Rekam 3d printing

Rekam KR-5 35mm Manual Film Camera With Built-in Flash

Click to zoom

Star Seller

Star Sellers have an outstanding track record for providing a great customer experience—they consistently earned 5-star reviews, shipped orders on time, and replied quickly to any messages they received.

| 389 sales |

5 out of 5 stars€24.60

Loading

Only 1 available

VAT included (where applicable), plus shipping

Rare find — this item is hard to come by.

Star Seller. This seller consistently earned 5-star reviews, shipped on time, and replied quickly to any messages they received.

Listed on Sep 13, 2022

11 favorites

Report this item to Etsy

Choose a reason…There’s a problem with my orderIt uses my intellectual property without permissionI don’t think it meets Etsy’s policiesChoose a reason…

The first thing you should do is contact the seller directly.

If you’ve already done that, your item hasn’t arrived, or it’s not as described, you can report that to Etsy by opening a case.

Report a problem with an order

We take intellectual property concerns very seriously, but many of these problems can be resolved directly by the parties involved. We suggest contacting the seller directly to respectfully share your concerns.

If you’d like to file an allegation of infringement, you’ll need to follow the process described in our Copyright and Intellectual Property Policy.

Review how we define handmade, vintage and supplies

See a list of prohibited items and materials

Read our mature content policy

The item for sale is…not handmade

not vintage (20+ years)

not craft supplies

prohibited or that use prohibited materials

not properly labeled as mature content

Please choose a reason

Tell us more about how this item violates our policies. Tell us more about how this item violates our policies.

Tell us more about how this item violates our policies.

Bagaimana Aplikasi 3D Printing dalam Dunia Kesehatan?

Aplikasi teknologi 3D printing memiliki kontribusi yang besar dalam dunia kesehatan. Salah satu implementasi printer ini adalah mencetak hasil pencitraan medis. Hasil rekam medis dari mesin MRI, USG, dan CT Scan dapat dicetak menggunakan printer 3D untuk kemudian ditindaklanjuti untuk menangani pasien. Peran teknologi percetakan 3D dalam dunia kesehatan contohnya sebagai berikut.

1. Bioprinting

Bioprinting ialah implementasi cetak 3D untuk membuat biomaterial seperti sel dan organ dengan jaringan yang mirip dengan organ aslinya. Teknologi ini menggunakan material bionik untuk menghasilkan struktur jaringan dari sejumlah lapisan.

Ada tiga tahap dalam proses bioprinting yaitu pre-bioprinting, bioprinting dan post-bioprinting. Proses pre-bioprinting merupakan pembuatan desain dari organ atau jaringan yang akan dicetak menggunakan CT-Scan dan MRI. Selanjutnya yaitu proses bioprinting, yaitu mengisikan bioink ke dalam catridge printer dan dideposisi berdasarkan mode digital. Terakhir yaitu post-bioprinting, stimulasi kimia dan mekanik dari bagian-bagian yang akan dicetak sehingga menghasilkan struktur jaringan atau organ yang stabil.

Meskipun gambar 2D sudah cukup memberikan peranan, tetapi visualisasi 3D memberikan gambaran lebih nyata terhadap organ tubuh manusia. Hasil cetak 3D lebih terlihat realistis dan menyerupai aslinya. Sehingga operasi dapat dilakukan dengan lebih efektif dan akurat.

Salah satu laboratorium riset yang telah melakukan percobaan ialah Organovo. Laboratorium riset ini melakukan penelitian dengan hati dan jaringan intestinal untuk menghasilkan obat yang tepat bagi penyakit terkait pada Mei 2018.

2. Pembuatan Replika Organ

Aplikasi 3D printing dapat dimanfaatkan dalam pembuatan replika organ tubuh manusia untuk mempermudah operasi atau pembedahan. Teknik ini telah terbukti mempercepat pembedahan dan menekan risiko kesalahan dalam proses pembedahan. Prosedur operasi yang dapat dilakukan mulai dari operasi wajah hingga operasi tulang belakang. Tak hanya organ tubuh manusia, replika organ tubuh hewan juga dapat dihasilkan dari print 3D.

Printer 3D dapat menghasilkan replika organ tubuh sebagai bahan percobaan dan latihan sebelum melakukan operasi yang rumit. Teknik ini dapat menekan terjadinya kesalahan, mempercepat prosedur operasi, dan menurunkan kemungkinan trauma pada pasien. Operasi yang telah berhasil dilakukan dengan teknik ini meliputi operasi wajah hingga operasi transplantasi.

3. Menghasilkan Peralatan Bedah

Pembuatan peralatan bedah yang lebih steril dapat dilakukan menggunakan teknologi cetak 3D. Instrumen operasi yang dapat dihasilkan meliputi forcep, ganggang pisau bedah, dan hemostat.

Presisi dan ukuran yang dihasilkan hampir serupa dengan instrumen aslinya. Instrumen ini dapat membantu mencegah kerusakan jaringan pada operasi yang melibatkan jaringan kecil.

Mesin printer 3D dapat menghasilkan peralatan medis berbahan plastik dengan harga yang lebih murah dibandingkan harus membeli dari supplier. Tenaga medis pun tidak perlu menunggu lama pengiriman dari luar.

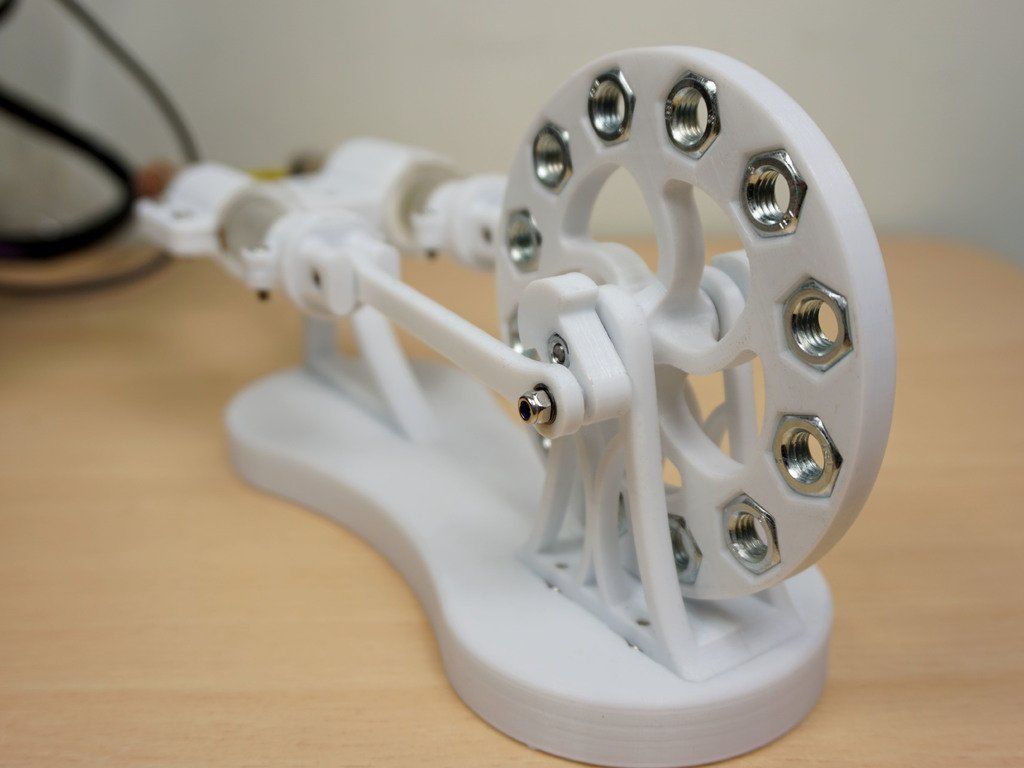

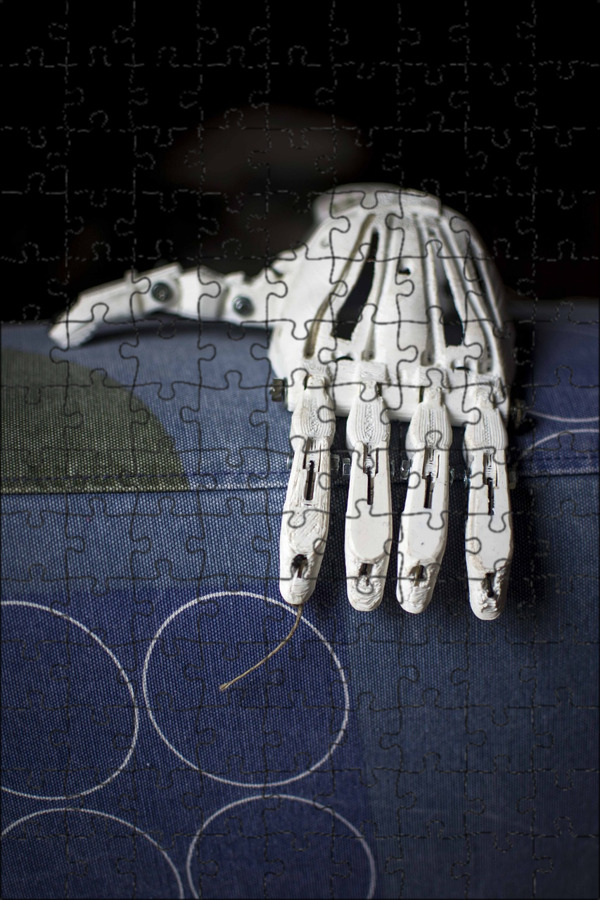

4. Pembuatan Lengan dan Kaki Palsu

Tangan dan kaki palsu sangat diperlukan bagi pasien korban kecelakaan, penyakit yang mengharuskan amputasi ataupun korban perang di negara-negara yang berkonflik. Harga produk prostetik umumnya sangat mahal dan hanya mampu dibeli oleh orang-orang tertentu. Adanya print 3D mampu membantu mereka yang membutuhkan dengan harga relatif lebih murah.

Selain itu, pembuatan kaki atau bagian tubuh palsu secara manual untuk pasien yang diamputasi biasanya memakan waktu selama berminggu-minggu, bahkan berbulan-bulan. Namun, menggunakan mesin cetak 3D, proses ini bisa dilakukan lebih cepat. Produk prostetik dapat dihasilkan dengan cepat dan biaya yang lebih murah.

Produk prostetik dapat dihasilkan dengan cepat dan biaya yang lebih murah.

Desain produk juga dapat disesuaikan dengan kebutuhan dan keinginan pasien. 3D print memudahkan pembuatan produk prostetik dengan desain, bentuk, warna, dan ukuran yang disesuaikan dengan kebutuhan pemakainya.

Sisi ekonomis dari penggunaan produk prostetik dari 3d print terutama jika digunakan pada anak-anak, karena tubuh mereka cepat berkembang dan prostetik yang mereka gunakan harus segera diganti menyesuaikan dengan postur tubuh mereka.

5. Produksi Tablet Obat

Printer 3D dapat dimanfaatkan untuk membuat tablet sesuai dengan komposisi yang diresepkan dokter. Dengan cara ini, biaya pembuatan obat bisa ditekan karena pihak rumah sakit dapat memproduksi obat-obatan sendiri. Seperti yang dilakukan oleh tim dokter dari University of Central Lancashire (UCLan) di Preston, Inggris.

Tak hanya itu, stok persediaan obat pun lebih stabil serta tidak ada lagi stok kedaluarsa yang menyebabkan kerugian anggaran belanja obat. Inovasi ini dicetuskan oleh Dr Mohamed Albed Alhnan dari School of Pharmacy and Biomedical Sciences. Bersama rekannya, ia juga berhasil menemukan bahan filamen pengganti untuk membungkus obat yang memiliki berat dan dosis sama seperti buatan pabrik.

Inovasi ini dicetuskan oleh Dr Mohamed Albed Alhnan dari School of Pharmacy and Biomedical Sciences. Bersama rekannya, ia juga berhasil menemukan bahan filamen pengganti untuk membungkus obat yang memiliki berat dan dosis sama seperti buatan pabrik.

6. Pembuatan Gigi Palsu

Printer 3D dapat dimanfaatkan untuk membuat implan gigi atau gigi palsu. Cara ini telah diterapkan di Singapura untuk menghasilkan gigi palsu dengan akurasi tinggi menyerupai gigi asli.

Umumnya, sebelum mencetak gigi palsu, dokter harus membuat citra gigi melalui CT scan atau X-Ray. Selanjutnya dokter gigi akan memastikan setiap gigi berada di tempatnya berdasarkan panduan ahli di laboratorium sebelum gigi palsu tersebut dibuat. Namun, pembuatan panduan memakan waktu berhari-hari hingga berminggu-minggu sehingga pasien harus sabar menunggu.

Kini, dengan teknologi 3D printing, pembuatan panduan bisa dilakukan dengan lebih cepat dan akurat hanya dalam hitungan jam. Proses juga dapat dilakukan di ruang praktik, sambil membahas pengobatan lebih lanjut kepada pasien. Setelah dicetak, implan diproses untuk modifikasi permukaan dan disinfektifikasi melalui sistem plasma.

Setelah dicetak, implan diproses untuk modifikasi permukaan dan disinfektifikasi melalui sistem plasma.

Aplikasi teknologi 3D printing ternyata tidak terbatas pada bidang seni dan industri manufaktur saja, melainkan juga pada dunia kesehatan. Masih tak terhitung lagi kegunaan printing 3D dalam dunia kesehatan untuk menyelamatkan hidup pasien. Dengan bantuan printer tiga dimensi, tenaga medis dapat melakukan tugasnya secara lebih efisien.

Research work "Perspectives of 3D printing" • Science and education ONLINE

Home Competition works Subject education Technical disciplines Research work "Prospects of 3D printing"

Author: Telepov Dmitry Aleksandrovich

Place of work / study (affiliation): MAOU "MSOSh No. 16", Miass, Chelyabinsk region, 8th grade

Supervisor: Shavaleeva Svetlana Alekseevna

How far science has advanced! How far man has gone in his reasoning and actions. From the words of my parents, I know that in their childhood there were no cell phones, laptops, the Internet. And if someone then told them that in a couple of decades they would have such a device in which there would be a color TV, and a camera, and a video camera, and a stereo tape recorder, and a radio, and a telephone, and even without wires, And it's also big enough to fit in your pocket. They wouldn't believe. And now I can not imagine how you can live without it. These items are completely normal for us. nine0003

From the words of my parents, I know that in their childhood there were no cell phones, laptops, the Internet. And if someone then told them that in a couple of decades they would have such a device in which there would be a color TV, and a camera, and a video camera, and a stereo tape recorder, and a radio, and a telephone, and even without wires, And it's also big enough to fit in your pocket. They wouldn't believe. And now I can not imagine how you can live without it. These items are completely normal for us. nine0003

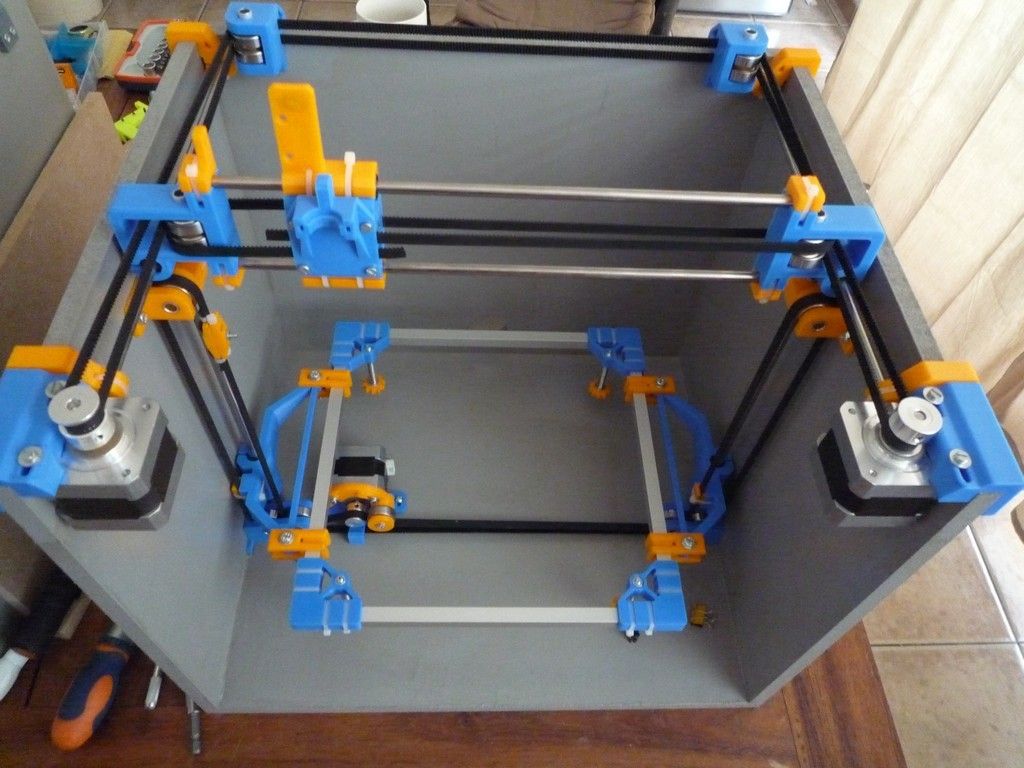

Since the beginning of the new millennium, the concept of "3D" has firmly entered our daily lives. First of all, we associate it with cinematography, photography or animation. But now there is hardly a person who has not heard about such a novelty as 3D printing at least once in his life. What is it and what new opportunities in creativity, science, technology and everyday life bring us 3D printing technologies, we will try to figure it out.

Does this “miracle item” have a future? And how will this technology serve a person? Is it good for him or not? So I decided to explore these issues in more depth. nine0003

nine0003

Objectives of research: theoretically and practically substantiate the theory of creation, practical use and efficiency of 3D printing technologies.

Tasks :

- Analyze the scientific literature on this problem.

- Track the history and types of 3D printers.

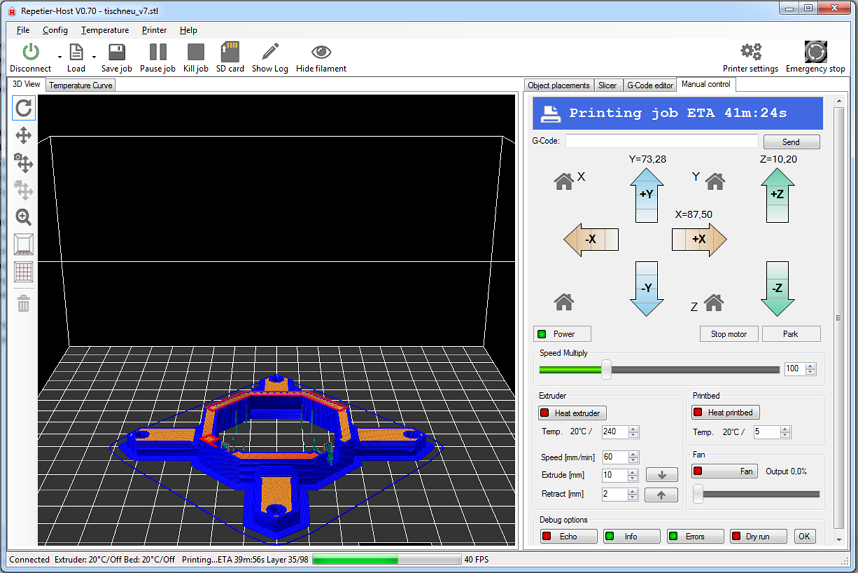

- To study the features of printing technology and the principle of operation of 3 D printers.

- To identify the achievements and prospects for the development of this technology. nine0032

- Discuss the uses and benefits of 3D printers.

- Create a three-dimensional model using a 3D printing device - a 3D pen.

Hypothesis : Let's assume that the capabilities of a 3D printer are very high at the moment, so it will probably be in great demand in the future.

Object research: the process of creation and the effectiveness of the use of 3D printers in the world of technology.

Subject of research: features of creating 3D models, practical use of 3D printers. nine0003

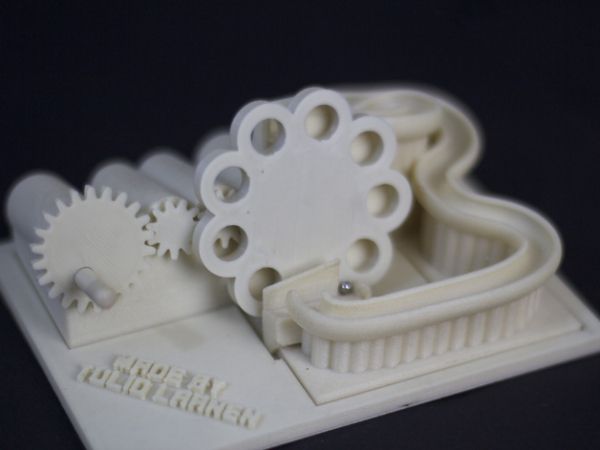

Product research: self-created 3D print models.

In the process of solving the set tasks, the following scientific research methods were used: analysis of scientific literature on the research problem; system analysis and statistical processing of the material.

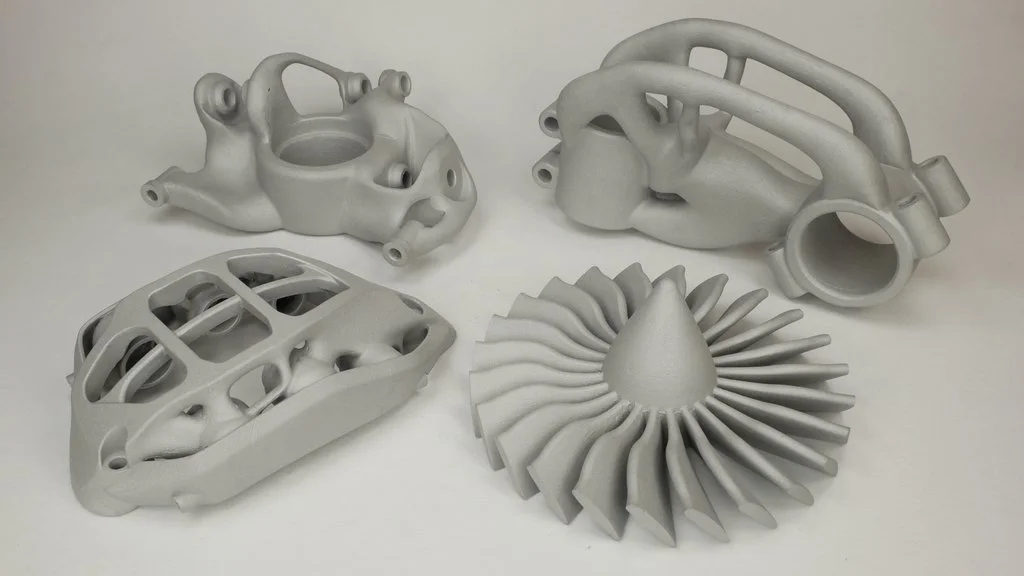

Significance research: today 3D printers are working tools for creating prototypes, finished products, models and all kinds of spare parts, including spare parts for protein life forms. The technology is developing, and in medical laboratories they are mastering printing with living cells to recreate the internal organs of a person. Thanks to this device, fantasy becomes reality. What is a 3D printer capable of? What are the prospects for using 3D printing technologies? nine0003

Loading...

Technical disciplines

Project "Virtual tour"

The full-text version of the work is available for viewing

Virtual tours that allow a person to get to a place of interest in an interactive mode are becoming more and more popular every day. Today it is an up-to-date advertising product, which makes it possible to show people the goods in full scale...

View work

Natural sciences, Engineering disciplines, Physical and mathematical disciplines

Research work "Field studies of the formation of ice cover on the Novosibirsk reservoir"

The relevance of the work is beyond doubt, since knowledge of the characteristics of ice and ice processes on rivers and reservoirs is of great importance for many sectors of the country's economy, in particular, for hydropower . Issues related to construction...

View work

Technical disciplines

Research work "Visualization of weather data using the Python programming language"

Undoubtedly, our life is connected with the weather, or rather, with nature. We are all in a hurry somewhere, we are afraid to be late. Or maybe it's worth slowing down? Look around and take a look? After all, everyone is interested in knowing what awaits us tomorrow. Predictions from ancient times...

View work

Technical disciplines

Research work "Electronic doorbell"

Full-text version of the work is available for viewing

Like all children, I love to play. From the whole variety of toys, I choose those with which you can build various models. When you create a complete model from a lot of details, it's exciting and amazing. For my birthday, they gave me an e...

View the paper

Technical disciplines

Research project "Comparison of Python and Pascal programming languages"

The full-text version of the paper is available for viewing

There are various programming languages, but some may differ from others as they are used. Scarcity breeds demand, so there is currently a demand for languages with further support for various platforms. Relevance. Today life...

View work

Event ended

Eco-friendly use of 3D printers in the home and industry

Vegetarianism, electric cars, green energy. Increasingly, people are beginning to think about the destructive impact of humanity and production on nature.

Global warming (this is especially noticeable in the last decade), pollution of the world's oceans, garbage dumps, the extinction of some animal species or even entire ecosystems. If you do not start to fight this today, then in a hundred years, hardly anything will remain of the former natural greatness. nine0003

3D printing, due to its versatility, helps many scientists and enthusiasts in various fields in solving large and global problems, for the conservation and ecosystems of our still green planet.

Sustainable production

First of all, 3D printers help to make production more environmentally friendly. Using 3D printing instead of traditional manufacturing methods helps reduce waste and greenhouse gas emissions. nine0003

Air Emission Reduction

Smoke, garbage, gases, toxic fumes are frequent "companions" of traditional production methods. However, they can be significantly reduced or completely eliminated if a 3D printer is working in the workplace or at home.

Mass production vs. 3D printing

At first glance, it seems that mass production is less harmful to nature than piece-by-piece production on a 3D printer. But it turned out that this is not entirely true. Joshua Pierce and colleagues traced the life cycle of three household items - an orange juicer, parts from a children's designer and a drainpipe segment. nine0003

Joshua Pierce, Michigan Technological University Scientist USA

It turned out that the production of, at first glance, such ordinary household items consumes a huge amount of resources - the extraction of raw materials and their processing, production, storage and delivery to the final consumer. In mass production, stamping or casting is usually used, after which plastic scraps are sure to remain.

In mass production, stamping or casting is usually used, after which plastic scraps are sure to remain.

3D printing can significantly reduce the production chain, and consequently, energy costs (by about 40-60%). After all, 3D printing (provided that the client has his own printer) does not require delivery - it is enough to send a digital 3D model. Printing can be more accurate and leave less plastic waste behind. A 3D printer can even produce hollow or lattice parts that are technically impossible to mass-produce by injection molding or moulding. nine0003

Reduced fuel consumption

In the world, more and more manufacturers of cars and motorcycles are beginning to develop the direction of electric motors. There are new and more affordable electric vehicles, the infrastructure for the maintenance of electrical engineering is developing. Many countries set themselves the goal of reducing the use of fossil fuels as much as possible in the near future.

3D Printed Strati Electric Car

But unfortunately, abandoning fossil fuels in the next few decades is a utopia. But 3D printing is already helping to at least reduce the amount of fuel consumed. This is achieved due to the maximum lightening of the weight of both the machine itself and the mechanical components of the internal combustion engine (internal combustion engine).

But 3D printing is already helping to at least reduce the amount of fuel consumed. This is achieved due to the maximum lightening of the weight of both the machine itself and the mechanical components of the internal combustion engine (internal combustion engine).

Engine hood hinge, 3D printed on the left and sheet metal on the right

Sustainable production

3D printing helps not only to reduce industrial emissions into the atmosphere, but also helps to find and implement new ideas. After all, each owner of a 3D printer can himself model and manufacture a device or object that, in his opinion, will help to resist climate change.

Eco glasses

Disposable plastic cups are a headache for environmentalists around the world. According to statistics, the average person uses a plastic cup for 15 minutes, and it will take from 400 to 450 years to decompose in the garbage. nine0003

Plastic, due to its properties, is difficult to replace, especially in the food industry, but some enthusiasts are trying to do it. Jun Aizaki thinks he can solve this problem with pumpkins.

Jun Aizaki thinks he can solve this problem with pumpkins.

HyO-Cups or natural cups

Even prehistoric people adapted to use bottle gourds as reservoirs for water. Thanks to the 3D printed shapes, you can give almost any shape to a growing pumpkin. nine0003

gourd in the form of a jug

Animal Rescue

3D printers are actively helping our smaller brothers. In addition to medical uses such as prosthetics, 3D printing helps preserve and restore entire ecosystems.

Animal prostheses

The biggest challenge in animal prosthetics is the creation of an often miniaturized but lightweight and precise prosthesis. Manually or by other methods, this is sometimes impossible. In this case, the only way out is 3D printing. nine0003

Curano Cat

Curano the cat lived a full life for 9 years, delighting his owners, until he got cancer. Curano's owners did everything possible to save their pet and although the cancer receded, Curano's back left leg was badly damaged. Amputation of the leg could create new problems and it was decided to try to replace the patella with an implant.

Amputation of the leg could create new problems and it was decided to try to replace the patella with an implant.

The miniature implant was 3D printed from a cobalt-chromium alloy using DMLS (Direct Laser Sintering) technology. It was impossible to manufacture by any other means, because the implant must not only be miniature and durable, but also completely repeat the complex relief for high-quality integration into the bone. nine0003

Holly horse

Holly is a ten year old mare who suffered from laminitis.

Laminitis is a disease of artiodactyls resulting from poor circulation of the hoof plates. Due to laminitis, Holly experienced severe pain in her legs, not only when walking, but also when standing.

Veterinarian Luke Wells-Smith heard of successful attempts to make custom titanium horseshoes for racing horses.

nine0003

3D printed titanium horseshoes

The guys from the Australian National Science Center were imbued with Holly's misfortune and decided to help. In collaboration with a equine orthopedist, special horseshoes were created for Holly. They made it possible to lighten the hoof and more evenly distribute the load on the legs.

In collaboration with a equine orthopedist, special horseshoes were created for Holly. They made it possible to lighten the hoof and more evenly distribute the load on the legs.

Holly's hoof scan

The new shoes helped Holly start not only walking without pain, but also running. nine0003

Akut sea turtle

The collision with the propeller of the boat was unfortunate for the Akut-3 sea turtle. Most of the upper and lower jaws were missing. This meant almost guaranteed slow death for the tortoise, but she was lucky.

The Tortoise Research and Rehabilitation Research and Rehabilitation Center, where the turtle ended up, turned to the Turkish company Btech, which specializes in medical 3D printing. Btech was able to scan and fabricate the missing part of the Akut jaw from titanium. nine0003

3D model of the prosthesis for Akut on the left and the finished prosthesis on the right

The surgeons succeeded in implanting the turtle's titanium jaw, and after a successful rehabilitation, it can be released into the wild.

Turtle with denture in place

Cleopatra tortoise

Nicola Novelli picked up and left a small land tortoise. But due to malnutrition, the shell of the turtle, Nicola called her Cleopatra, was deformed (had the shape of a pyramid) and thinned. If the shell had cracked, then Cleopatra could have died from an infection. nine0003

Cleopatra's deformed, pyramidal shell

Nicola approached Colorado Tech University with a request to make a prosthesis for Cleopatra. Specialists from the university and a 3D printing company in Denver scanned and made a shell overlay from polylactide, a biodegradable, biocompatible polymer. Due to the complex relief of the shell, the model had to be printed in parts. nine0003

Cleopatra with escutcheon

Since Cleopatra is still a teenager and will continue to grow with age, the “prosthesis” will have to be changed periodically.

Hermit crab houses

In the wild, it's bad to be small and weak. But hermit crabs were able to adapt and use empty shells of gastropod mollusks as a reliable shelter.

Hermit crabs

Due to the pollution of the beaches, many hermit crabs, in search of a new "house", fell into deadly traps from plastic bags, bottles, canisters and died. And natural shelters are becoming less and less. Hermit crabs have to use plastic garbage, which is not at all suitable for this.

Hermit crabs use rubbish as a home

Some enthusiasts are trying to help the unfortunate crustaceans and are trying to make them a worthy replacement house.

For example, MakerBot employees created the project "Shelter", where they offer anyone who wants to design a 3D model of a shelter for a hermit crab. The best works will be 3D printed and tested by crayfish.

From concept to implementation of 3D printed crayfish houses

But the Japanese artist Aki Yamomata, inspired by the idea of a peaceful exchange of land between countries, implemented a project of printed transparent houses for hermit crabs in the form of small towns.

Cancer in a new home made with photopolymer printer

To make sure the new inhabitants liked the houses, they were based on tomographic images of shells, finalized in a 3D editor. Finished models are made of transparent resin on a photopolymer printer. nine0003

Conservation and support of ecosystems

In addition to prosthetics, 3D printing helps, although not to avoid some environmental disasters, but at least to slow them down. And this can give scientists more time to figure out the reasons and reach out to people.

Great Barrier Reef

It is the largest and oldest coral reef in the world. It is so huge that it can be seen from space (the area of the Great Barrier Reef is about 344,400 square kilometers). In addition, corals are home to many species of fish and other marine life. nine0003

Great Barrier Reef from space

But despite its gigantic size, it is endangered. Due to rising water temperatures, pollution of the world's oceans and climate change, the endosymbiotic algae that give corals their bright color are slowly dying out.

Due to rising water temperatures, pollution of the world's oceans and climate change, the endosymbiotic algae that give corals their bright color are slowly dying out.

Scientists from the University of Sydney are using 3D scanning and 3D printing to save the Great Barrier Reef. Using 3D scanning, a detailed map of the reef was built. With it, you can track and predict the most vulnerable places. nine0003

Using a 3D printer, scientists are making a variety of structures that can support the Great Barrier Reef. For example, sections are printed that serve as a home for algae-eating fish that kill corals. Previously, special blocks or prepared, sunken ships were used for this purpose, but 3D printing makes it possible to imitate the natural structure of the reef much more accurately.

Sandcrete mix artificial reef

Restoring dead ecosystems

Scientists plan to use this technology not only to maintain existing ecosystems, but also to restore those that have disappeared. After all, to date, about a third of the world's coral reefs have been destroyed.

After all, to date, about a third of the world's coral reefs have been destroyed.

Thanks to 3D printing, there is a chance to at least slightly improve the situation. Using the new Modular Artificial Reef Structures (MARS for short) technology, scientists are trying to introduce 3D printed structures that can become a home for reefs. nine0003

Artificial “reef” on the left - recently installed, on the right - after some time

The advantage of such block structures is the ease of installation. Indeed, for their immersion and installation, cranes or other equipment are not required. Several divers can deliver them to the bottom in separate blocks. Each block has hollow sections that are filled with rebar and special concrete for durability. nine0003

Modular system installed

One of the largest 3D printed "coral reefs" has already been placed in the Maldives.

Waste reduction

In addition to restoring ecosystems, it is necessary to reduce household waste emissions. And here 3D printing becomes a valuable assistant.

And here 3D printing becomes a valuable assistant.

Cora Ball

Cora Ball is a development of the Rozalia Project. The Cora Ball is a small plastic ball that picks up the microfibers that spill from our clothes during the wash. This way, dirt and fibers that may have entered waterways and oceans will remain in the bin. After all, these microparticles can be eaten by fish and other animals. nine0003

Prototype Cora Ball

Although mass production was planned to be done by molding, the first batches and prototypes of Cora Ball were made on a 3D printer.

The second life of broken things

Any mechanism wears out and fails over time. Often, to restore the working capacity of the mechanism, it is enough to make a small plastic part. So thanks to 3D printing, many things do not end up in a landfill, further polluting our planet, but get a second life. nine0003

RU machine

Radio-controlled cars have long become not only children's toys. Many adults do not mind remembering their childhood and racing on an impromptu track.

Many adults do not mind remembering their childhood and racing on an impromptu track.

RU machine

The weak point of all RC machines is the plastic suspension. For expensive replica models, you can almost always find spare parts, but for rare or Chinese models, they are not.

Instead of throwing away an almost working toy, you can make a broken element on a 3D printer. When modeling, you can even increase the strength of the part by adding stiffeners in weak places. nine0003

1/18 scale car rear hub

Some enthusiasts 3D print the entire chassis. This makes it easy to replace broken elements and quickly refine and correct design flaws.

3D printed RC car chassis

The second life of the meat grinder

Even such seemingly eternal things as a metal meat grinder can break. The most annoying thing is that a part that does not have a strong load has broken. nine0003

nine0003

Clamping nut for a meat grinder, made on a 3D printer

A variety of materials allows you to print on a 3D printer a replacement for almost any plastic part. It can be a gear for a blender, a plastic handle for a washing machine and much more.

In some situations, when the model is rare and old, there are no even original used spare parts. 3D printing allows you to give your favorite home appliance many more years of life, instead of rotting in a landfill. nine0003

Vehicle seal

Sometimes a small, cheap piece breaks in an important knot. But the manufacturer sells the necessary spare part only in the collection. Because of this, you have to not only overpay for the necessary part, but also throw away the unnecessary, albeit almost working, mechanism.

Washer nozzle for Toyota Avensis - 3D printed on the left, original on the right

A 3D printer becomes a “lifesaver” if you need to make a spare part that is already difficult or impossible to get. For example, this part is no longer produced, but the BU option could not be found, or delivery will cost more than the part itself. nine0003

For example, this part is no longer produced, but the BU option could not be found, or delivery will cost more than the part itself. nine0003

Green Energy

The transition to green energy is an important step in reducing emissions of greenhouse (and not only) gases into the atmosphere.

Wind energy

Wind energy is a renewable and “clean” energy source. Despite some disadvantages (variability of wind power and therefore uneven power generation), it is promising for some countries. For example, in Denmark, in 2019, windmills generated 48% of the electricity consumed. nine0003

There are several options for wind turbines - with a vertical and horizontal axis of rotation.

Main types of wind turbines

Vertical-axial wind turbines have a lower efficiency compared to horizontal-axial ones, but their use requires that the wind speed be more than 6 m/s. In Russia, the average annual wind speed does not exceed 5 m/s, so wind turbines with a vertical axis are more often used. nine0003

nine0003

Home wind generator

In Russia, "clean" energy sources are not very popular because of their high price. 3D printing helps enthusiasts design and build low-cost models of wind turbines.

3D Printed Home Wind Turbine

In an apartment building, there is hardly a place where a wind generator will be effective, but for example, in a country house, it can be a good helper in case of a power outage. nine0003

Wind turbine production optimization

An industrial wind generator is a complex mechanism of gigantic size.

Industrial wind turbine blade

Using only 3D modeling techniques, it can be difficult to correctly calculate all the parameters. Thanks to 3D printers, it is possible to create a miniature copy of a wind turbine and test it in a wind tunnel. This helps to optimize and refine the design of wind generators, making them more efficient. nine0003

Wind Turbine Prototype Being Tested in Wind Tunnel

And some companies offer to print towers for wind turbines on a 3D printer. GE Renewable Energy, 3D printing specialists COBOD and LafargeHolcim (a manufacturer of cement and other building materials) have teamed up to develop the world's tallest wind turbine towers. This will reduce the cost of installing wind turbines and make them higher (200 meters instead of 100) than from other materials. nine0003

GE Renewable Energy, 3D printing specialists COBOD and LafargeHolcim (a manufacturer of cement and other building materials) have teamed up to develop the world's tallest wind turbine towers. This will reduce the cost of installing wind turbines and make them higher (200 meters instead of 100) than from other materials. nine0003

3D printed wind turbine tower

After all, the higher the wind generator, the more electricity it can generate in a year. For example, a 5 MW turbine at a height of 80 meters will generate approximately 15.1 GWh per year. The same turbine at a height of 160 meters - 20.2 GWh per year, which is 30% more.

Solar energy

Solar energy is obtained using special panels, consisting of photovoltaic cells, in which a series of physical and chemical processes take place under the influence of sunlight. There are several types of solar cells - monocrystalline, polycrystalline, amorphous (flexible, film). nine0003

In Russia, solar panels are not very common due to the unprofitability of use in high latitudes.

Currently, developments are underway for the production of panels on a 3D printer, but the main use of 3D printing in solar energy is to print prototypes and accessories for panels.

Accessories for solar panels

South Dakota-based Peppermint Energy created FORTY2. FORTY2 is a portable solar panel with enough power to run a laptop, lighting, etc. nine0003

For the production of a prototype case, 3D printing was used on an industrial Stratasys printer. Thanks to 3D printing, it was possible to quickly produce several functional prototypes of the case and remove all the flaws.

For example, the first version of FORTY was too bulky and inconvenient to transport. The original design was greatly simplified. The use of a 3D printer has reduced production costs by about $250,000. nine0003

Hydropower

Most renewable energy sources (solar, wind) are fickle. Electricity obtained in this way must be “stabilized” - stored in batteries.

Water in this regard is more predictable. Industrial hydroelectric power plants have a number of disadvantages. For example, flood risk, desertification, human migration, etc. Small hydro-generators, in general, are devoid of the shortcomings of their industrial counterparts and do not have such a devastating effect on the environment. nine0003

Vortex turbine

The Belgian startup team Turbulent is trying to create a compact hydroelectric generator that is enough to provide electricity to 1-2 private houses. This will help people who are far from the power grid to provide their homes with electricity using the energy of streams or small rivers.

Hydro generator prototype from Turbulent

To make the turbine more accessible and cheaper, 3D printing has been chosen as a manufacturing method. According to statistics, 1.3 billion people do not have access to electricity networks, even more residents have constant power outages and are forced to use other, not environmentally friendly, energy sources (for example, gasoline / diesel generators). nine0003

nine0003

River turbine

Ted Christopher spent several years developing a prototype river turbine capable of generating electricity without impacting the environment. The result of his developments was the Volturn system, named after the god of the river in Greek mythology.

The Volturn has a horizontal design that generates power and deflects river debris such as rocks, plants or logs.

The prototype was 3D printed and tested in local rivers. 5 turbines combined into a single system will be able to provide electricity to about 40 houses. nine0003

Plastic recycling

Plastic. Its properties, for the modern world, become both a salvation and a curse for the environment. On the one hand, plastic products are light and durable, you do not need to spend a lot of time on their manufacture. At the same time, not all types of plastic can be recycled. On average, a plastic product can decompose from 400 to 700 years, and unfortunately plastic rots not only in landfills, but also pollutes nature and the oceans. nine0003

nine0003

Filament recycling

During 3D printing, plastic debris is inevitably left behind. These can be model supports or broken products, during the printing of which something went wrong.

3D printing failed

But used plastic can be shredded, mixed with fresh pellets, and reused (as long as the plastic is not biodegradable). In this case, 3D printing becomes almost waste-free. nine0003

On the Internet, you can find many options for home machines for the production of plastic thread. It can be a self-assembly machine, partially printed on a 3D printer.

Home Self Assembling Filament Machine

Or a finished machine made at the factory. Pellets for plastic production can be easily ordered online.

nine0140

Home filament machine

Plastic bottle filament

In addition to recycling used filament, enthusiasts have learned to print even from plastic bottles.