Projet 3d printer for sale

ProJet 2500 3D Printer | 3D Printing Supplies and Equipment

Product of Interest:

ProJet 2500 3D Printer

SKU: projet25003DS

The 3D Systems ProJet 2500 3D printer enables industrial quality parts at an affordable price. Utilizing the high-throughput MJP printhead and allowing for hands-free post processing, the ProJet 2500 empowers your team to print more parts sooner and to design better products faster.

Skip to the end of the images gallery

Skip to the beginning of the images gallery

Professional Quality Parts

Print precision rigid and elastomeric parts with true-to-CAD accuracy, superior surface finish and high-quality edge fidelity for true functional testing. Capable of printing in Ultra High Definition mode, the ProJet® MJP 2500 Plus makes it possible to print even smaller features, down to 300 microns or finer.

Speed and Throughput

Step up from desktop 3D printing to 24/7 usability and get more parts sooner to design better products faster. The ProJet MJP 2500 printers' industrial print head and optimized print parameters deliver up to 3 times faster print speeds than similar class printers for better efficiency and higher productivity.

Simplicity

Driven by the powerful 3D Sprint client software, ProJet MJP 2500 printers deliver high fidelity functional parts with speed, ease and low operational costs. The new MJP EasyClean System is an incredibly simple and hands-free way to remove supports from MJP parts in under 30 minutes without manual labor.

3D Printer

3D Printing Materials

System Details

Documents

3D Printing Process

MultiJet Printing (MJP)

Printing Material

Wide range of VisiJet materials including engineering-grade, rigid, elastomeric, high temperature resistant and biocompatible materials.

Build Envelope Size

294 x 211 x 144 mm (11.6 x 8.3 x 5.6 in)

Popular Materials

VisiJet Armor

VisiJet HT-90

VisiJet M2R-TN

ProJet 2500 Material Selection PDF

Software

3D SPRINT Software included

3D Printer Footprint

1120 x 740 x 1070 mm (44.1 x 29.1 x 42.1 in)

Weight

211 kg (465 lb)

Power Requirements

100-127 VAC, 50/60 Hz, 15A, single-phase | 200-240 VAC, 50/60 Hz, 10A, single-phase

- MultiJet 3D Printing Brochure PDF

- ProJet 2500 Material Guide PDF

- 3D SPRINT Software Brochure PDF

ProJet 2500 Customer Success Stories

Bushnell

Learn More

PPI-Time Zero

Learn More

PROJET MJP 2500W | CAD BLU

PROJET MJP 2500W

$54,700.00

The ProJet MJP 2500W is a 100% wax 3D printer that prints fine wax patterns for direct metal casting and precision jewelry patterns. The 2500W adjusts to your workflow, delivering larger builds at high productivity. Price is printer only.

The 2500W adjusts to your workflow, delivering larger builds at high productivity. Price is printer only.

Best For:

Business Financing Available

Business Financing Available

Availability: Available on backorder Categories: 3DS, INVESTMENT CASTING, JEWELRY, MJP- WAX

- Description

- Additional information

- Vendor Info

- More Products

Description

Benefits

Main Features

Applications

Materials for the PROJET MJP 2500W

Casting Reliability

The ProJet MJP 2500W 3D prints in VisiJet M2 CAST 100% wax material to deliver durable, high-quality jewelry patterns for reliable performance and results throughout existing lost-wax casting processes and equipment.

VisiJet M2 CAST melts like standard casting waxes, with negligible ash content for defect-free castings. It is durable for handling and casting fine features, and its high contrast deep purple color allows for easy fine details visualization.

High Productivity

Featuring fast wax patterns production, at up to 10x faster print speed than similar class solutions, and even faster workflow with single-lane builds, the ProJet MJP 2500W improves the casting room efficiency. With a 3.7x larger build volume capability than similar class printers and 24/7 operation, the high productivity of this affordable printer means fast amortization and high return on investment.

Streamline your file-to-pattern workflow with the advanced 3D Sprint software capabilities, fast and versatile MJP print speeds and batch support removal to deliver high quality, ready-to-cast jewelry patterns.

High Resolution Patterns

Consistently print true-to-CAD and fine feature definition jewelry patterns with exact, razor-sharp edges and extreme crisp details. Smooth surface and sidewall quality mean less expensive handwork and a faster pattern-to-finished piece workflow. These highly accurate, fine wax patterns are directly printed, without the time, costs and geometric limitations of tooling.

Smooth surface and sidewall quality mean less expensive handwork and a faster pattern-to-finished piece workflow. These highly accurate, fine wax patterns are directly printed, without the time, costs and geometric limitations of tooling.

3D Sprint Software

Setting the new standard in 3D printing

PROJET MJP 2500W Printer Tech Specs (English)

Download

Interested in Printing a Part Today?

Bring your design to life and create real functional parts with our additive and traditional manufacturing technologies. Get an instant quote or consult with our experts to start your project today.

Get a Quote

What Can CAD BLU do for your business?

We sell more than 3D printers. We provide the best technology, product excellence, customer service and solutions in the market.

Contact Us

Additional information

| Color | Black, Blue, Red |

|---|---|

| Size | Extra Large, Large, Medium, Small |

| Build Volume | 510 x 280 x 350 mm |

| Print Speed | 13. |

| XY pixel size | 137 microns (Average accuracy of 50 microns) |

| Layer Thickness | 25, 50, 100, 200 microns |

| Curing speed | 3-8 seconds per layer (at 100 microns dependent on resin) |

| Compatible resins | Daylight Magna resins SoftwarePhotocentric Studio |

| Connectivity | USB, Ethernet, WiFi |

Vendor Information

- Address:

- No ratings found yet!

-

3DS, Aerospace, Automotive, Dental, INVESTMENT CASTING, MEDICAL, SLS

sPRO 140 SLS

-

DLP (Digital Light Processing), Figure 4 Standalone, Materials, Polypropylene and Polypropylene-like, Tough & Durable

FLEX-BLK 20, 1 kg (FIG 4)

$249. 00

00

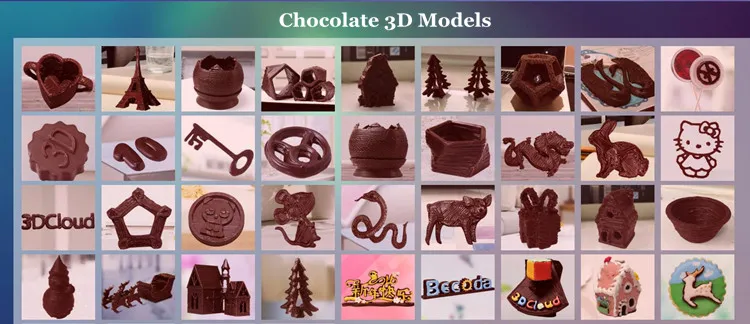

Cool 3D projects using 3D printing

3D printing

Subscribe to the author

Subscribe

Don't want

12

Chapter 1. Background. In this article I will talk about why you need a 3D printer at home and what you can do with it. And you can make and print on a 3D printer any part, both plastic and rubber. but the secret of success lies in the fact that it is not enough to have a 3D printer, but you also need to be able to model parts and properly prepare them for the printing process. Anyone can afford to buy a printer, or you can assemble it yourself. But it takes time to learn how to model. A lot of my projects required the manufacture of non-standard parts, which is why the idea of buying a 3D printer was born. nine0003

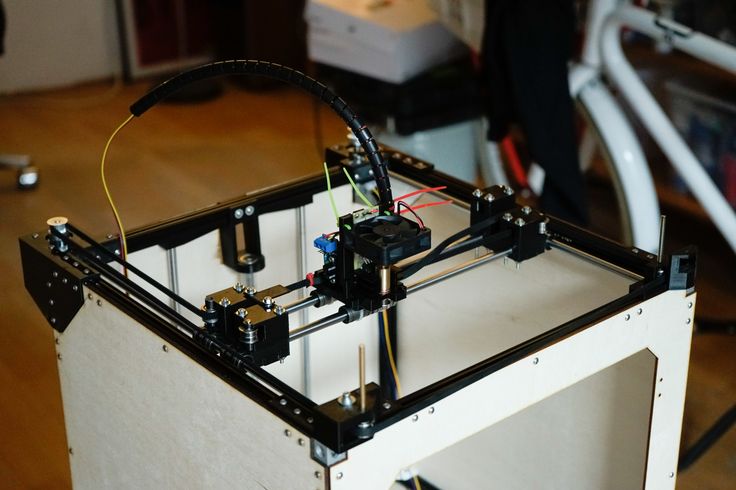

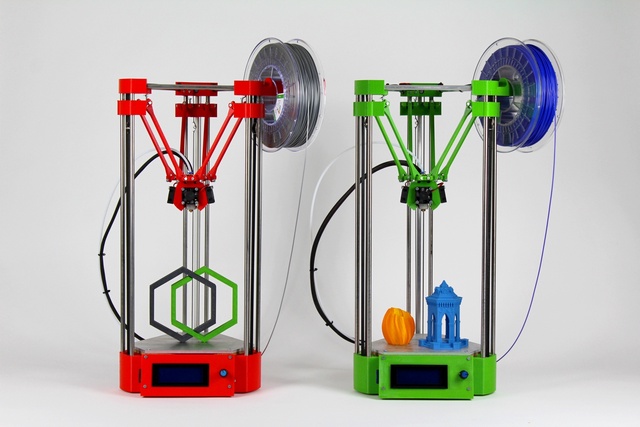

Chapter 2. Exploring the world of 3D printing and technology. My first printer was Anet A8. And like all beginner 3D printers, the first thing I started printing was upgrades for it.

Since stock printers from the budget segment, in my opinion, it is necessary to refine them so that they give more or less good results in printing. I described in detail about all my improvements on the site, who are interested can familiarize themselves with and apply for their Anet (https://3dtoday.ru/blogs/alexforward/konkurscrealityv). The printer turned out to be very functional and gave rise to a new printer with CORE XY kinematics. The printer turned out to be of decent quality and produced a good print result. And most importantly, it was more compact, had its own heat chamber, direct extruder, and the print speed on it was faster. This project is also described in detail by me https://3dtoday.ru/blogs/alexforward/klassnyi-3d-printer-po-tipu-core-xy-iz-orgtexniki-konkurscreality

But these were all finished projects modeled by other people, I just took the best and brought it to life. More serious projects already required the study of 3D modeling programs.

Chapter 3. Program selection and training . To study 3D modeling, I chose Compass 3D from Ascon. I think one of the best programs, since it is used by the majority, Compass is actively used in industry and enterprises, many free study lessons. But the most important factor, my brother, who works as a design engineer at the factory, can easily fix jambs when creating a model or suggest how best to do it. By the way, the program is easy to study on your own and does not require basic skills. I learned it from scratch, having no idea about 3D modeling at all. My first completed projects using Compass 3D and 3D printing were the creation of fittings (legs, handles, plastic dowels, etc.), electronics cases, radio-controlled models. nine0003

Program selection and training . To study 3D modeling, I chose Compass 3D from Ascon. I think one of the best programs, since it is used by the majority, Compass is actively used in industry and enterprises, many free study lessons. But the most important factor, my brother, who works as a design engineer at the factory, can easily fix jambs when creating a model or suggest how best to do it. By the way, the program is easy to study on your own and does not require basic skills. I learned it from scratch, having no idea about 3D modeling at all. My first completed projects using Compass 3D and 3D printing were the creation of fittings (legs, handles, plastic dowels, etc.), electronics cases, radio-controlled models. nine0003

Toys and accessories.

Tool. I will give an example of my template for installing handles and locks for interior doors. This template is my own developed copy of the existing model on the Internet. In terms of money, the template cost me almost 10 times cheaper than it is sold on the Internet.

But in order to create a part consisting of several parts, and print everything the first time, so that everything fits together, Compass 3D has a wonderful assembly function for this. In it, in fact, you can check whether the parts fit together and immediately make changes and corrections to the model. According to this principle, I implemented projects for the modernization and upgrade of my friends' 3D printers. nine0003

JGAurora print carriage upgrade. First, 3D models were made separately. Then, with the help of the assembly, they were brought to mind and adjusted to each other. The carriage became lighter, there was an adjustment of the tension of the belts along the axis, better blowing of the parts and, most importantly, the installation of an E3D V6 hotend.

Full upgrade of Anycubic I3 Mega. But in this project, half of the details were borrowed from other users.

Before

Now

This is just a part of my work. In fact, a huge number of parts and spare parts were printed. Not always everything worked out the first time, especially printing with ABS plastic was hard to master. I mostly print ABS as it is the cheapest material and is easily machined. Yes, it has many disadvantages, but for my purposes, ABS is the best material.

In fact, a huge number of parts and spare parts were printed. Not always everything worked out the first time, especially printing with ABS plastic was hard to master. I mostly print ABS as it is the cheapest material and is easily machined. Yes, it has many disadvantages, but for my purposes, ABS is the best material.

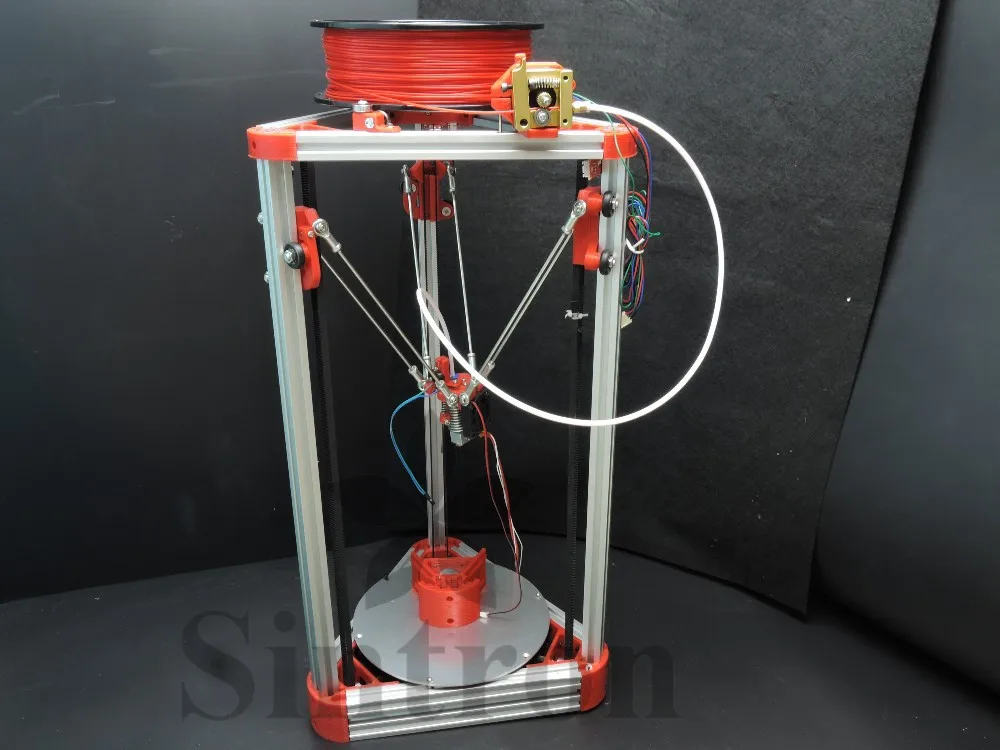

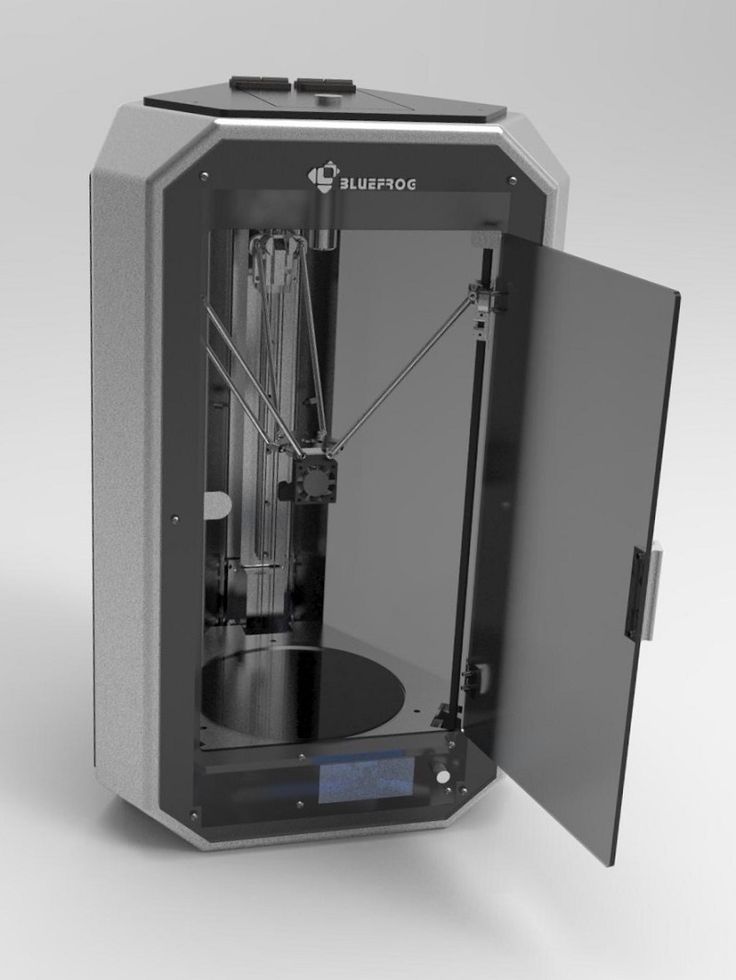

Chapter 4. Summing up. Having received basic knowledge of 3D printing and modeling, I decided to assemble a 3D printer for my purposes, so that it would be an indispensable assistant and meet the following requirements:

1. Printing with ABS plastic - need a hot table and closed case

2. E3D V6 hotend - for fast repair and availability of spare parts at low prices

3. Good print quality and printing speed - fast production of parts

4. Compact - takes up little space on the desktop

5. The printer must be popular with users - a large number of upgrades and the availability of information on maintenance and repair.

Ultimaker Original proved to be ideal for these requirements. This printer has all the files for its creation and refinement in the public domain, produces excellent print quality at high speeds. nine0003

To make an airtight chamber from a draft, I developed drawings for the doors and the hood of the printer, since I could not find these parts, and I made a box for tools. As a result, the printer takes up minimal space on the table. Someone will say that it is easier to buy a new one. I do not argue with this, but my goal was to minimize the cost of building a 3D printer, which is several times cheaper than the original. At the moment, Ultimaker is already hard at work creating my next projects. At the moment, a machine for sharpening knives and scissors has already been developed, it is waiting for its implementation. nine0003

And plans to build a CNC router and laser engraver from a structural profile for home use with a small area. These tools will significantly expand the scope of modeling and product creation.

3D idea

Subscribe author

Subscribe

Don't want

12

Total Z industrial 3D printers

FDM and SLS 3D printers, drying and post-processing equipment nine0003

About company

FDM 3D printers

Industrial 3D printers Total Z PRO series

450-PRO 950-PRO

Total Z High Performance LPRO Series 3D Printers

1000-PRO-LL

nine0004 Total Z G3 Series Desktop 3D Printers250-G3 250-G3 (2X) XL250-G3(2X)

Total Z G5 Series Desktop 3D Printers

G5

SLS 3D printers Total Z

SLS-250

Portal systems for 3D printing with granules nine0093

Total Z AnyForm FGF

Total Z machines for drying and post-processing

Total Z D5Vacuum drying chambers

Help prepare plastic for printing. Remove moisture from hygroscopic materials. Reduce the risk of plastic "boiling", extruder breakage, deterioration of the surface quality of the product. nine0003

Remove moisture from hygroscopic materials. Reduce the risk of plastic "boiling", extruder breakage, deterioration of the surface quality of the product. nine0003

Watch →

Total Z MPC-310Acetone baths

Equipment for chemical post-processing of finished objects. Helps to achieve a glossy and smooth product surface.

Watch →

Total Z UB-450; 500; 650; 950; 1200;Ultrasonic baths nine0005

Machines for physical and chemical post-processing of models. Remove the supporting plastic from the surface of finished products. They clean the material in places inaccessible for manual processing.

See 5 models →

Our capabilities

The equipment complies with Russian and international standards

Consumables for printers and equipment are always in stock nine0003

We participate in R&D, cooperate with research institutes

We work with defense enterprises and government customers

Operational warranty service

Departure and training on the territory of the customer

Implemented projects by industry

Aviation industry and special products nine0005

Supply of an industrial 3D printer for the project of the MS-21 passenger aircraft of Irkut Corporation.

Supply of high-temperature 3D equipment for the laboratory of additive technologies of VIAM.

Supply of a 3D printer for printing with experimental materials for the production of the Central Institute of Aviation Motors.

Shipbuilding

Selection of samples of engineering plastic for the project of printing body elements for a shipyard. nine0003

Auto industry

Supply of equipment for 3D prototyping to the plant of the AvtoVAZ group.

Rocket and space

Supply of the first production equipment for 3D printing to the Center for Additive Technologies of JSC RCC Progress.

Foundry nine0005

Fabrication of a matrix using FDM 3D printing for the production of piece metal parts that have been discontinued or to replace parts with a long delivery time.

Education

Production of a desktop 3D printer for schoolchildren and students in collaboration with a team of developers of teaching materials for classrooms. nine0003

Electronics

Implementation of 3D equipment at the Symbol East Kazakhstan Region.

Prototyping of lighting equipment for the Pyaterochka grocery store chain.

Agroprom

Complex equipping of the research agro-engineering center with equipment.

Aviation industry and special products nine0005

Supply of an industrial 3D printer for the project of the MS-21 passenger aircraft of Irkut Corporation.

Supply of high-temperature 3D equipment for the laboratory of additive technologies of VIAM.

Supply of a 3D printer for printing with experimental materials for the production of the Central Institute of Aviation Motors.

Shipbuilding

Selection of samples of engineering plastic for the project of printing body elements for a shipyard. nine0003

Auto industry

Supply of equipment for 3D prototyping to the plant of the AvtoVAZ group.

Rocket and space

Supply of the first production equipment for 3D printing to the Center for Additive Technologies of JSC RCC Progress.

Foundry

Fabrication of a matrix using FDM 3D printing for the production of piece metal parts that have been discontinued or to replace parts with a long delivery time. nine0003

nine0003

Education

Production of desktop 3D printers for schoolchildren and students in collaboration with a team of developers of teaching materials for classrooms.

Electronics

Implementation of 3D equipment at the Symbol East Kazakhstan Region.

Prototyping of lighting equipment for the Pyaterochka grocery store chain. nine0003

Agroprom

Complex equipping of the research agro-engineering center with equipment.

Services

3D printing

Casting

Reverse engineering

prototyping nine0251

Upcoming Events

New models of Total Z industrial 3D printing systems in Moscow at the Interplastica exhibition

Interplastica is a key event for the plastics and rubber market, which annually brings together experts from all over the world at one business platform.

3 mm per hour

3 mm per hour