Resin for lcd 3d printer

LCD/MSLA 3D Printer Photopolymer Resins

Technical Specifications

- Resins designed for LCD 3D printers or have been tested to work with LCD 3D printers

LCD/MSLA Resins

Liqcreate Resins

High-quality resins for use on all open source LCD and DLP 3D Printers.

MH Build Series Resin

Top Tier, Affordable Resin for Producing High Detail Parts

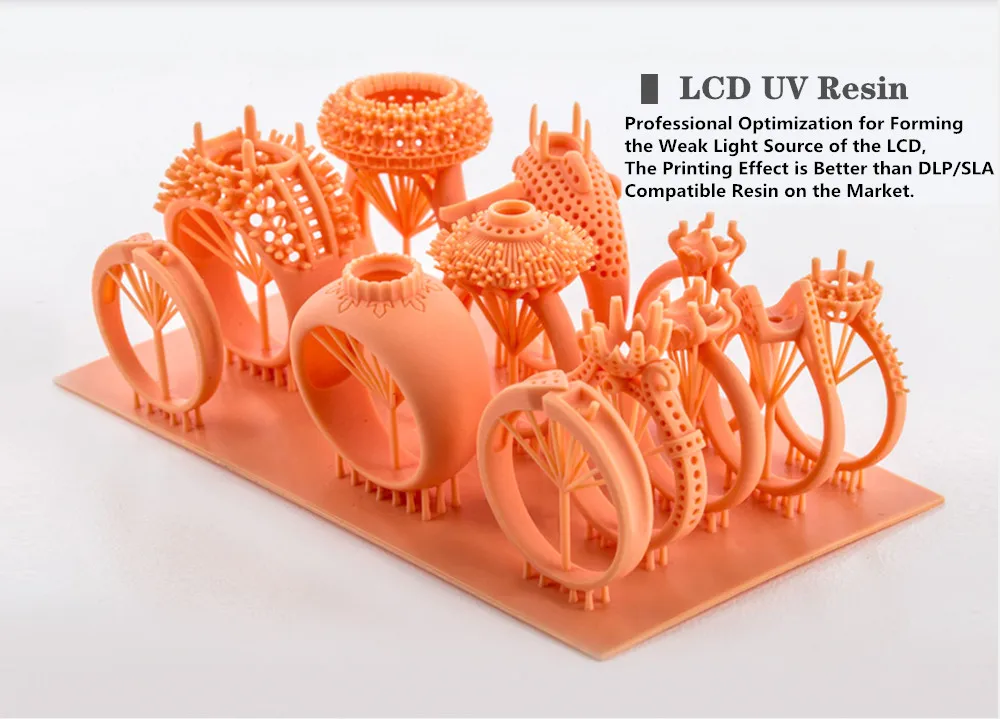

PhotoCentric 3D UV LCD Resins

Formulated to work with a wide range of UV backlit DUP 3D printers

Siraya Tech Resins

Produce fantastic quality models and parts with Siraya Tech's LCD/MSLA Photopolymer 3D Printer Resin that works with Peopoly Phenom, Elegoo Mars, and more.

Uniz Resins

LCD resins designed for use on Uniz Slash 3D Printers

Zortrax Inkspire Resins

Zortrax DLP 3D resins formulated for prototyping and end-use parts.

Guides & Articles

How To: Perfectly Level Your Resin 3D Printer's Build Plate

With any 3D print, a perfect first layer is essentially, especially so with resin 3D printing. Let's take a look at how you might be able to increase the adhesion of your resin 3D prints.

How To Succeed with LayerLock SLA Build Surfaces

Successfully achieve strong bed adhesion for Laser, DLP, and SLA resin prints using LayerLock SLA Resin 3D Printing Build Surfaces.

How to Succeed When 3D Printing with MH Build Resin

Make SLA resin 3D printing easier with this helpful detailed article on how to successfully fine-tune photopolymer resin to your 3D printer.

MH Build Resin Profile Settings for SLA 3D Printing

Succeed with MH Build Resin using these helpful printer and support ChiTuBox profile settings for your specific SLA machine.

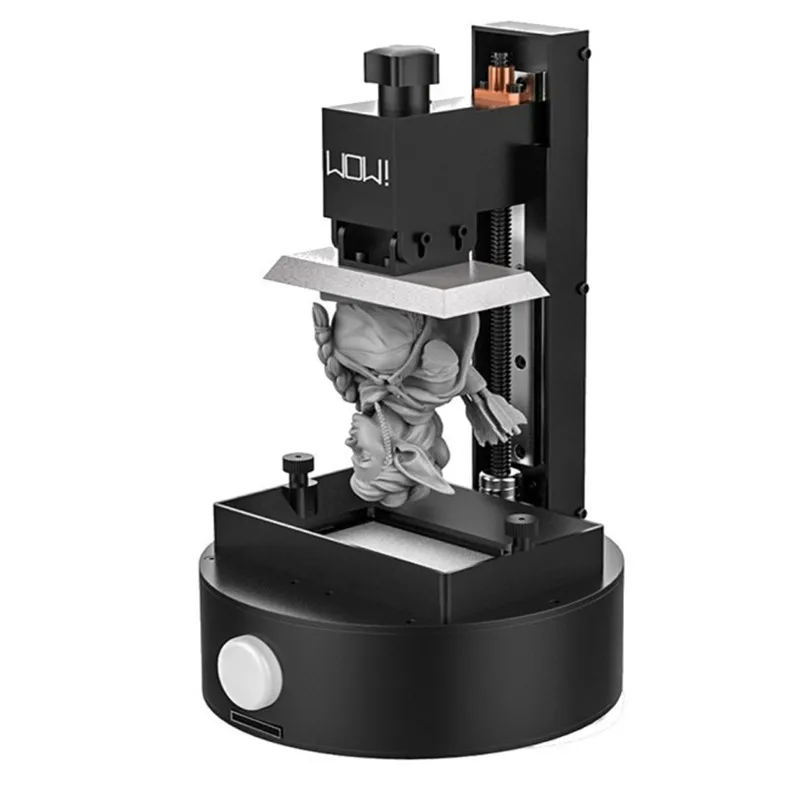

Tech Breakdown: Peopoly Phenom Noir Resin 3D Printer

For high definition resin 3D printers, Peopoly is hard to beat, and with the Phenom Noir you can print faster than ever.

Getting Started with the Peopoly Moai SLA 3D Printer

MatterHackers' Pros detail the unboxes and set-up steps of the awesome Peopoly Moai SLA 3D printer.

How To: Print, Clean, and Post-Process SLA 3D Prints

Laser and resin 3D Printers have a very different workflow from the more common extruder and plastic 3D printers. Learn what it takes to use these high-resolution machines.

How To: Safely Handle, Use, and Dispose Resins for SLA 3D Printers

3D prints from SLA 3D printers solidify liquid resin to create high-resolution parts. These resins need to be handled with care from opening to disposal.

Tech Breakdown: Peopoly's Moai SLA 3D Printer

MatterHackers' pros take an in-depth look at why this incredibly precise resin 3D printer is quickly becoming a crowd favorite.

DLP 3D Printer Resins | MatterHackers

- Home

- Store

- 3D Printer Resins

- Application

- DLP Resins

Stereolithography (SLA) photopolymer resin 3D printing uses additive manufacturing techniques to produce printed parts out of liquid plastic resin. DLP (Digital Light Processing) SLA 3D printing uses an LED light source with a digital micromirror device (DMD) to project layer-by-layer images onto the build plate to form the final object. Some modern DLP 3D printers now cut out the DMD in favor of a panel of micrometer-sized LED lights. This projecting of the entire layer at once makes it one of the faster photopolymer resin 3D printing technologies currently available. When using SLA technology, it's important to use the right material that is designed to work with DLP curing technology. Check out the collection below of resins by reliable brands like Liqcreate, MakerJuice, SprintRay, PhotoCentric, and more who produce great quality resins that have been successfully tested to succeed with DLP SLA for investment casting, model making, and design applications.

DLP (Digital Light Processing) SLA 3D printing uses an LED light source with a digital micromirror device (DMD) to project layer-by-layer images onto the build plate to form the final object. Some modern DLP 3D printers now cut out the DMD in favor of a panel of micrometer-sized LED lights. This projecting of the entire layer at once makes it one of the faster photopolymer resin 3D printing technologies currently available. When using SLA technology, it's important to use the right material that is designed to work with DLP curing technology. Check out the collection below of resins by reliable brands like Liqcreate, MakerJuice, SprintRay, PhotoCentric, and more who produce great quality resins that have been successfully tested to succeed with DLP SLA for investment casting, model making, and design applications.

DLP Resins Collections

All DLP Resins Browse by Resin Application

Technical Specifications

- Resins for DLP 3D Printers

DLP Resins

Liqcreate Resins

High-quality resins for use on all open source LCD and DLP 3D Printers.

MH Build Series Resin

Top Tier, Affordable Resin for Producing High Detail Parts

PhotoCentric 3D UV DLP Resin

Created to work with a wide range of DLP SLA printers.

SprintRay Resins

Silky smooth resins for modeling and dental casting.

Guides & Articles

How To Succeed with LayerLock SLA Build Surfaces

Successfully achieve strong bed adhesion for Laser, DLP, and SLA resin prints using LayerLock SLA Resin 3D Printing Build Surfaces.

Tech Breakdown: Peopoly Phenom Noir Resin 3D Printer

For high definition resin 3D printers, Peopoly is hard to beat, and with the Phenom Noir you can print faster than ever.

How To: Print, Clean, and Post-Process SLA 3D Prints

Laser and resin 3D Printers have a very different workflow from the more common extruder and plastic 3D printers. Learn what it takes to use these high-resolution machines.

Learn what it takes to use these high-resolution machines.

Tech Breakdown: Peopoly's Moai SLA 3D Printer

MatterHackers' pros take an in-depth look at why this incredibly precise resin 3D printer is quickly becoming a crowd favorite.

How To: Safely Handle, Use, and Dispose Resins for SLA 3D Printers

3D prints from SLA 3D printers solidify liquid resin to create high-resolution parts. These resins need to be handled with care from opening to disposal.

Tech Breakdown: Zortrax Inkspire UV LCD Resin 3D Printer

The Zortrax Inkspire UV LCD 3D resin printer uses high-resolution LCD UV light to cure liquid resins at an incredible level giving any user amazing 3D prints.

Tech Breakdown: An In-depth Look at the MoonRay S 3D Printer

MatterHackers pros take a detailed look at this high resolution, easy-to-use resin 3D Printer.

Choosing a liquid photopolymer for a 3D printer.

Classification of materials for SLA/DLP 3D printing.

Classification of materials for SLA/DLP 3D printing. Contents:

- Introduction

- SLA Overview

- SLA Standard Resins

- Standard photopolymer resin - Standard

- Clear Photopolymer Resin - Clear

- Engineering photopolymer resins

- Rigid photopolymer resin - Tough (like ABS)

- Durable photopolymer resin - Durable (PP-like)

- Heat resistant photopolymer resin - Heat resistant

- Rubber-like photopolymer resin - Rubber-like (Elastic)

- Ceramic photopolymer resin - Ceramic filled (Hard)

- How to choose the right resin for your application

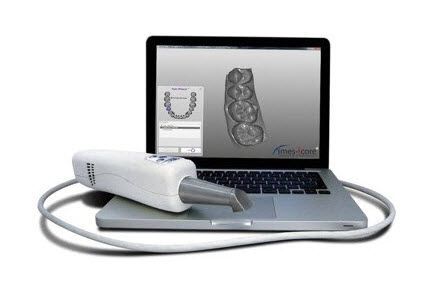

- Dental and medical SLA resins

- Medical Device Photopolymer Resin - Custom Medical Appliances (Class I Biocompatibility)

- Dental Long Term Biocompatible Resin (Class IIa Biocompatible)

- Biocompatibility class I vs biocompatibility class IIa

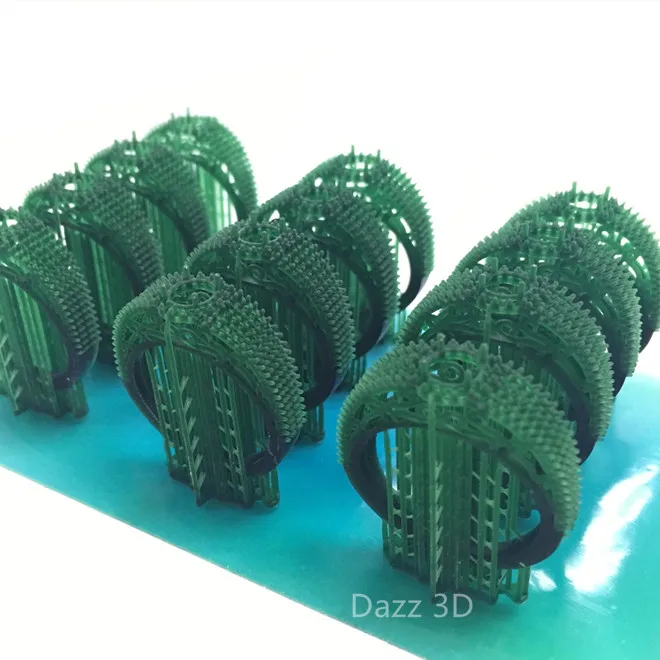

- Cast SLA resins

- Cast resin for jewelry making

- Generalized rules

Hello everyone, Friends! With you 3DTool!

This article compares photopolymer resins using Formlabs SLA 3D printing products –

Catalog of photopolymer 3D printers

Photopolymers from FormLabs

Detailed review of the Formlabs Form 3 3D printer

Introduction

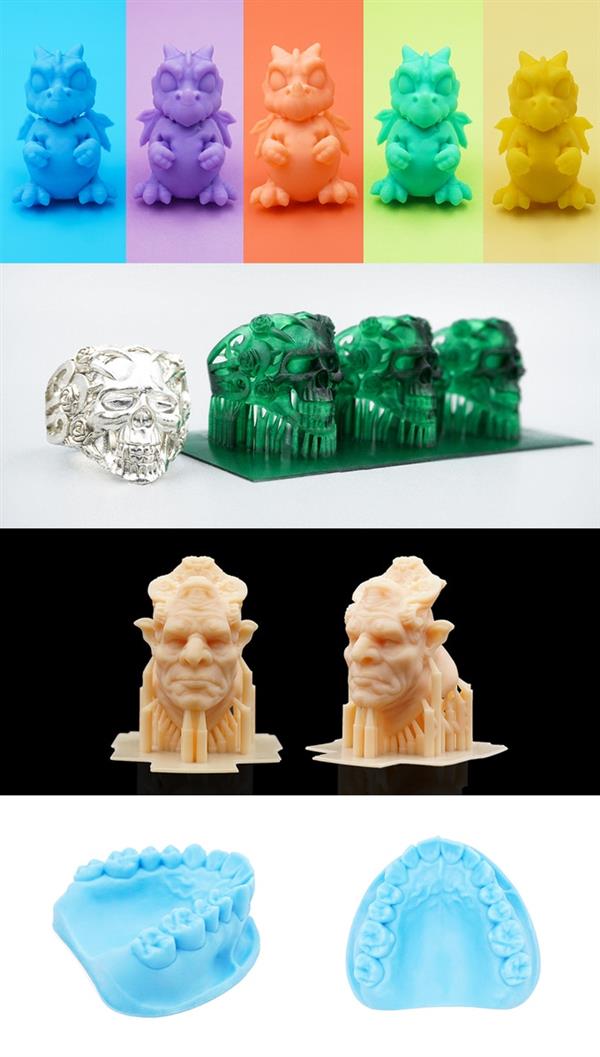

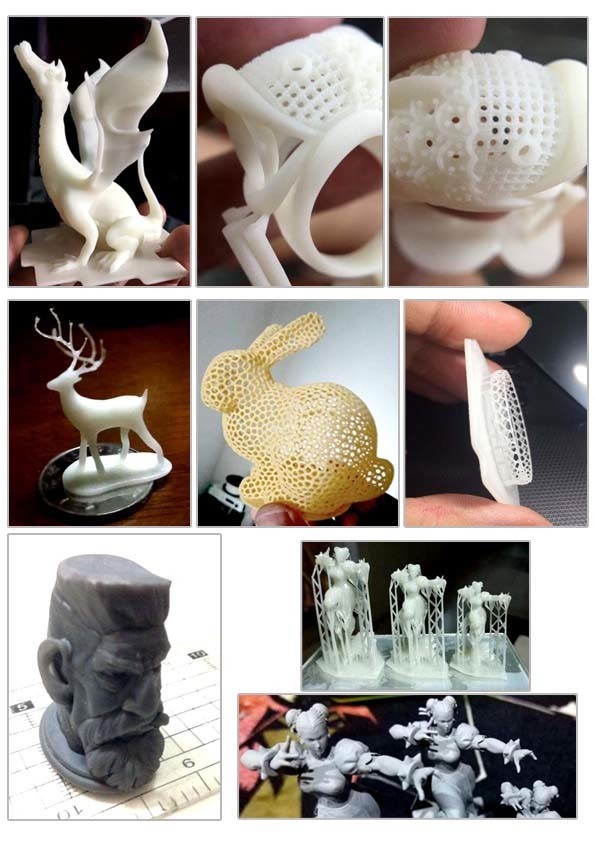

The stereolithography prints plastic parts with high resolution, good fine detail and smooth surface. Due to the variety of photopolymer resins available for SLA, this technology is used in many different industries:

-

"Standard" photopolymers are used for prototyping

-

Engineering photopolymers have certain mechanical and thermal properties

-

Dental and medical photopolymers have biocompatibility certificates.

-

Cast photopolymers have a zero ash content after burning.

SLA 3D Printing Resin Overview

SLA uses a laser to cure a liquid photopolymer resin. This process is called photopolymerization. Various combinations of polymers and other additives that are part of the resin allow you to get different material properties.

The main advantages and limitations that are common to all resins in SLA 3D printing are:

Benefits:

Weaknesses:

Base Resins for SLA

Post-Processing SLA/DLP 3D Printing Article

Standard photopolymer resin - Standard

Standard resins produce parts with high stiffness, detail and a smooth surface. The low cost of resins, from $250 per liter, makes them ideal for prototypes.

The color of the resin also affects its properties. For example, in FormLabs products, gray resin is suitable for models with fine details, and white resin for parts that require the smoothest possible surface.

Benefits of using Standard grade resins:

Cons Standard:

Also included in the class of "Standard" photopolymer resins from FormLabs is the Color KIT - a set of special dyes and "Color Base" photopolymer resin for mixing and obtaining a variety of color solutions. This eliminates the need for painting parts after 3D printing.

This eliminates the need for painting parts after 3D printing.

FormLabs Engineering Photopolymer Resins

Engineering resins have a range of properties for injection molded plastics.

All engineering resins require additional UV curing, such as using the Form Cure, to achieve their maximum properties.

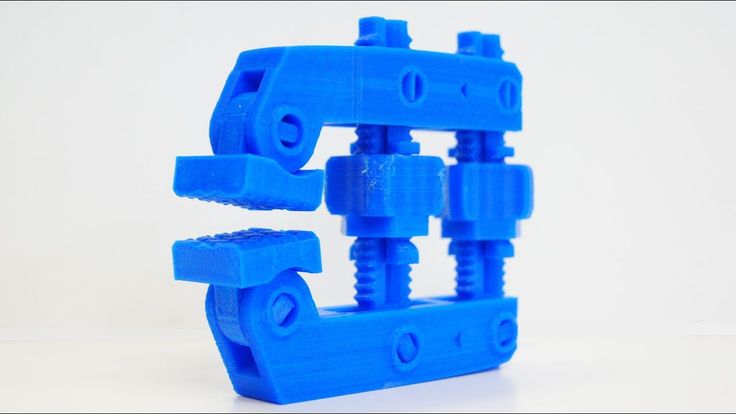

Tough photopolymer resin - Tough (ABS equivalent)

Tough resin was developed for models that need to withstand high loads and be durable.

This material produces strong, shatter-resistant parts and functional prototypes such as snap-on housings.

Pros:

Cons:

Ideal for: functional prototypes, mechanical parts

Durable photopolymer resin - Durable

Durable resin is a wear-resistant and flexible material with mechanical properties similar to polypropylene.

Durable photopolymer produces models with a smooth glossy surface and high resistance to deformation.

Durable Resin is ideal for:

- Bushings and bearings;

- Various functional compounds

Pros:

Cons:

-

Not suitable for thin wall parts (recommended minimum wall thickness 1mm)

-

Low heat distortion temperature

-

Low flexural strength (lower than hard resin)

Ideal for: functional prototypes.

Refractory Photopolymer Resin - Formlabs High Temp Resin

The heat resistant resin is ideal for parts that require high temperature resistance and operate at high temperatures.

Formlabs High Temp Resin provides the highest melting point (HDT): 238°C at 0.45 MPa.

The resin should be used to print detailed, accurate prototypes with high heat resistance.

Pros:

Cons:

Flexible Resin

Rubber-like resin allows flexible parts to be made. This material has a low tensile strength and high elongation at break and is well suited for parts that will be bent or compressed.

It can also be used to add ergonomic features to multi-material assemblies such as: dies, wearable prototypes, handles, pads and grips.

Pros:

-

High flexibility (high elongation at break)

-

Low hardness (simulates 80A durometer rubber)

-

High impact resistance

Cons:

-

Doesn't have all the properties of real rubber

-

Requires extensive support structures

-

Material properties deteriorate over time as the part is exposed to ultraviolet radiation (sunlight)

-

Not suitable for thin wall parts (recommended minimum wall thickness 1mm)

Ideal for flexible prototyping.

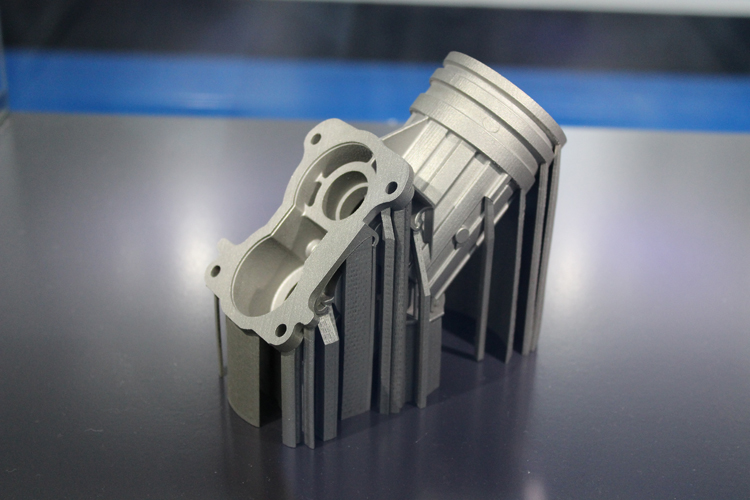

Ceramic photopolymer resin - Rigid Resin

This resin is reinforced with glass, which provides very high rigidity and a polished surface. The polymer is very resistant to deformation and is excellent for 3D printing thin elements.

Ideal for: molds and tooling, jigs, manifolds, retainers, electrical and automotive fixture housings

Thermal management components printed with SLA ceramic (hard) resin. Image credit: Formlabs

How to choose the right resin for your application

The table below shows the main mechanical properties of photopolymers for SLA:

Source: Formlabs

Standard resin ( standart ) has high tensile strength but is very brittle (very low elongation at break) so it is not suitable for functional parts. The ability to create a good part surface makes it ideal for visual prototypes and art models.

Durable ( durable ) resin has the highest impact strength and elongation at break of any other SLA material. Best suited for prototyping parts with moving parts and latches. It lacks, however, the strength of thermoplastic 3D printing materials such as SLA nylon.

tough tough resin is a compromise between the material properties of tough and standard resin. It has a high tensile strength, so it is best suited for rigid parts that require high hardness.

heat resistant resin ( heat resistant ) can withstand temperatures above 200 o C, but has poor impact strength and is even more brittle than standard resin.

ceramic ( ceramic reinforce ) resin has the highest tensile strength and flexural modulus, but is brittle (poor elongation at break and toughness). This resin is preferred for thin wall parts that require increased rigidity.

The graphs below compare the mechanical properties of the most common SLA materials visually:

Comparison chart for elongation at break and toughness for common SLA printing specifications and standard media. Image courtesy of Formlabs.

Stress-strain curves for conventional SLA technologies and standard materials. Image credit: Formlabs

Pros:

Cons:

- Moderate wear and tear resistance

Ideal for: Surgical aids and appliances

Dental Long Term Biocompatible Resin - Dental Long Term (Class 2A biocompatible)

0114

These resins are specially formulated for long term dental fixtures. Class 2A biocompatible resins can come into contact with the human body for up to a year.

High resistance to breakage and wear make this resin ideal for making rigid cotter pins or retainers.

Pros:

Cons:

-

High price

Ideal for: durable dental instruments, fracture and wear resistant medical parts, rigid cotter pins, retainers

What is the difference between class 1 and class 2a biocompatibility?

Class 1 biocompatibility rules apply to materials that are allowed to be used for:

-

non-invasive devices that come into contact with intact skin

-

devices for temporary use or short-term use in the mouth or ear canal or in the nasal cavity

-

reusable surgical instruments

Class 2a biocompatibility rules apply to materials that are allowed to be used for:

-

devices that come into contact with bodily fluids or open wounds

-

devices used to introduce substances into or remove substances from the human body

-

invasive short-term devices such as invasive surgical items

-

long-term implantable devices placed in the teeth

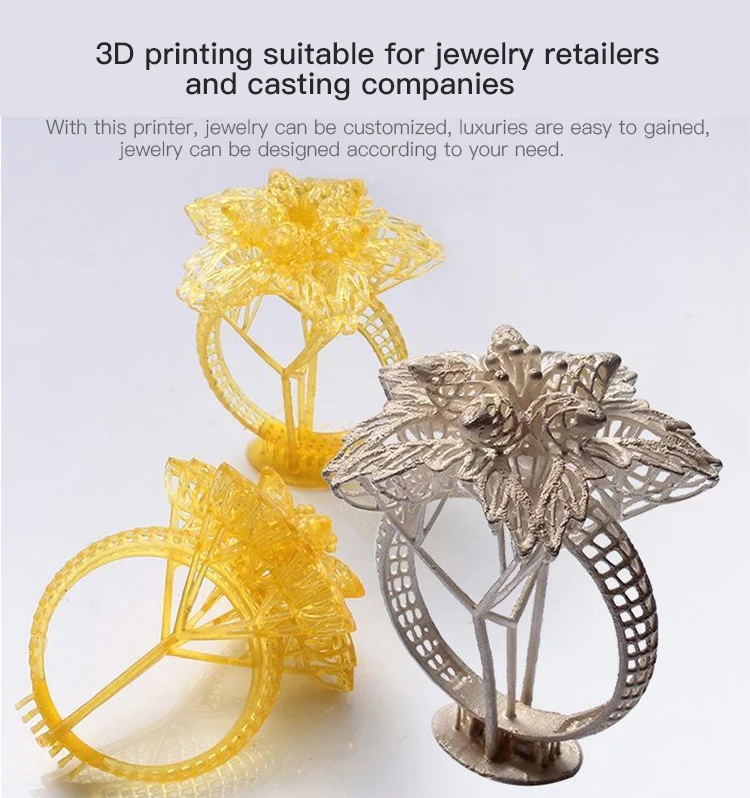

Photopolymer resins in SLA 3D printing for jewelers

Jewelry resins

This material allows you to print models with fine details and a smooth surface without leaving ash or residue after burning.

Cast resin allows you to get the finished product directly from design to precision casting with just one 3D printed part. It is suitable for making jewelry and other small and complex components.

Pros:

Cons:

Ideal for: investment casting, jewelry making

SLA/DLP 3D printer catalog

Photopolymers from FormLabs

Post-Processing SLA/DLP 3D Printing Article

Well, that's all we have! We hope this article was useful for you!

You can order Formlabs SLA 3D printers or ask your questions and find out the status of your order, you can

- Email: [email protected]

- By phone: 8(800)775-86-69

- Or on our website: http://3dtool.ru

-

Don't forget to subscribe to our YouTube channel:

Subscribe to our groups in social networks:

In contact with

DLP and LCD 3D Printers: What's the Difference?・Cults

Resin 3D printing is a popular technology in the 3D printing industry, and every market has a number of these 3D printers in its product range. It finds wide application in various industries and its development is a priority to improve print quality, financial viability and access to a wider user group.

It finds wide application in various industries and its development is a priority to improve print quality, financial viability and access to a wider user group.

DLP and LCD are two of the most prominent technologies in resin 3D printing. Both work on a similar principle and are comparable in many ways. However, there are also some obvious differences that users should be aware of before purchasing a resin 3D printer.

In this blog we will focus on DLP and LCD 3D printers. We will discuss the main technologies used, their individual advantages and disadvantages, and how they suit your specific 3D printing needs.

Resin 3D printing belongs to the broad category of vat light curing, which is considered one of the main types of 3D printing technologies. The concept is based on the ability of light-sensitive resins in the liquid phase to solidify under the influence of light radiation.

Resin 3D printing uses this ability to create 3D objects from thinned resins that are selectively exposed to light to cure the desired areas of the resin. Only those parts of the resin that have solidified under the influence of the light source become part of the 3D printing, while the rest remain liquid.

Only those parts of the resin that have solidified under the influence of the light source become part of the 3D printing, while the rest remain liquid.

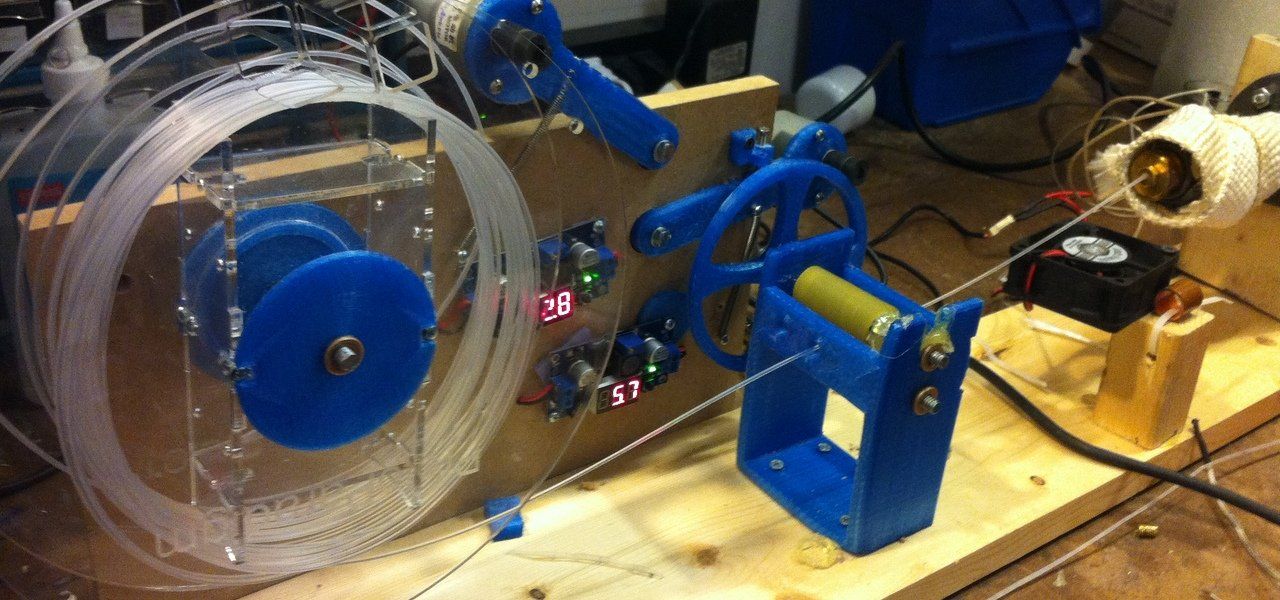

A common configuration for resin 3D printing includes a tray, or reservoir (in technical terms), that is filled with liquid resin, a light source, and a mechanism for directing the light source to a specific point in the resin to be cured.

In addition, there is a build platform that can move up and down inside the tank with amazing precision. For each new layer, the building platform is lowered to the bottom of the tank, leaving only a tiny gap (0.5 mm in most cases) in which the layer adjacent to the platform is built. For subsequent layers, the platform continues to rise slightly each time, while each new layer fits into the resulting gap and is bonded to the top layer. The 3D printed resin model is built upside down as light passes through the bottom of the tank.

That's what resin 3D printing is all about! Now let's move on to two interesting technologies that we want to talk about.

Digital Light Processing, or DLP, uses a digital light projector as a light source to cure resins. This light source is characteristic of this technology and is the main difference between it and LCD displays.

The projector projects light onto a unique device called a DMD (Digital Micromirror Device), which consists of a very large number of very small mirrors, each of which is capable of deflecting light from the projector in different directions. For each layer, these mirrors are arranged in a specific orientation that reflects the digital light beam from the projector onto the tank in the exact shape of the printed layer/layer.

Mirrors cannot change the nature of the light source in any way, they only direct it. This means that the number of pixels produced on the build platform is the same as the number of pixels on the projector. So if the layer is slightly smaller than the projector's beam, the image is actually slightly sharper and more accurate than what is being projected! However, this also has a downside. The opposite happens if the printed piece is larger than the projector screen. In this case, the resolution is reduced, and there is also a risk of distortion at the edges, since the light is refracted too far (like an elephant's foot when printing with filament).

The opposite happens if the printed piece is larger than the projector screen. In this case, the resolution is reduced, and there is also a risk of distortion at the edges, since the light is refracted too far (like an elephant's foot when printing with filament).

Modern, more expensive DLP 3D printers use advanced technology to minimize this distortion problem and maintain layer quality despite being enlarged. As a result, these DLP 3D printers can safely be considered professional products.

DLP technology has been around for a long time due to the age of the light source: projectors are century old devices widely used in movie theaters. Therefore, the technology is tried and tested.

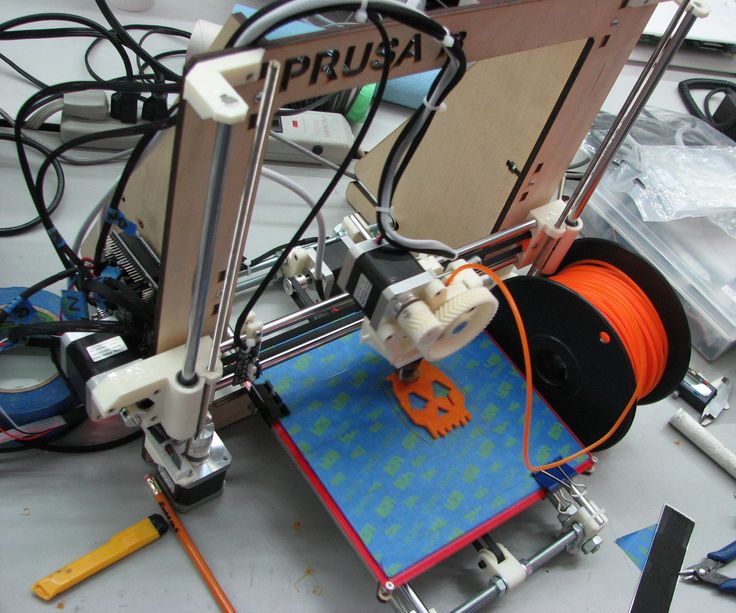

LCD 3D printing, also known as MSLA 3D printing, is a relatively new technology compared to DLP technology. As mentioned above, it uses a non-DLP light source: UV LEDs that shine through the LCD screen.

Although LCD also creates full layers at the same time as DLP 3D printers, the quality of the layers depends on the screen resolution. The higher the pixel density of the LCD screen, the better the print quality. In addition, there are no problems with distortion, as the print created on the LCD is transferred to the resin unchanged without deviation. Since the original projection size on the LCD screen does not change, the print area is limited by the screen area, so larger prints require a larger screen.

The higher the pixel density of the LCD screen, the better the print quality. In addition, there are no problems with distortion, as the print created on the LCD is transferred to the resin unchanged without deviation. Since the original projection size on the LCD screen does not change, the print area is limited by the screen area, so larger prints require a larger screen.

Cost is a tricky issue when it comes to LCD 3D printers. The material is cheap because the LCD screens used in these devices are practically the same as in smartphones. The problem, however, is that they need to be replaced frequently to maintain quality. The idea that LCD 3D printers are cheap is true, but you need to be aware of the running costs involved.

DLP and LCD are similar in many ways: technology, print quality, speed, applications, etc. Are they the same? But are they the same? No.

There are a few things to consider before choosing one or the other. First, let's talk about print quality. As mentioned above, it is comparable for both 3D printers. The finish is smooth, the layers are indistinguishable. However, DLP has an edge in this regard. Cheaper options compare well with LCD printers, but if you consider mid-range DLP 3D printers (which support layer distortion and warp), the build quality is much more detailed and subtle.

As mentioned above, it is comparable for both 3D printers. The finish is smooth, the layers are indistinguishable. However, DLP has an edge in this regard. Cheaper options compare well with LCD printers, but if you consider mid-range DLP 3D printers (which support layer distortion and warp), the build quality is much more detailed and subtle.

In terms of cost, LCD is the cheapest option. Even if the screen has to be changed, the technology itself is so accessible and cheap that DLP is still more expensive. But this comes at the expense of quality, which must be known.

Compatibility with the resin material is another factor to consider. Most resins can be used with both DLP and LCD 3D printers, but some are only suitable for one or the other. It depends on the energy intensity of the light source. The LCD uses a low power light source, so resins that cure quickly are suitable. If any other resin is used, it will not cure properly and the structural integrity of the model will be compromised. Naturally, DLP is compatible with resins that take some time to cure due to the high density of the energy source.

Naturally, DLP is compatible with resins that take some time to cure due to the high density of the energy source.

In general, it all depends on the specific application. People who require professional-grade quality and who have a large budget should always choose DLP as it is better suited for detailed work. Consumers who are just starting out or have low-precision tasks on a budget should consider LCD 3D printers, which are also very good in many ways.

This page has been translated using machine translation. Suggest the best translation

Previous

ShareNext

Similar publications

Known for its quality desktop 3D printers and high market share in the 3D printing industry, Creality 3D launched its revolutionary Infinite-Z 3D printer, the 3DPrintMill, on Kickstarter on November 19, 2020.

Read more Whether you're a 3D printing enthusiast or an educator, you've probably come across the problem of filaments absorbing moisture.