Design and 3d print

How to Design for 3D Printing

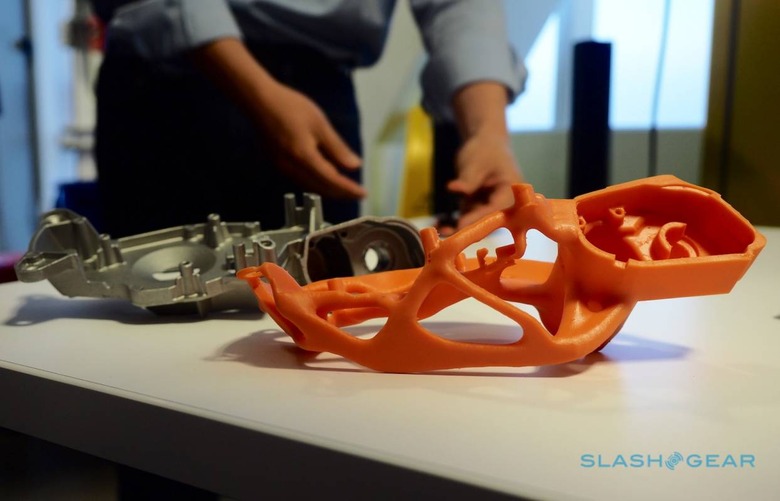

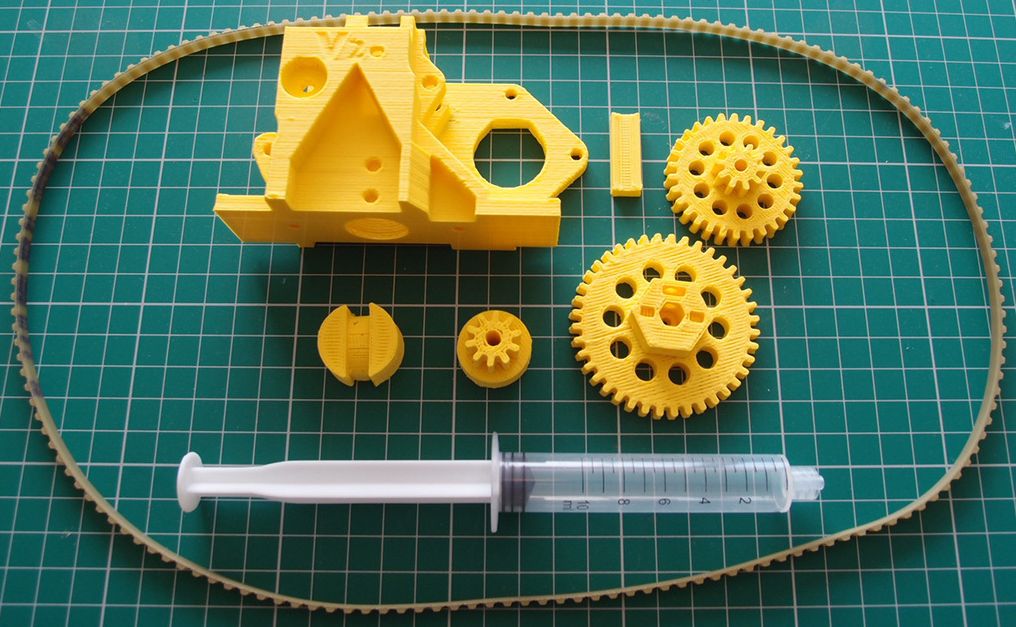

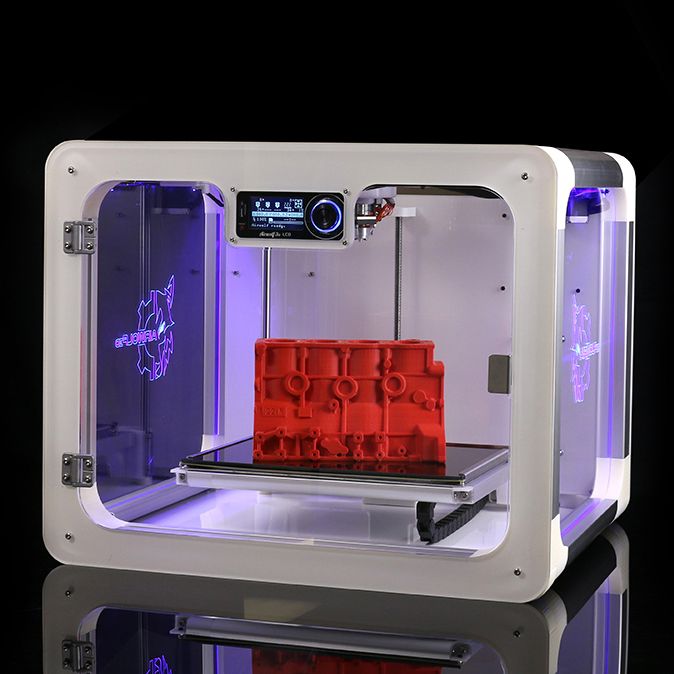

Once reserved for high-end research, the evolution of 3D printing now encapsulates everything from rapid prototyping to full-scale manufacturing.

For product innovators, industrial designers, and budding 3D printing enthusiasts ready to take design concepts to tangible products, this guide will walk you through the how-to’s of mastering quality 3D printing and finishing your prototype for presentation.This will allow you to create high-quality 3D concepts and products in record time.

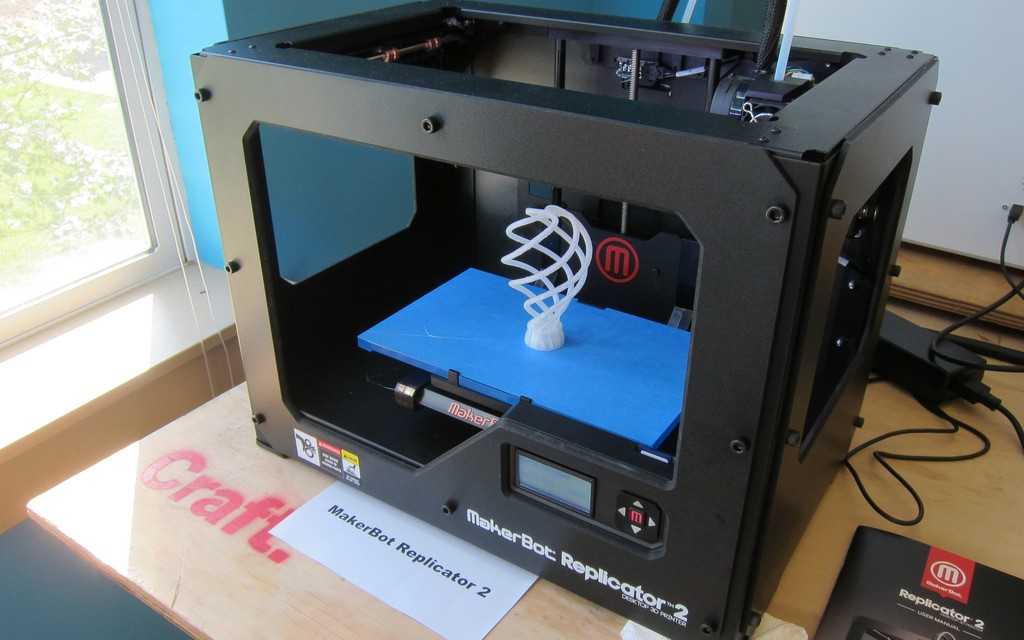

To demonstrate that you can achieve high-end results economically, we printed each model in this guide with a Fused Deposition Modeling (FDM) printer.

Following is an overview of the topics covered. Read through in order or skip ahead to the section most relevant to your process.

- Improving Print Quality: your choice of printing equipment is directly linked to how fast your product prints and the level of detail that you can achieve

- Perfecting Design Parameters: in order to be printable, your geometry needs to have volume and manifold geometries

- Managing Supports: beyond a certain point, your printed material won't be able to print onto thin air (surprise!) and requires designed 3D printed supports, which will affect the look of your final object

- Model Orientation: the direction that the material is layered to create your object and how it will impact the final look and feel of your object

Though it may seem daunting at first, using 3D printing your designs to test and iterate product concepts trims the design to manufacturing timeline, making the learning curve worth the time investment, even in the short run.

To hone in on leveling up your design workflow, rapidly developing new ideas, or launching a successful business with a product concept, go through this A-Z checklist of design principles for 3D printing to cover your bases before pressing print.

With the aim of speeding up manufacturing, we recommend Shapr3D CAD software to create 3D models within a plans-for-your-next-move user interface that markedly cuts your design time.

blog

Download Shapr3D for Windows:

Also available for iPad and Mac and fully supported on Wacom tablets.

Download Shapr3D for iPad:

Also available for Windows and Mac and fully supported on Wacom tablets.

Try Shapr3D

Available for Windows, iPad and Mac and fully supported on Wacom tablets.

The Principles in Action

Wayne State University’s industrial design professor, Claas Kuhnen, gives an overview of creating a cohesive design process and addresses common design-to-print issues in this video.

The Right Modeling Mindset

Keep in mind when 3D printing that the digital version of your design will have to deal with the laws of physics when it comes out of your 3D printer's nozzle.

The Importance of the Right Modeling Mindset -A tangled print of a 'T' shaped overhang succumbing to the punishing power of gravity

Overhangs that stretch effortlessly out into the ether on your iPad screen may come crashing down into a melted plastic mess from your printer. Perfectly concentric holes in your model may better resemble a deflated basketball in the real world. You may find that the thread you're trying to fit that screw into has nothing to do with the size of the thread on the screw anymore.

To anticipate and prevent these challenges, keep each guide item in mind during your design process.

Printer Setup

One of the biggest factors that will affect your 3D prints is the nozzle. The nozzle size and material will influence the strength, print time, and quality of your final product. While this is only true for FDM methods, similar resolution settings and issues will still appear with other 3D printing methods.

Nozzle diameters generally range between 0.1 – 1.0 mm. When you're selecting a 3D printing nozzle, you're deciding how much filament is extruded and how fast, which will naturally produce different results. While a smaller printing nozzle (<0.4 mm) predictably extrudes less material than a larger printing nozzle (>0.4 mm), the impact this will have on your print is more complex.

The standard nozzle size that most 3D printers come with is 0.4 mm. This size lets you print layer heights between 0.1 - 0.3 mm, so you can manufacture detailed objects in a reasonable amount of time.

Tip: When choosing a printer head, determine the final use case. Use a larger nozzle to print strong objects quickly. Give more detailed prints a smaller nozzle. The following are some general tips to guide you:

Use a larger nozzle to print strong objects quickly. Give more detailed prints a smaller nozzle. The following are some general tips to guide you:

Use larger nozzles (>0.4 mm) for:

- Printing things fast. Larger nozzles equal larger flow rates and more material deposited.

- Increased toughness. The energy absorption increases to 25% when printing objects with 0.6 mm nozzle versus 0.4 mm nozzle.

- Printing with abrasive filaments. Smaller nozzles easily clog, making them a difficult tool for printing coarser filaments - opt for a larger nozzle in this case.

- Models with low print resolution. Larger nozzles work best for prints without thin or fine details because they print thicker layers.

Use smaller nozzles (<0.4 mm) for:

- Small details. Print highly detailed models with small nozzles to extrude material more finely.

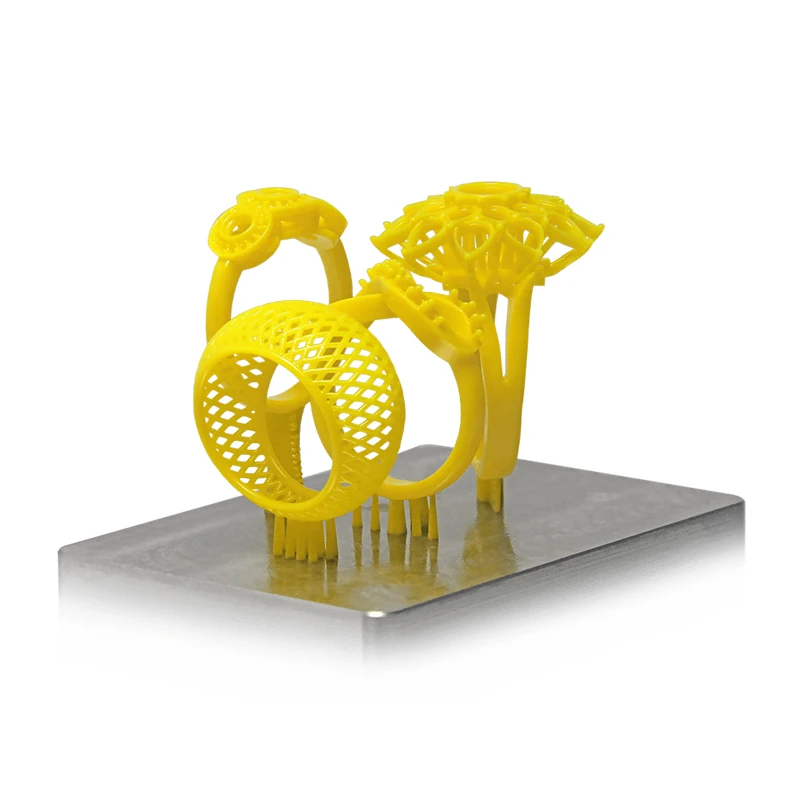

- Many features. Printing with a smaller nozzle takes more time, so it's only worth your while if you are manufacturing a more decorative piece and have a lot of time. Plain objects make more sense to be printed with a larger nozzle. Example applications for small nozzles include jewelry, text printing, or miniatures.

- Low layer height. Generally speaking, layer height should be 80% or less of the nozzle diameter, so a smaller nozzle will require lower layer height.

- Easily removable supports. Using smaller nozzles will result in a thinner support structure that can be more easily detached from your object after the print.

Dual Extrusion Printers

Dual extrusion printers have a second nozzle and extruder, so you can print parts using two different materials, switching between filaments as needed.

With a dual extrusion printer, you can combine a standard material with support materials. By printing supports with a different material, easily remove or dissolve them from the final print without leaving any marks. Dual extrusion printers also let you print using two different colors, or reinforce one printing material with a stronger one.

Nozzle Material

The nozzle material will also affect your print quality and speed so let’s look at the different options available.

Brass Nozzles

These are the de facto standard for most FDM 3D printers. This nozzle material provides good thermal conductivity and stability. Keep in mind that while it's the most common, it can't handle all types of filaments. Brass nozzles are best for non-abrasive filaments including PLA, ABS, Nylon, PETG, TPU, and more.

Hardened Steel Nozzles

Unlike brass nozzles, hardened steel wears less when printing abrasive materials like carbon fiber, glass fiber, metal-filled filaments like steel-filled, iron-filled, brass-filled, and other exotic filaments.

The wear-resistance of steel nozzles beats brass nozzles 10 times over, but the possible presence of lead in the nozzle makes them unfit for printing anything that will come in contact with food or skin. Stainless steel nozzles make a strong lead-free alternative for FDA-approved products, as well as a compatible option with light, abrasive materials.

Ruby Tip Nozzles

Ruby tip nozzles have a brass body with a ruby tip. The ruby tip increases the nozzle's durability and the body maintains good thermal conductivity, making this nozzle type the most precise, albeit expensive, option for regular use.

Slicing Software

Choosing the right slicing software for your designs and machine is also paramount. Many users will use Cura as it’s free, easy-to-use, and compatible with a huge range of machines. However, if you’re a professional user you may opt-in to purchasing something more comprehensive like Simplify3D.

For most users a free slicer will completely suffice. However, paid software can help speed up your manufacturing process and optimize the 3D printing process on the whole. When doing large scale additive manufacturing or highly detailed models a paid slicer can save time, costs, and in some cases increase the print quality too.

However, paid software can help speed up your manufacturing process and optimize the 3D printing process on the whole. When doing large scale additive manufacturing or highly detailed models a paid slicer can save time, costs, and in some cases increase the print quality too.

What's the best slicing software to use?

The best free slicer is Cura, and the best paid option is Simplify3D. The fundamental capabilities of Cura typically meet the average hobbyist’s needs. Professionals who benefit from more options should opt for a paid software for higher quality and faster outputs.

Materials Used

When carrying out your design you’ll also need to consider the material that you’ll be printing with. Later on this article we discuss design and production factors that are of significant importance. However, these are recommended with common materials in mind.

For example if you’re using flexible materials, reinforced plastics, or metals the processes and design requirements can be opposite ends of the spectrum.

Design Parameters

Before you print, aim to make your design watertight by eliminating discontinuities on the surfaces of your 3D model

If you're 3D printing a model that you exported from Shapr3D, you can check this off your list! The app ensures solid model design, without non-manifold intersecting surfaces.

If you're modeling using surface modeling software, you'll want to post-process your work, clean up any holes and check for any of the kinds of intersecting surfaces or shared edges (collectively called non-manifold geometries) listed below.

Solid model of a water bottle prototype in Shapr3DManifold geometries

Using manifold geometry makes for a successful print. . An easy way to understand manifold geometry is by understanding non-manifold geometry.

Non-manifold geometry means that when the 3D shape is unfolded, the normals of the 2D shape don't all point in the same direction due to a shared edge or two faces connected at a single point.

Tip: To make sure that your model is printable, check for any of the following errors and adjust them to create a manifold shape:

T-type non-manifold geometry

If three faces share a single edge, make it printable by adding volume to the third face or deleting it completely.

Model of a non-manifold object with connecting faces attached at a shared edge

Bow-type non-manifold geometry

In this instance, multiple surfaces connect at one point and don't share an edge. Either disconnect the two geometries or delete one of them.

Model of a non-manifold object with connecting faces attached at a single point

Non-manifold geometry also occurs when there's a shape without volume.

Open geometry

In order to print a geometry, it needs to have a volume, so a shape with “missing” surfaces or no volume isn't viable. This would be the equivalent of asking your 3D printer to print one straight line and expecting it to come out in 3D.

You can create volume in your model by adjusting the wall thickness or adding additional surfaces to your geometry.

Model of an open geometry without volume that is adjusted for 3D printing by increasing wall thickness and/or adding sides.

Wall thickness

Wall thickness goes hand-in-hand with non-manifold geometries, as we saw above, geometries without volume can't be manufactured. Walls that are too thin make small parts on the model unable to be printed or very fragile, with a high chance of breaking.

Assess your printing material and the height of your wall to determine whether it needs additional support. A wall that's already bolstered by ribs or webs (we'll get to those soon) can be thinner than a freestanding wall.

3D Printing Walls: Exterior, interior and infill layers printed with a thinner layer setting and nozzle size

Tip: Wall thickness should typically be two or three times the nozzle's width. Walls with thicknesses greater than 0. 8 mm can be printed successfully with all processes.

8 mm can be printed successfully with all processes.

Start with a strong base

Adhesion is a huge difficulty with 3D printing. If your model, or even a part of it, doesn't stick directly to the 3D print bed when the first layer is printed, it could detach and warp your print resulting in much plastic, time, and dreams down the drain.

Tip: avoid large flat surfaces and round the corners of your 3D models to enhance the success of a clean print

Printing with too high heat and not allowing the first layer to cool properly will increase the risk of a bulge, and make it hard to fit pieces together. Affectionately named ‘elephant's foot,' this mostly appears with large parts where the weight of the object pushes down on the first layer.

The importance of starting with a strong base;Two 3D prints of the bottom of a water bottle with the version on the right showing a slight bulge, or 'elephant's foot'

Add a ‘raft'

Sidestep this issue by adding a raft for your "foot" to land smoothly on. A raft in 3D printing is a flat surface area made up of horizontal latticework, added beneath your part. It helps eliminate the elephant's foot and improves adhesion to the printer bed.

A raft in 3D printing is a flat surface area made up of horizontal latticework, added beneath your part. It helps eliminate the elephant's foot and improves adhesion to the printer bed.

Work with a ‘brim'

You can also avoid your model tipping overby creating a brim underneath it. A brim is a skirt attached to the edges of the model printed with an increasing number of outlines to create a large ring. Brims create suction and hold down the edges of your part by helping it stick to the bed. They're much faster to print than rafts.

Adhesion Brim Base Support - Adding a brim in Lulzbot's CURA slicer softwareWarm up your nozzle with a ‘skirt'

Finally, you have skirts. Sometimes, an elephant's foot is the result of an unleveled build plate or incorrect nozzle height.

Skirts surround the part, but don't actually touch it, and they help warm up the extruder by establishing a smooth filament flow. By observing the skirt quality, you can adjust any leveling issues before printing your model.

By observing the skirt quality, you can adjust any leveling issues before printing your model.

Tip: Besides printing with a raft, skirt, or brim, you can also lower the bed temperature by 5° C increments or, as a last resort, alter your model by adding a 5° chamfer on the bottom edge of the print to mitigate the bulge.

Overhangs and Support Material

Overhangs are fun to design and hard to print—here's where gravity puts up a fight.

An overhang that stretches out beyond 45 degrees requires you to include supports so that your build doesn't tip or lose form. There's nothing wrong with supports, but unless you print with a soluble material using a dual extrusion printer head, they'll probably leave a mark when you take them off.

Tip: As a good rule of thumb, you can get away with about 1-2 widths of a print path without support. Everything else will require printed support.

While supports are doable, they're not always easy to remove and will likely leave a rough spot or mark on your print.

3D Printing Overhangs - 3D printed model illustrating to what extent overhangs can print without supportsThe image below shows a 'Y' model with arms that begin with an overhang less than 45 degrees. Notice that further up the arms where the overhang reaches beyond 45 degrees and would require supports, the integrity of the print breaks down.

Follow the 'YOTH' rule

- A Y-shaped overhang that’s less than 45 degrees prints easily without any need for support. If it's over 45 degrees, count on adding supports.

- “O” shaped overhangs, or holes in most cases, create more concentric circles with supports included

- "T" shaped overhangs beyond a 1-2 vertical layers require supports

- “H” shaped overhangs depend on the size of the bridge between the two vertical geometries.

Check your printer and print material to see how long of a bridge you can print without supports.

Check your printer and print material to see how long of a bridge you can print without supports.

Designing support Structures in your slicer software

If you do need supports, create them in your slicer software. Here's what that looks like on Lulzbot's free CURA slicer interface.

Basic 3D Printing Supports - Supports designed in Lulzbot CURA's slicer softwareYou can also design custom supports in your modeling software that are easier to snap off and take up less surface area. Conical supports taper at the top to support your print while printing faster and using less material.

Advanced 3D Printing Supports - Conical supports designed in Lulzbot CURA's slicer softwareRegardless of size, removing supports and polishing your prototype will take some work after your print.

Printing holes

Holes are a special kind of 'overhang,' that 3D printers struggle to print. These shapes require the machine to create a round shape by layering materials on top of each other. Because the final layer at the top of your circle will be straight, the end result is a hole that's not quite round and doesn't quite match the diameter of the hole in your model.

3D Printing Holes - 3D printed O 'flat-lining' on topYou can print out the hole with the slightly flatter top, and use a screwdriver or similar tool to round it out after it's finished.

Teardrop and slot designs for holes

To deal with the pesky issue of holes, you can also try designing a few additional tweaks in your model. One alternative is to model a teardrop-shaped hole in your geometry. This way, you can use the hole for its intended purpose without having to drill out the additional layer at the top of the hole.

This technique minimizes the need to use supports, but only when you orient the part facing upwards, which limits object rotation.

3D Printing Holes With Support - If your object has to be rotated in a specific direction a teardrop-shaped hole may not be feasible — in this case, add supports to your holeIn the same vein, you can add a slot underneath a hole that you need to insert a rod into, which allows the hole to expand. Then use two clamps to secure the hole together.

Ribs

If you're printing a piece that has a protruding feature jutting out from the base, you'll run the risk of that piece breaking, even during the printing process.

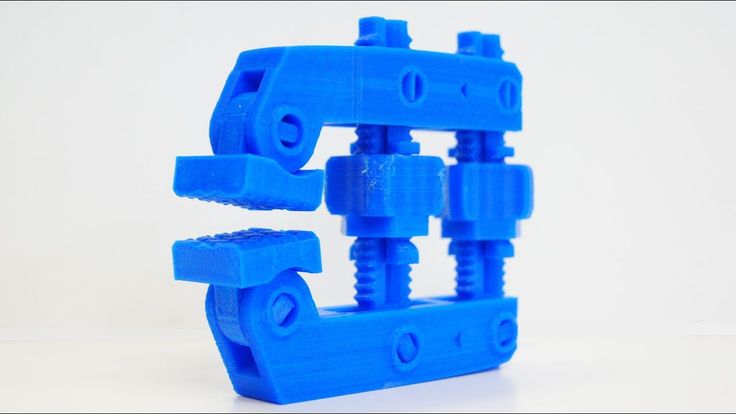

To avoid broken 'arms and legs,' add triangle supports or 'ribs' around protruding pieces to support the base. Ribs strengthen fragile protruding features by supporting perpendicular angles. Without additional support around their bases, these structures are more likely to snap off.

Webs

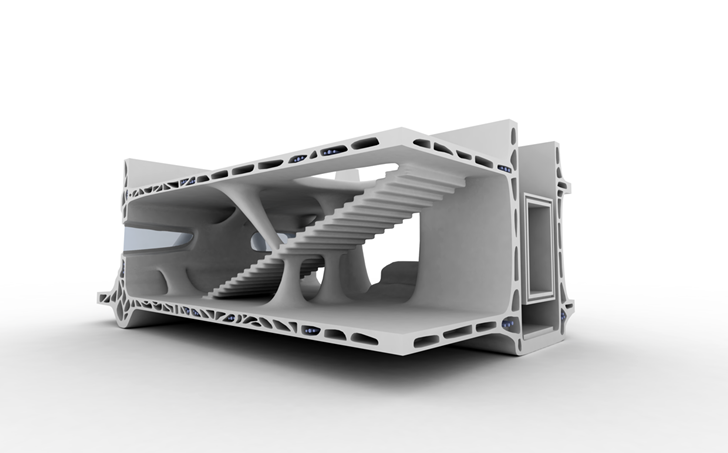

'Webs' are another form of built-in support used to maintain the integrity of shells. They consist of a network of supportive structures and protruding pieces that help a body keep its shape without having to print a solid structure (saving hours, or even days). If you're testing different shapes and ergonomic structures, design webs or infills into your object to speed up the process.

3D Printing With Webs - Solid model of a waterbottle prototype with web support modeled in Shapr3DThreads

The heat naturally occurring during a print increases the difficulty of printing threads by contracting the details and making them unusable for your original purpose. The smaller and more detailed the threads, the more difficult the print

Before printing, add an additional tolerance between 0.5-1 mm to your model to make up for any heat shrink or imperfections. Small blobs on a tight-fitting thread will act like sand in a gearbox, making it impossible to screw the part on.

To create a better thread, round the crest and roots in the design process — sharp edges tend to concentrate stress.

Alternatively, you can design additional ‘dog point' heads onto your screw. This flat, unthreaded tip helps a successful print and is helpful for locating a groove on a shaft. Ensure the length of a dog point head measures at least 0.8 mm.

Model of a Screw With Dog Point HeadInfill

If designing a large part, save both time and material by considering different infill patterns that use less material. You can manipulate these in your 3D printing slicer. Hollow, geometric shapes characterize infill patterns with the density and shape of the infill affecting the strength of the final printed material.

3D Printing Infills - hexagon, honeycomb, concentric circles, and 'wiggle' infills give cost-saving alternatives to solid objectsHexagon or honeycomb infill is the strongest, most efficient infill and also the fastest to print. Honeycomb infills mimic naturally occurring hexagon patterns used throughout nature.

Honeycomb infills mimic naturally occurring hexagon patterns used throughout nature.

Explore printing a ‘wiggle' infill to give your piece a distinct look. Triangular infills have a high lateral load-bearing capability, making it a good choice for bridges.

Part Orientation

The right part orientation improves the strength, appearance, and print time of your piece. To ensure optimal strength, manufacture in additive layers parallel to the layers of your object.

When designing your piece, consider the load-bearing capacity and direction of the parts, and then orient the part accordingly.

As a rule, orient cylindrical features like columns vertically for a smoother surface finish. Orient holes with faces parallel to the XY plane for a better resolution as well.

Orientating Your 3D Print - Printing horizontally versus printing vertically will have a different effect on both the texture and support design of your objectExporting your STL file

When you're exporting a file for 3D printing, always use the highest setting STL file. STL files are a list of triangles, and cannot store separate bodies. As such, an STL export of touching bodies may merge. Make sure to separate each body where possible.

STL files are a list of triangles, and cannot store separate bodies. As such, an STL export of touching bodies may merge. Make sure to separate each body where possible.

For graphics, export in medium or experiment with a low setting. You may need to remesh or generate a quad mesh if the mesh isn't uniform. If post-processing is required, export using the highest setting.

It's time to get your hands dirty

There you have it, the top design considerations to cover before 3D printing your prototype.

To prepare for manufacturing your model and save yourself from shaking your fist at gravity, go through and assess these factors one last time:

- Printing nozzle and material for your use case

- Wall thickness and overhang angles and lengths in your 3D model (and how they'll hold up in your 3D object)

- Model orientation

- Build plate adhesion

- Infill patterns

blog

Download Shapr3D for Windows:

Also available for iPad and Mac and fully supported on Wacom tablets.

Download Shapr3D for iPad:

Also available for Windows and Mac and fully supported on Wacom tablets.

Try Shapr3D

Available for Windows, iPad and Mac and fully supported on Wacom tablets.

What software to use for 3D printing: The complete guide

David Roberson13 May 2021

Guide

Before starting to 3D print, you will need to make sure you have gathered all the necessary software “ingredients” that will guide you through the printing process, from preparing your 3D model to managing printers themselves.

These include:

CAD software to create a 3D model (you can also use an existing 3D model, if you do not wish or need to design one)

Slicing software

Software to operate your printer remotely (this is optional, but can be convenient)

This article will go through each of these ingredients, and will also touch on how the Ultimaker platform creates a seamless end-to-end flow between hardware, software, and materials, empowering you to unlock the magic of 3D printing and make innovation happen.

What is a “slicer”?

A 3D printing slicer – also known as slicing or print preparation software – is a program that converts a 3D model into a language your 3D printer understands.

Slicing software, such as Ultimaker Cura, digitally cuts a model into flat layers, which your printer can then print one by one. With the Ultimaker platform, however, slicing software is not always needed, thanks to integrations that allow you to print directly from CAD or the Ultimaker Digital Library.

Preparing a 3D print using Ultimaker Cura software

What is the best CAD software to design 3D prints?CAD, or computer-aided design, software enables you to design a 3D model from the ground, up. There are many types of CAD software, each with its own benefits. AutoCAD, created by Autodesk, is perhaps the best-known among them since it was one of the first CAD software programs available for personal computers when released in 1982. Other CAD platforms include:

Fusion360 – great for designing and creating efficient mechanical parts

3ds Max – used in all types of 3D model creation, including video game design, architecture, and 3D printing

TinkerCAD – A free, browser-based CAD tool that allows users to build 3D models out of various shapes.

Popular with CAD novices and for STEAM education

Popular with CAD novices and for STEAM educationBlender – free, open-source 3D model creation software

Siemens NX – for designing and creating advanced 3D models

Solidworks – for designing and creating professional parts for industrial use

Catia – Advanced design software used for creating surfaces and engineering systems

Before you begin 3D printing, be sure to do your research and pick the CAD software that’s right for your use case. This way, you’ll get the most out of the model you choose to design and print.

Also check which file types your slicing software is compatible with, so you can make your 3D designs into 3D prints.

A design in CAD software (left screen), slicing software (right), and the finished print

How to design parts for 3D printing?

When designing for 3D printing, there are best practices to help you get the best results from your 3D printer and the parts it creates. Design parts optimized for 3D printing will improve print success rates, reduce costs through lower wastage, and boost the speed of your product development cycle.

Design parts optimized for 3D printing will improve print success rates, reduce costs through lower wastage, and boost the speed of your product development cycle.

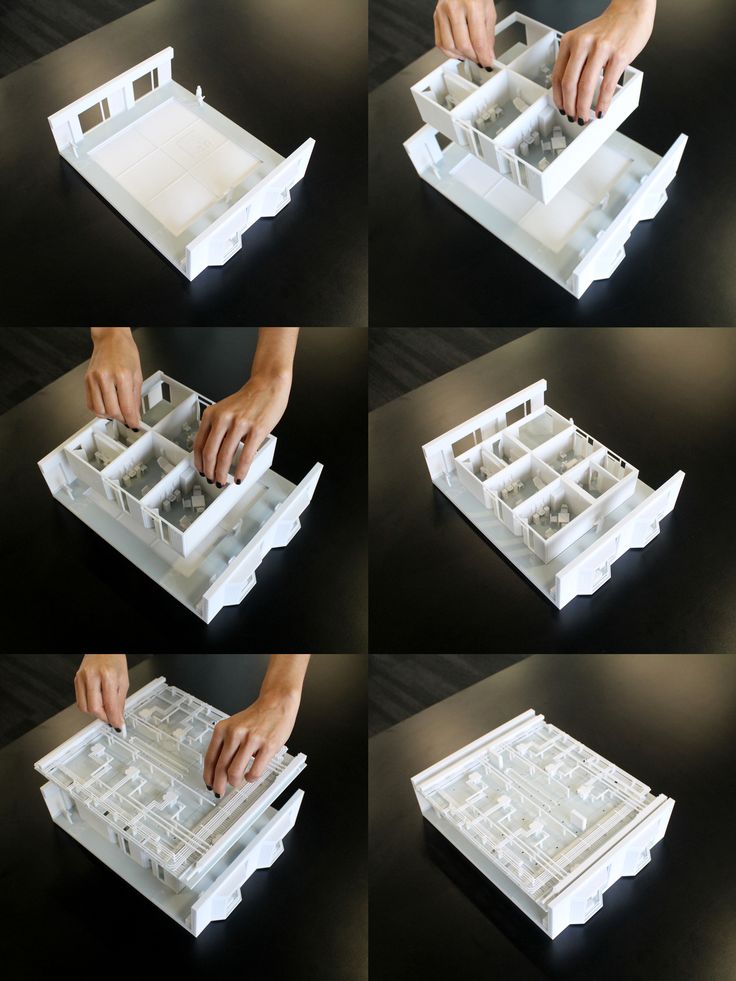

Consider build volume. Your 3D prints can only be as large as your printer’s build volume. Be sure to know its dimensions, then create a part that can either be printed within those dimensions in one go, or plan to use modularity (printing then combining separate parts).

Decide orientation early. Because FFF prints layer by layer, determining the print orientation early in the process helps drive design choices, text alignment, and snap features.

Evaluate overhang support requirements. FFF printed parts are self-supporting up to 45 degrees. Overhangs below 45 degrees must be supported from below with support material.

Follow bridging support guidelines. For most basic filaments, FFF printing does not need support when bridging materials within a 10 mm gap.

Pay attention to nozzle size. When designing small features, you should consider height, wall thickness, and nozzle size. Larger nozzles will print faster than smaller nozzles, but at a cost of increased minimum thickness and height for your models.

When designing small features, you should consider height, wall thickness, and nozzle size. Larger nozzles will print faster than smaller nozzles, but at a cost of increased minimum thickness and height for your models.

Design with hole diameters in mind. Generally, 3D printed hole features should not be smaller than 2 mm. If accurate holes are required, it is recommended to design the holes smaller than intended and post-process with a drilling operation.

Avoid sharp corners. Sharp corners can be modelled in CAD, but the print may warp. Increasing the area of the surface in contact with the bed will decrease the likelihood of the warpage.

For a deep dive into these factors and more, check out our blog on design for 3D printing.

What software do I need to start a 3D print?

This depends on how much of the 3D printing workflow you need to perform.

As long as you already have access to a 3D model, you will typically need software that can slice that model, so your printer can get to work. Once you have started to print, you can also use software to manager your 3D printer (or printers) remotely.

Once you have started to print, you can also use software to manager your 3D printer (or printers) remotely.

But as we saw earlier, the slicing step can be avoided if you have a 3D printer integration installed in your CAD tool. If you already have access to a 3D printable file (such as a G-code on a USB stick) you can also go ahead and print without the need for any slicing software, as your digital file is already ready to print.

Controlling 3D printers remotely with Ultimaker Digital Factory software

Managing 3D printers remotely

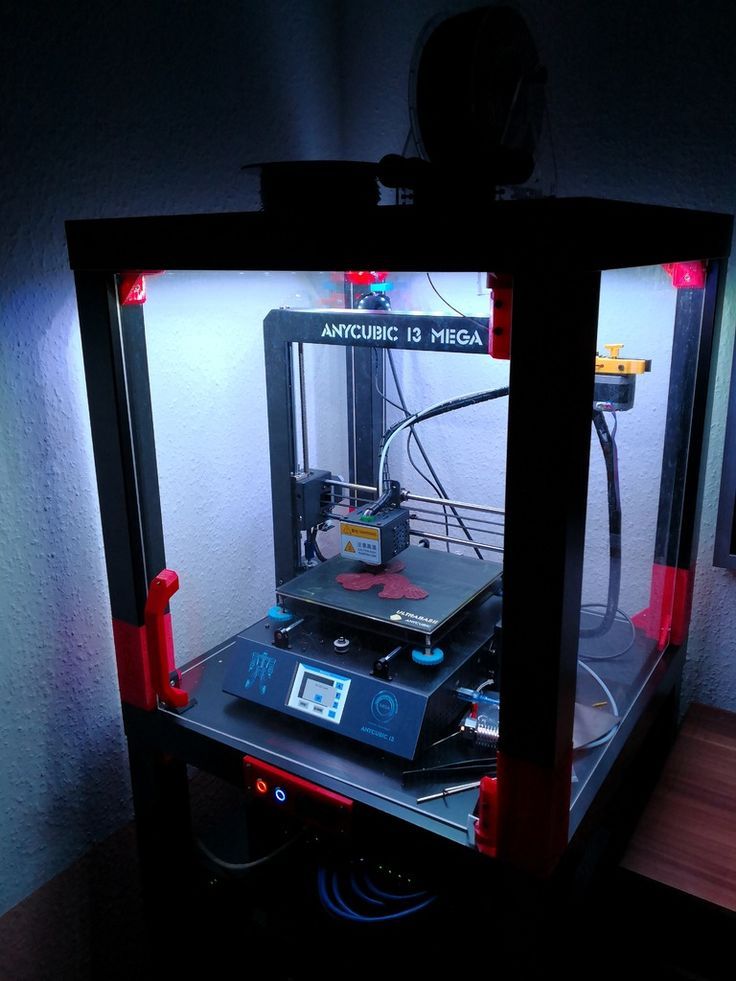

Ultimaker S-line printers, the Ultimaker 2+ Connect, and the Ultimaker 3 can make use of a network connection to access cloud-based services on Ultimaker Digital Factory. By linking a printer to your Ultimaker account, your printer can then be controlled remotely, from outside of its local area network.

Want to learn more about 3D printing software?

Download our free white paper, “Important 3D printing software features,” which will help you determine the best 3D printing software for your business needs, as well as examine settings, print profiles, and other features that can help you get the most out of your printing experience.

Get the white paper

3D printer in design - what designers need 3D printing for

Why 3D printer in design is needed

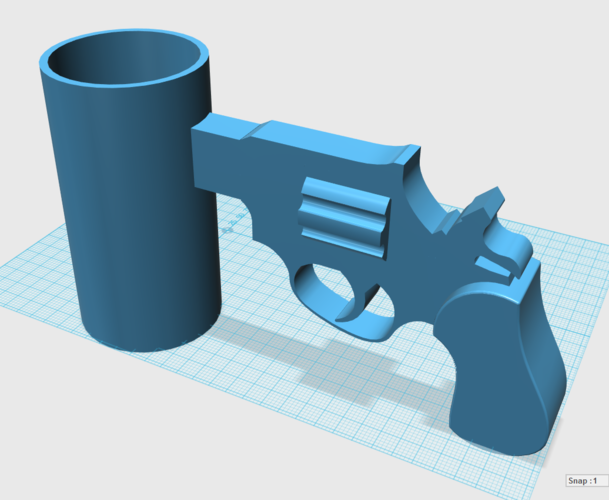

3D printing technologies have found application in almost every industry, opening up new horizons in the production of various products. Designers did not ignore the unique technique, adapting 3D printers to implement their creative ideas. A 3D printer in design is, first of all, a reliable tool in the hands of a skilled craftsman, through which new ideas and concepts come into the world.

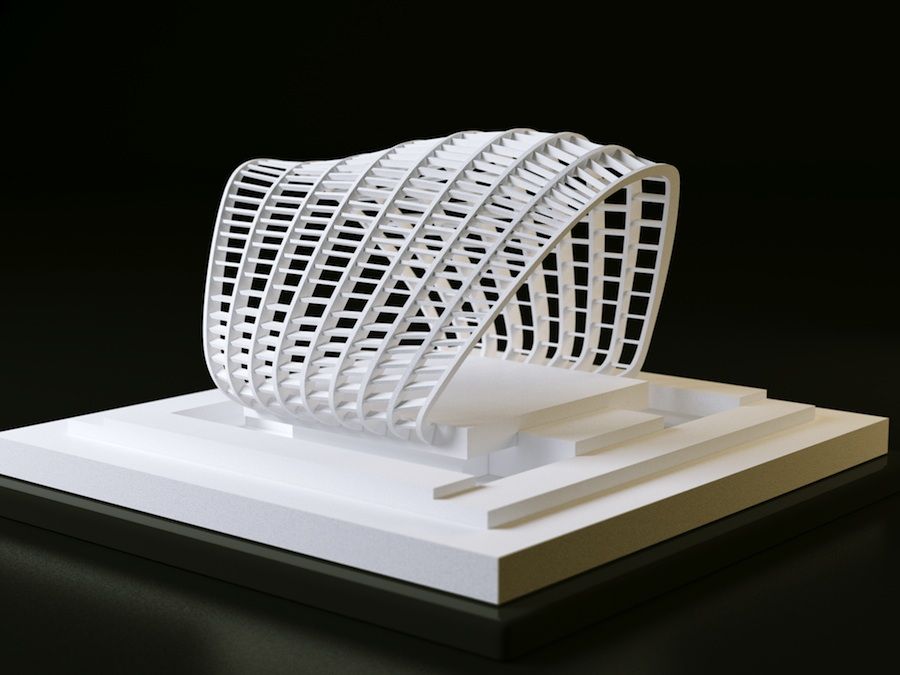

It is with the help of 3D printing that it becomes possible to bring to life the most daring concepts that until then could not go beyond ideas and sketches. A 3D printer in design opens up new horizons for creativity, allowing you to realize your plans in the most unusual way. To do this, designers have all the variety of 3D printing technologies in their arsenal.

3D printing for designers

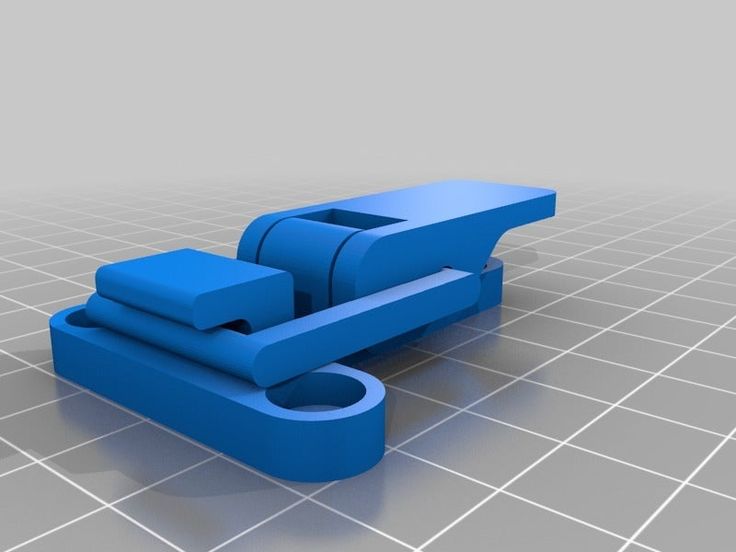

Let's take a closer look at what a 3D printer is for in design. In fact, this device has no specific application. It will become an indispensable assistant both at the stage of creating a conceptual model, and for the manufacture of a full-fledged design product. Benefits of 3D printing:

In fact, this device has no specific application. It will become an indispensable assistant both at the stage of creating a conceptual model, and for the manufacture of a full-fledged design product. Benefits of 3D printing:

- Variety of possibilities. 3D technologies are valued for various advantages, one of which is the ability to produce absolutely any product. Just think: everything that you imagine and can embody in the form of a 3D model will be reproduced in volume using a 3D printer;

- Speed. One of the main advantages of 3D printing, which distinguishes it from traditional production methods. Instead of weeks and months of painstaking work, a 3D printer will print your product in a matter of hours;

- Wide choice of materials. Do not forget about the huge amount of available 3D plastic and photopolymer resins. Each material has specific properties and is suitable for a wide range of applications. In addition, most of them are available in various colors;

- Ability to produce modular structures.

If your ideas are too big, and even the largest 3D printers in existence (not counting construction and robotic arms) are not able to realize them in full size, remember that there is always the possibility of breaking a 3D model into several parts, which will then be assembled together. manually;

- Possibility of post-processing. Most 3D printing methods provide for the possibility of post-processing finished products. That is, if your idea includes coloring the product, you can not be afraid of difficulties in this matter;

- Availability. And the last thing that 3D printers for designers bribe new users to is the affordable cost of 3D printing. The development of large products, as well as objects of an unusual shape, is especially beneficial.

Which 3D printer is suitable for design

Designers have all existing 3D printing technologies at their disposal. Need precision? SLA printing is your choice. Looking for professional quality? Pay attention to the corresponding models of 3D printers. The most affordable option? FDM printing is perfect! Choosing a 3D printer for design should be based on personal wishes and tasks that need to be implemented. Before choosing, it is recommended to study in detail the features of each 3D printing technique, which you can read about here.

And we recommend buying a 3D printer for design in our store. There are many devices for 3D printing for every taste. The store presents FDM and SLA 3D printers, professional devices for 3D printing and 3D metal printers. Here you will find devices with different construction area and printing accuracy. In addition, we offer a wide range of 3D plastics and photopolymer resins. For all questions, write to us by e-mail, or call the numbers listed in the "Our Contacts" section.

Back to Home

Design Trends: 3D Printing | AD Magazine

Design News

This year has seen a real boom in design projects with the direct participation of 3D printers that work real miracles.

This year has seen a real boom in design projects with the direct participation of 3D printers, which work real miracles. Designers actively used the fruits of technological progress, materializing the most unimaginable projects, from underwear and jewelry to ready-to-live-in houses. Summing up, we have chosen the most beautiful of them.

1. The artist Sebastian Errazuriz, in memory of his heartfelt affections, has created a collection of women's shoes with a 3D printer, one pair per novel. Shoes 12 Shoes for 12 Lovers embody the most important thing in each of the artist's women, having lost their direct function (it is not very comfortable to walk in them), but becoming an object of art.

Sebastian Errazuriz; Cubify; The Sugar Lab; Ultravirgo; Albert Sanchez; shapeways; Thiago Mangialardo; Pieter Hoogendoorn; Marko Koops

2. Another collaboration between fashion designer Iris Van Herpen and legendary architect Rem Koolhaas culminates in the creation of shoes inspired by the roots of millennial trees. The project was carried out not without the help of a 3D printer.

Sebastian Errazuriz; Cubify; The Sugar Lab; Ultravirgo; Albert Sanchez; shapeways; Thiago Mangialardo; Pieter Hoogendoorn; Marko Koops

3. At the same time, Janne Kuttanen, a Finn, 3D printing pioneer and creative director of 3D Systems, invited girls to replenish their wardrobe daily by printing a new pair of plastic shoes on a portable 3D printer literally overnight. The designer suggests that very soon home 3D printers will be an everyday reality, but for now, a pair of custom-printed sandals from the CubeX Shoes collection in 6 hours can be ordered on the website. Their convenience is highly doubtful, but this is the first step towards a consumer revolution, as a result of which we will be able to print everything we want, even food, for ourselves. Janne Kuttanen is currently working on this.

Sebastian Errazuriz; Cubify; The Sugar Lab; Ultravirgo; Albert Sanchez; shapeways; Thiago Mangialardo; Pieter Hoogendoorn; Marko Koops

Sebastian Errazuriz; Cubify; The Sugar Lab; Ultravirgo; Albert Sanchez; shapeways; Thiago Mangialardo; Pieter Hoogendoorn; Marko Koops

Sebastian Errazuriz; Cubify; The Sugar Lab; Ultravirgo; Albert Sanchez; shapeways; Thiago Mangialardo; Pieter Hoogendoorn; Marko Koops

4. Young architects in Los Angeles are more concerned with the aesthetic side of the issue - Kyle and Liz von Hasseln, The Sugar Lab, using a 3D printer, use abstract sugar sculptures to decorate wedding cakes and more. Basically, these are complex geometric structures, which you can look at for hours, but it’s scary to touch - even from a light touch, they instantly crumble into sweet dust.

Sebastian Errazuriz; Cubify; The Sugar Lab; Ultravirgo; Albert Sanchez; shapeways; Thiago Mangialardo; Pieter Hoogendoorn; Marko Koops

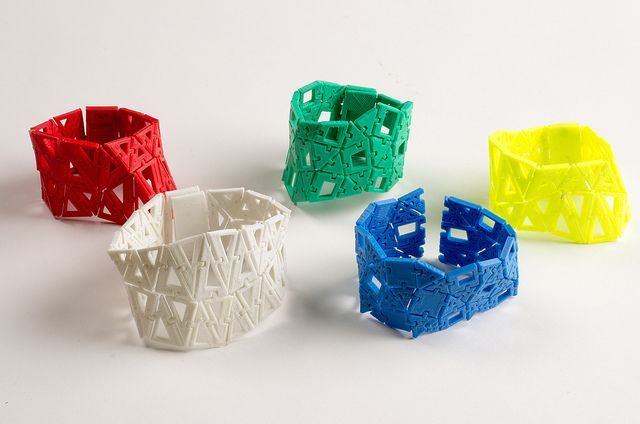

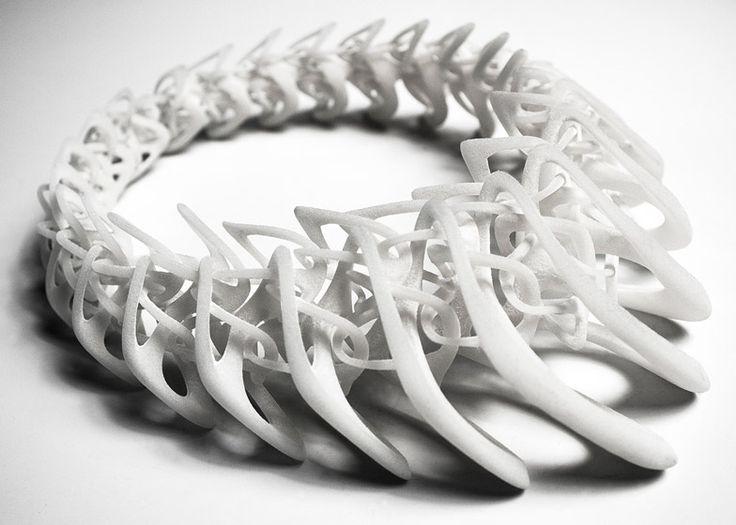

5. London-based architect Daniel Widrig created a cross between jewelry and clothing called the Kinesis collection. The artist made these wearable sculptures in an attempt to understand the unlimited possibilities of 3D modeling and printing. The skeletal object was created on the basis of a scan of the body of a person who would later wear it. So whatever it is, it fits perfectly.

Sebastian Errazuriz; Cubify; The Sugar Lab; Ultravirgo; Albert Sanchez; shapeways; Thiago Mangialardo; Pieter Hoogendoorn; Marko Koops

6. The Ultravirgo studio makes 3D volumetric monograms for an individual order, combining the first letters of two names in a three-dimensional pendant. It turns out spectacularly and inexpensively - jewelry is made of silver or stainless steel.

Sebastian Errazuriz; Cubify; The Sugar Lab; Ultravirgo; Albert Sanchez; shapeways; Thiago Mangialardo; Pieter Hoogendoorn; Marko Koops

7. Three-dimensional printing has given a real carte blanche to fashion designers who rushed to materialize their wildest fantasies, which were previously technically impossible to realize. An openwork Verlan Dress was created by American Francis Bitonti with students using a 3D printer during a summer master class on new design methods and the use of modern technologies.

Sebastian Errazuriz; Cubify; The Sugar Lab; Ultravirgo; Albert Sanchez; shapeways; Thiago Mangialardo; Pieter Hoogendoorn; Marko Koops

In collaboration with Michael Schmidt, Francis Bitonti's Brooklyn studio designed another dress: Dita's Gown for Dita Von Teese, a flexible plastic mesh evening gown worn by the burlesque queen at the opening of a new New York hotel.

Sebastian Errazuriz; Cubify; The Sugar Lab; Ultravirgo; Albert Sanchez; shapeways; Thiago Mangialardo; Pieter Hoogendoorn; Marko Koops

8. The American design studio Nervous System, which has been 3D printing for several years, has come up with jewelry made of small links articulated together, modeled and printed on a 3D printer, using the simplest laws of kinetics.

Sebastian Errazuriz; Cubify; The Sugar Lab; Ultravirgo; Albert Sanchez; shapeways; Thiago Mangialardo; Pieter Hoogendoorn; Marko Koops

9. Even the manufacturers of such a seemingly traditional item of women's clothing as underwear, this year decided on a stunning experiment with modern technologies: the legendary brand Victoria's Secret released one of its angels on the podium during the final show in an openwork 3D outfit of the Snow Maiden. The finest lace shimmering under the spotlights is made of interconnected tiny fractals, hundreds of snowflakes, which conditionally cover the nakedness of the model.

Sebastian Errazuriz; Cubify; The Sugar Lab; Ultravirgo; Albert Sanchez; shapeways; Thiago Mangialardo; Pieter Hoogendoorn; Marko Koops

Sebastian Errazuriz; Cubify; The Sugar Lab; Ultravirgo; Albert Sanchez; shapeways; Thiago Mangialardo; Pieter Hoogendoorn; Marko Koops

10. Brazilians Estudio Guto Requena brought sound to life. Their Noize chairs are the noise of the city, the sounds of mobile phones on the streets of São Paulo, loaded into a computer program that transforms them into a visual relief, and printed on a 3D printer.

Sebastian Errazuriz; Cubify; The Sugar Lab; Ultravirgo; Albert Sanchez; shapeways; Thiago Mangialardo; Pieter Hoogendoorn; Marko Koops

11. Ivan Sench has always loved expensive vintage cars, but he couldn't afford them. With the advent of the 3D printer, his life has changed - there is now a 1961 Aston Martin DB4 in the garage. True, this is just a model, it is not yet on the move and is far from perfect. But Ivan Sench is not upset, continues to work and is sure that soon 3D printers will be able to make any dreams come true.

Sebastian Errazuriz; Cubify; The Sugar Lab; Ultravirgo; Albert Sanchez; shapeways; Thiago Mangialardo; Pieter Hoogendoorn; Marko Koops

12. 3D printing is not only for industrial designers, fashion designers and jewelers. Architects also see great potential in the new way of materializing objects. For example, the Dutch architectural bureau Janyap Reussenaars Universe Architecture plans to implement a project called The Landscape House over the next year, the world's first residential building built using 3D printing technology.