Sindoh 3dwox 2x 3d printer

3DWOX 2X | Sindoh 3D Printer

3DWOX

2X

Together, We Build Better

DRIVER & UTILS SUPPLIES WHERE TO BUY

- BUILD UP TOGETHER

- 2X’s two nozzles work interdependently,

achieving the highest efficiency possible.

The nozzles accompany each other, creating multicolor,

multi-material models.

- Print Bed Revolution

- Combinations of technologies give birth to brilliant innovations.

Starting from the DP200’s heating bed to DP201’s Flexible Bed,

we have now redefined the standards of the print bed,

bringing both advantages together.

- MATERIALS EXPANSION

- 3D printing is a reality and is getting closer to becoming a

practical tool in everyday life. To satisfy this demand,

our goal is to offer as many material options for our customers.

Now with 3DWOX 2X, you can print PLA, ABS, Flexible

and PVA filaments and a whole lot more is coming your way.

- Voice Guidance

- 2X is ready to help you throughout your printing.

Should there be any errors occurring, 2X will guide users

through trouble-shooting methods. Just listen to what

2X has to say. You will know what to do.

- Printing Silence

- 2X is powerful and robust yet,

the most silent 3D printer you’ve ever heard of.

With its library noise level of 40 dB(A),

you can now enjoy all kind of things, such as

getting other works done, eating an ice cream or simply

going to sleep without being disturbed.

Let 2X bring peace in mind with silence.

- Healthy Printing

- 3D Printers use various materials that can create

dusts during printing and we came up with a dust-safe answer.

2X’s High Efficiency Particulate Air filters,

designed to arrest very fine particles effectively,

will trap the dust and dirt from the materials.

Filter it out and create a healthy printing environment.

- Keeping the Bests

of the Original - At Sindoh, we have always believed that 3D Printing

should be easy. With 2X, you can still enjoy the

best functionalities from the original such as print monitoring,

auto-loading, bed leveling and email notification.

It is still amazingly simple.

3DWOX 2X

SPECIFICATIONS

- Print Technology FFF

- Print head Dual Nozzle

- Nozzle Diameter 0.4mm

- Max Build size (WxDxH) 228 x 200 x 300mm (8.

9"x7.9"x11.8")

9"x7.9"x11.8") - Material PLA, ABS, Flexible, PVA(Requires PVA Nozzle)

- Connectivity USB Flash Drive, Ethernet, WiFi, USB Cable

- Layer Thickness 0.05 ~ 0.4 mm

- Filament Diameter 1.75mm

- Size (W×D×H) 490 x 466 x 573mm (19.3"x18.3"x22.6")

- User Interface 5” color touch screen

- Leveling Auto Leveling Measurement + Manual Adjustment

- Auto-loading Cartridge Automatically loads filament to nozzle

- LED Lamp For Internal Lighting

- Monitoring Camera Check print status remotely with laptop or smartphone via WiFi connection

- Slicer 3DWOX Desktop Slicer

Sindoh Cloud Slicer - Software Compatibility Solidworks Add-in 2016 or above

AutoDesk TinkerCAD - Operating System Window 7 or above

Mac OSX 10. 10 above

10 above - Note Standard VGA driver on operating system, or a graphics card doesn't support OpenGL 2.0, may cause unknown error in 3DWOX Desktop.

닫기

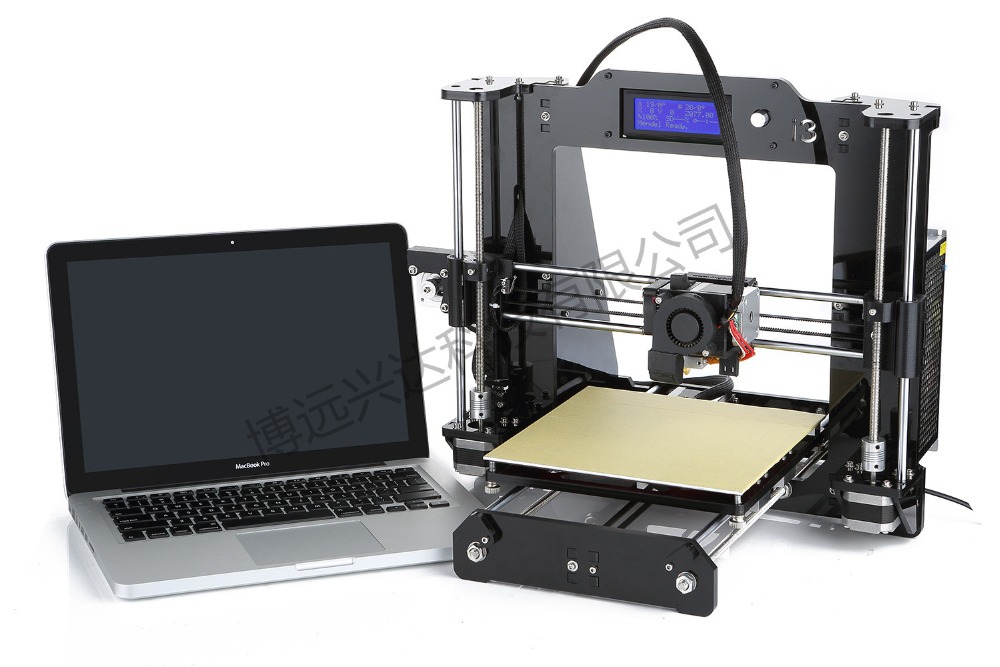

REVIEW: The Sindoh 3DWOX 2X, an accurate, user-friendly dual extrusion 3D printer

Our engineering team has put together a hands-on review of the Sindoh 3DWOX 2X 3D printer.

As the latest addition to its desktop range, the 3DWOX 2X from South Korean manufacturer Sindoh, responsible for the 3DWOX1, DP200 or DP201, is an Independent Dual Extrusion (IDEX) FFF 3D printer.

With over two years on the market, the company has branded the 3DWOX 2X as an easily-usable machine aimed both beginners and expert users. The 3D printer holds a maximum build size of 228x200x300mm, a heated bed up to 110°C, as well as a vocal guidance feature for trouble-shooting.

The following is an extensive review conducted by the 3D Printing Industry engineering team to evaluate the key claims of the 3DWOX 2X. The claims are as follows:

The claims are as follows:

– Quality and accuracy

– Multi-material prints

– Ease of use / very user-friendly

– Wide range of materials

– Quiet operation

3DWOX 2X hardware: Print heads and cartridge

Unlike its predecessor, the 3DWOX1, the 3DWOX 2X is a dual extruder 3D printer. This allows for 2 different materials to be used in the same 3D printed model. The nozzles work interdependently, optimizing the production of the model, to create the multicolor, multi-material models. As a result, the weight of the print heads are reduced. Moreover, this system requires an accurate calibration which can be time consuming.

The print heads have a bowden extrusion system which puts the stepper motor supplying the filament away from the print heads. Furthermore, the filament is driven through a PTFE tube to the nozzle in the print head. This enables an increased print speed as well as precision as the heavy motor is not on the head – solidifying the claim of quality and accuracy.

Nevertheless, the drawback of this configuration is that it often reduces the quality of flexible filament prints as tolerances between the extruder gears can be too loose to be pushed toward the nozzle in the PTFE tube. In spite of this, the 3DWOX 2X handled the flexible filament well on TPU tests.

The 3DWOX 2X is equipped with a cartridge system for each loaded spool. This keeps the spool in the machine in a dry controlled area as the cartridge is closed off. Additionally, each spool has its own RFID chip which sends information such as the filament type, and the quantity used, to the printer. Third party filaments can also be used in the open materials mode.

Dual print heads in the 3DWOX 2X.Slicer and print setup

The 3DWOX 2X is compatible with several slicing softwares. For the purposes of this review, the 3DWOX Desktop Slicer was used due to its straightforward interface. The buttons on the right hand side of the screen allow users to reposition the model by moving it, rotating it, or scaling it. Two modes are available in this software, easy mode and advanced mode.

Two modes are available in this software, easy mode and advanced mode.

The engineering team found that the advanced mode is more suitable for those wanting to dive deeper into the parameters as it unlocks additional settings such as temperature control, retraction settings, print speeds for walls, infill, first layers, and outer contours.

Additionally, the ‘layer color’ option enables multi-color or multi-material models. Overall, the slicer was deemed to be very easy to use and the color/material distribution to the nozzles to be rather intuitive.

The Sindoh Slicer user interface.When setting up the 3DWOX 2X, the team loaded and unloaded the filament with ease thanks to the cartridge. The printer also automatically heats the nozzle and extrudes the filament to ensure the nozzle is primed and ready.

Print bed calibration, which is a semi-automatic process, took the team 5 minutes while XY calibration for the dual extruder system took 10 minutes as this step must be repeated a few times. Wi-Fi connection to the printer took no more than 2 minutes to complete. A USB drive can also be inserted directly into the 2X.

Wi-Fi connection to the printer took no more than 2 minutes to complete. A USB drive can also be inserted directly into the 2X.

Single extruder print tests

Using Sindoh’s white PLA, several single extruder tests were conducted. The tests included a model of the 3D Benchy, a well-known benchmarking model. The 3D printed Benchy produced on the 3DWOX 2X showed good quality overall as the layers are not too visible. There were only a few strings visible between gaps as well as some artifacts which can be easily removed by hand.

3D Benchy made on the 3DWOX 2XTo test repeatability, 3 parts were all printed 5 times. As the reference dimensions are known from the original 3D model, the engineers were able to determine the discrepancy between measured dimensions and original dimensions, and the dispersion between them. The parts are printed in groups of 3 (1 square, 1 polygon, 1 tube).

Repeatability test on the 3DWOX 2XTo illustrate differences between the 3D printed models during the repeatability tests, the average or mean of the objects were calculated. The mean of differences is the mean of the differences between the measurements and the reference. It can be said that the difference between reference and measure under 0.1 deems the 3D printer as accurate. From the tested parts, the 3DWOX 2X was seen to be consistent and precise. It should also be noted that the printer operated rather quietly.

The mean of differences is the mean of the differences between the measurements and the reference. It can be said that the difference between reference and measure under 0.1 deems the 3D printer as accurate. From the tested parts, the 3DWOX 2X was seen to be consistent and precise. It should also be noted that the printer operated rather quietly.

| Hole φ | Height | Width | Length | |

| Reference | 12 | 10.000 | 15 | 15 |

| Print 1 | 11.83 | 10.100 | 15.02 | 15.02 |

| Print 2 | 11.99 | 10.080 | 15. 01 01 | 15.04 |

| Print 3 | 11.95 | 10.010 | 15.05 | 14.95 |

| Print 4 | 11.88 | 10.070 | 15.01 | 15. 09 09 |

| Print 5 | 11.99 | 10.110 | 15.05 | 14.99 |

| Mean of differences | 0.07 | 0.07 | 0.03 | 0.04 |

| Mean of real values | 11.93 | 10.07 | 15.03 | 15.02 |

| Standard deviation (σ) | 0.07 | 0.04 | 0.02 | 0.05 |

| Mean + 3 x σ | 12.14 | 10. 19 19 | 15.09 | 15.18 |

| Mean – 3 x σ | 11.72 | 9.96 | 14.97 | 14.86 |

The table above shows the square model measurements and calculations from the repeatability tests.

Overhang tests were performed to determine the maximum overhang angle possible without supports. The model used is composed of 6 walls printed in an increasing overhang configuration. The first overhang angle is 40°. The following ones are shifted by 5°until 65°.The overhangs under 45° were well printed, however, those above were not as smooth. The surface of the last overhang was inferior, according to the team, as they deemed the overhang limit to be 60°.

3D printed overhang model.Bridging tests ranging from 5mm to 60mm were printed to evaluate the cooling ability of the printer. The team gathered that the quality remained up until the 15mm length bridge. A tower test successfully hit the 300mm height limit on the printer, while a circular trajectory test, evaluating the printer’s ability to print parts with circular sections, was generally satisfactory.

A tower test successfully hit the 300mm height limit on the printer, while a circular trajectory test, evaluating the printer’s ability to print parts with circular sections, was generally satisfactory.

Retraction and small part tests were also conducted on the 3DWOX 2X. From the spiked model, retraction was proven to be very good as there was no stringing between the spikes. Following this, small nut and bolt models no more than 28mm were produced.They were shown to have good detail with no defects. The parts were then easily screwed together.

3D nut and bolt to showcase precision of the 2X.Dual extrusion and real application tests

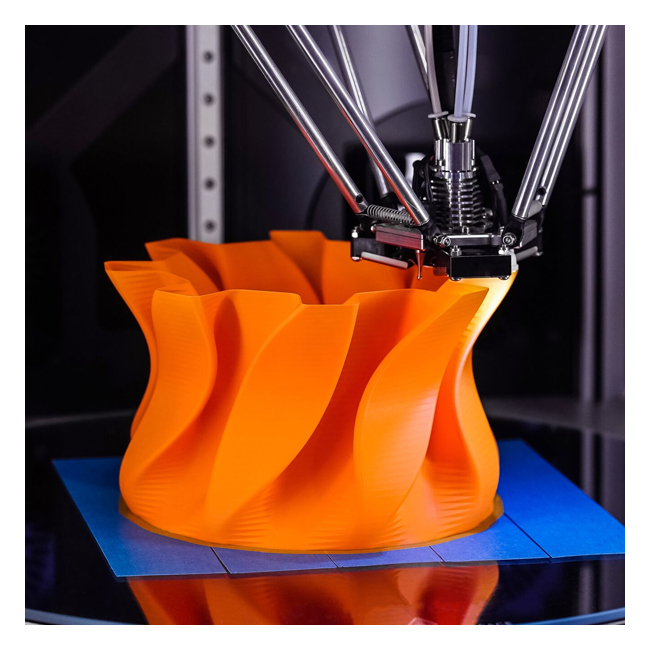

To understand the capabilities of the interdependent nozzle system, multicolor models including a two-tone 3D Benchy, vase, digger and figurine were printed using blue and white PLA. The first trial of the Benchy was not successful due to a small discrepancy between the white and blue layers and the calibration. Nonetheless, after recalibration, the second trial was able to reduce the visibility of the shift between the layers.

The multicolored vase model was printed to determine if the seam between two colored areas were well executed. The overall quality of each zone was good and the surface was smooth. However, the seam between the two colors left some gaps in some areas, meaning the vase was not watertight.

2X 3D printed two tone vases.A 3D Benchy and moving crane were also printed simultaneously to test the quality of the models. Both prints were considered to be printed accurately, particularly due to the successfully produced joints and the minimal gaps between parts, allowing for easy movement on the articulated digger model.

The 3D printed benchy and diggerTPU and PVA supports

Moving on to TPU, the team aimed to test the printer’s ability to process flexible filaments. At a nozzle temperature of 240°C and bed temperature of 70°C, the team printed a smooth phone case with absolutely no stringing. This was a pleasant surprise, as printing flexible filament on a bowden configuration is not often an easy process.

This was a pleasant surprise, as printing flexible filament on a bowden configuration is not often an easy process.

The 3DWOX 2X’s ability to print models with PVA support was also tested. High detail models with lots of overhangs were produced using PLA. The final model was well printed showing no shift between the supports and the printed parts. The team found that the supports easily dissolved in warm water resulting in clean prints. The dual nozzles are very accurate when it comes to differentiating support layers from parts of the model, this can be observed in the image below depicting the accuracy on the small openings.

The PVA supported Colosseum model.A straightforward, competent 3D printer

From our extensive review, the team found the Sindoh 3DWOX 2X 3D printer to be a reliable, user-friendly, system capable of manufacturing large and small models with very few defects. Its dual extrusion system also enables multi-colour parts or PVA supported parts, great for detailed models and useable parts.

Nonetheless, it was noted that the 3DWOX 2X could improve with a more precise method for XY calibration. Moreover, after having done the calibration 2 or 3 times, the print heads are still not always perfectly calibrated. A “mirror” mode would also increase the system’s capabilities given its IDEX system. It is to be noted that some filament combinations are not possible. For example PLA loaded in the first print head and TPU in the second one. In addition, the size of the workspace is small when compared to the 3D printer’s overall footprint.

The Sindoh 3DWOX 2X is a very competent machine that allow users to print with confidence. The cartridge system improves the accessibility of materials as various filaments, including third party filaments, can be handled. An office environment would be suitable for this 3D printer due to its quiet operation and its vocal guidance also facilitates the use of the machine for early users.

The 3DWOX 2X is available from authorized resellers around the globe.

For in-depth reviews and other news, subscribe to the 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Find talent for a project, or advance your career in 3D printing – join 3D Printing Jobs to apply and advertise.

Featured image shows the 3DWOX 2X 3D printer. All photos by 3D Printing Industry.

Sindoh 3DWOX 2X - office 3D printer | FDM

Sindoh 3DWOX 2X - office 3D printer

Advantages:

- FDM printing technology

- Made in South Korea

- Printing with various plastics

- Silent and environmentally friendly

Sindoh 3D printers are made in South Korea. The corporation has a reputation of a reliable and responsible supplier, which is confirmed by many years of successful experience in the office equipment market. nine0003

When designing and manufacturing 3D printers, Sindoh's key goal was to make the machine as user-friendly as possible, as well as provide a comfortable and safe working environment. To this end, the devices implement such solutions as automatic loading of plastic, remote control over the printing process, a technological working platform that does not require the application of adhesives, environmental protection with a HEPA filter, and others.

To this end, the devices implement such solutions as automatic loading of plastic, remote control over the printing process, a technological working platform that does not require the application of adhesives, environmental protection with a HEPA filter, and others.

Sindoh 3D printers feature an extremely low noise level (40-55 dB), which allows them to be used in any place without compromising quiet and attention-demanding activities. nine0003

Sindoh equipment is a great option for those who are just getting started with 3D printing, such as students of secondary schools and universities. Sindoh 3D printers are actively used for the rapid production of layouts and prototypes, as well as final products that do not have high requirements in terms of their strength and temperature properties.

| Terioprint LP-1050 MF Engineering System | |

| Functions | Copier, network plotter, network B/W and color scanner |

| Plotter | |

| Print method | Electrophotography (LED, dry electrostatic transfer, one-component toner, photoconductor) |

| Approval | 600dpi | nine0029

| Print speed | 6. 6 m/min continuous, 10 A/min paging 6 m/min continuous, 10 A/min paging |

| Warm-up time | less than 3 min |

| Paper feed | 2 roll paper trays |

| Media | Paper (60-110 g/m 2 ), Vellum (52 g/m 2 , 60 g/m 2 , 80 g/m 2 , 90 g/m 2 ), Transparency |

| Print margins | Borderless (edge-to-edge) printing possible |

| Print output | from the front |

| Maximum print width | 914 mm |

| Maximum print length | 10 m |

| Weight | 205 kg |

| Energy consumption | 1. 95 kW maximum 95 kW maximum |

| Dimensions | 1200 x 605 x 1145 mm |

| Print controller | nine0029|

| Memory | 2 GB |

| Hard disk | 500 GB |

| Interface | Ethernet 1000/100/10, USB |

| Network protocols | TCP/IP (ftp, lpr, socket) |

| Data formats | TIFF, HPGL, HPGL/2, HP-RTL, CALS; Batch direct printing with software: PDF, JPEG, PNG, BMP |

| Logical ports | 10 |

| Web functions | Embedded web page |

| Scanner | |

| Approval | 150, 200, 300, 400, 600dpi, optical - 600dpi |

| Monochrome | up to 240 mm/s (14. 4 m/min) (300dpi) 4 m/min) (300dpi) |

| Color mode | up to 240 mm/s (14.4 m/min) (200dpi) |

| Gentle scan mode | Yes, feed speed 60 mm/m (3.6 m/min) |

| Original thickness | nine0031 0.05 - 1.6 mm|

| Scan width | Max: 914 mm, Min: 210 mm |

| Scan length | 10 m |

| Interface | Ethernet 1000/100/10 BaseT (shared with plotter) |

| Scan to file features | nine0031 Scan to PC using Network Twain |

| Delivery functions | Direct scan to remote network folders (100 destinations), scan to ftp, scan to USB flash, scan to E-mail, scan and send data to remote network inkjet plotters |

Terioprint LP-2070/1050 engineering systems use standardized consumables and life parts. This is convenient from the point of view of maintaining a warehouse while using both one and the other model. nine0003

This is convenient from the point of view of maintaining a warehouse while using both one and the other model. nine0003

Consumables

Terioprint consumables are materials and parts that are user replaceable.

Toner LP-761

Supplied in 2x450 gr cartridges. The resource of two cartridges is 1600 linear meters with 5% filling of the sheet.

Process cartridge LP-852 (cartridge with photoconductor)

Process cartridge includes a photo shaft and a cleaning blade. Resource - 30 km. The process cartridge can be replaced by the user as easily as adding toner or installing a new paper roll. This is one of the advantages of Terioprint engineering devices, which allow minimizing service costs. nine0003

Charge Filament Module

Charge Filament Module can also be replaced by the user. The module includes 2 threads that work in turn. The total resource of the charge filament module is 15 km.

Waste toner bottle (LP-850- for LP-1030/1040/1050, LP-851 for LP-2050/2060/2070)

The waste toner bottle can be replaced, or the waste toner bottle can be emptied and reused. Volume - 2.5 liters for LP-1050; 3 liters for LP-2070. nine0003

Volume - 2.5 liters for LP-1050; 3 liters for LP-2070. nine0003

End-of-life parts

End-of-life parts are parts that require periodic replacement with the participation of a service engineer. Teriostar resource parts are shown in the table:

| Life, m | ||

|---|---|---|

| U00120892400 | Curing unit heating roller | 100,000 |

| U00120894600 | Curing unit pressure roller | 100,000 |

| U00120767500 | Fuser Thermistors and Separators | 100,000 |

| U00058834100 | Developer unit separation rollers | 100,000 |

| U00118918100 | nine0031 Transfer roller unit100,000 | |

| U00087924300 | Conveyor belts | 100,000 |

Presentation TORUS Terioprint LP-1050 MF

Review of Sindoh 3D printers with print examples

Good afternoon!

In this review, we will introduce the readers of the 3dtoday portal to the Sindoh line of 3d printers (South Korea). nine0003

Sindoh printers are an affordable solution for those who value comfort and convenience when using technology.

The equipment uses plastic filament extrusion technology (FDM / FFF), the most popular polymers on the market are available for printing - PLA, ABS, ASA, PETG, TPU, PVA, HIPS and others.

Sindoh has many years of experience in the office equipment market, founded in 1960. Today Sindoh is an international corporation with regional offices in China, Japan, Europe and America. nine0003

Sindoh specialists carry out all stages of product development, from research and development to production. The company's production factories are located in three regions - South Korea, China and Vietnam. The total staff is about 4000 people.

The company's production factories are located in three regions - South Korea, China and Vietnam. The total staff is about 4000 people.

Sindoh has gained worldwide fame thanks to its MFP printers. Today, the manufacturer's portfolio consists not only of copiers, but also of professional 3D equipment, software and consumables. nine0003

The 3D division was founded in 2013 and the first printer (DP200) was introduced 3 years later. Today Sindoh offers the following FDM printer models:

• 3DWOX 1

• 3DWOX 2X

• 3DWOX 7X

• fabWeaver A530

Sindoh's main task was to design 3D printers that would make 3D printing easy and affordable not only for professionals, but also for those who are starting their acquaintance with additive manufacturing technologies. Below we will talk about the features of printers that provide users with comfortable work. nine0003

Automatic plastic loading

Original manufacturer's plastics supplied with cartridges. The spool of material is located inside the cartridge, which in turn is loaded into a special section of the printer. The device itself pulls the thread through the supply tube to the print unit, eliminating the need for the user to do this manually.

The spool of material is located inside the cartridge, which in turn is loaded into a special section of the printer. The device itself pulls the thread through the supply tube to the print unit, eliminating the need for the user to do this manually.

Also on the cartridge is a smart chip that transmits basic information about the plastic to the display of the device - type, color, material residue. nine0003

At the same time, all Sindoh printers have an "open" architecture - there is no strict binding to the original filaments, it is also possible to use Russian polymers.

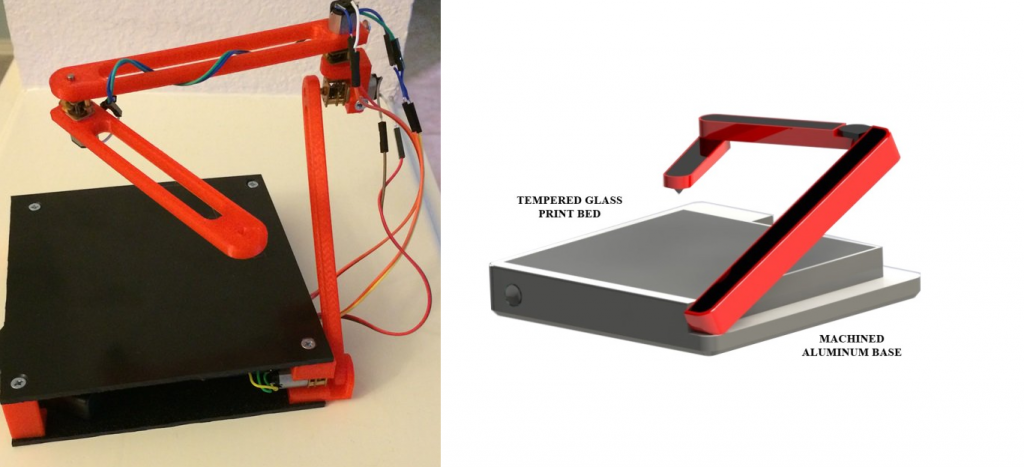

Flexible Heated Print Bed

Experienced FDM 3D printer users know how common it is to fix the first layer of a product on the desktop.

The Sindoh Printer Platform ensures strong adhesion of the part without the need for auxiliary agents - glue, spray, varnish, etc. nine0003

The build platform is flexible so that after the print is finished, the model can be retrieved quickly and easily. All that is required of the operator is to regularly wipe the printer table with isopropyl alcohol.

All that is required of the operator is to regularly wipe the printer table with isopropyl alcohol.

Intuitive user interface

Each Sindoh printer has a full-color touch screen on the body that controls the main functions - loading and unloading plastic, calibrating the working platform, connecting to a Wi-Fi network, etc. nine0003

The printers are also equipped with a voice assistant that will report on the current status and tell you how to solve problems that have arisen in the process.

Automatic platform calibration

Sindoh printers automatically determine the current position of the desktop and suggest what actions need to be taken to align it. The user simply needs to turn the adjustment screws under the platform the number of steps shown on the display. nine0003

Remote monitoring and control

A webcam is located inside the printer's working chamber, which transmits video of work to the manufacturer's proprietary application. The application can be installed on a PC, smartphone or tablet.

The application can be installed on a PC, smartphone or tablet.

The operator can not only remotely monitor the print, but also start, pause or cancel the job.

Quiet and safe workflow

Sindoh 3D printers are virtually silent, ranging from 40db to 55db depending on the model. nine0003

The units are equipped with charcoal filters that protect the environment from harmful fumes produced during the melting of the plastic.

Thus, printers can be placed in a typical office or classroom without compromising the environment and people in the room.

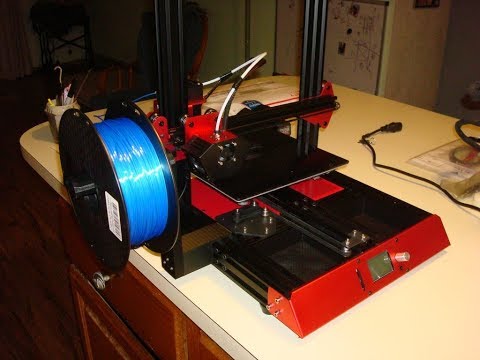

3DWOX 1

Junior printer in the manufacturer's line. The 3D printer is equipped with a single extruder and is suitable for printing products that do not differ in complex geometry. nine0003

Key features:

• Working area - 210*200*195 mm

• Number of extruders - 1

• Extruder heating temperature - 250°C

• Platform heating temperature - 110°C

• Layer thickness – 0. 05 – 0.4 mm

05 – 0.4 mm

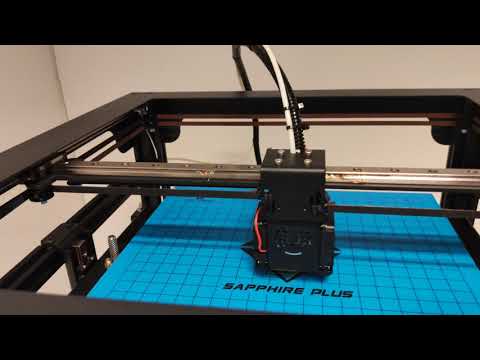

3DWOX 2X

3D printer with two independent extruders. Two printing units allow you to grow products of complex geometric shapes using support material. A two-color 3D printing option is also available. nine0003

Main features:

• Working area - 228*200*300 mm

• Number of extruders - 2 independent

• Extruder heating temperature - 250°C

• Platform heating temperature - 110°C

• Layer thickness - 0.05 - 0.4 mm

3DWOX 7X

Large area 3D printer. The device is suitable for printing medium-sized products and small-scale production of final plastic products.

Key features:

• Working area – 380*390*450 mm

• Number of extruders – 2 independent

• Extruder heating temperature - 250°C

• Platform heating temperature - 110°C

• Layer thickness – 0.05 – 0.4 mm

fabWeaver A530 Senior 3D printer in the Sindoh line. The working chamber of the printer is equipped with an active heating function, providing the best print quality with engineering polymers.

An optional smart workstation is supplied with the printer, which can accommodate up to 4 plastic cartridges. Switching between cartridges, in case of running out of material in one of them, occurs automatically, which ensures uninterrupted operation of the printer. nine0003

Key features:

• Working area – 310*310*310 mm

• Number of extruders - 2 independent

• Extruder heating temperature - 290°C

• Platform heating temperature - 110°C

• Chamber heating temperature - 75°C

• Layer thickness – 0.05 – 0.4 mm

Our engineers use Sindoh 3D printers to print large format copier components. 3D printing allows us to get the right spare parts in a short time and at minimal cost. Below are products made from ABS plastic on Sindoh printers. nine0003

Salt cell test print

The Upper Panel Club A0 Printer

Bunker for Toner

Our company is the official SINDOHE Producer to the Russian Federation.