Recycled plastic 3d printer filament

Which plastics can be recycled into filament for 3D printing?

Posted at 18:26h in Tech Corner by Francesco

Transforming plastic waste into new filament allows you to reduce waste. However, not all plastics are recyclable. Let’s see together how the most used plastics behave.

We all know the importance of recycling plastic materials, and how necessary this is to safeguard our planet. To get an idea of how much plastic impacts on the environment, just consider that according to various studies every minute the equivalent of a truck full of plastic waste is dumped into the oceans (source: Greenpeace).

Everyone can help turning the tide on plastic. We as 3D printing enthusiasts are required to have special attention: every day we handle plastic materials, and in the printing process we inevitably produce a certain amount of waste.

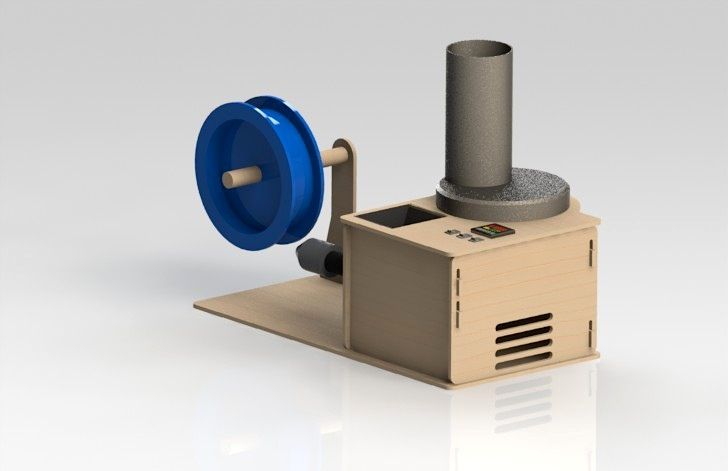

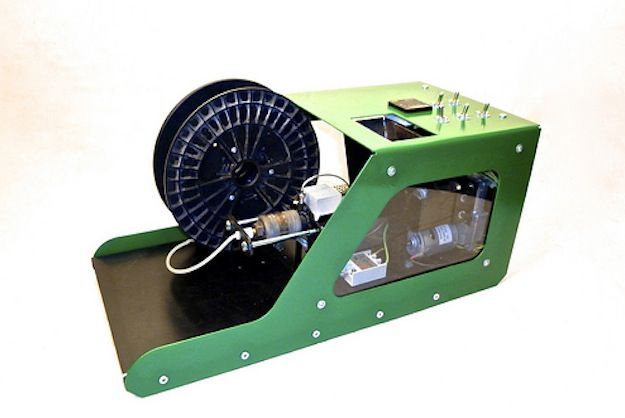

We designed our domestic extrusion system to go in this direction and help mitigating this issue: in fact, it allows to transform the waste materials of 3D printing into new filament, in order to bring them back into the production line and reduce waste. This way you use less plastic and save on the purchase of new filament.

However, not all plastics are recyclable at home, and not all behave in the same way: for this reason it is essential to correctly identify the plastic material you are working with. Doing this is quite simple: for most plastics all you need to do is check the distinctive number in the typical “recycle” icon. At this point, you can immediately understand whether the material can be turned into filament or not.

Here are the main plastic materials:

PETE or PET (1)

This is probably the most common material, frequently used for bottles, flacons and much more; it is very difficult to transform it into a new filament. Sometimes it can absorb the smell of food and liquids for which it is used as a container and above all it is designed for blow molding. For this reason extruding it is complex.

HDPE (2)

This material is used in the production of plastic bottles, food containers, corrosion resistant pipes. You can get new filament by recycling it, although it is recommended to have a cooling system to ease the process (like the one made available by our Spooler).

You can get new filament by recycling it, although it is recommended to have a cooling system to ease the process (like the one made available by our Spooler).

PVC (3)

Used for food packaging, construction and medical equipment. Due to its potentially dangerous chemical composition, PVC is not recyclable at home.

LDPE (4)

LDPE is widely used for the manufacture of various containers, disposable bottles, bottles for detergents, pipes, plastic bags. It is a potentially recyclable material, although chopping it is not easy due to the shape of the elements in which we find it, which are not always easy to treat. For this reason we recommend not to extrude this material due to the difficulties it presents.

PP (5)

Polypropylene is one of the most used plastic materials, and can easily be turned into new filament.

PS (6)

Commonly known as polystyrene, it is used to make food trays, cutlery, plates, caps, packaging and more. It can be recycled into filament without too much effort (in any case it is possible that particular types of polystyrene cannot be extruded).

It can be recycled into filament without too much effort (in any case it is possible that particular types of polystyrene cannot be extruded).

Other plastic materials (7)

This group includes numerous plastics; for more information on extrusion, we recommend that you visit the dedicated page on our website.

Finally, a small clarification: although extrusion is possible for the materials we have indicated, each plastic, even of the same type, can show a different behavior (due to the injection molding of the original parts). Furthermore, the quality of the extrusion can depend on various factors, such as the external temperature or the size of the starting granules.

For more information on extrusion of the most common materials, please download for free the guide below. We remain available for further information or for specific assistance requests.

Download Felfil Materials Guide

This device recycles plastic water bottles into 3D printing filament (and it's open source)

Here's a prototype of the Polyformer.

Plastics, ecologically speaking, have gotten a pretty bad reputation over the years, often quite deservedly so.

Nonprofit ocean conservation organization Oceana reports that two garbage trucks worth of plastic enters the world's oceans every minute. That's 33 billion pounds of plastic entering oceans every year. Mapping service Arcgis has charting data that shows there are five major patches of plastic-covered ocean covering 20 million square kilometers (7.72 million square miles). That's enough plastic to blanket Alaska, Texas, California, Montana, and New Mexico (The United States' five largest states by area).

The US Environmental Protection Agency reports that the US generated 35.7 million tons (roughly the weight of 17.8 million Tesla Model 3 vehicles) worth of plastic. Overall, only 8.7% of the plastic produced is recycled, but that rate differs based on the type of plastic because different types of plastics have very different chemical properties.

PLA, or polylactic acid, is the most common type of plastic used in 3D printing. It's a very easy-to-use material, it adheres to the print bed well, and is reasonably robust for many uses. It deteriorates in the sun and can be brittle, but the vast majority of items I've made have been printed with PLA because it works well in extrusion 3D printers.

PLA has some pluses ecologically, as well. Rather than being made from fossil fuels, it's made from renewable resources like corn, cassava, sugarcane or sugar beet pulp. PLA is also biodegradable, although there are some definite footnotes to that claim. It doesn't compost well. About half of the material decays over time, but the rest can remain for hundreds or even thousands of years. You don't want to dump PLA in landfills for the same reason. But PLA does incinerate rather nicely, leaving no residue or toxic fumes.

When it comes to recycling, PET (or polyethylene terephthalate), is something of a winner. According to the EPA, nearly 30% of all PET has been recycled. This is hugely important because PET is the material used to make plastic water bottles and jars. According to the University of Southern Indiana, Americans use 2.5 million plastic bottles every hour, most of which are thrown away after use.

This is hugely important because PET is the material used to make plastic water bottles and jars. According to the University of Southern Indiana, Americans use 2.5 million plastic bottles every hour, most of which are thrown away after use.

A modified variant of PET, known as PETG (polyethylene terephthalate glycol-modified), is also quite popular in 3D printing. PETG replaces the ethylene glycol in PET with cyclohexanedimethanol, which adds six additional carbon atoms. This makes the molecular structure less tight, and that allows the plastic to melt at a lower temperature.

PETG will melt at about 230 degrees C. By contrast, PET (the water bottle plastic) will melt, but at temperatures closer to 280 degrees C. That's near the top end of the temperature range for most hobby-level extruders on 3D printers.

The fact that PET can technically be 3D printed opens up a simple question: How can we turn water bottle plastic into 3D printable filament?

Reiten Cheng, an industrial designer who just graduated this spring from Pasadena's ArtCenter College of Design, seems to have an answer. And it's open source. He calls it the Polyformer.

And it's open source. He calls it the Polyformer.

Polyformer heated extrusion mechanism

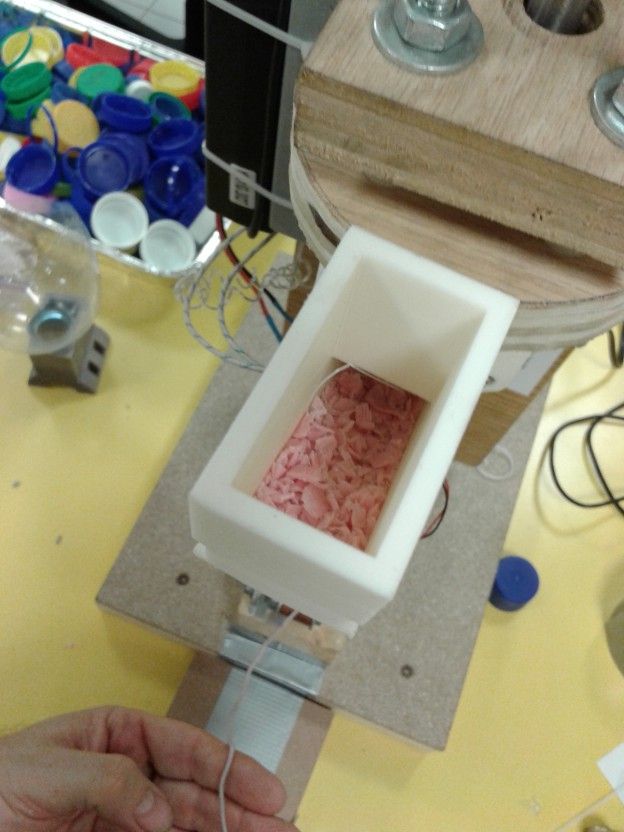

Image: Reiten ChengThe idea for the Polyformer is simple. Use a pair of scissors to cut the bottom off of a water bottle. Insert the bottle in the Polyformer. The device slices the bottle into strips. An extruder heats the strips and pushes out plastic filament. From used bottle to ready-to-use filament, it's an idea with potential.

Image: Reiten ChengWhile filament does come in larger and smaller amounts, most filament is sold on 1 kilogram spools. When I spoke to Cheng on his Polyformer Discord channel, he told me that roughly 33 bottles would create a kilogram spool of filament.

Image: Reiten ChengI see this as a great community or makerspace project. A school or makerspace could collect the bottles and turn them into filament spools.

3D printed parts and additional components that make up the Polyformer

Image: Reiten ChengAs I mentioned above, PET is a bit of a challenge to 3D print, especially with how stringy it gets and how difficult it is to dial in the temperature settings. But once that's figured out, a school or makerspace could have a virtually infinite (and free) supply of this very robust 3D printing material.

But once that's figured out, a school or makerspace could have a virtually infinite (and free) supply of this very robust 3D printing material.

Slicing mechanism

I was particularly curious about how the bottles are cut. Discord user @Alextrical told me that, "It's the bearings that cut the bottle, the edges slide over each other and shear the plastic similar to scissors." So this would be safe in a community environment, and there are no issues involved in sharpening or replacing blades.

It should be noted that Cheng isn't the first to build a PET plastic bottle to filament recycling device. He cites as inspiration Joshua Taylor at recreator3d.com, which has plans and parts lists for a similar device. Taylor's approach is to convert a Creality Ender 3 3D printer into a "Plastic Bottle Pultrusion Unit".

It's an interesting approach -- upcycling a 3D printer to make a device that recycles plastic bottles to be used as filament for a 3D printer.

So what about you? Do you think you'll build a device like this? Do you want to do your part in recycling plastic bottles by turning them into 3D printing filament? Let us know in the comments below.

3D Printing

- The best 3D printers: From FDM to resin

- These are the most googled 3D printing questions of 2022, answered

- The top 3D printers under $500

- This device recycles plastic water bottles into 3D printing filament

You can follow my day-to-day project updates on social media. Be sure to follow me on Twitter at @DavidGewirtz, on Facebook at Facebook.com/DavidGewirtz, on Instagram at Instagram.com/DavidGewirtz, and on YouTube at YouTube.com/DavidGewirtzTV.

Recycling plastic for 3D printing, PET.

Reviews

Follow author

Follow

Don't want

15

The article refers to Re-fill (recycled PET plastic for 3D printing).

This time we're looking at converting plastic into 3D printing filament.

Recycling is not as easy as it sounds, and many companies have tried before and now to start using recycled filament for their 3D printers. Anyone who has tried to make their own filament on a small scale will understand how difficult it is, even with the newer plastic pellets.

Anyone who has tried to make their own filament on a small scale will understand how difficult it is, even with the newer plastic pellets.

Last year I was very lucky: I got 3DFilaprint and it was a big recycling project, it taught me that making quality filament is very, very difficult.

I produced several batches of recycled ABS for a local shop. I have even tried to recycle some polypropylene and PET, with limited success.

Of course, the easiest way is to use ready-made PET, PLA and WoodFill granules. Making my own colored WoodFill yarn was a lot of fun and exciting. Doing it professionally - for your home 3d printer, to make it from plastic scrap, having previously cleaned it, melted it and squeezed it out, is not at all an easy task.

I posted this photo of the failed print above - the print failed due to a mechanical printer error - it's not the fault of the bad filament.

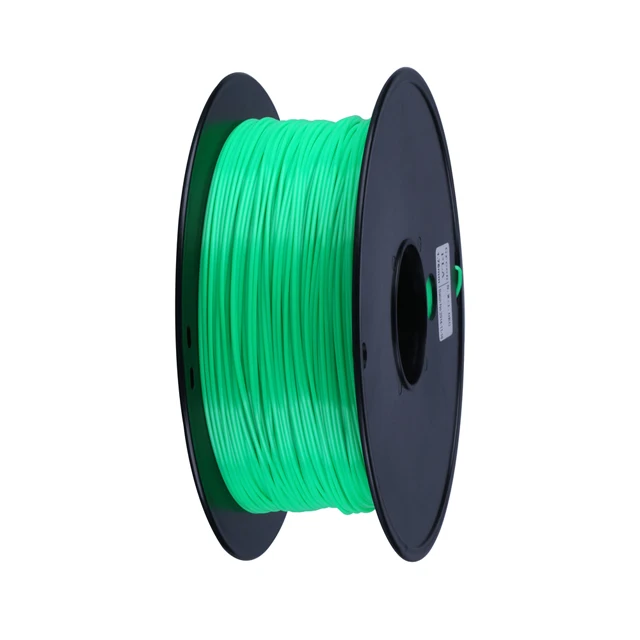

I was very happy to win a Refil PET reel. It contains up to 90% recycled plastic bottles. The team has been working on this plastic for the last 3 years. How much you get is 750 grams of thread, while the total weight including packaging is about 900 grams. What it looks like -

It contains up to 90% recycled plastic bottles. The team has been working on this plastic for the last 3 years. How much you get is 750 grams of thread, while the total weight including packaging is about 900 grams. What it looks like -

I had a full roll of clear PET and a sample of black ABS filament, which is made from recycled car panels. PET is indeed very transparent. It's so transparent, in fact, that I'm even a little concerned that it's really recycled material and not new. I was expecting bubbles and maybe even a few slight color casts or a slight opacity.

PET plastic bottles and recycling symbol.

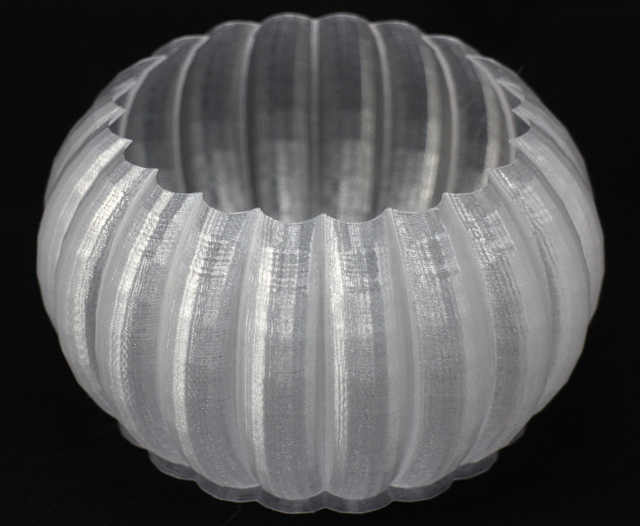

The most important aspect is dimensional accuracy. My spool was 1.75mm and I'm more picky about it than 2.85mm thread. I measured about 50 times at the beginning, middle and end. The whole spool was 1.76mm - almost negligible deviation. How do they print? I started printing at a normal PET temperature of 230 degrees C and printed a simple single layer vase for optical clarity testing.

Singvers classic bottle.

Printed in actual size - for comparison - glass on the left, PET on the middle and white PLA on the right. It was once a PET bottle, and now, after being recycled and 3D printed, it's a PET bottle again :) But printing at 230 is not very good for this particular type of PET material -

Bubbles as far as I can tell not moisture content. Lowering the print temperature corrects this issue.

You won't get sharp prints even with good PET, the layering process causes a slightly translucent final print.

I love all types of PET and use Taulman t-glass and ColorfabbXT regularly. In the image above, you can see the same print with these different PET materials.

You can print whatever you want with PET, although it will be very slow.

Follow author

Follow

Don't want

15

More interesting articles

Prim3d

Loading

11. 09.2022

09.2022

887

eight

Follow author

Follow

Don't want

Hi all!

Anycubic 4max DUAL printer arrived for maintenance. Ec clogged up a bit...

Read more

one

Subscribe to the author

Subscribe

Don't want

We present you a review of a large-format device for post-processing SLA 3D models - Form Wash L...

Read more

113

Subscribe to the author

Subscribe to the author

Don't want to

The review is a continuation of the story about the practical use of laser engraving at home . ..

..

Read more

9 projects that print on a 3-D printer from plastic waste

1

1 waste that was not so long ago sent straight to landfill is increasingly involved in reuse, and 3D printers play a significant role in this.

By using post-consumer plastic as a raw material for 3D printing, corporations, small businesses and even individuals can create new products with real value while removing plastic waste from the environment. Let's figure out what is created from plastic waste using a 3D printer and who does it.

How to prepare material for 3D printing from plastic waste

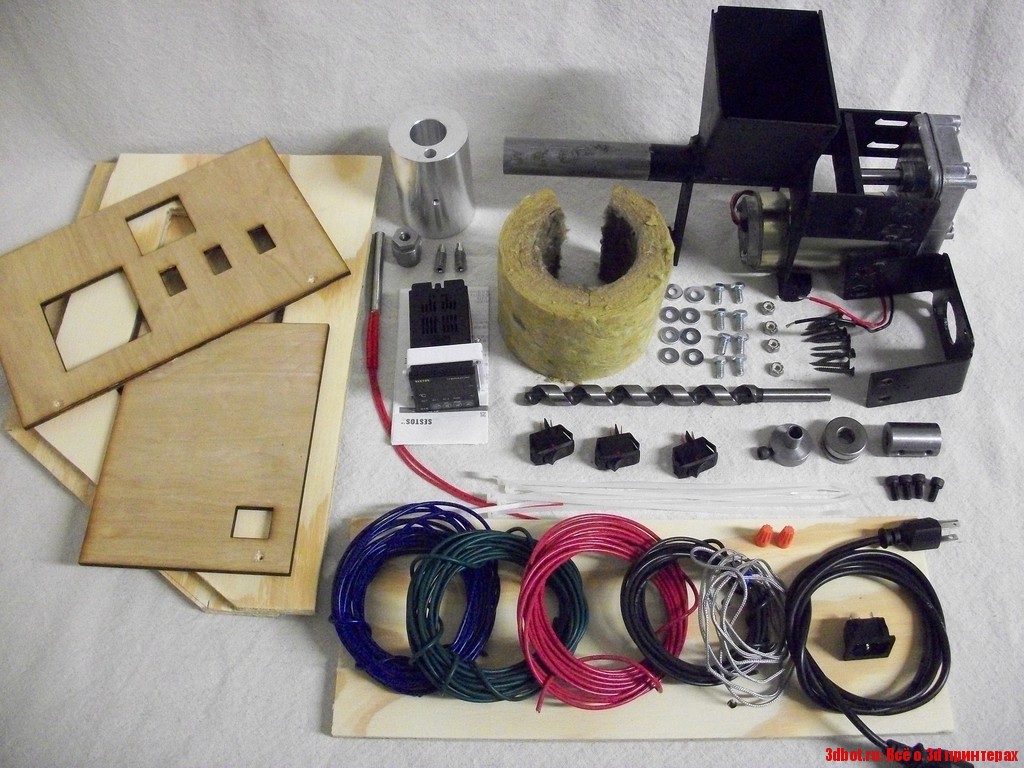

The process of making useful products from local plastic waste using 3D printing is quite simple. Known as distributed recycling and additive manufacturing, or DRAM for short, it involves the following steps:

• Plastic waste collection.

• Waste sorting and cleaning.

• Shredding waste into plastic pieces.

• Extruding 3D printing filament from plastic shred with an extruder.

• Product printing.

Video: thenewraw.org

Thread made in this way retains almost all the same qualities as pure plastic, but is much cheaper. According to a study by Aubrey L. Verne (et al.) of Michigan Technological University, a 3D printer can print objects at a cost 1,000 times less than if commercial polymer fibers were used.

There are different types of shredders, extruders and 3D printers on the market today, both in terms of cost and complexity of the tasks performed.

For example, for home use, manufacturers have long used a simple blender or grinder to grind up 3D print stock and failed prints, but this is not a long-term or high-volume solution.

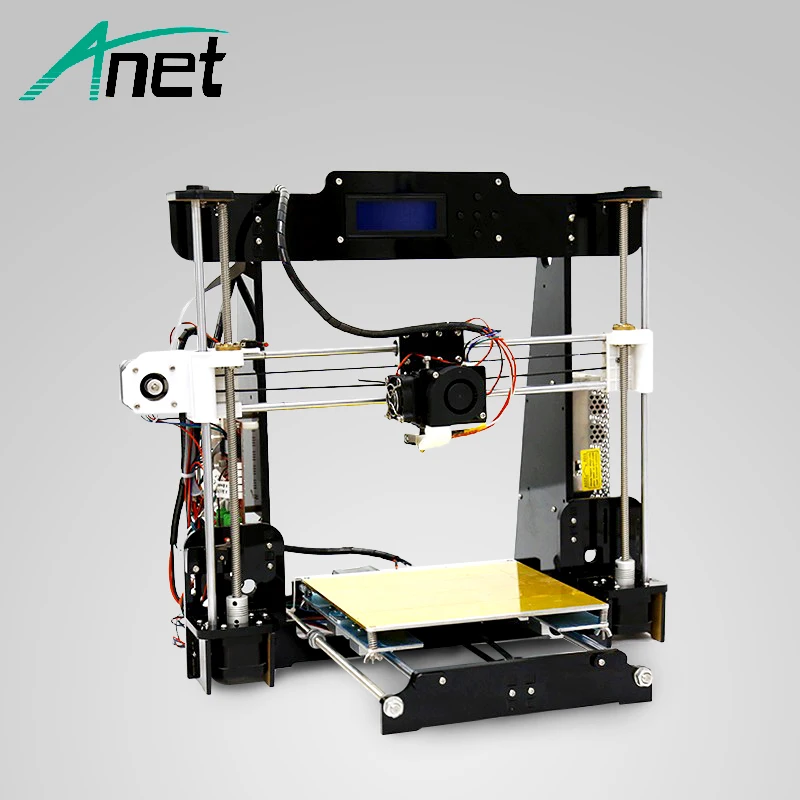

More and more 3D printers can print with raw shredded plastic or bulky plastic pellets instead of filament. This simplifies the process and reduces energy consumption. The cost of a simple 3D printer can be $2,000, and a complex industrial one can cost more than $150,000.

The cost of a simple 3D printer can be $2,000, and a complex industrial one can cost more than $150,000.

Introducing 9 successful projects that prove that 3D printing from household plastic waste is a viable solution for removing plastic from the environment, while also making a difference.

Plastic Bottle Olympic Podiums

Unbeknownst to everyone, recycled plastic has taken center stage at the Tokyo 2020 Olympic Games. Each of the 98 podiums where medals were presented to Olympic winners was 3D printed from waste plastic.

Catwalk material has been collected by Japanese citizens over the past two years through a program sponsored by consumer goods giant Proctor & Gamble. More than 2,000 bins have been set up across the country to collect empty drink bottles, shampoo containers and other plastic waste. Plastic waste has also been fished out of the seas surrounding Japan.

After the games, some of the podium plastic will be used to educate the public about sustainability, and much of it will be recycled back into packaging for P&G products.

Plastic waste bins

Screenshot: 3D printed waste container by Justina Zdanovichiute, in collaboration with R3direct.

(Source: Justyna Zdanovichute/CC BY-NC-ND 4.0)

How about collecting plastic waste in trash cans made from the same waste? Italian design company R3direct makes them and more using 3D printing. The company has one stated goal: to design and 3D print products from plastic waste. R3direct's product list grows longer every year, from artwork made from local plastic waste to practical urban furniture.

R3direct states that their printing technology can use plastic pellets immediately after grinding, skipping the filament extrusion step. This allows them to further reduce their energy consumption and CO2 emissions with 3D printed furniture made from waste plastic.

Trendy Fishnet Seats

Photo: facebook/@bluecycle

New Raw, a company based in the Netherlands, has created a series of marine plastic Second Nature chairs in collaboration with Blue Cycle, a Greek initiative to recycle use of marine plastic waste from shipping and fishing.

New Raw has also teamed up with The Coca-Cola Company for the Zero Waste Future program in Thessaloniki, Greece. Consumers will bring their plastic waste to the Zero Waste Lab, which has a plastic recycling facility and a robotic arm, to create custom-made modern furniture.

One of the partnership's furniture series is called Elements and includes a solarium, walk-in closet and walkway made from recycled marine plastic waste. There's no better way to showcase the potential of recycling plastic waste than to let people enjoy a clean beach while lying on a lounge chair made from what used to pollute the water.

New Raw is launching a Print Your City program in several neighborhoods that allows local residents to recycle their plastic waste through a robotic 3D printing process that can turn sorted plastic into outdoor furniture.

Music festival waste sunglasses frames

Photo: instagram/@yuma.labs.circular closed loop models.

Yuma Labs uses both powder pad 3D printing and injection molding to make their sunglasses. The raw materials are recycled soda bottles and bio-based nylon. In the future, the frames of sunglasses can be completely recycled.

Yuma Labs partners with companies, cities and events such as the Tomorrowland Music Festival to collect the plastic waste generated at the event. And the sale of sunglasses, then printed on a 3D printer from this garbage, covers the cost of collecting plastic.

Yuma Labs also organizes and participates in community events to raise awareness about recycling. For example, in 2019 they organized an event at the Stormkop playground in Antwerp where children had to pull plastic trash from a nearby river. The company then 3D-printed it into children's sunglasses.

As Yuma Labs says, it's not just the production of sunglasses or the recycling of plastic that matters. They hope to inspire others with their example for a broader transition to a circular economy.

They hope to inspire others with their example for a broader transition to a circular economy.

Plastic Waste Urban Lightweight Vehicle

Utility Vehicle (ZUV) is an electric trike with a 3D printed frame made from recycled polypropylene plastic.

Developed by Austrian design firm EOOS and Dutch 3D printing company The New Raw, ZUV aims to do more than reduce plastic waste. Its creators hope it can become the new type of zero-emission vehicle for cities around the world.

According to the developer's plans, consumers can 3D print the ZUV's polypropylene frame using a 3D printing service such as Craft Cloud and then take it to a bike shop to have the motor, wheels, lights and handlebars installed.

The square ZUV has a rear wheel drive and a spacious trunk. It can be ridden by two adults. EOOS hopes to raise awareness of the environmental impact of urban transport and offer an alternative mode of transportation based on a circular economy. 9The 0003

9The 0003

ZUV is currently only in the prototype stage and its blocky look may not be to everyone's liking. However, the concept is promising, and the car has every chance of becoming an ordinary city landmark.

Coffee station made from coffee waste

Photo: lofbergs-com.mynewsdesk.com

Swedish coffee group Löfbergs is partnering with 3D printing company Sculptur to turn coffee waste into new coffee stations. The collaboration is part of Circular Coffee Community's commitment and the group's goal of zero coffee waste by 2030. The world's first 3D printed waste-based coffee station is already up and running and others are underway.

The coffee stations are 3D printed from a by-product of the coffee roasting process and polypropylene. Further development will allow the use of polypropylene from recycled coffee big bags, making coffee stations almost 100% renewable.

“Our new coffee station is a prime example of a closed loop—recycling leftovers from our own primary raw material, coffee, to create an entirely new and associated sustainable product. ” , says Lars Aen Tegersen, Director of Innovation and Circular Transformation at Löfbergs.

” , says Lars Aen Tegersen, Director of Innovation and Circular Transformation at Löfbergs.

Cozy office space made from plastic bottles

Photo: instagram/@architechcompany interiors.

Modular circular workspace printed from recycled PET (supplied by the Port of Rotterdam) using a CFAM printer and reinforced with fiberglass. The convenient and strong workplace easily disassembles and moves. The round shape ensures pleasant acoustics of the workspace, it is equipped with ventilation, heating, electricity and LED lighting.

Beautiful objects made from garbage

Photo: instagram/@therogerie

The Rogerie, a Canadian company, removes waste from the environment, with the help of small suppliers who remove it from landfills and oceans, and creates from this waste beautiful, useful items.

The Rogerie's 3D printed product catalog includes mugs, bathroom accessories, teapots and a wide selection of flower pots, among others. Customers love these products - by purchasing them they are contributing to the removal of plastic waste from the environment.

Customers love these products - by purchasing them they are contributing to the removal of plastic waste from the environment.

The company's founders say they are constantly looking for new waste streams and also have their own recycling program. They are willing to use anything from old TVs to food packaging and car parts.

Coffee stirrer chandeliers

Photo: instagram/@utilizestudios

The Utilize project turned used coffee stirrers into chandeliers, soft plastic items into wicker baskets, and fishing tackle into chairs. And all this with the help of an oven and a desktop 3D printer from Ultimaker.

Utilize is more than a design studio, it specializes in helping companies transition to a circular economy and build sustainable products. They aim to help businesses reduce, reuse and recycle waste through 3D printing.

“The biggest surprise was how many types of waste we can use – soft plastics, organics, polypropylenes and polyethylenes – we kind of asked why isn’t everyone doing this?” , said Utilize Project founder Matthew O'Hagan in an interview with Stuff magazine.