3D printer monthly box

Maker Box Plans - Maker Box

Pick the plan that fits your interests

We’ll focus on you getting the best selection of 3D printing filaments available

All plans are 1.75mm filament, which is compatible with the vast majority of printers

Pick the plan that fits your interests

We’ll focus on you getting the best selection of 3D printing filaments available

All plans are 1.75mm filament, which is compatible with the vast majority of printers

Give it a Try!

Get the Filament Intro Mystery Box filled with 5 samples of filament and a code for a discount off new subscription! Ships within a few days

Project & Accessory Addons Now Available

There are now options available to add a Project & Accessory and Micro-Controllers for all subscription boxes. For more information check out the Project & Accessory Page

MAKER BOX EXPLORER

$23/mo

The 4 monthly samples will be selected from different manufacturers and material types

This is the plan to pick if your goal is to explore a wide range of filaments

Filaments that use special nozzles, enclosures, or heated bed may be included

Free shipping in the US, International plans also available.

Best Deal

MAKER BOX EVERYTHING

$36/mo

This box is custom curated with 8 new filament samples (monthly) or 16 samples (bi-monthly)

Combines the Easy and Explorer plans at a discount

Free shipping in the US, International plans also available.

Best Deal

MAKER BOX EVERYTHING

$36/mo

This box is custom curated with 8 new filament samples (monthly) or 16 samples (bi-monthly)

Combines the Easy and Explorer plans at a discount

Free shipping in the US, International plans also available.

View Plans

Best Deal

MAKER BOX EVERYTHING

$36/mo

This box is custom curated with 8 new filament samples (monthly) or 16 samples (bi-monthly)

Combines the Easy and Explorer plans at a discount

Free shipping in the US, International plans also available.

View Plans

Best Deal

MAKER BOX EVERYTHING

$36/mo

This box is custom curated with 8 new filament samples (monthly) or 16 samples (bi-monthly)

Combines the Easy and Explorer plans at a discount

Free shipping in the US, International plans also available.

View Plans

MAKER BOX EASY

$19/mo

The 4 monthly samples will be 4 colors from a single manufacturer

The material will be PLA or something that prints at typical PLA settings

No special nozzles, enclosures, or heated

bed

Free shipping in the US, International plans also available.

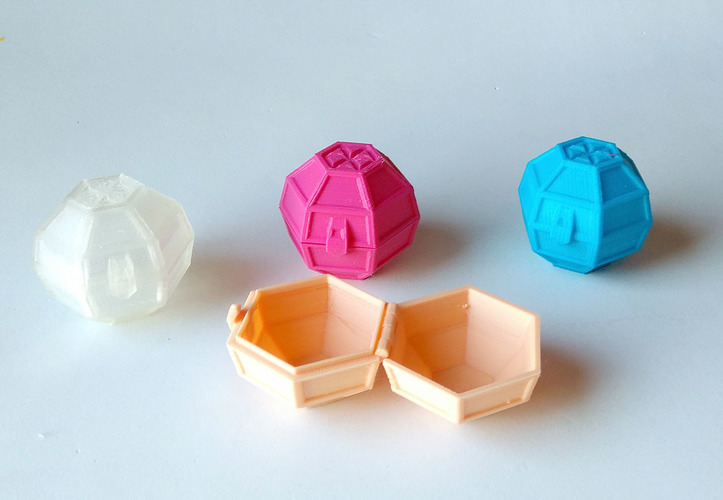

Maker What's Inside - Maker Box

Samples, discounts, and more delivered straight to your doorstep

Compare all Plans and Pricing

There are now options available to add a Project & Accessory and Micro-Controllers for all subscription boxes. For more information check out the Project & Accessory Page

For more information check out the Project & Accessory Page

Easy Plan

Each month features 4 samples of filament in different colors from a single manufacturer. The samples are normally 50g/16m, but some manufacturers will offer bonus lengths of up to 75g.

The material will be PLA or something that prints at typical PLA settings. No special nozzles, enclosures, or heated bed.

Fun surprises that may include stickers, candy, and a coupon for a discount on your favorite filament.

Free shipping in the US, International plans also available.

Explorer Plan

Each month features 4 samples of filament from different manufacturers. The samples are 16m. Different materials have different densities, but for PLA this works out to be 50g. For ABS it is closer to 40, and for some of the metal fills we have featured it is over 100g.

We strive to introduce our members to every different type of filament out there. ABS, PLA, PETG, Nylon, Fluoropolymer, PP, PC, PBT, PCTG, TPU, with many different blends, and fillers such as metals, glass, carbon fiber, kevlar, etc. All have been featured in the box. Our members are some of the most involved people in the 3D Printing community and industry and they all say that they have discovered something they have never heard of in this box at some point!

All have been featured in the box. Our members are some of the most involved people in the 3D Printing community and industry and they all say that they have discovered something they have never heard of in this box at some point!

Fun surprises that may include stickers, candy, and a coupon for a discount on your favorite filament.

Free shipping in the US, International plans also available.

Everything Plan

The Makerbox Everything plan contains ALL the samples from the Easy Plan and the Explorer Plan with a sweet bundled discount!

Each month features 4 samples of filament in different colors from a single manufacturer. The samples are normally 50g/16m, but some manufacturers will offer bonus lengths of up to 75g.

The material will be PLA or something that prints at typical PLA settings. No special nozzles, enclosures, or heated bed.

Each month features 4 samples of filament from different manufacturers. The samples are 16m. Different materials have different densities, but for PLA this works out to be 50g. For ABS it is closer to 40, and for some of the metal fills we have featured it is over 100g.

For ABS it is closer to 40, and for some of the metal fills we have featured it is over 100g.

We strive to introduce our members to every different type of filament out there. ABS, PLA, PETG, Nylon, Fluoropolymer, PP, PC, PBT, PCTG, TPU, with many different blends, and fillers such as metals, glass, carbon fiber, kevlar, etc. All have been featured in the box. Our members are some of the most involved people in the 3D Printing community and industry and they all say that they have discovered something they have never heard of in this box at some point!

Fun surprises that may include stickers, candy, and a coupon for a discount on your favorite filament.

Free shipping in the US, International plans also available.

90,000 programs for modeling and printing on a 3D printerContent

-

- Program programs

- File types for 3D printing

- Free programs

- Paid programs for 3D modeling

- Programs for cutting 3D models (slicers)

- Free slicers

- Paid slicers

- To summarize

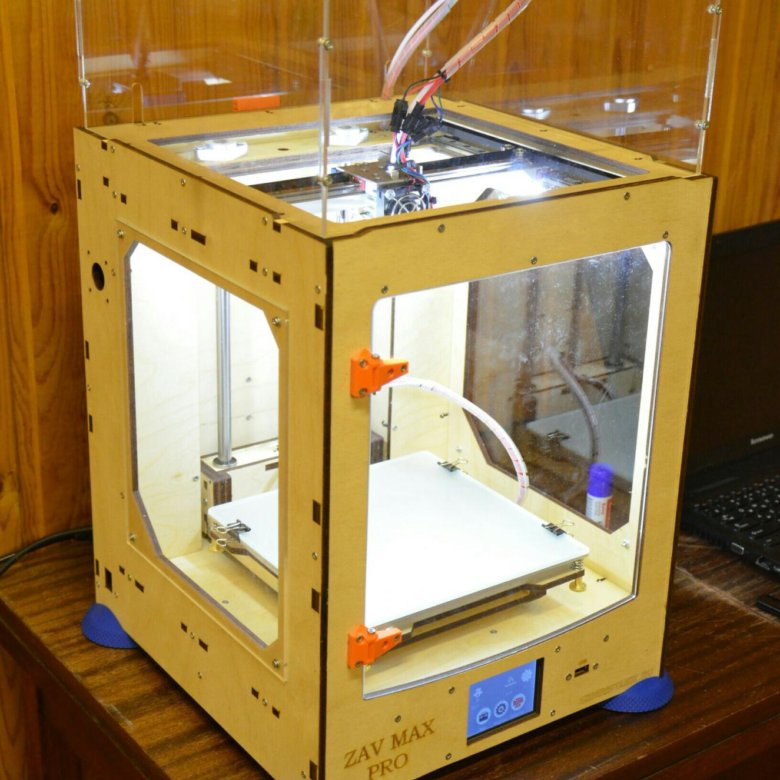

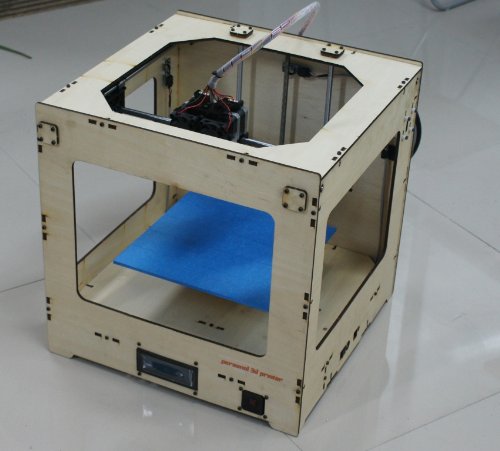

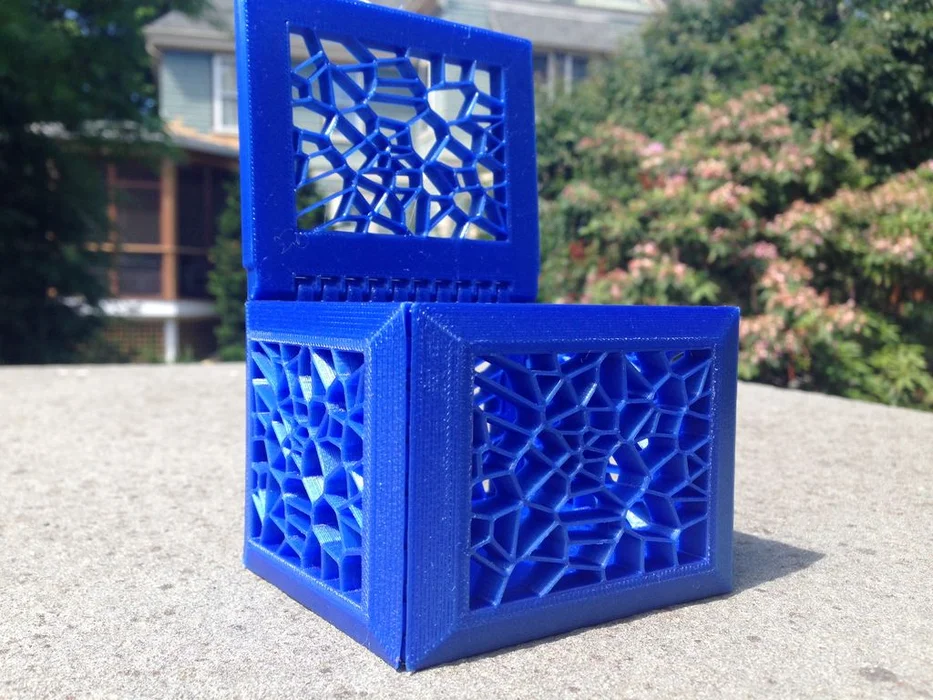

The whole cycle of creating a part on a 3D printer can be fit into three stages: Creating / finding a model, cutting a model in a slicer, printing on a 3D printer. Each stage is tied to its own program. Models are created in special programs, then in the slicer the model is “cut” into steps that the printer will sequentially execute. The resulting list of steps (commands) is either placed on a memory card and run from the printer itself, or sent to the printer via a wired/wireless connection. As a result of all these actions, we get the product. Therefore, looking for a “3D printer program” is wrong: you need to look for a modeling program and a slicer.

Each stage is tied to its own program. Models are created in special programs, then in the slicer the model is “cut” into steps that the printer will sequentially execute. The resulting list of steps (commands) is either placed on a memory card and run from the printer itself, or sent to the printer via a wired/wireless connection. As a result of all these actions, we get the product. Therefore, looking for a “3D printer program” is wrong: you need to look for a modeling program and a slicer.

3D modeling software

Programs for 3D modeling are divided into two large groups:

Obviously, when creating a drawing, an engineer needs precise tools: a ruler, pencil, compass, etc. But the artist needs more free tools: brushes, pastels, palettes and others. Programs are divided according to the same principle: in engineering programs there are all the tools that allow you to accurately specify the characteristics of each element of the part, while in art programs tools are created to give smoother forms so that the model looks as natural as possible. Of course, in art programs, you can simulate technical products, but this is comparable to drawing a drawing with pastel: inconvenient, difficult and inaccurate. Therefore, it is very important to determine why you need a simulation program.

Of course, in art programs, you can simulate technical products, but this is comparable to drawing a drawing with pastel: inconvenient, difficult and inaccurate. Therefore, it is very important to determine why you need a simulation program.

Tip: It is best to learn one or two programs at a professional level, as this will allow you to create complex models. But you should also know the basics in other programs, since a large circle of knowledge allows you to more flexibly choose the approach to creating models.

File types for 3D printing

To begin with, it is worth understanding what types of files are involved in the manufacturing process of the part. The first step is to create a model. It can be saved in the format of the program itself (for example, KOMPAS-3D files have the .m3d extension, while 3ds Max has the .MAX file extension). Such files can only be opened in the programs in which they were created. But we need a universal format - STL. All programs can save models in this format. It stores the polygons that create the model.

But we need a universal format - STL. All programs can save models in this format. It stores the polygons that create the model.

All files are divided into 3 categories:

-

Files that store polygonal information (STL, OBJ, etc.). They are analogues of a raster image. It is possible to increase the quality of 3D models in this format only by smoothing, but in this case small details will be lost, and the file weight will increase greatly.

-

Files that store the steps for creating a part (STEP, STP, etc.). Here you can draw an analogy with vector images. Each element is specified either using simple dot connections (for example, as in a cube or pyramid), or using formulas (any curved, rounded objects). Models in this format can be scaled without loss of quality, while maintaining a relatively small file size.

-

Utility files that store steps for a 3D printer (GCODE, GCOD). These files store the commands that the printer executes and, in some cases, comments (for example, with what settings the model was cut).

Some slicers can simulate the movements of the printer, thereby rendering the model, but it is impossible to convert a file from this format to a full-fledged model.

Some slicers can simulate the movements of the printer, thereby rendering the model, but it is impossible to convert a file from this format to a full-fledged model.

Be careful! If you are not sure that the GCODE file is intended for your printer, then you should not print it, because the print area for each printer is different. On third-party firmware there is no limit on the maximum travel distance, some third-party software commands may lead to incorrect operation of the control board. If the printer tries to move the print head out of the printable area many times, then it can harm itself!

If the files are in the same category, then they can be easily converted from one format to another with almost no data loss. The formats indicated in brackets are a kind of “transits”. For example, Inventor has its own file format - itp, and Fusion 360 has its own - f3d. But if you save the file in Inventor in the generic STEP format, you can open it in any engineering program and then save it in that program's format.

But if you save the file in Inventor in the generic STEP format, you can open it in any engineering program and then save it in that program's format.

Free programs

Usually, free programs are either limited in functionality or created by enthusiasts, which is why they have a very crooked interface and a lot of errors. But their functionality is enough to create simple models, and in some cases, such programs can completely replace paid software.

Tinkercad

In essence, this is not even a program, but a website, that is, it does not need to be installed on a computer and it opens from any device that has Internet access. But this is its main disadvantage - without Internet access, you will not be able to download any model for yourself, because each project is initially saved in the cloud. You also need to register to use this site. Initially, the site was created for children, so each tool is intuitive. The program is suitable for modeling simple products: gaskets, bushings, adapters, covers, boxes, etc.

Pros:

Cons:

-

Inability to work without the Internet

-

Each individual project needs to be downloaded

-

Limited number of tools

FreeCAD

This program is designed to create technical products: fasteners, bushings, hinges and more. Since this is an open source project, it is distributed free of charge. At the same time, it has all the necessary functionality for opening and editing files with the .step extension - a universal format for all engineering programs. It is also worth noting the ability to add addons - special subroutines that allow you to perform any actions in a fully automatic mode. For example, there is an addon that makes it easier to create various gears. In this program, you can create more complex products: mechanisms, gearboxes, hinges, etc.

Pros:

Cons:

OpenSCAD

This CAD is closer to programming languages than to modeling: each object or any action is specified as a code. This allows you to create universal models. For example, a coin sorter: once you write the “model code”, you can create a huge number of variants of this model for different countries, changing just a few parameters. This program, like the previous one, is an open source project, as a result of which it is regularly updated.

This allows you to create universal models. For example, a coin sorter: once you write the “model code”, you can create a huge number of variants of this model for different countries, changing just a few parameters. This program, like the previous one, is an open source project, as a result of which it is regularly updated.

Pros:

-

Works on weak PCs

-

Ease of creating universal models

-

Easy to learn if you have programming experience

Cons:

-

No Russian interface

-

Is a programming language

-

Difficult to create curvilinear geometry

Free Shipping

Add to compare

Item added to compare Go

| Manufacturer | Anycubic |

Free shipping

Add to compare

Product added to compare Go

| Manufacturer | Phrozen |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Raise3D |

Free shipping

Add to compare

Product added to compare Go

| Manufacturer | Anycubic |

Meshmixer

Art program for entry-level 3D modeling. There are simple tools for processing STL files and functions for restoring “broken” files. Using Meshmixer, you can conveniently cut the model into several parts, as it is possible to set the size of the print area of your printer. And one of the most useful tools is the installation of tree supports. This function has already appeared in many slicers, but it is in meshmixer that they can be flexibly configured and installed manually. Despite the many tools, this program is rather auxiliary, as there are more suitable programs for creating a model from scratch.

There are simple tools for processing STL files and functions for restoring “broken” files. Using Meshmixer, you can conveniently cut the model into several parts, as it is possible to set the size of the print area of your printer. And one of the most useful tools is the installation of tree supports. This function has already appeared in many slicers, but it is in meshmixer that they can be flexibly configured and installed manually. Despite the many tools, this program is rather auxiliary, as there are more suitable programs for creating a model from scratch.

Pros:

Cons:

-

Limited functionality for creating 3D models

-

Lack of Russian interface

-

Some operations require a powerful PC

Blender

A completely free program with huge possibilities not only for creating models, but also for animation, rendering, simulations and much more. It is mainly used by multipliers, but due to the large number of extensions, this program covers a huge range of tasks. At first glance, Blender may seem too complicated, but everyone can master the basic functionality. Also worth noting are constant updates that improve performance and add new tools. A large community of people working in this program and developing it will help with the solution of many problems.

It is mainly used by multipliers, but due to the large number of extensions, this program covers a huge range of tasks. At first glance, Blender may seem too complicated, but everyone can master the basic functionality. Also worth noting are constant updates that improve performance and add new tools. A large community of people working in this program and developing it will help with the solution of many problems.

Paid 3D software

This category includes programs for professionals and enterprises, as well as their simplified versions for home use. Many companies have begun releasing a product at a low price for home use, although initially the designs were intended only for enterprises and were priced accordingly. The common advantage of these programs is great functionality and constant support. For example, Autodesk Inventor was first released back in 1999 and is updated annually. Next, we will look at the most popular of them.

Fusion 360

The new product from Autodesk tried to combine several tasks at once: modeling, simulation and rendering. In many ways, it adopted the functionality of the previously mentioned Inventor, but supplemented it with a simple interface: many tools are similar to those that can be used in the previously mentioned Tinkercad. You can also edit STL files in it, albeit with a limited set of tools.

In many ways, it adopted the functionality of the previously mentioned Inventor, but supplemented it with a simple interface: many tools are similar to those that can be used in the previously mentioned Tinkercad. You can also edit STL files in it, albeit with a limited set of tools.

The main feature of this program is cloud data processing, such as simulations and renders. At the same time, almost all functions can be performed offline using the power of a PC. To process tasks in the cloud, you need to buy additional tokens, but when creating models, they are not necessary. It is worth considering that despite the presence of a native file format (f3d), all files are initially stored on Autodesk servers, and then they can be saved to your computer.

There is a version for schools and universities, but obtaining such a license requires the educational institution to register and issue you a personal license.

Pros:

Cons:

Price: from 7,123₽ to 25,721₽ for 1 year

Netfabb

The program is designed to prepare the model before slicing. In many ways, it is similar to meshmixer, but it does not have the tools to create a model from scratch. Merging several models in STL format can be called a distinctive function, but the most important tool is the “repair” of models. That is why everyone should install this program, even if you have another model editor or model repair built into the slicer. Also in Netfabb it is very convenient to cut the model into several parts for printing separately. At the moment, the Netfabb functionality is built into Fusion 360 and is not officially available separately, but can be found on third-party resources as a separate program.

In many ways, it is similar to meshmixer, but it does not have the tools to create a model from scratch. Merging several models in STL format can be called a distinctive function, but the most important tool is the “repair” of models. That is why everyone should install this program, even if you have another model editor or model repair built into the slicer. Also in Netfabb it is very convenient to cut the model into several parts for printing separately. At the moment, the Netfabb functionality is built into Fusion 360 and is not officially available separately, but can be found on third-party resources as a separate program.

Pros:

-

Great functionality for repairing the model

-

Convenient cutting into pieces

-

Easy to learn all the necessary tools

Cons:

Price: from 18 024₽ for 1 month

KOMPAS-3D

A professional program created by Russian developers for Russian enterprises. It has a huge functionality, but at the same time, each function has a description, and the main tools have explanatory animations, a huge database of standards and GOSTs is built in. The program is free for all students and does not require verification of documents. There is also a paid version of KOMPAS-3D HOME, which, although intended only for home use, retains all the functionality of the “professional” version. Because of this, and also because of the low price, this CAD system is the best choice as the first professional program for creating complex 3D models.

It has a huge functionality, but at the same time, each function has a description, and the main tools have explanatory animations, a huge database of standards and GOSTs is built in. The program is free for all students and does not require verification of documents. There is also a paid version of KOMPAS-3D HOME, which, although intended only for home use, retains all the functionality of the “professional” version. Because of this, and also because of the low price, this CAD system is the best choice as the first professional program for creating complex 3D models.

Pros:

-

Completely Russian interface

-

A large number of tools

-

Availability of a free student version

-

Very low price

Cons:

Price: from 1 490₽ for 1 year

SolidWorks

One of the oldest programs on the market that has become a standard. If you learn how to work in SolidWorks, then you can work in any CAD. It has a relatively simple interface, an average number of tools that are enough even for professionals, but since the program is designed for production, many functions will only interfere with work. It should be noted that this program is available in Russian, and this is one of the reasons for the prevalence of this program in Russia.

If you learn how to work in SolidWorks, then you can work in any CAD. It has a relatively simple interface, an average number of tools that are enough even for professionals, but since the program is designed for production, many functions will only interfere with work. It should be noted that this program is available in Russian, and this is one of the reasons for the prevalence of this program in Russia.

Pros:

-

Easy to learn

-

The presence of the Russian interface

-

Large community of people using SolidWorks

-

Widespread in Russia

Cons:

Price: from 8,431₽ to 292,560₽ for 1 year

Inventor

The main program at many enterprises, but due to the simplicity of the interface and the presence of the Russian language, it is easy to learn. In many ways, it is similar to SolidWorks, both in functionality and in purpose. The main distinguishing feature of this program is a large number of high-quality video tutorials and text courses. It is studied at many universities both around the world and in Russia.

The main distinguishing feature of this program is a large number of high-quality video tutorials and text courses. It is studied at many universities both around the world and in Russia.

Pros:

-

Prevalence among the Russian community

-

Lots of learning materials

-

Intuitive interface

-

Availability of student version

Cons:

Price: from 106 860₽ for 1 year

SelfCAD

It is the simplest program for technical modeling. As easy to learn as Tinkercad, but not for kids, but for professional 3D printing. This program is not CAD, so there is no editing history, which allows, for example, to change sketches without entering edit mode.

You can download this program for free, but this version will have limited functionality. There are also paid versions with monthly payment or a one-time purchase forever. Only paid versions have a simple slicer, but its functionality is extremely limited.

Only paid versions have a simple slicer, but its functionality is extremely limited.

Pros:

Cons:

-

Small functionality

-

Big cost

Price: from 1160₽ ($14.99) for 1 month

3ds Max

The program is designed to create 3D models and render images. It has great functionality, but it is extremely difficult to learn due to the lack of the Russian language and a complex interface. This is due to the fact that 3ds Max was originally developed for 3D animation and video game studios. It was to create a simple and free analogue that the previously mentioned Blender was created. Due to the above reasons, this program is not suitable for creating 3D models for subsequent printing on a 3D printer, but nothing prevents you from doing this.

Pros:

Cons:

Price: from 9 791₽ for 1 month

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Phrozen |

Free Shipping

Add to Compare

Product added to comparison Go

| Manufacturer | Anycubic |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | PICASO 3D |

Free Shipping

Add to Compare

Product added to comparison Go

| Manufacturer | Phrozen |

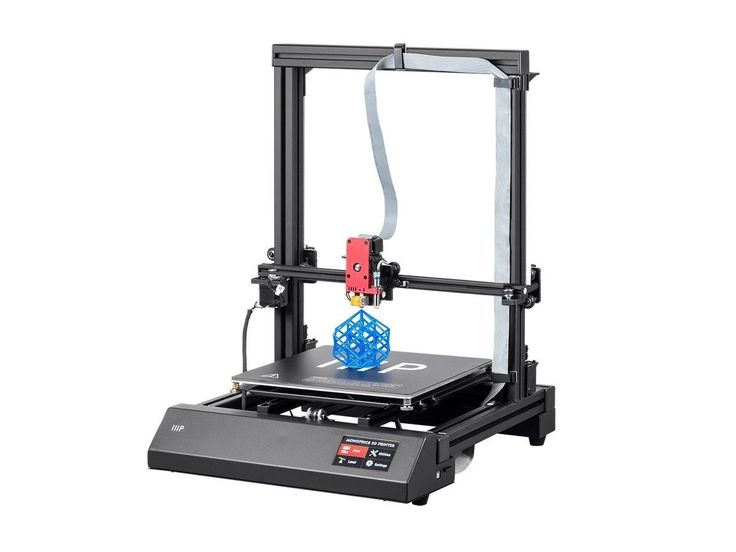

3D cutting software (slicers)

Having any model in STL format, you cannot immediately place it in the printer and start printing, because the printer only executes commands, and these commands form a slicer. According to the etymology of the word, one can understand that the program cuts the model into layers, or rather into separate commands. But the number of cutting options for one model is almost endless. In this regard, a large number of programs have appeared that allow you to fully customize the operation of the slicer, or rather, how it will split the model into separate commands. The slicer itself consists of two parts: the core and the shell. The slicer core performs slicing based on the specified parameters, and the shell allows you to set these parameters and visually evaluate the slicing result before sending the model to print. In addition, many slicers have built-in functionality for direct access to the printer, which allows you to manually control the printer and carry out its settings and diagnostics. Next, we will consider the most popular slicers, which have their positive and negative sides.

According to the etymology of the word, one can understand that the program cuts the model into layers, or rather into separate commands. But the number of cutting options for one model is almost endless. In this regard, a large number of programs have appeared that allow you to fully customize the operation of the slicer, or rather, how it will split the model into separate commands. The slicer itself consists of two parts: the core and the shell. The slicer core performs slicing based on the specified parameters, and the shell allows you to set these parameters and visually evaluate the slicing result before sending the model to print. In addition, many slicers have built-in functionality for direct access to the printer, which allows you to manually control the printer and carry out its settings and diagnostics. Next, we will consider the most popular slicers, which have their positive and negative sides.

Free slicers

The availability of free slicers is due to the fact that without them the printer becomes a useless machine that can only heat coffee and play a melody with the help of motors. Therefore, many companies that create 3D printers supply slicers with them, while laying them out in the public domain. Often these are large companies such as Ultimaker, CraftUnique, Prusa, etc.

Therefore, many companies that create 3D printers supply slicers with them, while laying them out in the public domain. Often these are large companies such as Ultimaker, CraftUnique, Prusa, etc.

Ultimaker Cura

It was originally created only for Ultimaker 3D printers, but soon became an open-source project. Now in its library of profiles you can find a huge number of printers from various manufacturers. Uses its own core Cura, which has many settings and functions: tree support, wireframe printing, color printing, etc.

Frequent updates bring innovations and even more profiles for various 3D printers. It is a standard choice for beginners, as it has two control modes: simple and professional. Recently, support for add-ons has appeared that allows you to save backup copies of settings, repair the model directly in the slicer, integrate various programs for 3D modeling, and much more.

It is also possible to control the printer by sending commands directly from the computer. But there is no feedback from the printer, apart from receiving information about the temperature of the nozzle and table.

But there is no feedback from the printer, apart from receiving information about the temperature of the nozzle and table.

Pros:

Cons:

Prusa Slic3r

Sometimes you can find other names: Slic3r Prusa Edition or Slic3r PE. Prusa decided not to reinvent the wheel, and took the open-source Slic3r project, partially reworked it and began to actively develop it. Like Cura, Prusa Slic3r has many printer profiles, but Prusa's printer profiles are the most optimized. The core of the slicer of our own design, while the number of settings is less than that of the same Cura.

A distinctive feature is the flexible adjustment of the layer thickness and the support of a special extruder capable of printing 5 different plastics at once (again, produced by Prusa). The program will be extremely useful for people who have more than one 3D printer: all settings are divided into 3 tabs, each of which can be saved to separate profiles. But the printer control console disappeared completely, only the send button for printing via wire remained. In general, this program will be a reliable and convenient slicer, especially if you have a large number of printers.

But the printer control console disappeared completely, only the send button for printing via wire remained. In general, this program will be a reliable and convenient slicer, especially if you have a large number of printers.

Pros:

Cons:

Repetier

This slicer was created more for remote control of the printer, but it can also cut models. One of the few programs where you can choose the slicing core: Cura, Sic3r, Prusa Slic3r. The number of settings for the slicing itself is extremely small, but they are enough to cut the test cube.

The most important plus of this slicer is the huge functionality for managing and configuring the printer. It is worth noting the convenient interface for sending commands, as well as customizable temperature graphs. This is extremely useful, for example, when tuning the PID or checking the movement of the axes. Even if you choose a different slicer, this program is handy to have in order to 3D print using GCODE from another slicer.

Pros:

Cons:

MatterControl 2.0

One of the few programs that combine functions for editing stl files and a slicer. You won't be able to create any serious model, but you can add text or cut out part of the model. The slicer has not so many settings, but they are enough for a beginner 3D printer. This slicer can be useful if you need to make art products with minor changes. Supports saving to the cloud.

Pros:

Cons:

3DprinterOS

This software is designed to remotely manage printers from anywhere in the world. All that is needed is to connect the printer to the computer and install this program on it. From now on, all printer management occurs through the web interface. In it, you can remotely change the model, cut it and put it on print. It is also possible to connect a camera and observe the printing process. There are very few slicing settings, some will not even be enough to calibrate the printer, not to mention serious printing.

Carefully! It is not recommended to leave the printer unattended, especially if it is no longer new: at any time there may be a risk of fire due to wiring or mechanical problems.

Pros:

-

Simple interface

-

Start printing from anywhere in the world

-

Ability to monitor printing

-

Availability of tools for editing the model

Cons:

IceSL

It is a combination of OpenSCAD with its “modeling language” and slicer. In addition, models can be edited using a “brush”, like the one in Meshmixer. It has many small pluses that are not found in other slicers, but it is not suitable for everyday use due to an inconvenient interface and a small number of slicer functions. This program can be described in one phrase: interesting, but not recommended.

Pros:

Cons:

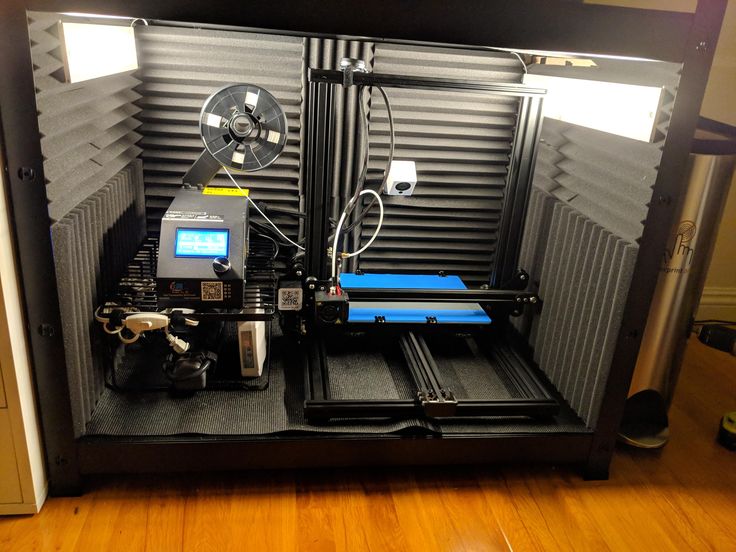

Octoprint

In many ways it is similar to 3DprinterOS, but is an open source project, as a result of which it has many additions. Designed for home use. It is the most popular way to remotely control the printer, and the user community is constantly growing. Therefore, it will be very easy to transfer your printer to remote control due to the large number of lessons and articles. The program itself does not have a slicer, but direct export of files from Slic3r is supported, which is already good in itself. Just like Repetier, it has an excellent printer management and monitoring console. But, unlike the aforementioned analogue, most of the functions will have to be configured manually.

Designed for home use. It is the most popular way to remotely control the printer, and the user community is constantly growing. Therefore, it will be very easy to transfer your printer to remote control due to the large number of lessons and articles. The program itself does not have a slicer, but direct export of files from Slic3r is supported, which is already good in itself. Just like Repetier, it has an excellent printer management and monitoring console. But, unlike the aforementioned analogue, most of the functions will have to be configured manually.

Pros:

-

Large user base

-

Lots of tutorial articles

-

Ability to create a video broadcast of the printing process

Cons:

Paid Slicers

At the moment, many paid slicers are no longer used, as free ones have either caught up or overtaken them. But some of them are still unique.

Simplify3D

One of the first thundered paid slicers. At the time of its introduction, it was the most advanced due to the ability to change the print settings for one model at different layer heights and the functionality of printing with more than one extruder. But at the moment it has been replaced by Cura and Prusa Slic3r. Nevertheless, the convenience of setting up print settings and their number still remain the main advantage of this slicer. Also worth noting is the excellent printer management interface, second only to Repetier host.

Another difference is the ability to manually install supports and a large number of filling patterns. Viewing models also has several features: changing the way models are displayed, viewing in section, displaying normals to planes.

Pros:

-

Lots of print options

-

Convenient printer management interface

-

Manual installation of supports

-

Changing print settings at different heights

-

Easy print setup with two extruders

Cons:

Price: from 11499₽ ($149)

Read also: A detailed review of 3D printing slicers: Ultimaker Cura, Simplify3D, IdeaMaker, UP Studio, FlashPrint

Astroprint

Many believe that this particular software is a direct competitor to 3DPrinterOS. The most important difference is user friendliness, achieved through a user-friendly interface and easy installation. The program is based on Octoprint, essentially providing only a server, a modified interface and several add-ons that allow you to fully manage the printing process while away from the printer - from finding a model, to cutting and printing. At the same time, the program positions itself as a serious business solution, so the company also provides special PCs and management consoles that make it easy to connect the printer to the system. A trial plan is available where only 2 printers can be connected, but all basic features will be available.

The most important difference is user friendliness, achieved through a user-friendly interface and easy installation. The program is based on Octoprint, essentially providing only a server, a modified interface and several add-ons that allow you to fully manage the printing process while away from the printer - from finding a model, to cutting and printing. At the same time, the program positions itself as a serious business solution, so the company also provides special PCs and management consoles that make it easy to connect the printer to the system. A trial plan is available where only 2 printers can be connected, but all basic features will be available.

Pros:

-

Easy connection and setup

-

Trial Availability

-

Interface specially designed for mobile devices

Cons:

Price: from 765₽ ($9.90) for 1 month

KISSlicer

This slicer is another representative of programs that failed to keep up with the times. Previously, its functionality was a cut above the rest, but now the same Cura has all the same settings as KISSlicer, and also adds its own. Of the useful in this program, we can note the function of joint viewing of GCODE and model.

Previously, its functionality was a cut above the rest, but now the same Cura has all the same settings as KISSlicer, and also adds its own. Of the useful in this program, we can note the function of joint viewing of GCODE and model.

There were two versions: free and PRO. The only significant difference between them is that the paid version has support for printing in multiple colors. At the moment the project is dead, even the main site does not work, but the program can still be found on third-party sources.

Pros:

Cons:

Price: from 3240₽ ($42)

Summing up

After considering all the popular programs, we can highlight the clear favorites:

For beginners in 3D printing, Tinkercad is the best 3D modeling software because it combines simplicity with the necessary functionality. The best programs for professional-level 3D modeling are KOMPAS-3D, Fusion 360 and Blender, due to the huge number of tools and a large community that makes it easy to find lessons and guides. Among the slicers, the Ultimaker Cura and Prusa Slic3r are the best choice for ease of use and flexibility when slicing models. But do not forget about such auxiliary programs as Meshmixer and Netfabb, which allow you to quickly edit or repair the model. You can learn more about some of the programs from this list on our website.

Among the slicers, the Ultimaker Cura and Prusa Slic3r are the best choice for ease of use and flexibility when slicing models. But do not forget about such auxiliary programs as Meshmixer and Netfabb, which allow you to quickly edit or repair the model. You can learn more about some of the programs from this list on our website.

Add to compare

Product added to compare Go

| Manufacturer | Tiger3D |

Add to compare

Product added to compare Go

| Manufacturer | Tiger3D |

Add to compare

Product added to compare Go

| Manufacturer | Tiger3D |

Add to compare

Product added to compare Go

| Manufacturer | Tiger3D |

3d printer maintenance

3DPrintStory 3D printing process 3d printer maintenance

3d printer, like any other piece of equipment, needs maintenance. And if you haven’t done it until today, it’s better to start right after reading this short article.

And if you haven’t done it until today, it’s better to start right after reading this short article.

I won't categorize maintenance into daily, weekly, or monthly because each of you types at a different rate. For someone, a 3d printer can stand turned off all week, while for someone it works 24 hours a day. Therefore, to a greater extent, you yourself have to determine how often you will carry out maintenance on your 3d printer.

Have you ever heard of preventive maintenance? This is one of the pillars of the concept of general equipment care, the essence of which is that after the equipment has been working for a certain period of time, preventive inspections, various types of scheduled repairs and revisions are made, excluding the possibility of equipment operation in conditions of progressive wear. So you and I, as owners of one piece of equipment or a whole fleet of 3d printers, must track down the precursors of major malfunctions - be it extraneous noise during printer operation or an unscrewed screw.

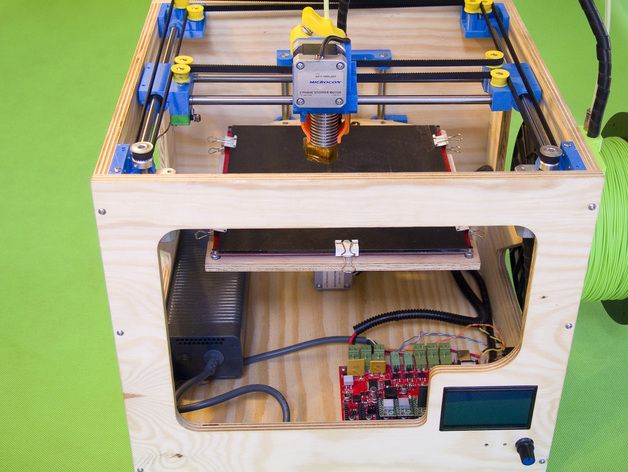

Technical inspection of the 3d printer

Therefore, the first thing we will talk about today is the control and inspection of the 3d printer components to identify deviations that lead to breakdowns, which in turn can lead to equipment downtime. What should you pay attention to first of all?

Extruder. It is worth checking it for leakage of the plastic melt and the nozzle-cylinder interface, so the accumulation of polymeric material can form either from above or below the heating block. In case of detection, at least pull the nozzle, or rather, disassemble and clean all elements from polymer material. By noticing the leaking nozzle in time, we can prevent the failure of the thermistor heaters.

From the extruder, move on to inspecting the kinematics. First to the shafts. Be sure to control the appearance of wear on the shafts, as it often happens that the user does not notice that the linear bearing is wedged, and corresponding marks, scuffs appear on the shafts. Up to a certain point, or rather, depth, they can be removed by grinding, and then not. Therefore, the sooner such wear is diagnosed, and the linear bearing is replaced, the less likely it is to get an expensive shaft replacement.

Up to a certain point, or rather, depth, they can be removed by grinding, and then not. Therefore, the sooner such wear is diagnosed, and the linear bearing is replaced, the less likely it is to get an expensive shaft replacement.

Just like shafts, belts are subject to wear. This can be either wear on the working surface of the belt or damage to the cord. In any case, during the inspection, check the condition and tension of the belt. Why tension? Because once you pull the belt, you can break the integrity of its cord. Naturally, such a belt will need to be changed. If you notice the wear of the belt in time, you will have time to order it and the 3d printer will not stand idle, waiting for the spare part to arrive.

Since we are talking about belts, it is worth checking stepper motor pulleys along with them. Namely, whether there is no idle rotation. If necessary, tighten the lock screws. Always check the kinematics of the 3d printer for any play. For the most part, play will affect the quality of the surface of the printed product, but this check should not be neglected. Take the carriage and move your hands to a break, try to pull it. If you do not notice characteristic knocks, then everything is in order. If you notice, then check the tension of the screws. Axes misalignment during 3D printing can also lead to both linear bearing failure and high shaft wear.

Take the carriage and move your hands to a break, try to pull it. If you do not notice characteristic knocks, then everything is in order. If you notice, then check the tension of the screws. Axes misalignment during 3D printing can also lead to both linear bearing failure and high shaft wear.

| |

You should also check if the fan for blowing the 3d printer board and the extruder heatsink is working. I understand that in some models of 3d printers, the manufacturer did not worry about ease of maintenance, but this should not be neglected, as overheating can lead to failure of the stepper motor drivers.

If you have something to add to the inspection list, write about it in the comments, and we will go directly to maintenance.

3d printer maintenance

What actually needs to be serviced?

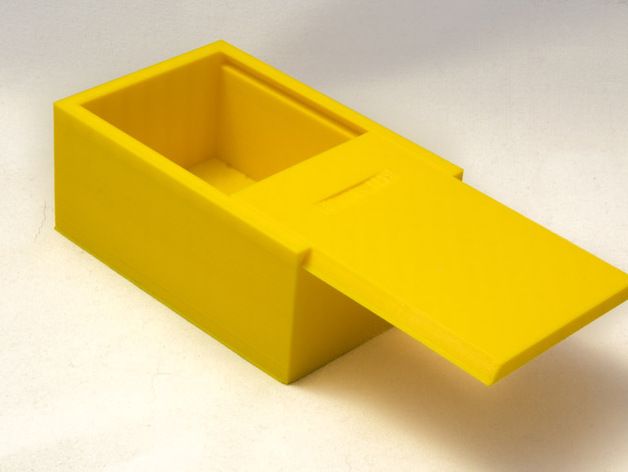

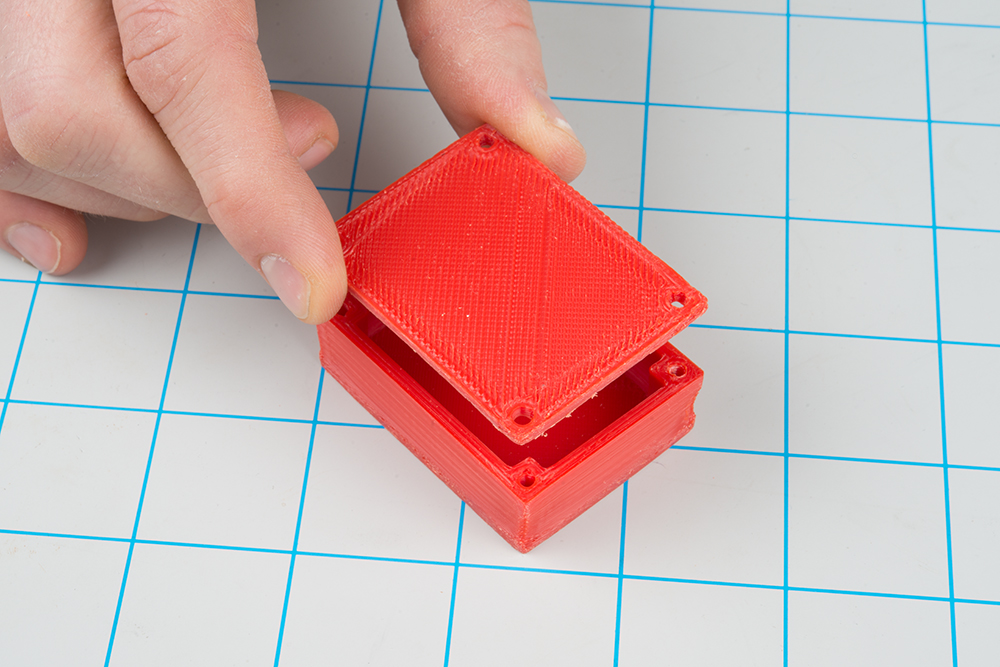

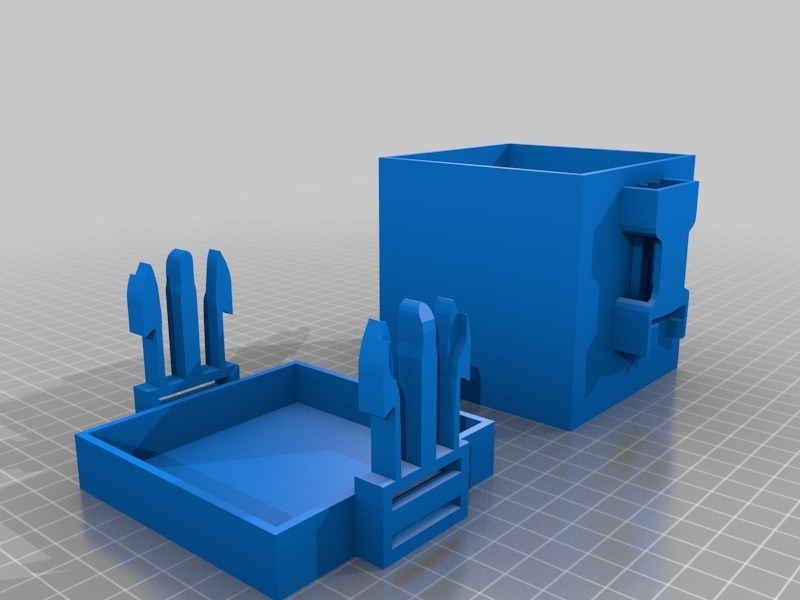

Let's start with cleaning. More specifically, from cleaning the filament feed mechanism. There are several ways to get it contaminated. You can get rid of one of them very easily by installing a so-called filament filter. It is a box with a sponge placed inside, which is designed to clean the bar from accumulated dust and other contaminants. A very simple thing. Link to the 3d model on Thingiverse. If you have a bowden extruder, you can clean the filament feed tube from dust by simply blowing it.

You can get rid of one of them very easily by installing a so-called filament filter. It is a box with a sponge placed inside, which is designed to clean the bar from accumulated dust and other contaminants. A very simple thing. Link to the 3d model on Thingiverse. If you have a bowden extruder, you can clean the filament feed tube from dust by simply blowing it.

Your 3d printer table also needs to be kept clean. I periodically wipe it with a cloth dipped in acetone. It is better to do this procedure with a glove in order to avoid skin contact with acetone.

The table lift screw also needs to be cleaned of dust and dirt before being lubricated. As for the lubricant itself, I read a lot of opinions on this matter and came to the conclusion that the best choice is ordinary Litol-24. I use it both for lubricating screws and for lubricating linear bearings. We lower the table down, apply lubricant to the screw above the nut, then raise the table to the upper end position and apply lubricant from below the nut and drive the table again. Then, if excess grease has formed, remove them.

Then, if excess grease has formed, remove them.

Also take the time to extruder. Clean the model fan and radiator from dust and dirt. The best way to do this is with a vacuum cleaner. In my 3d printer, the manufacturer did not bother about the ease of removing the extruder, so this procedure is quite time consuming.

Pay attention to the shafts. If your linear bearing seals are working well, then you should see a buildup of dust mixed with grease in the end positions of the axles. It is worth deleting it as it accumulates. The easiest way to do this is with a paper towel.

Moving on to the lubrication of linear bearings. In theory, they should be stuffed with the right amount of grease at the factory. Moreover, this basic packing is calculated for the entire life of the bearing, but whether the Chinese do it or not is unknown. When I bought linear bearings, I found that they are only covered with a liquid lubricant to prevent corrosion, so it’s better to remove it and fill it with the same lithol inside, because it doesn’t make sense to smear it on the guides, since the seals will simply remove it and nothing will get inside.