Mycusini chocolate 3d printer

mycusini® 3D Schokodrucker - Profitechnik für zuhause

3D Schokodrucker mycusini

Inkl. 3D Choco mit Gelinggarantie & über 1.000 3D Vorlagen

Mit unserer Erfahrung im Profibereich bringen wir die faszinierende Technologie des 3D Lebensmitteldrucks in die private Küche

Tauchen Sie ein in eine grenzenlose Welt kreativer 3D Choco-Objekte

★★★★★"Ich hätte nicht gedacht, dass es so einfach ist. Die wunderschönen und leckeren Dekorationen machen gewaltig Spaß".

Marion Strauch, Backbloggerin, www.marions-kaffeeklatsch.deDeutschland

★★★★★"Genial - ich möchte schreien vor Begeisterung. Und so einfach zu bedienen! "

Winnie Lee, Tortenkünstlerin, www.instagram.com/ohcakeswinnieLuxemburg

★★★★★"Meine Mama und ich haben gleich unsere Namen gedruckt - toll. Auch die Schokolade ist super lecker."

Brigitte Klinger, Gran CanariaSpanien

★★★★★"mycusini war der erste 3D Drucker, der dauerhaft in der Küche geduldet wurde.

Mark Bernhardt"

Geschäftsführer Qube Tech, Deutschland

HobbybäckerInnen

aufgepasst

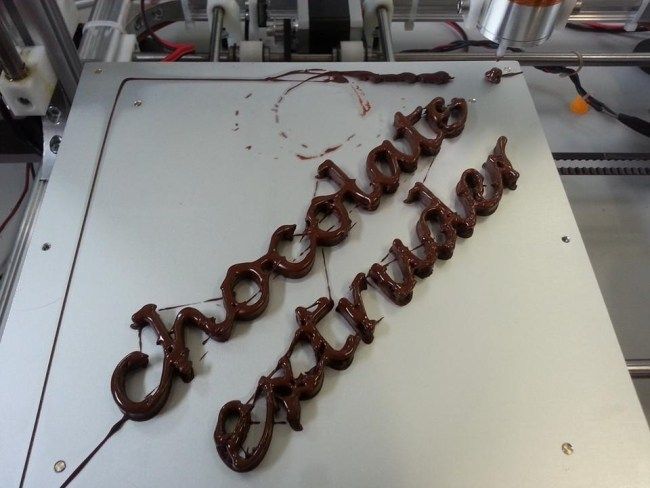

Torten Toppings, individuelle Schriftzüge, Pralinenhohlformen

Zum Shop

Unendliche

Möglichkeiten

Zahlreiche Anwendungen und über 1.000 Vorlagen im mycusini Club

Zu den Anwendungen

Persönliche Geschenke

zum Vernaschen

Individuelle Geschenke zu Geburtstag, Hochzeit, Taufe & Co

White, Pink, Blue und Dark

3D Choco

sowie Dark in den Varianten Himbeere, Orange und Kokos

Mehr zur 3D Choco

Einfach zu

bedienen

mycusini 3D Choco einsetzen, kurz vorheizen und los geht's.

Wie es funktioniert

3D Drucker Lebensmittel mycusini Zubehör ServicesRüblikuchen mit Frosting (mit veganer Alternative!)

Granola Cups

Bienenstich

The mycusini 2.0 enables bespoke 3D printed chocolate-making

Stay up to date with everything that is happening in the wonderful world of AM via our LinkedIn community.

Print4Taste first debuted their mycusini 3D chocolate printer on Kickstarter in 2019. A few months ago, the company released the mycusini 2.0 – an upgraded version of the original. Prior to the Kickstarter campaign, the mycusini 3D chocolate printer was completely unknown, but is now a feature in many private kitchens around Europe.

A few months ago, the company released the mycusini 2.0 – an upgraded version of the original. Prior to the Kickstarter campaign, the mycusini 3D chocolate printer was completely unknown, but is now a feature in many private kitchens around Europe.

Chocolate is a naturally good fit for amateur 3D printing, considering the physical properties that allow it to heat and melt easily, and cool at room temperature. Not to mention the affordability of the ‘filament’. The food industry, and particularly the baking industry, are well-suited markets for this technology that allows for completely customized designs, such as elaborate chocolate sculptures, bonbons, or simple chocolate ornaments, that, before 3D printing, have never been possible to create, and eat.

“Our customers immediately recognized that mycusini allows them to go beyond the limits of

manual work and to live out their creativity. In addition, it is very easy to use. The creation of

a chocolate object does not require any prior knowledge,” said Gerd Funk, CEO of Print4Taste GmbH.

The mycusini 2.0 has a base of 24 x 23cm and is no bigger than an average kitchen coffee machine. Each printer comes with free access to the mycusini Club – which provides users with the access to easily create their own 3D objects, individual lettering, and names.

The mycusini 2.0 features a large (3.5″/88.9mm) touch color display for quick access to the integrated template library with over 1,000 creative objects, including object previews, a multilingual user interface (German, English, Spanish, Italian, and French), an illuminated print area with dimensions of 90 x 90 x 45mm, easy cleaning thanks to rounded corners (production platform can be removed for cleaning, too), and prints with the company’s 3D Choco Refills.

The mycusini 3D Choco varieties include Dark Vegan, White, Pink, Blue, Dark, Dark Orange, Dark Raspberry, Dark Coconut, Green, and Yellow.

According to the mycusini website, the 3D Choco is highly economical – with one cartridge filling, the user can produce approximately 2-3 3D Choco objects, or 3-12 letterings, depending on the object size and height. One cartridge filling is, for example, enough for 12 Simon letterings, 4 piris, or 4 butterflies.

The mycusini 2.0 3D chocolate printer packages range from €578 to €720, and is currently available for purchase, with free shipping to German customers.

Related Articles

Back to top button

Chocolate printing

The dream of any sweet tooth is a big chocolate house. In order for a fantasy to come true, it is not necessary to participate in popular marathons of desires, just go to an online store and buy a chocolate printer.

3D printing based on your favorite treat has not been around for very long, but it is already actively expanding horizons in many niches. Creating sweets of the original form is a complex process. Conventional bars are made in factories by pouring molten sweets into molds and then cooling them to a solid state. This method is not suitable for casting thin details, without which the formation of elegant structures is impossible. They are made with a printer. nine0003

How does it work?

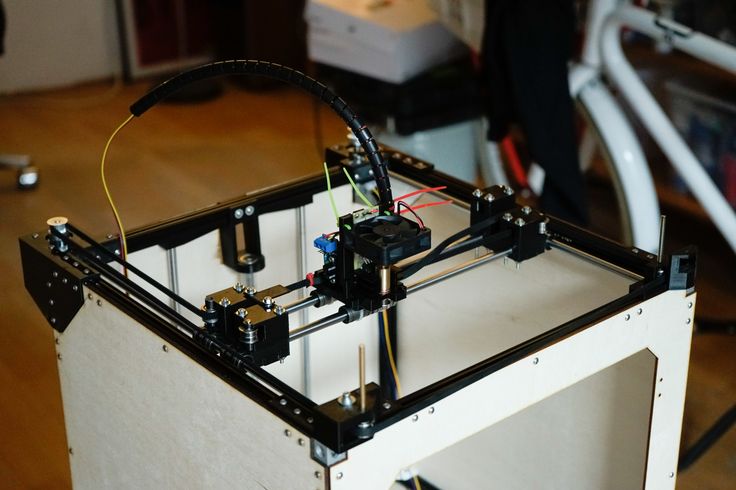

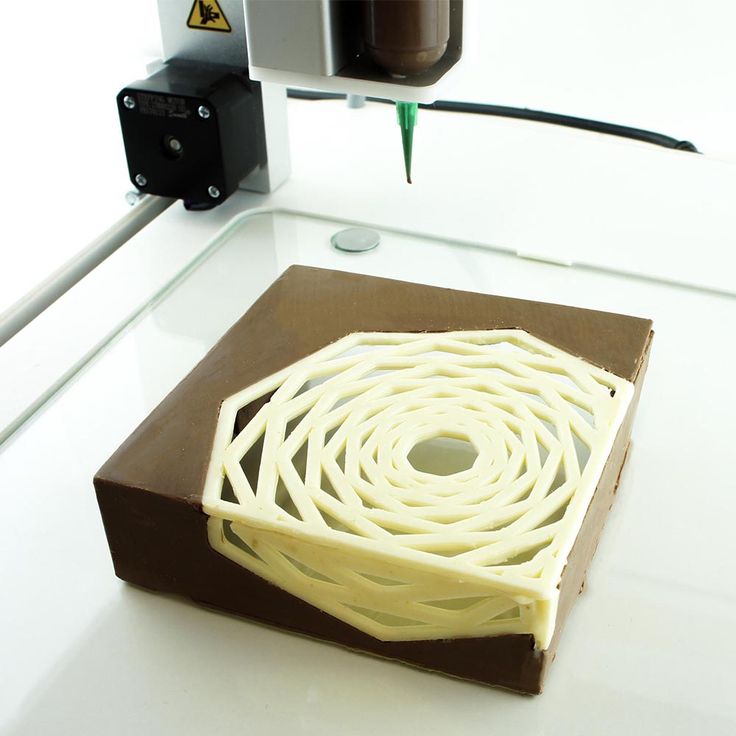

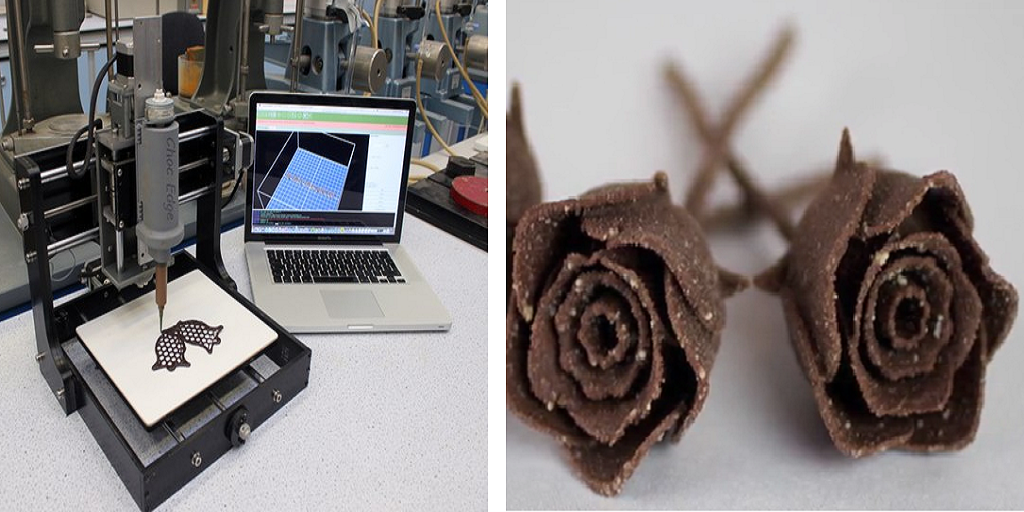

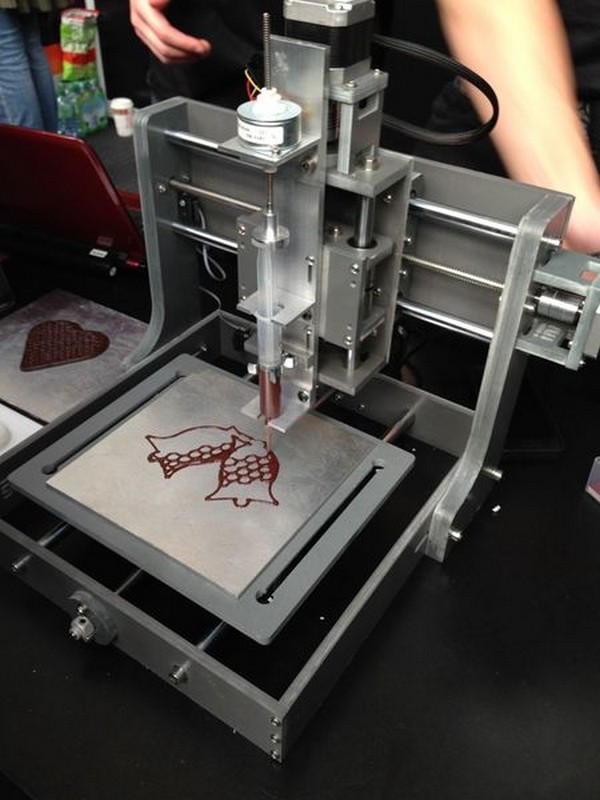

Figure 1. Layered chocolate 3D printing

There are several methods that chocolate printing is based on: melt extrusion, selective laser sintering (SLS), inkjet printing and spraying.

The most popular way to 3D print food products is extrusion, a method of processing raw materials in which they are crushed. It differs from the principles of FDM / FFF (fuel deposition modeling) by the absence of a thread. Instead, a cartridge with chocolate is used. nine0003

nine0003

Two types of extrusion are known: cold and hot. The first is carried out at room temperature without a phase transition.

Hot melt - the principle in which the nozzle moves and layers the melted treat into the desired shape. Then the finished product is cooled to a solid state. Every printer has an automatic extruder height calibration feature. It allows you to adjust the density of the layers.

Figure 2. Chocolate print products

Chocolate melts at 32-37°C, hardens at 20-25°C. This means that the printer must constantly heat the liquid during the process of creating the parts so that they do not have time to harden before they take on the desired shape. But it is worth considering the different viscosity of white, milk and dark chocolate. If the individual heating conditions are not met, the structure will lose its shape. It is recommended to use a high quality machine tempered product with a high solids content. For complex templates, developers are advised to reduce the print speed to give the product more time to dry and harden. The optimal pace is 15-20 minutes per 1 cm of height. nine0003

The optimal pace is 15-20 minutes per 1 cm of height. nine0003

Modern devices are aimed at both experienced users and beginners. The manufacturing process is simple and can be figured out in a few minutes, but the first print will take you at least an hour, even if the chosen template is easy.

Most manufacturers provide instruction booklets for beginners, and some create entire YouTube channels with useful life hacks for their developments.

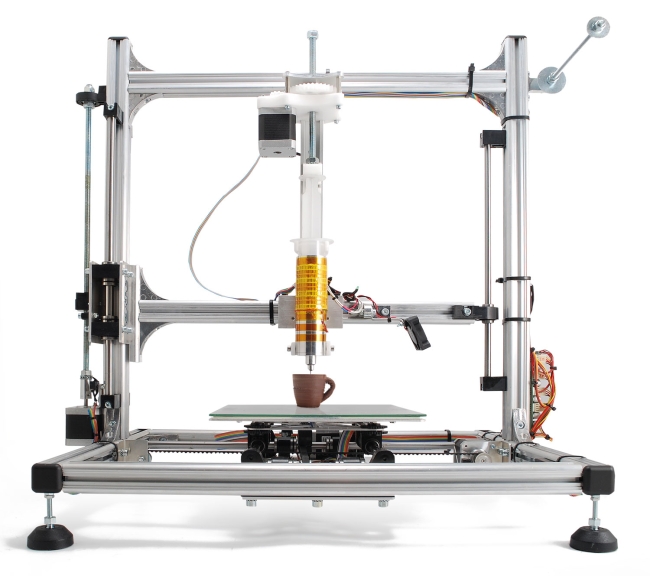

Focus

Figure 3. Focus 9 3D printer0014

By flow is a family business founded in the Netherlands in 2015. Their Focus project is the world leader in 3D food printing. Easy to use and maintain, the device is stylish and compact. The printer uses a syringe to apply the paste to the board. The highlight of its interface is the ability to download any chocolate recipe. The product comes with ten refillable cartridges and four nozzles of different sizes.

Choc mate 2

Figure 4. Choc mate 2 3D printer

Choc mate 2 3D printer

The idea of creating this development belongs to the young Chocolate3 team. They started their journey with Kickstarter. The sample quickly gained popularity and raised the necessary amount to launch mass production in just a few months.

The company has developed a system that can process any type of chocolate without constant temperature control by the user. They managed to improve the nozzle and make it thinner and longer. This increased the printing speed: in 10 minutes you can make up to 90 pieces 0.3 cm high.

With Choc mate 2 you can create 3D text, patterns and small 3D shapes. But the main icing on the cake is the ability to upload your own print templates designed in TinkerCAD. Printer sensors control the parameters of the given forms and make letters and lines the same in width and height. The development is open source and available for experimentation.

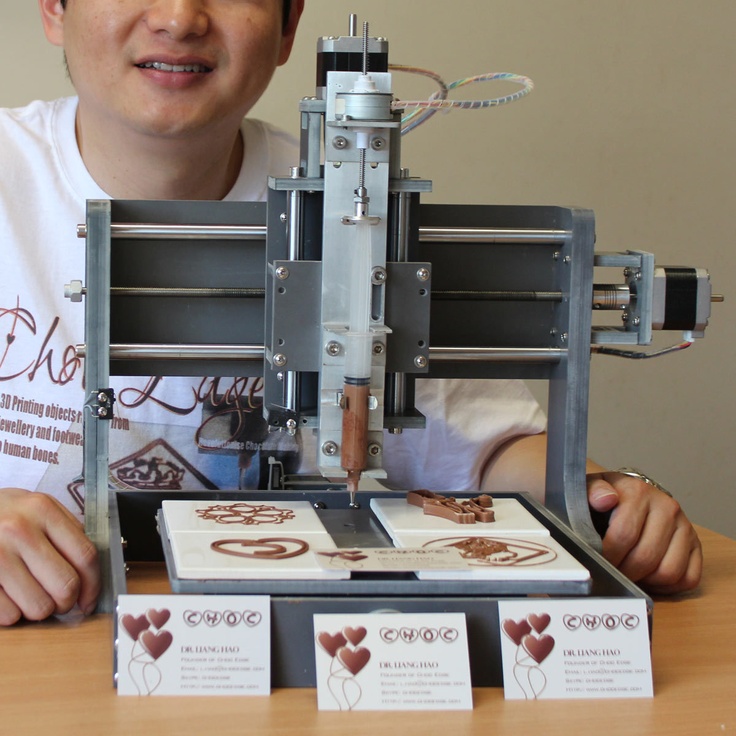

Mycusini

Figure 5 Mycusini 3D Printer

Mycusini is another successful Kickstarter project owned by Print2Taste. Unlike other models, this printer comes with individual chocolate sausage fillings. In order to get started, you need to cut the workpiece into two equal parts and place one of them in the cartridge with the smooth side down. When everything is ready, the mechanism will begin to heat up and drown the sweetness.

Unlike other models, this printer comes with individual chocolate sausage fillings. In order to get started, you need to cut the workpiece into two equal parts and place one of them in the cartridge with the smooth side down. When everything is ready, the mechanism will begin to heat up and drown the sweetness.

Mycusini has the highest strength and detail of construction among all presented devices. You can upload scans and photos to its interface. This will allow you to print portraits of your loved ones and friends, and you won't have to spend time choosing a gift anymore! nine0003

Figure 6. Chocolate 3D objects

Another advantage is the ability to print solid scale models. Creating a two-meter sofa will not work, but a house for your beloved pet is quite. However, there is a risk that the hut will be quickly eaten.

The supply of some models may be limited due to the geopolitical situation, but is this a reason to give up on your dream? Currently, there are a huge number of instructions for building your own chocolate 3D printer. Skillful makers have learned to use all available tools and were able to integrate even the popular children's designer into their devices. We have compiled a selection of the most interesting instructions for you:

Skillful makers have learned to use all available tools and were able to integrate even the popular children's designer into their devices. We have compiled a selection of the most interesting instructions for you:

- extruder for Ultimaker;

- printer from LEGO;

- choco printer.

Do you think 3D food printing is just fun or a progressive platform for experimentation? Share your thoughts in our VKontakte group.

Top

Some of the most amazing 3D printing materials currently available

3D printing with classic materials such as plastic, metal or ceramics is widespread. In the meantime, there are many alternative materials that are not only unusual, but can make a 3D printed part even more special. In our selection, we introduce you to these unusual materials. From chocolate and salt to recycled plastic waste or ashes, now you can create the most extraordinary items. In some cases, these materials are even proving to be a great alternative to plastic, reducing overconsumption and the associated environmental impact. Today we're going to take a look at these amazing 3D printing materials. nine0003

Today we're going to take a look at these amazing 3D printing materials. nine0003

3D printing material from the sea

Today, filaments are still the most commonly used 3D printing materials, mainly because FDM machines are readily available. But did you know that some threads are made from shellfish and crustaceans? The French company Francofil offers materials from PLA and shells of mussels, scallops and oysters. Their shells come from recycled food service waste and are shredded to become threads. The materials are made in France and can be printed like normal PLA. nine0003

Photo: Francofil

Local Salt

Emerging Objects is an American company that uses new technologies with innovative materials to create impressive projects. Among the most prominent initiatives is Saltygloo, a salt 3D printed structure. The salt used was collected from San Francisco Bay. Due to climatic conditions, about 500,000 tons of sea salt are produced here annually. Salt has been used to additively manufacture lightweight structures on a large scale. In addition to Saltygloo, the company is known for other salt projects such as the GEOtube tower and building houses. nine0003

Salt has been used to additively manufacture lightweight structures on a large scale. In addition to Saltygloo, the company is known for other salt projects such as the GEOtube tower and building houses. nine0003

Photo: Matthew Millman

Chocolate is the sweetest 3D printable material

This 3D printable material may not be as exceptional as some of the others on the list, but it is certainly one of the most used. The chocolate 3D printing process is similar to FDM technology, but it has different cooling properties than plastic, so the process takes longer. The popularity of this technology has grown over the years, prompting many companies to develop various designs and even chocolate 3D printers. Among the best known is the collaboration between 3D Systems and Hershey's, one of the world's largest chocolate makers. We also featured some 3D printers that can make delicious sweets like mycusini or Print2Taste. If you want to know more about this technology, don't miss the video below. nine0003

nine0003

3D printed material from the ashes to remember your loved ones

The Spanish company Narbón is introducing new technologies and innovations in the funeral industry. 3DMemories uses 3D printing to create original, unique and exclusive ceramic jewelry from the ashes, hair, DNA or skeletal remains of a loved one. To do this, the pattern must be processed and then combined with porcelain before the decorations can be 3D printed. Then the enamel is applied and the product is fixed. The service offers a wide range of products for men and women. Undoubtedly, 3DMemories with its range of jewelry is an exceptional way to remember a loved one. nine0003

Photo: Narbón

Wood-Based Threads

Wood or vegetable threads have also been available on the market for some time. For example, the Dutch company ColorFabb offers several alternative threads in this category. What started in 2014 with BambooFill has expanded in subsequent years with CorkFill and WoodFill. Wood fibers, usually blended with a PLA/PHA base, give parts a natural, high-quality finish. Whether used to make figurines, pieces of furniture, or wall decorations, the threads can be used anywhere the look of wood is desired. Since ColorFabb discontinued BambooFill, a similar product can be purchased in Wood Bamboo form from AzureFilm. According to the company, 40% of recycled wood is mixed with 60% of polymers for this purpose. However, to avoid problems when printing with this filament, it is recommended to reduce the print speed. nine0003

Wood fibers, usually blended with a PLA/PHA base, give parts a natural, high-quality finish. Whether used to make figurines, pieces of furniture, or wall decorations, the threads can be used anywhere the look of wood is desired. Since ColorFabb discontinued BambooFill, a similar product can be purchased in Wood Bamboo form from AzureFilm. According to the company, 40% of recycled wood is mixed with 60% of polymers for this purpose. However, to avoid problems when printing with this filament, it is recommended to reduce the print speed. nine0003

Left: ColorFabb, Right: Azure Film

Other Uses for Linen

Another alternative to traditional filaments is a composite of PLA and linen from French manufacturer Nanovia. The company says the composite is not only a sustainable alternative to traditional filaments, but also offers the ability to achieve different shades of brown by applying different print settings. This can be achieved simply by changing the print temperature during production. As for the finish, the manufacturer recommends sealing the printed parts with UV protection to keep them intact for as long as possible. nine0003

As for the finish, the manufacturer recommends sealing the printed parts with UV protection to keep them intact for as long as possible. nine0003

Photo: Nanovia

Sugar 3D Printing

Sugar Lab was acquired by 3D Systems almost ten years ago and, as the name suggests, has focused on sugar 3D printing. Using the 3D Systems ChefJet Pro printer, the company creates intricately shaped candies and decorations. The Los Angeles-based company claims to be able to produce candy in all flavors and colors. Whether it's birthdays, weddings or Christmas parties, The Sugar Lab offers all sorts of 3D printed candies. As for quantity, the 3D printer seems to be capable of producing up to 100 candies a day. While The Sugar Lab is the most famous company using sugar as a printing material, other companies like The Modernist Cuisine are also trying their hand at 3D printing with sugar. nine0003

3D printing with glass

Glass has been popular in many industries for many years and is also used in additive manufacturing. Several researchers, such as those at MIT or Lawrence Livermore National Laboratory (LLNL), have developed 3D printing solutions to print on glass. For example, an MIT team has developed the G3DP2 machine, which can process 5 kg of glass per hour. With this machine, the researchers were able to create three-meter-high glass columns at Milan Design Week. Recently, the Glassomer startup has also unveiled its glass 3D printing technology. The company is developing a material made from fine glass powder and a plastic binder that can be processed on SLA printers. nine0003

Several researchers, such as those at MIT or Lawrence Livermore National Laboratory (LLNL), have developed 3D printing solutions to print on glass. For example, an MIT team has developed the G3DP2 machine, which can process 5 kg of glass per hour. With this machine, the researchers were able to create three-meter-high glass columns at Milan Design Week. Recently, the Glassomer startup has also unveiled its glass 3D printing technology. The company is developing a material made from fine glass powder and a plastic binder that can be processed on SLA printers. nine0003

Photo: Glassomer

Recycled plastic filament

Sustainability is gaining more and more attention in additive manufacturing, and many companies are looking for alternatives. In recent years, several exciting products have been developed to make 3D printing more sustainable by making filaments from recycled plastic. One such project is Print The City by The New Raw, in which plastic from the waste of the people of Amsterdam and Thessaloniki is turned into 3D printed filament and used to print benches and other outdoor furniture. Another initiative is the Million Wave Project, which aims to produce recycled PET filaments for 3D printed prosthetic limbs for those in need. Another example is the ZUV tricycle, which was printed in Austria by EOOS using filaments made from 70kg of plastic waste from supermarkets in Vienna. nine0003

Photo: New Raw

Ivory Inspired 3D Printing Material

Among the many materials used for 3D printing, there are those that have been specifically designed to meet specific requirements and solve old problems in an innovative way. One such material is Digory, which was developed by the University of Vienna in collaboration with Cubicure GmbH to meet the need for the restoration of ancient ivory monuments and objects. It is a synthetic resin containing calcium phosphate particles and silica powder. Researchers have developed this new material with ivory-like characteristics and properties to restore objects using 3D printing or SLA technology. The similarity between these two materials is striking - there is almost no difference! nine0003

The similarity between these two materials is striking - there is almost no difference! nine0003

The Digory material on the right is very similar to the real ivory on the left (photo courtesy of Vienna University of Technology).

Clay as a greener material for 3D printing

One of the unusual 3D printing materials that has certainly attracted attention in recent years is clay. Technically, this is a subset of ceramic 3D printing that, although difficult to print, is known for its incredible properties, in particular the use of clay was especially popularized by the work of the Italian company WASP. For example, we recently saw WASP and Honda use 3D clay printing to create greener vehicles. There are many other uses, although many of them focus on sustainability due to the clay's properties. This can be seen in projects such as archiREEF terracotta tiles for coral restoration in Hong Kong, or 3D printed clay containers designed to reduce food waste. nine0003

nine0003

Photo: Jonathan Keep

Diamond - 3D printing of the hardest material on Earth

It may surprise many that one of the hardest materials on Earth, diamond, can actually be printed. Back in 2019, Sandvik Additive Manufacturing announced the first ever 3D printed diamond composite. It is not shiny, but will allow manufacturers to 3D print super-hard material, which will help revolutionize, especially in the tool industry. Diamond is often used in industries such as mining and drilling, machining, and medical implants, especially for its wear-resistant properties, but it is difficult to process. Sandvik claims that this breakthrough in composites will now allow very complex shapes to be 3D printed, and the company has high hopes for its use in the near future. nine0003

Human cell printing

When it comes to 3D printing in the medical sector, people often think of bioprinting. In bioprinting, cellular structures, including human structures, are made from bioink loaded with stem cells.