Bio ink 3d printing

Bioprinting Explained Simply! - CELLINK

- March 29, 2019

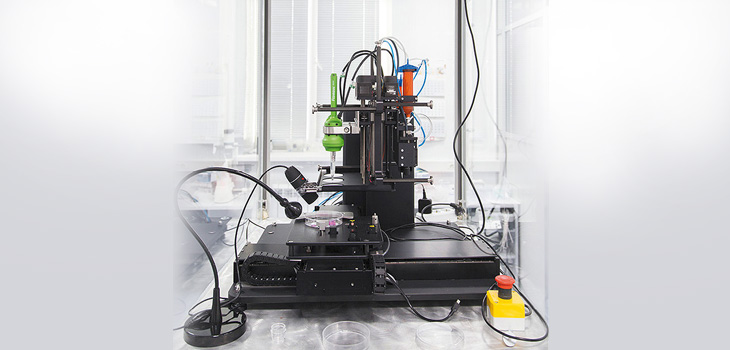

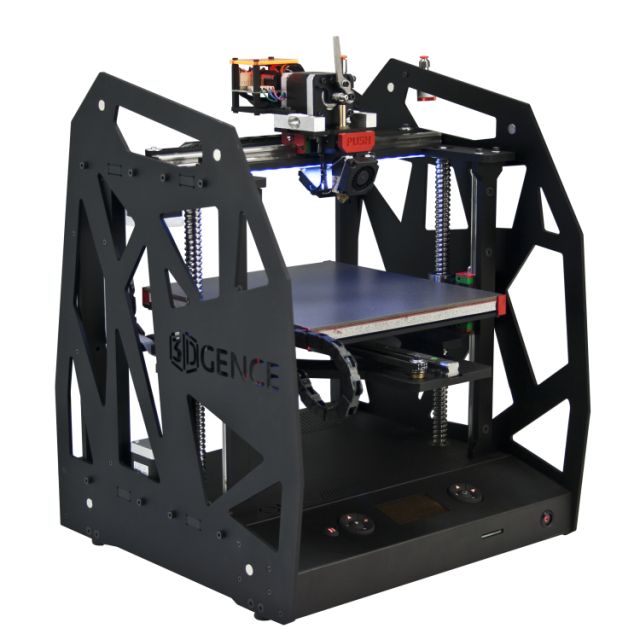

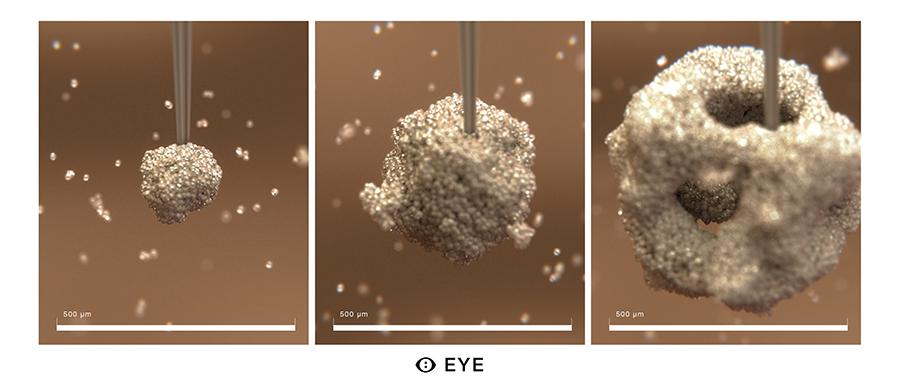

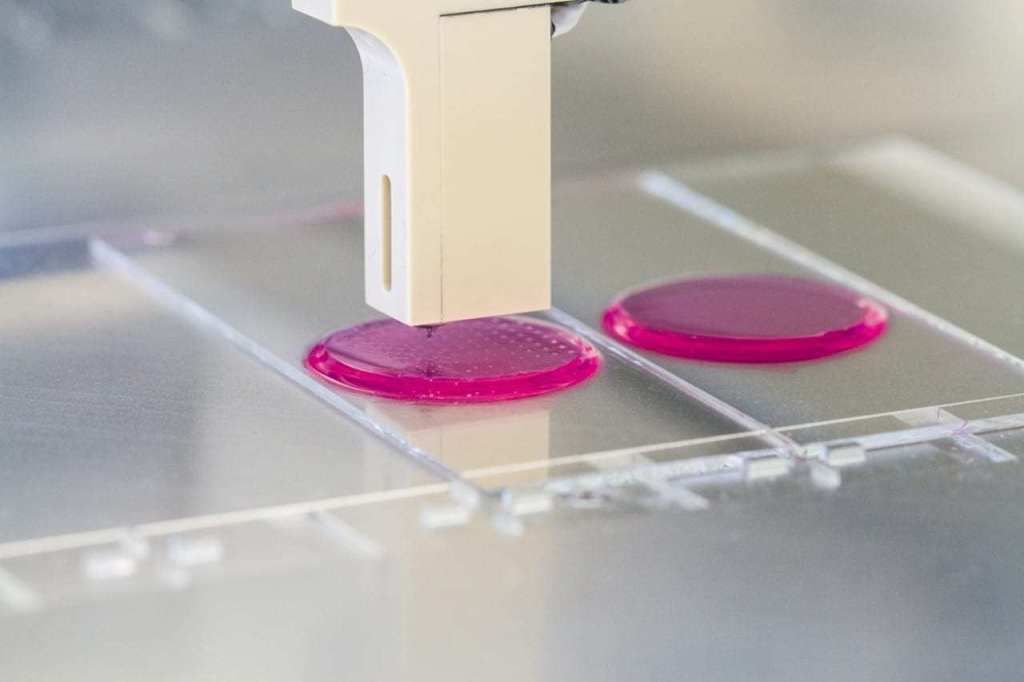

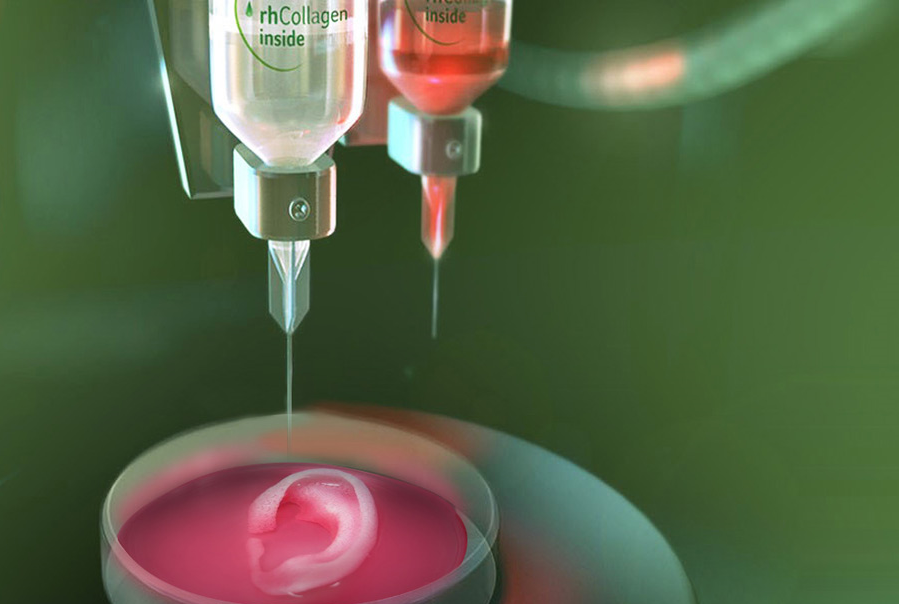

Bioprinting is an additive manufacturing process similar to 3D printing – it uses a digital file as a blueprint to print an object layer by layer. But unlike 3D printing, bioprinters print with cells and biomaterials, creating organ-like structures that let living cells multiply. Although bioprinting is a relatively new technology, it has huge potential to benefit industries like regenerative and personalized medicine, drug discovery and cosmetics. Find out how bioprinting works.

The three basic steps of bioprinting:

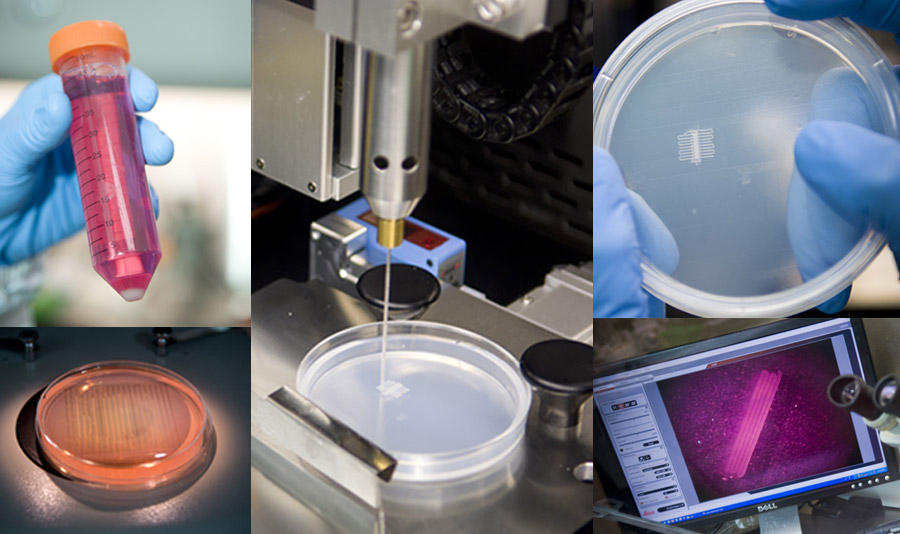

1. Pre-bioprinting. This involves creating a digital file for the printer to read. Today, these files are often based on CT and MRI scans. Researchers prepare cells and mix them with their bioink, using a live-cell imaging system to ensure there are enough cells to bioprint a tissue model successfully.

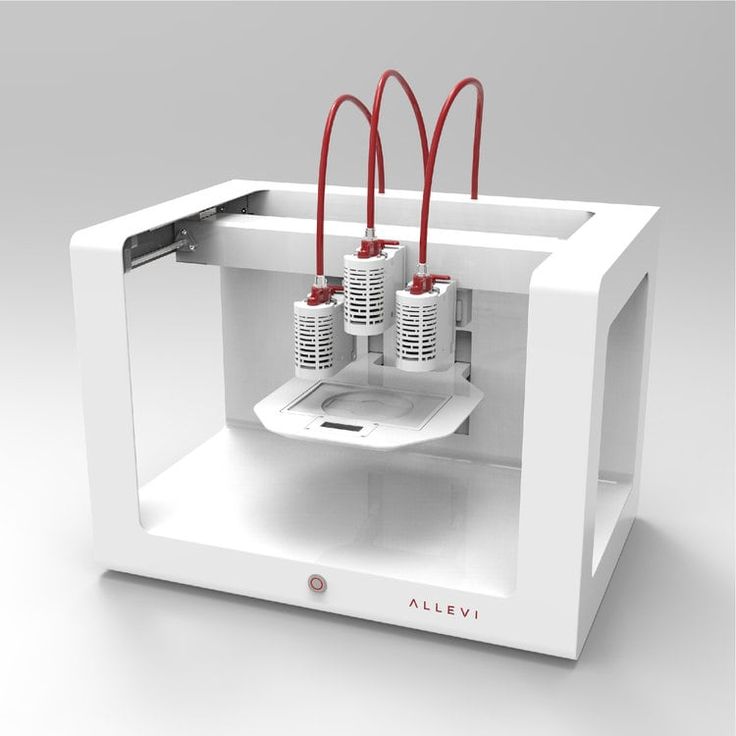

2. Bioprinting. Researchers load the cell-laden bioink into a cartridge and choose one or multiple printheads, depending on the structure they’re trying to build. Developing different types of tissue requires researchers to use different types of cells, bioinks and equipment.

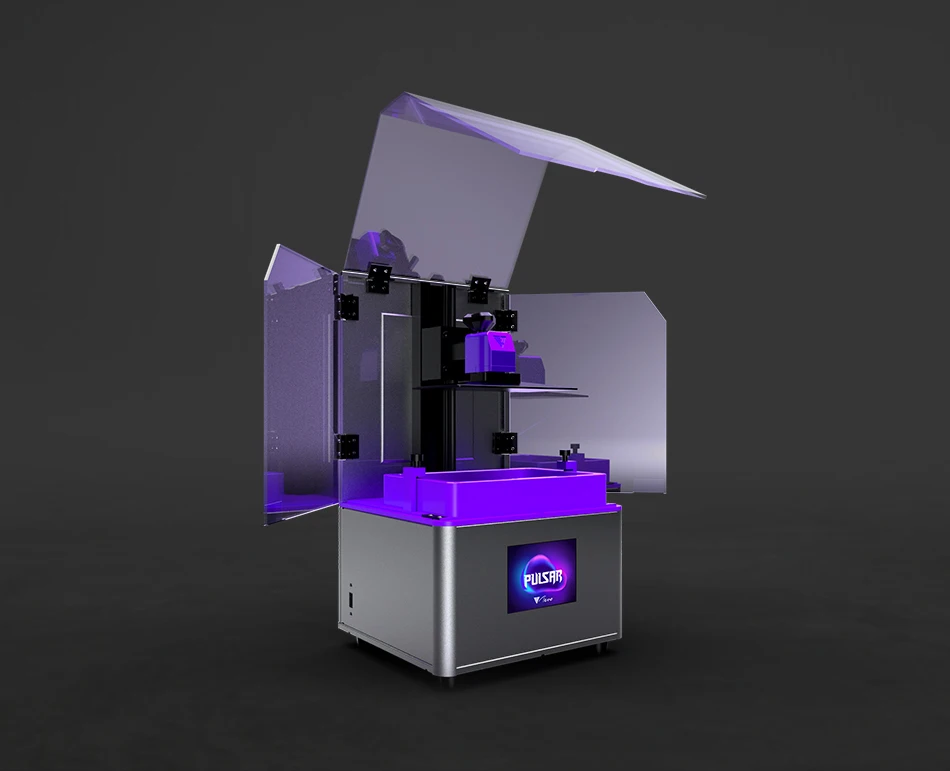

3. Post-bioprinting. Most structures are crosslinked to become fully stable. Crosslinking is usually done by treating the construct with either ionic solution or UV light – the construct’s composition helps researchers determine what kind of crosslinking to use. Then the cell-filled constructs are placed inside an incubator for cultivation.

What are (some of) the applications?

Today’s bioprinting technologies are still new to many researchers. As scientists in the field continue making discoveries, bioprinting can have a huge impact on a range of application areas.

Drug development:

Many of today’s studies rely on living subjects – an inconvenient and expensive method for both academic and commercial organizations. Bioprinted tissues can be used instead during the early stages, providing a more ethical and cost-effective solution. Using bioprintined tissue can help researchers determine a drug candidate’s efficacy sooner, enabling them to save money and time.

Bioprinted tissues can be used instead during the early stages, providing a more ethical and cost-effective solution. Using bioprintined tissue can help researchers determine a drug candidate’s efficacy sooner, enabling them to save money and time.

Artificial organs:

The organ donation list is so long that patients wait years before getting the help they need. Being able to bioprint organs could help clinicians keep up with patients or eliminate the list entirely. While this solution is far down the line, it is one of the most impactful possibilities in the field.

Wound healing:

A lot of tissue-specific bioinks are available today, enabling researchers to work with artificial skin cells, neurons, hepatocytes and more. One day, clinicians could use these models for therapeutic procedures like skin grafts, bone bandages for combat wounds or even plastic surgery.

This is still a new and emerging field – biocompatible 3D printing was invented in the early 1980s, with cell-embedded bioprinting being invented in 2003 by Thomas Boland, and we’ve come a long way in a short time! As more researchers get access to the latest bioprinting technology, the innovating will only accelerate. One thing is for sure: we can’t wait to see what CELLINK’s collaborators are discovering in just a few years’ time!

One thing is for sure: we can’t wait to see what CELLINK’s collaborators are discovering in just a few years’ time!

Contact us - Let's work together!

Let's work together.

Our offices

-

Sweden, Gothenburg

Headquarter

Address

Långfilsgatan 7,

412 76 Gothenburg,

Sweden -

USA, Massachusetts

Address

155 Seaport Boulevard,

Suite 2B,

Boston, MA, 02210 -

Singapore

Address

1 Fusionpolis Place

Galaxis West Lobby,

Unit 03-321

Singapore (138522)+65 8750 2284

-

Japan, Kyoto

Address

#302 Creation Core Kyoto

Mikuruma, 448-5 Kajii-cho,

Imadegawa-Sagaru, Kawaramachi-dori,

Kamigyo-ku,

Kyoto-city, Kyoto, 602-0841, Japan+81 (75)746-3032

-

USA, Virginia

2000 Kraft Dr.

,

,

Suite 2125

Blacksburg, VA 24060 -

USA, California

Advanced BioMatrix

Address

5930 Sea Lion Pl,

Carlsbad, CA 92010, USA -

India, Bangalore

Address

1st Cross, Pete Krishnappa Layout,

K Channasandra Main Road

Kalkere Post, Horamavu

Bangalore-560043, India+91 (0) 98808 58741

-

United kingdom, Brighton

Address

Room 411

Spaces Mocatta House

Trafalgar Place

Brighton, East Sussex

BN1 4DU, UK

Distributors

If we have a distributor in your area, please contact them if you need any assistance, or if you’d like more information about our products and services.

-

Colombia

Medical3D

Calle 35 #17-77

Bucaramanga, 680005

ColombiaRequest a quote

-

Costa Rica

Grupo RodCas

Calle 57A

San José

Costa RicaRequest a quote

-

Indonesia

PT Laborindo Sarana

Arteri Raya Pondok Indah, St No.

8A

8A

South Jakarta,

Indonesia, 12240 -

Mexico

CTR Scientific

Av Abraham Lincoln 3410-Pte,

Mitras Nte., 64320 Monterrey,

N.L., MexicoRequest a quote

-

Peru, Bolivia, Paraguay

First Source Biotech

Jr. Trujillo #531

Lima, 15076

PerúRequest a quote

-

Chile

Biotecom

Av. Condell 653,

Santiago, 7501123,

ChileRequest a quote

-

Brazil

SOTELAB

Rua Teixeira e Sousa, 231

São Paulo – SP, 05003-050

BrasilRequest a quote

-

Saudi Arabia

Naizak Global Engineering Systems – Lab Systems Division

King Fahd Road, Sinayiat Alfawaziya, Al Khobar 34627, Saudi Arabia

-

United Arab Emirates

Leader Life Sciences

Laboratory Complex,

Dubai Science Park Office #219, 2nd Floor

Dubai, UAE -

China

Beijing Cycloud Biotechnology Co.

, Ltd

, LtdRoom 201, Floor 2, Unit 2, Building 2, NO.25, Jinghai fourth road, Beijing Economic and Technological Development zone, Beijing

-

China

Gaia China Co., Ltd

Shanghai Pudong New Area Zhangjiang Hi – Tech Park

236 Haique Road, #1221, Shanghai 201203, China -

South Korea

Chayon Laboratories, Inc.

Address: 22 Yeoksam-ro 7-gil

Gangnam-gu, Seoul, 06244, KOREARequest a quote

-

Czech Republic

CHROMSPEC s.r.o.

Lhotecka 594

Mnisek pod Brdy

252 10 Czech Republic -

Hungary

Per-Form Hungária Kft.

Address: 1142 Budapest, Ungvár u. 43.Request a quote

-

Spain

Izasa Scientific

Address: Aragoneses 13, 28108 Alcobendas. Madrid

Request a quote -

Portugal

Izasa Scientific

Address: Avenida do Forte nº 6. Edificio Ramazzotti – 3º2.24, 2790-072 Carnaxide

Request a quote -

France, Lyon

Espace Florentin

59 chemin Moulin Carron

69870 DARDILLY, France -

Singapore

Gaia Science

Address: Block 102 E Pasir Panjang Road #02-07,

Singapore-118529

Request a quote -

Malaysia

Nano Life Quest

Address: No. 2A, Jalan Sepadu 25/123A Axis Industrial Park, Seksyen 25, 40400 Shah Alam, Selangor D.E. Malaysia SGR 40400

2A, Jalan Sepadu 25/123A Axis Industrial Park, Seksyen 25, 40400 Shah Alam, Selangor D.E. Malaysia SGR 40400

Request a quote -

South Korea

Doctor Bio. INC

Address: 309 Ho, Expo Officetel, ManNyeun-Dong,

Se-Gu Daejeon South Korea

Request a quote -

China

Premedical Laboratories Co., Ltd.

Address: Rm 401,IBI Mansion, 9# Kexing Rd,

Fengtai, Beijing, China

Request a quote -

China

Cold Spring Biotech Corp

Address: Rm.A2111, Vantone New World Plaza, No.2 Fuwai Street, Xicheng District, Beijing 100037, P. R.China

R.China

Request a quote -

Southern africa

SEPARATIONS

Address: 9 Will Scarlet Road,

Robindale, 2194 South AfricaServes: Botswana, Eswatini, Lesotho, Mozambique, Namibia, South Africa & Zimbabwe.

Request a quote

-

Israel

Almog Diagnostic and Medical Equipment Ltd.

Address: 4 Hacharuv St., Haman Industrial Park

Shoham 608580 POB349, IsraelRequest a quote

-

Italy

TWIN HELIX SRL

Address: Via Federico Borromeo, 4,

20017 – RHO (MI), Italy

Request a quote -

Taiwan

LIH YUAN ENTERPRISE CO.

, LTD.

, LTD.

2nd FL., 20-Chang Road,

P.O. BOX 10056, Hsien-tien,

Hsien-tien, Taipei, Taiwan

Taiwan R.O.C.

Request a quote -

Poland

Sygnis Bio Technologies

Address: Zwirki i Wigury 101, 02-089 Warsaw, Poland

Request a quote -

Thailand

SCIONA ASSOCIATED

Address: 30 Soi Ramkhamhaeng 76 Yak2

Haumak Bangkapi Bangkok

10240

Request a quote -

Norway

Nerliens Meszansky AS

Address: Økernveien 121,

NO-0579 Oslo

Norway

Request a quote -

Turkiye

TERRALAB LABORATUVAR MALZ.

SAN. VE TİC. A.S.

SAN. VE TİC. A.S.

Address: Cetin Emec Bulvari 1328. Sok. No: 14/9

A.Ovecler 06460 Ankara, Turkiye.

Request a quote -

Lithuania

INTERLUX

Address: Aviečių st. 16,

LT-08418 Vilnius, Lithuania

Request a quote -

Estonia

INTERLUX OÜ

Address: Lõõtsa 5, Tallinn

114 15, Estonia

Request a quote -

Latvia

INTERLUX

Address: Aviečių st. 16,

LT-08418 Vilnius, Lithuania

Request a quote

3D printing of organs - scientists have created bio-ink suitable for freezing

Topic of the day

- home

- Technology

December 23, 2021, 12:42 Print

Researchers have created a new type of bio-ink.

- You will also be interested >

-

Always in touch: how to charge your smartphone when the power goes out 23.11 18:33

-

Tiny Japanese spacecraft will not be able to land on the moon 23.

11 18:00

11 18:00 -

Internet outages reported in Ukraine after Russian missile attack 23.11 17:20

-

Earth could have appeared earlier than thought - scientists 23.11 13:12

-

Archaeologists discover mysterious Viking swords in Sweden 23.

11 11:56

11 11:56 -

Twins born from frozen embryos in 1992 ► Video 23.11 05:42

-

Scientists have told why the Egyptians actually mummified their dead 22.11 19:18

-

With wings and a proboscis: scientists have found the remains of ancient bizarre creatures 22.

11 17:05

11 17:05 -

NASA showed images of the moon taken by the Orion spacecraft 22.11 14:36

-

Musk plans to add encrypted messages and video chats to Twitter 11/22 12:36

-

The Orion spacecraft successfully completed its first lunar flyby. 21.

11 17:08

11 17:08 -

Scholars voted to add new prefixes to the International System of Units 21.11 14:43

-

Latest news

- Without light: how not to get depressed during a power outage 05:00

- UK removes Chinese cameras from government buildings over security risks 04:55

- What we handed over to IRIS-T motivated other allies to provide Ukraine with their air defense systems - German ambassador 04:39

- "Leica that saw the Holodomor": the National Museum of the Holodomor-Genocide presented a unique exhibition 03:46

- Head of Foreign Office James Cleverley arrived in Ukraine 03:25

All news

Welcome! Registration Password recovery Log in to be able to comment on content Register to be able to comment on materials Enter the e-mail address to which the registration was made and the password

will be sent to itForgot your password? To come in

The password can contain uppercase and lowercase Latin letters, as well as numbers The entered e-mail contains errors

Register

Name and surname must consist of letters of the Latin alphabet or Cyrillic The entered e-mail contains errors This email already exists The First and last name field has no errors Email field has no errors

Remind password

The e-mail entered contains errors

No account? Register! Already registered? Sign in! Don't have an account? Register!

Unique 3D printing material based on pollen

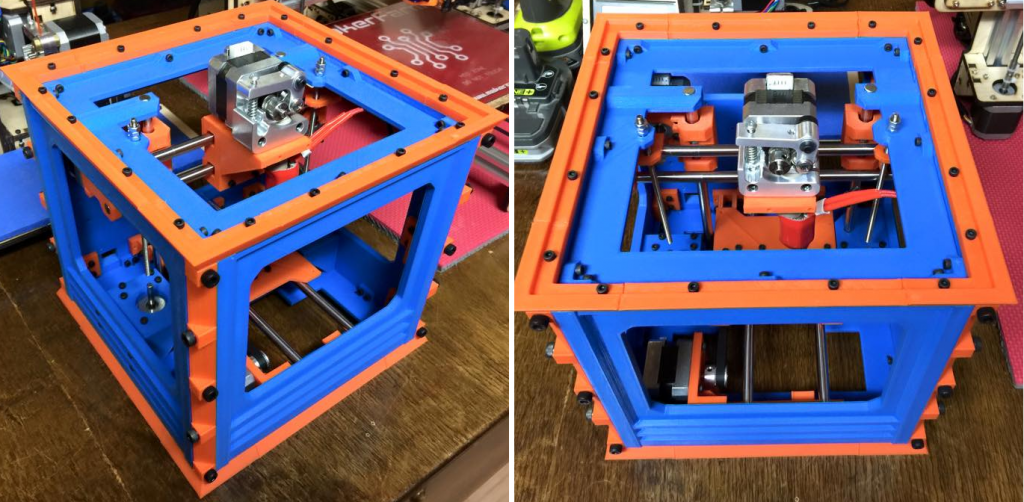

Researchers at Nanyang Technological University (NTU) have developed a 3D bioprinting ink with sunflower extract that could kick-start a new generation of biomedical devices.

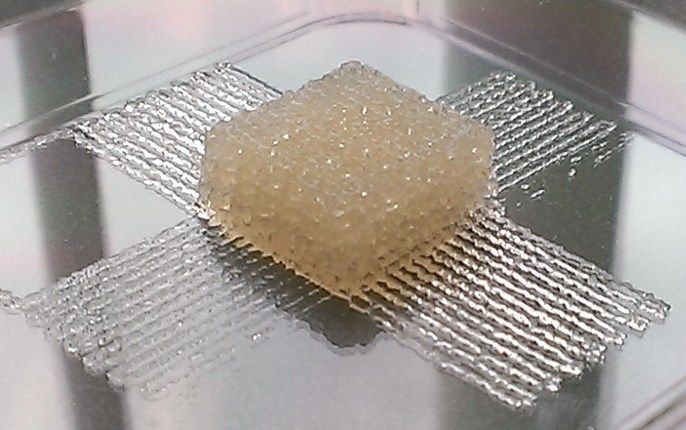

Unlike conventional malleable bio-inks, pollen-based bio-inks can be configured to be more rigid so they can be 3D printed into structures without losing integrity between layers. Scientists who have already used their inks to create scaffolds for tissue regenerative cells now believe they have significant potential in tissue engineering, toxicity testing and drug delivery.

“Bioprinting can be challenging because the material of the ink used is typically too soft, meaning that the structure of the intended product can break down during printing,” explained study co-lead author Cho Nam-Joon. “By tuning the mechanical properties of sunflower pollen, we have developed a pollen-based hybrid ink that can be used to print structures with good structural integrity.”

“Given that there are many types of pollen, pollen microgel suspensions have the potential to be used to create a new class of sustainable 3D printing materials.”

Chart depicting researchers' pollen-based 3D printing method. Image from Advanced Functional Materials magazine.

Image from Advanced Functional Materials magazine.

Bioprinted Reinforced Hydrogels

Due to its inherent ability to incorporate living cells, Direct Ink Writing (DIW) 3D printing is becoming an increasingly popular means of creating biomedical devices such as tissue scaffolds. Similarly, hydrogels are often used in DIW because they are customizable, they facilitate cell attachment, and are able to accurately mimic biological tissues.

However, according to NTU researchers, hydrogels are also characterized by low mechanical stability and bioinertness, which requires the creation of "hybrid" inks that "provide functions and properties unattainable by any hydrogel."

In the past, some scientists have found that integrating nanofibers or nanoplates into hydrogel bioinks strengthens them and prevents printer nozzles from clogging. Others have developed support matrices made up of hydrogels, cells, and rubber that help keep printed structures in place before they are fully cured, as well as provide increased stability and resilience through recycled ingredients.

Inspired by the latter, the NTU team created a suspension of microgels from renewable pollen grains. The scientists argue that given its uniform size and regulated and consistent rheological behavior, the pollen provides ideal support matrices, and its ability to respond to stimuli could give it potential drug delivery capabilities.

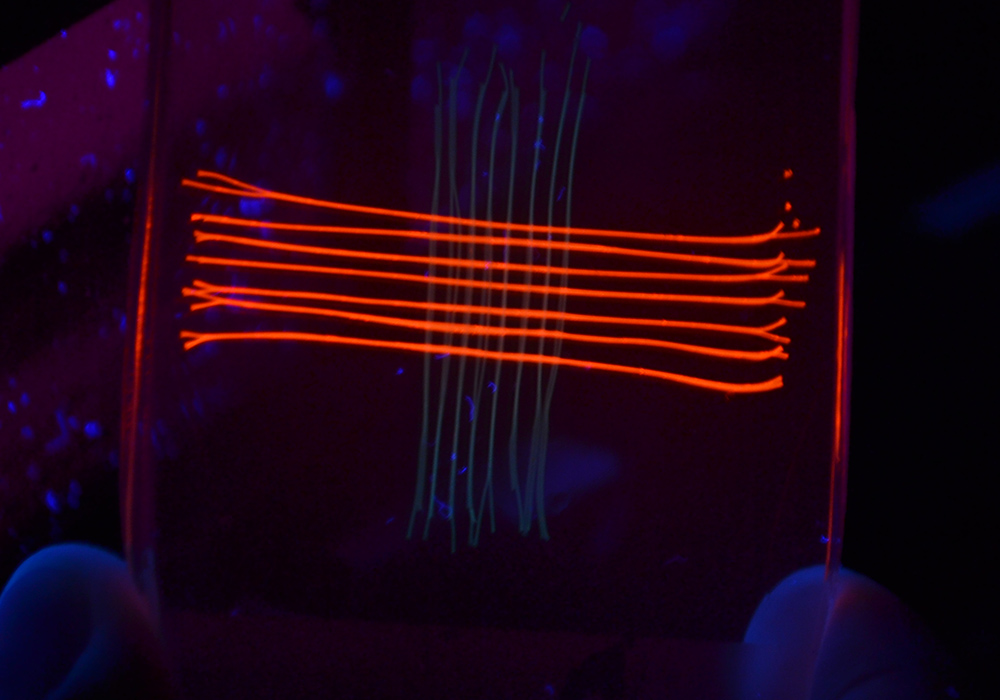

Researchers have developed two different inks, one for cell loading devices and the other for biomedical support. Image from Advanced Functional Materials magazine.

Pollen-Based Biomedical Devices

To create their new bioink, the researchers started by using a soap-making method to turn sunflower pollen into a microgel suspension. This substance was then mixed with alginate, rubber and hyaluronic acid, resulting in a mixture of pollen grains with a softer outer layer than usual, which allowed them to be compressed in the printer nozzle without jamming.

In fact, during early testing, scientists discovered that they could extrude their bio-ink with any given amount of pollen content without clogging up their 3D printer. After demonstrating the initial viability of their material by creating multilayer microstructures, the team then proceeded to fabricate dye-loaded scaffolds to evaluate its drug delivery potential.

After demonstrating the initial viability of their material by creating multilayer microstructures, the team then proceeded to fabricate dye-loaded scaffolds to evaluate its drug delivery potential.

Interestingly, the amount of dye released during these experiments varied over time, so due to sensitivity to pollen stimuli, the bioink can be tuned to release drugs according to the dosages for a particular patient. Given that pollen is also biocompatible, the researchers were also able to load their scaffolds with cells, creating a five-layer structure that demonstrated 94% cell viability.

The scientists 3D-printed their ink to create an 'elbow mesh' with 'good structural fidelity'. Image from Advanced Functional Materials magazine.

Finally, the team increased the rubber and alginate content of their inks to test their ability to produce more traditional biomedical devices. In practice, this meant creating a device in the form of a silicone rubber dome, which, according to the scientists, “demonstrated good structural accuracy” and “improved print resolution” thanks to the pollen base.

The researchers intend to further optimize their slurry by improving its recyclability after several heating cycles, but they already see it as a viable way to avoid jams during 3D printing, and given its stimulus-responsive behavior, they say that it could be an "abundant and readily available source material" for future biomedical applications.

"Our findings could open up new possibilities for creating flexible membranes that precisely fit the contours of human skin, such as wound dressings or face masks," said study co-author Sun Juha. “Using our biocompatible, flexible and low-cost inks, we can make membranes that are tailored to the contours of human skin and able to flex without breaking.”

As the 3D printing industry continues to search for sustainable alternatives to oil-based polymers, scientists are increasingly looking to Mother Nature for answers. For example, researchers at the Portuguese University of Aveiro and the Institute of Materials of Aveiro have recently developed a bamboo-based ABS material that they say produces "higher quality parts.