3D printing solution

Industrial 3D Printing & Additive Manufacturing

Industrial 3D Printing & Additive Manufacturing - StratasysUSA & Canada

Select your country and region

- Americas

- English

- Español (México)

- Português (Brasil)

- EMEA

- English (United Kingdom)

- Deutsch

- Español

- Français

- italiano

- APAC

- 中文(简体)

- 日本語 (日本)

- 한국어(대한민국)

- English (India)

USA & Canada

The additive manufacturing leader

Stratasys provides complete polymer 3D printing solutions for every stage of the product life cycle, across design, manufacturing, and healthcare. Learn how Stratasys innovations help the world’s leading organizations change lives, gain business agility, and seize competitive advantage with additive manufacturing.

Learn More

We empower people to create without limits for an economical, personalized, and sustainable world.

We envision a world in which ideas become reality through 3D printing technology. The imagination of the human mind is unlimited. The limitations are physical ones that we can overcome. We are freeing engineers, manufacturers, educators, designers, doctors, and other creators from those constraints. Through the potential of additive technologies, impossible human challenges become possible.

About us

Solutions for your industry

Automotive

3D printing is helping Eckhart improve the lives of factory-floor workers.

Read More

Aerospace

INFN reduces costs by 90% with agile manufacturing.

Read More

Dental

Dynaflex use the J700 for accurate, high-output of clear aligners.

Read More

Medical

Children's Hospital Colorado turns to anatomical models to treat congenital heart disease.

Read More

Consumer Products

Kinetic Vision uses 3D printing to sell unique features of AeroFlexx liquid packaging.

Read More

Transportation

Angel Trains and DB ESG 3D-print spare train parts to reduce lead times by 94%.

Read More

Our Recycling + Returns Program is part of our commitment to Mindful Manufacturing™. It supports our users through a program that accepts used cartridges, canisters, spools, print engines and containers for return or recycle. With easy-to-follow return instructions and printable labels, we can all do our part for a more sustainable world.

With easy-to-follow return instructions and printable labels, we can all do our part for a more sustainable world.

Learn More

Stratasys has acquired Xaar 3D.

Stratasys has now acquired all outstanding shares of Xaar 3D, the joint venture behind SAF technology and our H Series solutions for production-scale additive manufacturing. The first 3D printer, the h450, is now available.

Learn more

Stratasys is Committed to Mindful Manufacturing™

We are proud to share our first Stratasys ESG & Sustainability Report. Our ESG strategy calls for advancing Mindful Manufacturing™, which is the thoughtful redesign of processes, parts and supply chains, utilizing 3D printing across the product lifecycle to maximize sustainability over time, all while supporting business growth.

Learn More

1960s supercars built with 21st century technology.

Radford Motors uses additive manufacturing from Stratasys to make their low-volume, highly customized specialty automobiles. But cars are complex. Learn how Radford uses multiple Stratasys 3D printing technologies to bring their iconic brand to life on the roads.

Watch Video

Fashion creativity unleashed.

Fashion designers are now producing one-of-a-kind garments with 3DFashion™ technology. Marvel at the complexity in design and optical illusions created by designers that are 3D printing their creations direct to textile. See unlimited creativity unleashed.

Learn More

patient care:

Digital Anatomy transforms lives.

Seattle Children’s is turning to Stratasys Digital Anatomy to plan complex pediatric surgical procedures. Synthetic digital twins of an actual patient’s anatomy, including the specific pathology in question, is transformative. Watch how it helped Nia.

Watch how it helped Nia.

View case study

3D Printers for Sale | 3D Printer Australia

3D Printers for Sale | 3D Printer Australia | 3D Printing Solutions3D Printing Solutions is Australia's premier online 3D Printer Superstore.

At 3D printing solutions, we are focused on stocking and supplying an extensive range of 3D printer gear, filaments and supplies to suit the unique requirements of business, education, home and government users in Australia.

One of our key philosophies has been to maintain a hands on approach with the brands we offer. Through consistent printing and testing, our team understand the nuances and advantages that each machine can offer to recommend the right solution for you. The printer brands we support are also used in-house every day as part of our 3D printing service.

- We only stock 3D printers and 3D Printer filament that give repeatable quality results.

- We've tested the products in our store and can advise on the best solutions.

- Service and support is handled right here in Australia.

- Australia wide delivery

- FREE Delivery for orders over $150*

*Some remote regions or products may be ineligible for free shipping.

Shop Now

3D Printers that print with the quality and ease that you expect

3D Printer Store

What's New

-

Raise 3D E2-CF

Price:

AUD ($8,995.00 Incl Gst) $8,177.27 Ex Gst

See details

-

Raise 3D Pro3 Plus

Price:

AUD ($15,750.

00 Incl Gst) $14,318.18 Ex Gst

00 Incl Gst) $14,318.18 Ex Gst

See details Add to cart

-

Raise 3D Pro3

Price:

AUD ($11,550.00 Incl Gst) $10,500.00 Ex Gst

See details Add to cart

More What's New...

Staff Picks

-

Ultimaker S3

Sale:

AUD ($7,735.

50 Incl Gst) $7,032.27 Ex Gst

50 Incl Gst) $7,032.27 Ex Gst

Price:

AUD ($8,595.00 Incl Gst) $7,813.64 Ex Gst

See details Add to cart

-

Vaquform DT2

Price:

AUD ($1,837.00 Incl Gst) $1,670.00 Ex Gst

See details Add to cart

More Current Specials. ..

..

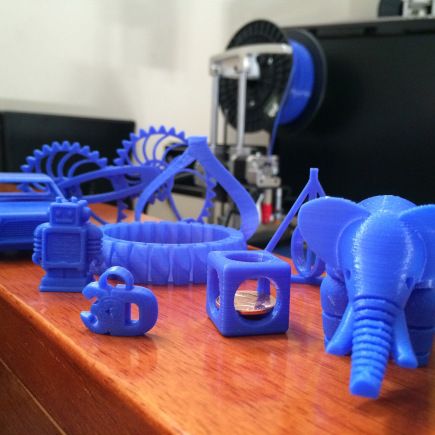

What can you do with a 3D Printer?

Need a replacement plastic part or want to prototype a new business idea?

The advancement of 3D Printing has changed the way individuals and organizations are solving challenges and approaching creative expression. With such a wide range of standard, engineering and industrial materials 3D Printing; can be a powerful tool for professionals, hobbyists, teachers and businesses to rapidly manufacture custom solutions.

- Automotive Repair

- Creative Expression

- Defence

- Education Models / Cutaways

- Low Production Manufacturing

- Moulding & Casting (Plastic, Silicone, Metal)

- Rapid Prototyping

- Replacement Parts

- Research & Development

- + more!

About 3D Printing

Need Help?

Dont know where to start? Or which filament will suit your application?

We have a broad range of support options including Telephone Support

Contact Us

Complete 3D Printing Solution - 3D Farms

Home

Complete solution for 3D printing - 3D farms

What is a 3D farm

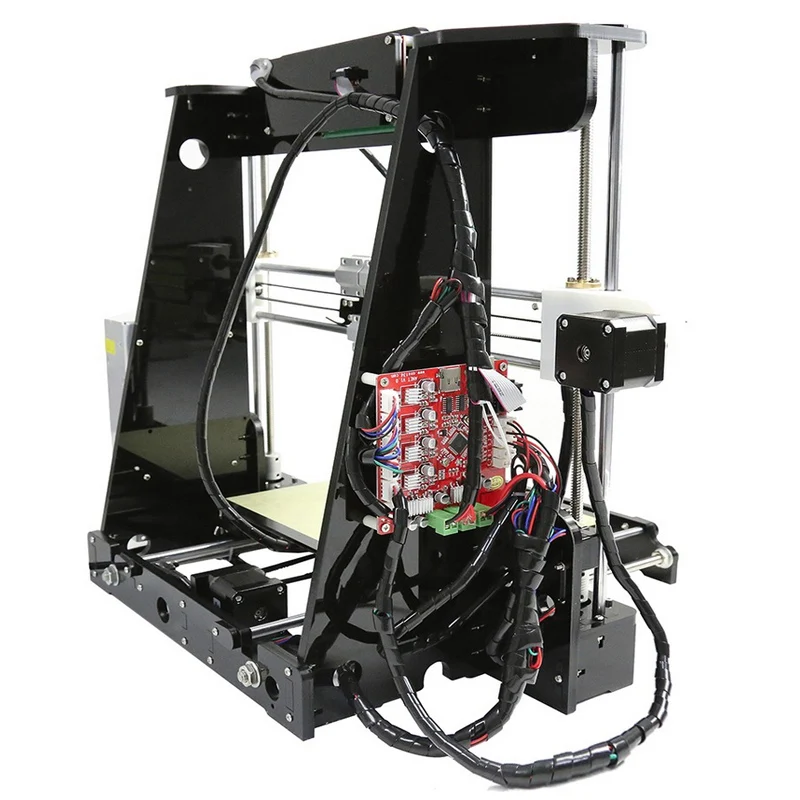

A 3D farm is a set of 3D printers, usually of the same type and performing standard tasks, within one enterprise.

A well-managed 3D printing farm can be a strong addition to an existing business or stand alone. Creating a cell from several 3D printers will increase production capacity, allow simultaneous production in several materials and offer 3D printing to customers as a paid service.

The use of 3D printing in production allows you to shorten the production cycle, reduce overhead costs and reduce the time needed to translate projects into a finished product.

3D printer farms are the best solution for starting or expanding your business. Their advantages:

- Easy scalability – from small workshop to factory

- Quick install and start

- Ideal for fast turnaround times

Why you need a 3D farm

For a large team

A 3D farm increases the efficiency of a team of engineers or designers - having several 3D printers will allow you to print models at the same time, without taking up a print queue and without waiting for several hours or days.

By dedicating one specialist to maintain the farm, you free the rest from the need to fill printers with material and control printing, which allows them to focus on their work.

For more productivity

Regardless of the industry, a production cell of several 3D printers allows you to increase production volumes.

The Formlabs farm, for example, which includes fifty Form 2 printers, produces about 650 models per week from different types of polymer, and only seven people work there. When printers are bundled together, there is no need for an operator for each device.

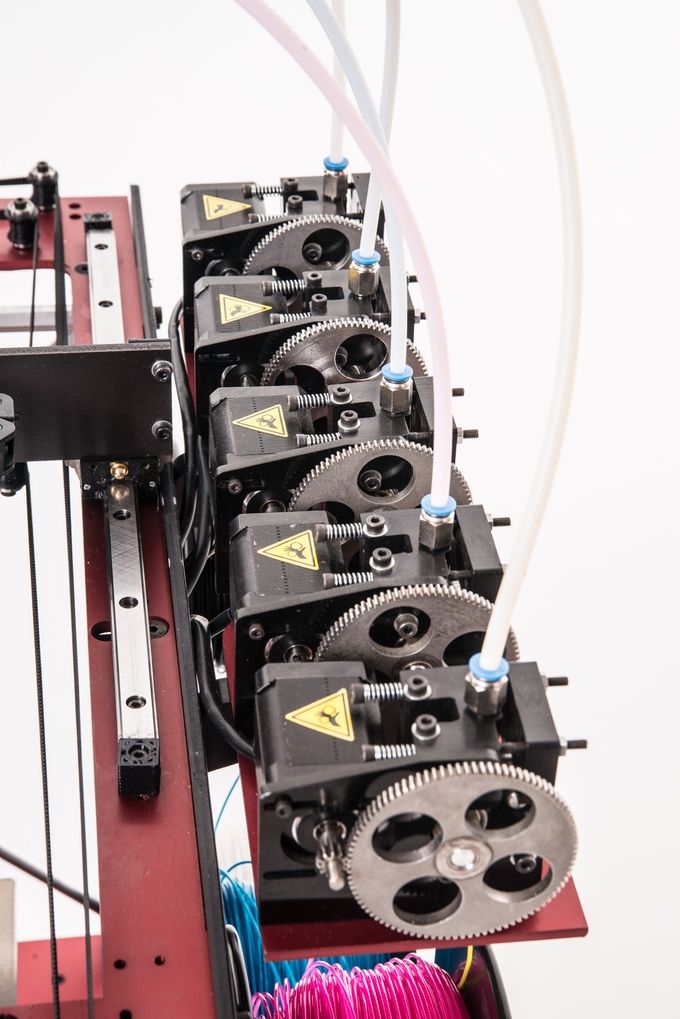

Multi-material

Most 3D printers print one material at a time. There are models of FDM printers with two or even three extruders, but such printers are also limited in the number of simultaneously used plastics. This forces you to wait until the end of printing to create the next model from a different material, which stretches the process for many hours. With a 3D farm, you can print parts from any number of materials at the same time, limited only by the number of printers in your farm.

With a 3D farm, you can print parts from any number of materials at the same time, limited only by the number of printers in your farm.

Custom print

3D print shop websites and 3D hubs accept 3D printing orders over the Internet, converting printer life into profit. Users who print too little to buy a 3D printer send them their models in .STL or .OBJ format and receive finished prints. This industry is growing, the service is gaining popularity. If you are interested in getting into this field and capturing your piece of the market, then it's time to get a small 3D farm, which can then be easily scaled up by adding new printers.

For Guaranteed Success

Even with the most reliable 3D printer, there is always the possibility of a breakdown, operator error or disruption due to unforeseen circumstances. If you have only one 3D printer, this situation can slow down the entire organization while it is being repaired, causing production delays and customer dissatisfaction. Having a farm of 3D printers, you are protected from suddenly being left without a 3D printing tool, and especially important orders can be duplicated by printing at the same time to ensure that force majeure is avoided.

Having a farm of 3D printers, you are protected from suddenly being left without a 3D printing tool, and especially important orders can be duplicated by printing at the same time to ensure that force majeure is avoided.

Options for execution

Fermlabs

FORMLABS FORM 2 Farm 2 is equipped with high-precision stereolithographic 3D printers that have proved to be well-produced by the quality standards in table stereolite.

Buy Formlabs Form 2

- High definition and quality

- Reliable printing process - ultra low reject rate

- An assortment of advanced photopolymers designed specifically for this printer, for any purpose

- Ideal for jewelry and dental applications

Ultimaker Farm

Ultimaker builds some of the most accurate and high quality FDM printers in the world. This solution is perfect for prototyping or custom 3D printing. The farm is equipped with Ultimaker 3 Extended 3D printers, which print simultaneously with two filaments in a working area of 215 x 215 x 305 mm.

Buy Ultimaker 3 Extended

- High quality printing from a renowned manufacturer

- Possibility of remote control via WEB

- Inexpensive and proven, familiar materials - Nylon, ABS, PLA, CPE

- Ideal for prototyping, small batch production of finished products

Makerbot Farm

MakerBot Farm is a centralized, scalable 3D printing center consisting of MakerBot Replicator + 3D printers.

The solution includes 3D printers and installation, custom printer manufacturer software, job training, technical support, and filament supplies.

Buy Makerbot Replicator +

- All settings standardized - high level of simplicity and reliability

- Optimized for PLA Makerbot

- All Inclusive - printers, installation, software, training, supplies and maintenance

Farm Custom

We will select 3D printers according to your requirements and create a project of the farm, taking into account the field of activity, the size and layout of the room, customer preferences, ergonomics and increasing efficiency.

To create an individual 3D farm project, please contact our staff.

To calculate the cost of and the timing of your order, send your request through the form or by mail:

stl@top3dshop. ru

ru

{simple_form}

ISL 3D printing solution for schools and colleges

One of today's barriers to the rapid adoption of additive technologies by schools is the lack of trained personnel to work with 3D printers.

Realizing this, our company offers not just a purchase of a 3D printer, but a turnkey solution for the school:

- Of course, this is the ISL 3D printer itself. You will receive a device completely ready for operation, tested in all modes of operation and configured. We will bring it ourselves, install it and run a test print for you.

- Training courses for teachers on 3D printing and working with an ISL 3D printer. We will teach you not just how to press buttons, but we will give you in-depth knowledge of how to prepare a model for 3D printing, printing itself, maintaining a printer, and teach post-printing processing of models. That is, everything you need to know for successful 3D printing, from start to finish.

- School consumables at special prices. We have tested a huge number of 3D printing plastics manufacturers, selected the best ones, signed contracts with them as 3D printer manufacturers and are ready to provide significant discounts from basic retail prices for educational institutions using ISL 3D printers.

- Technical and service support. We guarantee ISL printers for 10,000 printing hours or 5 years (whichever comes first). To date, no manufacturer offers such conditions. All this time we will carry out service and maintenance by our specialists. We take care of all possible problems, freeing you for the main thing - to give a quality education to our children!

Request for proposal

By submitting the form, I agree to the processing of personal data and confirm that I have read the terms and conditions of the online store

We all remember very well that studying at school was not very visual. Acquaintance with scientific achievements occurred mainly through textbooks, formulas and rare laboratory work. But in recent years, technology has been helping to move from theory to practice. And 3D printers help students in such practical interaction with the world.

But in recent years, technology has been helping to move from theory to practice. And 3D printers help students in such practical interaction with the world.

Recently, 3D printers are increasingly appearing in schools and universities. The main reason for these changes is that technology has become more accessible.

However, additive technologies have not yet become widespread. And this is primarily due to a lack of understanding of why they are needed in schools. So let's look at how 3D printers can benefit schoolchildren and their teachers.

So, first of all, 3D printing is visual.

For example, in lessons such as math, only textbooks and a blackboard are used as visual aids. Of course, with this approach it is difficult to enjoy the process of education. 3D printing can fundamentally change this situation and turn the most boring lesson into a captivating visual story.

Teachers of physics, chemistry, labor and mathematics will find the fastest use of a 3D printer.

The advantage of a 3D printer is that it allows an idea to become a reality. Quite often, study involves studying diagrams and drawings in a textbook and only in rare cases watching a video. It is often difficult for the student to imagine what the book is about. For example, how the tectonic plates of the earth shift and provoke earthquakes. Of course, illustrations help to capture the general essence, but creating physical objects for demonstration to schoolchildren is undoubtedly the best solution. With the help of printed objects, even complex concepts about the structure of the world, how technology works, etc. can be explained.

Second, the 3D printer is a source of fun learning. Working with the printer, the student puts his knowledge into practice.

Studying mathematics, every student at least once experienced strong doubts that any equation will be useful to him in life. A 3D printer is able to clearly demonstrate how important mathematical formulas are in practice. Before printing, an object must be designed in a CAD program, and its use requires a certain amount of mathematical knowledge. Thus, the student has to apply the knowledge gained in the lessons to create a real project.

Before printing, an object must be designed in a CAD program, and its use requires a certain amount of mathematical knowledge. Thus, the student has to apply the knowledge gained in the lessons to create a real project.

A student learns to create!

The use of 3D printers in schools gives students the opportunity to create their own projects, develop creativity, test materials. This can lead to both failures and unexpected successes. In any case, practical work contributes to the assimilation of a particular topic.

Thirdly, doing 3D printing, the student spends less time on gadgets.

The Internet has become an important tool in education. He turned a guilty “I don’t know” into a confident “Googling now.” Through the Internet, students can easily master a huge amount of new material. However, this results in more screen time. Long-term work at the computer causes headaches and myopia. The introduction of 3D printers into schools means kids will be more likely to engage with physical objects rather than hang out on social media. 3D printing for kids is a chance to develop their imagination, explore the real world and create collections of printed objects.

3D printing for kids is a chance to develop their imagination, explore the real world and create collections of printed objects.

So how can 3D printing be used in different classrooms? Here are a few examples:

Mathematics

Students can print geometric shapes as well as city infrastructure models to solve problems.

Geography

Dry theoretical data is 3D printed into physical objects. So, you can see in practice how soil erosion looks like, mountains form, etc.

History

The 3D printer can print replicas of fossils and other artifacts that can be seen in museums but not touched.

Biology and Chemistry

Students can print 3D models of molecules, cells, viruses, organs and their elements. 3D printing will help understand how biological processes work.

Even today there is confidence that in the very near future 3D printing will bring more and more benefits to the education sector.