Renishaw 3d printer price

Metal 3D printing

Metal 3D printing Skip navigationRenishaw is a systems manufacturer and solutions provider for additive manufacturing (AM).

Additive manufacturing with Renishaw

Renishaw is a leading manufacturer of advanced metal additive manufacturing systems and expert provider of customer-tailored solutions.

Renishaw's expertise

We design and manufacture additive manufacturing systems for manufacturing components in a variety of metals using a process called metal powder bed fusion (or laser melting). Our expertise in process development and our experience in using the technology in our own manufacturing operations enable us to provide turn-key and optimised additive manufacturing solutions for a broad range of applications in the industrial and healthcare sectors. Find out more about additive manufacturing systems and services for your industry...

What is AM?

Additive manufacturing (AM), also called 3D printing, creates a three-dimensional part from a digital file.

Thin layers of material are used to create complex shapes which cannot be produced by 'traditional' techniques such as casting, forging and machining.

AM provides new design possibilities, including opportunities to combine multiple components in production, minimise material use and reduce tooling costs.

Additive manufacturing products

Total solutions for metal additive manufacturing.

Find out more

Industrial applications

Learn about products and services for applications including aerospace, automotive, tooling and creative industries.

Find out more

Healthcare applications

Discover what additive manufacturing can bring to dental and maxillofacial applications.

Find out more

Solutions Centres

Your pathway to innovative additive manufacturing (AM).

Learn more

Our technology

Learn about our metal powder bed technology and how it can benefit your business

Find out more

Case studies

Learn more about how others have used additive manufacturing in a variety of applications and industries.

Learn more

AM Guide

Your guide to additive manufacturing. View feature articles, white papers, presentations, videos and more.

Browse the AM Guide

Metal additive manufacturing technology

Learn about our metal powder bed technology and how it can benefit your business.

Discover our technology

Where we specialise

Performance

Improving the predictability of additive manufacturing to create a consistent and stable process boosts process throughput and the delivery of functional parts.

Safety

When you own or operate an AM system, you are responsible for safety. With Renishaw, you can be confident that you have chosen a supplier whose equipment meets the highest standards, so that your processes and procedures offer appropriate levels of protection.

Innovative processes

Our additive manufacturing (AM) solutions enable the production of lattice structures, and part consolidation for lightweighting, complex internal galleries to optimise fluid flow, and design for AM (including topological optimisation).

Solutions Centres

Renishaw Solutions Centres provide a secure development environment in which you can build your knowledge and confidence using additive manufacturing technology.

How can we help you?

Get in contact with your local office to find out more information or to tailor a support package to your exact requirements.

Contact us

Rapid prototyping bureaus

Providing versatile systems to enable you to consult, design and build precision finished parts from a variety of materials for your customers. Renishaw's end-to-end solutions enhance any additive manufacturing service bureau's capabilities.

Product owners and designers

Metal additive manufacturing allows metal parts to be built without the need for traditional tooling and with few limitations in geometry. Equally, it is complementary to traditional subtractive methods and can be readily integrated into existing production operation.

Research and education

Renishaw partners with many universities, researchers and academic institution on metal additive manufacturing projects.

The open parameter ethos for materials used on our systems helps to encourage development of parameters for new materials.

Manufacturers and subcontractors

Developing additive manufacturing capabilities can be the natural next step in developing your company's manufacturing capabilities.

Renishaw is an experienced adopter of additive manufacturing as a complementary process to its conventional manufacturing operations.

Want the latest industry insights?

Your industry-focused resource for expert advice, professional solutions and practical guidance on all things additive manufacturing.

Browse the AM Guide

Stay in touch

Connect with us on LinkedIn, keep up to date with the latest news about additive manufacturing

Follow us on Twitter and receive updates about news, events and products

YouTube

Watch the latest videos from Renishaw relating to additive manufacturing

Follow us on Facebook and receive updates about news, events and all things additive manufacturing

RenAM 500 metal additive manufacturing (3D printing) systems

Scale from lab to volume production with the RenAM 500 series of additive manufacturing machines

The RenAM 500 series provides the complete platform for scaling your AM application.

Configurable with one (500S) or four (500Q) high-power 500W lasers, and automatic or flexible (Flex) powder and waste handling, utilise the same industry leading gas flow system, safety and precision digital optics from material proof of concept all the way to volume production.

Introducing the new RenAM 500 Flex

The new Flex range features the same industry leading optical, chamber and gas-flow design as the rest of the RenAM 500 series and so produces the same high-quality parts, but with additional flexibility when changing powder. You can quickly change powders in-house, to meet demand, and parameters and material properties transfer seamlessly between systems thanks to the common build environment.

Uniquely, if you no longer require a flexible AM system, the powder system can be converted to automatic sieving and recirculating for volume production.

With the RenAM 500 series, each stage of the lab to volume production can be performed on a single machine platform and upgraded as your application requires, ensuring seamless transition to volume manufacturing.

The RenAM 500 series features a build volume of 250mm x 250mm x 350mm.

Lab - material prove out

With the Reduced Build Volume (RBV) accessory fitted to a RenAM 500 system, material prove out can be performed with as little as 0.25 litres of powder, with the same processing environment and optics as the fullscale production system.

Isolated powder handling eliminates contamination risk, enabling rapid multi-material development.

With Renishaw's open parameter ethos, you have freedom to optimise machine settings to suit the material being processed and your specific geometry.

Pre-production - part prove out

With the new RenAM 500 Flex, available with one or four lasers, you can access every part of the powder system, enabling streamlined switching between materials. The gravity fed powder system can be topped-up during a build without opening the chamber door, and dosing can be adjusted mid-build.

With full build volume capability, the same industry leading gas flow system and precision optics as the rest of the RenAM 500 series, any part development can be directly transferred to other RenAM 500 series systems.

A Flex system can also be converted to have on-system powder sieving and recycling - boosting productivity on the same qualified machine.

Volume manufacturing - productivity focus

With four lasers that can address the entire powder bed, automatic powder recycling and patented vacuum atmosphere preparation, the RenAM 500Q can build up to 150 cc/hour. Coupled with a compact footprint, the system delivers standout cost savings for metal component volume production.

The RenAM 500 series supports Industry 4.0 workflows, with optical and system process monitoring, and connection to Renishaw Central production management software.

Core features of the RenAM 500 series

Common to all RenAM 500 series machines is the same industry leading gas flow system, precision dynamic control and software for connected digital workflows.

Intelligent gas flow system

The RenAM 500 series features a high-volume cascading gas system which provides uniform processing conditions as well as superior removal of process emissions from the laser path. The gas circuit includes an intercooler which provides active thermal control, even with 2kW of laser power available. Precise thermal management further contributes to the stable atmosphere and consistent build environment that leads to better and more consistent metallurgy.

The gas circuit includes an intercooler which provides active thermal control, even with 2kW of laser power available. Precise thermal management further contributes to the stable atmosphere and consistent build environment that leads to better and more consistent metallurgy.

Renishaw's dual SafeChange™ filter system efficiently removes process emissions from the gas stream, enables tight control over system pressure loss, and helps precisely maintain optimal gas flow. Individual filters can be swapped out mid-process without interruption and the intelligent pre-conditioning system will ensure no disruption in build conditions.

The RenAM 500 series' fully sealed vacuum chamber enables Renishaw's patented atmosphere generation system to quickly prepare a high purity argon build environment with minimal gas consumption. The combination of vacuum purging and high integrity system sealing also maintains powder quality and increases longevity.

High precision dynamic control

The RenAM 500 optical system features dynamic focusing, enabling all lasers to precisely address the entire bed simultaneously. This flexibility ensures build times are minimised by enabling the laser energy to be optimised over the entire powder bed.

This flexibility ensures build times are minimised by enabling the laser energy to be optimised over the entire powder bed.

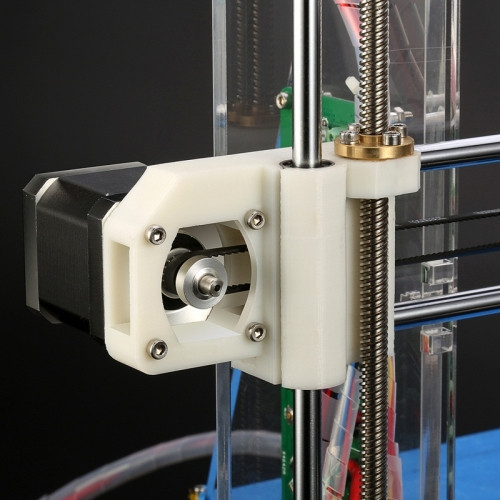

The system uses a monolithic water-cooled additively manufactured galvanometer mounting, designed and manufactured in-house by Renishaw. Unlike separate mountings found on other multi-laser AM systems, the RenAM 500 series design features tight alignment of the optics and internal conformal cooling channels. This is a key enabler for precision laser control.

Harnessing Renishaw's industry-leading metrology technology, the RenAM 500 series features a RESOLUTE™ optical encoder with a 1 nm z-axis resolution for high accuracy positional sensing.

The kinematic recoater mounting ensures rapid and repeatable positioning of the powder spreading recoater blade. Together, these features help maintain a precise relationship between the optical system and the working plane, which is vital for accurate part manufacture. The flexible recoater blade is forgiving for both solid and lattice geometry manufacture.

Exceptional metallurgical performance

The intelligent gas flow and precision control of the RenAM 500 series enable production of components with >99.9% density, maximised strength and ductility.

The uniform extraction of process emissions, exceptionally low oxygen and moisture content, and consistent optical control, eliminates sources of chemical, micro-structure or mechanical defects.

Download the material datasheets to see representative mechanical properties of the wide range of supported metal powders.

Smart manufacturing technologies

Intelligent sensing technology is utilised throughout the RenAM 500 series, with software solutions tailored for exploiting the benefits of Industry 4.0.

Embedded in the in-house designed optical system are LaserVIEW and MeltVIEW hardware which provide high bandwidth monitoring of both the output laser intensity and optical emissions from the AM process across the near-infrared spectrum. CameraVIEW provides layer-by-layer images for powder dose monitoring.

This rich process monitoring data can be visualised, compared and further data processed in near real-time through Renishaw's InfiniAM software suite. The voxel-based visualisation toolset enables high resolution analysis of each component weld as well as powder dose. As part of Renishaw's open ethos, the software architecture supports user plugins, enabling custom algorithmic manipulation of the data to suit research and production environments.

Renishaw Central, our manufacturing data platform, provides real-time connection to monitor, record and analyse RenAM 500 series sensor data, as well as Renishaw's portfolio of industrial metrology products. Through the web interface, or mobile app, you can monitor in-progress atmosphere, powder and temperature data from the machine, or drive insight through historic build analysis.

As well as supporting standard connection interfaces such as MTConnect, Renishaw Central is built as an API that can be directly consumed into existing ERP and MES software.

In support of your preferred digital workflow, Renishaw's AM build preparation software QuantAM is available as a Post Processor in a wide range of industry leading CAD/CAM packages, by direct consumption of the API, or as a standalone application. The standalone application offers a stage-based workflow to easily guide users from parametric or triangulation CAD, through orientation, support generation, build layout and slicing. All print settings are open and editable by default, with design-of-experiment tools ideal for custom material optimisation.

Configurable powder management

The RenAM 500 series can be configured with either closed loop powder recirculation or an open gravity fed system. Coupled with four high powered lasers addressing the entire build volume, powder recirculating reduces operator intervention and delivers ultra-productivity and lower part costs for volume production.

The open gravity fed system (Flex) has a simplified powder pathway, which is suited to users who want to regularly swap build materials. All elements of the powder module can be quickly cleaned or replaced to prevent material cross-contamination. RenAM 500 Flex systems can be converted in-situ to have powder recirculating, enabling seamless transition between material research and production phases of application development.

All elements of the powder module can be quickly cleaned or replaced to prevent material cross-contamination. RenAM 500 Flex systems can be converted in-situ to have powder recirculating, enabling seamless transition between material research and production phases of application development.

Find out more

Explore the possibilities presented by advanced additive manufacturing by visiting our AM guide to learn more about how we make exceptional quality cost-effective components, or read case studies from RenAM 500 series customers.

Visit the AM guide Read case studies Find your local office Contact us

Finance options

Renishaw's in-house finance options are simple and competitively priced, enabling you to choose the most appropriate solution for your business.

Learn more

Fixed monthly costs to match your cashflow requirements.

A hire purchase/capital lease agreement with Renishaw provides all the benefits of ownership without the initial capital outlay. After a deposit you pay regular instalments covering capital repayment, interest and maintenance.

After a deposit you pay regular instalments covering capital repayment, interest and maintenance.

Operating lease for additive manufacturing equipment

Low monthly payments, no disposal worries and a purchase option at the end of the agreement. An operating lease gives you maximum flexibility.

Learn more

Additive manufacturing systems

- Metal additive manufacturing systems

- Laser melting systems software

- Additive manufacturing solutions centres

- Metal powders supply

- Ancillaries

- Application and product training

Renishaw plc 3D printers

Application

Application

Professional

Industrial

Personal

Commercial

3D printer type

3D printer type

Tabletop

Food

Professional

For home

Chocolate

Jewelry

Russian

Reprap

Dental

Full color

Industrial

Not expensive

Medical

For training

Material type

Material type

Plastic

606

Metal

50

Photopolymer

245

Other

144

Manufacturer

Manufacturer

3D Systems

84

PICASO 3D

8

Stratasys Ltd

38

Leapfrog BV

6

EnvisionTEC

51

Myriwell

4

3D-Experts

3

PrintBox3D

4

FELIXrobotics

11

Solidoodle

8

WANHAO

32

ROKIT

5

SeeMeCNC

4

mUVe 3D LLC

1

RepRapPro

5

Formlabs

9

Afinia

1

Airwolf 3D

6

Type A Machines

2

iRapid

1

RoBo 3D Printer

3

Mixshop Inc

4

IonCoreLtd

1

Old World Laboratories

1

XYZprinting

13

Panowin Technologies Co. , Ltd.

, Ltd.

2

MiiCraft

7

Portabee 3D Printer

2

Zeepro

1

Pirate 3D

1

Qualup SAS

2

BEETHEFIRST

3

Heacent

2

Robot Factory

2

Kuhling&Kuhling

1

3Dfactories

3

Tangible Engineering USA Corporation

1

DWS Lab

1

Sedgwick

2

3DJoy

4

Futura Elettronica

1

Makible Ltd

2

ALT Design

1

Active 3D

2

Trinitylabs

1

Sumpod Ltd.

4

Brahma3

1

Hyrel 3D

5

Omni3D

4

BCN3D Technologies

7

Boots Industries

2

ORD Solutions

2

Ironvault

1

2PrintBeta

3

Unique Design

3

Hot Proceed

1

3DD Plas

2

York3dPrinters

1

Code-P

4

Deezmaker

3

Ruian Maitian Network Technology Co

2

CB-Printer

1

Print Technologies Pty Ltd.

5

MaukCC

1

Choc Edge Ltd

2

Shenzhen WeisTek Co.,Ltd

5

Delta Tower

2

Tegelbeckers Ltd

1

Deltaprinter

1

MindKits

1

Robot Co, Ltd

1

Romscraj

2

Fabmaker

1

Peerbhai Robotic

1

Sintermask GmbH

1

KL Services Group Inc

1

Fochif Mechatronics Technology Co. , Ltd

, Ltd

4

Teil3

1

Maker's Tool Works, LLC.

2

Gaminu

1

re:3D

1

inDimension3

4

Acuity Design

1

Essential Dynamics

1

Isis3D

1

Velleman

1

Kentstrapper

4

Blue Eagle Labs

1

Gubbels Engineering

2

Zortrax

8

3dBotic

1

MakerGear, LLC

1

Jelwek

1

it is 3D

2

Cablysa Systems, S. L.

L.

3

Ac123Dc

1

E3D Online

1

Hydraraptor

1

MakerBot Industries, LLC

8

Delta Micro Factory Corporation

3

Ultimaker B.V.

11

Solidscape Inc.

8

MBot3D

4

B9Creations

4

Jinhua Flashforge Technology Co., Ltd

26

Tinkerine Studio Ltd

3

Aleph Objects Inc.

4

DeltaMaker

1

Reprap Austria

3

IC3D LLC.

1

Ultibots, LLC.

2

Intelligent Machine Inc.

1

Metamaquina

1

Shenzhen Mootooh Engineering Co., Ltd.

1

Multitec GmbH

3

German RepRap GmbH

3

Sharebot

17

Nova 3D

1

QU-BD Inc.

4

RDMCU

1

Full Spectrum Laser LLC

1

PieceMaker Technologies

1

Printbot, Inc.

7

Terawatt Industries

1

botObjects

1

Lunavast

2

Maker Farm

3

NWRepRap

1

eMotion Tech

1

Printed Worlds

1

Reprapsource

1

Twelvepro Co

1

Replicator Warehouse

1

Stellamove Inc.

1

Make Mendel

6

Rapide 3D

2

Makealo

1

Crew Ltd.

1

Open cube

1

3D Kits

1

Coombes Solutions Ltd.

1

SHARK Limited Partnership

1

Smartfriendz

1

3D Monster

1

Kikai Labs

2

THY3D

1

Tantillus

1

RepRap Diffusion

1

QSQM International Co.

1

Tumaker

1

Makism 3D Corp.

3

3dBotZ

1

ZMorph 3d

1

Eckertech Inc.

1

Imec Proto

6

miniFactory Oy Ltd

1

printMATE 3D

1

CMET Inc.

5

Arcam AB

6

3Geometry Manufacturing Systems Pvt Ltd

8

Electro Optical Systems

15

Trump Precision Machinery Co. , Ltd

, Ltd

4

Wuhan Binhu Mechanical & Electrical Co., Ltd.

11

Optomec Inc.

1

Shaanxi Hengtong Intelligent Machine Co., Ltd.

9

Matsuura Machinery Corporation

1

ExOne Company, LLC

6

Concept Laser GmbH

9

Instrument Tech Co, Ltd

7

UnionTech

8

Renishaw plc

2

D-MEC Ltd.

3

Realizer GmbH

5

SLM Solutions GmbH

5

Fabriconic LLC

3

Mark Forged

8

Keyence Corporation

2

SYS + ENG

1

Lithoz GmbH

1

DWS s.r.l.

12

Beijing TierTime Technology Co. Ltd

17

Carima

3

Mcor Technologies Ltd.

3

Asiga

11

Rapid Shape GmbH

14

solido ltd.

1

Blueprinter ApS

1

Kevvox Pte Ltd.

2

JER Education Technology Co., Ltd

1

Azuma Engineering Machinery Inc.

2

Space Monkey

1

Trimaker

1

Most Fun

1

Iniciativas 3D

1

IdeaLab 3d

1

MendBot Labs

Bonsai Lab

2

MakerDreams

1

i3Dbot Co. , Ltd

, Ltd

2

Natural Machines

1

Cyrus3D

ITALYmaker

Something3D

Cagelli Distribution

E Crew Vis

BigRep GmbH

2

Voxeljet Technology GmbH

5

Sciaky Inc.

Mankati

4

F&B rapid production

3

3DQuality

17

Workshop Churyumov

2

Unimix

2

Center for Additive Technologies

3

ENNOVA

1

Exclusive Solutions

2

Magnum

5

SHEKLA

1

D-Force

3

BigRep

4

Roland

1

Alphabet 3D

2

MAKEX

1

3D Master Kit

7

Shining 3D

25

3NOVATICA

3

AVS Robotics

1

IMPRINTA

11

Createbot

5

AIO Robotics

1

RK-3D

1

SPETSAVIA

3

3DiY

14

Wonwall

1

Apium Additive Technologies

3

3DSUN

1

Cheap3D

1

3rd

1

EGL3D

1

Creality 3D

42

UNIMATECH

2

VolgoBot

3

ZVER 3D

3

Zenith

2

MicroFactory

1

Hewlett Packard

2

Shenzhen Anet Technology Co Ltd

15

MASS PORTAL SIA

11

Cyberon

2

PHOTOCENTRIC

2

TotalZ

11

3dcon

2

Raise3D

6

OOO RUSSIAN ENGINEER

1

Vortex-3D

5

Flying bear

11

Print3D

5

ROBOINO

1

SoloPrint

1

Fun Distribution

1

Alekmaker

2

Cronos

2

TEVO 3D

9

3D printers from China

2

ZAV 3D printer

4

Epo3d

1

FLSUN 3D

3

WINBO

19

PROTOTYPE

1

UNIZ TECHNOLOGY

2

W2P Engineering GmbH

4

MAESTRO

1

Pi 3D printer

1

Shenzhen Tronxy Technology Co

23

Kelandi

1

Geeetech

21

3DCeram

2

Omaker

1

Builder 3D Printers

6

Creatable Labs

1

ROBOZE

3

Desktop Metal

1

Sintratec

2

CreatBot

10

ANYCUBIC

29

3dlaboratorio

2

OOO SPC "Lasers and Equipment"

2

Prusa Research

6

Prismlab

3

ivilol

2

Geralkom-3D

7

EqMex

1

Tsar3D

2

Zhuhai CTC Electronic Co. , Ltd

, Ltd

3

Shenzhen Aurora Technology Co., Ltd

6

Monoprice

1

Shenzhen Salon Technologies Co., Ltd.

1

Shenzhen Sundystar Technology Co., Ltd

2

Shenzhen Easythreed Technology Co., Ltd

1

WOW Innovation Technology Co., Ltd.

2

Jinhua Xingzhe 3D Technology Co., Ltd

1

Shenzhen Zhongxin Microscience Software Co., Ltd.

1

Shenzhen Yaying Trading Co. , Ltd

, Ltd

5

Z Bolt Co.

2

Anisoprint

1

Shanghai 3D ARTEL Science and Technology Co.

3

FABERANT 3D printers

1

Self-assembly 3D printers

4

Z Rapid Tech

21

Zonestar

13

3DGence

3

BLB Industries

1

Hard Light

1

Stereotech

2

TPM3D

7

Artillery

4

Phrozen Tech Co. , Ltd.

, Ltd.

8

INDIGO 3D

1

Aconity3d

6

OR Laser

3

Farsoon Technologies

5

QIDI Technology

11

Shenzhen Twotrees Technology Co., Ltd.

7

Mingda

18

Elegoo

14

Longer

9

Sunhockey

2

DUPAS3D

1

Kelant

5

Voxelab

3

DIYMARIA

1

VSHAPER

CREASEE

CNC Barcenas

5

Vistar

11

Kingroon

1

IdeaFormer

3

F2 Innovations

3

Sindoh

8

Eplus3D

8

Print Technology

Print Technology

Plastic Jet Printing (PJP)

8

MultiJet Modeling (MJM) Technology

1

SLA printing technology

Sterolithography (SLA) technology

2

Film Transfer Imaging (FTI)

MultiJet Printing (MJP)

20

Multi-Jet Modeling (MJM) Technology

2

Stereolithography (SLA)

115

Selective Laser Sintering (SLS)

65

Direct Metal Sintering (DMS)

6

Granular

5

Fused deposition modeling (FDM/FFF)

962

DoD/SCP Technology

6

PolyJet 3D printing Technology

19

The EnvisionTEC 3D-Bioplotter 3D printing technique

2

Direct Light Projection (DLP)

31

Photopolymerization

Digital Light Projection (DLP)

5

Digital Light Processing (DLP)

64

Additive Layer Manufacturing (ALM)

2

Laser Stereolithography (LSLA)

1

Direct Light Processing (DLP)

1

Electron Beam Melting (EBM)

6

Laser welding CLAD

6

Laser sintering (LS)

4

Layer by layer manufacturing (LOM)

5

Selective laser melting (SLM)

31

Laser Engineered Net Shaping (LENS)

1

Direct Metal Laser Sintering (DMLS)

11

Laser metal melting (LC)

10

Direct Metal Tooling (DMT)

7

Solid Creation System (SCS)

3

Ultrasonic Additive Manufacturing (UAM)

3

Composite Filament Fabrication (CFF)

1

Drop on Demand (DOD)

1

Lithography Ceramic Manufacturing

1

Melted and Extruded Modeling (MEM)

7

Drop-On-Demand (DOD)

Sliding Separation Process (SSP)

9

Smooth Curvature Printing (SCP)

2

Plastic Sheet Lamination (PSL)

1

Selective Heat Sintering (SHS)

1

ColorJet Printing (CJP)

7

Micro-SLA

1

DLP-SLA

3

WDM (Layer Waxing)

2

SLA-sla

Direct Metal Printing (DMP)

7

HP Multi Jet Fusion technology

2

3D Daylight Polymer Printing (DPP)

2

Smart-Positioning-System Technology (SPS)

2

LCD Stereolithography

62

UV LED DLP

4

Single Pass Jetting (SPJ)

1

Atomic Diffusion Additive Manufacturing (ADAM)

1

bioprinting

3

Powder Binder Jetting (PBJ)

10

Reset Filters

Sprint 3D High Precision Aluminum 3D Printing!

aluminum 3D printing is a relatively new technology in the production of high strength metal products. Using aluminum alloys, you can create almost any product - from home decor and souvenirs to parts of industrial equipment or even aircraft.

Using aluminum alloys, you can create almost any product - from home decor and souvenirs to parts of industrial equipment or even aircraft.

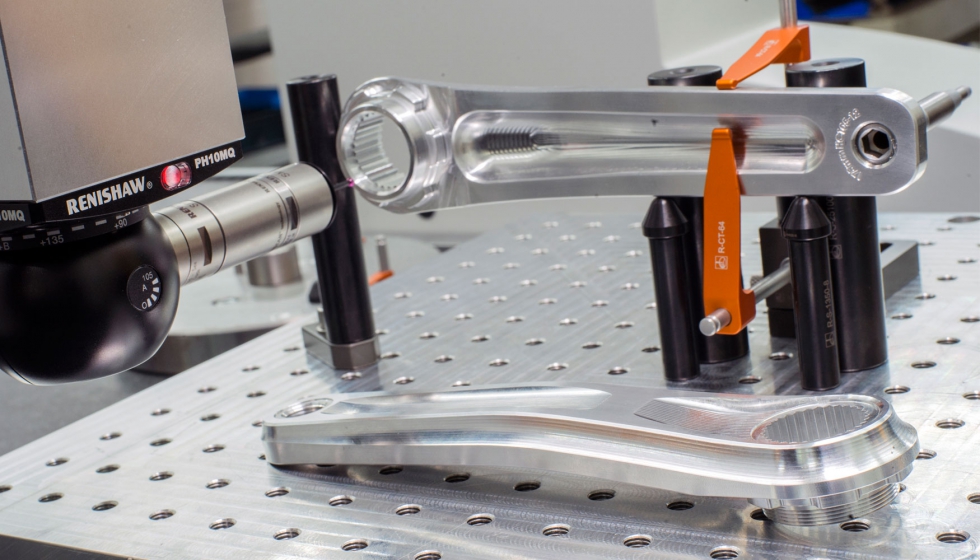

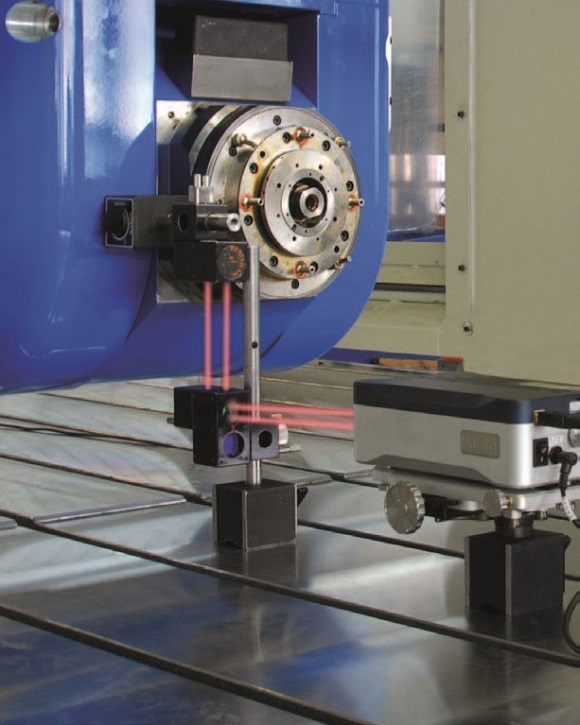

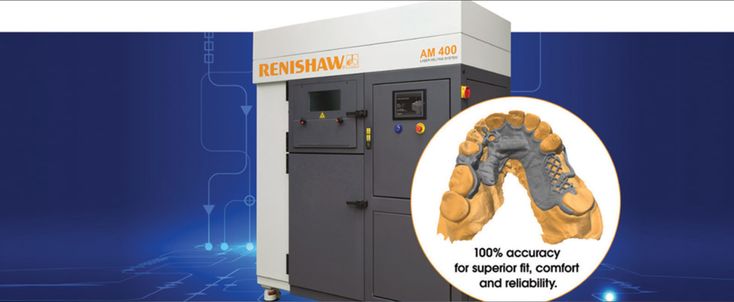

SPRINT3D is already using 3D printing technology with aluminum for its customers. We use the latest equipment - 3D printer for printing from aluminum Renishaw AM400 (SLM), which allows growing products of almost any complexity based on metal powders.

We invite you to learn more about aluminum 3D printing, features and benefits.

Why aluminum 3D printing is a new step in production

First and foremost are the materials used. Not just powdered aluminum is used. The material itself is quite malleable. But when nanoparticles are mixed with raw materials, crystallization occurs, which greatly increases the strength of finished products and prevents the formation of cracks during their hardening.

For the first time, the technology was successfully applied in the aerospace segment.

It was practically inaccessible to the general public. Commercial/Industrial aluminum 3D printer is a new phenomenon. But even today it solves the most difficult tasks:

It was practically inaccessible to the general public. Commercial/Industrial aluminum 3D printer is a new phenomenon. But even today it solves the most difficult tasks:

- Allows small-scale production of metal products. The main advantage is high geometric accuracy, which was previously unavailable.

- Suitable for low volume production and prototype printing. For example, to check the ergonomics of the product and carry out the necessary checks.

- This is the best choice for tool making. Complexity, dimensions, geometry - everything is individual.

We use the most suitable production material, aluminum alloy AlSi10Mg-0403. It contains aluminum alloyed with silicon (no more than 10%), magnesium, and other components in small quantities. Thanks to silicon, the alloy becomes much stronger than pure aluminum. In addition, an oxide layer is formed on the surface of the printed products, which has increased corrosion resistance. It can even be enhanced using chemical anodizing technology.

It can even be enhanced using chemical anodizing technology.

4 key benefits of

3D printing with aluminumThere are many more benefits, but we will focus on the main ones:

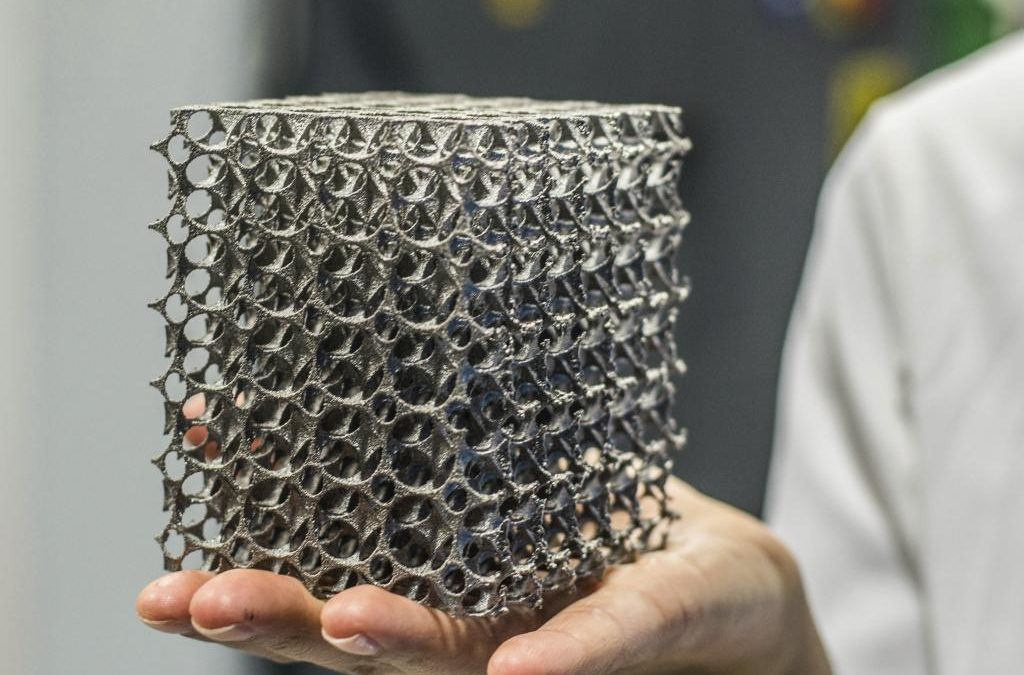

- Increased flexibility in design and production. For example, the technology allows the creation of complex internal channels, mesh structures and bionic elements. Previously, this required the serious work of specialists and the introduction of expensive technologies into production.

- Short design and production times. 3D printing with aluminum is much easier and faster than creating similar products with other methods. First of all, due to the maximum automation of the process.

- Reduced finished weight. Similar blanks made using other technologies weigh more. This puts some restrictions in terms of operation and their implementation in various units, tools and mechanisms.

- Reduced financial costs in production.

With the same budget and volume of material, it is possible to produce a numerically large batch of products and, in general, reduce costs by at least a few percent.

With the same budget and volume of material, it is possible to produce a numerically large batch of products and, in general, reduce costs by at least a few percent.

Existing math models that have been used for 3D printing on other equipment can be quickly and inexpensively optimized for 3D printing with aluminum on new equipment. At all stages of production, product control is ensured. For this we use computed tomography. This allows you to eliminate even the slightest defects.

Our

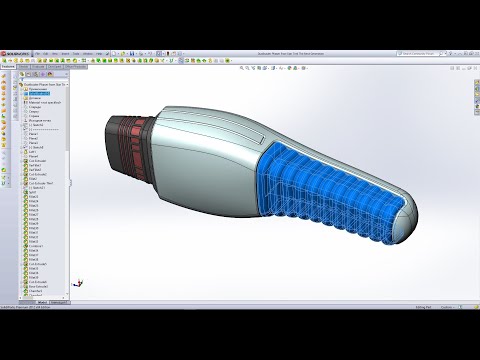

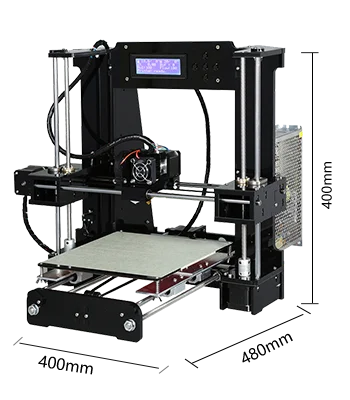

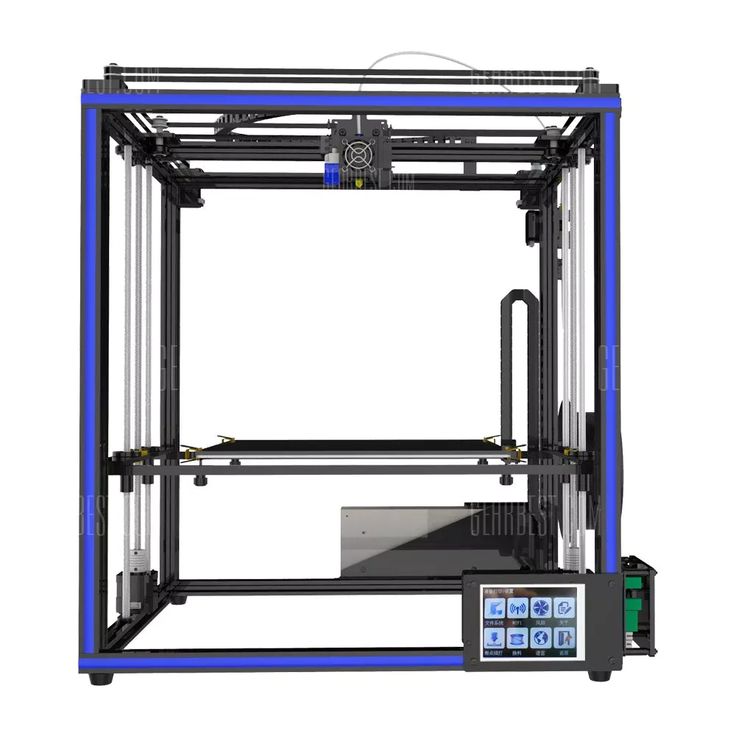

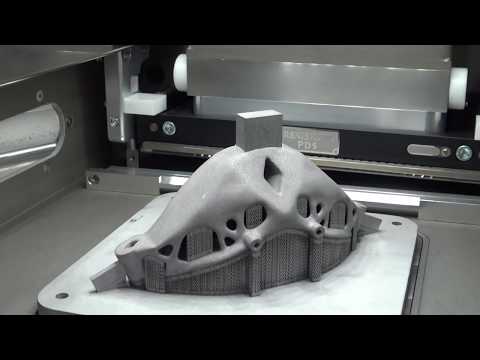

Aluminum 3D Printer AM400 AM400 is a versatile printer that allows you to work not only with the mentioned AlSi10Mg-0403, but also with other metal powders. But we use it mainly in conjunction with aluminum powder materials. One of the key advantages of this printer is the ability to quickly change the printing system between different types of metal. This reduces production time and allows different materials to be processed on the same machine.

Main parameters of the model:

- Working area: 25 cm x 25 cm x 30 cm.

- The level of argon use is at least 60% lower than in analogues.

The printer is already widely used in the aerospace industry. The reason is the ability to reduce the weight of the product, while maintaining all its parameters and strength indicators. The AM400 allows you to create particularly complex parts. For example, with complex internal cooling circuits. Previously, this was not possible due to the use of outdated metal casting methods. They did not allow creating models of high complexity.

The AM400 aluminum 3D printer is ideal for small batch production. But if necessary, it can also be used for mass production.

Selective Laser Melting Technology and Features

The AM400 supports the SLM laser melting technique. This is one of the newest destinations used in the most demanding segments:

- engineering sector;

- space/aerospace;

- production of spare parts and structural products.

3D printing with aluminum paired with SLM technology allows you to create functional metal products with increased construction accuracy. For example, you can implement complex systems of channels within the product for cooling.

Key features of the SLM:

- The vacuum technology used saves 60 to 80% argon.

- Prepare equipment for production in no more than 15 minutes.

- Focal spot - 70 microns. This gives an improved quality of model building in this class.

- The powders used are practically not in contact with the atmosphere.

- For R&D powders, the integrated small chamber can be used.

- Renishaw branded encoders provide increased durability.

And this is only a small part of all the benefits.

Our offer

SPRINT3D company prints metal parts, engine elements, components of complex metal structures. We also carry out 3D printing with aluminum for the medical industry.