Recycled 3d printer

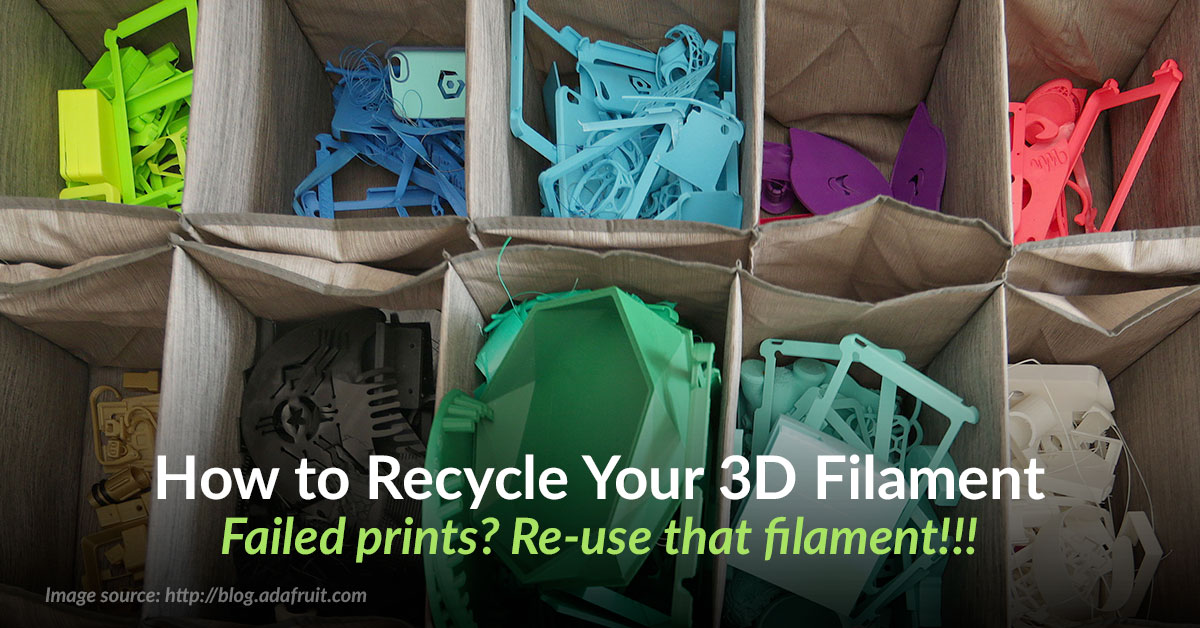

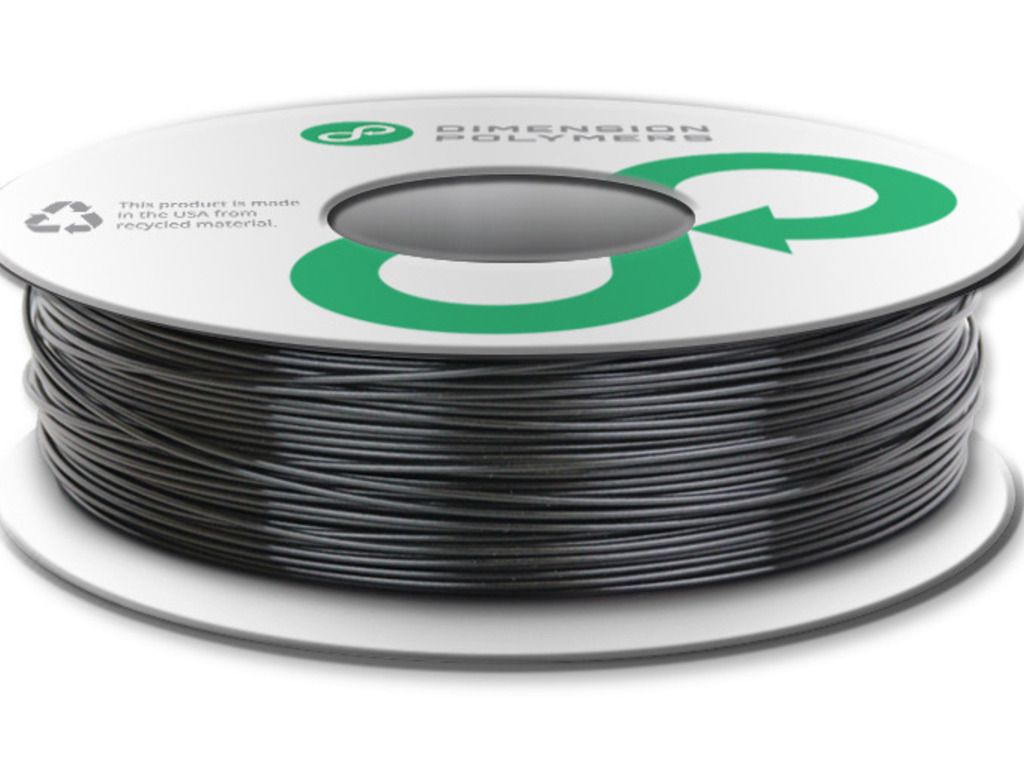

Closed Loop Plastics Recycled 3D Printer Filament

Closed Loop Plastics’ Party Pink is an upcycled high impact polystyrene (U-HIPS) 3D printing filament made entirely from post-consumer plastic cups and lids. Each spool is produced in Long Beach, CA, where plastic waste from the community is given new life as 3D printer filament for makers, engineers, and enthusiasts everywhere. The finished product is an affordable, high-quality U-HIPS 3D printing filament that provides a sustainable way to prototype your next great design. Every millimeter of Closed Loop Plastics Party Pink U-HIPS 3D printing filament has already served someone as a cup to hold a delicious beverage. Instead of ending up in a landfill, however, the team at Closed Loop Plastics collected, granulated, decontaminated, and extruded the cup into a structural material that can now serve you once again as filament for your 3D printer! Party Pink U-HIPS 3D printing filament is a product you can feel great about buying and using.

Guides & Articles

How to Succeed When 3D Printing with Polypropylene

Successfully produce 3D printed parts out of polypropylene filament with these tips on achieving stronger bed adhesion and minimizing shrinkage.

How To Succeed When 3D Printing With PLA Filament

Discover the best practices for 3D printing with PLA filament - from finding the right temperature, to which surfaces to 3D print on, this step-by-step guide will help you succeed with 3D printing PLA.

How To Succeed When Printing With ABS

ABS filament is a versatile material that's a great option for when you need your 3D-printed parts to be strong and heat-resistant. Learn how to print this material like a Pro in this in-depth guide.

Printing Tips & Tricks: ABS Bed Adhesion

ABS: stronger, more durable, and more heat-resistant than PLA.

An excellent 3D printing material, but ABS is prone to warp. Stop warping on your ABS prints, and create strong bed adhesion to produce flat prints by following these tips.

Stop warping on your ABS prints, and create strong bed adhesion to produce flat prints by following these tips.

Living Hinge: Design Guidelines and Material Selection

Bring your prints to life by adding an additional degree of motion to your designs - living hinges are the foundation of expanded mechanical solutions.

Printing with Bronzefill

Bronzefill filament is made with real bronze powder and offers a unique look and feel for your decorative 3D printed parts

How To Succeed When 3D Printing With Nylon

Learn how to 3D print Nylon like a pro. Nylon is a stronger and more durable alternative to PLA or ABS and easy to 3D print with using these Tips and Tricks.

3D Printer Troubleshooting Guide

Use this guide to help you identify and solve the most common issues that may occur while 3D printing.

3D Printer Filament Comparison Guide

There are many different kinds of 3D printer filament, and each one has it's own strengths for different projects. Knowing these differences is key to a successful 3D printing experience and so we have created a Filament Comparison Guide with everything you need to know about every type of filament available.

Knowing these differences is key to a successful 3D printing experience and so we have created a Filament Comparison Guide with everything you need to know about every type of filament available.

Machine to Recycle Waste Plastic Into Filament for 3D Printing Wins Major Award

3D printing news News Machine to Recycle Waste Plastic Into Filament for 3D Printing Wins Major Award

Published on November 22, 2022 by Claire S.

The James Dyson award is an international competition led by the eponymous entrepeuneur. It rewards engineering or design projects which ‘solve a problem’, and the Polyformer certainly does this. Reiten Cheng and Swaleh Owais have developed a machine which recycles plastic from water bottles into filament for FDM 3D printing, making it accessible for developing countries. The project was the recipient of the prestigious Sustainability division of the James Dyson Award.

The designers were inspired by a 3D printing website which features recycling and sustainability stories. They wanted those in developing countries to be able to benefit from 3D printing technologies while also repurposing waste materials. Owais completed this project in Rwanda at the Deutsche Gesellschaft für Internationale Zusammenarbeit (GIZ) GmbH, hoping to make a product which can solve the high shipping costs of filament into Africa.

They wanted those in developing countries to be able to benefit from 3D printing technologies while also repurposing waste materials. Owais completed this project in Rwanda at the Deutsche Gesellschaft für Internationale Zusammenarbeit (GIZ) GmbH, hoping to make a product which can solve the high shipping costs of filament into Africa.

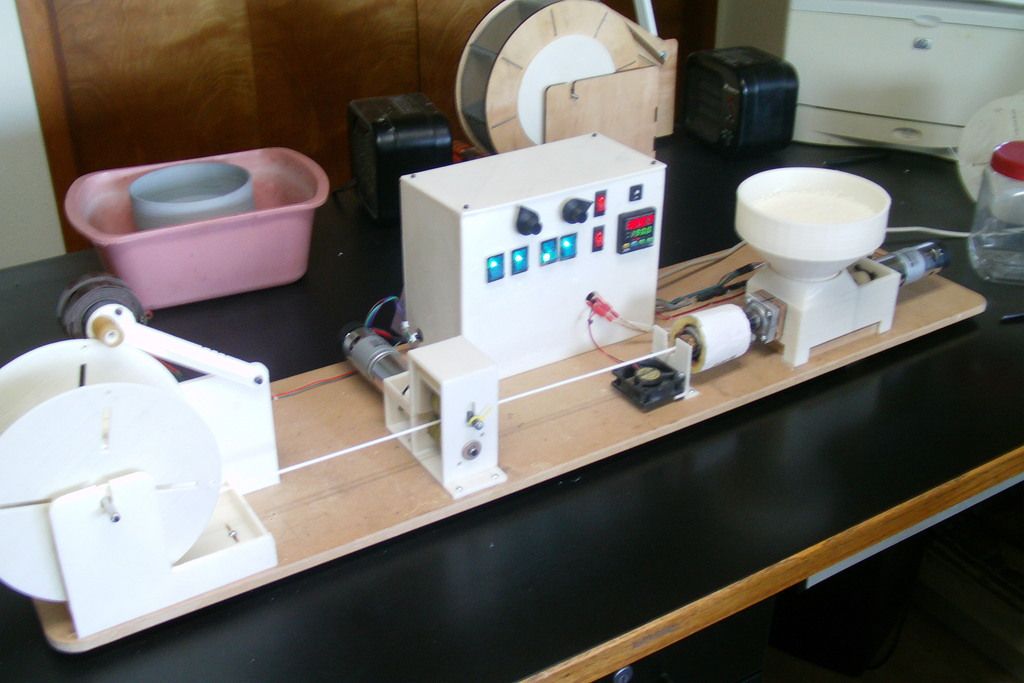

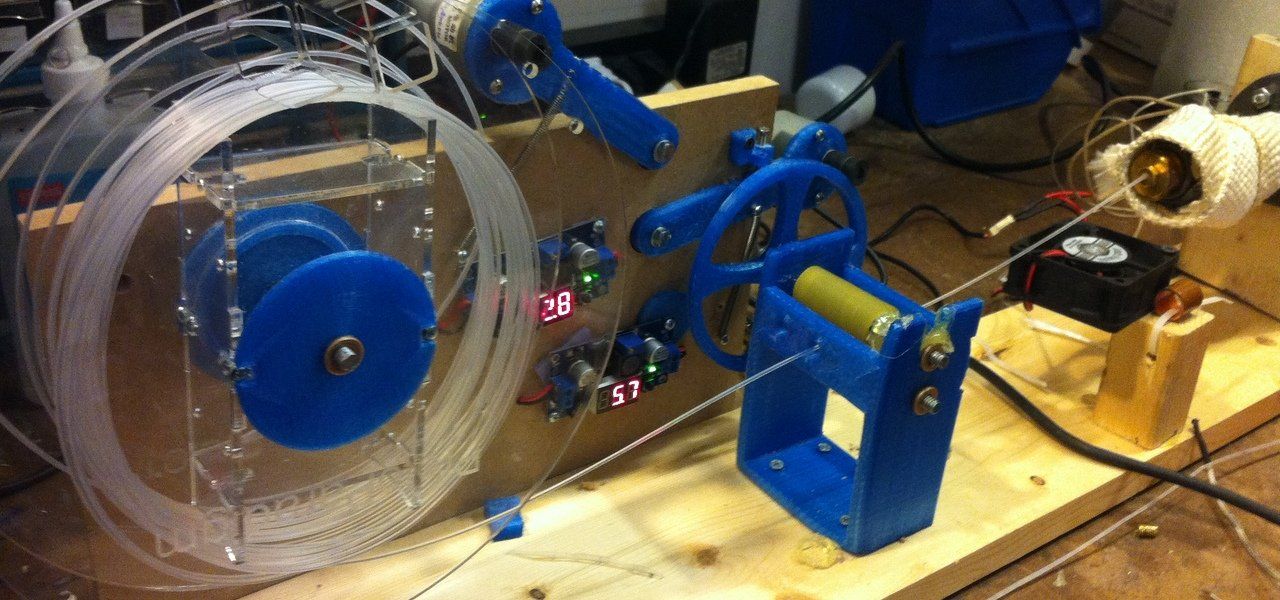

Construction of the Polyformer machine. (Photo credit: Reiten Cheng)

Recognition and Awards

The Polyformer was awarded the James Dyson award for Sustainability, chosen by the inventor himself. The Award is given every year to innovative projects and the pair will use the prize money to produce more Polyformers for use in 3D printing labs in Rwanda. This can go some way to solve litter by recycling plastic. They plan to then collect user feedback and expand the project to other developing countries. Further side projects to complement the Polyformer are also in the works; for example, the Polyjoiner will automatically connect filament strands together and the Polydryer will evaporate water from PET to prevent negative print quality. Finally, the Polyspooler will automatically create spools of filament for ease of use.

Finally, the Polyspooler will automatically create spools of filament for ease of use.

Sir James Dyson, Founder and Chief Engineer at Dyson commented, “By turning used plastic bottles into 3D printer filament, Polyformer helps reduce the amount of waste going to landfill and provides a cheap and plentiful material for engineers and designers, especially in developing countries. Their idea will provide new opportunities for other inventors to prototype their ideas using 3D printing.”

The Technical Stuff

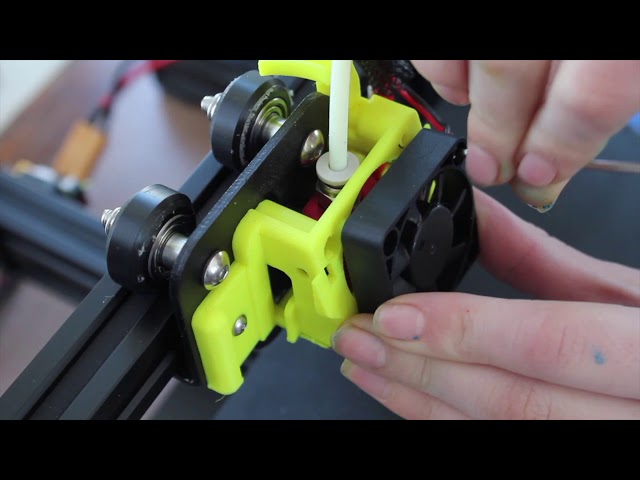

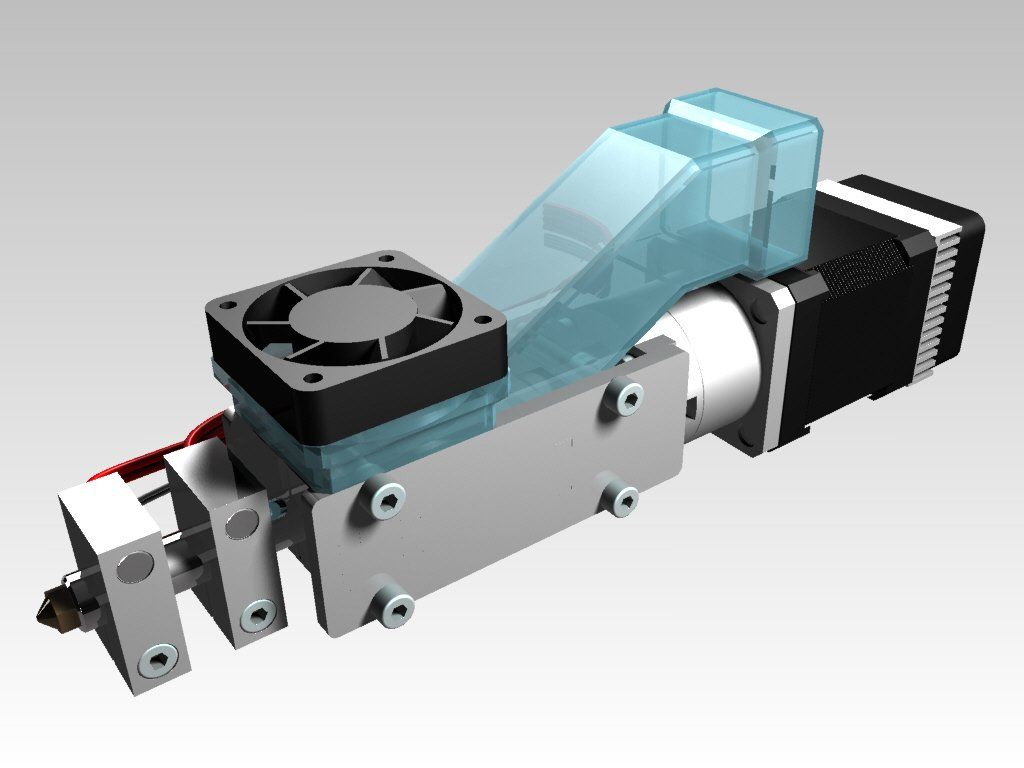

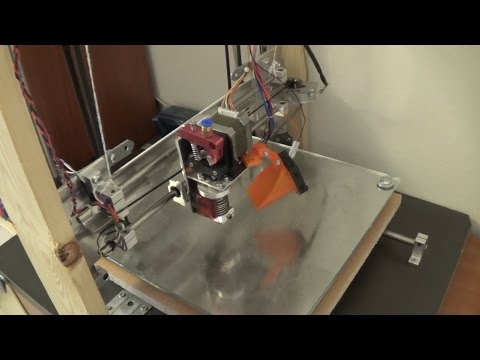

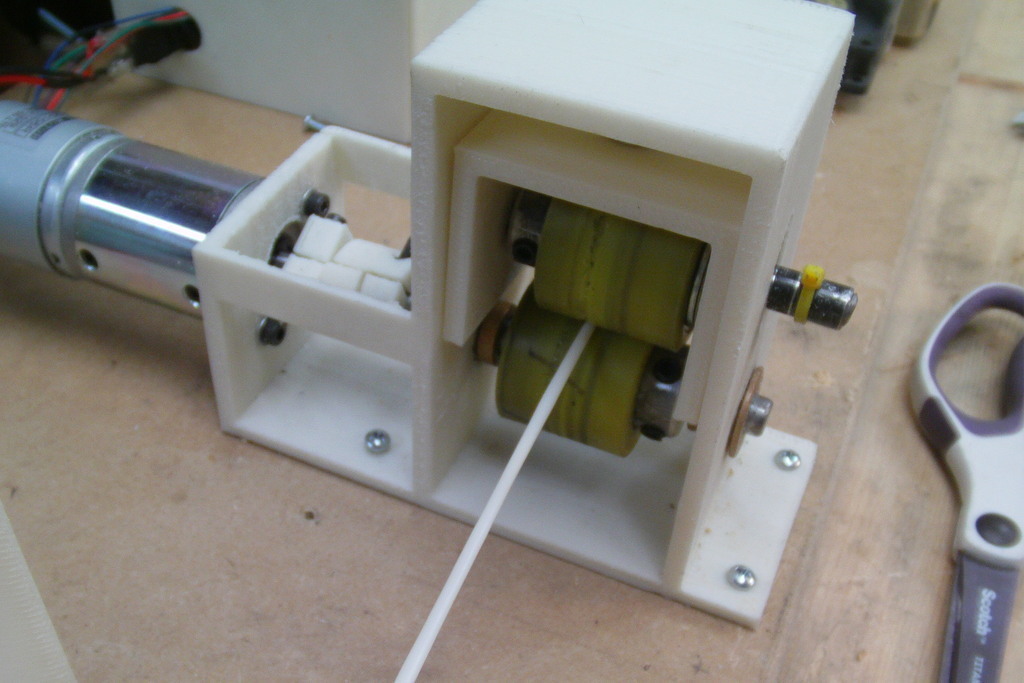

The Polyformer has a modular architecture. To make the filament, a slicing tool can cut the plastic bottle into a ribbon to be fed into the hot end. The ribbon is thermoformed into a 1.75mm filament, which can be mounted to the motorized spool. Once this filament is made it can be transferred o a 3D printer. The Polyformer is designed to be built with mainly 3D printed parts to make it more accessible globally. Furthermore, all the technology is open-source. The designers made the decision to make it publicly available without a patent so that others may create their own. Other criteria chosen by Cheng and Owais were a simplified process, avoiding supports and post-processing as much as possible to create a compact, easy to assemble and easily modifiable machine.

The designers made the decision to make it publicly available without a patent so that others may create their own. Other criteria chosen by Cheng and Owais were a simplified process, avoiding supports and post-processing as much as possible to create a compact, easy to assemble and easily modifiable machine.

The complete Polyformer machine. (Photo credits: Reiten Cheng)

The Polyformer innovation lies in its dual benefits of waste prevention and improved accessibility of 3D printing to developing nations. They are not the first to seek to reuse waste products – for example, a US company will build 10 homes using recycled plastic. On a smaller scale, researchers in Singapore have used recycled glass for sand printing. You can find out more from the designer’s website HERE, and more information about the James Dyson Award can be found HERE.

What do you think of the Polyformer and the James Dyson Award? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

9 Projects 3D Printing From Plastic Waste

Plastic waste, which not so long ago went straight to landfill, is increasingly being recycled, not least 3D printers.

By using post-consumer plastic as a raw material for 3D printing, corporations, small businesses and even individuals can create new products with real value while removing plastic waste from the environment. Let's figure out what is created from plastic waste using a 3D printer and who does it. nine0003

How to prepare material for 3D printing from plastic waste

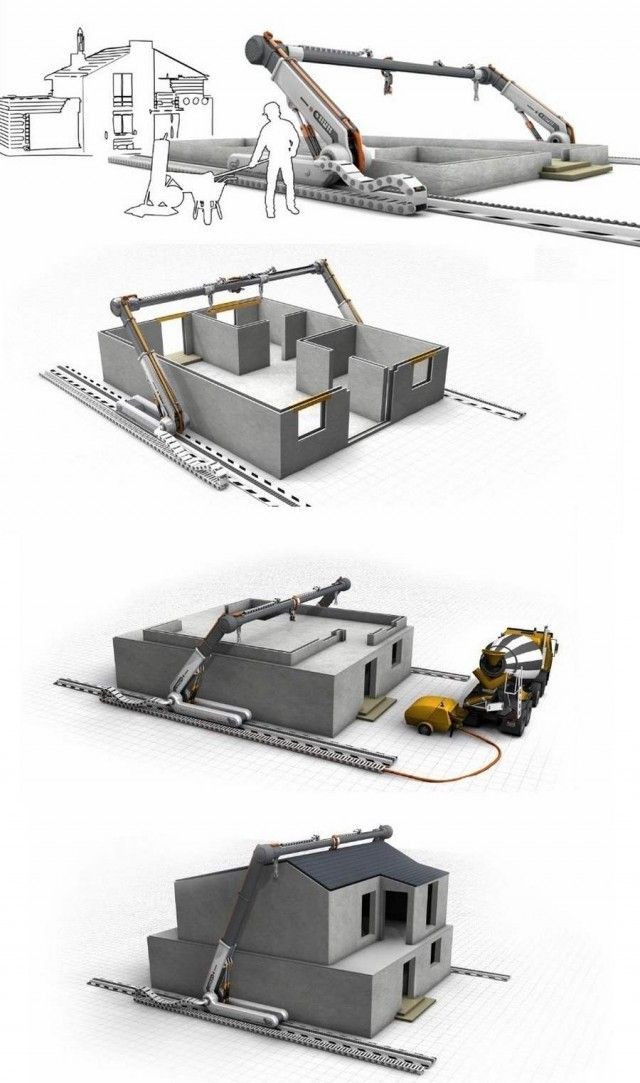

The process of making useful products from local plastic waste using 3D printing is quite simple. Known as distributed recycling and additive manufacturing, or DRAM for short, it involves the following steps:

• Plastic waste collection.

• Waste sorting and cleaning.

• Shredding waste into plastic pieces.

• Extruding 3D printing filament from plastic shred with an extruder. nine0003

• Product printing.

Video: thenewraw.org

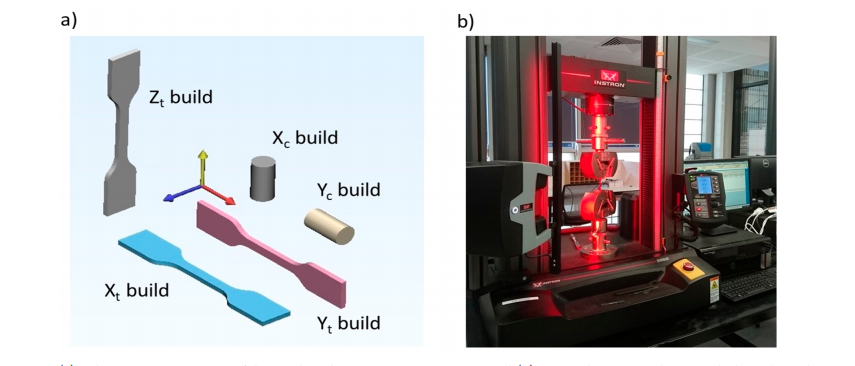

Thread made in this way retains almost all the same qualities as pure plastic, but is much cheaper. According to a study by Aubrey L. Verne (et al.) of Michigan Technological University, a 3D printer can print objects at a cost 1,000 times less than if commercial polymer fibers were used.

There are different types of shredders, extruders and 3D printers on the market today, both in terms of cost and complexity of the tasks performed. nine0003

For example, for home use, manufacturers have long used a simple blender or grinder to grind up 3D print stock and failed prints, but this is not a long-term or high-volume solution.

More and more 3D printers can print with raw shredded plastic or bulky plastic pellets instead of filament. This simplifies the process and reduces energy consumption. The cost of a simple 3D printer can be $2,000, and a complex industrial one can cost more than $150,000. nine0003

The cost of a simple 3D printer can be $2,000, and a complex industrial one can cost more than $150,000. nine0003

Introducing 9 successful projects that prove that 3D printing from household plastic waste is a viable solution for removing plastic from the environment, while also making a difference.

Plastic Bottle Olympic Podiums

Unbeknownst to everyone, recycled plastic has taken center stage at the Tokyo 2020 Olympics. Each of the 98 podiums where medals were presented to Olympic winners was 3D printed from waste plastic. nine0003

Catwalk material has been collected by Japanese citizens over the past two years through a program sponsored by consumer goods giant Proctor & Gamble. More than 2,000 bins have been set up across the country to collect empty drink bottles, shampoo containers and other plastic waste. Plastic waste has also been fished out of the seas surrounding Japan.

After the games, some of the podium plastic will be used to educate the public about sustainability, and much of it will be recycled back into packaging for P&G products. nine0003

Plastic waste bins

Screenshot: 3D printed waste bin by Justina Zdanovichute, in collaboration with R3direct.

(Source: Justyna Zdanovichute/CC BY-NC-ND 4.0)

How about collecting plastic waste in trash cans made from the same waste? Italian design company R3direct makes them and more using 3D printing. The company has one stated goal: to design and 3D print products from plastic waste. R3direct's product list grows longer every year, from artwork made from local plastic waste to practical urban furniture. nine0003

R3direct states that their printing technology can use plastic pellets immediately after grinding, skipping the filament extrusion step. This allows them to further reduce their energy consumption and CO2 emissions with 3D printed furniture made from waste plastic.

Trendy Fishnet Seats

Photo: facebook/@bluecycle use of marine plastic waste from shipping and fishing. nine0003 New Raw has also teamed up with The Coca-Cola Company for the Zero Waste Future program in Thessaloniki, Greece. Consumers will bring their plastic waste to the Zero Waste Lab, which has a plastic recycling facility and a robotic arm, to create custom-made modern furniture. One of the partnership's furniture series is called Elements and includes a solarium, walk-in closet and walkway made from recycled marine plastic waste. There's no better way to showcase the potential of recycling plastic waste than to let people enjoy a clean beach while lying on a lounge chair made from what used to pollute the water. nine0003 New Raw is launching a Print Your City program in several neighborhoods that allows local residents to recycle their plastic waste through a robotic 3D printing process that can turn sorted plastic into outdoor furniture. Photo: instagram/@yuma.labs.circular closed loop models. nine0003 Yuma Labs uses both powder pad 3D printing and injection molding to make their sunglasses. The raw materials are recycled soda bottles and bio-based nylon. In the future, the frames of sunglasses can be completely recycled. Yuma Labs partners with companies, cities and events such as the Tomorrowland Music Festival to collect the plastic waste generated at the event. And the sale of sunglasses, then printed on a 3D printer from this garbage, covers the cost of collecting plastic. nine0003 Yuma Labs also organizes and participates in community events to raise awareness about recycling. For example, in 2019 they organized an event at the Stormkop playground in Antwerp where children had to pull plastic trash from a nearby river. The company then 3D-printed it into children's sunglasses. As Yuma Labs says, it's not just the production of sunglasses or the recycling of plastic that matters. Utility Vehicle (ZUV) is an electric trike with a 3D printed frame made from recycled polypropylene plastic. Developed by Austrian design firm EOOS and Dutch 3D printing company The New Raw, ZUV aims to do more than reduce plastic waste. Its creators hope it can become the new type of zero-emission vehicle for cities around the world. nine0003 According to the developer's plans, consumers can 3D print the ZUV's polypropylene frame using a 3D printing service such as Craft Cloud and then take it to a bike shop to have the motor, wheels, lights and handlebars installed. The square ZUV has a rear wheel drive and a spacious trunk. It can be ridden by two adults. EOOS hopes to raise awareness of the environmental impact of urban transport and offer an alternative mode of transportation based on a circular economy. ZUV is currently only in the prototype stage and its blocky look may not be to everyone's liking. However, the concept is promising, and the car has every chance of becoming an ordinary city landmark. Photo: lofbergs-com.mynewsdesk.com Swedish coffee group Löfbergs is partnering with 3D printing company Sculptur to turn coffee waste into new coffee stations. The collaboration is part of Circular Coffee Community's commitment and the group's goal of zero coffee waste by 2030. The world's first 3D printed waste-based coffee station is already up and running and others are underway. nine0003 The coffee stations are 3D printed from a by-product of the coffee roasting process and polypropylene. Further development will allow the use of polypropylene from recycled coffee big bags, making coffee stations almost 100% renewable. “Our new coffee station is a prime example of a closed loop—recycling leftovers from our own primary raw material, coffee, to create an entirely new and associated sustainable product. Photo: instagram/@architechcompany interiors. Modular circular workspace printed from recycled PET (supplied by the Port of Rotterdam) using a CFAM printer and reinforced with fiberglass. The convenient and strong workplace easily disassembles and moves. The round shape ensures pleasant acoustics of the workspace, it is equipped with ventilation, heating, electricity and LED lighting. nine0003 Photo: instagram/@therogerie Canadian company The Rogerie is working to remove waste from the environment, with the help of small suppliers who remove it from landfills and oceans, and create from this waste beautiful, useful items. The Rogerie's 3D printed product catalog includes mugs, bathroom accessories, teapots and a wide selection of flower pots, among others. The company's founders say they are constantly looking for new waste streams and also have their own recycling program. They are willing to use anything from old TVs to food packaging and car parts. Photo: instagram/@utilizestudios The Utilize project turned used coffee stirrers into chandeliers, soft plastic items into wicker baskets, and fishing tackle into chairs. And all this with the help of an oven and a desktop 3D printer from Ultimaker. nine0003 Utilize is more than a design studio, it specializes in helping companies transition to a circular economy and build sustainable products. They aim to help businesses reduce, reuse and recycle waste through 3D printing. “The biggest surprise was how many types of waste we can use – soft plastics, organics, polypropylenes and polyethylenes – we kind of asked, why isn’t everyone doing this?” , said Utilize Project founder Matthew O'Hagan in an interview with Stuff magazine. “We started in 2018, right out of college, by finding a way to recycle red “party” plastic cups into 3D printing filament. That idea has now grown into a pretty cool company that takes plastic waste and turns it into 3D printable material.” For 4 years, Closed Loop Plastics has been creating new materials, new colors and enabling anyone with access to a 3D printer to participate in the circular economy by printing with their products. nine0003 "We give people access to certified and fully sustainable materials right in their printers without any major adjustments or changes to their process." Will tells the story of how CLP was born: “I started 3D printing in 2015 as part of the UC Irvine team for the Solar Decathlon, which is a competition for building solar-powered houses. “The first thing we did was think about recycling. At first we recycled printed plastic, but then we realized that we do not have a critical mass of plastic waste from 3D printing alone. We have figured out how to use waste from other sources, such as food containers, to really solve this problem and create a high performance polystyrene (HIPS) recycling element. We made it possible for people to use material for really interesting purposes, instead of sending it to the landfill. Our ideas have definitely gone big. To give you an idea, our first product we were going to sell as a company was a recycling cart (similar to an audio visual cart) and the idea was that it could be rolled around a plastic waste recycling lab. It's been a few years, and now we've reached the point where we're applying for municipal bonds to build county-level infrastructure so CLP can build these businesses that recycle hundreds of thousands of people's plastic waste every day. When we think about it, it's amazing. nine0003 We have moved from a decentralized lab-based approach to a wastewater infrastructure-based approach. I think that's cool, and it reflects the education that Aldrin and I received as environmental engineers, combined with our other co-founder, Sharon To, with a background in computer engineering. Closed Loop Plastics was originally focused on high impact polystyrene (HIPS) material (as Will explains below), but its use opens up endless possibilities for almost all plastics. “We chose HIPS because we needed a recycled plastic that was not so specific that it could only be used in 3D printing. We wanted something that could be used in 3D printing, but not only in it. . HIPS plastic is a widely used material for supports or for rough 3D printing. We wanted to try recycling it because it's a great thermoplastic and very easy to recycle in its original state. After we settled on HIPS, we needed to focus on getting it clean and ready for 3D printing. We first offered it in Party Pink, which was an unpigmented color, essentially a mix of all the different HIPS plastics we put in our system. CLP ensures the quality of its filament by monitoring the diameter and dynamically controlling the output. Diameter tolerance is a key point of failure for any filament, as Will explains: “We knew that if our filament had poor diameter tolerance (getting wider, smaller, changing shape, etc.) then it would be difficult for users to print with it. We are seeing an amazing expansion of our product. Since our U-HIPS is a highly durable material that does not get dirty (after processing), printing on it is easy and does not require additional surface treatment. It is easy to print from and does not require surface treatment. It can even be used on a system that is not closed. There are many things about our U-HIPS product that make it truly unique, allowing manufacturers of any experience level to participate in the circular economy at any level right now. We have a client, Leviathan 3D Printing on the East Coast, who reported receiving our product from Matterhackers and is delighted with the print results. CLP has built a solid fan base that enjoys using its products, and manufacturers have found some really innovative uses for it. The company recently featured on its blog some fantastic handheld body surf planes made by an Orange County High School teacher. He surfaced and painted them, and they look like a finished product. “We had a lot of people in the early days who thought it wouldn't get accepted because it was too hard stuff to use,” Will explains. “As our product has grown and improved in quality, we have seen many people adopt it and dedicate themselves to making it work on their systems. We have people prototyping in their labs, students using it for various projects, and even a few professional prototyping agencies using it to create all sorts of cool things.

Music festival waste sunglasses frames

They hope to inspire others with their example for a broader transition to a circular economy. nine0003

They hope to inspire others with their example for a broader transition to a circular economy. nine0003 Plastic Waste Urban Lightweight Vehicle

nineThe 0003

nineThe 0003 Coffee station made from coffee waste

” , says Lars Aen Tegersen, Director of Innovation and Circular Transformation at Löfbergs.

” , says Lars Aen Tegersen, Director of Innovation and Circular Transformation at Löfbergs. Cozy office space made from plastic bottles

Beautiful objects made from garbage

Customers love these products - by purchasing them they are contributing to the removal of plastic waste from the environment. nine0003

Customers love these products - by purchasing them they are contributing to the removal of plastic waste from the environment. nine0003 Coffee stirrer chandeliers

- nine0023 "Why isn't this being done?"

- nine0023 "Why isn't this being done?"  . I was put in charge of the tool room of the future, mostly because I was a sophomore engineer and didn't know much, so I took Aldrin and a few other college buddies with me and created this tool room. As a prize, we were presented with a 3D printer, and then for the first time we thought: “Well, we are environmental engineers, and this is an environmentally friendly economy. How can we make 3D printing sustainable? It was a neat prototype tool, but it used a lot of plastic, so we wanted to find a solution to recycle the plastic that goes back into the 3D printer.” nine0024

. I was put in charge of the tool room of the future, mostly because I was a sophomore engineer and didn't know much, so I took Aldrin and a few other college buddies with me and created this tool room. As a prize, we were presented with a 3D printer, and then for the first time we thought: “Well, we are environmental engineers, and this is an environmentally friendly economy. How can we make 3D printing sustainable? It was a neat prototype tool, but it used a lot of plastic, so we wanted to find a solution to recycle the plastic that goes back into the 3D printer.” nine0024

So we started thinking about how to make 3D printing green, and then it became clear that our job was to figure out how to make the use of plastic generally green on our planet. nine0024

So we started thinking about how to make 3D printing green, and then it became clear that our job was to figure out how to make the use of plastic generally green on our planet. nine0024  Aldrin and I can think in terms of large-scale infrastructure, and Sharon can think in terms of focused control systems, and all this has led to successful team dynamics. We trust each other and our skills, which allows us to change direction as needed and expand our scope.” nine0053

Aldrin and I can think in terms of large-scale infrastructure, and Sharon can think in terms of focused control systems, and all this has led to successful team dynamics. We trust each other and our skills, which allows us to change direction as needed and expand our scope.” nine0053  As our clients grew, they were interested in additional colors, and then we added Nebula Black. This was our first experience of introducing any additives into the process. It was a great experience that made us learn a lot. There were blockages here, there were running out of machine parts, but we realized that we could create a new, differentiated product. We are still testing for other colors and even new materials. We are going to test 3D products with new plastics like PLA, PETG and ABS. We are constantly thinking about making something more accessible to the market, because HIPS is not as widely used as other types of plastic.” .

As our clients grew, they were interested in additional colors, and then we added Nebula Black. This was our first experience of introducing any additives into the process. It was a great experience that made us learn a lot. There were blockages here, there were running out of machine parts, but we realized that we could create a new, differentiated product. We are still testing for other colors and even new materials. We are going to test 3D products with new plastics like PLA, PETG and ABS. We are constantly thinking about making something more accessible to the market, because HIPS is not as widely used as other types of plastic.” .  help. So we've built a system that monitors the ovality and diameter of the filament about a thousand times per second. Tons and tons of samples are required, then we can adjust the speed of extrusion and material drawing. We can change it in the process. Many plastic manufacturers produce a low-quality batch and have to throw it away, so our ability to correct during the printing process is really useful. nine0024

help. So we've built a system that monitors the ovality and diameter of the filament about a thousand times per second. Tons and tons of samples are required, then we can adjust the speed of extrusion and material drawing. We can change it in the process. Many plastic manufacturers produce a low-quality batch and have to throw it away, so our ability to correct during the printing process is really useful. nine0024  They used it to create student projects for accessibility reasons. The students designed things to be used by other people with limited hand capabilities. It is the epitome of recyclability and the circular economy and it is great to see our product being used in this way.” nine0003

They used it to create student projects for accessibility reasons. The students designed things to be used by other people with limited hand capabilities. It is the epitome of recyclability and the circular economy and it is great to see our product being used in this way.” nine0003

Learn more