Robobeast 3d printer

Meet the RoboBeast: The world's toughest 3D printer

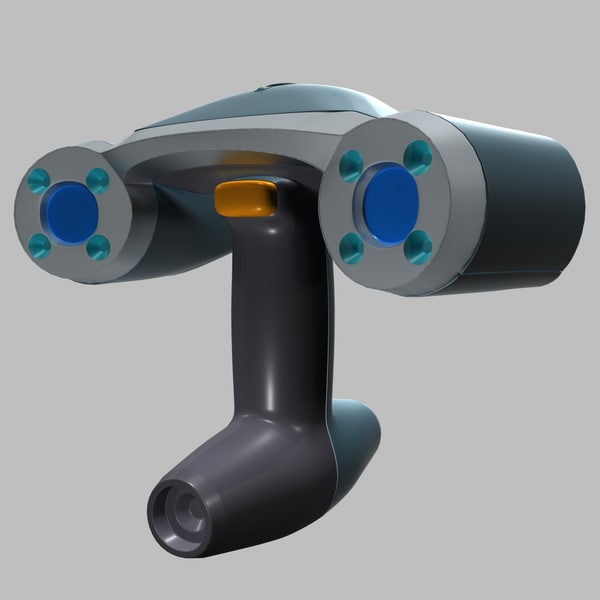

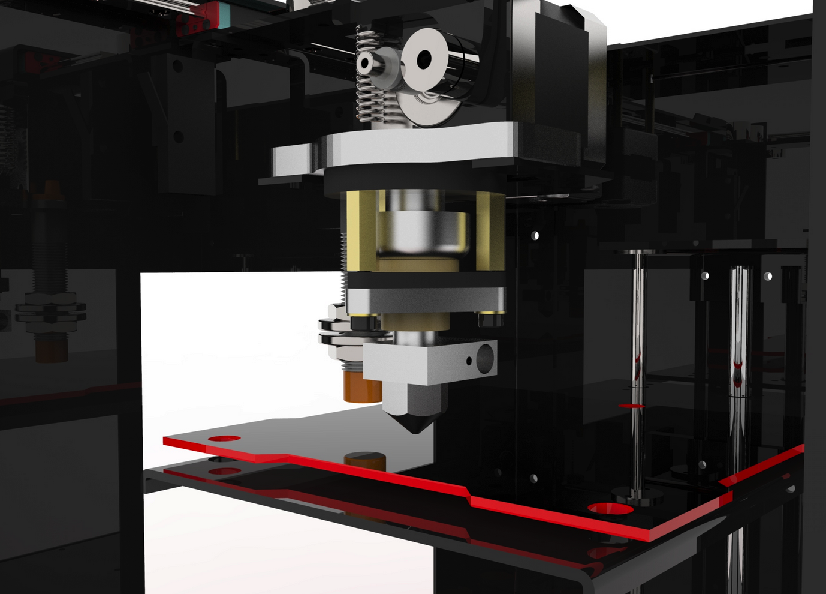

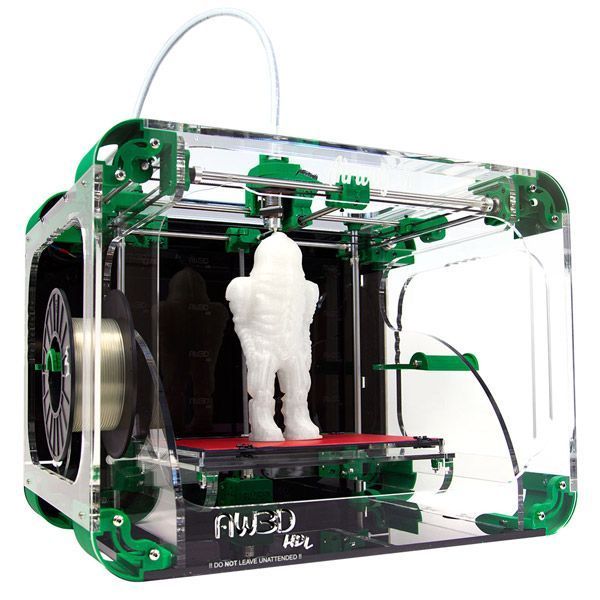

The RoboBeast. Image: RoboHand

The problem with most 'affordable' 3D printers, says South African inventor Richard van As, is that they're too fragile to be of much use in the field. Ever since the first low cost RepRap 3D printers appeared in 2007, speculation has been rife about how they could change the lives of those living at the bottom of the economic pyramid by giving them access to complex manufacturing techniques at a low cost.

Up until now, that is.

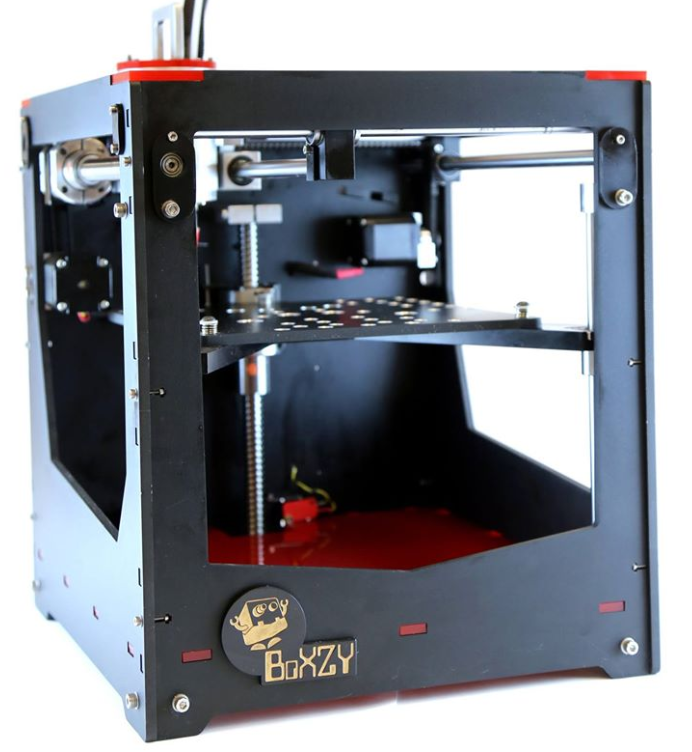

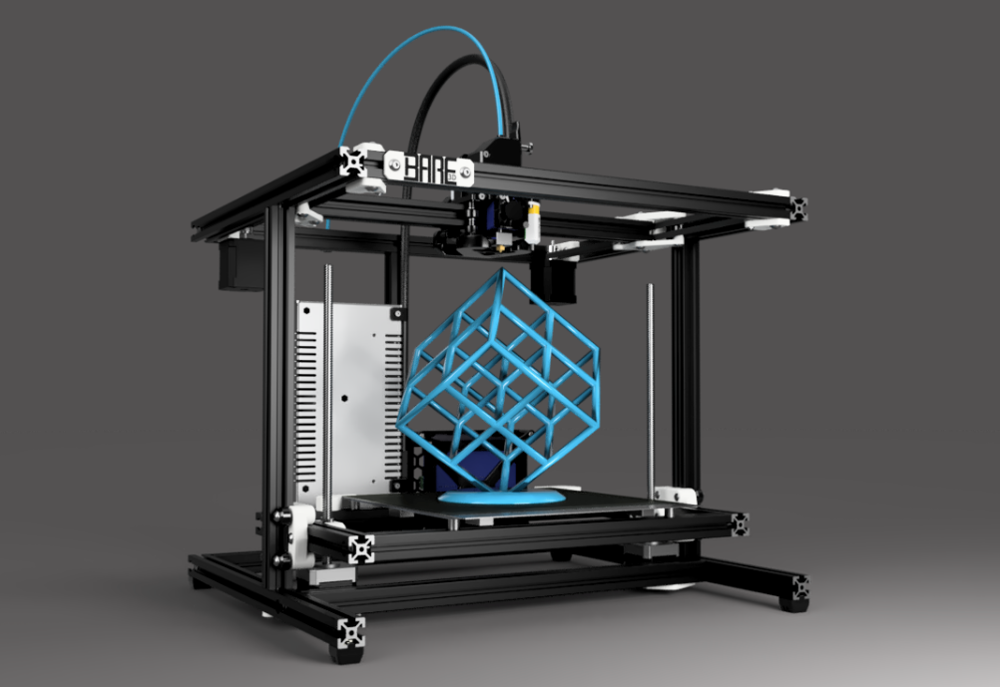

Enter RoboBeast, a RepRap-derivative 3D printer designed by van As that's made to be thrown into the back of a 4x4, driven deep into the African bush, and will work flawlessly first time when it's set up.

van As, a carpenter by trade, shot to fame a year ago following an article in Popular Mechanics. The feature described how, after losing four fingers on his right hand in a work-related accident, he collaborated with an American inventor to create RoboHand, a functioning prosthetic hand made from orthoplast and 3D printed parts.

Since then, van As has been inundated with requests for help and interest from international press, physicians and NGOs. Helping those who were either born without fingers as a result of amniotic band syndrome or who have lost the use of their hands through work or war has become his life's work.

The last time RoboHand hit the headlines was in January, following a trip to South Sudan in which 3D printers and RoboHand parts were delivered to people injured during the civil war who couldn't afford medical prosthetics through Project Daniel. Although van As himself wasn't part of the trip, he was involved with Project Danial and through it became aware of the biggest problem with 3D printing in rural areas.

Low cost printers are finicky things: for the most part, RepRap-based designs can only print a few parts before they require recalibration or servicing. Dealing with extruder blockages or tuning voltage outputs on motor drivers requires a certain amount of skill and technical knowledge. Broken parts are common.

Broken parts are common.

In order to realistically enable a clinic in an isolated area to produce RoboHands, van As needed a printer which was bulletproof: simple to use, self-calibrating and capable of being knocked around without losing its ability to print.

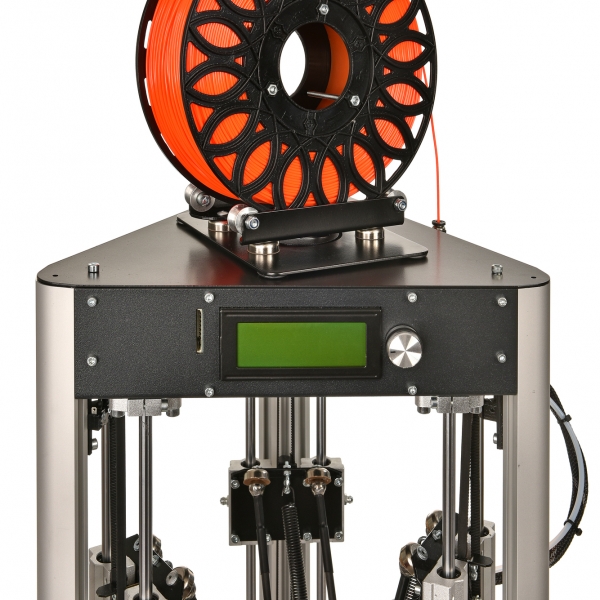

And thus RoboBeast was born. With the help of local hackers — including the creator of another South African 3D printer, RepRap Morgan — and advice from Printrbot's Brooke Drum, van As came up with a rigid design for a 3D printer within a three-month window.

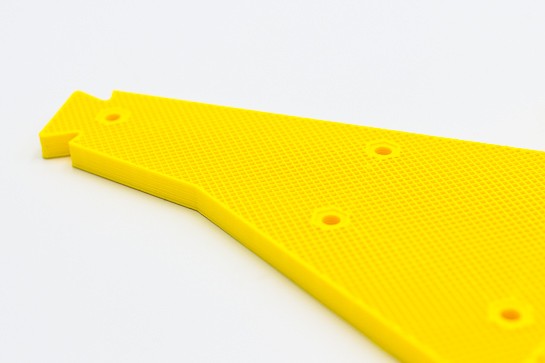

RoboBeast's frame is constructed from extruder aluminium supports, with laser cut perspex sheets protecting the electronics. The print bed is larger than most, at 300x400x400mm, and the 0.3mm print nozzle will adjust its movement automatically to compensate should the bed become uneven. Unlike other extrusion-based 3D printers, you can move RoboBeast while it's printing and even turn it upside down without affecting the quality of the print.

It uses an aluminium extruder designed by Printrbot, as well as controller circuits from the same company.

Perhaps most importantly, RoboBeast is designed to run off of a battery pack and will be sold with a solar charger. The battery should last for five hours, van As explains, which is around the length of time it takes to print all the parts for an adult RoboHand.

RoboHand designs are preloaded onto an SD card in a variety of common sizes. Getting the plastic parts is as simple as selecting the right size and waiting for five hours while it prints.

And while RoboBeast is more expensive than, say, a basic Makerbot it's not prohibitively so - at around R27,000 ($2,500) a pop, it's affordable enough for field work and NGOs to consider in disaster relief work.

The first RoboBeast machine is already up and running, and van As says he has started work on five more. It's first real test will be coming up in the next few months when he plans to take it to one of the continent's most dangerous and difficult areas to access. Quite where that is, however, he won't say.

Read more on 3D printing

- 3D printing: Will it mainstream adoption in 2014?

- MakerBot Replicator Mini aims to bring 3D printing to wider audience

- Bioprinting human organs and tissue: Get ready for the great 3D printing debate

RoboBeast: The toughest 3D printer in the world, designed in South Africa

Search

“I used to describe myself as ‘just a South African guy with an idea’,” says Richard van As, modestly, “Now I guess you could call me ‘just a South African guy with another idea’. ”

”

But what an idea it is. To design and build the world’s toughest, roughest low-cost 3D printer and unleash it upon the world to do good.

Once upon a time – say, oh, yesterday – 3D printers were fey things which would collapse under the pressure of a hard stare. Mechanically sensitive to the slightest knock and happy to overheat under the gaze of a warm bulb, common or garden 3D printers for home or light industrial use are best built in one very stable position and left there lest they require many hours of tinkering to produce useable prints again.

Not any more: enter RoboBeast, the Chuck Norris of printers which was unveiled to the general public today.

RoboBeast is designed to be ‘bulletproof’. It requires no set-up software tweaks, or mechanical adjustment of the frame before you print. It’s designed to be thrown in the back of a Land Rover, carted off into the bush, and to start working as soon as the power is on. You can move it during operation and the print head stays steady: it can even print if flipped upside down.

And yet at heart, it shares exactly the same DNA as the RepRap open hardware design that underpins every ‘affordable’ 3D printer commercially available or (relatively) easy to build at home. It’s an open source design – you can build one yourself if you like – and it’s been created specifically to help amputees in worn-torn and inaccessible areas of the world.

If that all that wasn’t enough to make you fall in love with RoboBeast, it gets better. The first RoboBeast has been designed and built in a two and a half month period which includes the Christmas break. And its inventor, van As, is the carpenter who shot to fame almost a year ago following a Popular Mechanics South Africa article about RoboHand.

‘Designer Digits‘ was the story of how vas As lost four fingers on his right hand in an accident at work, and how through an online collaboration with US inventor Ivan Owen he developed not just a DIY prosthetic for himself, but the pair went on to create a one for a five-year-old boy named Liam too. By adapting the design so that it could be customised and built by anyone with access to a RepRap-style 3D printer, RoboHand was born.

By adapting the design so that it could be customised and built by anyone with access to a RepRap-style 3D printer, RoboHand was born.

The story went truly viral. Van As explains that he’s been interviewed countless times by hundreds of journalists about RoboHand, and has been invited all over the world to tell the story and work on more collaborations. He receives hundreds of mails a day about RoboHand, and has been kicked off of his webhost because of the volume of traffic.

At CES this year, a second chapter was added to the RoboHand story thanks to Project Daniel – through which US inventor Mick Ebeling took Makerbot printers to Sudan in order to build prosthetics for some of the thousands of children injured in the civil war there. Although van As didn’t accompany Ebeling to Sudan, he was involved in the project.

Again, the story was picked up by almost every major news organisation in the world.

Keeping up with RoboHand has been demanding work. Even with the whole-hearted support of family and friends, it’s been a long time since van As was able to take on a carpentry job.

“I’m basically unemployed now,” he laughs, “This is what I do now.”

Towards the end of last year, van As moved the RoboHand project into House4Hack, the Centurion makerspace which is run by volunteers and has been home to other world-class 3D printing inventions. The award winning RepRap Morgan was designed there, and South Africa’s leading 3D print and open source hardware specialist community and shop, Open Hardware, came out of the House4Hack community too.

The original plan was to create a ‘botfarm’ of 3D printers in a backroom at House4Hack which would be capable of producing printed RoboHands en masse for people who can’t afford medical prosthetics.

“We work on a ‘pay it forward’ system,” says van As, “Amputees contact us asking for help and where we can, we send them a RoboHand. Then, if they’re able to work where they weren’t before, they can consider a donation to help us keep going.”

Van As says that the finnicky nature of current 3D printer designs is frustrating though. After the experience with Project Daniel the need for a printer which just works, and will continue to work no matter what, became pressing.

Around the back Touch screen controls means anyone can use the Beast. The Beast at full size. The next iteration will probably be bigger.Enter RoboBeast. With the help of other House4Hack members, a prototype of the super-tough printer has been put together in just two and a half months from design to full operation, and van As says four more are currently being built. Final dimensions haven’t been decided on, but the build will be considerably bigger than the 200x200x200mm cube that most RepRap-type printers are capable of.

Final dimensions haven’t been decided on, but the build will be considerably bigger than the 200x200x200mm cube that most RepRap-type printers are capable of.

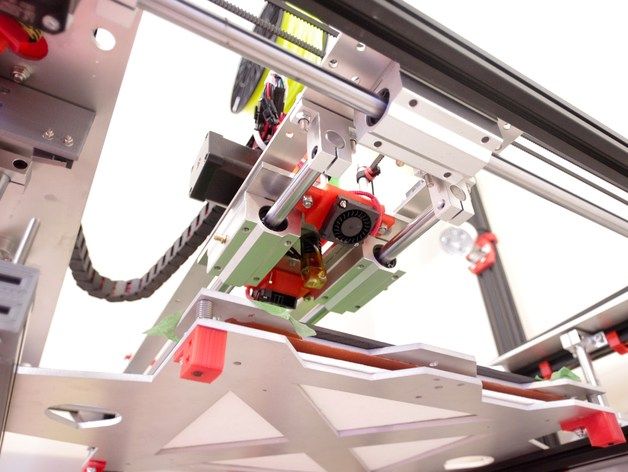

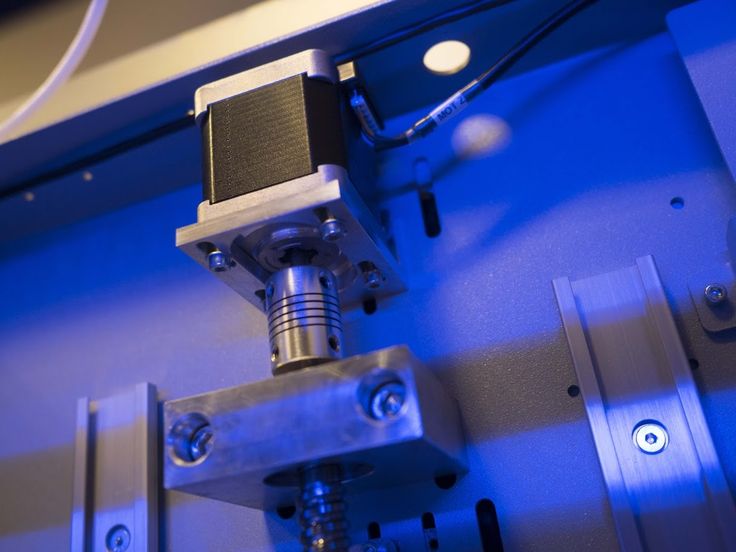

The electronics which drive the printer are all off-the-shelf components. The controller is an Arduino motherboard with a standard RAMPS add-on ‘shield’ for driving the motors, as well as a touchscreen LCD panel and SD card reader.

Where RoboBeast differs from most open hardware printers, though, is that there are very few printed parts inside. A core ethos of RepRap culture is to create machines that can reproduce most of their working parts themselves: the name itself is a contraction of ‘self-REPlicating RAPid prototyper’.

For RoboBeast, however, van As has used mostly cut-to-order aluminium struts and a custom milled extruder. The result is something far more durable and robust. Using software tweaks inherited from Quentin Harley’s RepRap Morgan, RoboBeast’s extruder head will also be able able to calibrate itself to compensate for any movement in the print bed, ensuring evenly layered prints regardless of whether or not the machine is level.

To make it easy to operate, RoboBeast’s SD card is loaded with preconfigured RoboHand models in a variety of sizes. Recipients just need to tap the correct size on the touchscreen and wait while the hotend – which melts the plastic filament and squirts it out in fine layers – does its finger-making dance around the build surface and builds a working RoboHand. The SD card is more or less inaccessible, trapped behind the perspex of the vent which covers the controller board. Other models can be set-up using the USB port.

For the final touch in self-sufficiency, van As plans to couple RoboBeast with a battery that will power the machine for up to five hours on a single charge. Co-incidentally, that’s almost exactly how long it takes to produce an adult RoboHand.

An adult RoboHand ready for use. A child’s hand, waiting to be attached to the arm brace. Now you too can handle the Beast. Using a metal extrusion mount means the Beast can also utilise a very small aperture – just 0. 3mm wide. The extra stability also means the Beast is quiet for a RepRap printer too. House4Hack has been home to outstanding innovation projects. At the moment, there’s no heated print bed to worry about as the Beast will mostly be using PLA plastics.

3mm wide. The extra stability also means the Beast is quiet for a RepRap printer too. House4Hack has been home to outstanding innovation projects. At the moment, there’s no heated print bed to worry about as the Beast will mostly be using PLA plastics. Naturally, this design is more expensive than building a ‘traditional’ 3D printer, but it’s not prohibitively so: van As reckons the total bill of materials will be around R27 000 ($2 500) per machine: considering an off-the-shelf MakerBot 2 costs $2 100, that’s not terrible value.

Now that RoboBeast has been unleashed up on the world, it even has its own website and Facebook page already, van As is planning to eventually build models to sell. It’s first big test, however, will come in a few months time when he’s planning an excursion to take RoboHand to places its never been and sorely needed. Where exactly that will be, however, he won’t tell. Yet.

Watch this space.

[Want more? RoboBeast website and Facebook page]

90,000 characteristics, pros and cons of each model 07. 04.2021

04.2021

Content

-

- What is a food 3D printer

- Field of use

- used raw materials

- 9000 9000 9000 9000

- Top 10 Best Food Printers: A List of the Most Current Models

- 1. PancakeBot 2.0

- 2. Wiiboox Sweetin

- 3. Choc Creator V2.0 Plus

- 4. Choc Creator V2.0 Plus Food 3D Printer with Cooling Chamber

- 5. byFlow Focus

- 6. Chefjet Pro

- 7. Foodini

- 8. Mmuse – Chocolate 3D Printer Commercial ArtcakesOT7 .90BOT Printer F5

- 10. ZMorph VX

- What is a food 3D printer

- Selection guide

- Output

A food printer is a high-tech device that is used to create culinary masterpieces. The decorative design of food products has reached a new level thanks to the use of modern technologies: high-quality and large-format printing is carried out on cakes, waffles, pancakes and even coffee. Here are the top best 3D food printers in different price categories for people who are fond of cooking.

What is a 3D food printer

The main feature of a food 3D printer is the raw materials used: instead of printing ink, the device is filled with edible ingredients. The database stores a large number of different recipes, and in order to print a dish, you just need to select one of them and activate the printing process. The final product is layered on a work surface or on a plate: it can be baked in the oven or sent to the freezer.

Application

Futuristic 3D Printed Sugar Candy

Cookies printed with icing

Chocolate logos of famous companies

Cream Photo Print

Buying a food 3D printer is worth the owners of coffee houses, author's bakeries and private workshops. The finished product has a unique shape and bright appearance. Food printers are often used to create custom wedding cakes, cartoon character cookies, Christmas gingerbread cookies, and so on. The possibilities of a baker who owns such a device are endless: the main thing is to buy quality products.

The possibilities of a baker who owns such a device are endless: the main thing is to buy quality products.

Raw materials used

The following ingredients are used as raw materials:

-

Chocolate without additives and impurities;

-

Mastic;

-

Sugar;

-

Whipped cottage cheese;

-

Vegetable and fruit pastes;

-

Fish and meat pates;

-

Flour;

-

Cheese, etc.

The confectionery pattern is applied to sugar, wafer or shock transfer paper. The first type has a sweetish aftertaste and aroma of vanilla. Due to the snow-white surface, no additional coating is required: the drawings look bright and clear. The wafer paper is made from rice flour and does not have a special taste, due to the light shade, the final drawings look less clear. Shock transfer paper is completely transparent and is suitable for transferring a design to a product (for example, a cake). For the packaging of finished products, food-grade plastic for a 3D printer is used.

For the packaging of finished products, food-grade plastic for a 3D printer is used.

Interesting! Food printers are involved in waste reduction. Unattractive fruit and confectionery leftovers are used in the preparation of printing mixes. This makes it possible to use the means of production more efficiently.

Types of 3D food printers

Cooking enthusiasts can take advantage of the following food printing devices:

-

Food 3D printers are devices that print dishes whose recipes are listed in a database. The final product is layer-by-layer superimposed on the work surface, and the raw material comes from filled cartridges;

-

Confectionery printers are used to transfer images onto specialty paper or to design small confectionery products such as candies. Such printers print an image on pre-prepared paper: rice, wafer or shock transfer;

-

Food plotters transfer the image not to paper, but directly to the finished product.

For example, a plotter is used to transfer an image directly onto a cake.

For example, a plotter is used to transfer an image directly onto a cake.

There are several types of food 3D printers:

-

Extrusion - paint is applied to the surface before the dish is created. The process is controlled by the computer with the loaded image. The system has an extruder that heats the food mixture, and the distribution of raw materials depends on the print head. The raw material is loaded into a syringe placed in the head. This means that in order to combine different shades, you have to periodically stop printing and change the syringe;

-

A carousel-type food 3D printer also has an extruder, but its main feature is the method of feeding raw materials: the containers rotate around the working surface, the supply and dosage of the material used depends on the recipe specified in the program. The storage can contain countless recipes, and operation does not cause difficulties even for an inexperienced user.

Popular brands

Eminent manufacturers offer the best value for money food 3D printer. Quality devices provide accurate printing, high speed, durability, simplicity and ease of use.

Wiibox

This company manufactures 3D printers with high build quality and high productivity. These are universal mechanisms that fill both chocolate paste and mashed potatoes. Numerous positive reviews confirm the high quality of Wiibox products.

byFlow

The Dutch company byFlow specializes in food printing technology. The pursuit of excellence helps the company open up new horizons: the technique prints products from spinach, meat emulsion and other materials. High build quality, ease of use and durability - all these characteristics are applicable to the products of this company.

Choc Edge

Choc Edge is committed to revolutionizing the world of chocolate making. Numerous experiments and focus on consumer feedback help to create more powerful devices that provide the optimal temperature for preparing and storing chocolate figures.

Attention! Printing dishes helps save time on cooking: instead of culinary worries, the user can simply activate the printing process and get on with other things.

Free shipping

Add to compare

Item added to compare Go

| Manufacturer | Choc Edge |

Available on credit. To checkout, add the product to the cart and follow the instructions Go

| Manufacturer | Wiiboox |

Free Shipping

Add to compare

Item added to compare Go

| Manufacturer | Choc Edge |

Top 10 Best Food Printers: List of the Most Current Models

Before you buy a food 3D printer, you need to familiarize yourself with the most popular devices on the world market. The top is based on ratings and customer reviews.

1. PancakeBot 2.0

PancakeBot 2. 0 is easy to use, which means it's suitable for inexperienced users too. Users can choose from suggested designs in the software, or create their own. Used to print pancakes.

0 is easy to use, which means it's suitable for inexperienced users too. Users can choose from suggested designs in the software, or create their own. Used to print pancakes.

Pros:

-

Ease of operation;

-

A wide range of proposed projects;

-

High speed.

Cons:

2. Wiiboox Sweetin

Buying a food printer from Wiiboox is worth not only for confectionery lovers, but also for ordinary chefs: the device prints cakes, cookies and even mashed potatoes. The main raw materials can be meat, cheese, chocolate, jam, mashed potatoes, dough and much more. A convenient touch panel helps to set the desired mode of operation, and a stylish appearance complements the interior of any establishment.

Pros:

-

Versatility: the ability to print not only sweet dishes, but also side dishes;

-

Attractive appearance;

-

High build quality;

-

Convenient control by touch panel.

Cons:

-

High price.

3. Choc Creator V2.0 Plus

When talking about which chocolate 3D printer to buy, it is worth mentioning the numerous advantages of Choc Creator V2.0 Plus. The new model has become more perfect: the developers have worked hard to eliminate the shortcomings of the previous version. The modern model has small dimensions, thanks to which it can be used in any kitchen, and the uniform heating of the syringe ensures high-quality and uninterrupted operation. In practice, the chocolate printer has shown tremendous potential: it prints complex figures from chocolate.

Pros of :

-

Attractive appearance;

-

Uninterrupted work;

-

Durability;

-

The ability to create durable and beautiful chocolate figures.

Cons :

4.

Choc Creator V2.0 Plus 3D food printer with cold chamber

Choc Creator V2.0 Plus 3D food printer with cold chamber

The new version of the Choc Creator V2.0 Plus printer is equipped with cooling chambers by popular demand. Users say that maintaining the optimal temperature in the room to preserve the integrity of chocolate figures is too problematic: therefore, the new device cools the raw materials. The price of a food 3D printer with a cooling system is slightly higher than a classic one, but the high performance of the final product justifies any costs.

Pros of :

-

Availability of a cooling system for finished products;

-

High printing precision;

-

Long service life;

-

Ease of use: You can turn the fans on and off with the side buttons.

Cons :

-

High price.

Attention! Confectionery food 3D printers are often used by artists to create edible masterpieces.

This is a unique technology that helps to unleash the creative potential of the chef.

5. byFlow Focus

Food printer from the Dutch company byFlow, which specializes in 3D printing of food. The compact high-tech device is used for the bakery industry, and the cartridges are suitable for the application of any pasty ingredients.

Pros:

Cons:

6. Chefjet Pro

Buying a ChefJet Pro food printer is a must for people who dream of making bright and stylish sweets. The device is created on the principle of inkjet printing: sugar-containing powder materials are used instead of paints. The final product is made by powder layering. The printer is suitable for combining different shades and creating gradients.

Pros:

-

The ability to create unique flavors;

-

Neat and bright printing;

-

Aesthetic appearance of the device.

Cons:

-

High price.

7. Foodini

The 3D food printer from Foodini works on the principle of a stationary printer, but instead of printing inks, layer-by-layer imposition of edible raw materials is used: dough, cream, chocolate, cream, etc. The device is versatile: the user himself can choose the material, or use ready-made cartridges with products.

Pros:

-

Practicality;

-

High build quality;

-

Attractive appearance;

-

Availability of an online platform with unique recipes.

Cons:

8. Mmuse – Chocolate 3D Printer

The closed MMuse 3D printer is suitable for chocolate printing. Chocolate beans are used as raw materials: they are heated in an extruder and fed to the work surface through the print head.

Pros:

Cons:

9. ZBOT Commercial Art Pancakes Printer F5

ZBOT Commercial Art Pancakes Printer F5 3D Printer

A food printer from Chinese manufacturers is used in the process of making pancakes of various shapes. Ease of operation allows the device to be used by children under adult supervision.

Pros:

-

Ease of operation;

-

High build quality;

-

Affordable cost.

Cons:

10. ZMorph VX

A multifunctional 3D printer capable of printing not only food, but also rubber, ABS plastic, polylactide, PVA, nylon, elastic and metal materials. The product is able to print with chocolate, butter, cookies, icing and other ingredients. In addition, there is a function of engraving and CNC milling.

Pros:

Cons:

-

High price.

Selection guide

The modern market offers a wide range of food printers. Before making a purchase, you need to carefully study the characteristics of each model and build on your own preferences. Experts have created several recommendations for choosing:

-

In case you want to create realistic images for confectionery 3D printing, pay attention to the diameter of the nozzle: the narrower it is, the more accurate the image will be;

-

It is better for people living in regions with a warm climate to purchase chocolate 3D printers with a cooling system: such devices ensure that the figurines are kept at the optimum temperature;

-

The possibility of self-refilling the cartridge is the most practical and economical way to operate the printer;

-

Print speed is an important consideration for restaurant owners. Large batches of dishes must be produced quickly, and for home use this is not a very strict selection criterion.

Output

In the catalog of our online store, you can choose the best food printers from famous brands to create culinary masterpieces. Explore our range, learn about the characteristics of each printer and make great purchases.

#Useful

Expert in the field of additive and subtractive technologies, 3D equipment and CNC machines with over 10 years of experience.

Share

all materials

3D Print

3D Print - Description

-

How to 3d print another 3d printer

How to 3d print another 3d printer? This question was asked by many of their owners and in this article we will answer what needs to be done!

Read

-

Makerbot

3d printer review This article will be devoted to the study of the Makerbot 3D printer line.

Read

-

3d printing problems and solutions

In this article, we will analyze the most common 3d printing problems!

Read

-

Connecting a 3d printer to a computer

In this article we will answer the question of how to connect a 3d printer to a computer.

Read

-

Ramps 1.4 connection in 3d printer

Why do you need a Ramps 1.4 shield in a 3d printer and how to connect it to Arduino Mega, read on!

Read

-

Repetier Host. Slicer setup. Part 2

In this article, we will continue to study Repetier Host, namely, we will teach you what parameters you need to set in various fields of the slicer and what they are for!

Read

-

Robotics for Beginners

Is it necessary to prepare your children for the future in the world of robots, how to do it right and what robotics circles for beginners teach in our new article!

Read

-

Repetier Host setup and instructions.

Part 1

Part 1 In this article, we will talk about one of the most famous and popular programs for 3d modeling and printing, namely Repetier Host.

Read

-

3D printer setup and calibration

After you have the idea to buy a 3D printer and assemble it yourself, you should understand how a 3D printer works and how to set it up

Read

-

Exploring the features of a 3D printer

This article is devoted to the study of the device of a 3d printer and an overview of its key components.

Read

-

Overview article about the world of modern 3D technologies

This article provides a brief overview of the 3D printing and modeling industry.

Learn more