3D printing service price comparison

How much does 3D printing cost?

As a 3d printing company, we always get asked: "how much does it cost to 3d print?".

Our answer has always been "it depends" as there are factors that contribute to the cost of 3d printing. You're looking at anywhere between $3 to $1000(or even more) for the cost to 3d print based on these factors.

So today, we're breaking down each factor for you. If you're 3D printing at home, then those factors are your material, electricity and 3D printer cost. But if you're looking for a 3d printing service or looking into starting a 3D printing business, this guide should help you understand how pricing works when it comes to 3d printing.

Factors that affect the price of 3D printing

Cost of buying and running a 3D printer

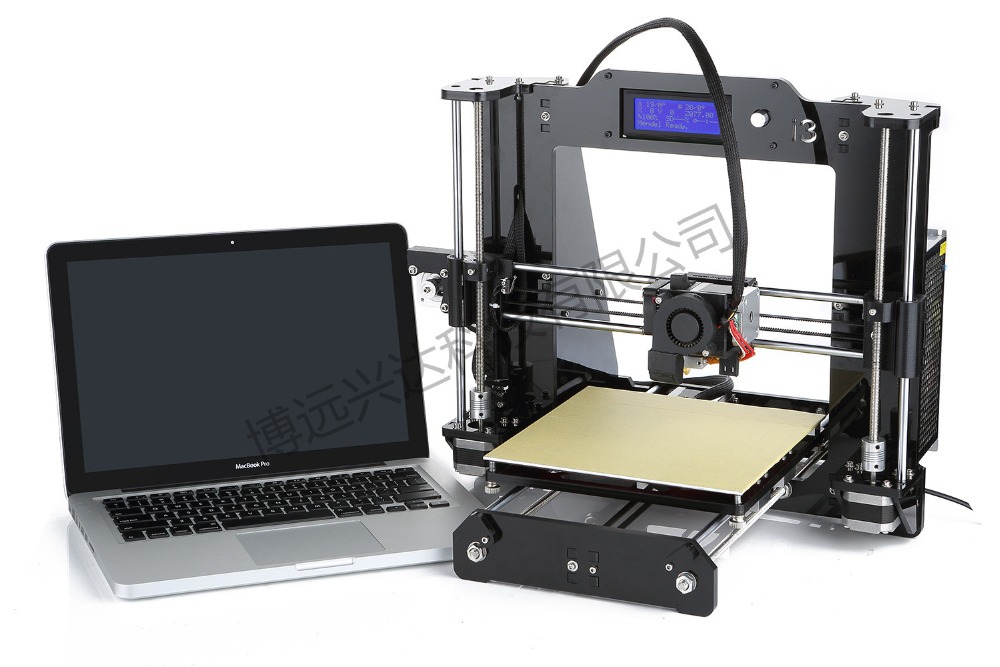

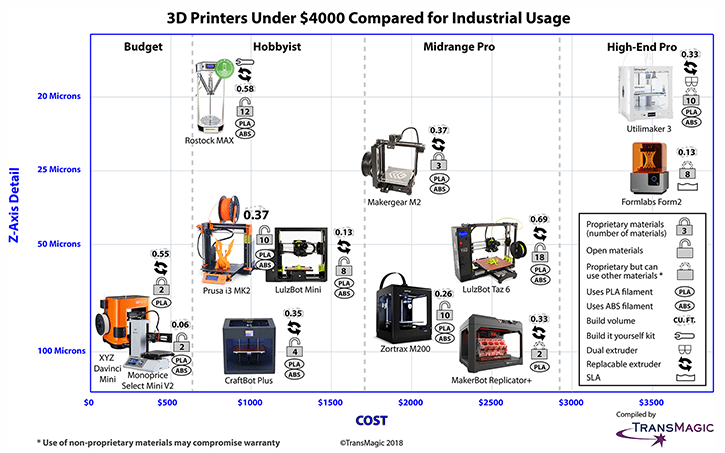

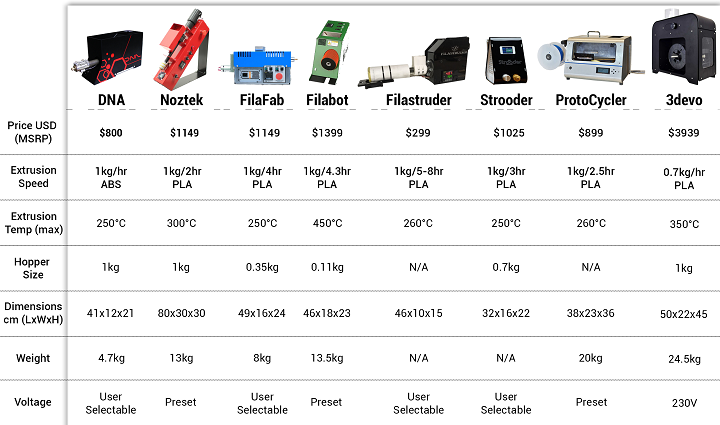

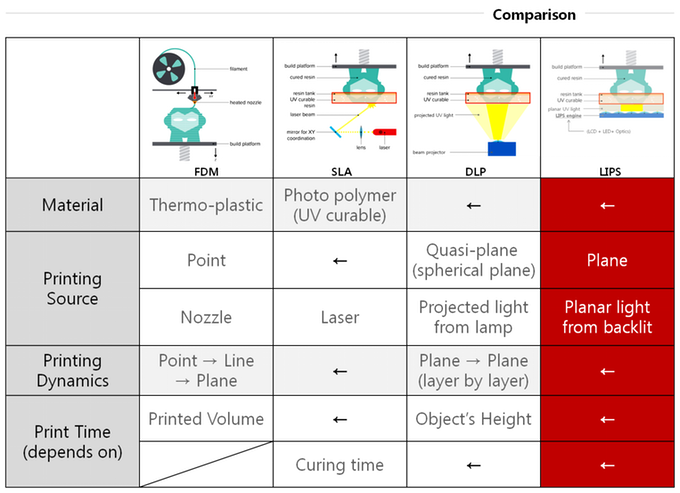

If you're starting a 3D printing business or looking to make money with 3D printing, you might want to consider the price of a 3D printer in calculating the cost to 3D print something. 3D printers can cost anywhere between $200 to $150,000 depending on the technology being used.

Let's say you purchased a $1500 3D Printer that you plan to use 8 hrs / day for 2 years. We're going to ignore repair cost, electricity, etc. for the sake of simplicity.

8 x 365 x 2 = 5840 total hours

$1500 / 5840 hrs = ~ $0.21/hr

So if your 3D model would take about 4 hours to 3D print, then you need to charge $0.84 on top of your price to account for your machine upkeep.

In a way, the time it takes to 3D print also adds to the cost of 3D printing.

3D Model

3D model of a dinosaur trophy"Send us the 3D model" is the second thing we tell our clients after telling them "it depends". Without the 3D model, it's tough to come up with an accurate quote for a 3D print even for seasoned veterans.

The 3D model gives us essential information that can help us quote a 3d print.

Model volume

With the 3d model on hand, we can calculate the total volume of the model, including the generated supports. The total volume lets us know how much material is needed to 3d print your file.

The total volume lets us know how much material is needed to 3d print your file.

In short, the larger the volume, the higher the cost. There are ways to reduce the cost of 3D printing, and one of them is to hollow your model.

A 3ft model can have less volume than a 1ft model if the 1ft model is solid on the inside, while the 3ft model is hollow.

That is why coming up with an estimate price of 3d printing without the 3d model is not easy.

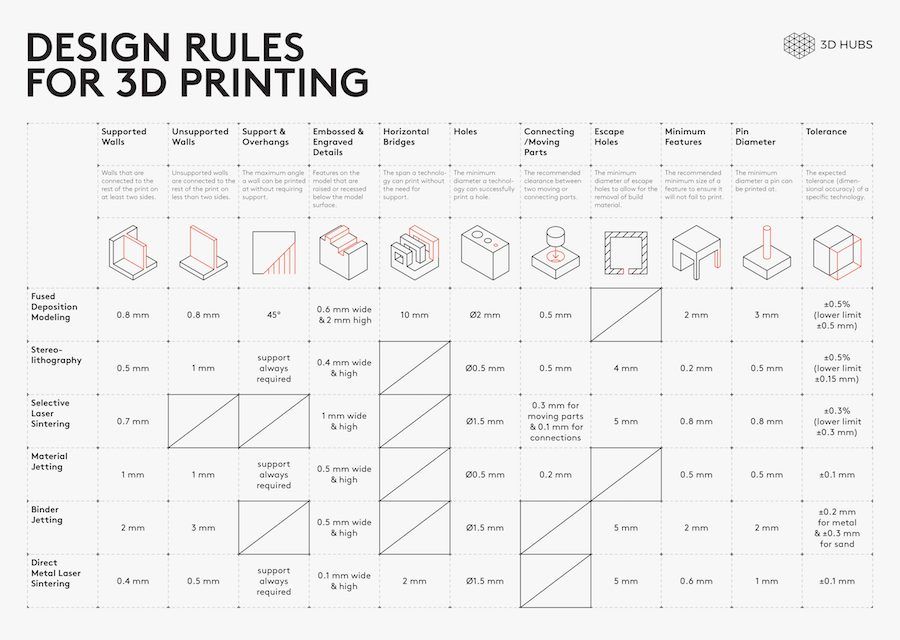

Complexity

Not all 3d models are created equal. Some are 3d print-ready, while some are just plain crazy. 3d printing takes preparation and planning. For some 3d printing services, everything is automated, which can make transactions faster. For simple products, this can be the right solution.

But what about complex parts and architectural models? We found that even with the most sophisticated algorithm, you still need some human guidance when it comes to 3d printing these type of projects.

A quick story, a client sent us a 3d model of an actual stadium. They wanted a 3d printed version of this. As we inspected the file, we saw that the model had multiple problems. There were loose joints, the walls were too thin, and there were 3d models inside the stadium itself.

They wanted a 3d printed version of this. As we inspected the file, we saw that the model had multiple problems. There were loose joints, the walls were too thin, and there were 3d models inside the stadium itself.

If we just 3d printed it right away, it would have cost us thousands of dollars on wasted material!

Take this into consideration. Are you willing to risk having your 3d model printed as is? Or do you want to make sure that the final print exceeds your expectations?

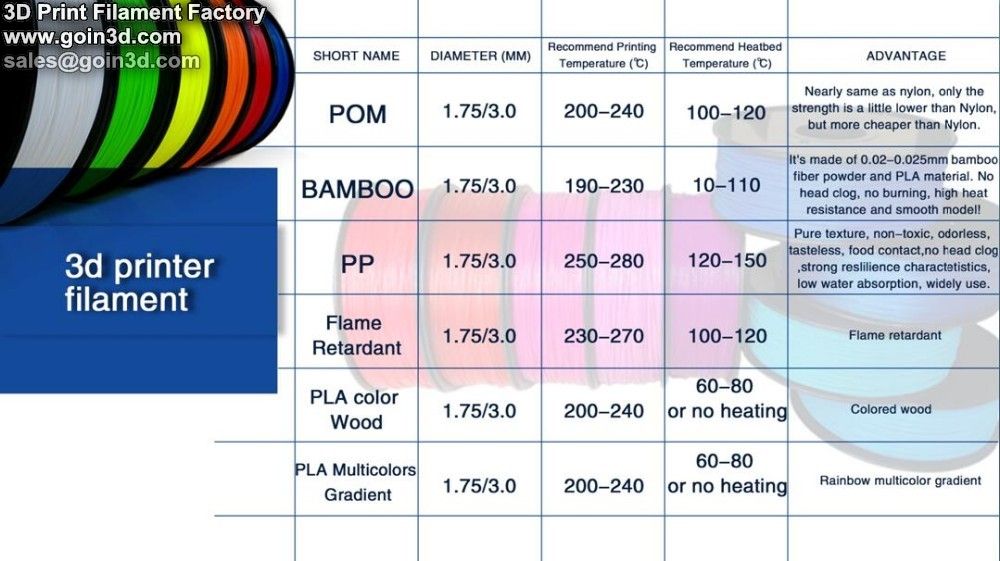

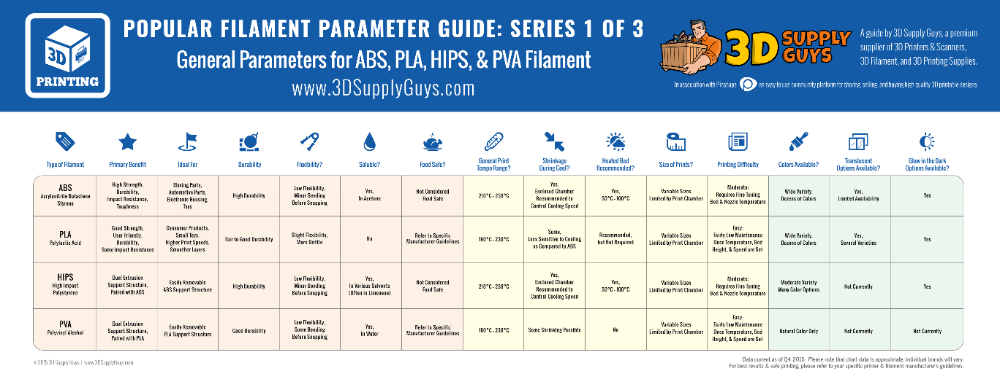

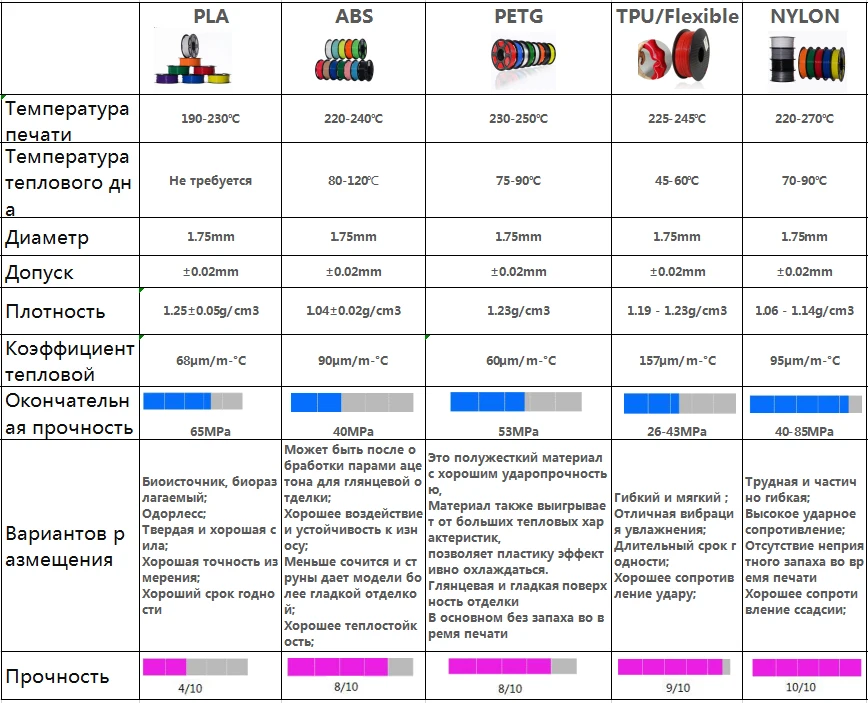

Type of material

The materials that you choose matters when it comes to the cost of 3d printing. There are tons to choose from so we are going to focus on the popular ones, thermoplastics and resin.

Thermoplastics: Filaments and Powder

Cost: $

Even if you are new to 3d printing, you have probably heard of "ABS" or "PLA". That's because these two are the most widely used 3d printing material out there. Hobbyists love these thermoplastics as they are cheap. These filaments can cost between $20 to $70 per kg.[1]

These filaments can cost between $20 to $70 per kg.[1]

Although they are cheap, getting a high-quality 3d print out of them is not easy. It will take hours of post-processing time to get smooth finishing from these prints. (More on that later.) In addition to that, 3d printing complex 3d models are nearly impossible using this type of material.

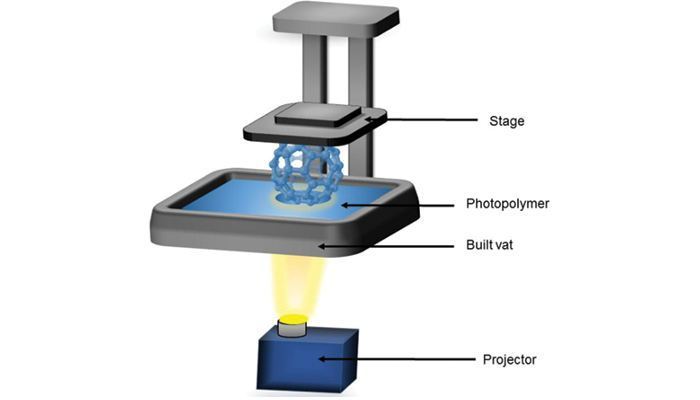

Thermosets: Resin

Cost: $$$

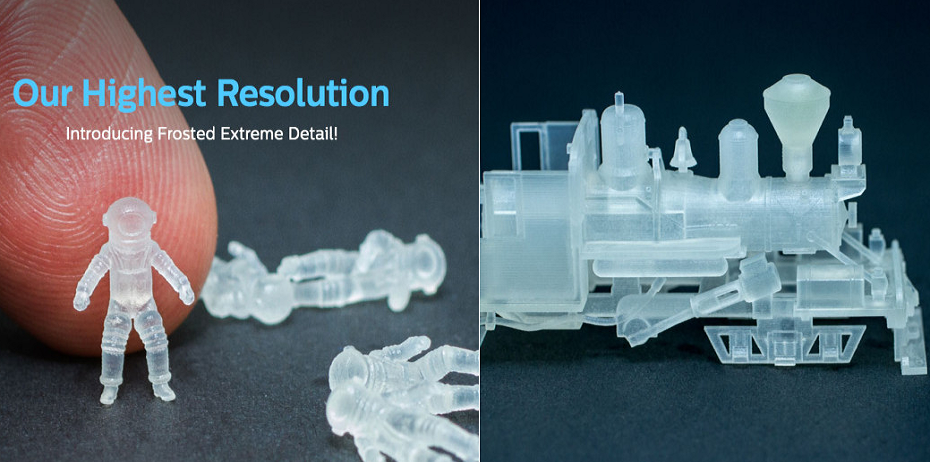

Resin is, in our opinion, the best 3d printing material out there. It's versatile for almost any complex project, and it would give you the best quality 3d print. But at the same time, resin material can get quite costly. Standard resin, on average, cost $50 per litre, and some resin materials can go up to $300 per litre. Luckily, 3d printing companies usually have access to discounted prices for this type of material.

Want to find out how much your 3D model will cost?

Use our instant quoting system to calculate how much it will cost to 3D print something.

GET 3D PRINTING COST

No signup required.

Post-processing

Most don't realize that 3d printing is not an instant process. Drop your file, print, and it's ready. (We hope it was).

After 3d printing, the resulting print needs to be cured, cleaned and polished before you can consider them useable. That is if the 3d printing service company cares about the quality of their product.

Polishing

Imagine polishing the one on the left to make it smooth? Photo courtesy of Formlabs.For filaments, don't even waste your time. As someone who spent hours removing supports, we don't want to you put you through that hell. If you value your time, the amount of time you will spend sanding these prints would cost a lot. And even then, the quality wouldn't be on par compared to resin.

For resin, it's simpler. Once the pieces are UV cured, we can polish it by hand or using a sandblaster.

Again, the 3d model matters as it could affect post-processing. Some models are so complex that the generated supports are very hard to clean. It would take some expertise and a lot of patience for someone to clean these prints.

Some models are so complex that the generated supports are very hard to clean. It would take some expertise and a lot of patience for someone to clean these prints.

Finishing

At PrintAWorld, the projects that we work on usually require more than just 3d printing. Our clients would ask for their 3d print to have a gold finishing, chrome or even an exact Pantone color. With current 3d printing technology, this is impossible to accomplish. So we offer metal plating and painting on top of our 3d printing services.

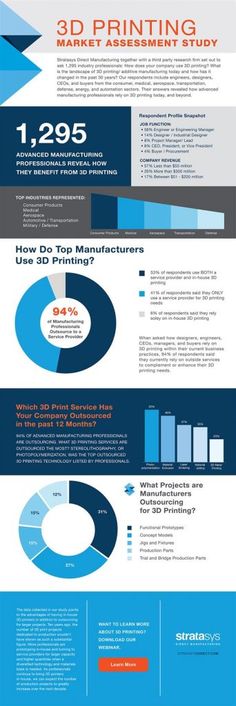

Profit margin

For 3D printing companies to stay in business, they need to add a profit margins on top of the 3D printing cost. Profit margins for a 3D printing business can be somewhere between 50% - 90% of material cost. We're using material cost as a basis for the sake of simplicity. But profit margins are actually much lower once you start including labor and overhead costs.

There is also a base price (or a minimum fee) that gets added if if the cost of 3D printing is less than a certain amount. It wouldn't make sense for a company to 3D print something for you for a print that costs $3. Even in a highly automated 3D printing service, there's still some labor involved. Either you add more quantity or pay the base price which is around $30-$90.

It wouldn't make sense for a company to 3D print something for you for a print that costs $3. Even in a highly automated 3D printing service, there's still some labor involved. Either you add more quantity or pay the base price which is around $30-$90.

3D printing service price comparison

Now that we know what factors affect the price of 3D printing, let's see how much it would cost to 3D print this popular WallStreeBets mascot by ChaosCoreTech.

For this test we will be using SLA 3D printing.

We modified the file so we can stress test the on-demand 3D printing services that offer SLA printing.

Scaled it up to 152mm or ~6" high

We hollowed the 3D model. Meaning, the insides are empty.

This makes it use less material, making it cheaper.

Speed up the 3D printing time for SLA, which should lower the cost.

3DHubs

Price: $537

3DHubs won't even allow you to print this in resin as it's bigger than what their manufacturers can print.

i.materialise

Price: $211.17

Cheaper than 3DHubs but they won't clean the supports for you at this price. If you need it cleaned, you need to pay extra.

Shapeways

Price: $2061.56

We're not sure why it's this expensive. They might have miscalculated the model volume which made it seem that this piece would require half a liter of resin to print. But, either way, Shapeways is the most expensive one out of this group.

Most Affordable

PrintAWorld

Price: $136.32

Disclaimer. This is our 3D printing company. For SLA 3D printing, we are definitely the cheapest compared to the others in this group. Removing the supports and polishing is even included in the service.

Try it out

Why are 3D printing services expensive?

3D printing services are expensive because we have to account for factors mentioned beforehand such as labor, post processing and overhead costs. We also have to account the industrial 3D printers that they use, which cost at least $100,000 and upwards. Plus, they have to add profit margin on top of that cost.

We also have to account the industrial 3D printers that they use, which cost at least $100,000 and upwards. Plus, they have to add profit margin on top of that cost.

This begs the question, is it better to buy a 3D printer instead?

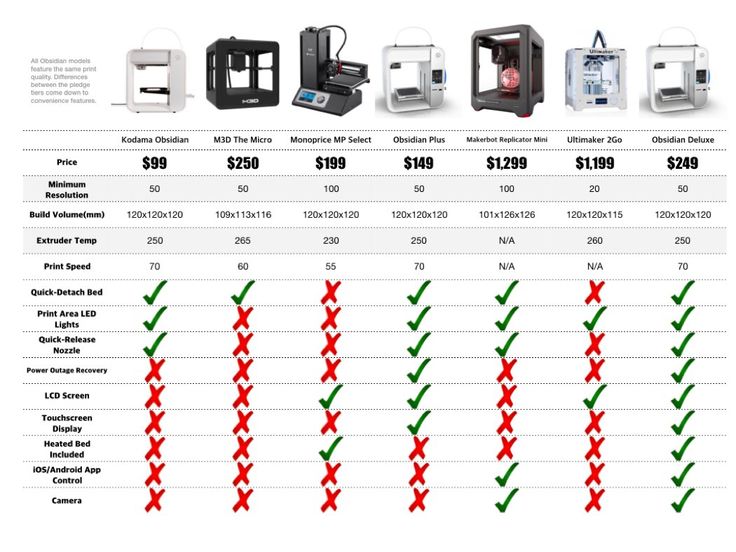

Should you buy a 3D printer or hire a 3D printing service?

3D printing services can sometimes cost more than an entry level 3D printer. So you might be wondering if it's better to buy a 3D printer instead.

Here's our thoughts on that:

If cost is a problem for you and you're only 3D printing for fun, then buying a 3D printer might be the better investment in the long run.

If your time is more valuable for you, then hiring a 3D printing service would be the better option. You'll have access to large scale 3D printers and capabilities that is impossible to achieve with DIY 3D printing.

Best Budget 3D Printer

Anycubic Photon Mono

The Photon Mono is the best LCD 3D printer that we've gotten our hands on. We own 8 of these machines and use it as part of our manufacturing process. It's cheap but the print quality is almost the same as the ones that we get from our Formlabs 3. If you're looking to buy your first 3D printer, we recommend going for a resin 3D printer like this one instead of buying an FDM printer.

We own 8 of these machines and use it as part of our manufacturing process. It's cheap but the print quality is almost the same as the ones that we get from our Formlabs 3. If you're looking to buy your first 3D printer, we recommend going for a resin 3D printer like this one instead of buying an FDM printer.

$229.00 from Anycubic

Commisions earned

In Summary

Multiple factors affect the price of a 3d printing service. If you add in all these variables, you're looking at anywhere between $30 to $15,000 for the cost of 3d printing. The price can even be lower or higher, depending on the scale of your project.

How much does 3D printing cost?

As a 3d printing company, we always get asked: "how much does it cost to 3d print?".

Our answer has always been "it depends" as there are factors that contribute to the cost of 3d printing. You're looking at anywhere between $3 to $1000(or even more) for the cost to 3d print based on these factors.

So today, we're breaking down each factor for you. If you're 3D printing at home, then those factors are your material, electricity and 3D printer cost. But if you're looking for a 3d printing service or looking into starting a 3D printing business, this guide should help you understand how pricing works when it comes to 3d printing.

Factors that affect the price of 3D printing

Cost of buying and running a 3D printer

If you're starting a 3D printing business or looking to make money with 3D printing, you might want to consider the price of a 3D printer in calculating the cost to 3D print something. 3D printers can cost anywhere between $200 to $150,000 depending on the technology being used.

Let's say you purchased a $1500 3D Printer that you plan to use 8 hrs / day for 2 years. We're going to ignore repair cost, electricity, etc. for the sake of simplicity.

8 x 365 x 2 = 5840 total hours

$1500 / 5840 hrs = ~ $0. 21/hr

21/hr

So if your 3D model would take about 4 hours to 3D print, then you need to charge $0.84 on top of your price to account for your machine upkeep.

In a way, the time it takes to 3D print also adds to the cost of 3D printing.

3D Model

3D model of a dinosaur trophy"Send us the 3D model" is the second thing we tell our clients after telling them "it depends". Without the 3D model, it's tough to come up with an accurate quote for a 3D print even for seasoned veterans.

The 3D model gives us essential information that can help us quote a 3d print.

Model volume

With the 3d model on hand, we can calculate the total volume of the model, including the generated supports. The total volume lets us know how much material is needed to 3d print your file.

In short, the larger the volume, the higher the cost. There are ways to reduce the cost of 3D printing, and one of them is to hollow your model.

A 3ft model can have less volume than a 1ft model if the 1ft model is solid on the inside, while the 3ft model is hollow.

That is why coming up with an estimate price of 3d printing without the 3d model is not easy.

Complexity

Not all 3d models are created equal. Some are 3d print-ready, while some are just plain crazy. 3d printing takes preparation and planning. For some 3d printing services, everything is automated, which can make transactions faster. For simple products, this can be the right solution.

But what about complex parts and architectural models? We found that even with the most sophisticated algorithm, you still need some human guidance when it comes to 3d printing these type of projects.

A quick story, a client sent us a 3d model of an actual stadium. They wanted a 3d printed version of this. As we inspected the file, we saw that the model had multiple problems. There were loose joints, the walls were too thin, and there were 3d models inside the stadium itself.

If we just 3d printed it right away, it would have cost us thousands of dollars on wasted material!

Take this into consideration. Are you willing to risk having your 3d model printed as is? Or do you want to make sure that the final print exceeds your expectations?

Are you willing to risk having your 3d model printed as is? Or do you want to make sure that the final print exceeds your expectations?

Type of material

The materials that you choose matters when it comes to the cost of 3d printing. There are tons to choose from so we are going to focus on the popular ones, thermoplastics and resin.

Thermoplastics: Filaments and Powder

Cost: $

Even if you are new to 3d printing, you have probably heard of "ABS" or "PLA". That's because these two are the most widely used 3d printing material out there. Hobbyists love these thermoplastics as they are cheap. These filaments can cost between $20 to $70 per kg.[1]

Although they are cheap, getting a high-quality 3d print out of them is not easy. It will take hours of post-processing time to get smooth finishing from these prints. (More on that later.) In addition to that, 3d printing complex 3d models are nearly impossible using this type of material.

Thermosets: Resin

Cost: $$$

Resin is, in our opinion, the best 3d printing material out there. It's versatile for almost any complex project, and it would give you the best quality 3d print. But at the same time, resin material can get quite costly. Standard resin, on average, cost $50 per litre, and some resin materials can go up to $300 per litre. Luckily, 3d printing companies usually have access to discounted prices for this type of material.

Want to find out how much your 3D model will cost?

Use our instant quoting system to calculate how much it will cost to 3D print something.

GET 3D PRINTING COST

No signup required.

Post-processing

Most don't realize that 3d printing is not an instant process. Drop your file, print, and it's ready. (We hope it was).

After 3d printing, the resulting print needs to be cured, cleaned and polished before you can consider them useable. That is if the 3d printing service company cares about the quality of their product.

Polishing

Imagine polishing the one on the left to make it smooth? Photo courtesy of Formlabs.For filaments, don't even waste your time. As someone who spent hours removing supports, we don't want to you put you through that hell. If you value your time, the amount of time you will spend sanding these prints would cost a lot. And even then, the quality wouldn't be on par compared to resin.

For resin, it's simpler. Once the pieces are UV cured, we can polish it by hand or using a sandblaster.

Again, the 3d model matters as it could affect post-processing. Some models are so complex that the generated supports are very hard to clean. It would take some expertise and a lot of patience for someone to clean these prints.

Finishing

At PrintAWorld, the projects that we work on usually require more than just 3d printing. Our clients would ask for their 3d print to have a gold finishing, chrome or even an exact Pantone color. With current 3d printing technology, this is impossible to accomplish. So we offer metal plating and painting on top of our 3d printing services.

So we offer metal plating and painting on top of our 3d printing services.

Profit margin

For 3D printing companies to stay in business, they need to add a profit margins on top of the 3D printing cost. Profit margins for a 3D printing business can be somewhere between 50% - 90% of material cost. We're using material cost as a basis for the sake of simplicity. But profit margins are actually much lower once you start including labor and overhead costs.

There is also a base price (or a minimum fee) that gets added if if the cost of 3D printing is less than a certain amount. It wouldn't make sense for a company to 3D print something for you for a print that costs $3. Even in a highly automated 3D printing service, there's still some labor involved. Either you add more quantity or pay the base price which is around $30-$90.

3DHubs has a minimum order of $90. It would be wiser if you order multiple quantities of your part to lessen the cost.3D printing service price comparison

Now that we know what factors affect the price of 3D printing, let's see how much it would cost to 3D print this popular WallStreeBets mascot by ChaosCoreTech.

For this test we will be using SLA 3D printing.

We modified the file so we can stress test the on-demand 3D printing services that offer SLA printing.

Scaled it up to 152mm or ~6" high

We hollowed the 3D model. Meaning, the insides are empty.

This makes it use less material, making it cheaper.

Speed up the 3D printing time for SLA, which should lower the cost.

3DHubs

Price: $537

3DHubs won't even allow you to print this in resin as it's bigger than what their manufacturers can print.

i.materialise

Price: $211.17

Cheaper than 3DHubs but they won't clean the supports for you at this price. If you need it cleaned, you need to pay extra.

Shapeways

Price: $2061.56

We're not sure why it's this expensive. They might have miscalculated the model volume which made it seem that this piece would require half a liter of resin to print.

But, either way, Shapeways is the most expensive one out of this group.

But, either way, Shapeways is the most expensive one out of this group.Most Affordable

PrintAWorld

Price: $136.32

Disclaimer. This is our 3D printing company. For SLA 3D printing, we are definitely the cheapest compared to the others in this group. Removing the supports and polishing is even included in the service.

Try it out

Why are 3D printing services expensive?

3D printing services are expensive because we have to account for factors mentioned beforehand such as labor, post processing and overhead costs. We also have to account the industrial 3D printers that they use, which cost at least $100,000 and upwards. Plus, they have to add profit margin on top of that cost.

This begs the question, is it better to buy a 3D printer instead?

Should you buy a 3D printer or hire a 3D printing service?

3D printing services can sometimes cost more than an entry level 3D printer. So you might be wondering if it's better to buy a 3D printer instead.

Here's our thoughts on that:

If cost is a problem for you and you're only 3D printing for fun, then buying a 3D printer might be the better investment in the long run.

If your time is more valuable for you, then hiring a 3D printing service would be the better option. You'll have access to large scale 3D printers and capabilities that is impossible to achieve with DIY 3D printing.

Best Budget 3D Printer

Anycubic Photon Mono

The Photon Mono is the best LCD 3D printer that we've gotten our hands on. We own 8 of these machines and use it as part of our manufacturing process. It's cheap but the print quality is almost the same as the ones that we get from our Formlabs 3. If you're looking to buy your first 3D printer, we recommend going for a resin 3D printer like this one instead of buying an FDM printer.

$229.00 from Anycubic

Commisions earned

In Summary

Multiple factors affect the price of a 3d printing service. If you add in all these variables, you're looking at anywhere between $30 to $15,000 for the cost of 3d printing. The price can even be lower or higher, depending on the scale of your project.

If you add in all these variables, you're looking at anywhere between $30 to $15,000 for the cost of 3d printing. The price can even be lower or higher, depending on the scale of your project.

Printing of ABS (ABS) plastic using FDM technology to order

Printing of ABS (ABS) plastic using FDM technology to orderPrinting ABS (ABS) with plastic using FDM technology to order

Technology: 3D PRINT

Loading ...

Loading ...

Loading ...

Loading ...

Loading ...

Loading ...

Loading ...

Loading ...

Loading ...

Loading ...

Loading ...

Price

no more than 12 o/cm 3

Processing cost

+ 50 o for processing 1 item

Printing time

from 1 to 3 days

Calculate the cost

Price

no more than 25 o/cm 3

+ 50 o for processing 1 item

Printing time

We print on the day of order*

Calculate the cost

Price

no more than 25 o/cm 3

Processing cost

+ 50 o for processing 1 item

Printing time

from 1 to 3 days

Calculate the cost

Price

no more than 70 o/cm 3

+ 500 o for processing 1 item

Printing time

from 5 to 7 days

Calculate the cost

Price

no more than 25 o/cm 3

Processing cost

+ 50 o for processing 1 item

Printing time

from 1 to 3 days

Calculate the cost

Price

no more than 25 o/cm 3

Cost per treatment

+ 50 o for processing 1 item

Printing time

We print on the day of order*

Calculate the cost

Price

no more than 12 o/cm 3

Cost per treatment

+ 50 o for processing 1 item

Printing time

from 1 to 3 days

Calculate the cost

Price

no more than 70 o/cm 3

Cost per treatment

+ 500 o for processing 1 item

Printing time

5 to 7 days

Calculate the cost

Need an alternative?

More accurate

Photopolymer

Higher quality

Polyamide

Beneficial for series production

Molding plastic into silicone

Feedback form for calculating the cost of 3D printing

If you have a finished 3D model, upload it to the online form to calculate the cost of 3D printing. nine0041 If you do not have a 3D model or need a preliminary consultation, contact us by phone +7 (499) 390-03-77, send a 3D model with questions to our mail [email protected] or fill out an application, we will contact you and answer all your questions.

nine0041 If you do not have a 3D model or need a preliminary consultation, contact us by phone +7 (499) 390-03-77, send a 3D model with questions to our mail [email protected] or fill out an application, we will contact you and answer all your questions.

Fields marked with an asterisk (*) are required

nine0000 SLS printing with polyamide on a custom 3D printer SLS printing with polyamide on a custom 3D printerSLS printing with polyamide on a 3D printer to order

Technology: 3D PRINT

Loading ...

Loading ...

Loading . ..

..

Loading ...

Loading ...

Loading ...

Loading ...

Loading ...

Loading ...

Loading ...

Loading ...

Loading ...

Loading ...

Loading ...

Loading ...

Loading ...

Loading ...

- nine0034

Price

from 150 o/cm 3

Cost per treatment

+ 50 o for processing 1 item

Printing time

from 3 to 7 days

Calculate the cost

Price

Considered individually

Processing cost

Calculated individually

Printing time

from 10 to 15 days

Calculate the cost

Price

Considered individually

Processing cost

Calculated individually

Printing time

from 10 to 15 days

Calculate the cost

Price

from 150 o/cm 3

Processing cost

+ 50 o for processing 1 item

Printing time

from 3 to 7 days

Calculate the cost

Need an alternative?

More accurate

Photopolymer

Cheaper

ABS

Beneficial for series production

Molding plastic into silicone

Feedback form for calculating the cost of 3D printing

If you have a finished 3D model, upload it to the online form to calculate the cost of 3D printing.