Sd300 pro 3d printer

My SD300 3D Printer

One step forward, two setbacks

My SD300 is electrically crippled, but I found a secondhand Invision LD that I've been trying to get running. The two machines are internally compatible, but this particular Invision LD had suffered damage in storage.

Before troubleshooting anything else, there's a fault in its height-check sensor that prevents the machine from completing its startup. As a result, the machine gets stuck in a silly repeated loop of repeatedly hooking and unhooking the iron bridge, where the height-check sensor resides.

It looked like the machine was moving the height-check sensor to the wrong position, so the table wasn't making contact with the sensor. Maybe the Y-axis isn't getting calibrated to the right position?

So I cleaned the Y-axis home sensors by blasting them with canned air.

That seemed to help.

Now the machine initializes and feeds PVC onto the build table, but it intermittently fails to trim the material. To trim the PVC, the machine is supposed to raise the build table until the white cutting board (green arrow) makes contact with the trimming knife. But the Y-axis position is still wrong, so it's positioning the trim knife too far away from the table (red arrow). I used the maintenance utility to re-calibrate "accurate XY home" but then the machine was even farther out of calibration!

So, what gives?

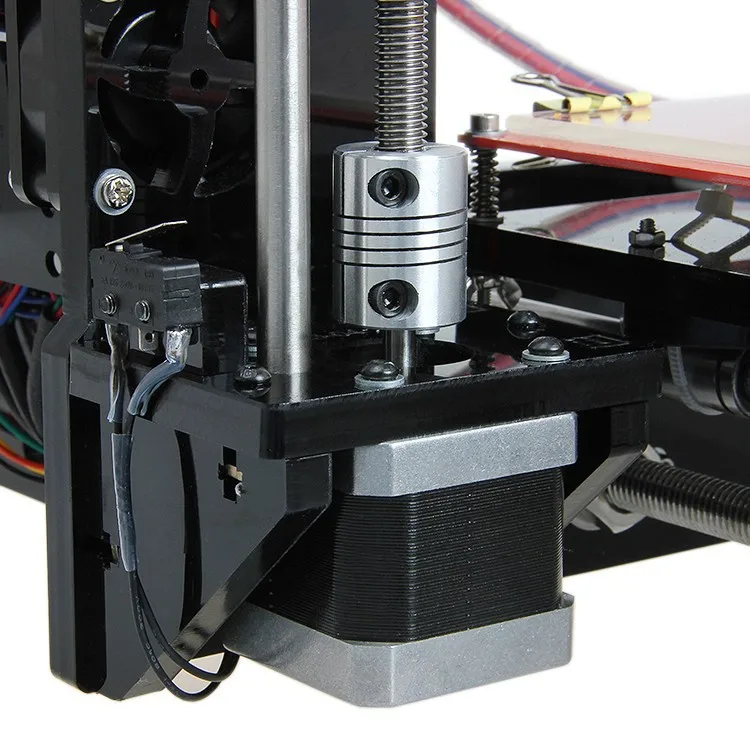

I lowered my camera into the machine and took a picture of the Y-axis home sensors.

The picture suggests the sensor on the left has been bent out of shape, possibly by an impact. The two sides should be absolutely parallel, but the nearer side has been bent to the right. It looks like its base is cracked through the mounting screws, which undoubtedly interferes with accurate sensing. That probably accounts for a lot of the machine's odd behaviors.

All right, I will replace this damaged sensor with an identical part from my SD300 and try again.

(Hoping.)

Rebirth, and working toward a New Ending

In its prime, my SD300 worked loyally through night and day to produce my toys and puzzles. So I'm not entirely content to let its story end so ungraciously.

Today is my birthday, so my wish is to get the machine running long enough to produce a "farewell" batch of puzzles. Or at least keep trying while my supplies last.

I found a secondhand Invision LD, a 3D printer of the same type but with a different brand name. It has all the same internal machinery as the SD300 so I hope I can exchange enough parts between the two machines to get one of them running.

The SD300's motor-control circuits don't work, probably deterioration from glue/solvent leaks, but the machinery is intact so I can use it for parts.

The Invision LD is electrically sound, but it arrived with a lot of mechanical faults. Can I get it running with parts donated from the SD300?

So far I've managed to resolve enough issues to get the machine started, but it sure isn't working properly yet. Glue keeps getting into the anti-glue pens, grossly contaminating all surfaces and making everything bond together. So far I've managed to build a few solid vinyl bricks!

Glue keeps getting into the anti-glue pens, grossly contaminating all surfaces and making everything bond together. So far I've managed to build a few solid vinyl bricks!

Conversely, the ironing pressure isn't always sufficient to bond things together even when they should stick together. For instance, the first layer doesn't always stick to the table--sometimes it just slides away!

Perhaps I will exhaust my supplies trying to repair the machine. That's acceptable to me because there's no need to keep trying after the supplies are gone -- that's all there is.

But maybe I'll get it running long enough to create some special tribute, a memento, a toy. That's worth a shot.

Either way, it'll be cathartic. Happy birthday, Scott.

Breakdown, a broken banjo bolt, and glue everywhere.

My SD300 broke down at the end of 2015, its first serious fault. The machine had clocked over 6000 hours of build time, plus an additional 10,000 hours of power-on time, so maybe it was just about time something broke.

The machine had clocked over 6000 hours of build time, plus an additional 10,000 hours of power-on time, so maybe it was just about time something broke.

I had to mail-order various replacement parts from overseas, so I did the work in short sessions over the course of several months. The machine is running now.

It started when I had left the SD300 running unattended, which wasn't uncommon. I came home to discover the machine halted with a severe fault, a broken-out panel underneath, and a puddle of solvent-glue.

No doubt there was a glue leak somewhere inside, so I removed the exterior cowl to trace it back to its source.

| Opening left side cowling to reveal cable carriers, wiring harnesses, and power driver circuits. |

Solvent-glue had leaked onto the cowling panel and melted through the bottom. |

| There was melty plastic residue all over the cable carrier for the iron bridge. |

| Rolling back the cable carrier revealed even more plastic residue. |

| A vinyl wiring harness had disintegrated where it crossed under the steel-armored tubing at the end of the cable carrier. |

| The solvent deposited plastic reside everywhere it leaked throughout the SD300. |

The source of the leak was a tiny, hollow banjo bolt that had broken in two. |

Evidently the leak originated at a hydraulic connection, referred to as a banjo fitting, where a steel-armored PTFE tube was attached to a manifold by way of a hollow bolt that had been broken in two. This is a common type of connection in hydraulic equipment, but the SD300 employs an uncommonly small size: that's a tiny 5 mm screw thread! It was really tough to find a matching replacement in North America, but I eventually managed to source a replacement through Airlines Pneumatics in the UK.

But the SD300 needed more than just replacing the broken bolt because the solvent glue had traveled along the armor of the PTFE tubing by capillary action and destroyed a vinyl wiring harness that had been routed through the same cable carrier. The damaged harnesses and fittings needed to be replaced, too.

That's enough about the damage. The machine is repaired, but I'll post pictures of my repair work separately.

Color! Using Dyes on 3D Printed Vinyl

Material for the SD300 is offered in a very limited selection of colors, so naturally I was intrigued by Sean Michael Ragan's blog post Stain PVC Pipe Any Color You Like. So I bought an assortment of Sculpt Nouveau solvent dyes and tested them on 3D printed vinyl parts from the SD300. They emerged brightly tinted in candy-like colors!

So I bought an assortment of Sculpt Nouveau solvent dyes and tested them on 3D printed vinyl parts from the SD300. They emerged brightly tinted in candy-like colors!

Solvent dyes are very highly concentrated, but they're formulated to be diluted with solvents--like the name implies! I tested a variety of PVC solvents, using disposable pipettes to measure similar volumes of dye. Not surprisingly, I got the best results from the most powerful solvent, SCIGRIP 2007.

The solvents I tested, starting with the most satisfactory:

- SCIGRIP 2007 (formerly Weld-On 2007) tinted the SD300's vinyl parts very quickly, reaching full color in 15-20 seconds. It also strengthens 3D printed parts and leaves a glossy finish.

- Oatey Un-purple Primer was almost as effective as SCIGRIP. It's a PVC pipe primer without the usual purple stain; instead it contains a UV-sensitive fluorescent dye that makes treated parts glow under blacklight.

- PVC Pipe Cleaner with THF (various brands) was substantially less effective than the solvents above, and it took longer for parts to absorb the dye. Look for THF or tetrahydrofuran under the caution label.

- PVC Pipe Cleaner without THF was least effective. It took more time, it did not strengthen parts, and it did not leave a glossy finish like the choices above.

After testing such a wide assortment of solvents, dyes, and tints, I made dozens of these little test puzzles so I handed them out at this year's International Puzzle Party in Ottawa.

I've also been experimenting with a subtle green tint, trying to imitate the appearance of real glass.

Building Puzzles for IPP34

I'm busily cranking out puzzles to exchange, trade, and sell at IPP34. In addition to a few old-standy puzzles here's a look at what's new from me this year. ..

..

Join The Club

For the Puzzle Exchange, this consists of two identical pieces that can be joined together to make a ♣ club shape. Testers at my office gave me plenty of feedback and guidance, and it took some real effort to implement their suggestions. My early revisions resembled an ordinary clover leaf, but testers insisted it needed a widely flared base in order to resemble a Club suit--it took some design ingenuity, but I made it work!

Curlicubes

Although I have built plenty of cubic dissections in the past, this one really surprised me! It has two identical pieces that can be joined together to make a cube, but they just as easily join into a variety of abstract shapes. It's a fancy-looking objet d'art when placed on a light stand, although it's hard to get a picture that shows how pretty it really looks.

Pink Marble & Yellow Marble

These are successors to the colored marbles from the Bag of Marbles which I had previously sold. Pink Marble is a two-piece puzzle, the first in the series that can only be joined together at one specific point on each piece. Yellow Marble is a three-piece puzzle that goes a step further; it's the hardest of the series, but not overly difficult for the average solver.

Pink Marble is a two-piece puzzle, the first in the series that can only be joined together at one specific point on each piece. Yellow Marble is a three-piece puzzle that goes a step further; it's the hardest of the series, but not overly difficult for the average solver.

Credit-card-size SIM storage

This isn't really a puzzle, but it's a useful device when traveling overseas. It exploits the SD300's laminated construction technique to build a thin storage device that's literally the size of a credit card, with storage pockets for four SIMs and an eject tool (or a paper clip). Very handy!

Glue Smear, a super-easy quick fix

Every now and then I've noticed a shiny stripe of SolGL glue across the top layer when a model is being built. There shouldn't ever be glue on the top surface because it can contaminate the Anti-Glue pens, which makes the model difficult to clean. Whenever it appeared this stripe was always perfectly centered, with neatly-defined edges. What's really strange is that it usually appeared when I'd just installed a new roll of fresh, clean material. How did it get there?

Whenever it appeared this stripe was always perfectly centered, with neatly-defined edges. What's really strange is that it usually appeared when I'd just installed a new roll of fresh, clean material. How did it get there?

After considerable searching I finally discovered the source of the contamination: looking into the material-supply chamber with the supply roll removed from the machine there's a bar across the bottom of the chamber to prevent the PVC from dangling out the bottom of the machine as it unrolls.

In the years I've been using the SD300 I have never cleaned there because the media door blocks the view of that area as the door opens.

When the door is fully opened, it totally blocks any view of that part of the machine. But when the door is closed, a full roll of material could easily come into contact with that area.

With the media door mostly-closed, I could see debris had accumulated in there over the years. And the bar was had traces of SolGL glue that had probably splashed there when I performed maintenance operations over the years. The glue stayed wet because SolGL doesn't dry up on its own, so naturally it rubbed onto PVC in the media chamber.

And the bar was had traces of SolGL glue that had probably splashed there when I performed maintenance operations over the years. The glue stayed wet because SolGL doesn't dry up on its own, so naturally it rubbed onto PVC in the media chamber.

No doubt a professional serviceman would have cleaned this area, but I never called in a serviceman because I'd always tried to maintain the machine for myself and it hasn't ever needed professional repairs.

I thoroughly cleaned these hard-to-reach areas using copious volume of alcohol to dilute the SolGL glue and paper towels to soak it up. Sure enough, that stripe of glue stopped contaminating the tops of models.

A free, easy fix!

More Nuts and Bolts

My Its' Nuts toy went on sale at Grand Illusions last month. Their initial inventory quickly sold out after it appeared in their monthly newsletter, so I made another batch on the SD300 to enable them to restock.

Grand Illusions is a web store packed with all sorts of deceptive novelties, plus an online toy museum and gallery.

Here's a video about Its' Nuts featuring Tim Rowett, an extraordinary toy collector who had purchased a copy of the toy directly from me last year at the International Puzzle Party 32 in Washington, DC.

Puzzle designer Evgeniy Grigoriev created his own version, which he titled the Incredible Screw. Grigoriev is famous for his twisty-cube puzzles, and twice set the record for building the World's Smallest Rubik's Cube. On his version, notice how the nuts move at different rates when he turns the bolt!

Matt Ruggles independently designed his own version, which can be downloaded from Thingiverse for anyone who wants to build it. Here's a picture comparing my original model (left) with his design (right).

Puzzle Party: IPP33 Opens

When I arrived in Japan for the International Puzzle Party many other puzzlers had already been there for quite some time, and they'd been out sightseeing and visiting. I joined a small group of friends on an unofficial trip to visit a few puzzle sights, including (pictured above) George Miller, Roxanne Wong (wearing my ivy cap) and her daughter Katherine, and Naoki Takashima.

First we visited Takafumi Haseda, who operates the Tribox puzzle store online. The store operates in a residential apartment converted into an office, a photo studio, and a stockroom packed with puzzle merchandise. Pictured, Andreas Nortmann (too tall!), Roxanne, and Takafumi venture into the stock room search for hidden treasures.

Pictured, Andreas Nortmann (too tall!), Roxanne, and Takafumi venture into the stock room search for hidden treasures.

Next we trekked to the office of Hanayama, the maker of the world's finest mass-produced brainteaser puzzles. Above, Oskar van Deventer and his wife discovered a sign that greeted his arrival outside the Hanayama office.

A room at Hanayama displayed their huge assortment of Japanese toys and games, in addition to their world renown collections of cast puzzles.

Our next destination would have been Puzzle Shop Torito, but the shop was scheduled to be closed for a few days. So we went sightseeing to the 2080-foot-high Tokyo SkyTree.

From the SkyTree we observed a puzzling building that exhibited an illusion like an MC Escher painting: the green roof appears to wrap around the two elevator towers in the center of the building, but the elevetor towers clearly connect to the green roof at different floors!

There's a glass floor for intrepid visitors willing to stand on thin air over 1000' above ground.

Back at the hotel, Dirk Weber successfully solved my Twisty Trillion puzzle.

Hanayama Puzzles exhibited a fascinating display that showed how many of their most famous puzzles evolved before they went into production.

My favorite entry in the 2013 Design Competition was Bram Cohen's Galaxy, which won a jury prize. It went on to be manufactured by Hanayama Puzzles, widely sold by puzzle stores like Puzzle Master.

Rundown of puzzles for IPP33

Peppermint, my entry for the puzzle exchange, was digitally manufactured in colorful ABS by Bradley Rigdon at PrintTo3D. I built prototypes on my SD300, those PVC models were a bit too flexible to give the right "feel" for this particular puzzle. Each piece is made in two colors, red and white; the colors play a subtle but important role.

Moiré Maze combines laser-cut acrylic and 3D printed vinyl. The challenge is to guide a small magnet through the maze from Start to Finish. That goal sounds simple enough, but it's easy to get lost in the visually-confounding patterns of rings reflected against a mirrored background.

The challenge is to guide a small magnet through the maze from Start to Finish. That goal sounds simple enough, but it's easy to get lost in the visually-confounding patterns of rings reflected against a mirrored background.

Cubic Trisection is one of the puzzles I also sold at IPP32 last year. The challenge is to assemble the three pieces into a cube, as shown. All three pieces are identical, but not symmetrical. Most users easily assemble the first two pieces, but encounter trouble adding the third.

Puckup is a two-piece assembly puzzle, which I'm selling in transparent material or a red-white color scheme. Tyler Barrett suggested a somewhat edgier name "What the Puck" but the simpler Puckup name had already been picked up on one of the puzzle forums.

Twisty Trillion is a successor to Puckup whose shape provokes a lot more confusion among users. Neither puzzle is fiendishly difficult, but Twisty Trillion takes most people a whole lot longer to figure out. I built them all on the SD300 using transparent vinyl because light reflects attractively inside the puzzle.

Neither puzzle is fiendishly difficult, but Twisty Trillion takes most people a whole lot longer to figure out. I built them all on the SD300 using transparent vinyl because light reflects attractively inside the puzzle.

I commissioned two copies of a Trillion Pendant to be built as puzzle jewelry--one in brass from i.Materialise, the other in silver from Shapeways. But neither model was delivered on time--Shapeways lost one of the pieces, and i.Materialise is over 3 weeks behind schedule. So I salvaged the partly-incomplete silver model by building its other half in luxuriously-dark blue vinyl, which contrasts gracefully with the silver piece. Frankly, it looks nicer than it would have if both pieces had been silver!

Here's a colorful assortment of marble puzzles, three of which will be available for sale as Bag of Marbles. The others are experimental designs, which I'd like to test on a few puzzlers at IPP. In particular, the pink and purple models are two closely-related designs, but my first few testers think the purple one is much harder than the pink one. Will others react the same way? IPP is a great opportunity to find out!

In particular, the pink and purple models are two closely-related designs, but my first few testers think the purple one is much harder than the pink one. Will others react the same way? IPP is a great opportunity to find out!

Older Posts Home

Subscribe to: Posts (Atom)

Practical Tech Tips for your Solido 3D Printer

With the Solido SD300 Pro printer becoming more prominent in the market place we thought we should share some quick tips that will help to keep your printer running smoothly.

Consumables Kit Storage

You can obtain the best results from your Consumables Kit for your Solido Printer if the kit is used immediately once the seals have been removed from the AG (Anti-glue) tank and the pens have been exposed to Anti-glue (such as printing your first part). If you are planning on switching out an incomplete consumables kit (a change of colored PVC build material for example) or not using the printer frequently – there are some simple things you can do to ensure that your AG Pens and AG reservoir maintain their consistency throughout the duration of the Roll of SolidVC Material.

- Keep the foil seals for the AG reservoir and replace them on the reservoir when it is removed from the Printer.

- Have Zip-Lock style bags on hand to store the AG reservoir, so that you do not loose any Anti-glue due to evaporation.

- Keep the original Zip-Lock bag that contained the AG Pens, placing the pens from a partial kit into the small bag and adding a drop of water will ensure that the pens remain pliable when used again.

- Ensure that the Glue Tank is removed from the Machine at the same time as the SolidVC plastic roll, confusing tanks can lead to running out of glue mid print.

- Label each item within your consumables kit, when you remove the SolidVC plastic roll from the printer have a log reporting how much of the roll remains and a checklist to ensure that you have removed all of the components of the consumables Kit.

Cleaning

The removal of stray SolidVC material from the Magnetic Pad that has been accumulated can be done with regular Rubbing Alcohol. This will ensure that the prints are not distorted by any plastic that has been left on the printer bed. We would recommend cleaning the Magnetic Pad after two or three parts have been printed.

This will ensure that the prints are not distorted by any plastic that has been left on the printer bed. We would recommend cleaning the Magnetic Pad after two or three parts have been printed.

Heating

It is often easiest to peel the models from the Solido Printer when they are warm, if you would like to reheat the SolidVC block for easier peeling, you can sit the block back on the magnetic pad while the printer is running (NOT PRINTING). The heating element within the printer should slowly bring the block back up to the optimal 35°C temperature without any distortion. You may have a case where there are delicate details within your model you would prefer to strengthen prior to peeling, allow the SolidVC block to cool should provide some added strength to those areas.

Frequent “Replace cutting knife” error messages

Aside from expected Cutting knife wear that delivers the “Replace Cutting Knife” Error another possibility is that there are air pockets trapped into the SolidVC material block. The Air Pockets can be cause be a number of sources, mostly involving glue distribution. If you are experiencing frequent “Replace cutting knife” errors, due to air pockets or uneven glue distribution – give us a call, a utility is available that will assist you in purging unwanted air from the glue system.

The Air Pockets can be cause be a number of sources, mostly involving glue distribution. If you are experiencing frequent “Replace cutting knife” errors, due to air pockets or uneven glue distribution – give us a call, a utility is available that will assist you in purging unwanted air from the glue system.

Anti-glue (AG) Pen Cleaning

The AG Pens can develop an uneven film of Anti-Glue (especially the 6mm Pen) that can harden and cause streaks through each layer of your print. One way to remove the hardened film from the AG Pens is to use a utility knife to scrape the film off the pen and allow it to pickup and appropriate amount of Anti-Glue from the reservoir. Only attempt to clean the AG pens if you detect an issue with the peeling of your models.

Anti-glue (AG) Pen Holders

The AG Pen holding clips in the tool station and attached to the XY head of the printer can become (sprung) over time and lead to poor replacement of the Pens into the tool station. If you receive frequent “Replace Tool” errors it may be time to replace the white clips and their associated metal supports. These can be ordered via our web store for a minimal cost and are beneficial to have on hand.

If you receive frequent “Replace Tool” errors it may be time to replace the white clips and their associated metal supports. These can be ordered via our web store for a minimal cost and are beneficial to have on hand.

Related Links

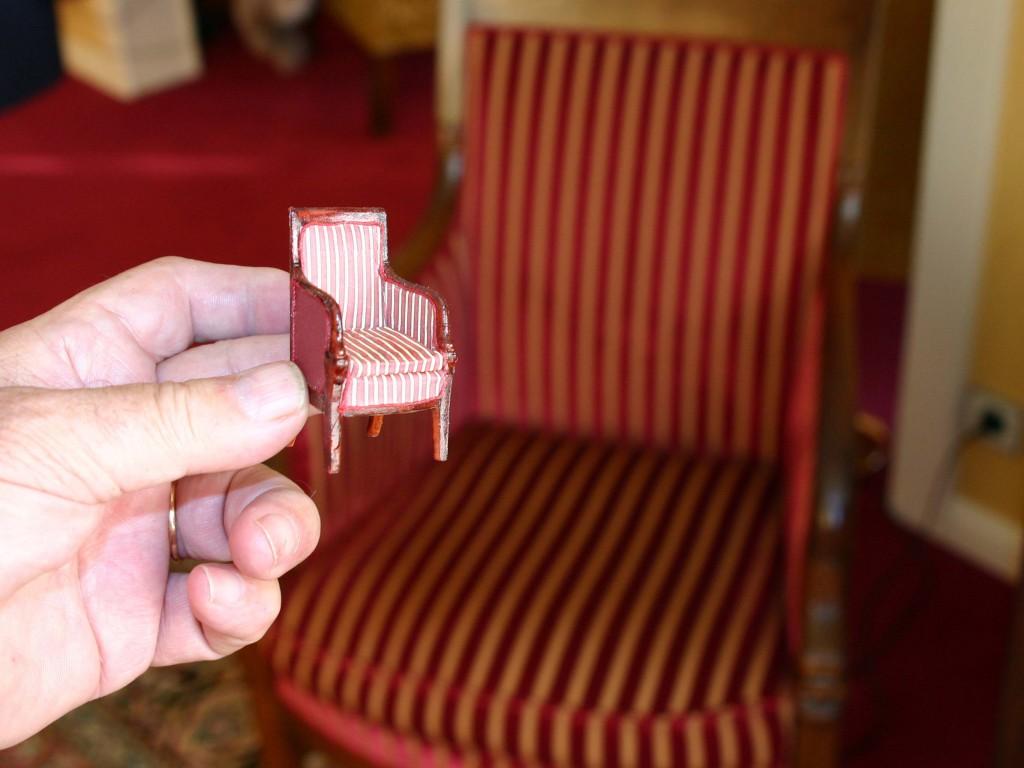

Desktop 3D Printer SD300Pro Comes to the Service of the Foundry

Hello Guest! Login

Home " Blogs of Experts and IT Companies » Desktop 3D printer SD300Pro comes to the service of the foundry

Possibility to post on the project has been stopped

CNews editors are ready to receive press releases from companies at [email protected].

We invite you to share your comments about CNews materials on our Facebook, Telegram and Twitter platform pages.

ITConsult Group of Companies has delivered a desktop 3D printer SD300Pro to MetalLitMash LLC. Now the SD300Pro has become a trusted assistant in the iron foundry.

Its owner, LLC MetalLitMash, is engaged in the production of medium and small-scale batches of foundry products. A typical technological process for obtaining a casting mold for a part includes modeling and creating a master model on a milling machine. Milling imposes its limitations on obtaining various geometric shapes of the master model, for example, it is almost impossible to obtain clear forms of convex marking letters on the planar and conical sections of the master model surface. nine0003

Using the SD300Pro Desktop 3D Printer, the factory was able to solve some of the problems associated with creating parts of the model that were impossible to mill. On the master model, a groove is simply left for an insert with a marking, which is printed on a printer and subsequently put on glue in this groove. Thus, the manual refinement of the master model, which is currently used at the enterprise, becomes unnecessary, as a result of which the time for launching into production is reduced, and the economic efficiency of work is also increased. nine0003

Thus, the manual refinement of the master model, which is currently used at the enterprise, becomes unnecessary, as a result of which the time for launching into production is reduced, and the economic efficiency of work is also increased. nine0003

“Our company MetalLitMash LLC is engaged in the manufacture of various cast iron castings for various sectors of the national economy. We ourselves are a young and growing company, and constantly implemented innovations allow us to develop faster. Everything that can be adopted to increase our competitiveness and efficiency, we will definitely use, - Alexey Ivanovich Belyakov, First Deputy General Director of MetalLitMash LLC, told . – The new desktop 3D printer SD300Pro from ITConsult helps us solve problems with finalizing master models. This method of setting the markings has greatly facilitated the work of our manual finishing specialists. Also, thanks to him, the time "lag" was reduced from the moment of preparing the casting model to launching it into production. So getting a 3D printer really worked in our favor.” nine0003

So getting a 3D printer really worked in our favor.” nine0003

LLC MetalLitMash - iron foundry. The main profile of the enterprise is the production of castings for various industries (machine-building, industrial, artistic casting). Currently, about 30,000 tons of castings are produced per year. MetalLitMash was created on the basis of the metallurgical production of the former Kolomna plant of heavy machine tools, in 2000. At the moment it is an enterprise with 100% foreign capital.

This material is a private record of a member of the Club.CNews community. nine0029 The editors of CNews are not responsible for its content.

9 years ago | tags: 3D printer, MetalLitMash, SD300Pro, master model, rapid prototyping

Comments

Other publications

The CNews team is ready to receive press releases from companies at [email protected]. nine0003

We invite you to share your comments about CNews materials on our Facebook, Telegram and Twitter platform pages.

SD 300 Pro Desktop 3D Printer

Transcription of page content

If your browser does not display the page correctly, please read the page content below

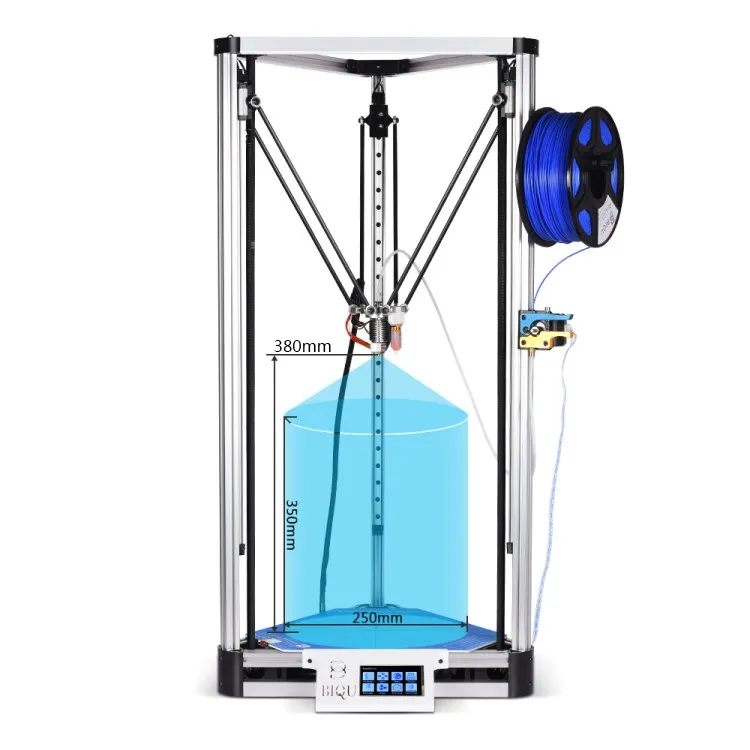

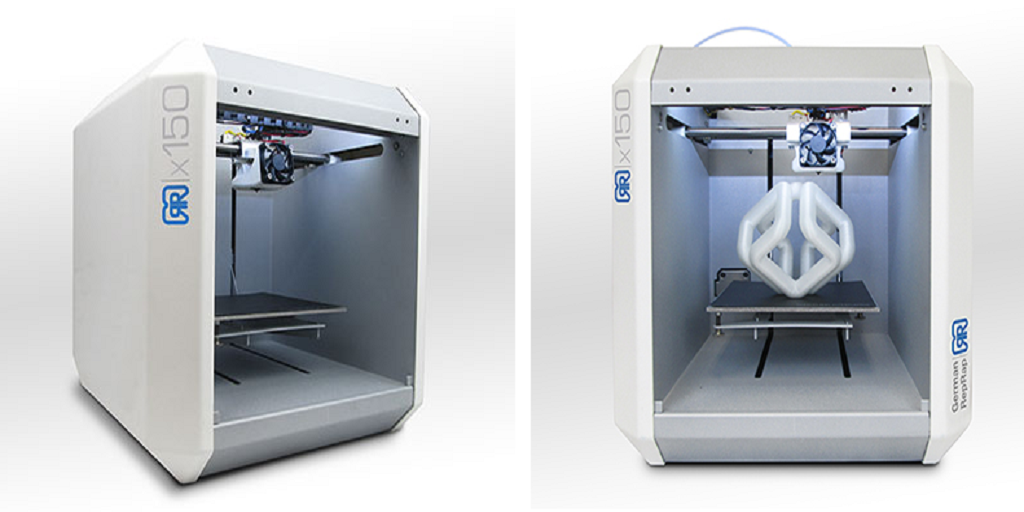

SD 300 Pro Desktop 3D Printer 1

About Solido 2000: Foundation of the company More than ten investors directed their funds to develop the world's first desktop 3D printer for rapid prototyping and related software supplies and consumables 2006: Product launch of SD300 OEM agreements with companies: Graphtec-Japan 3DSystems - USA 2007: Start of beta testing of a new model - SD 300 Pro 2009: SD 300 Pro latest design announced Location: Headquarters in Israel (Rosh Ha-A'yin) Production facilities in China (Nanjing) US Logistics Center (Phoenix, AZ) Logistics center in Europe (Leggiuno, Italy) Asia Logistics Center (Shanghai) Affiliate network: and more than 100 distributors and partners worldwide 2

Production facilities in China (Nanjing) 3

Our goals and mission Short term To enable every designer and constructor to easily in use and cost effective way print 3D models using our SD 300 Pro 3D printer.Long term Our desktop 3D printer will become the desktop standard 3D printer for both home and office and industrial use. 4

Recommendations Overall, I was very impressed with the Solido SD300Pro 3D printer for a number of reasons. Some of the advantages of the machine are ease of use, low initial cost, low total cost of ownership, quality and performance printed details (transparency, stiffness and strength) are complemented unique ability to produce ''loops''. Also impressive are the portable dimensions and no practical requirements for maintenance other than replacement Supplies. Jeffrey Rowe MCAD Cafe Editor I received the details from Solido while sitting at my desk for a few days, and after scrutinizing them, I must say I'm impressed. Very impressed. New the version of the Solido 3D printer and the parts it produces will change thinking. Terry Wohlers Chief Consultant and President Wohlers Associates Inc.The end goal of 3D printing is to print a CAD model in the same way as printing a conventional document. Solido SD300Pro can print your designs right in your office, quietly, accurate and inexpensive. Solido cost shows that the dream of printing prototypes is easy within the reach of professional constructors and designers. The SD300Pro printer is source of change for the gaming industry. Scott Harris Co-founder of Solidworks Inc. and member Board of Directors Solido 5

Exhibitions Euromold 2009 USA Brazil China Germany 6

Business partners in Europe 7

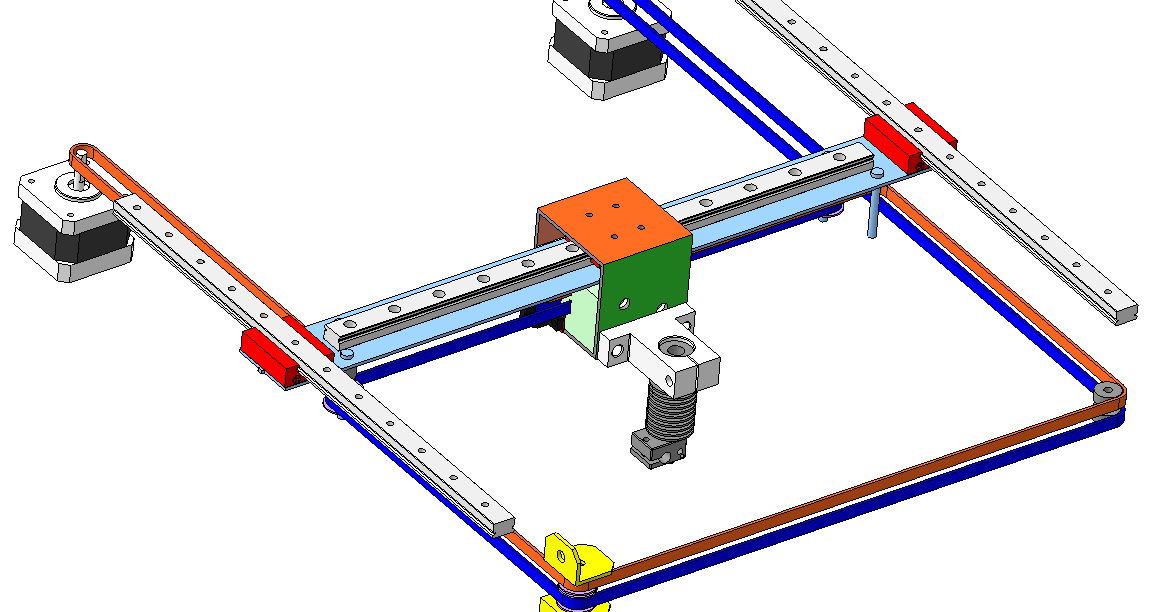

3D printer SD 300 Pro Creation of 3D models Concept models Models for quick evaluation Demo details Functional check of collectability Rapid production office environment True desktop size Low noise No hazardous substances No post-processing required Application: Industrial production Education Automotive industry Consumer goods and electronics Product design and construction 8

Overview.Rice. one Front side: Top cover Side cover Glue cartridge replacement door materials Heating system Control panel Bath Plastic laying shaft Desktop XY head Main knife Auxiliary knife Anti-glue cartridge 9

Overview. Rice. 2 Backside: Switch Fuse Power cable entry USB input Cooling systems Anti-glue cartridge 10

Overview. Rice. 3 User panel: Liquid crystal display Work indicator Error indicator Menu/Next Button OK button Stop/Resume button 11

Consumable kit Plastic sheet roll Glue Cartridge Cartridge with anti-adhesive substance Anti-glue pencils P.S.: Adhesive, anti-adhesive and roll of plastic must be shared. NEVER mix Components 12

SDView Software Toolbar Dimensions printing Imports STL files Places models on desktop Dimensions models Scale, copy, rotate, cuts, connects, etc.Table Provides geometry preview Direction of axes coordinate models Has more details Manages files (SDM) Build models Parts to be trimmed 13

3D printing steps: 1. Pulling plastic sheet, 2. Bonding, 3. Smoothing Table and magnetic pad Adhesive Roll for stacking plastic Roll of plastic sheet 14

3D printing steps: 4. Cut off Channel Model layer Cut off parts XY cutting knife 15

3D printing steps: 5. Anti-adhesive treatment Anti-glue stick 16

3D printing steps: 6. Pulling plastic sheet, 7. Bonding, 8.![]()