Indiegogo 3d scanner

Investigation on Eora 3D Scanner IndieGogo Campaign

by edi

Aerospace

As reported earlier this week, crowdfunding has served as a proving ground of sorts for 3D scanning and printing, where only a select few campaigns have shipped an actual product to backers that retains the innovation and functionality originally promised in their sleekly produced informational video. Too many campaigns have received media attention and monetary support without difficulty, only to fall far short of expectations when it came time to deliver. Others have been flat-out duds and even a few could be labeled cash-grabs.

Just as bad are those campaigns that do end up delivering, but in the aftermath of initial funding, woefully mismanage relations with backers: providing intermittent updates, tepid statements of reassurance, and not responding to repeated emails. Putting backers through the wringer with regret and something like buyer’s remorse is not how a new company should establish a core base of loyal customers (I’m still waiting on my $10 LED ring upgrade and free rolls of filament, Deltaprintr.)

The reputation of the entire industry as represented on crowdfunding platforms has been cast in serious doubt. At this point, there are enough horror stories out there to be found online that even the casual consumer knows to approach any 3D related project on Kickstarter, Indiegogo, or the like with serious trepidation. For better or worse, increased scrutiny of anything crowdfunded has heightened the burden of proof on more recent campaigns.

Once expected as a perk for backing a project, it is now almost obligatory to provide a paper trail so-to-speak of real progress. Campaigns should be ready to provide relevant facts, figures, pictures, dates, and deadlines in order to stave off backers who are now quick to discern that no update for a month or two portends a delay in shipment at the very least. It might be a sad commentary that a crowdfunding campaign should receive praise for merely fulfilling their expected role as benefactor of public support, but I think a company like Eora 3D deserves recognition for involving its backers in the manufacturing process from start to finish. It is a welcome relief from the typical smoke and mirrors that seems to have become the norm for crowdfunding.

Eora 3D has provided consistent updates on the scanner’s progress to backers without prompting and best of all when tested the team was super responsive to me when contacted through Facebook, despite providing no indication I was a backer or interested in a pre-order. They were quick to respond with real information, too, not some cryptic response like, “we’re working on it, watch our page for updates in the future.” Eora 3D told me the device is now undergoing the certification process and the laser housing is reaching finalization. I was promised an additional update like the ones they’ve provided in the past would be published in a week. I’ll be sure to report back if they don’t, but I trust they will.

They were quick to respond with real information, too, not some cryptic response like, “we’re working on it, watch our page for updates in the future.” Eora 3D told me the device is now undergoing the certification process and the laser housing is reaching finalization. I was promised an additional update like the ones they’ve provided in the past would be published in a week. I’ll be sure to report back if they don’t, but I trust they will.

Not only has Eora 3D’s crowdfunding campaign provided credible information on manufacturing, assembly, testing, packaging and shipping, but their updates are always supported with photographic evidence and a straightforward run-down of where things stand for all essential steps of the manufacturing process.

They have also shown a level of detail-oriented thinking that has gone into all aspects of the device. A meticulous attention to design that we have come to expect of modern tech devices was proudly reported in Eora 3D’s most recent update, “we have trialed, at last count, at least 50 different samples with various surface finishes. ”

”

Detailing their obsessive attention to getting things right is encouraging proof that the team is putting their effort into the initial product–not just getting it out the door to initial backers, only to perfect it for fully paying consumers in the future. This is has been a major problem in the past with campaigns who have used backers as almost guinea pigs for cobbling together the idea into a full-fledged product, only to offer a better version later on when they pivot in order to turn a profit. A backer of Eora 3D should be reassured they are not getting the “Kickstarter” version of the scanner.

Eora 3D, especially in their latest update, has been incredibly transparent and upfront about their progress in a way that might actually alleviate distrust of the industry. Eora 3D aren’t out of the woods yet when it comes to offering the innovative device they’ve promised, but judging by their latest update and quick response time, they have a chance to offer real hope that crowdfunding is still a viable arena for ideas to shine forth that would otherwise persist in the shadows of a tinkerer’s basement.

Tags: 3dprint, 3dprinting

Matterform’s 3D scanners raise most Indiegogo dollars in Canada

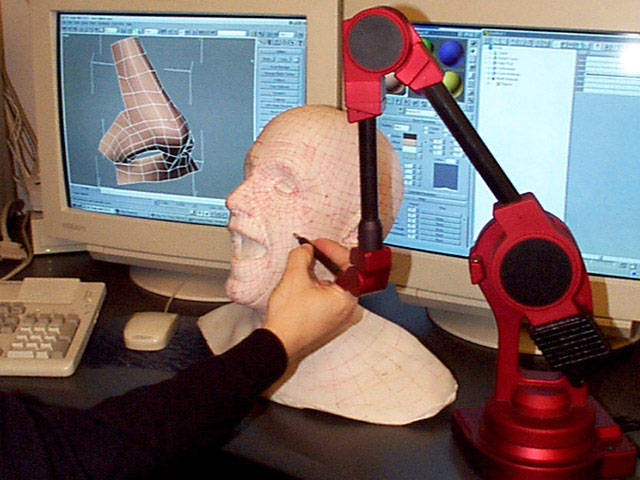

A demonstration of Matterform's 3D scanner.

Technology

Scanners to use a high definition camera and dual laser lines to capture 3D objects in as little as three minutes

By Raju MudharPodcast Co-Host/Producer

Thu., May 2, 2013timer3 min. read

A Toronto company’s 3D scanner technology is the latest to cash in on the buzz over 3D printing, which projects a future where one day we’ll be able to order an item and print it out in our homes.

Matterform is owned by Drew Cox and Adam Brandejs, and the pair just became the poster children for Canadian crowdfunding success.

The company just wrapped up its 35-day Indiegogo campaign, seeking $81,000 to fund, build and sell its initial batch of 3D scanners, but it ended up raising $471,000: enough to make almost five times as many scanners as originally planned.

The company now holds the distinction of being most funded Canadian campaign, which also makes it the most funded campaign anywhere outside of the United States and the most raised on Indiegogo in Canadian dollars. (Kickstarter, a more well-known crowdfunding site, isn’t open to Canadian ventures.)

“We didn’t expect it at all. We weren’t even sure that we were going to hit our initial goal,” says Brandejs. “I remember looking at when we were at $60,000 and thinking, ‘I don’t know, I don’t know,’ the entire time.”

“Our original plan was that we hoped to actually sell 300 units and we were going to make them by hand,” says Cox.

Brandejs, the tinkerer of the pair, originally planned to have the scanner parts 3D-printed and then assemble the products by hand. They are now going to use manufacturers to build them. Fortuitously, they had sourced companies and had contingency plans in place for just such a pleasant outcome.

Originally called the Photon 3D Scanner — it has to be rebranded due to trademarks issues with the name — it is a portable, easy to use, lightweight scanner that folds up when not in use. It’s similar to a regular scanner, except, you can place a 3D item on the scanning bed and, using a high definition camera and dual laser lines, it can capture 3D scans in as little as three minutes.

The pair thought they would capture the hacker/maker crowd with the product but were surprised by how many different types of people wanted it. That majority of backers paid the starter level $599 for a single scanner.

“There were all sort of weird and crazy requests, like artists who want to use it to expand their media. There’s an archaeologist interested in scanning in finds for his research,” said Cox. “There’s even a dad, who has a kid who has made stuff out of Plasticine and he wanted to scan it in and save it.

There’s an archaeologist interested in scanning in finds for his research,” said Cox. “There’s even a dad, who has a kid who has made stuff out of Plasticine and he wanted to scan it in and save it.

“There a lot of dentists, who want to be able to take moulds of people’s teeth and not have to send them out of the office,” says Brandejs. “There was also a lot of interest from scientists, to help with their research and do a bunch of stuff that we honestly don’t even understand.”

One of the benefits of using a 3D scanner is not having to know modelling software.

“Right now, in a lot of the 3D printing space, you have got to know Solidworks and CAD in order to really use these things. But with a scanner it kind of changes that a little bit, because it means you don’t have to do the software, you can basically put something on there, get an image and then print it on your 3D printer. It allows an opening to get people to start playing with this technology that they keep hearing about,” says Brandejs.

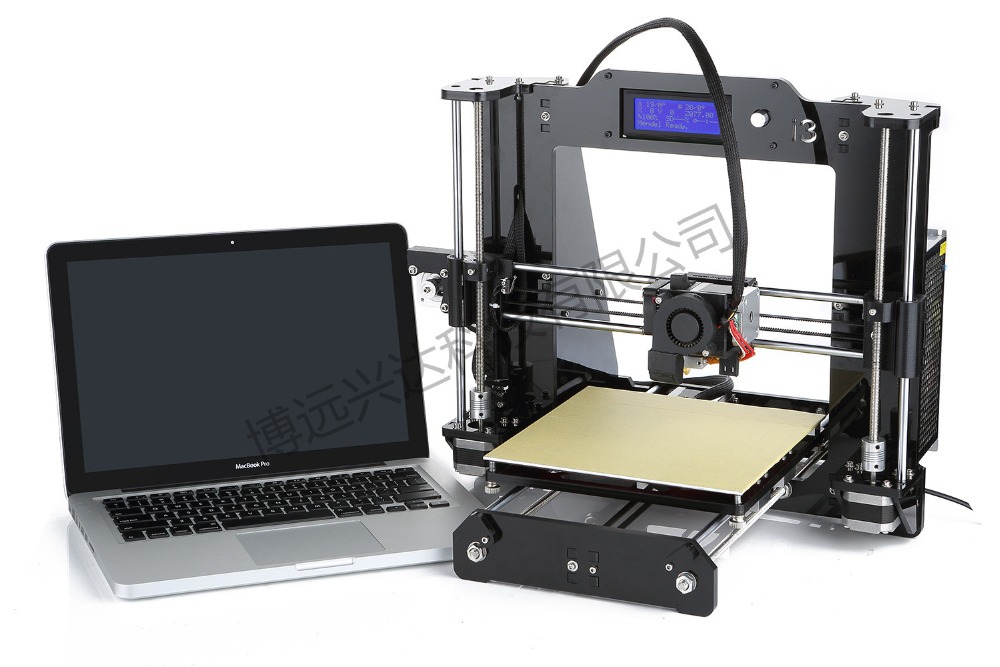

Both Cox and Brandejs feel there is a lot of hype around 3D printing and that we still are a few years always from ideal in-home 3D printers. The printers are getting smaller, produce higher quality prints and are getting cheaper, but it is still very early days.

For now, they have to fulfil their orders, with the first batch of 3D scanners scheduled to go out at the end of July and subsequent orders filled in the four months after that.

Beyond renaming and rebranding their product, their next goal is to start selling scanners through their website.

SHARE:

Report an error

Journalistic Standards

About The Star

JOIN THE CONVERSATION

Conversations are opinions of our readers and are subject to the Code of Conduct. The Star does not endorse these opinions.

Campaign launched on Indiegogo to support Stalactite 102, a foldable 3D printer powered by DLP technology

Archive

with 3D printers.

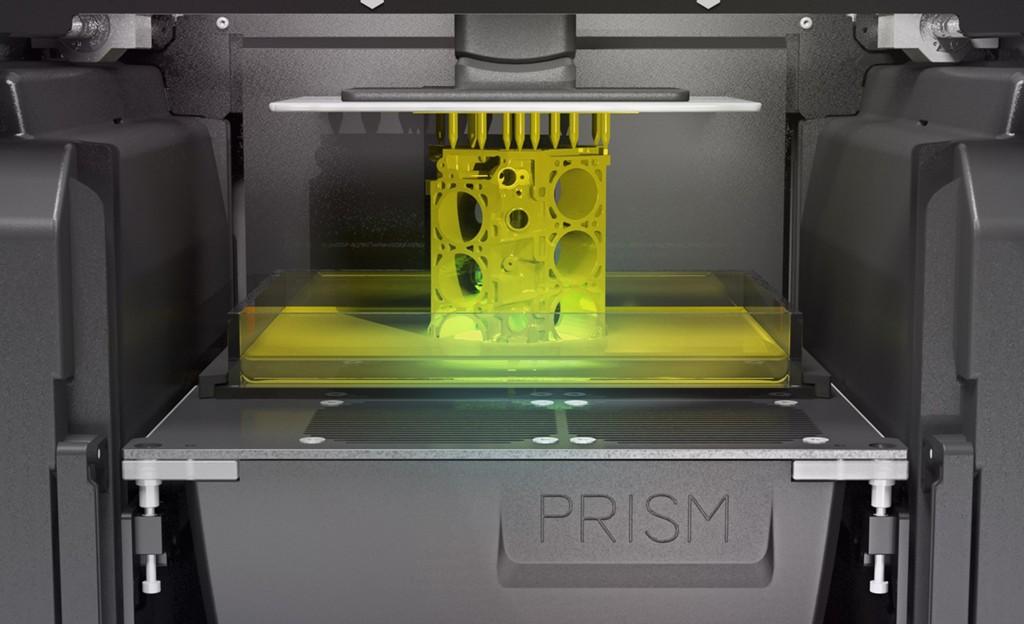

This time, let's talk about the Stalactite 102 3D printer based on DLP (Digital Light Processing) technology, printing with liquid photopolymer.

This time, let's talk about the Stalactite 102 3D printer based on DLP (Digital Light Processing) technology, printing with liquid photopolymer. DLP projector based printers have become popular in the last few years. With the help of a projector, often used for PowerPoint presentations, such a 3D printer can turn a liquid substance into products with many small details. The projector illuminates the surface of a liquid polymer, which hardens under the influence of radiation with a certain wavelength. So layer by layer appears until the model is ready.

Stalactite, a young company from Barcelona, wants to raise 50,000 euros on indiegogo. For 1850 euros (there are only five printers available) or 1999 euros (for the very first investors) you will receive a fully assembled 3D printer based on SLA (Laser Stereolithography) technology. The Stalactite 102 is a compact, foldable device that anyone can use to bring their ideas to life. The printer comes with a proprietary program for fast model cutting, automatic support and a patented dual cleaning system.

Specifications:

- Working area: 102 mm x 76.8 mm x 180 mm

- Minimum layer thickness: up to 25 microns

- High resolution X/Y (100 microns in NORMAL mode, 50 microns in FINE mode)

- Machined aluminum and laser-cut steel parts

The company also has its own printed materials. At the time of the printer's launch, four different materials will be on the market at the most affordable prices.

STANDARD: base material, suitable for general purposes. nine0003

PROTOTYPING: a material similar in properties to ABS or Nylon plastic. Ideal for making cases for electronic devices and stands for Iphone.

ELASTIC: elastic and flexible resin.

WAXY: has properties similar to model casting wax. You can resort to the lost wax casting method and cast your product from bronze, silver, gold.

Last October, the STALACTITE 3D printer was among the 10 winning projects that outperformed 5,000 entrants in the HighTech XL Start-Up BootCamp Accelerator competition held in Eindhoven, the Netherlands. nine0003

nine0003

The company plans to ship the printers in August 2014. For more information, check out the Stalactite Campaign page on Indiegogo.

Article prepared for 3DTODAY.ru

Subscribe to

Subscribe

I do not want

TOP 10 of the most funded 3D printers on Kickstarter and Indiegogo

no secret that many young companies production of 3D prints are placed on the Kraandfords platforms "Kickstarter" and "Indiegogo". This often makes the creators a good financial investment to start their business, and gives the world new interesting ideas and developments. nine0003

In this article, we decided to present the TOP 10 most funded 3D printers that have raised hundreds of thousands of dollars.

1. M3D

Launched on Kickstarter in 2014, raising $3,401,361 kinematics. Initially, the goal was to raise $100,000, but within 30 minutes after the start, $37,000 was raised. The project was financed by a record amount, which has not yet been exceeded. nine0071

The project was financed by a record amount, which has not yet been exceeded. nine0071

The next model the company exhibited was the M3D PRO 3D printer, which raised $487,497 on Kickstarter and $954,437 on Indiegogo, which is also considered a good result.

2. TIKO

Launched on Kickstarter in 2015 and received $2,950,874

Thanks to its low price of $99 (basic) and $139/$179 (with various additional features) 3D printer with delta kinematics ranked second in funding.

Initially it was stated that this baby prints with a resolution of 50 - 200 microns, although it has very small dimensions and a small number of additional components. The TIKO case is closed, has a flexible work surface, is equipped with WIFI and can accommodate a kilo spool of plastic.

Unfortunately, the manufacturer did not cope with all the tasks and the fate of this 3D printer after funding was not in favor of its creators.

3.

FORM 1

FORM 1

First seen on Kickstarter in 2012, col 2 9$45,885.

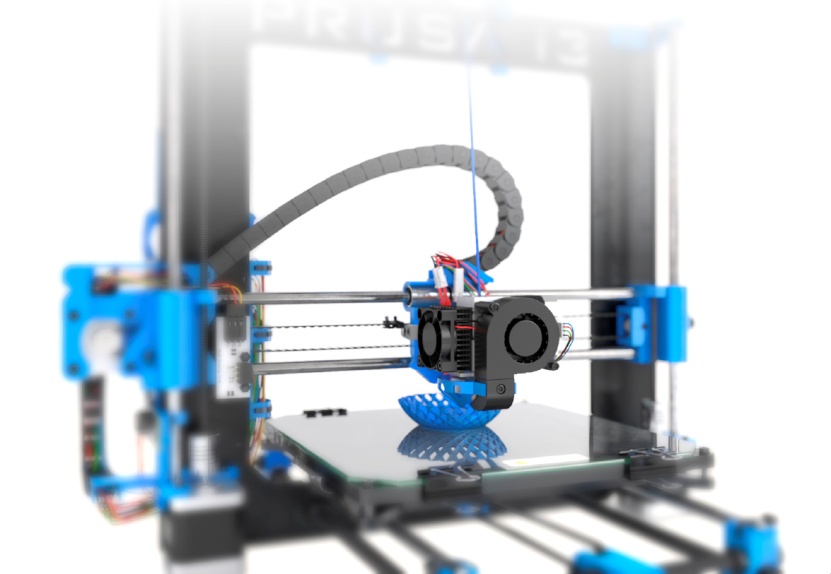

Was the most popular project on Kickstarter. Formlabs, the creator of the 3D printer, set out to invest $100,000, and raised much more. FORM is one of the first consumer grade portable SLA 3D printers. In 2012, this technology was revolutionary in the world of 3D printing. Compared to 3D printers with FMD printing, SLA was the perfection of additive technologies, the layer thickness was 0.025mm.

Today, Formlabs is one of the leading companies in the field of 3D printing and has released a new 3D printer FORM 2.

4. OLO

Launched on Kickstarter in 2016, raised $2,321,811.

This is the world's first smartphone 3D printer. OLO technology is simple and unique because the main part of a 3D printer is a smartphone that almost everyone has. With a smartphone and OLO technology, you can build 1 cm in about 46 minutes, or 1 inch in 1 hour and 55 minutes. For only $99, you're just a 3D printer and a fun toy.

OLO works with flat-screen smartphones of almost any size or brand, even large 5.5-inch displays. By downloading the STL file through the application on the phone, the user will receive a real 3D object. nine0003

5. Snapmaker

Launched on Kickstarter in 2017, raised $2,277,182.

Snapmaker is a multifunctional budget machine that includes a 3D printer, CNC and laser engraver. The device has an innovative modular design, and high-precision linear modules.

In addition to simple and quick assembly, the device has simple software. Allows you to quickly change modules, adapting it to different tasks. And the price is an interesting $199.

Snapmake, without changing its idea, develops devices with an increased working area based on the same linear modules. nine0003

6. FLUX

Launched on Kickstarter in 2014, raised $1,641,075

Continuing the MFP theme, FLUX is a buildable delta with different attachments: 3D printer, CNC, laser engraver and 3D scanner. The goal of the team from Taiwan was to raise $100,000, in 10 days they raised $1,200,000

The goal of the team from Taiwan was to raise $100,000, in 10 days they raised $1,200,000

The device has many advantages. Having such potential, you can easily realize your idea.

The control is carried out by a smartphone through a special application. The price of a 3D printer with an engraving version and a laser was 679$.

This year FLUX Delta+ 3D printer posted its project on Indiegogo and raised $1,095,266 so far.

7. Obsidian

Appeared on Kickstarter this year, raised $1,631,827.

Kodama's campaign after the successful TRINUS project on Kickstarter posted a new Obsidian 3D printer that hit the $100,000 goal in just three minutes and $500,000 in three days. Today, nine days after the start, this amount has exceeded $1 million.

So what's so special about the Obsidian 3D printer? The first advantage is the resumption of printing from an interrupted place, for example, when there is a power outage. Another innovation is the ability to use the exclusive and world's first thread with obsidian powder. The inventors say they are negotiating with a factory in German to produce tungsten nozzles as a future addition. nine0003

The inventors say they are negotiating with a factory in German to produce tungsten nozzles as a future addition. nine0003

8. TRINUS

Launched on Kickstarter in 2016, collected $1,621,021 This is a development by Kodama Worldwide, the originally announced amount of $500,000 was overcome in 54 minutes after the start. These guys also decided to combine a 3D printer and a laser engraver, while the cost of the device should not exceed $500. As you can see, users appreciated it not only on Kickstarter, but also on the Italian crowdsourcing site Thunderclap, where they also exceeded their expectations. nine0003

What's special, Trinus is made of high quality aluminum and steel parts. It not only has a metal frame, but also has metal internal components. No loose belts or plastic gears. As a result, according to the manufacturers, Trinus has a level well above its price.

9. Buccaneer

This startup saw the world thanks to Kickstarter in 2013, it raised $1,438,765.

This project was one of the saddest. In May 2013, a team from Singapore, Pirate3D, announced that they wanted to make 3D printing in FDM technology available to the public, and named the price of a 3D printer at $ 347 (even $ 100 less for first donors), which, at that time, was very cheap. nine0071 The presentation of the device was incredible, especially when its price was compared with other 3D printers, the initial amount of $100,000 was raised in 10 minutes. But after the end of the project and the incredible success, the creators fell silent for six months, and then announced that the Buccaneer should cost $ 300 more, of course there was a lot of criticism, some scandalous investors began to consider official actions to return the funds.

Most of those who financed the company wanted their money back, and the print quality of the resulting 3D printers was very poor. In October 2015, the company's CEO - Brendan Goh decided to announce - 60% of orders cannot be realized due to lack of money.