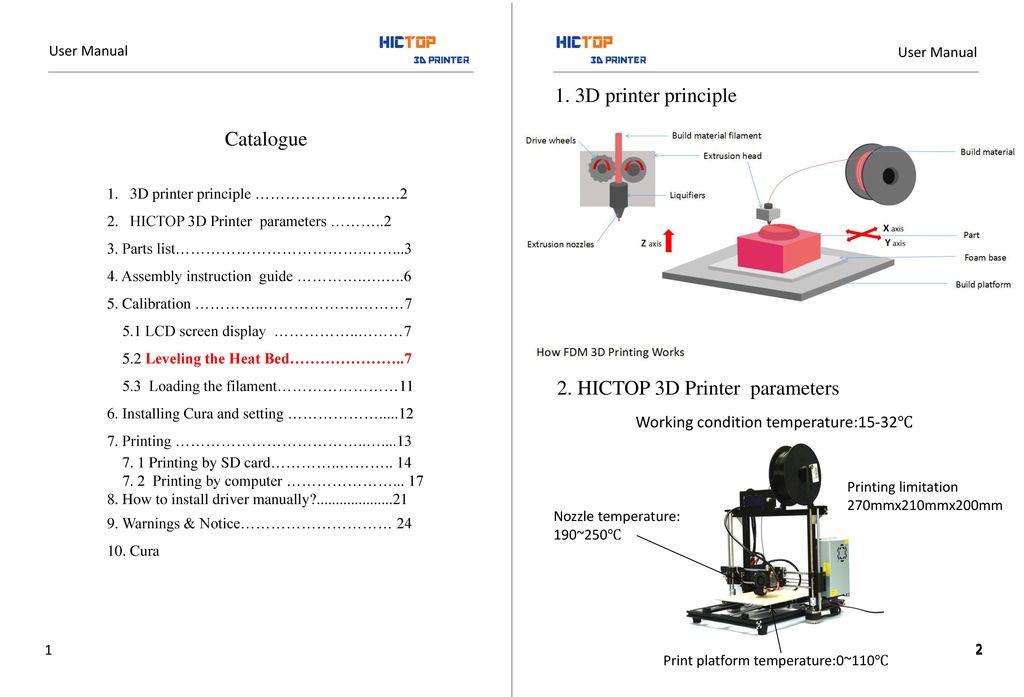

Printer Installation

To begin, you will need to carefully unpack the box and remove any stops. The next step is to install the printer on the surface using the building level. This will allow you to place the device as evenly as possible, which will provide better printing. nine0003

Note. Some 3D printers come with a level for installation.

Next, you will need to connect the printer to your computer and install the necessary drivers. The software disc comes with the 3D device.

Preparation for work

To get started, you need to calibrate the working surface - without this, printing quality products is impossible. This process is carried out automatically or manually. The attached instructions have detailed information on how to perform manual calibration. nine0003

Extruder patency test

The next important step is setting up the extruder. First of all, you will need to check its nozzle. If the printer has already been used, the nozzle should be cleaned of solidified particles that will interfere with the throughput of the material. Refueling the 3D printer The thread is fed into the extruder directly from the spool. But there is one caveat - for this you must first warm it up. To thread the thread, you will have to make a small effort in order to loosen the presser mechanism. nine0003

First of all, you will need to check its nozzle. If the printer has already been used, the nozzle should be cleaned of solidified particles that will interfere with the throughput of the material. Refueling the 3D printer The thread is fed into the extruder directly from the spool. But there is one caveat - for this you must first warm it up. To thread the thread, you will have to make a small effort in order to loosen the presser mechanism. nine0003

Working with models

Models can be created using a variety of 3D modeling programs. The process of manufacturing three-dimensional parts is creative, requiring careful preparation. The better and more detailed the model is drawn, the better the 3D layout will be at the output.

Start printing

After creating the model in the program and preparing the printer for work, you need to send the file for printing and wait for the result. The print speed varies depending on the printer model and specifications, as well as the media used. nine0003

nine0003

Processing the finished product

3D printed products usually do not please the user with an ideal appearance: the parts have an uneven surface. But this is typical for models of 3D printers on FDM, SLA and DLP devices, which are distinguished by higher print quality. Owners of FDM printers should not despair - a simple processing of products will give products an attractive appearance and make the surface smooth.

Several powerful ways to post-process 3D printed parts:

- Mechanical - carried out by sanding the surface with sandpaper or a special sponge for grinding.

- Chemical - Surface treatment with aggressive solvents such as acetone and dichloroethane.

- Mixed - In this case, the above two processing methods are used.

What are the possible errors and how to avoid them?

Even a novice can master the technology of 3D printing, but, despite this, the production of the first products causes excitement for the user. Simple operation, detailed instructions and recommendations on the Internet will allow everyone to deal with almost any printer model. But there are a few useful life hacks, the knowledge of which will help you avoid typical beginner mistakes:

Simple operation, detailed instructions and recommendations on the Internet will allow everyone to deal with almost any printer model. But there are a few useful life hacks, the knowledge of which will help you avoid typical beginner mistakes:

- Calibrate and test the 3D printer before starting work.

- Be sure to use the correct file extension for quality printing.

- Do not remove the finished product from the printer immediately after it has been processed: this may damage the part and cause defects.

- If errors occur during the 3D printing process, try restarting the device - this usually helps.

- If restarting the printer still does not help, try changing the settings or re-entering the model. nine0010

- When assembling the 3D printing devices, follow the enclosed instructions carefully.

- Use only the correct materials for your 3D printer.

- Subscribe to useful 3D printing channels and articles.

Following the above tips will allow you to set up your 3D printer, get it ready for operation and, most importantly, print your first 3D products. Choose a model according to your budget and capabilities, and it will not be difficult to master the basics of 3D modeling and get the first details if you follow the instructions and recommendations. nine0003

Choose a model according to your budget and capabilities, and it will not be difficult to master the basics of 3D modeling and get the first details if you follow the instructions and recommendations. nine0003

- March 21, 2021

- 8662

Get expert advice

How a 3D printer works, what can be printed on a 3D printer

The 3D printer is a technology that allows you to create real objects from a digital model. It all started in the 80s under the name "rapid prototyping", which was the goal of the technology: to create a prototype faster and cheaper. A lot has changed since then, and today 3D printers allow you to create anything you can imagine. nine0003

Contents:

- What is 3D printing?

- How does a 3D printer work?

- What can be printed?

The 3D printer allows you to create objects that are almost identical to their virtual models. That is why the scope of these technologies is so wide.

That is why the scope of these technologies is so wide.

What is 3D printing?

3D printing is an additive manufacturing process because, unlike traditional subtractive manufacturing, 3D printing does not remove material, but adds it, layer by layer - that is, it builds or grows. nine0003

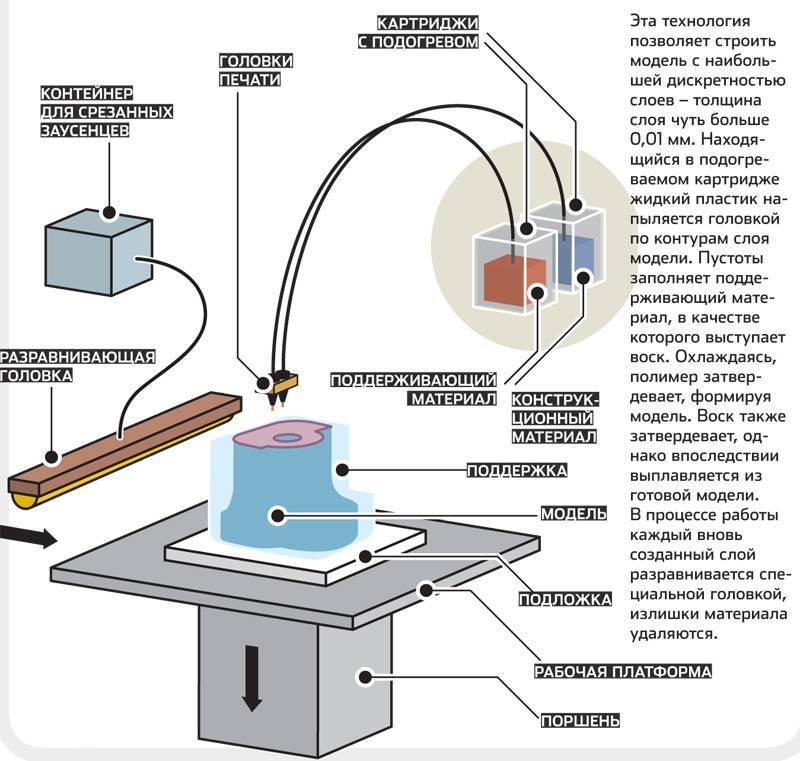

- In the first step of printing, the data from the drawing or 3D model is read by the printer.

- Next is the sequential overlay of layers.

- These layers, consisting of sheet material, liquid or powder, are combined with each other, turning into the final form.

With a limited number of parts, 3D printing will be faster and cheaper. The world of 3D printing does not stand still and therefore there are more and more different technologies competing with each other on the market. The difference lies in the printing process itself. Some technologies create layers by softening or melting the material, then they provide layer-by-layer application of this same material. Other technologies involve the use of liquid materials, which acquire a solid form in the process under the influence of various factors. nine0003

Other technologies involve the use of liquid materials, which acquire a solid form in the process under the influence of various factors. nine0003

In order to print something , you first need a 3D model of the object, which you can create in a 3D modeling program (CAD - Computer Aided Design), or use a 3D scanner to scan the object you want print. There are also easier options, such as looking for models on the internet that have been created and made available to other people.

Once your design is ready, all you need to do is import it into the Slicer, a program that adapts the model into codes and instructions for a 3D printer, most of the programs are open source and free. The slicer will convert your project into a gcode file ready to be printed as a physical object. Simply save the file to the included SD card and insert it into your 3D printer and hit print. nine0003

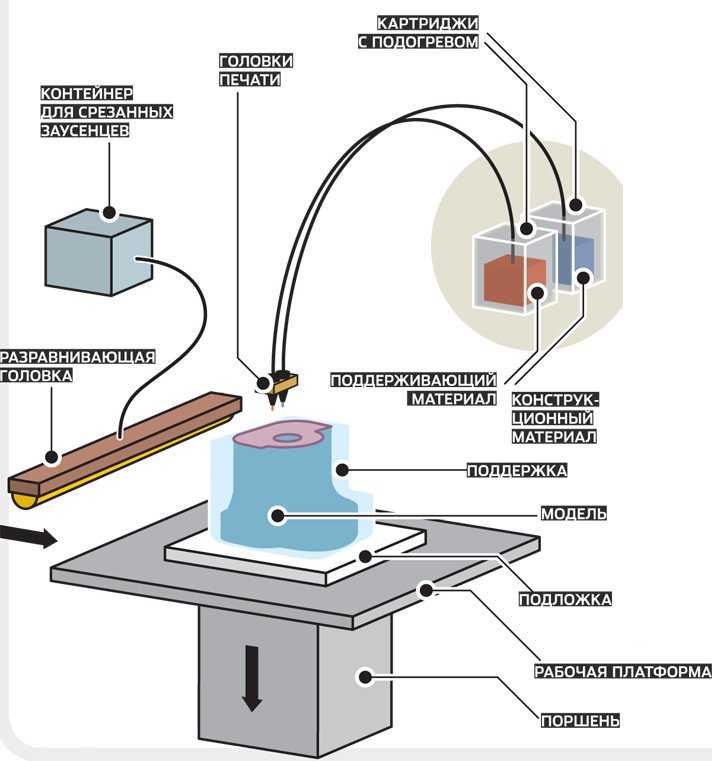

The whole process can take several hours and sometimes several days. It all depends on the size, material and complexity of the model. Some 3D printers use two different materials. One of them is part of the model itself, the other acts as a prop that supports parts of the model hanging in the air. The second material is subsequently removed.

It all depends on the size, material and complexity of the model. Some 3D printers use two different materials. One of them is part of the model itself, the other acts as a prop that supports parts of the model hanging in the air. The second material is subsequently removed.

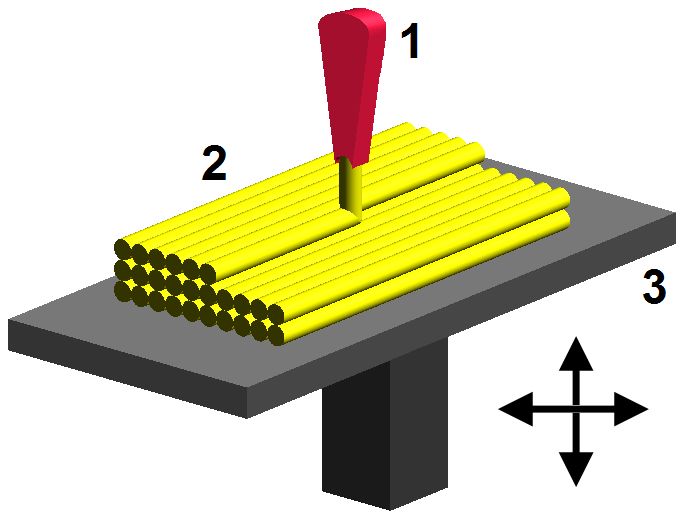

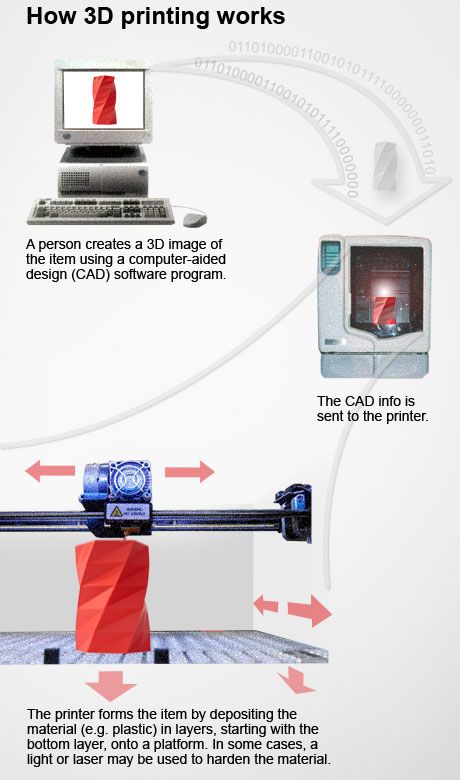

How does a 3D printer work?

Although there are several 3D printing technologies, most create an object by building up many successive thin layers of material. Typically desktop 3D printers use plastic filaments (1) which are fed into the printer by the feeder (2) . The filament melts into the print head (3) which extrudes the material onto the platform (4) creating the object layer by layer. Once the printer starts printing, all you have to do is wait - it's easy.

Of course, when you become an advanced user, playing with the settings and tweaking your printer can lead to even better results.

What can be 3D printed? nine0005

The possibilities of 3D printers are endless and they are now becoming a common tool in fields such as engineering, industrial design, manufacturing and architecture.