3D printer business reddit

How to make money with a 3d printer?

How profitable is 3D printing?

But first, let's answer this question. Can you really make money with a 3D printer?

The answer is yes and no. It depends on the niche that you serve. If you're 3D printing for the general consumer, then your profit margin might not be high because it's for personal use. Consumers love cheap stuff. You'll barely cover your cost because of the amount of labor required to finish just one job. But if you're serving clients where 3D printing solves a costly problem that they have, then they are more willing to pay you a lot more to solve it for them.

Here's what we mean by that.

Scenario A: Joe is looking to 3D print a door handle because his door handle broke.

Scenario B: Amanda is looking to 3D print a prototype of a product she plans to sell on Kickstarter.

Believe it or not, we get a lot of Joe's looking to get a quote for their missing appliance part. And most of them are surprised by how expensive 3D printing is and why can't it be as a cheap as Amazon!

We turn them away. Cheap clients are not worth your time.

Best entry level 3D Printer

Don't have a 3D printer already?

Phrozen Sonic Mini 4k 3D Printer

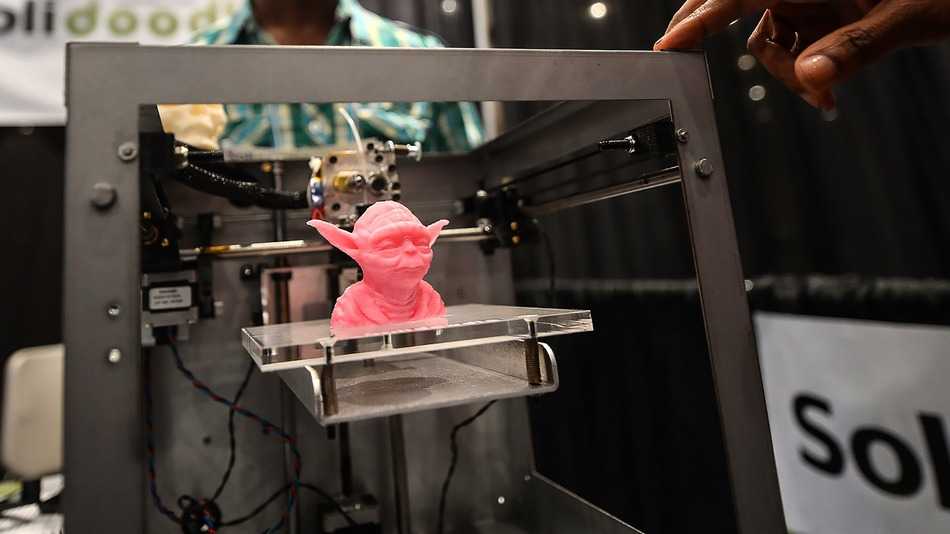

Check out this Phrozen Sonic Mini which is very popular among 3D printed miniatures enthusiasts.

$349.99 from Phrozen3D

Commisions earned

Different ways to make money with 3D printing

We've listed a couple of ways you can make money with a 3D printer. Some of these ideas are really good, some of them are bad. But we're listing them any way and it's up to you to make that decision if it's even worth considering.

Let's dive right in!

1. Sell pre-made 3D prints on Etsy

Etsy is one of the biggest marketplace for 3D printing. A lot of 3D printing hobbyists and even professional gravitate towards Etsy because of its large audience who are into handcrafted stuff. Some of them have even made a name for themselves on Etsy, whether that's selling pre-made items with a little bit of customization or selling full on 3D printed objects.

Some of them have even made a name for themselves on Etsy, whether that's selling pre-made items with a little bit of customization or selling full on 3D printed objects.

When we were starting out back in 2016, we were the first ones to start selling 3D printed planters. Made boatloads of money but ultimately had to stop because of copyright issues. But also partly, because it wasn't where we imagined company .

Remember how we said cheap clients aren't worth your time. On Etsy, you will encounter a lot of cheap clients.

Pros

- Quick way to validate your 3D printing idea

- Benefit from Etsy's huge audience

- Running ads are cheaper compared to Google

List of 3D printed products that you can sell on Etsy:

D&D miniatures

Planters

Vase

Freezing Bernie

How do you choose which products to sell?

On Etsy, you will see a lot of people selling different variations of the same thing - planters, iphone holder, headphone holder, etc.

Why?

Because these things sell!

Like it or not, Etsy will be full of copycats and originality doesn't matter. If your product sells, people will copy it. (And vice versa)

How can you stand out on Etsy?

There's a lot you can do to stand out, but here are some of the common ones that we hear over and over again.

Offer something unique that differentiates your product. Whether that's offering higher quality 3D print (resin), custom finishing, etc.

Avoid competing for price. It becomes

Ask your happy clients to leave a review

Take high quality product photos

2. Offer a specialized 3D printing

This comes down to finding a niche that you're comfortable to work with or if there's enough margin for you to be profitable.

Here's a list of niches you can offer your 3D printing services to:

Tabletop Miniatures

Toy Designers

Jewelry Designers

Architecture firms

Engineering firms for prototyping services

Pros

- You can standardize your process

- Repeatable business

- Easier to master one industry than be a jack of all trades

- You can become a known expert in that industry

3.

Start a 3D printing business in your local area

Start a 3D printing business in your local areaWe'll start off by saying that starting a 3D printing business is the most difficult thing to do out of all the other ideas on this list.

Pros

- Potential for high profits

- Local advantage over online only 3D printing companies

We were fortunate that we were located in NYC, where there is huge demand for 3D printing, and that we started in the early days when 3D printing was still new.

We're not saying this because we don't want you to compete with us, but we're saying this because we want you to know the risks involved in the 3D printing business. Many 3D printing companies have gone out of business because they could not make a sustainable profit to keep the lights on.

The amount of work that you have to put in on fulfilling custom orders is a lot. If you don't opt for an automated system, you end up doing a lot of back and forth with clients. And if you do opt in for these instant quoting systems, you can get a lot of low end jobs and lose out on clients with a very custom need.

The real money in offering a 3D printing service, especially if your a small business, is if you can differentiate yourself from merely becoming a commodity.

For us, we had to become more than just a 3D printing service. It sounds corny, but that was the reality. We had to offer other services that would add value to 3D printing. For example, a marketing agency came to us for 3D printed trophy in 24k gold. But we know that we can't 3D print gold. We can either tell them to take it to a metal plating shop or we can do it ourselves and charge on top of it.

We can charge a lot more because:

We're taking all the risk. If that metal plating fails, we have to 3D print again.

We're making their lives so much easier by being an expert at this field.

And if they're on a really tight deadline, we can charge even more because we're guaranteeing results.

Clients who care more about their time and results are willing to pay you a lot if you can deliver.

So we've partnered with a local metal plating company and later on started offering metal plating services for 3D printing.

Having capabilities more than 3D printing will allow you to charge more than just the 3D print by itself.

Whether that's painting, or creating molds. Whatever it is, you need to find the right clients.

Bonus: Offer 3D scanning services

3D scanning and printing services are perfect way to increase money you can make from owning 3D printer. Although this would require buying a 3D scanner, it's a good option to think about when increasing your chances of landing a 3D printing client.

4. Sell your 3D printing designs

Making money with 3D printing isn't only limited to running your 3D printer 24 hours a day. You can also make money from selling 3D models!

This might be hard if you don't have any design skills. You can either learn or hire a designer on Fiverr or Upwork.

Pros

- You can make money while you sleep

- More scaleable than running a 3D printing business

Patreon Business Model

Here's how it works. People pay you an X amount every month for you to publish 3D models for them.

People pay you an X amount every month for you to publish 3D models for them.

This business model is very popular among the tabletop miniature community.

The above picture is from LordOfThePrint's Patreon. They're one of the popular designers focused on building 3D designs for tabletop gaming. They currently have 1,933 subscribers as of this writing. Assuming only 5% of that is merchants, (about 100) that's $3,866 of monthly recurring revenue!

Take this WallStreetBets 3D model by ChaosCoreTech for example. We spent $50 to have the rights to sell their design for a month. Imagine having 10 Etsy sellers wanting to sell your 3D model. That's have $500 of passive income every month for a few hours of design work!

Merchants/Etsy sellers are great target to sell your 3D models to because:

They'll use it to make more money

They know that your 3D model would print properly because you also know how to 3D print. You might also include supports to make it easier for them

You can show them how it would like 3D printed, thus, making it even easier to sell.

Marketplace Business Model

Some prefer to sell their designs as one-off product that people can just buy online without having to subscribe monthly.

Places where you can sell your 3D models

MyMiniFactory

CGTrader

TurboSquid

5. Start a YouTube Channel

We know that this is easier said than done. Creating content requires time, effort and consistency. With the amount of 3D printing related youtube channels out there, it might be hard to stand out.

But we're not here to stop you from starting your own channel. We're just here to tell you that you can make money with it.

Pros

- Potential for high earnings

- You can use your audience to make more money aside from YouTube Ads

6. Sell an online 3D printing course

If your confident enough with your 3D printing skills and you have knack for teaching others, then selling an online course about 3D printing can

What should you teach?

Again, you need to find a problem where people are willing to pay money for. If you search "3D printing" on Udemy, you'll find 3D printing courses that people are paying for.

If you search "3D printing" on Udemy, you'll find 3D printing courses that people are paying for.

It doesn't have to be "how to operate a 3D printer", it can be a course on "how to operate a profitable 3D printing business". With this strategy, you'll attract clients who are willing to pay money to make more money.

Pros

- Passive income

The following ideas are not so good

So you can probably skip to the end if you wish to.

7. Rent your 3D printer for events

With the pandemic and all, this is probably not a good idea. But it's still an idea right?

The business is very similar to a photo booth. A bar mitzvah will hire you for 3 hours to 3D print keychains for them.

But 3D printing takes a long time. They are going to complain that you didn't 3D print for everyone.

Yup, bad idea.

8. Sell your 3D printer

You can quickly make money if you sell the 3D printer you just bought. Guaranteed.

Guaranteed.

All jokes, aside

9. 3D print the word "money"

You will literally make "money" with a 3D printer with this strategy.

In summary

Yes, you can make money with a 3D printer. And there are a lot of ways that you can do it, whether that's selling 3D printed items, digital goods, or even offering a 3D printing service in your local area. Is it easy to make money 3D printing? It's not. You still need to work hard(and smart) to become successful in the 3D printing business.

How to Attract Clients To Your 3D Printing Business | by Zmorph SA

Making money out of your 3D printer is not an easy task but certainly achievable. Here are some tips for running a 3D printing business.

To help your business grow and thrive, we gathered tips and advice from industry professionals, successful entrepreneurs, and your potential clients. These tips won’t work like a magic spell and make you rich in a blink of an eye, but could be helpful in establishing and maintaining your business.

3D Printing group on Facebook gathers a huge number of 3D printing enthusiasts, makers, and professionals. Everyone can join it, get his questions answered or share his knowledge. We asked people on the group for their advice for beginning 3D printing business owners. Ja Stoddart shared this with us:

Don’t give up yer day Job, while you are getting started, Go to School, get a degree in Design or Engineering, and a minor in Business, Get some Creed, and never stop trying.

It’s actually a great piece of advice before you start. Don’t rush things because the competition is huge. Sometimes it’s better to focus on your studies or getting more experience in an already established company. This is also a good time for you to start building your credibility and contact list.

Good sample pack and a set of example prints are a must-have for every 3D printing businessTips on how to attract clients to your #3Dprinting #business #entrepreneurship

CLICK TO TWEET

Be visible before you launch a 3D printing business. Talk with people and make new friends. You won’t succeed without a proven record of activity on forums, Facebook groups, 3D Hubs Talk, 3DPrinting Reddit, and other places. You need to list and regularly visit all these places where your potential clients might be. Be nice and helpful while posting under your real name or nickname that you’ll carry into your future company.

Talk with people and make new friends. You won’t succeed without a proven record of activity on forums, Facebook groups, 3D Hubs Talk, 3DPrinting Reddit, and other places. You need to list and regularly visit all these places where your potential clients might be. Be nice and helpful while posting under your real name or nickname that you’ll carry into your future company.

Answering questions, sharing your knowledge, and commenting on the state of 3D printing technology won’t take you far, though. The next step is building your online portfolio. Either with the machines that you’ve built, original hardware designs, 3D models, or high-quality prints. Photos of your works on Instagram and videos on YouTube can do wonders, especially when you invest some additional time into editing them and promoting around the web.

Source: Simone FontanaItalian designer Simone Fontana started building his recognition long before launching his own company 3DNA. He’s been printing and post-producing impressive props, like guns from video games or even a working skateboard. His advice for online activity is:

His advice for online activity is:

You need to be always really active on social media. I find Instagram and YouTube really powerful and sometimes for some designs, Reddit can be extremely useful.

Overall the best thing is to combine social networks. I often post on Reddit about my youtube video, and for instance, once I was able to receive over 50k views in less than 24 hours. This will bring more attention and work.

Simone also recommends sharing at least some of your designs for free, so people can make them themselves and get to know your work better this way. There’s always the danger of someone else trying to profit out of your work, though. Remember to add watermarks on your models as well as make sure that you’re the first one to post them in all major 3D printing file libraries.

When running your own 3D printing business you need to meet a lot of new people, talk with hundreds of potential clients. Jacob Rogers points out that:

You either need huge margins or a huge customer base, because most people do not repeat as customers at the consumer level.

Large prints with high-profit margins can grow a small business, but you end up maintaining on countless small, low-profit prints.

These small, low-profit prints took most of Jacob’s time and resources. He wasn’t able to maintain his business because of that and decided to go back to designing yacht components.

Source: Alex Tapia / 3D Printing Facebook groupMany professionals working with 3D printing we talked to mentioned that it’s the design side that can get you more profit than doing prints on request. Dorian Ferrari’s advice is:

The best money is going to be on the design side. I have my printers on 3D Hubs, I’ve made $750 from it. My design services pay the bills plus. Treat every customer as if they’re a priority. Price fair, but ensure you price appropriately. Develop a niche, as it will separate you, and bring you better clients. General modeling services are almost a commodity as everyone with a free or cheap CAD or design program believes they can model.

What I’ve specialized in are servicing inventors and small businesses that don’t know how to get a concept through production. I help my clients all the way from product concept to mold-ready designs that can be produced in injection molding machines.

As it turns out many potential customers expect a full range of services — not only printing an item but designing it from scratch. Greg Carror has a similar experience:

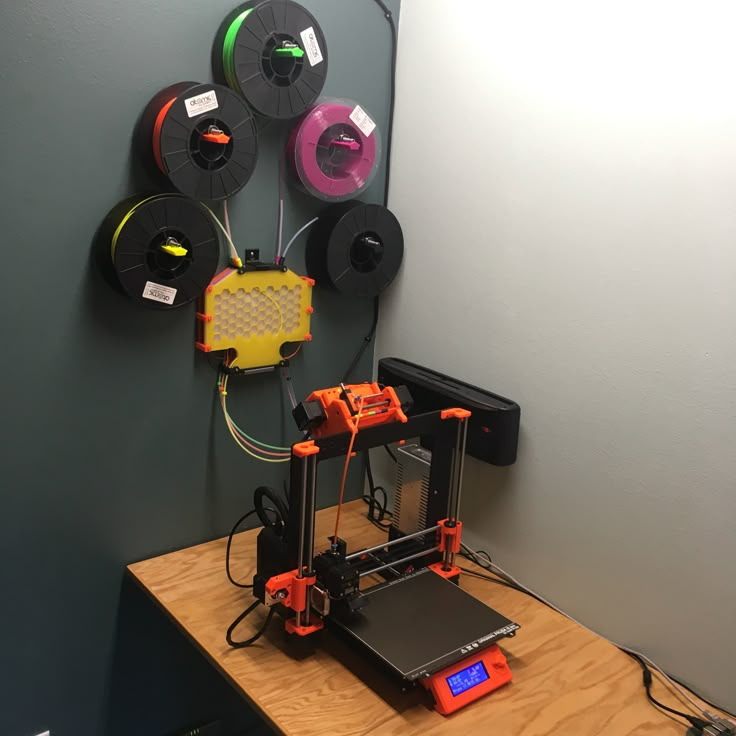

Going beyond simple 3D printing services can boost your business significantlyWe currently have 50 Prusa i3s and concentrate mainly on designing new 3D products for businesses. Most marketing companies we work with have told us their clients believe getting volume prints with SLS/Full Color is still too expensive.

We design branded, functional products that businesses can give out to their customers. You can make money as a hobbyist on 3D Hubs but as a company, you need volume or high-end prints.

Once you get some credibility by doing various projects for a wider range of clients, it’s good to look for a niche you’re the best at. Sometimes you can discover it by accident as it may not be the industry or type of projects you initially thought about. Just like Robert Bateman did:

Sometimes you can discover it by accident as it may not be the industry or type of projects you initially thought about. Just like Robert Bateman did:

I design my own products, sure I also print interesting things I find online but I do not sell them. I made trays for a company that uses them to fill bottles in their Electronic Cigarette Juice operation, It pays pretty well, I also make small gears for Business copiers that they can no longer get parts for. Just go and do it, it will be successful if you work at it.

Robert is right in saying that you probably won’t succeed overnight but can achieve a lot by gaining experience and learning new things with every project. You should also keep your eyes and ears open for new products, gadgets or jigs and fixturesthat you could design and sell to companies. Again, having many contacts on your list can help in building your 3D printing business this way.

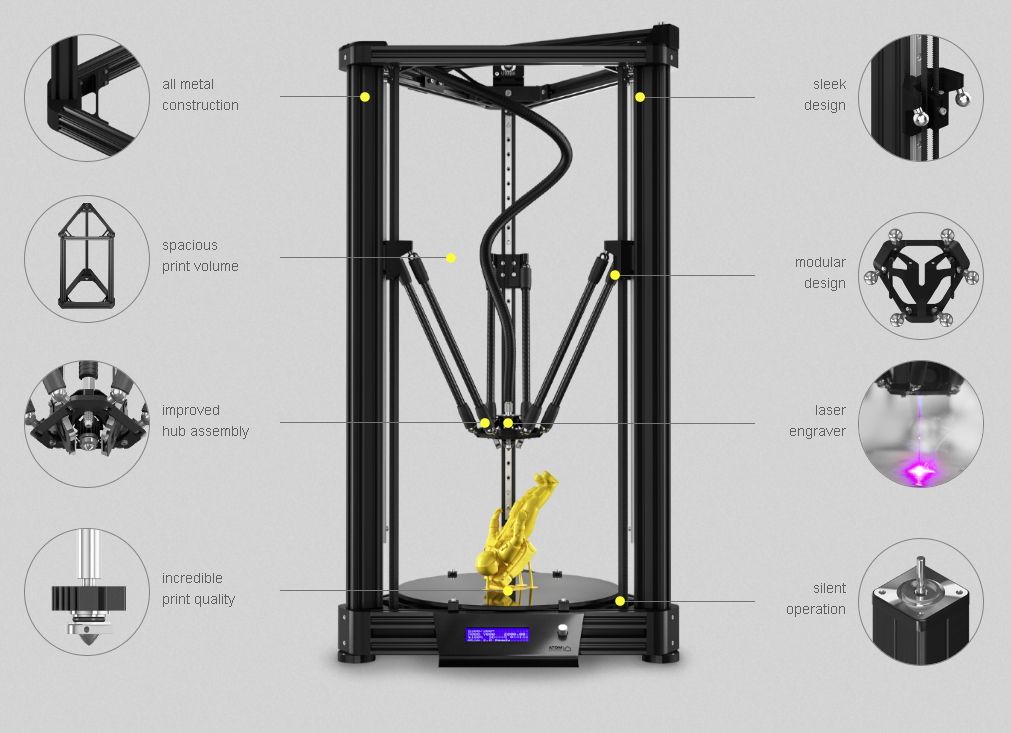

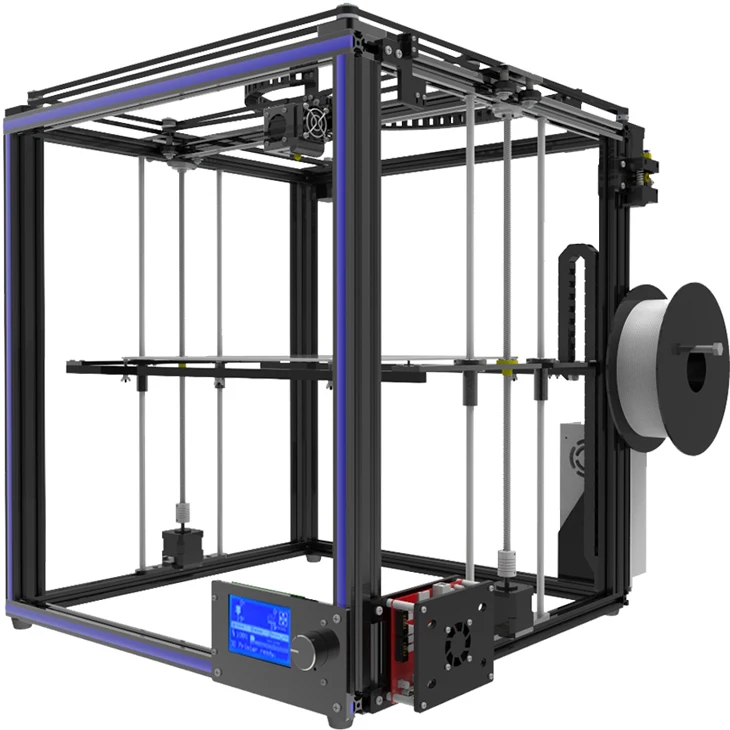

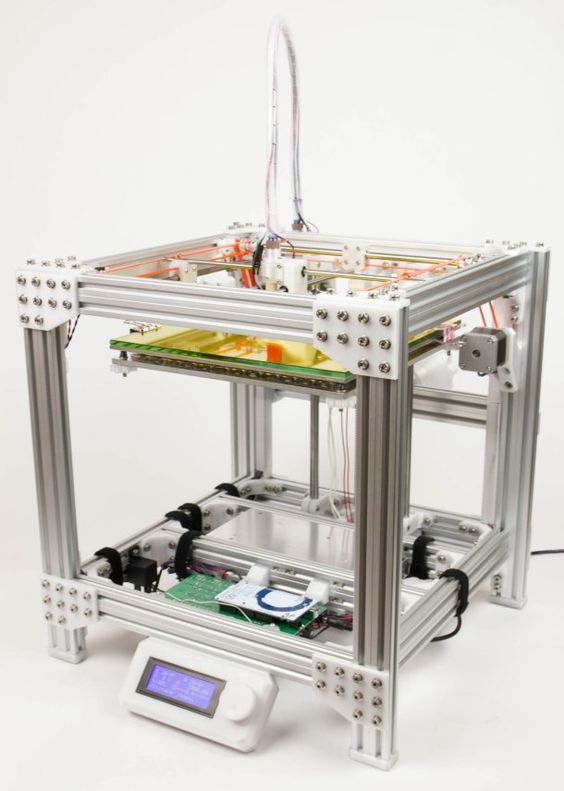

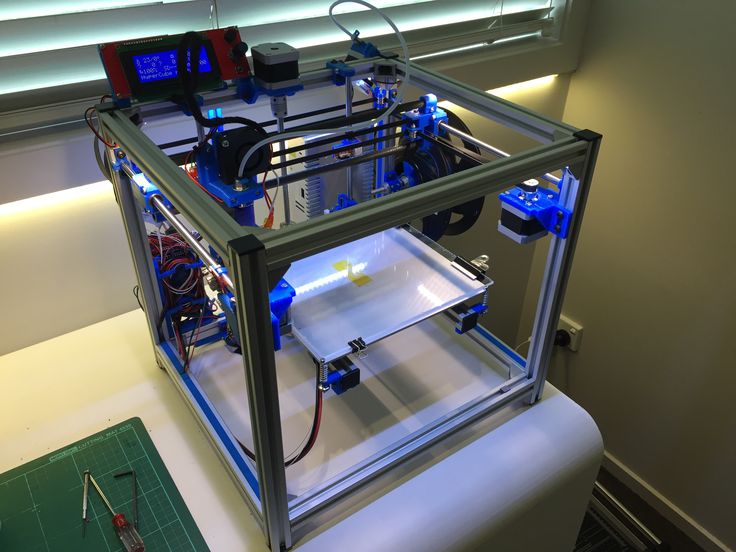

Source: JavelinThe quality of prints depends not only on your skills but also from the machine that you use to manufacture the object. This is why for running a 3D printing business you need reliable tools that can operate at peak efficiency around the clock. Some build their own 3D printers based on open source DIY designs but most of the companies and professionals utilize ready-to-use desktop machines.

This is why for running a 3D printing business you need reliable tools that can operate at peak efficiency around the clock. Some build their own 3D printers based on open source DIY designs but most of the companies and professionals utilize ready-to-use desktop machines.

Preet Jesrani from DesignBox3D told us why he would recommend ZMorph multitool 3D printers to people starting and already running their businesses:

ZMorph 2.0 SX in actionIf you are planning on printing batches of pendants or necklace pieces for example, as long as the design can be printed, you can go about the task of researching which printer will be the most suitable.

When you plan to focus on 3D printing with plastic-based materials, ZMorph 2.0 SX Basic Set will be an excellent choice due to the built-in closed loop functionality. But if you plan on using various mediums for creating your products or prototypes, there is no question — choose a ZMorph 2.

0 SX Full Set able to 3D print, cut with CNC toolhead, and engrave with a laser.

When running your 3D printing business never forget about 3D Hubs. It’s currently the biggest and most popular platform for ordering custom 3D prints from local providers. It changed a lot in recent years with more and more professionals looking for high-quality prints from reliable partners, so you should be ready for that.

3D Hubs is a place to be for all 3D printing business.Balazs Kisgergely from 3D Hubs shared with us the following tips:

- Create a great (visual) profile to get orders. Start with lower introductory prices and increase them later.

- Do all it takes to get good reviews, they’ll attract more customers.

- Printing for orders is a great way to start a business and build out a customer base if you don’t have one.

- Give away promo material with your orders so customers will remember you, plus you can advertise your design business this way.

- Try to find your niche (architecture, engineering, design for customers, etc.).

- Use Facebook and LinkedIn to get in touch with your customer base. I can also recommend 3D Hubs Talk for community and advice.

- For promotion, I’d say Instagram is by far the best. Build out a following, follow others who are relevant, do share 4 shares and generally read a lot of tips online.

- Don’t be afraid to reach out to 3D printing and your local media. They love local stories and you’ll get featured if you actually make great designs or products.

- In the meantime try Etsy and Ebay for selling 3D printed gadgets, figures, and trinkets people would like.

You can always use this piece of advice Bass Blom wrote us on Facebook…

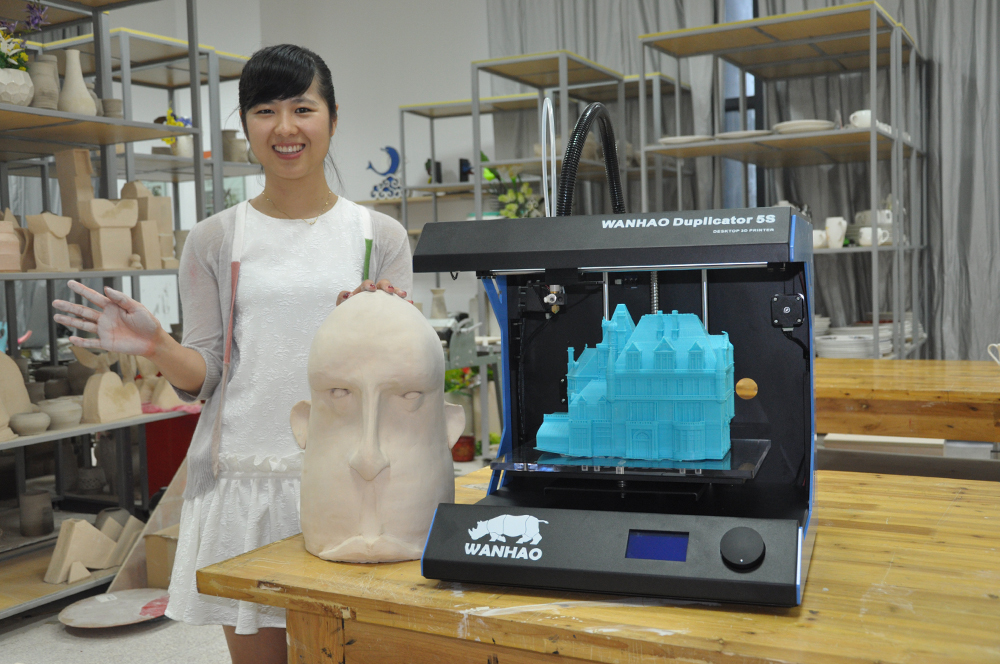

use plenty pretty girls in pics ;)

There’s no simple and universal set of rules on how to succeed with your 3D printing business. Different things work depending on time, place, and even people’s moods. Sometimes you just need to adapt to the situation, just like many successful entrepreneurs do, so always try to be flexible and keep an open mind.

Sometimes you just need to adapt to the situation, just like many successful entrepreneurs do, so always try to be flexible and keep an open mind.

Leave a comment below and share your stories, so other people can learn from your experience.

3D printer for building houses as a business: equipment, cost

Few people know that a 3D printer for building houses as a business can be a very profitable acquisition. 3D printing of houses, which is actively gaining popularity, brings excellent profits: the use of such equipment in construction can reduce the construction time to several days and reduce the cost of the entire process several times.

| nine0010 |

In this article we will talk about how to buy a 3D printer for printing houses and how to organize a construction business based on such equipment.

Contents of the article:

- How to build houses using a 3D printer

- How fast can you build with a 3D printer

- How much does it cost to build houses using a 3D printer

- Cost of a 3D printer for construction

- Models 3d -printers

- Investment and payback

How to build houses using a 3D printer

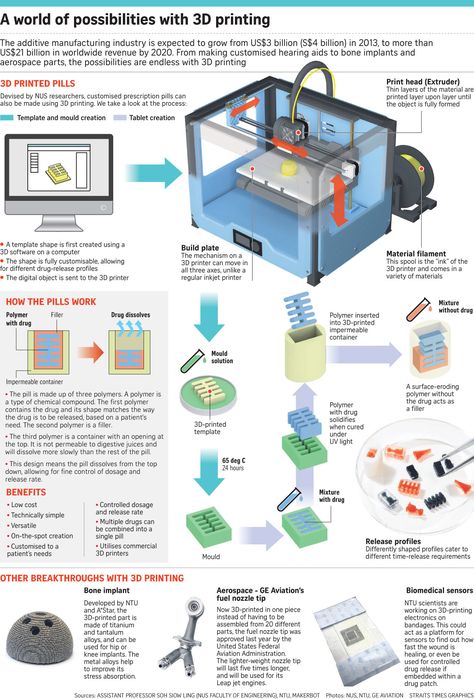

Contrary to popular belief, recently appeared building 3D printers print houses and building structures not from plastic or silicone, like their usual "brothers", but from concrete.

Typically, standard 500 grade cement-based formulations are used for this kind of printing. nine0040

As in the case of conventional 3D printers, the principle of operation of a construction printer is extrusion. First you need to prepare a mortar, which includes cement, fiberglass, sometimes expanded clay and other materials. The printer then extrudes this solution through special nozzles, applying it layer by layer to the base, which allows you to build the walls of a small building in just a couple of hours .

The printer allows you to quickly "print" all walls and other structures, such as stairs, but roofing must be done by traditional methods - printers capable of printing a high-quality roof do not yet exist.

Of course, after the completion of construction, external and internal finishing, laying of communications, installation of windows and doors will be required.

How fast can you build with a 3d printer

The average print speed of a modern construction printer is seven to ten square meters. meters per minute, and China is already actively using devices that can print more than 50 "squares" per minute. nine0003

meters per minute, and China is already actively using devices that can print more than 50 "squares" per minute. nine0003

In just a couple of hours, these machines can print a whole house of 200 square meters. Taking into account the finishing and laying of all necessary communications, construction takes from one month to six months.

How much does it cost to build houses using the

3D printer? nine0003

For example : the cost of building a small, about 100 square meters, typical country house is only 2.5-3.5 thousand dollars. The cost of such a house with doors, windows, roofing, communications, with external and internal decoration is about 8-10 thousand dollars.

A similar brick building will cost at least twice as much. nine0040 You can sell a printed house with a full finish for 16-25 thousand dollars.

nine0040 You can sell a printed house with a full finish for 16-25 thousand dollars.

Such a low cost of construction is ensured by low prices for materials and their extremely accurate dosing, as well as high quality of construction: printing does not give any deviations in the corners, and subsequently there is no need to “finish” anything - all walls, openings for doors and windows almost perfectly even, there are also no cracks - the wall turns out to be monolithic.

Construction 3d printer cost

So far, the 3D printing house building industry is in its early stages of development, and few companies produce equipment.

Cheapest to buy printer made in China . The products of the Russian company CJSC Spetsavia, which is based in Yaroslavl, will cost a little more. In terms of price-quality ratio, they are the best on the market.

Models of building 3d printers

Let's consider several models of 3d printers offered by Spetsavia: nine0003

- S-4063 : This small device is used to print small architectural forms, individual elements for houses, concrete structures up to 18 square meters.

The cost of the device: 8.5 thousand dollars.

The cost of the device: 8.5 thousand dollars. - S-6045 : The machine can be used to print complex designs up to 12.6 square meters. The cost of the device: 21 thousand dollars.

- S-1160 : This printer can print large structures and buildings up to 280 square meters. Device cost: 29one thousand dollars.

Investment and payback

The acquisition of a printing device and materials will cost approximately 35 thousand dollars. At least $5,000 more will be needed to pay the workers and complete the construction after the concrete structures have been erected.

During the construction of cottages and country houses with a cost of up to 10 thousand dollars (construction period from two to three months) and their sale for 17-18 thousand dollars, the net profit will be about three to four thousand dollars per month, from one house built. nine0003

Business payback period - up to one and a half years.

As you can see, the printing of houses can be a very profitable business , especially since today the competition in this area is still quite low.

How to use a 3D printer in business

0035

Hello! This article is intended to help those who are wondering which 3D printer to choose for their business. We will look at examples of real companies, their personal experience and selection criteria - what guided them when choosing a 3D printer for their business, and how they evaluate its role in production.

Table of Contents

Introduction

Things to Do with Your Own 3D Printer

Idea 1: Making Unique Things

Case: Making costumes and props for cosplay

How much can you earn on this

What 3D printers are suitable for this task?

Picaso Designer X Pro

Idea 2. Prototyping for industrial production

Prototyping for industrial production

Case: REC

Building a business

What equipment is suitable for this

How much can you earn on this?

Idea 3. Production of food products

chokolama.ru

Which 3D printers are suitable for this 9,0003

Printer Chocola3D

How much can earn

Idea 4. Studio of the creation of 3D copies of people

Build ?

Which equipment is suitable?

How much can you earn from this? nine0003

Idea 5. Copying and making museum copies

Case: Erarta Museum

Ultimaker 3 Extended printer

Idea 6. Making houses

How does it work?

Which equipment to choose?

What are the benefits of 3D construction printing?

Idea 7: Making architectural models

Case: Studio 911

Picaso 3D Designer X

Case: Setl City

Idea 8: Making aligners for dental clinics

What is the business based on?

Which equipment to choose?

How much can you earn in this business?

Idea 9. Making gingerbread molds

Making gingerbread molds

What is the business idea?

Which equipment is suitable?

What profit does it bring?

Idea 10. Creating an Additive Technology Center

Case: Top 3D Shop

How much can you earn on this

Options

Conclusions

Introduction

3D printing is a versatile tool used in many industries. In this article, we will use examples to describe the various possibilities for building a business using a 3D printer.

Top 50 3D Printing Business Ideas & Opportunities for 2020

Do you want to start or invest in a business with future growth potential? If YES, here are the top 50 3D printing business ideas and opportunities for 2020. nine0040

To keep things simple, 3D stands for 3D printing, which means an additive technology in which objects are created in many very thin layers. Imagine a future where a device connected to a computer can print solid objects. A future where we can have both tangible goods and intangible services delivered to our desktop computers or brick-and-mortar stores over the Internet.

Imagine a future where a device connected to a computer can print solid objects. A future where we can have both tangible goods and intangible services delivered to our desktop computers or brick-and-mortar stores over the Internet.

3D printing offers a wide range of business opportunities that can bring cash to your bank accounts now and even more in the future as the business gets better over time. Here is a list of 50 profitable 3D printing business ideas that you can consider if you want to join this business in the future:

50 Profitable business ideas and 3D printing opportunities

- JEWELRY AND

.

Start your 3D printing business in 2020: discover 15 ideas

The MX3D team has created a 3D printed metal bridge in the city of Amsterdam. Indeed, 3D printing is a great method to create urban environments such as bridges. What for? The new XL 3D printers enable architectural scale 3D printing. This makes it possible to 3D print projects the size of bridges. This bridge will be located directly over the Oudezijds Achterburgwal! It will be the most massive metal structure ever created on a 3D printer. nine0003

This makes it possible to 3D print projects the size of bridges. This bridge will be located directly over the Oudezijds Achterburgwal! It will be the most massive metal structure ever created on a 3D printer. nine0003

Create sustainable projects

11. Simusolar

Simusolar is a company established in 2014 that develops and implements small-scale sustainable solar energy solutions for rural communities in Tanzania. Using our online 3D printing service, they designed solar-powered LED lights for Lake Victoria fishermen to replace their petrol lights when they fish at night. You can find more information about this project in this blog post. nine0003

12. Adidas

We have already seen on our blog that additive manufacturing is an amazing manufacturing method for making custom shoes. Adidas has been creating various 3D printing projects and working on sneakers made from plastic found in the ocean. This actually shows how plastic can be recycled and used in 3D printing. Plastic Recycling parts may become more and more important in the 3D printing industry in the coming years. nine0003

This actually shows how plastic can be recycled and used in 3D printing. Plastic Recycling parts may become more and more important in the 3D printing industry in the coming years. nine0003

13. Feetz

Feetz is an American startup run by Lucy Beard that specializes in custom made footwear that is comfortable to wear and beautifully styled. They can be adapted to any legs! Fitz uses 3D printing technology to protect the environment. Indeed, 3D printing also means no material waste ! When using this technology to manufacture your products, you only use the amount of material you need to print your objects, and these 3D printed shoes prove it. nine0003

Creating spare parts

14. Jaguar

Jaguar, a well-known car manufacturer, uses 3D printing to create spare parts for its old cars. The company used 3D scanning to recreate the classic 1957 XKSS model. Additive manufacturing is the best way to recreate parts that are no longer manufactured by and not available on the market. It offers new business opportunities even for big brands like Jaguar! You need to create 3D files of the unique parts you need and print them! nine0003

Additive manufacturing is the best way to recreate parts that are no longer manufactured by and not available on the market. It offers new business opportunities even for big brands like Jaguar! You need to create 3D files of the unique parts you need and print them! nine0003

Space production

15. Made in space

.

Step-by-step guide to using a 3D printer (10 tips for 3D printing)

How to use a 3D printer? Where to use a 3D printer?

If you're new to 3D printing and still don't know how to use your 3D printer to maximize your productivity, then this page is for you!

I'll help you get started with 3D printing by giving you a step-by-step guide. In addition, I will leave tips to help you achieve better 3D printing results. So, let's get started! nine0003

How to 3D print

I understand that experience level matters in how he or she starts 3D printing. So, this section aims to help beginners learn how to use 3d printer at home or in the classroom.

So, this section aims to help beginners learn how to use 3d printer at home or in the classroom.

To give an overview of the whole process, I'll walk you through the basics of 3D printing and how to 3D print step by step.

9029 Step-by-Step Guide to Using the 3D Printer for Beginners1

This section is for beginners who don't know how to get started with their first 3D printing after getting their 3D printers.

Step 1 : Unpack

Remove the printer from the box. Make sure you remove all packaging materials, including tape and zip ties.

Step 2 : Prepare the built plate.

Make sure the print sticks to the bed. You can use blue masking tape, hairspray, polyimide tape, glue stick, or BuildTak sheets to do this. nine0003

Step 3 : Heat up the printer

Heat up your new printer and load the filament of your choice. PLA is highly recommended for beginners because it is easier to use.

You need to familiarize yourself with your material because there are threads that require special heat to adhere to the substrate and maintain an overall excellent print.

Step 4 : Load/unload filament.

Depending on your 3D printer, some of them give you the ability to load and unload filament in the controller menu. Just make sure the extruder is not loaded with filament because the factory usually tests the machine and there might still be a streak in the extruder. If there is filament, it needs to be removed. You can easily do this by pressing the trigger or button. nine0003

When the extruder is empty, load new filament. If your 3D printer has a filament loading option, you can use it. Otherwise, you will have to wait for the extruder to heat up, press the release lever and insert the filament into the filament hole.

As soon as you see the flow of threads from the nozzle, then you're done!

Step 5 : Level the bed.

Leveling a bed is a complex process that can be time consuming and tiring. If the desktop is not level, it may result in inaccurate printouts. So, you must do it right. nine0003

The second type is very easy to use. If you have the former, make sure the bed leveling screws are as tight as possible in all four corners.

Once your 3D printer bed is level, you also need to adjust the x-height. You must do this to balance filament flow and layer adhesion.

After that, you need to set a value in the software so that the printer knows what the gap between the nozzle and the build plate is. nine0003

Step 6 : You are ready

At this point, prepare the file with your favorite slicer and save the .gcode file for your 3D printer to recognize and print.

7 tips for using 3D printers for home and school

Using a 3D printer is not as easy as you think. Yes, there are plug and play 3D printers that work right out of the box, but you have to be wise when it comes to choosing a 3D printing machine, because at some point you are likely to run into a problem. nine0003

Yes, there are plug and play 3D printers that work right out of the box, but you have to be wise when it comes to choosing a 3D printing machine, because at some point you are likely to run into a problem. nine0003

So here are some tips for you.

1. Choose a 3D printer with good support

There are cheap 3D printers on the Internet, but if you are going to choose one, you must consider the manufacturer and available support. It's best if you get it from a local supplier for more affordable support.

This way, if you encounter any problem, you can easily go to it and fix it. No need to send it in and wait weeks to get it fixed. nine0003

2. Level the bed and install the nozzle

Leveling the bed and installing the nozzle will improve the quality of your 3D printing. To make things easier, you can use a sheet of paper to determine the distance between the nozzle and the cradle.

When the nozzle is clean and at the wrong distance from the platform, the paper will have minimal pull resistance. It will also go under the nozzle without force.

It will also go under the nozzle without force.

How to know if the bed needs to be leveled:

- The height and the width of the thread varies

- The difference between the thread lines

- The incandescent thread only in places sticks to the construction surface

How to find out whether the nozzle should be installed:

The nozzle is too high 9000

Nozzle too low

- First coat barely visible or too thin

- Nozzle pushes filament in chute already on worktable

- filament builds up on nozzle

- No filament coming out on build plate

3.Be careful with nozzle temperature nozzle temperature, because if it is too hot, filaments can remain between the individual parts. When assembling tall elements, the heat melts the earlier layers, which can lead to warping.

nine0003

nine0003 To avoid this error, use a one centimeter cube built on the opposite side of the build plate. This will remove the hot nozzle from the print and leave enough time for it to cool.

.

11 interesting case studies of companies using 3D printing

So now you think you're ready. Last year, you explored everything in the world of 3D printing, scouring YouTube and Reddit for every last detail and understanding of this revolutionary new technology. nine0003

You may even have found the time to go out and buy a Sinterit 3D printer for your workplace. Naturally, you want to start your own 3D printing business.

However, before you dive into the depths of the world of 3D printing, you should take the time to understand how 3D printing is changing the industries around us so you can add value to your future 3D printing business. A little lost? Don't worry, Interesting Engineering will support you today.

SEE ALSO: 7 INDUSTRIES IN 2019 THAT WILL BE CURRENTLY 3D PRINTING DEFECTS IN 2019 of the world and check out some small examples of companies doing interesting things with these technologies. So, put on your 3D printed glasses.

Business is a Boomin

Source: 3D Hubs

2019 will be an exciting year for 3D printing. As mentioned in 3D Hubs Q1 2019 3D Printing Report: “The most significant change in 2018 has been the evolution of our perception of the technology. 3D printing is no longer just used for prototyping; Additive is now a viable production method.”

From Bugatti to Adidas, 3D printing has already touched these industries with its technology affecting both the design process and the manufacturing process. With a market size well over 10 billion , the world of 3D printing is expected to grow by almost 23.5% annually over the next five years. So you may have come at the perfect time.

Source: 3D Hubs

According to the

survey of 400+ companies in the 3D Hubs report, 3D printing has two main functions across a wide range of industries: prototyping and additive manufacturing.As a prototyping solution, 3D printing is used to accelerate product development, and as a manufacturing technology, it is used to produce end-use parts. nine0003

3D printing for prototyping dramatically speeds up the design process by providing low cost functional prototypes and widely available solutions for companies of all sizes.

On the production side, companies are using this technology for things like mass customization, on-demand production, and even distributed production.

3D printing is everywhere

Source: 3D Hubs

As you can see from the subtitle, 3D printing is almost everywhere. However, there are some industries that are currently more attracted to technology than others. Going back to the 3D Hubs report, you will notice that 65% demand for 3D printing technology is driven by engineers working in the development of industrial, electrical or consumer products.

Going back to the 3D Hubs report, you will notice that 65% demand for 3D printing technology is driven by engineers working in the development of industrial, electrical or consumer products.

3D printing caught fire in the automotive industry: 3 out of 4 companies in the US and Germany (BMW, Ford, Volkswagen, Audi, Porsche, Mercedez-Benz, GM) are now using 3D printing for mass production of parts. for their vehicles or for the production of spare parts.

Source: 3D Hubs

However, the arts and media, medicine, and even the service industry have even caught the 3D printing bug. So, which companies are doing interesting things with 3D printing? We're glad you asked.

Office space for 3D printing

Source: Dubai Future Foundation

Company : Dubai Future Foundation

Industry: Construction

. Slowly but surely there are companies all over the world that promise to create houses and build them for much less money and time than what you are usually used to. nine0003

Slowly but surely there are companies all over the world that promise to create houses and build them for much less money and time than what you are usually used to. nine0003

Dubbed "The Office of the Future", this project is part of Dubai's broader strategy to use 3D printing to improve people's lives. With 20 feet tall , 120 feet long and 40 feet wide , the 3D printing used for the office building not only helped reduce labor costs by 50% , it only required 17 days to print.

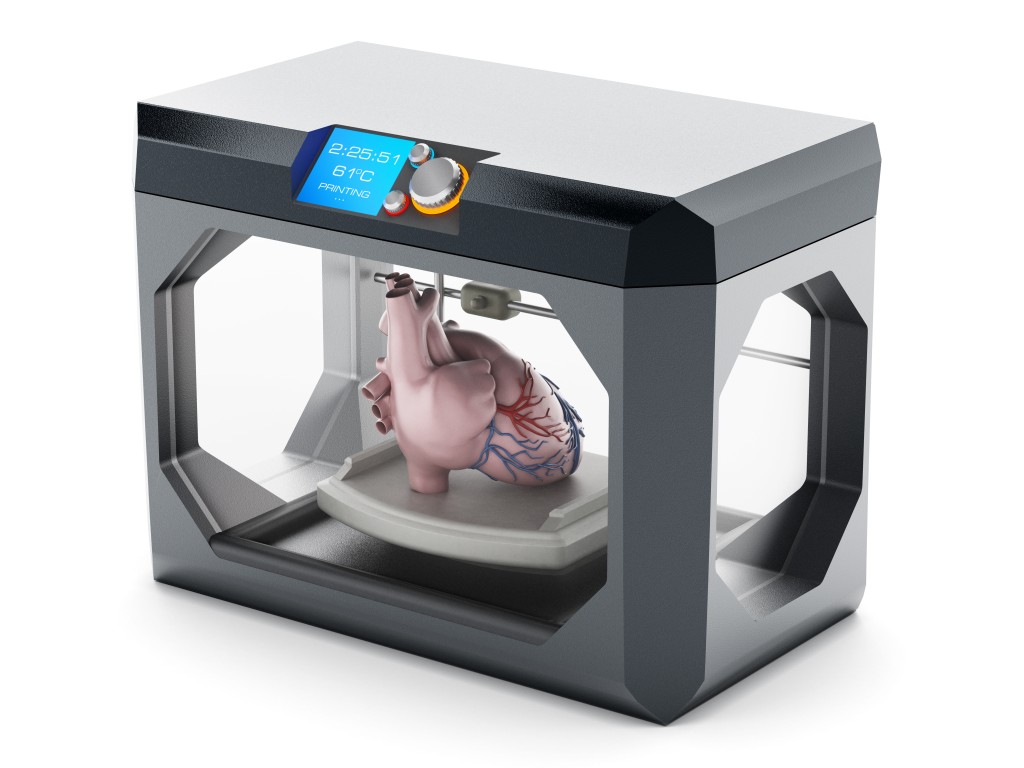

3D printed organs to save lives

Company: MBC Biolabs / Prellis Biologics

Industry: Medical

Implanting 3D printed organs in an injured person may seem like something out of a science fiction movie, but Prellis Biologics may well assure that it is a real possibility in in the nearest future. Within the MBC Biologic incubator, a small team has made viable steps towards 3D printing hearts, livers, kidneys and lungs.

Within the MBC Biologic incubator, a small team has made viable steps towards 3D printing hearts, livers, kidneys and lungs.

Classic car reengineering

Source: Mercedes

Company: Mercedes

Industry: Automotive

Finding a classic car can be tricky, but getting the right service or finding the right parts for your favorite classic can be difficult. eerily. 3D printing is changing that. Combining retro and future, the Daimler Group has teamed up with Mercedes Benz to find a way to 3D print spare parts for much sought-after Mercedes-Benz classics like the elegant 300 SL Coupé or SL Roadster. nine0003

Mercedes was able to take decades-old designs and sketches and breathe new life into them by printing the necessary parts from a variety of metallic materials.

3D-torture of the soles of sneakers

Source: Adidas

Company: Adidas

industry: Shoes / Fashion

may occur when most of your wardrobe will be fully printed on the 3D printer. Adidas Futurecraft Sneakers 4D shoes give us a glimpse into the future. nine0003

Adidas Futurecraft Sneakers 4D shoes give us a glimpse into the future. nine0003

In collaboration with 3D printing leader Carbon, Adidas has released a limited edition shoe with a durable and smooth 3D printed sole. The shoes were a success, hinting at the potential of 3D printing in the fashion world.

Riding a 3D printed bike

Company: MX3D

Industry: Transport

The project, called Arc Bike, was developed by a group of students with design experts from Delft University of Technology -printing MX3D. The six-axis robotic arm took three months to build, and the steel bike was built in the air without the need for support structures typically used for more complex prints. nine0003

3D printing Art baking

Source: Dinara Kasko

Company: Dinara Kasko

Industry: Using her Ultimaker 3D printer along with other 3D printing tools, Kasko has created visually appealing geometric kinetic cakes that look so good you almost don't want to eat them. Her work has taken over the internet, inspiring some companies to rethink how food is perceived. , and explore the role 3D printing will play. nineOl000 bring their designs to life at virtually no cost. Some fashion designers even create completely wearable pieces with the help of technology.

Her work has taken over the internet, inspiring some companies to rethink how food is perceived. , and explore the role 3D printing will play. nineOl000 bring their designs to life at virtually no cost. Some fashion designers even create completely wearable pieces with the help of technology.

Anouk Wipprecht's work is related to 3D printing. The 3D printed animatronic dress, dubbed the "Spider Dress", reacts to external stimuli by protecting the person with its web-like limbs from anyone who dares to get too close. nine0003

3D printing for space exploration

Source: NASA

Company: NASA

Industry: Aerospace

to travel with everything aboard the ship, why not 3D print while traveling or even at your destination? Here are some of the problems that NASA believes it is currently addressing. nine0003

Source: NASA

In addition to NASA's plans to potentially use 3D printing as a way to build housing in space, in 2018 NASA developed a spacecraft with 3D printed components. 3D printed spacecraft could significantly speed up space exploration.

3D printed spacecraft could significantly speed up space exploration.

3D printing for bridging

Source: MXD3

Company: MXD3

Industry: Architecture / Construction

MXD3 literally bridges the gap between design and 3D printing. As part of a project in Amsterdam, the team created a fully functional stainless steel bridge that will cross one of the oldest and most famous canals in the center of Amsterdam, Oudesijds Achterburgwal . More impressively, the bridge itself was built using two automated manipulators.

3D printed food

Source: byFlow

Company: byFlow

Industry: Food

Why not 3D print your own edible tableware. The launch of byFlow allows users to do just that.