What is the hot end in a 3d printer

E3D 3D Printer Hotends | MatterHackers

Technical Specifications

- Fully Assembled HotEnds

- HotEnd Kits

- Available in 1.75mm and 2.85mm (3.00mm)

E3D Hotends

RapidChange Revo

Change nozzles easily and quickly with E3D's revolutionary hotend ecosystem.

E3D v6 Hotends

Experience precision 3D printing with E3D's industry-leading v6 hotends.

E3D Volcano

Designed to print large layer heights at lightning fast speeds

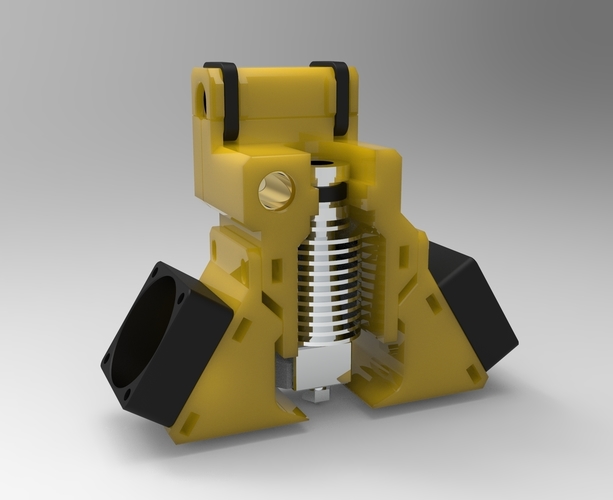

Titan Aero

The renown All-Metal v6 Hotend and Titan Extruder in one.

E3D Lite6 Hotends

An economical hotend that will help fine-tune your 3D printed parts.

E3D Plated Copper Volcano

E3D now offers their amazing Volcano HotEnd system in Plated Copper.

E3D SuperVolcano

Nozzles and hotends built for 3D printing high speed, super strong parts.

E3D Spare Parts

Find replacement parts for all E3D 3D printer accessories.

E3D Nozzles

From small to big - these nozzles are perfect for any 3D printer upgrade.

Guides & Articles

How To 3D Print Transparent Resin Parts

Getting transparent 3D printed parts can be quite challenging, but the team of engineers at Liqcreate have developed a process that anyone can do at home.

How To Succeed: 3D Printing with Nylon and Nylon Composites

Nylon and nylon composites perform exceptionally well in a variety of uses, it just takes a gentler touch to print it successfully.

How To Succeed When 3D Printing With Nylon

Learn how to 3D print Nylon like a pro. Nylon is a stronger and more durable alternative to PLA or ABS and easy to 3D print with using these Tips and Tricks.

3D Printing 101: How to Succeed with a Perfect First Layer for Every 3D Print

The first layer of your 3D print is the foundation of everything that comes after, which makes it such an important part of the 3D printing process.

How To: Use a Vacuumformer to Rapidly Create Unique Products

Extruding plastic isn't the only way you can have a manufacturing tool on your desktop; thermo-forming is a rapid and easy-to-use supplement to your toolchest.

Tech Breakdown: Pulse SNAP Toolheads

Not only does the Pulse SNAP simplify maintenance by allowing you to quickly swap out the entire hotend, it makes hotend and nozzle changes even easier.

How To: Mayku FormBox Desktop Vacuum Former

The FormBox Desktop Vacuum Former is a perfect addition to your 3D printing workflow. Expand your production and use new materials!

How To: Anneal Tough PLA for Stronger 3D Printed Parts

PLA isn't known for its thermal resistance, but 3D printing materials have advanced to create Tough PLA: the same easy-to-print material with new advanced properties.

How to Succeed When 3D Printing with Polypropylene

Successfully produce 3D printed parts out of polypropylene filament with these tips on achieving stronger bed adhesion and minimizing shrinkage.

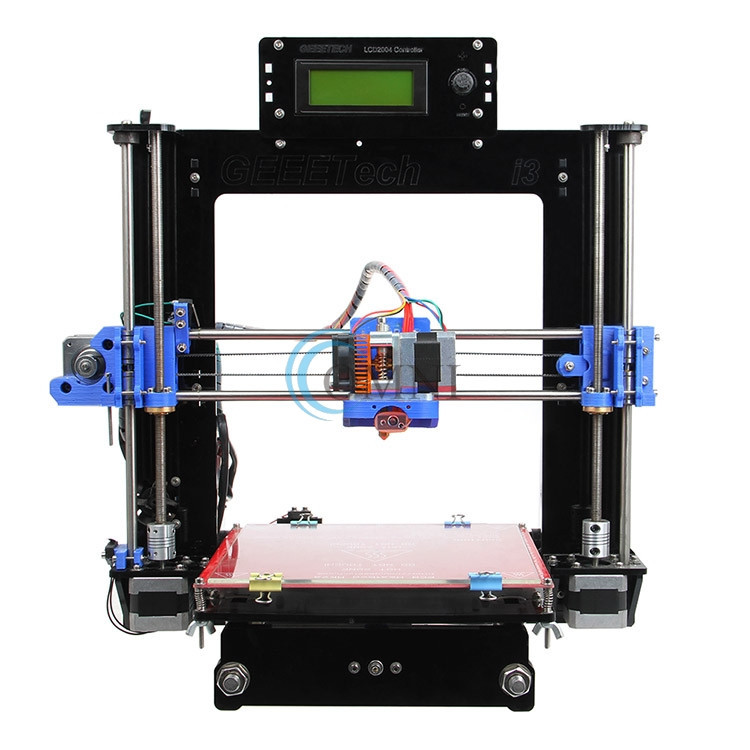

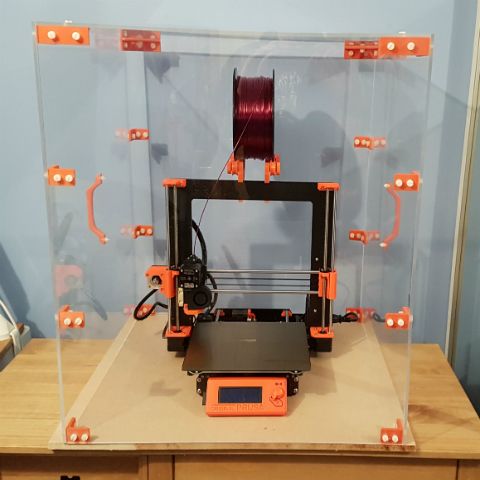

How To: Setup a Desktop Fabrication Station for 3D Printing

Preparing your workspace for your new 3D printer can be exciting, just make sure you take into consideration some key tips before getting started.

Anatomy of a HotEnd – E3D Online

HotEnds, liquifiers, toolheads, extruders, shooty-squirty-plastic guns - just what are these and why are they so important to the 3D printers? What makes a good HotEnd, what makes a bad HotEnd, and what makes an excellent HotEnd? We at E3D have been making them since 2012, and we’ve learnt a thing or two.

A HotEnd is a component integral to the build of 3D printers; unlike many of other components, the HotEnd cannot be 3D printed and is thus known as a ‘Vitamin’ , (other vitamin parts include belts. Motors, pulleys, motherboards, etc).

In a nutshell, HotEnds act as a ‘glorified glue gun’ which is fed spaghetti-shaped plastic by a filament drive, or as they’re more colloquially known, an extruder. Sometimes these two components are one and the same, sometimes they’re fixed together, and sometimes they’re a distance away and are connected by a tube of PTFE.

Sometimes these two components are one and the same, sometimes they’re fixed together, and sometimes they’re a distance away and are connected by a tube of PTFE.

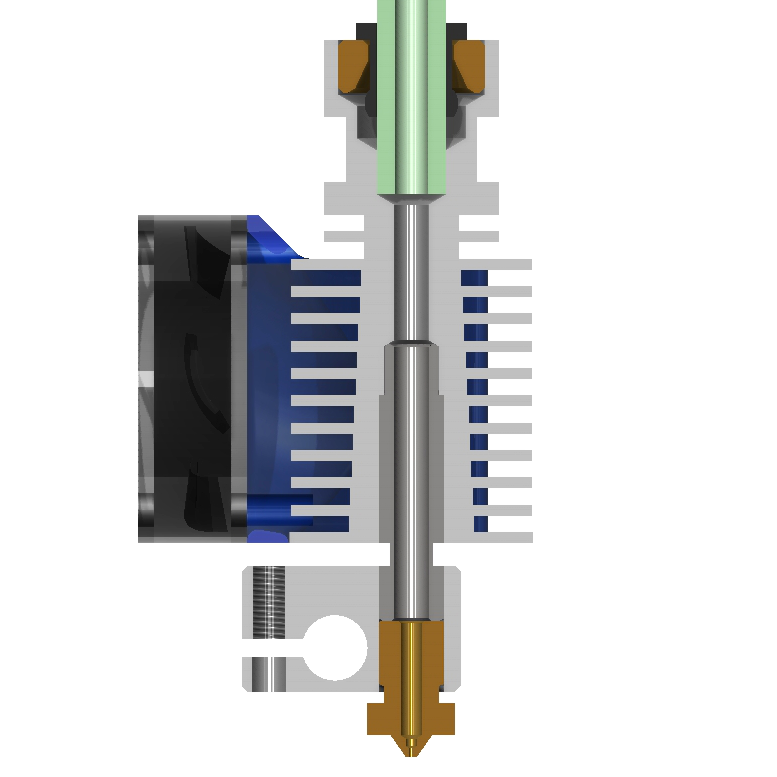

Either way, the filament is driven by the extruder into the top orifice of what’s known as the HotEnd’s ‘cold side’, through the HotEnd, and into the ‘hot side’, here the plastic becomes gooey, and then viscous, before eventually extruding through the nozzle at the bottom of the HotEnd’.

Once extruded, filament is laid down into a path; this path will eventually form one layer (or one slice) of the print.

Simple right? Not necessarily. HotEnds have seen continual development for the 30 or so years since their inception and are in fact quite complex components.

Although making a HotEnd of your own might sound easy - engineering a HotEnd capable of operating without leaks, clogs, heatcreep or other disruptions for 10,000s hours of continuous use is a totally different story. It even took us a number of goes to get it right, hence why our HotEnd is the V6.

It even took us a number of goes to get it right, hence why our HotEnd is the V6.

The HeatSink makes up the majority of what is known as the ‘coldside’ or cooling system for the hotend. It operates as a heat exchanger redirecting heat away from the filament path. This is achieved by maximising surface area exposed through the use of precisely machined fins; keeping the coldside cool, in what we call active cooling.

The active cooling’s effect is exemplified through the use of a mounted DC fan (using a duct) that blows air into the HeatSink’s fins - this ensures continuous circulation of the surrounding air and steers cool air in and around the fins.

In some more advanced cooling systems other techniques are used, such as passive cooling, pumped air cooling and even liquid cooling.

Liquid cooling is typically reserved for advanced extrusion systems and is more efficient than fan cooling. A continuous stream of cool water is pulled from a reservoir and through the HeatSink, continuously collecting heat transmitted as it travels through the HeatSink. This heated water is then delivered back into the fan-cooled reservoir and recycled.

This heated water is then delivered back into the fan-cooled reservoir and recycled.

Liquid cooling is the go-to cooling method when printing in heated enclosures (where fan cooling alone is less effective) or when working with high temperature polymers such as PEEK.

The HeatBreak is a threaded metal tube which both mechanically secures, and thermally separates the coldside of the HotEnd from the hotside. The HeatBreak is typically made of stainless steel, or in some cases titanium due to its lower thermal conductivity.

The HeatBreak is made up of 2 sides: one which threads into the HeatSink and stays cold; and the other which threads into the HeaterBlock and stays hot. It is within the HeatBreak that the filament’s property changes into one of a more viscous material in a process not too dissimilar to melting.

Hot side versus cold side

As the material travels through the HeatSink, it is both cold and solid and easily slides down the bore of the HotEnd. The material then enters the HeatBreak and as it travels down further, the temperature of the surrounding HeatBreak begins to increase - both heating and softening the polymer. This softening transition happens in the most constricted point in the middle of the HeatBreak; a section we’ve (very creatively) named:

The material then enters the HeatBreak and as it travels down further, the temperature of the surrounding HeatBreak begins to increase - both heating and softening the polymer. This softening transition happens in the most constricted point in the middle of the HeatBreak; a section we’ve (very creatively) named:

The property change experienced by polymers is unique. Unlike how an ice cube melts, the polymer doesn’t transition immediately into a liquid. Instead, the polymer enters a soft rubbery state, gradually becoming more and more putty-like. Eventually it becomes a viscous fluid of molten polymer at the hot side of the HeatBreak.

As the material softens, it resists downward travel by deforming and adhering to the walls of the HeatBreak; this tendency is actually often the cause of many clogs in poorly designed and manufactured HotEnds.

Whereas in an E3D V6, we carefully manage the transition zone by keeping it very short (2mm) and manufacturing the HeatBreak with an internal gloss-like surface finish, preventing the softened material from adhering to the walls of the HeatBreak.

As it so happens, the adherence of the filament is utilised by the HotEnd as a means of coaxing the molten polymer into the hotside and out the nozzle.

You see, as the filament enters the transition zone and softens, it also expands. This forms a soft rubbery plug between the gooey fluid on the hotside, and the solid brittle filament. This expanded plug creates a pressure seal which allows the solid filament to act like a piston and push the molten plastic out the nozzle, where this rubbery plug is the seal of the pistoné.

As it so happens, many users do not realise that this is a completely normal part of how a HotEnd functions, and upon removing filament from their HotEnd they are concerned to see the expanded tip on the end; they may fear the worst - when in reality everything is fine.

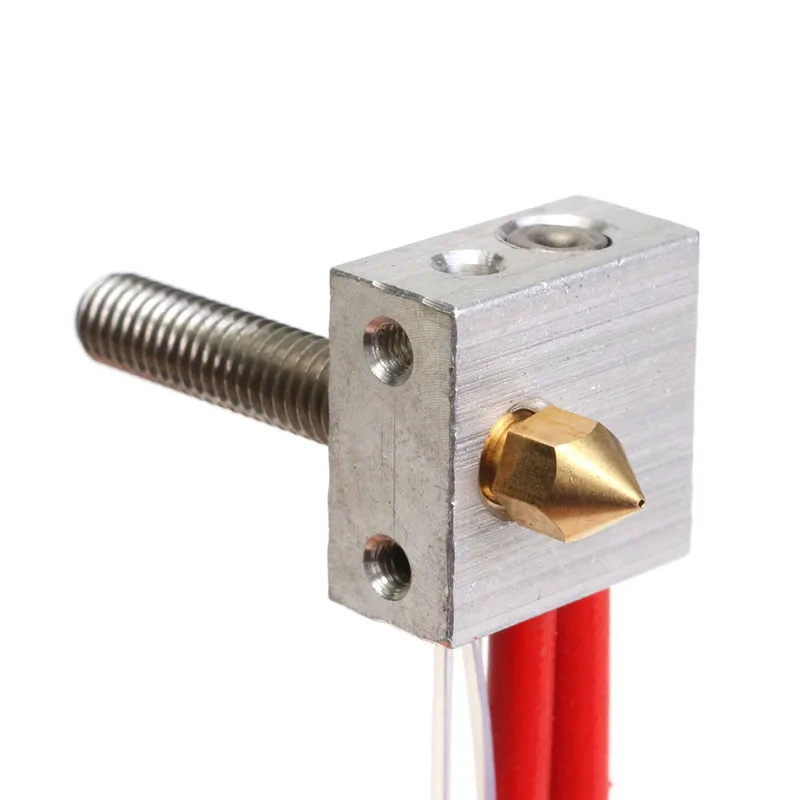

Serving a contrasting duty to the HeatBreak, the HeaterBlock is often made out of aluminium or copper - these being materials with high thermal conductivity. The HeaterBlock is responsible for mechanically and thermally coupling the heater, the sensor and the nozzle into a single collaborative system.

Perhaps more importantly, the HeaterBlock acts as a reservoir of heat for the nozzle to top up with, keeping its temperature stable and reducing thermal fluctuations.

The heater cartridge is an electrically-powered, tube-shaped device, embedded with a heating coil. Electricity cycles current through thin wires in the head of the heater cartridge. The tightness of the wire causes many collisions between the electrons and atoms within the wire which in turn generates heat. These wires are coiled into closely knit rings allowing heat between the individual coils to be shared and thus maximised.

Standard E3D heater cartridges have a power output of 30 watts which is tuned to allow the hotend to print at 300°C. We have intentionally chosen this wattage to maximise material potential of the HotEnd. Although printing above 300°C is possible with our standard heater cartridge, heating the aluminium block higher than 300°C causes it to soften and lose integrity; similarly the thermistor will also fail.

Printing more advanced polymers (which require temperatures above 300°C) is easiest with the use of high temperature heater cartridges (65W). Printing at these heights requires the use of specialized plated copper HeaterBlocks to prevent the block softening. Our high temperature range allows users to print upwards of 500°C; which is more than enough for any polymer ever conceived.

The thermistor is a specific type of sensor responsible for detecting the temperature of the HeaterBlock. Based on the detected heat, the sensor sends a signal to the heater cartridge switching it on or off. This in turn cajoles the hotside into retaining an idealised temperature - in a process more commonly known as a control loop.

- If the block is below the desired temperature the signal switches on the heater cartridge

- If the block is above the desired temperature the heat sensor switches the heater cartridge off.

Some temperature sensors do their job better than standard thermistors. Those who want sharper results and faster reactions can upgrade to PT100s or even thermocouples - these use alternative methods at sensing temperatures which are more complicated yet more reliable than standard thermistors.

Those who want sharper results and faster reactions can upgrade to PT100s or even thermocouples - these use alternative methods at sensing temperatures which are more complicated yet more reliable than standard thermistors.

Bowden tubing is a more atypical part of the HotEnd as it is only required for certain HotEnds. Typically made from slippery materials like PTFE, bowden tubing serves the purpose of cleanly delivering filament into the top of the HeatSink. With this role in mind, bowden tubing is much more vital in printers utilising bowden setups, than those using direct drive.

- In a direct drive setup the extruder is mounted to the top of the HotEnd, feeding directly into the HeatSink.

- In bowden setups, the extruder is mounted elsewhere on the printer and feeds filament into bowden tubing. The other end of the tubing is inserted into the top of the printer’s HeatSink and is held in place with a collet clip.

The most effective bowden tubing has a well constrained, slippery filament path to prevent friction and backlash within the tube as represented on the below diagram.

Standard PTFE tubing vs. Capricorn PTFE tubing with it’s more constrained filament path.

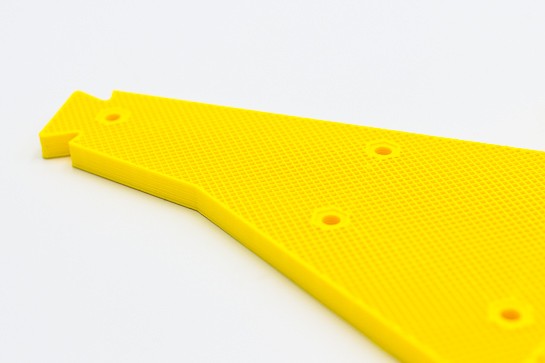

The nozzle is the final piece which completes our HotEnd puzzle, and perhaps the most important.

The internal geometries of a nozzle are precisely angled to allow optimal flow from its orifice and prevent clogs; its external geometries are also important. A well designed nozzle will have a flat tip surrounding its extrusion point which effectively ‘trowels down’ the layers of filament ejected from it. This flattening of layers is vital to ensure they bond to each other and the bed during the printing process.

As it turns out there is also an optimal ratio between the diameters of the hole and the flat tip, this ratio is something we employ in the production of every single nozzle we offer at E3D.

Nozzles are interchangeable and fit the user’s purpose. If the user wishes to print as rapidly as possible, they should opt for a nozzle with a large orifice diameter. Alternatively, if a user wishes to have a highly detailed print, they should use a nozzle with a tiny orifice diameter; the baseline size for most nozzles is a 0.4mm diameter.

Alternatively, if a user wishes to have a highly detailed print, they should use a nozzle with a tiny orifice diameter; the baseline size for most nozzles is a 0.4mm diameter.

In a similar vein, nozzle materials are also switched out to take advantage of the strengths each material possesses.

For instance, hardened steel nozzles excel when faced with abrasive filaments such as carbon fibre, which would otherwise tear up a brass nozzle’s internal geometries.

Whereas, plated copper nozzles stay robust when heated to high temperatures, which nozzles made of other materials would soften at; making them ideal for printing polymers with substantial glass transitions.

Nowadays, a well constructed, all-metal HotEnd can print essentially every polymer out there; so a better question might be - what is a polymer?

Plastic is a type of polymer, but not every polymer is a plastic. Thermoplastic is a specific type of plastic possessing a malleable and stringy nature when heated. Thermosetting plastics do not possess this nature, and instead blacken under heat. Some thermoplastics are also ‘resins’, meaning that they also contain any number of additives, colours or fillers which change their overall consistency and take them out of that stringy malleable nature essential for FDM 3D printing.

Thermosetting plastics do not possess this nature, and instead blacken under heat. Some thermoplastics are also ‘resins’, meaning that they also contain any number of additives, colours or fillers which change their overall consistency and take them out of that stringy malleable nature essential for FDM 3D printing.

The first thermoplastics utilised by the industry were ABS and PLA, with PLA still being a fan favourite today due to how easy it is to print with. However, over the years HotEnds have grown to cope with a multitude of unique polymers such as PETG, Nylon, PVA and even PEEK.

“PLA is one of the hardest materials to thermodynamically manage...”

It may surprise you to know, but despite its popularity, PLA is one of the hardest polymers to thermodynamically manage. Makers enjoy PLA’s low printing temperature and its extremely sticky nature (with dreamlike interlayer adhesion) but this stickiness is ironically a common cause of HotEnds clogging. It was through iterative procedure that we eventually landed on the internal HotEnd geometries we have today, optimising flow rates and minimizing clogs from not only PLA, but other tenacious polymers.

It was through iterative procedure that we eventually landed on the internal HotEnd geometries we have today, optimising flow rates and minimizing clogs from not only PLA, but other tenacious polymers.

Interestingly, a polymer tends to retain its cool and stiff, glass like state throughout the majority of a heating process. It is only when the polymer reaches a certain temperature (usually somewhere around 200°C), when the polymer suddenly becomes viscous and rubbery - this point is known as the polymer’s ‘glass transition’. Here the polymer may take on a whole host of other property changes that vary wildly dependent on which polymer you’re working with.

Polymers undergoing the ‘glass transition’ exhibit an interesting habit - they expand and build pressure. This pressure forces the nozzle to extrude filament, which in turn undergoes a phenomenon known as ‘die swell’. Die swell refers to how built up pressure in the polymer springs back to its original size when released. Die swell predominantly occurs as the polymer is ejected from the nozzle.

Die swell predominantly occurs as the polymer is ejected from the nozzle.

It is for this reason that nozzle size doesn’t quite parallel with extrusion width; tracks laid down by the HotEnd are often wider than the nozzle’s orifice size. Die swell leads to confusion in individuals who measure the width of the track with calipers.

HotEnds rely on the same pressure which causes die swell in order to function. Filament feeding into the HotEnd must stay back-pressured to keep the HeatBreak plugged and the viscous polymer beneath it flowing.

As a result of this, HotEnds experience something called ‘pressure delay’ - the appearance of less filament coming out the HotEnd than being fed into it.

Another common oversight made by makers is that they assume that when filament is extruded from the HotEnd, it is the same temperature as the nozzle. As previously detailed, the filament doesn’t spend enough time within the hotside to match its temperature. So naturally, the hotside is heated to an increased temperature to ensure the filament reaches a viscous state.

Ergo, although PLA ‘prints’ at 200°C, it really leaves the nozzle is around 150-160°C.

A large majority of clogs in poorly made HotEnds are caused by 'heatcreep'. Heatcreep is a plague on the function of HotEnds: heat will attempt to clamber its way up your HotEnd and cause the filament to liquify early, expanding above the designated transition zone of the HeatBreak. Heatcreep is a tenacious beast that will clog your HotEnd if you let it.

Thankfully, heatcreep can be tamed and prevented; all it takes it a precisely machined, temperature-balanced HotEnd. Care should be taken to ensure the cold side of the HotEnd dissipates enough heat to cope with the temperature of the hotside; but not too much cooling to prevent the hotside reaching its desired temperatures.

So in short, HotEnds are complicated - more complicated than they’re given credit for; and they’re difficult to manufacture well. At E3D we’ve spent been designing HotEnds since 2012 and have done all the worrying for you, ensuring ideal functionality with every piece. Keeping you printing and not have you worrying about: what on earth ‘glass transition’ is; whether or not your temperature is properly balanced or if you'll wake up to a failed print and a clogged nozzle the next morning.

Keeping you printing and not have you worrying about: what on earth ‘glass transition’ is; whether or not your temperature is properly balanced or if you'll wake up to a failed print and a clogged nozzle the next morning.

Check out our range of HotEnds.

Hotend in the category "Appliances and Electronics"

Original CREALITY 3D Spider High Temperature Speed Hotend other 500° . for Ender 3/3Pro/3V2/Ender-6

Delivery across Ukraine

1 960 uah

Buy

aikonss

Hotend Kit extruder, aluminum Projeve thermal block, Bowden pipe CR-1 CR-1 CR-1 CR-1 PTFE 10S

Delivery across Ukraine

350 UAH

Buy

ELEKSTOK

Creality Spider Hotend Kit high temperature nozzle 500C for Ender-3, Ender-3PRO, Ender-6 9Ol000 Ma Store

Hotend E3D V6 24V assembly Direct, for 1.75 filament and tube 4MM

Delivery from Kyiv

470 UAH

Buy

Ma Store

Zortrax Moduł Hotend (INVEVENTURE) (DBAL0913093320)

Under order

Delivery in Ukraine

760 UAH

7 690 UAH

Buy

Click24

Zortrax Modu midnd (M300 DUAL)

Under order 9000

7 690 UAH

Buy

Click24

Heater 6*20mm 30W 12V with wires (1m!)

ends

Delivery

75 UAH

Buy

0003

MA store

Heating element for 3D printer hotend extruder. 12 and 24 Volta

12 and 24 Volta

is not available

150 UAH

Watch

Aluminum heating unit V5 (Hotend MK7/MK8/E3D)

Non -access printers and 3D pens

Aluminum heater block MK7/MK8 (hotend MK7/MK8/E3D)

Not available

65 UAH

Watch

U3DF - Ukrainian factory for the production of consumables for 3D printers and 3D handles

Ekstruder Ekstruder Bloc Ekstruder

Not available

9000

0.2 mm

Not available

26 UAH

Watch

U3DF - Ukrainian factory for the production of consumables for 3D printers and 3D pens

E3D V5/V6 hot end heating block nozzle 0.25 mm

Not available

30 UAH

Watch ,6 mm

Not available

26 UAH

See

U3DF - Ukrainian factory for the production of consumables for 3D printers and 3D pens

See also

Hot end heating block nozzle MK7/MK8 0.2 mm

Not available

29 UAH

View

0. 4 mm0003

4 mm0003

Inaccessible

29 UAH

Watch

U3DF - Ukrainian factory for the production of consumables for 3D printers and 3D handles

Half Hotland MK7/MK8 0.5 mm

Unavailable

29 UAH

Watch

U3DF - Ukrainian factory for the production of consumables for 3D printers and 3D pens

Heating element for hotend 3D printer extruder. 12 and 24 volts 24 V

Not available

150 UAH

View

High Temperature Full Hotend Kit

Not available 50 W. [#X-3]

Not available

UAH 54

Watch

Ardu.prom.ua (Non-ship cover from 150 UAH!)

Hotend MK8 aluminum heating block | 3D Printer Accessories

N/A

Price specify

Watch

Hotand Extruder E3D V6 1.75mm

Inaccessible Not available

345 UAH

Watch

Double-Shop

E3D V6 extruder heating block for 3D printer

Not available

Watch Specify the price

0003

Watch

INTERNET-SHOP "ZAKUPIS"

Extruder for 3D printer - a complete guide Heatle

Learn the basics of direct drive and Bowden extruders, hot and cold ends, nozzle sizes and materials, and find the best 3D printer cartridge for your needs.

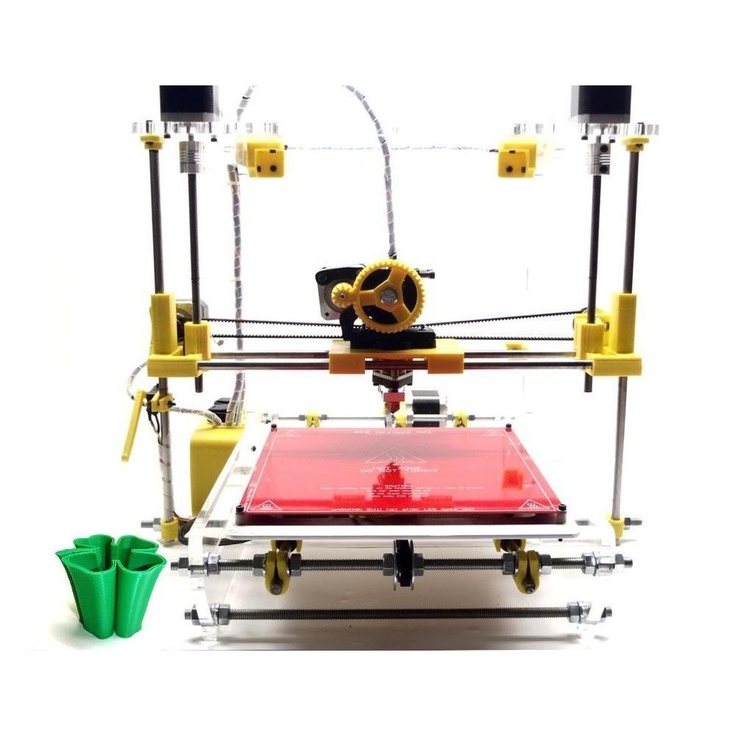

The 3D printing process can be briefly described as follows: a filament of plastic material is fed into a heated metal block with a nozzle, where it is melted and extruded in a given form. This path is repeated, gradually building up until a solid three-dimensional object is formed.

The entire business task of handling the material, melting it and exiting for printing takes place in a block called extruder 3d printer .

In this article, we will look at the main sections of the 3D printer extruder, the options and advantages of different styles of extruders, popular models on the market, as well as cartridge heaters for 3D printers and other items.

What is an extruder

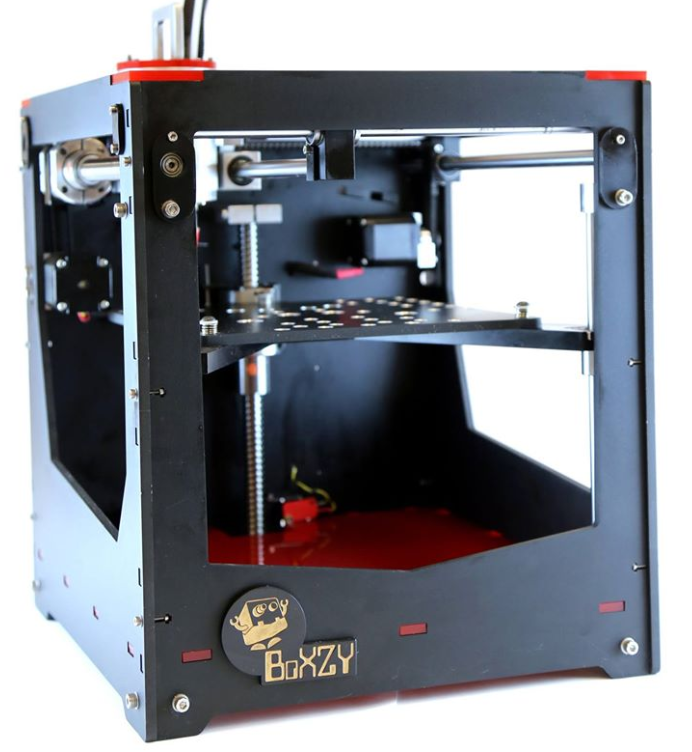

The 3D printer extruder is a set of parts that together process and move plastic filament.

Some consider the extruder to be just the motor and associated parts that push and pull the filament, others the entire assembly including the heated part that melts and deposits the filament.

For simplicity, this article treats the entire assembly as an extruder. To begin with, while explaining the key components of a 3D printer extruder, we will divide it into two elements: a cold zone and a hot zone.

Cold zone

As the name implies, the cold zone is exactly that - cold. It's The top part of the 3D printer's extruder system, into which the filament is fed and then passed into the hot zone to be melted and extruded onto the print platform.

The appearance and location of the cold zone on your 3D printer depends on whether it is a direct drive or Bowden drive extruder (both of which are detailed below).

There is no filament heating here. The cold zone consists of the extruder motor and gear train, which are usually mounted either on the printer frame or on the print head itself, depending on the type of extruder, and a PTFE tube to smoothly guide the filament into the hot end.

What happens in the cold zone?

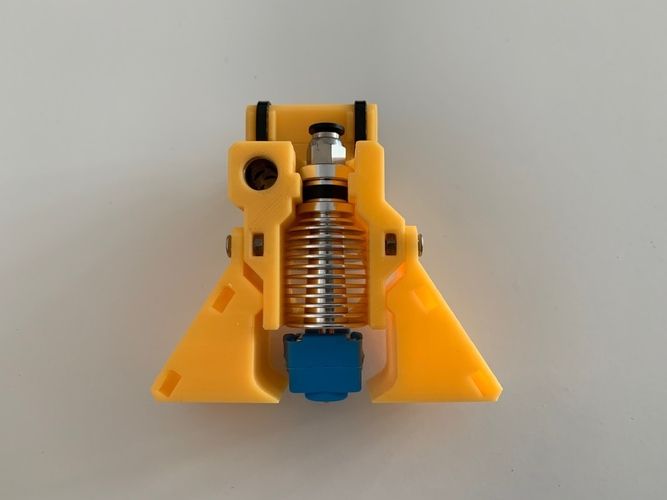

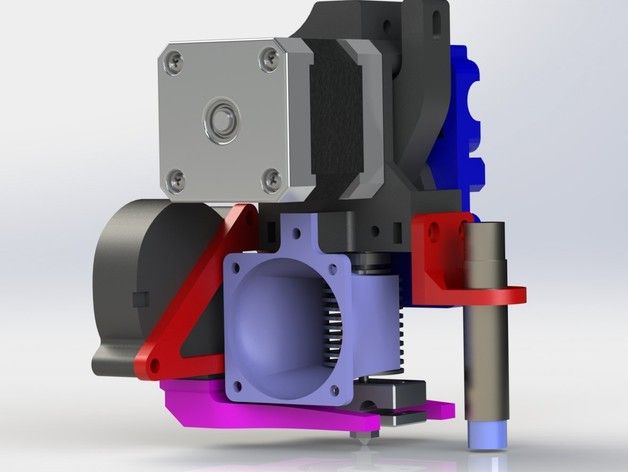

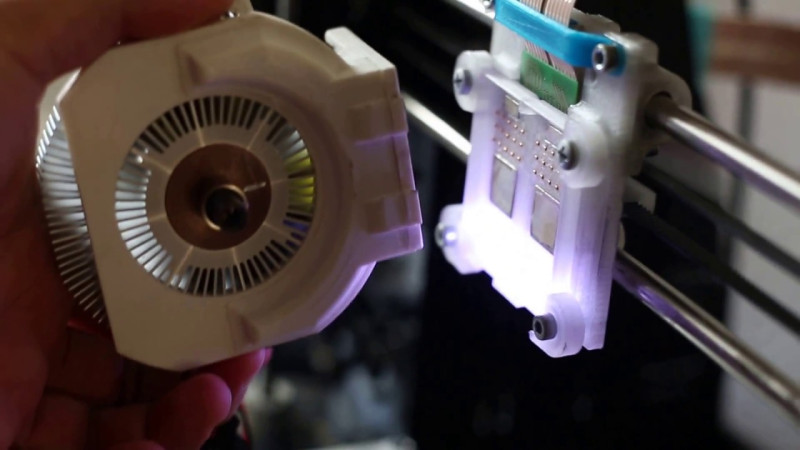

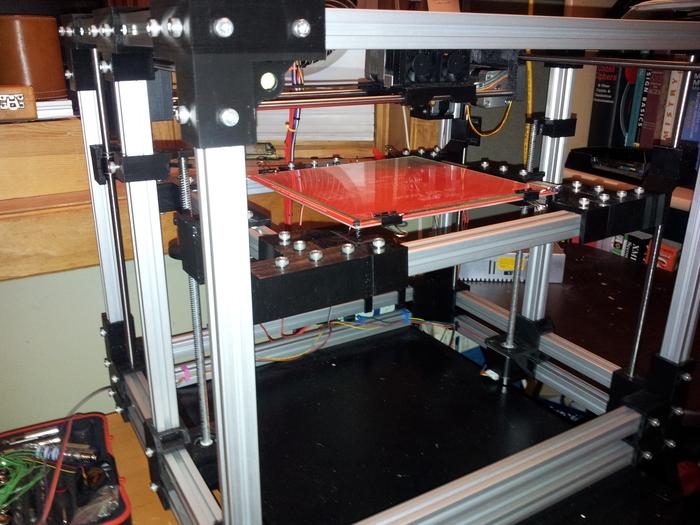

With the heatsink removed on this e3D Titan Aero, we can see the inner workings of the 3D printer's extruder.

Essentially, the cold zone consists of a stepper motor, some form of gear, a toothed bolt or gear, a spring-loaded idler (usually a bearing of some kind) to hold the filament, and then a PTFE tube to guide the filament.

A humble stepper motor with a metal gear required for a 3D printer's extruder drives the filament extrusion in most if not all modern desktop 3D printers.

However, one stepper motor is not enough to feed the filament to the hot end. The parts attached to and operating the stepper motor drive shaft must physically grab the filament and push it on its way to the hot end.

In this cutaway view of a 3D printer extruder, we see a metal gear and a plastic gear with a toothed shaft.

This usually uses a combination of toothed gears and toothed bolts or shafts (in the image above we see a metal gear and a plastic gear with a toothed shaft) serving as a pressure wheel along with a bearing or other rigid frictionless material.

Here we see a plastic lever with an integrated bearing, an extension spring and a plastic gear with a toothed shaft. Together they apply pressure to the filament and force it through the extruder.

Alternatively, there are versions of the cold end of the 3D printer extruder that use a slightly different arrangement of parts to feed the filament. Such deviations are often claimed to provide increased traction and yarn delivery.

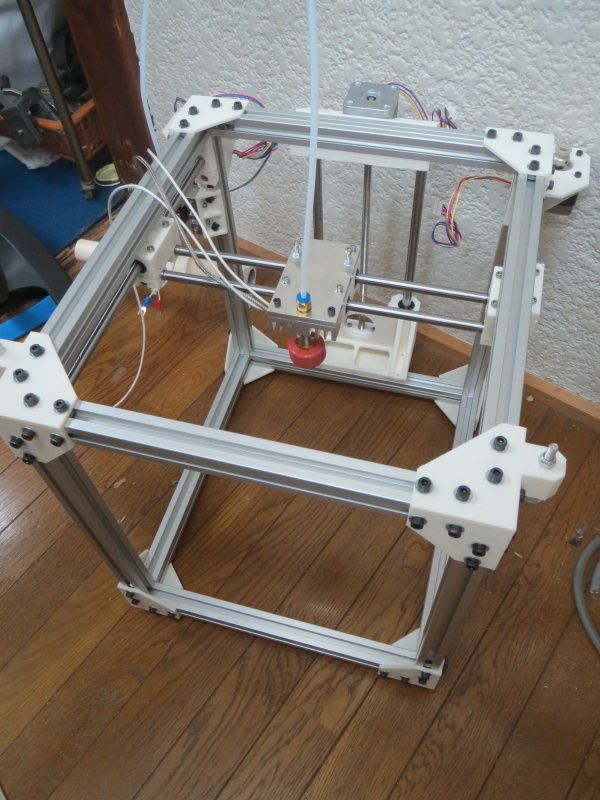

Here we see both sides of the Prusa i3 Mk3 cold end, including the Bondtech extruder gear train.

As mentioned, there are varieties of 3D printer extruder that use these parts in slightly different layouts. Each has its pros and cons. Next, we will look at what is the difference between a direct drive 3D printer extruder and a Bowden 3D printer.

Direct drive extruders

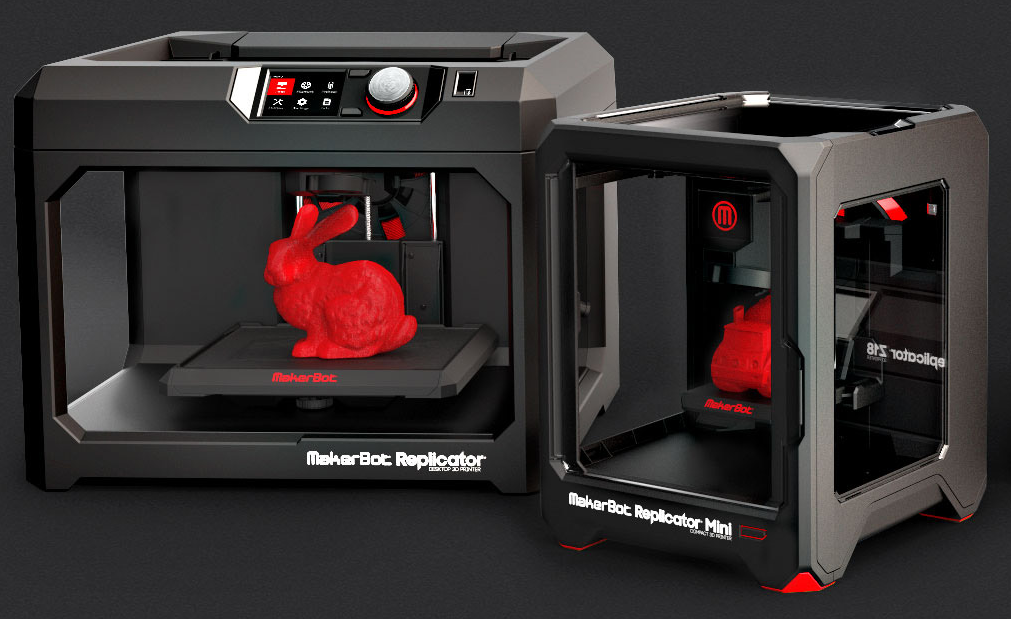

The Direct Drive 3D Printer Extruder is different in that it places the extruder motor directly above the heating unit. This arrangement minimizes the travel distance of the filament to the hot end and can enable more reliable 3D printing of flexible filaments.

This arrangement minimizes the travel distance of the filament to the hot end and can enable more reliable 3D printing of flexible filaments.

The advantage of using direct drive is more precise retraction control. Due to the location directly above the hot end, there is less distance between the clamp and the thread passing through the thermal barrier into the heating block. Consequently, the filament has less room to bend and deform under pressure.

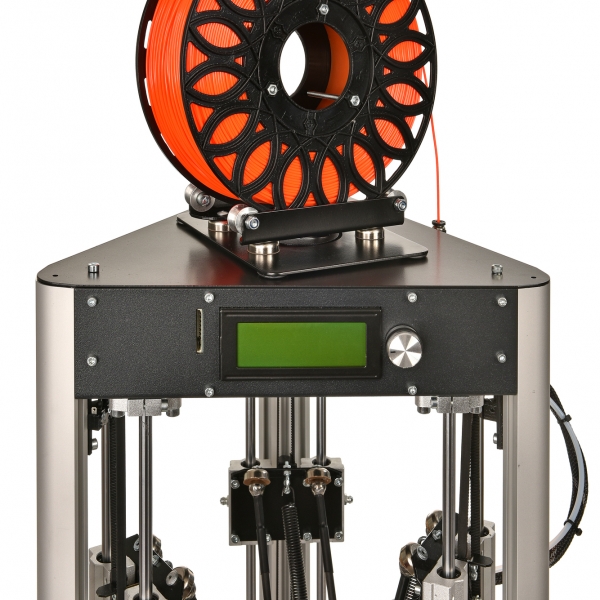

Bowden extruders

Bowden Style 3D Printer Extruder The does not mount directly on the top of the hot end like a direct drive 3D printer extruder, but the motor and gear assembly mounts on the frame of the printer. This gives this type of extruder an advantage over its head-mounted direct drive brother: speed.

By placing the mass of the 3D printer's extruder on the frame instead, the printhead is freed up to print at higher speeds without sacrificing print quality.

A side effect of placing the 3D printer's extruder this way is that the filament now has to travel a long way in a tube that's a fraction wider than it is. There should be enough room along the entire length of the tube for a slight bend in the thread. When pulling in the thread between strokes, this slack in the thread shortens the pull-in distance. Without correction (i.e., an increase in retraction), this results in a delay in relieving the pressure exerted on the hot end. In short, you can get confused if you don't change your retract settings.

There should be enough room along the entire length of the tube for a slight bend in the thread. When pulling in the thread between strokes, this slack in the thread shortens the pull-in distance. Without correction (i.e., an increase in retraction), this results in a delay in relieving the pressure exerted on the hot end. In short, you can get confused if you don't change your retract settings.

Heating block (Hotend)

Inside the knot, known as the hot end, the filament passes into a heated chamber where it changes from solid to liquid. Sounds simple, and mostly it is. Although there is a lot more to make the filament silky extrude onto the build plate.

What happens in the heating zone?

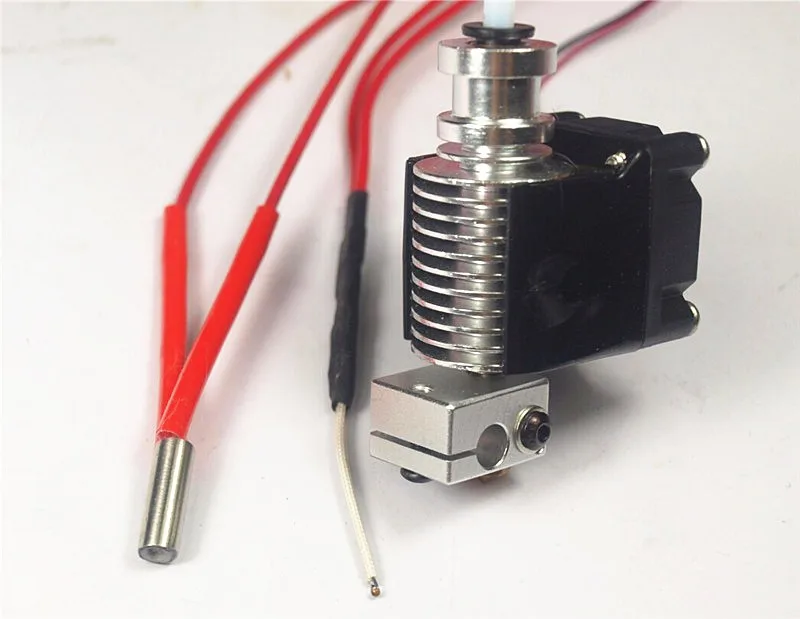

The E3D Titan Aero combines a heating block and an extruder in one compact unit. The hot end usually only has the central parts of this image: the heatsink (and fan), the heating element (micro cartridge heater), the heater block, the thermistor, and the nozzle.

A typical 3D printer hot end consists of a specific sequence of parts. There is a slight difference depending on whether you are using PTFE/PEEK or a full metal hot end. Here we explain the all-metal hot block.

First, it is a filament supply tube. In both a Bowden 3D printer extruder and a direct drive extruder, it will just be a PTFE tube coming from your cold filament feeder.

You can sometimes find direct drive 3D printer extruders where the filament runs straight into the print head.

On a Bowden 3D printer's extruder, this feed tube inserts the filament directly into the thermal barrier via a heatsink. The thermal barrier that is screwed into the heatsink is often a threaded stainless steel (or other non-conductive metal such as titanium) tube.

Split in two (note the two separate threads in the image below - longer for the heatsink, shorter for the heater block) and machined on the inside, the thermal break allows the filament to pass freely into the extrusion nozzle.

Clockwise from bottom left: steel thermal barrier, aluminum heating block and brass nozzle.

But since we're dealing with precision and a material that liquefies for rapid recooling, the 's temperature management is critical. The thermal barrier, in combination with the heat sink, maintains a certain limit at which the filament is exposed to high temperatures.

The top, which is actively cooled by a heatsink and dedicated fan, prevents heat from escaping from the hot end and weakening the filament before it is where it needs to be for extrusion. This unwanted phenomenon is known as thermal creep.

The lower part of the thermal barrier is located inside the heater block together with the cartridge heater, the temperature switch thermistor and the nozzle.

The heater block, usually made of aluminum, ensures a smooth transition of the filament from the open end of the thermal break tube to the nozzle.

The temperature to melt the filament has to come from somewhere, and this is where the cartridge heater comes into play.