Rival 3d print

▷ nerf rival mods 3d models 【 STLFinder 】

Nerf Rival

thingiverse

3D printed nerf rival https://youtu.be/PplPKkfyCLY

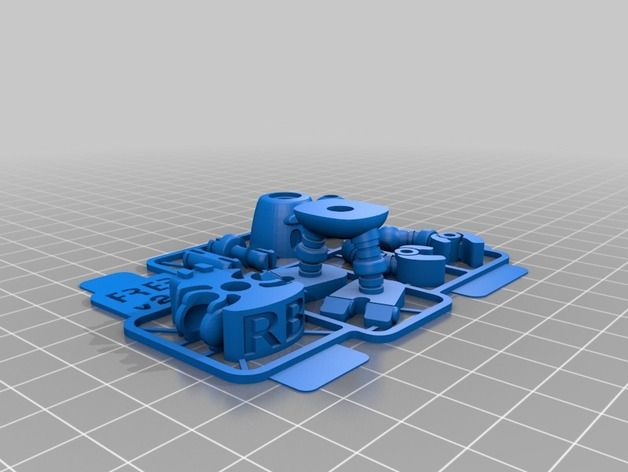

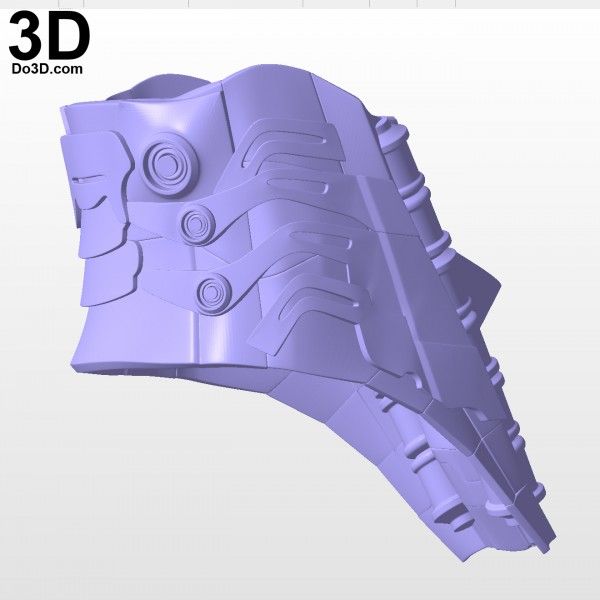

Part Rival zeus Nerf

grabcad

Separator of Nerf Rival Zeaus

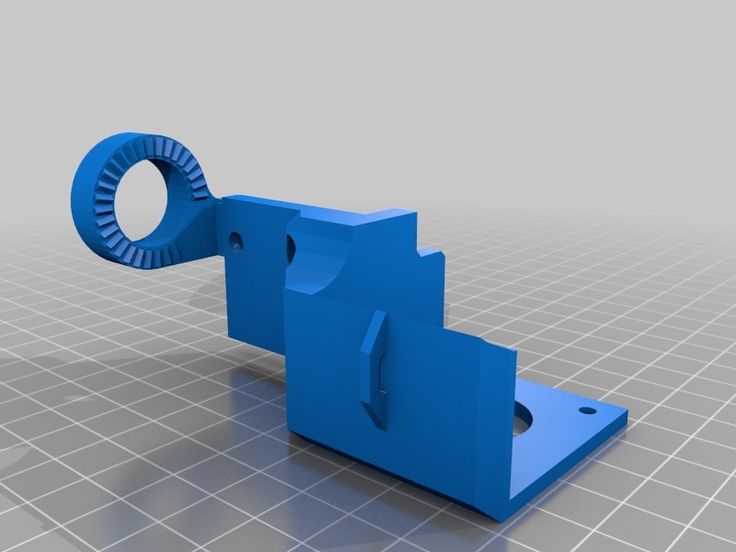

nerf rival mag holder

thingiverse

nerf mag holder for rival rails. Nothing more. ...pls let me know how it works.

Nerf Rival Gear Replacement

thingiverse

Middle gear from Nerf Rival. ...Edit: Uploaded one with the correct height and modified hole size.

Sight for Nerf Rival

thingiverse

This thing was created for the Nerf Rival Kronos Sorry for the bad pics.

nerf rival mag holster

thingiverse

nerf rival mag holster, left or right side. ...loops through belt holds 2 mags each and fits all rival mag types.

Nerf Rival Magazine Clip

thingiverse

so I made a nerf rival tactical rail magazine clip. Not much more to be said. ...So yea...

Not much more to be said. ...So yea...

reflex nerf rival sight

thingiverse

One-print nerf rival sight, no further action needed, make sure you print it face-down though.

Nerf Rival Perses Trigger

thingiverse

Trigger for Nerf Rival Perses. will only work with upgraded switches. ... works perfectly with the Perses rev trigger by haphazardlynamed

Nerf Rival Fast Mag

thingiverse

# Nerf Rival Fast Mag An attachment for quickly swapping between magazines. Fill the other magazine as you go. The space between the magazine holders can fit up to 6 additional rival balls. ...Only works with 12 round magazines.

Fill the other magazine as you go. The space between the magazine holders can fit up to 6 additional rival balls. ...Only works with 12 round magazines.

Nerf Rival Scope

thingiverse

For those who are looking for a nerf scope compatible with nerf rival. I will upload pics sooner or later. you may have to sand the end cap. ...please post your prints!

plastic nerf rival dart

thingiverse

This is a plastic nerf rival dart I have yet to try it but you might need a larger diameter or smaller please try it and tell me if it works.

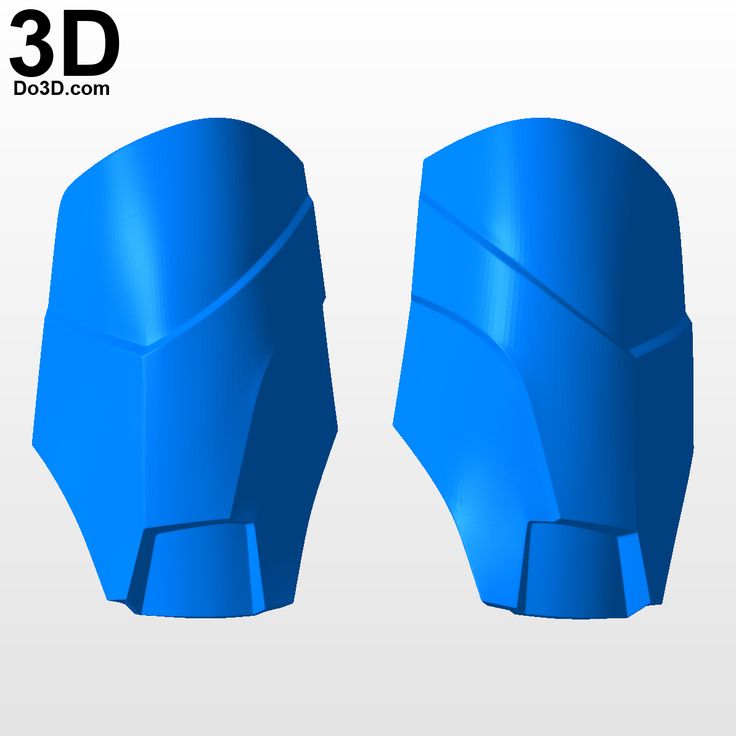

Nerf Rival Grip

thingiverse

Foregrip Designed for the Nerf Rival Perses will also work on the Khaos. Hardware is a #10-32 x 1-1/4" machine screw and nut. ...Might require minor filing to get it to fit nicely due to tolerances.

Hardware is a #10-32 x 1-1/4" machine screw and nut. ...Might require minor filing to get it to fit nicely due to tolerances.

Nerf Rival RMR

thingiverse

An RMR style sight for Nerf rival blasters. In V3 I added a Iron sight post for easier aiming. ...I have also included the fusion 360 file for easier customization.

Nerf rival silencer

cults3d

This is a prop silencer for Nerf rival Nerf guns. it contains the same features as a real silencer, but fit specifically for the Nerf Helios xviii-700 blaster. 4x M3 screws and bolts are necessary, but if you have glue, that works also. As well as...

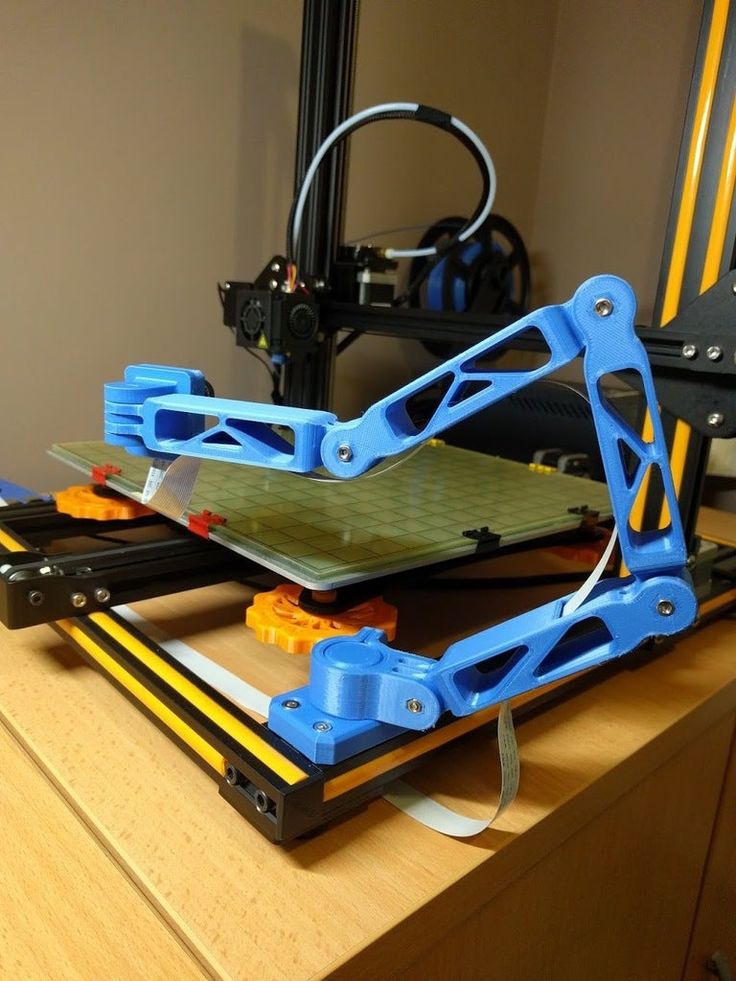

Nerf Rival Ball Collector

thingiverse

Inline adapter for Shop-vac that allows dirt through but ejects Nerf Rival balls into a quick-attach hopper for easy collection. Designed with loose tolerances so it can be printed with a 0.6mm nozzle with thick layers.

...

Assembly/use video:...

Designed with loose tolerances so it can be printed with a 0.6mm nozzle with thick layers.

...

Assembly/use video:...

Nerf Rival Kronos Holder

thingiverse

This holder is designed to vertically store a Nerf Rival Kronos. It has a thick base to lower the center of gravity and prevent it from tipping along with a snug fit to keep the blaster secure. It can be vertically stored on a shelf or mounted on a...

Nerf Rival Rail Sights

thingiverse

These are sights for NERF RIVAL rails.

The design is based on the speed loader mounts of Andrew_Overby. I reduced it to the rail mount, shortened it and then attached sights onto it. There is also a small borehole to lock it in place on the rail.

There is also a small borehole to lock it in place on the rail.

Nerf Rival Apollo Rail

thingiverse

Coworker got a Nerf Rival Apollo and an extra magazine, which came with clips so you could put the magazine on the rail on the gun. ...However we both thought it kinda looked silly to have the big magazine hanging off the front of the gun, so after a...

Nerf Sight RIVAL

thingiverse

Here is a Nerf Sight that I made only for the Rival gun's.. At least the Helios.. I don't have other guns to try it on.. I am assuming the rails are the same dimensions...

-Assembly-

Put a dab of super glue on a piece of paper and hold the. ..

..

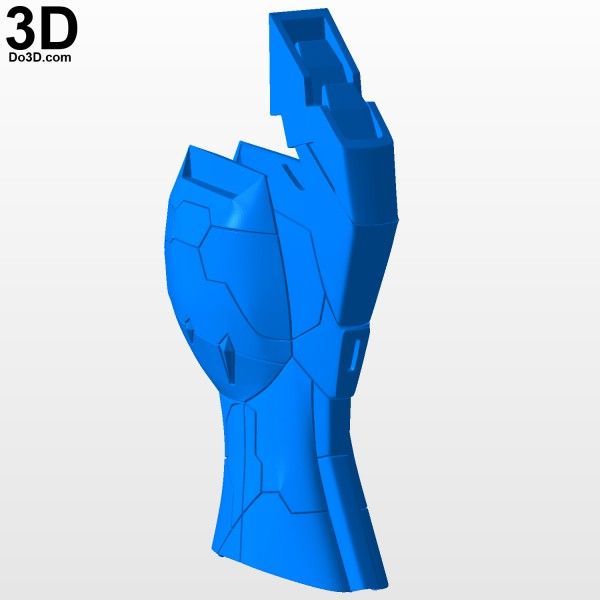

Nerf rival Assist

myminifactory

The nerf rival assist is an automated nerf gauntlet and turret the shoots nerf rival bullets with the press of a button. What makes this special is that it can be controlled from far away because it uses an IR sensor. The Nerf rival assist has proven...

Nerf Caliburn - Rival

thingiverse

CHANGE NOTE 08/07/19 - Magwell Updates CHANGE NOTE 08/07/19 - Updated Rmuzzle and TrenchR CHANGE NOTE 04/24/19 - Minor revision to RTooth5 CHANGE NOTE 01/11/19 - Updated RMagRelease2 to fix compatibility issue with new Rival mags with the "stairs"...

Nerf Rival GoPro mount

thingiverse

Just a simple GoPro mount for Rival Rail

Nerf Rival Magazine Holster

thingiverse

This is a remixed design of a Nerf Rival Magazine Holster. The original author did not provide a step file, so I created my model from scratch in fusion 360 (basing some geometry on their design).

I modified the cutout geometry so that the...

The original author did not provide a step file, so I created my model from scratch in fusion 360 (basing some geometry on their design).

I modified the cutout geometry so that the...

Nerf Rival Kronos Speedloader

thingiverse

HI, this is my speedloader 'system' for Nerf Rival Kronos. You need to replaced the 'flap' with this parts. It allows you to load rounds without needing to flip open the flap and also make loading easier as you can drop 1-2 rounds in and then push...

Working Nerf Rival Catapult

thingiverse

This is a catapult that fires Nerf Rival rounds. Some superglue is required for assembly. The spin rod itself should not be glued, it

can be inserted in any number of holes, raising or lowering the trajectory of the catapult.

This is one of...

Some superglue is required for assembly. The spin rod itself should not be glued, it

can be inserted in any number of holes, raising or lowering the trajectory of the catapult.

This is one of...

Nerf Rival Hera Muzzle

thingiverse

The sub-series of Phantom Corps are just awesome and the [Nerf Rival Phantom Corp Hera](https://amzn.to/2FtaNzP) is beautiful and awesome out of the box. But there's always room for improvement. Originally, my plan was to replace all the orange...

Nerf Rival Tactical Rail

thingiverse

Having recently acquired a Nerf Rival Apollo and secondary magazine, I had a need for a second tactical rail, since the only stock rail is directly in front of the priming lever, gets in the way, and makes the gun look like a derpy unicorn when the. ..

..

Nerf Rival Saturn Grip

thingiverse

This is my replacement grip for the Nerf Rival Saturn XX-1000. It features an upright pistol grip as well as a standard Nerf stock attachment point. There are several replacement grips that are available for the Saturn that look great, but none of...

Nerf Rival Dueling Tree

thingiverse

This is a modular system for the Nerf Rival series, although it may work with other Nerf projectiles. This is a dueling tree similar to the real thing. You shoot against another person, the first of whom gets the targets to the opposing side wins. ...

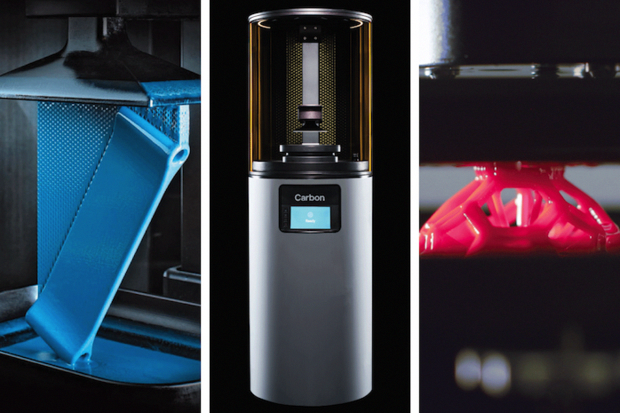

3ders.org - SteelSeries offers 3D printable nameplate for its Rival optical gaming mouse

Nov. 11, 2014

11, 2014

SteelSeries is known for its high-performance PC gaming peripherals. In 2013, the company introduced the Rival Optical Gaming Mouse. The Rival features advanced optical sensor for high precision and 30 million-click lifespan. Its ergonomic right-hand design features an advanced anti-sweat coating and rubber side grips to deliver optimal texture, feel, and comfort. On top of that, the Rival offers multiple levels of customization ranging from 16.8 million color illumination options, to SteelSeries ExactTech settings powered by the new SteelSeries Engine 3 software.

Bruce Hawver, SteelSeries CEO said, "The new ergonomic shape and state of the art hardware deliver unmatched levels of precision, comfort and durability. Combining this level of hardware with new SteelSeries Engine 3 software, users will find an entirely new customization experience that redefines how a mouse can be configured."

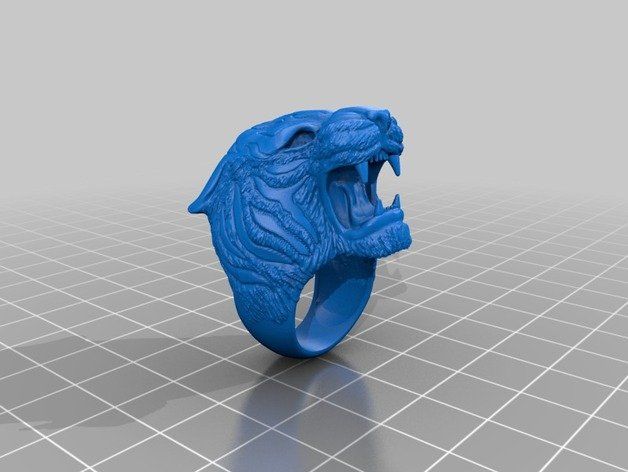

Very recently, SteelSeries has added a 3D printable nameplate to its offering. By default the Rival comes with 2 interchangeable nameplates. But if you have a 3D printer, you could just customize the part and 3D print your own nameplate using the 3D models provided by SteelSeries on its site. You can also order your mouse with 3D printed nameplate online, and your part will come 3D printed from Shapeways.

By default the Rival comes with 2 interchangeable nameplates. But if you have a 3D printer, you could just customize the part and 3D print your own nameplate using the 3D models provided by SteelSeries on its site. You can also order your mouse with 3D printed nameplate online, and your part will come 3D printed from Shapeways.

SteelSeries is one of the few companies developing products that allows customers to make it their very own items. Recently SteelSeries showed off their customisable Rival Mouse at PAX in Melbourne, Australia (Oct 31 ~Nov.2, 2014), an event that brings gamers from all over Australia to play against each other and share their gaming experience. Steelseries teamed up with Australia company The 3D Printer to offer 3D printed name plates for the Rival at the event. All parts were 3D printed on site on a BEETHEFIRST 3D printer from BeeVeryCreative, showing you how the customised part prints and fits into the mouse.

Posted in 3D Printing Applications

Maybe you also like:

- Building a portable NES using 3D printer

- Artists completes Echoviren, 'world's first 3D printed architectural structure'

- Mixee Labs launches 3D printed Dogbone Tag for your furry friends

- Coca-Cola launches mini bottles with 3D-printed mini-you

- 3D printed bow tie flashes when someone gets too close

- Next month "We Print Originals" to recreate classic moments in HK

- NRG3: A 3D printable roller wrench tool on Kickstarter

- Japanese police use 3D printing to help find wanted criminals

- Giant loudspeaker maker is investing in 3D printing

- Square Enix sent a takedown notice to 3D-printed Final Fantasy VII Figures

Printing cup 56 cm high for the CTF championship

3D printing

In October, 3DQuality was at the Open Innovations Forum in Skolkovo.

At this event, the organizers of the STF Safety Cup in Russia met with us, who gathered the winners and prize-winners of the strongest regional competitions among students, schoolchildren, secondary school students and two teams of organizers of their competitions.

At this event, the organizers of the STF Safety Cup in Russia met with us, who gathered the winners and prize-winners of the strongest regional competitions among students, schoolchildren, secondary school students and two teams of organizers of their competitions. What is CTF?

CTF (Capture the flag) is a team game, the main goal of which is to capture the "flag" from the opponent.

In this case, these are competitions between teams of "Hackers", which at the program level had to seize control of the robot and help it to take out the opponent's robot.

A decision was made between us to cooperate in the production of prize cups for teams of winners and prize-winners of the competition, and specifically we were faced with the task of printing 3 cups: 54 cm, 30 cm and 24 cm. About printing one of these cups, the largest, We will tell you in the post below.

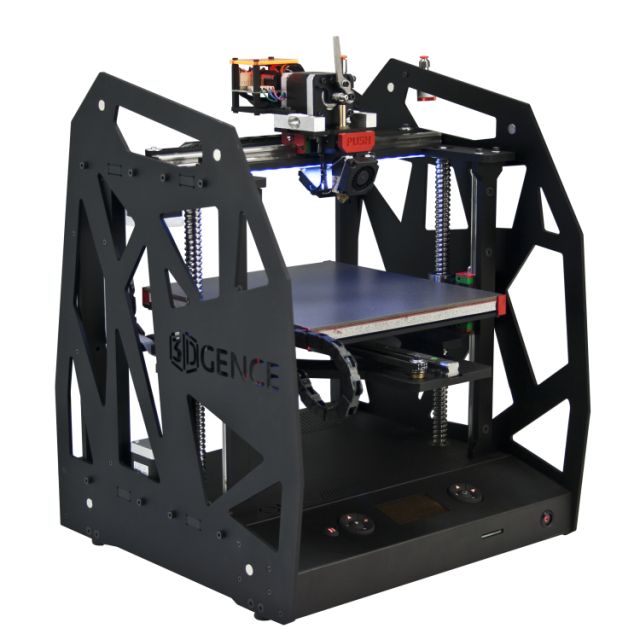

The cup model was provided by the organizers themselves, with the participation of our common partners. A number of approvals reduced the printing time so that we had to deliver the finished models in 10 days, but the production capacity allows us to solve even other tasks. Printing was carried out on 3 Prism Pro V2 3D printers.

A number of approvals reduced the printing time so that we had to deliver the finished models in 10 days, but the production capacity allows us to solve even other tasks. Printing was carried out on 3 Prism Pro V2 3D printers.

The largest cup took 162 hours to print.

The products also required post-processing. The most important thing was to process the cup in such a way that it would look like after printing.

The following shows all the steps of cup processing starting from the video of its printing.

1. Removing supports and sanding.

Grinding took place in several stages, at first there was a rough processing, namely the removal of all supports, the “cobweb” was treated with a hair dryer. Then there was a pass with a grinder with different abrasive properties and at the end we went through an engraving machine.

2. Primer.

Primed with conventional automotive spray primer on plastics.

3. Painting.

Painted with matte black spray car paint in 3 coats.

All cups have found their deserved winners.

And for us it was another interesting experience)

Join our groups on VKontakte, Facebook, Instagram and Youtube channel:

https://vk.com/3dpzone

https://www.facebook.com/ 3DQuality.ru/

https://www.instagram.com/3dquality.ru/

https://www.youtube.com/channel/UCjWtWxi9m5f3pQxxT1z66rw

Follow author

Follow

Don't want

6

More interesting articles

DrProg

Loading

11/08/2022

1322

9

Subscribe to the author

Subscribe

Don't want

We continue to reveal the incredible opportunities of enterprises from the Middle Kingdom, up to . ..

..

Read more

0

Subscribe to the author

Subscribe

Don't want

Ones Technology is a research and development center under the Ministry of Industry of Turkey. According to G...

Read more

Leoluch

Loading

09/07/2015

357319

346

Follow author

Follow

Don't want

Good afternoon, dear visitors of the portal.

Today I decided not to leave in art...

Read more

Put printing on stream: 3D wire printer created in Russia | Articles

The introduction of the Russian wire printer will reduce the time for manufacturing spacecraft parts from several months to several hours. At the same time, unlike powder analogs, it will be able to produce large-sized metal structures, which will expand the use of additive technologies in mechanical engineering. For the first time, the new technique is planned to be used in the manufacture of titanium balloons for space technology , produced by the RCC Progress (part of the state corporation Roscosmos). Further implementation of the technology will make it possible to abandon welded joints in bicycle frames, car bodies and aircraft fuselages, which will increase their service life. An industrial version of the new printer is scheduled to be released in the first half of 2020, after which mass production of the device will be launched.

At the same time, unlike powder analogs, it will be able to produce large-sized metal structures, which will expand the use of additive technologies in mechanical engineering. For the first time, the new technique is planned to be used in the manufacture of titanium balloons for space technology , produced by the RCC Progress (part of the state corporation Roscosmos). Further implementation of the technology will make it possible to abandon welded joints in bicycle frames, car bodies and aircraft fuselages, which will increase their service life. An industrial version of the new printer is scheduled to be released in the first half of 2020, after which mass production of the device will be launched.

Drip by Drip

Modern metal powder printers are mainly used to print small parts that are installed in critical assemblies and expensive prototypes. The applicability of the technology can be expanded by replacing powder with wire — in this case, the industry will be able to use additive technologies for the production of large-sized metal structures, and the printing speed will increase by an order of magnitude . Russian scientists supported this idea by creating the first domestic wire 3D printer.

Russian scientists supported this idea by creating the first domestic wire 3D printer.

Printer_2

Photo: metalworking-expo.com

- Our installation uses a standard welding or specially made wire, which is melted under the influence of electron beams in a vacuum chamber, - said Evgeny Kolubaev, director of the Institute of Strength Physics and Materials Science of the Siberian Branch of the Russian Academy of Sciences. “Layer by layer, molten droplets of wire metal are connected, forming products of complex shape.

According to the expert, this technology is good because with the right mode, pores do not form in the material and there is no oxidation, which protects the metal from loss of strength.

An added benefit of the development is the ability to print a single part using multiple wires of different metals, eliminating traditional welds and rivets. In this case, they are replaced by transition zones, which consist of several materials at once, forming a durable composite.

Printer_3

Photo: Depositphotos

According to scientists, it is the areas of welds and other types of joints that most often suffer under dynamic loads, which limits the life of products such as bicycle frames, car bodies and aircraft fuselages . Thus, in the future, wire printing technology can extend the life of vehicles and increase the safety of their use.

Quick Detail

The new printer will primarily be used to produce space technology parts. In particular, with its help it is planned to modernize the process of production of titanium balloons at the Progress RCC enterprise. These products are used in spacecraft to store fuel components, oxygen and other substances necessary in flight.

— The traditional technology for the production of balloons is rather complicated and involves the production of special molds and tooling along the way, which noticeably slows down the work and increases the production time for one blank to about six months (after that it is necessary to carry out its final machining), — Evgeny Kolubaev explained. - If we talk about 3D printing of a blank, then it does not require the development and manufacture of additional devices, and the technological cycle takes hours, not months.

- If we talk about 3D printing of a blank, then it does not require the development and manufacture of additional devices, and the technological cycle takes hours, not months.

Thus, as a result of the introduction of technology, spacecraft can be created much faster and cheaper.

Printer_1

Photo: Depositphotos

— Wire printing technology has been developing in the world for about 10 years, and the emergence of new devices in Russia really expands the industry's opportunities for creating large-sized products - even despite the fact that the blanks obtained by the new method have rather rough surfaces and require subsequent machining, - considers acting. Alexey Merkushev, Director of the Regional Engineering Center of the Ural Federal University. “At the same time, the new printers can be useful not only for the production of spacecraft components on Earth, but also for printing metal products in space (for example, on board the ISS), since the wire does not scatter in zero gravity like powder.

Learn more