Types of fdm 3d printers

The Types Of FDM 3D Printer

Published on August 5, 2022 by Alex M.

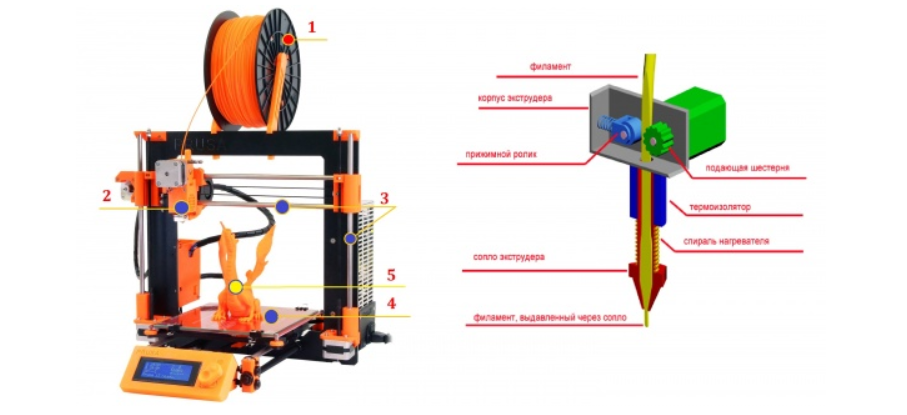

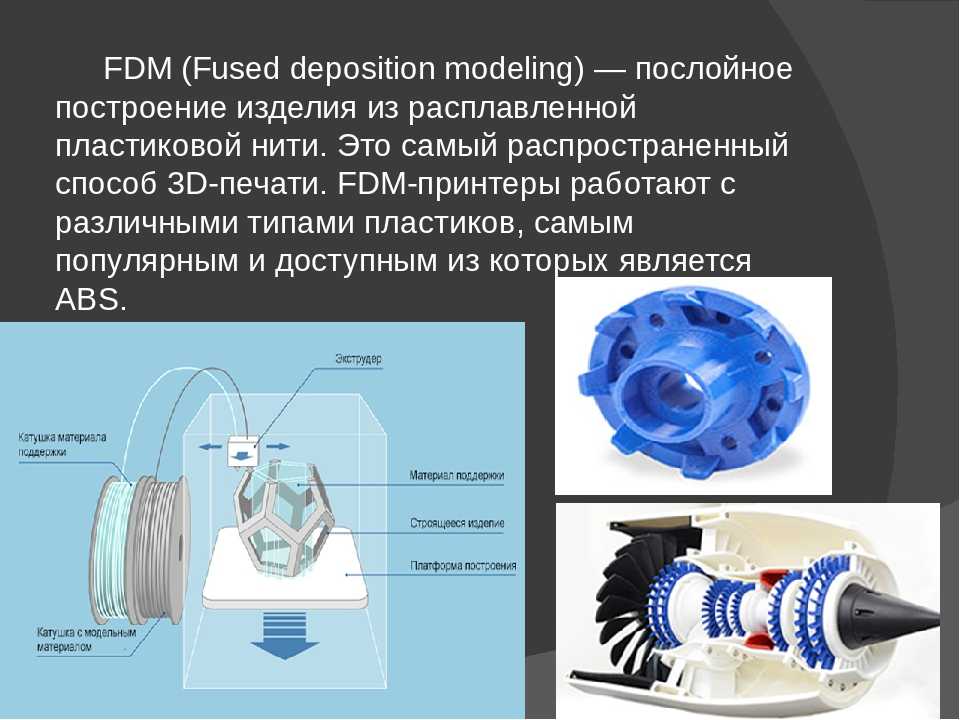

When we talk about 3D printers, a number of 3D technologies might come to mind. If we focus on FDM (fused deposition modeling), we can find different types of interesting machines that aim to achieve different results. As we know, FDM technology is based on the extrusion and deposition of molten material layer by layer on a printing plate. The most common filaments used with this process are PLA and ABS, although other more technical thermoplastics such as PETG, ASA, Nyon, Ultem, etc. can also be used. In this comprehensive guide, you can find out about the differences between Cartesian, polar, delta, hybrid printers, as well as printers which use robotic arms and the general operation of a 3D printer.

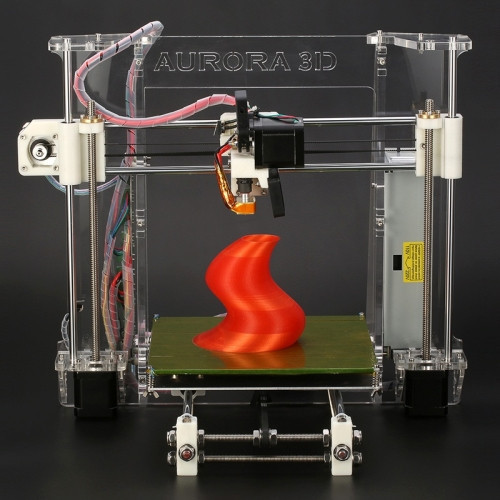

1. Cartesian FDM 3D Printers

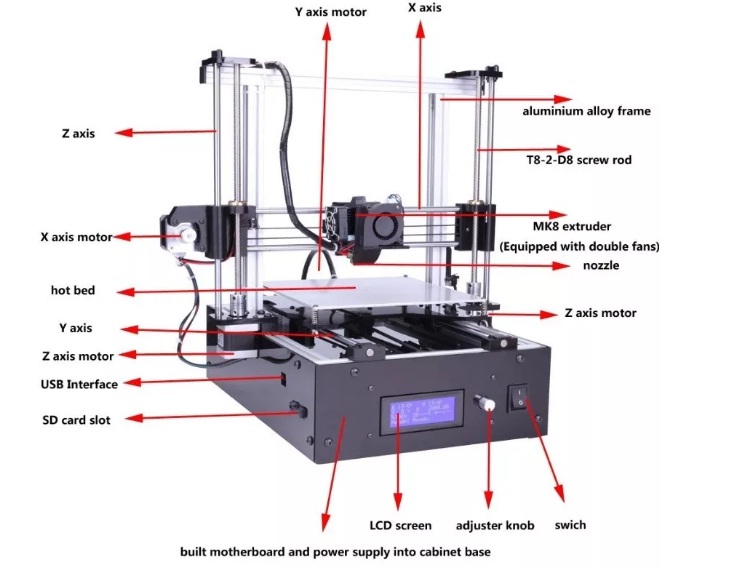

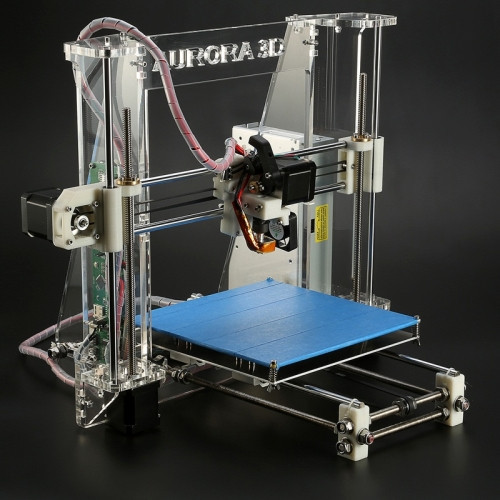

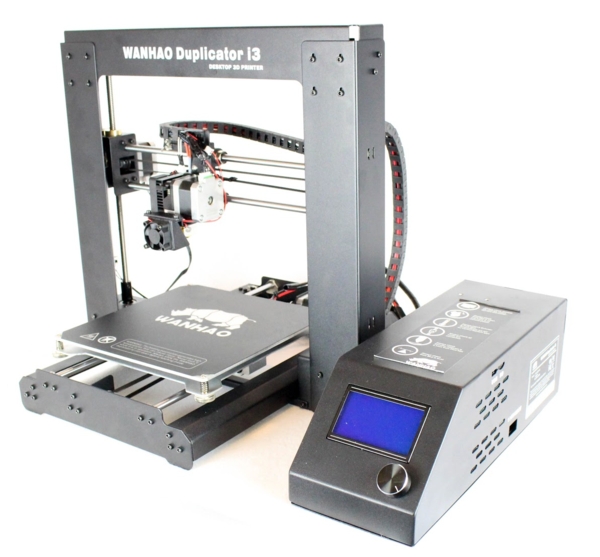

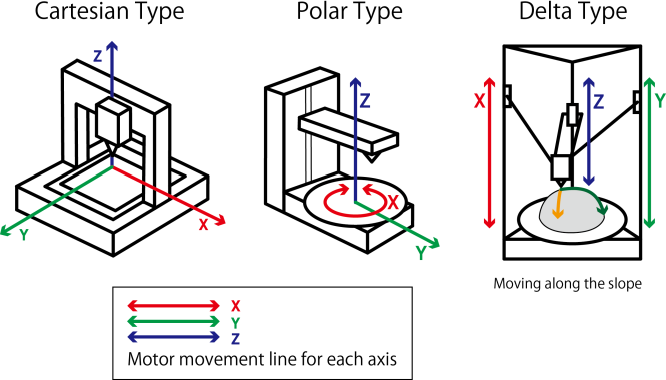

Cartesian 3D printers are the most common FDM 3D printer found on the market. Based on the Cartesian coordinate system in mathematics, this technology uses three orthogonal axes- X, Y, and Z- to determine the correct positions and direction of the print head. Depending on the model and manufacturer of the printer, the print platen of this machine will be in charge of the Z axis, allowing the extruder to be positioned on the X and Y axes, so that it can move in four directions.

Two well-known brands in the Fused Deposition Modeling market that use Cartesian technology for their FDM 3D printers are Ultimaker and MakerBot. The main advantage of these solutions is that they are generally inexpensive and are sold as kits to be assembled by the user.

2. Polar 3D FDM Printers

Polar 3D printers’ positioning is not determined by the X, Y, and Z coordinates, but by an angle and length. The coordinate sets describe points on a circular grid instead of a square, not determined by X, Y and Z axes, but by angle and length. This means that the plate rotates and moves at the same time, with the extruder moving up and down. These printers are ideal for objects which follow a spiral, such as a plant vase or traffic cone.

This means that the plate rotates and moves at the same time, with the extruder moving up and down. These printers are ideal for objects which follow a spiral, such as a plant vase or traffic cone.

The main advantage of Polar FDM 3D printers is they only two engines, whereas Cartesian printers need at least three. In the long term, the polar printer has greater energy efficiency and can make larger objects while using less space. However, polar printers have an inconsistent accuracy; as they rotate in a circle, there is much more accuracy in the centre than in the outer area.

3. Delta FDM Printers

These printers are being seen more and more on the FDM 3D printing market. They operate with Cartesian coordinates. This involves a circular printing plate that is combined with an extruder that is fixed at three triangular points (hence the name ‘Delta’). Each of the three points then moves up and down and left and right, thereby determining the position and direction of the print head. Therefore, the manufacturing limits of these machines are defined solely by the diameter of the base and the height of the arms. Delta printers, with a fixed print tray, were designed to speed up the printing process. Another advantage of Delta printers is that they can be resized, without affecting quality. However, they can prove more difficult to calibrate.

Each of the three points then moves up and down and left and right, thereby determining the position and direction of the print head. Therefore, the manufacturing limits of these machines are defined solely by the diameter of the base and the height of the arms. Delta printers, with a fixed print tray, were designed to speed up the printing process. Another advantage of Delta printers is that they can be resized, without affecting quality. However, they can prove more difficult to calibrate.

4. FDM 3D Printing with Robotic Arms

Robotic arms are most commonly known for assembling components on industrial production lines, especially in large automotive plants. While 3D printing has begun to incorporate robotic arms into their production process, most notably seen in the 3D printing of homes and buildings, this technology still remains in the development stage. Robotic arms are primarily used for the assembly of parts.

Robotic arms are primarily used for the assembly of parts.

Although not a commonly used printing process, this FDM printing method is beginning to see an increase in use. This is because the process is not fixed to a printing plate, making it much more mobile. In addition, thanks to the flexibility when positioning the FDM 3D printer head, it is easier to create complex structures, which are sometimes larger thanks to the length of the arms. It should be noted, however, that the final print quality is still far from that of conventional Cartesian printers, so many companies are working on developing it. Major manufacturers of robotic arms include Kuka and ABB, whose solutions are used by many companies including COBOD and Massive Dimension.

Hybrid 3D printers

Hybrid manufacturing is defined as a combination of additive (3D printing) and subtractive (CNC machining, milling) methods in a single solution. It is a machine that allows the exchange of tools for model creation. In the case of FDM 3D printers that incorporate subtractive heads, most tend to have a Cartesian structure. However, there are other cases, such as the Kraken project, which rely on a robotic arm capable of extruding material, but which also use subtractive methods, making it a hybrid manufacturing project. It should be remembered that any solution that incorporates both technologies will have a higher price tag, although the benefits can be far greater as it expands the capabilities of part creation.

It is a machine that allows the exchange of tools for model creation. In the case of FDM 3D printers that incorporate subtractive heads, most tend to have a Cartesian structure. However, there are other cases, such as the Kraken project, which rely on a robotic arm capable of extruding material, but which also use subtractive methods, making it a hybrid manufacturing project. It should be remembered that any solution that incorporates both technologies will have a higher price tag, although the benefits can be far greater as it expands the capabilities of part creation.

Hybrid 3D printers offer more printing possibilities.

Which type of FFF / FDM 3D printer do you use? Let us know in a comment below or on our Facebook and Twitter pages. Don’t forget to sign up for our free weekly newsletter, with all the latest news in 3D printing delivered straight to your inbox!

The 4 Types of FDM 3D Printer Explained (Cartesian, Delta, Polar & Scara)

FDM 3D printers have existed since the late 1980s, but only in the last decade have become affordable 3D printer options for the everyday maker. Unbeknownst to most, there are 4 different types of FDM 3D printer. So, if you are unsure whether a Cartesian 3D printer, Delta 3D printer, Polar 3D printer, or even a Scara 3D printer is best suited to your needs, this article will explain all.

Unbeknownst to most, there are 4 different types of FDM 3D printer. So, if you are unsure whether a Cartesian 3D printer, Delta 3D printer, Polar 3D printer, or even a Scara 3D printer is best suited to your needs, this article will explain all.

- This article discusses the different types of FDM 3D printer. We also have an article explaining every different type of 3D printer.

This buyer’s guide analyzes the differences between each of the four main types of FDM 3D printer based on your needs, and recommends the 3D printers we feel are best within each 3D printer type. We explain how each type of 3D printing came to prominence, the advantages and disadvantages of each, and niches that each type of FDM 3D printer fulfills especially well.

Cartesian 3D Printers

Cartesian 3D printers are the most common FDM 3D printer type. Name a 3D printer you like, and it will almost certainly be a Cartesian 3D printer. These were the first printers that emerged from the RepRap 3D printer movement over a decade ago that brought 3D printer prices down from tens of thousands of dollars, down to a few hundred currently.

Fun fact: Cartesian FDM 3D printers are named after the Cartesian coordinate mathematical system first discovered by René Descartes back in the 17th century.

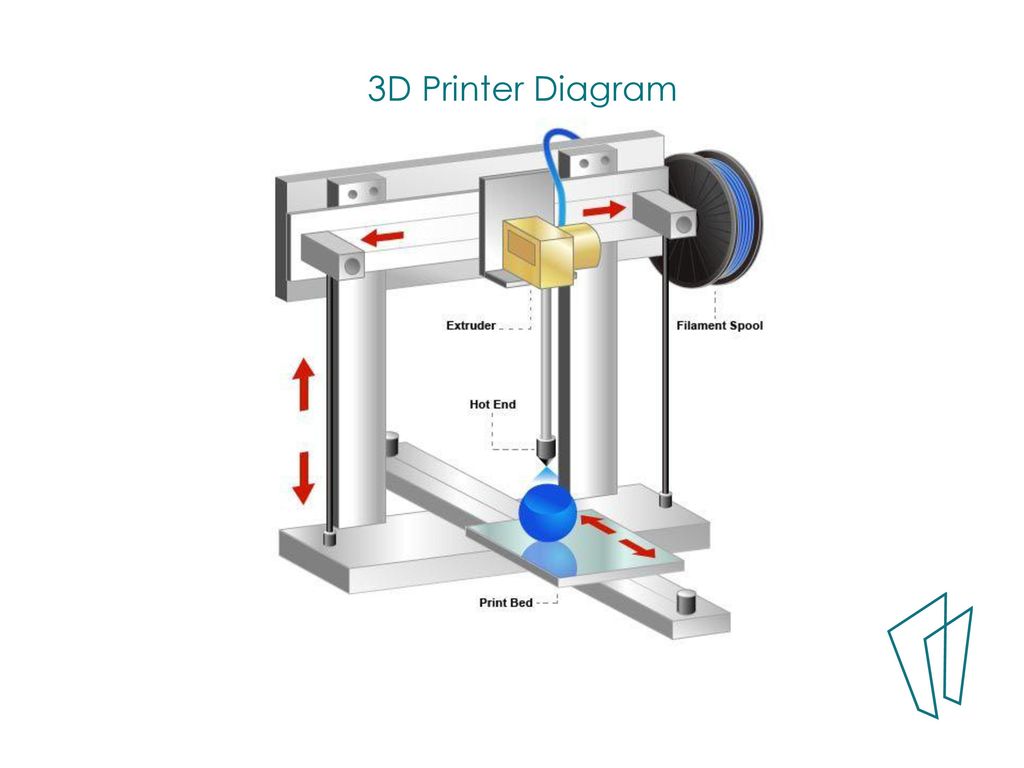

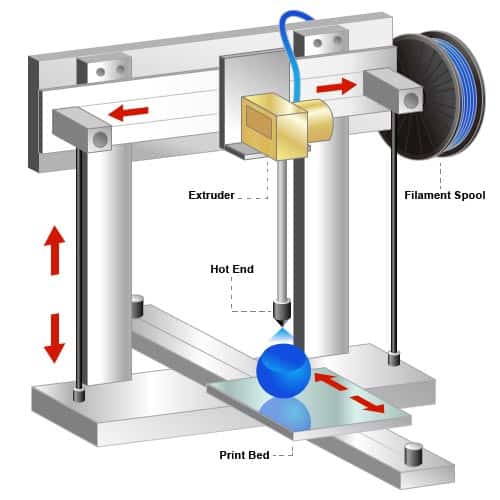

These types of FDM 3D printer follow the exact same mathematical pattern: they rely on X, Y, and Z coordinates to place a print head in the correct place to print the plastic filament.A basic model of how a Cartesian 3D printer operates.

Usually the print head moves on the X- and Y-axes, whilst the print head or bed moves up and down on the Z-axis. Some 3D printers move the extruder up and down for each layer, whereas some Cartesian 3D printers have the print bed move up and down instead. This creates an overall strong printing structure, leading to consistent, accurate and steady prints.

They are simple, reliable and can be easily disassembled and upgraded, leading to a number of excellent 3D printer kits being developed, such as the popular Ender 3.

3DSourced is reader-supported. When you buy through links on our site, we may earn an affiliate commission. Learn more

Learn more

Best Cartesian 3D Printer Options

| Name and brand | Build volume (mm) | Price | Best price available at: |

|---|---|---|---|

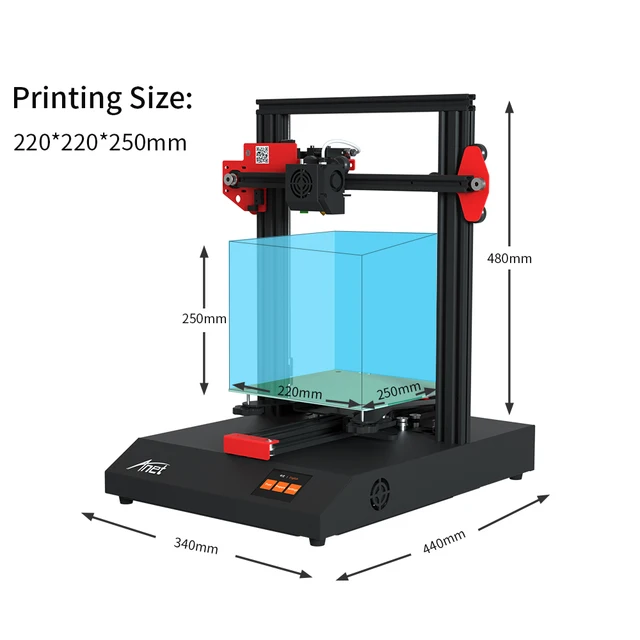

| Creality Ender 3 | 220 x 220 x 250 | $220 | Amazon here |

| Dremel 3D45 | 254 x 154 x 170 | $1,400-$1,900 | Amazon here |

| Ultimaker S3 | 230 x 190 x 200 | $3,850 | Dynamism Store here |

| Raise3D Pro2 | 305 x 305 x 300 | $3,999 | Dynamism Store here |

This is why many successful 3D printer companies have opted to build Cartesian FDM 3D printers, including Creality, Makerbot, Ultimaker, Raise3D and many more. Though other types of FDM 3D printer have become more popular in the last two years, Cartesian 3D printers are still the main FDM printer type in use today.

For filaments for Cartesian and Delta 3D printers, we recommend the following:

- Matterhackers ABS filament

- Matterhackers PLA filament

- Matterhackers PETG filament

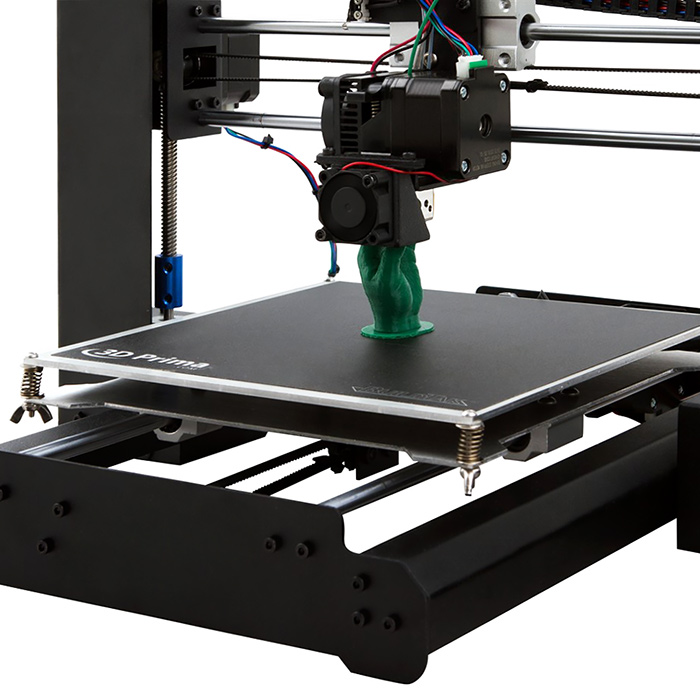

Delta FDM 3D printers

Though not as popular as Cartesian 3D printers, delta 3D printers are becoming increasingly seen as FDM technology advances and becomes cheaper. Popular Delta 3D printers include FLSUN‘s printers, as well as the very affordable Monoprice Mini Delta.

| Name and brand | Build volume (mm) | Price | Where to buy |

|---|---|---|---|

| Monoprice Mini Delta | 110 x 110 x 120 | $167 | Amazon here |

| FLSUN Q5 | 200 x 200 x 200 | $299 | Amazon here |

| FLSUN QQ-S | 255 x 255 x 360 | $379 | Amazon here |

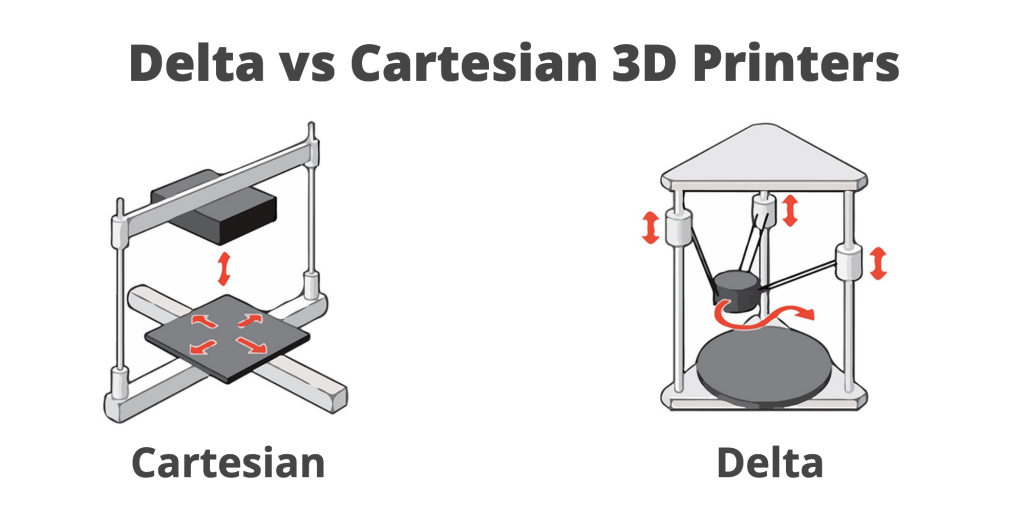

Delta 3D printers involve a circular print bed with a 3D printer extruder featuring three fixed triangular points. Each of these three points can move both upwards and downwards within the cylinder print structure, to be able to place the print head where it needs to be to print.

Each of these three points can move both upwards and downwards within the cylinder print structure, to be able to place the print head where it needs to be to print.

Delta printers first came to prominence via early RepRap designs, that advanced and became well-loved models like the Rostock and Kossel. Companies like WASP have since taken delta 3D printing to the next level, building some of the fastest 3D printers in the world, as well as delta clay 3D printers.

Overall, Delta 3D printers are very similar to Cartesian printers, though there are some slight differences.

- You can view our full delta 3D printer buyer’s guide here.

Cartesian vs Delta 3D Printers: Comparison

The major difference between these two types of FDM 3D printer is where each printer type can print compared to where the print bed is.

For example, in a Cartesian 3D printer each part can only move in one direction — a certain distance down each axis. However, within a Delta 3D printer, the print head is more flexible and can move in any direction, and instead the print bed stays still.

Delta printers are slimmer and taller — they require more height but also offer the ability to print taller structures as a result. So if you’re printing tall parts, go for a Delta 3D printer. Though Cartesian printers must be larger than the same delta printer to have the same build volume, they are consistent and do not lose accuracy towards the edges of the print area.

These differences create a trade-off: Cartesian 3D printers are considered more accurate, with better quality prints; Delta 3D printers are however considered to be faster. The print quality difference, if any, is minimal, whereas the speed of delta 3D printers is exponentially higher than Cartesian 3D printers.

Cartesian 3D printers are also best for printing flexible filaments like TPU, as they often use direct drive extruders which are considered better for flexibles than Bowden extruders, which always feature on delta 3D printers. So for makers looking to print flexible parts, such as 3D printed shoe soles, tires, door stoppers and other parts, you’ll prefer a Cartesian printer.

So for makers looking to print flexible parts, such as 3D printed shoe soles, tires, door stoppers and other parts, you’ll prefer a Cartesian printer.

If you are choosing between a Cartesian 3D printer or a delta printer, think about whether your priority is speed, or print quality and consistency.

Polar 3D Printers

- Notable polar 3D printers: Polar 3D.

Polar 3D printers aren’t as similar to Cartesian printers as Delta, but there are again some aspects that will seem familiar.

They’re called polar because they use a polar coordinate system, whereby every other point on the print bed is determined by its position compared to the central point in the middle of the print bed. This sounds complex, and is difficult for our brains to compute, as each point is not a nominal place but is relative to this central point.

Polar 3D, a polar 3D printer that debuted at CES a few years back.As a result, instead of the square or rectangle print beds on Cartesian printers, Polar 3D printers have circular print beds that rotate and lift up and down to allow for efficient 3D printing.

Fun fact: though the term polar coordinates is attributed to Gregorio Fontana, Alexis Clairaut first conceived of polar coordinates across three dimensions, whilst Swiss mathematician Leonhard Euler was the first person to develop them.

Calculating distance and angle from the central point, with a print bed that spins itself into the correct position, means that an overhanging structure for the extruder and hot end is not required. The L-shaped Polar 3D printer build (rather than cuboid or cylindrical for Cartesian and Delta printers) is efficient, and means that very little maximum build area is lost, with quite large parts printable on a relatively small 3D printer — a massive advantage if you don’t have much space.

Additionally, Polar 3D printers require just two engines to print, working with just angle and length in calculating print areas. On the other hand, Cartesian and Delta printers typically require 3 engines to power each axis. This is theoretically more efficient in terms of energy usage.

SCARA / Robotic Arm 3D Printer

- Example printer: RepRap Morgan, Dobot 3D printer, house 3D printers

The last, and strangest type of FDM 3D printer, are robotic arm 3D printers, also known as SCARA 3D printers.

SCARA stands for Selective Compliance Assembly Robotic Arm.

If you’ve ever been inside an industrial manufacturing plant, or seen clips of one on the news, you’ll have seen huge mechanical arms, welding metals or assembling parts. These robotic arms, used for 3D printing, are scara 3D printers.

Undoubtedly, these are the coolest looking printers. However, we won’t exaggerate like these are already accessible and you can pick one up for a few hundred dollars — these are not cheap like Cartesian printers yet. In fact, most Scara 3D printer applications are in the building of 3D printed houses and other industrial projects.Robotic arms are increasingly used in 3D printing, especially in large, industrial projects like houses.

Advantages of robotic arm 3D printers include additional flexibility when printing. This is because printing is not fixed to a print plate and is therefore more mobile and versatile, making it easier to print geometrically complex parts. Scara 3D printers move in the most similar way to human hands, and print faster than Cartesian printers.

This is because printing is not fixed to a print plate and is therefore more mobile and versatile, making it easier to print geometrically complex parts. Scara 3D printers move in the most similar way to human hands, and print faster than Cartesian printers.

However, there are trade-offs with print quality in most cases. When 3D printing large cement walls these slight imperfections aren’t an issue, however when printing intricate, small parts, Scara 3D printers cannot effectively compete with those such as Cartesian or Polar 3D printers.

At a certain size, super large 3D printers have to become Scara 3D printers. This is because for printing huge structures, like houses, you have to be able to move the house 3D printer to the location. Cartesian and delta 3D printers have structures around them, with the large cube or cylindrical structures making them suitable for remaining stationery in a factory, such as for rapid prototyping. Scara 3D printers on the other hand are better suited as industrial 3D printers. Huge robotic arms can be moved to the site of the build, as we have seen with house 3D printing projects like Apis Cor, to deposit layers of cement to build walls.

Huge robotic arms can be moved to the site of the build, as we have seen with house 3D printing projects like Apis Cor, to deposit layers of cement to build walls.

We expect to see more Scara 3D printers in the future for these industrial house-building projects, so keep an eye out.

That’s it! Hopefully our guide sheds some light on which type of FDM printer is best for your printing needs. If you’re still not completely sure, we have a bunch of other great guides and rankings to help you choose, including:

- Best FDM 3D printer.

- Best dual extruder 3D printer.

- Our favorite 3D printers overall.

- The best online 3D printing services

FDM 3D printer

- 1 Description

- 2 General process

- 3 Structural elements

- 3.1 Body

- 3.2 Extruder

- 3.3 Working platform

- 4 Preparing digital model

- 5 Seal

- 6 Application

Description

Fused Deposition Printing (FDM) printing technology has become widespread among individuals and small businesses due to its wide capabilities, relative simplicity and good affordability. The popularity of this method deserves a more detailed description of the process and the printers used. In this section, we will look at the nuances of the design of printers and the application of technology in practice. nine0028

The popularity of this method deserves a more detailed description of the process and the printers used. In this section, we will look at the nuances of the design of printers and the application of technology in practice. nine0028

General process

Like all 3D printing methods, FDM belongs to additive manufacturing technologies. The term "additive" is an Anglicism from the word "additive", meaning "addition" or "by addition". The term is intended to separate technologies for the production of complex three-dimensional products that differ from the usual "subtractive" ("subtractive" - "due to separation") methods - milling, drilling, grinding, etc.

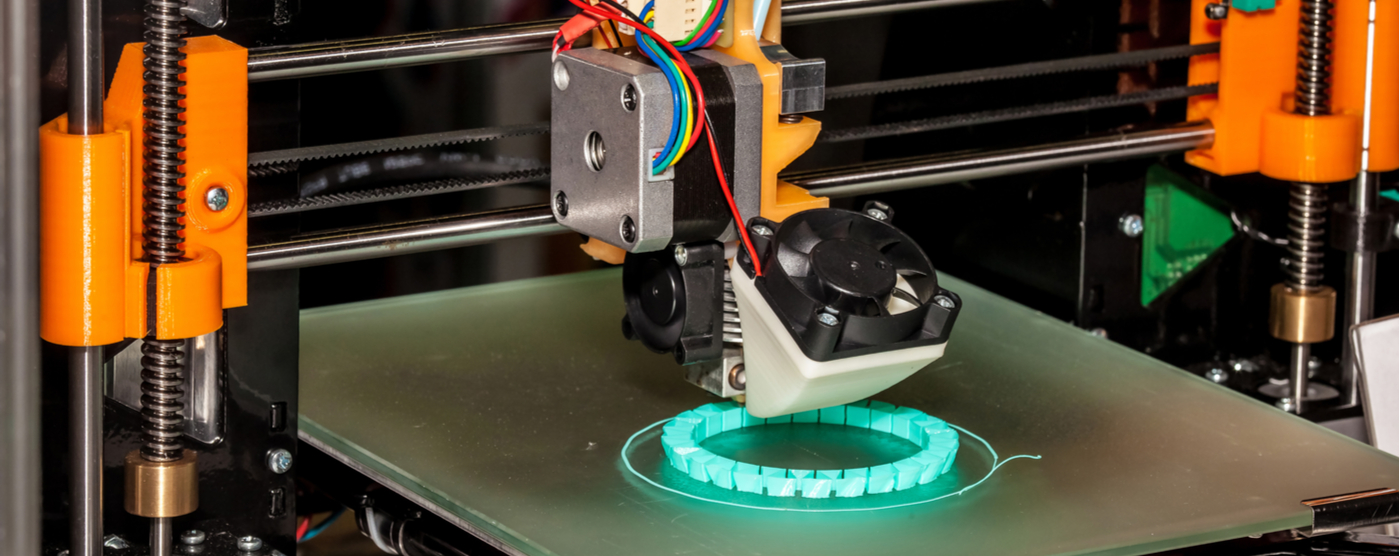

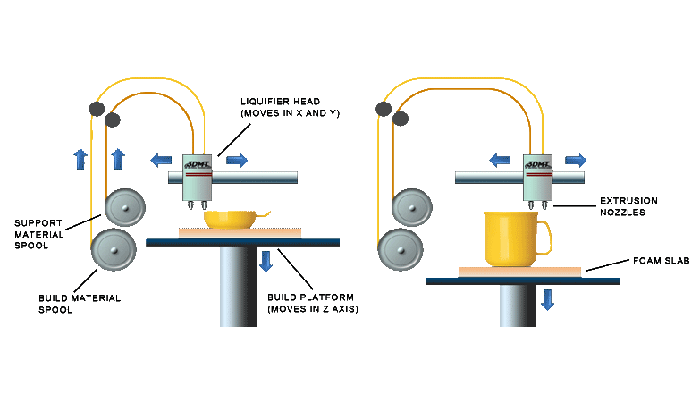

FDM can be considered one of the most technologically simple 3D printing methods. The process is based on the successive layering of a thin thread of molten plastic up to the creation of a solid three-dimensional object. A plastic thread wound on a spool is used as a consumable. Occasionally, individual bars of plastic are used. The standard thread diameter is 1.75mm or 3mm. nine0028

Occasionally, individual bars of plastic are used. The standard thread diameter is 1.75mm or 3mm. nine0028

The printing process consists of a number of steps:

- Create or import a digital 3D model

- Processing of a digital model for printing with the addition of supporting structures

- Location and orientation of the digital model on the desktop

- Slicing - cutting a digital model into separate layers with data conversion into instructions for the printer, called the G-code

- Direct print

- If necessary, physical or chemical treatment of the finished model

Structural elements

Enclosure

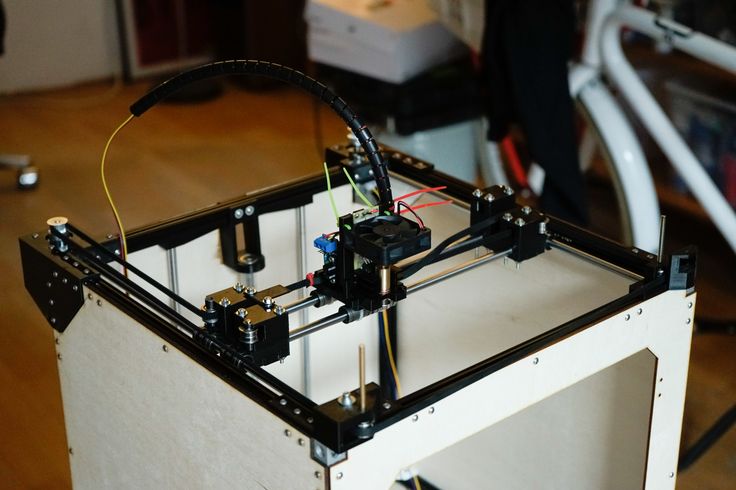

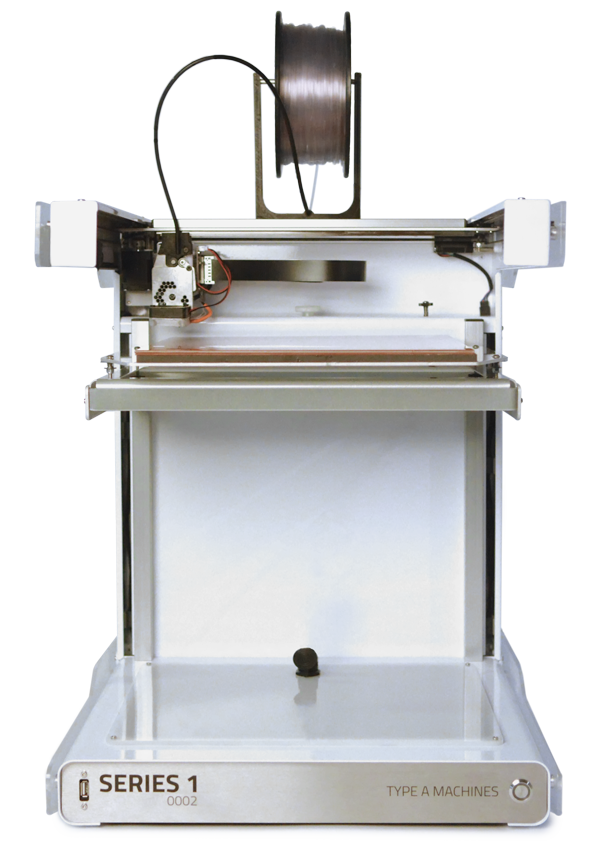

Ultimaker 3D Printer with open wooden enclosure

Many elements are important in the design of an FDM 3D printer that are not always obvious to the inexperienced person. So, the material of the case matters in the event that it carries the load. Many FDM printers are available with wooden cases - this solution seems cheap and unsightly, but in fact it helps to absorb vibrations during printing, which has a positive effect on the quality of the manufactured models. On the other hand, a steel or aluminum frame ensures the durability and impact resistance of the device. nine0028

Many FDM printers are available with wooden cases - this solution seems cheap and unsightly, but in fact it helps to absorb vibrations during printing, which has a positive effect on the quality of the manufactured models. On the other hand, a steel or aluminum frame ensures the durability and impact resistance of the device. nine0028

The open or closed design of the printer also matters. A well-ventilated working chamber is useful when printing with polylactide (aka PLA plastic), as this material vitrifies for a long time. If the printed layers do not have time to solidify and seize, they may spread, or deformation of the underlying layers under the pressure of the upper ones.

On the other hand, many popular materials (such as ABS and nylon) have a high degree of shrinkage. By "shrinkage" is meant the reduction in volume of the material as it cools. In the case of the same ABS plastic, excessively fast and uneven cooling of the applied layers can lead to their twisting, or deformation and cracking of the model as a whole. nine0028

nine0028

PICASO Designer 3D printer with closed plastic case

In this case, the case with closed cladding comes in handy, allowing you to achieve slow, uniform cooling of the material.

Finally, the shape of the FDM printer can also be linked to the coordinate system used.

Thus, the most popular option is the Cartesian or, more precisely, in most cases, the rectangular coordinate system.

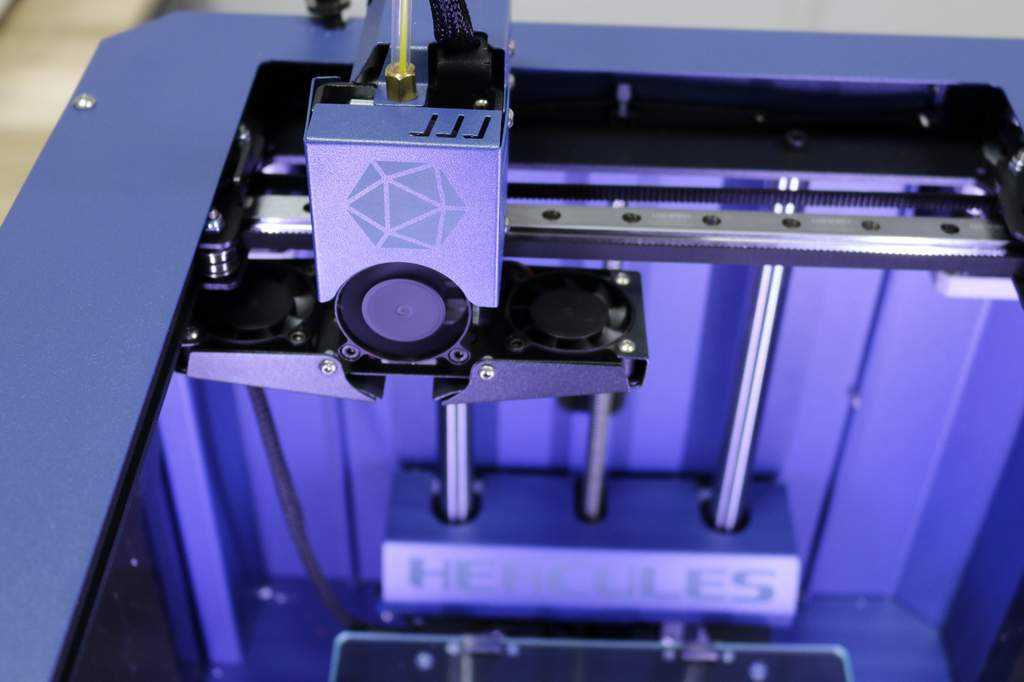

Delta-shaped coordinate systems are gaining popularity recently - such devices are called "delta robots" and offer certain benefits in terms of printing accuracy and ease of expanding the vertical size of the construction area. nine0028

Structural elements and rails are usually made of aluminum or steel. The extruder and platform are driven by belts or screws.

3DPrintBox printer extruder, partially disassembled. You can clearly see the pink plastic thread and the pulling mechanism - two gears with grooves in the teeth

Extruder

The next important element is the extruder, that is, the print head of the printer. These devices may vary in design, but generally contain the same basic components: nine0028

These devices may vary in design, but generally contain the same basic components: nine0028

- Thread feeder for feeding the thread into the nozzle

- Nozzle used to melt the filament and extrude the molten material

- Heating element for heated nozzle

- Fan

As a rule, the pulling mechanism consists of gears or screws driven by an electric motor.

Obviously, the electric motor drives the gears to feed the filament into the nozzle. In the nozzle, the thread is melted, followed by extrusion of a viscous material. nine0028

An extremely important point is the sharp temperature gradient between the bottom and top of the nozzle - this is exactly what the fan is installed for.

At the transition of the glass transition temperature, the plastic becomes soft, but not yet viscous, expanding in volume.

3DPrintBox extruder assembled. The electric motor of the traction mechanism is visible (top), double fan (middle) and nozzle with attached electric heating element (bottom)

The electric motor of the traction mechanism is visible (top), double fan (middle) and nozzle with attached electric heating element (bottom)

In this state, the friction of the material with the inner walls of the nozzle increases.

If the length (and, as a result, the area) of this section is too large, then the total coefficient of friction may become unbearable for the pulling mechanism.

Thus, the length of the nozzle section with unmelted filament and the length of the section with molten material do not really matter, but the length of the plastic section at the glass transition temperature should be as short as possible. nine0028

The most effective solution to this problem is the use of heat sinks and fans to cool the filament and the top of the nozzle.

In fairness, the residence time of the plastic in the molten state should also be minimized, since many thermoplastics lose their plasticity after prolonged exposure to high temperatures, and the resulting solid particles can clog the nozzle.

Diagram of the transition of a plastic filament from a solid to a viscous state. The length of the middle section should be as short as possible to prevent problems with material push through

Typically, this kind of problem does not occur in normal, stable extrusion because the nozzle length is too short.

Clogging of the nozzle can occur due to internal irregularities or errors in the manufacture of the thread: the resulting stagnation leads to the gradual formation of grains, which are then carried away by the flow of molten plastic and clog the outlet.

The most common nozzle materials are aluminum and brass. nine0028

Hole diameter may vary, but average is 0.3mm.

Smaller bores allow for higher resolution, while larger bores increase build speed and reduce the risk of nozzle clogging.

Work Platform

The 3D Systems Cube 3D Printer Platform moves in the X and Z axes and the extruder moves in the Y axis

The work platform serves as a surface for building models. nine0028

nine0028

Depending on the coordinate system used, the platform can be movable or static.

Typically, in printers using the Cartesian coordinate system, the movement of the platform in the vertical plane is responsible for the vertical positioning of the extruder relative to the platform itself.

Some models also add movement of the platform along one of the axes in the horizontal plane, which allows you to slightly reduce the dimensions of the device, provided that the case is open. nine0028

An example of such printers is the popular 3D Systems Cube.

The delta robot work platform remains in place. Positioning of the extruder in three planes is carried out solely by the movement of three manipulators

Delta printers ("delta robots") use static platforms.

The positioning of the print head in all three dimensions is carried out exclusively by the movement of the extruder itself. nine0028

As a rule, the extruder is suspended on three manipulators, whose coordinated movement along vertical guides moves the die.

Asymmetric movement controls the positioning of the extruder horizontally by changing the angle of the manipulators, and symmetrical movement - vertically.

Alternatively, a movable platform and a stationary extruder can be used, but these designs are not yet widely used.

Experimental Quantum Delta Printer uses "inverted" design with moving bed and stationary extruder

A distinctive feature of all Delta printers is the cylindrical shape of the build area. One of the advantages of such designs is the ease of building up the working area. So, to increase the height of the building, you only need to install guides and cables of increased length.

However, even static platforms are not completely immobile. Before starting printing, platform calibration is required, that is, the elimination of a possible tilt. Calibration mechanisms can be either manual or automatic, depending on the printer model. nine0028

In the case of manual calibration, the user will be required to consistently position the nozzle at different points on the platform.

To measure the distance, special templates are used, and in the cases of the most simple or home-made designs, simply sheets of office paper, whose thickness corresponds approximately to 100 microns.

More advanced devices like the MakerBot Replicator use special sensors to accurately measure distance. Tilt adjustment is made by rotating the spring-loaded screws on which the platform rests. nine0028

Calibration of the platform is often carried out with the help of adjustment screws, although most printers help in this task by moving the extruder in succession to different points of the platform.

If the nozzle height is too low, extrusion will simply not occur.

If too large, the filament will not adhere to the surface and the printer will print "in the air", creating intricacies of plastic filament that have nothing to do with the given model. nine0028

A combination of these two effects can result from platform tilt. No matter how perfect the design of the printer, users are encouraged to trace the construction of the first few layers of the model.

No matter how perfect the design of the printer, users are encouraged to trace the construction of the first few layers of the model.

Perforated printer worktable Up! Plus 2 provides good adhesion of the plastic to the surface, but requires careful maintenance, as the holes are easily clogged

Depending on the design, the working platform can be equipped with a removable table. nine0028

This solution is often used in printers with closed housings that make it difficult to remove models from the platform or clean the surface.

In the case of perforated tables, this solution is absolutely necessary, since the surface is cleaned by soaking in solvents.

The disadvantage of removable tables is the possibility of backlash if the fasteners or clamps are sufficiently weak.

Heated aluminum platform with removable glass worktable for PICASO Designer 9 printer0057

When printing on certain materials such as ABS or nylon, the bed is equipped with a heating element. The purpose of the heating is to slow down the cooling of the lower layers in order to prevent their twisting caused by the shrinkage of the thermoplastic. You can read more about this phenomenon and methods of struggle in the section "How to avoid deformation of models during 3D printing".

The purpose of the heating is to slow down the cooling of the lower layers in order to prevent their twisting caused by the shrinkage of the thermoplastic. You can read more about this phenomenon and methods of struggle in the section "How to avoid deformation of models during 3D printing".

The materials used to make work tables are very diverse. Among them, aluminum, steel, acrylic can be mentioned - the presence of heating, of course, narrows the choice of materials. Glass has recently become a popular choice due to its high resistance to deformation and the ease of achieving a perfectly flat surface during production. Some manufacturers even use volcanic glass because of the low thermal conductivity, which slows down the cooling of the initial layers of the model. nine0028

Preparing a digital model

Popular open source slicer ReplicatorG

Creating digital 3D models is not part of the 3D printing process. To create models, conventional computer-aided design systems (“CAD” or “CAD” in English terminology) are used, including 3D editors such as SolidWorks, AutoCad and LightWave, among many.

To create models, conventional computer-aided design systems (“CAD” or “CAD” in English terminology) are used, including 3D editors such as SolidWorks, AutoCad and LightWave, among many.

The process of preparing a model for printing begins with importing a 3D model in .STL format into a special program called a slicer. Such programs perform the functions of graphical editors, allowing you to add reference elements necessary to support model attachments. Many slicers allow you to add support structures automatically without requiring any effort on the part of the user. In addition, slicers allow you to place models on the desktop and change their spatial orientation. nine0028

Advanced programs also allow you to change fine print settings - the thickness of the applied layer, nozzle temperature, take into account the consumable used.

The capabilities of slicers are closely related to the capabilities of the printers themselves. Some models have a "closed code" that requires the use of branded slicers. Some of the more popular open source slicers include Repetier-Host, ReplicatorG, and Skeinforge.

Some of the more popular open source slicers include Repetier-Host, ReplicatorG, and Skeinforge.

Building model support structures in Repetier-Host 9 slicer0057

After the digital model is placed on the virtual desktop, the necessary supports are created and the settings are made, slicing is performed directly - cutting the three-dimensional model into virtual layers with a thickness corresponding to the thickness of the applied plastic layers. Each such section will serve as a template for building a specific layer of the physical model. The end result is provided in the form of a G-code, a set of commands for a 3D printer that determines the movement of the extruder and platform during the printing process. G-code can be transferred directly from a computer using a direct connection, or written to a memory card or USB stick for offline printing, provided that the printer is equipped with the necessary interface and control module. nine0028

Printing

Some 3D printing enthusiasts make their own scrapers to remove finished models from the desktop

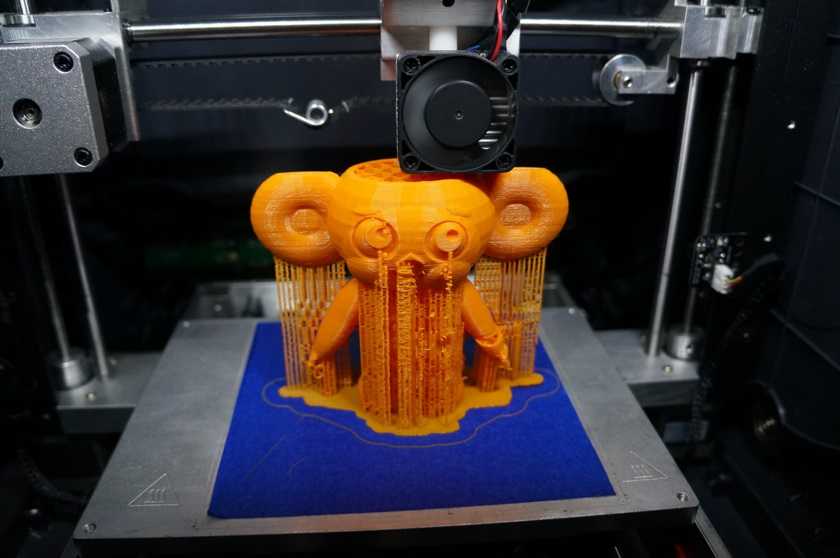

Printing can take quite a long time, often in hours. The duration depends on the speed of printing and the size of the models being produced. Print speed, in turn, depends on the complexity of the model, the perfection of positioning algorithms, layer thickness and nozzle diameter. Interrupting the printing process may result in the loss of the model. Although some printers allow you to temporarily stop the process to replace the consumable, a long pause will cause the upper layers to cool. When printing is resumed, subsequent layers may not "grab" with those already printed. nine0028

The duration depends on the speed of printing and the size of the models being produced. Print speed, in turn, depends on the complexity of the model, the perfection of positioning algorithms, layer thickness and nozzle diameter. Interrupting the printing process may result in the loss of the model. Although some printers allow you to temporarily stop the process to replace the consumable, a long pause will cause the upper layers to cool. When printing is resumed, subsequent layers may not "grab" with those already printed. nine0028

Fine scrapers are used to remove finished models from the table. At the same time, it is recommended to wait for at least partial cooling of the model in order to avoid damage to still soft layers or burns when touching still hot plastic. In addition, if you have enough patience, you can wait for complete cooling and shrinkage, which in most cases automatically leads to the separation of the model from the table.

Demonstration of support structures as part of the finished model

Depending on the working plastic, mechanical or chemical processing may be possible. Thus, models made of ABS plastic can be processed with acetone vapor, which leads to smoothing of roughness and printed artifacts, but can also lead to the loss of the most delicate features of the model. Basically, processing is reduced to the removal of supporting structures of hinged elements of the model. When printing on printers with a single extruder, the supports are made of the same material as the model itself, complicating the process somewhat. When using printers with two or more print heads, it is possible to build supports using water-soluble polyvinyl alcohol (PVA plastic). For more information on the plastics used in FDM 3D printing, see the FDM Consumables section. nine0028

Thus, models made of ABS plastic can be processed with acetone vapor, which leads to smoothing of roughness and printed artifacts, but can also lead to the loss of the most delicate features of the model. Basically, processing is reduced to the removal of supporting structures of hinged elements of the model. When printing on printers with a single extruder, the supports are made of the same material as the model itself, complicating the process somewhat. When using printers with two or more print heads, it is possible to build supports using water-soluble polyvinyl alcohol (PVA plastic). For more information on the plastics used in FDM 3D printing, see the FDM Consumables section. nine0028

Application

3D printed controller prototypes for the Xbox One game console

The relative cheapness of FDM printers and consumables makes this technology widely popular. First of all, such devices are used for rapid prototyping. Various plastics allow you to create functional models of various products. Thus, ABS plastic, which is popular in FDM printing, is widely used in the mass production of various household products, automotive parts, tools, toys, souvenirs, etc. The sufficiently high accuracy of 3D printing makes it possible to obtain functional prototypes that practically do not differ in workmanship from traditional cast products. nine0028

Thus, ABS plastic, which is popular in FDM printing, is widely used in the mass production of various household products, automotive parts, tools, toys, souvenirs, etc. The sufficiently high accuracy of 3D printing makes it possible to obtain functional prototypes that practically do not differ in workmanship from traditional cast products. nine0028

The MakerBot Mini 3D Printer was designed for home and educational use

This application of technology allows significant savings in the development of new designs. Microsoft used 3D printing to create about 200 prototypes of the Xbox One controller, while Dell placed an order for 5,000 M200 FDM printers from Poland's Zortrax for use in affiliates around the world. nine0028

Although the productivity of FDM 3D printing is quite low, the relative cheapness allows the use of FDM printers for the production of small batches of finished products - souvenirs, toys, etc.

Improvement in technology and a significant reduction in the cost of devices allows FDM printers to gradually take root in everyday life. The benefits of 3D printing at home are clear—even fairly simple devices are capable of producing household appliances or broken plastic parts as needed. The cost of home production already makes such an application profitable in comparison with the purchase of finished products. The only significant obstacle to the widespread adoption of 3D printers in everyday life can be considered the reluctance of most people to go into the details of three-dimensional digital design. This barrier is gradually being eroded with popular services such as Thingiverse, Shapeways and Cubify offering a variety of print-ready 3D designs. Many of the available digital models are provided free of charge. nine0028

The benefits of 3D printing at home are clear—even fairly simple devices are capable of producing household appliances or broken plastic parts as needed. The cost of home production already makes such an application profitable in comparison with the purchase of finished products. The only significant obstacle to the widespread adoption of 3D printers in everyday life can be considered the reluctance of most people to go into the details of three-dimensional digital design. This barrier is gradually being eroded with popular services such as Thingiverse, Shapeways and Cubify offering a variety of print-ready 3D designs. Many of the available digital models are provided free of charge. nine0028

3D printed Liberator pistol questioned government's ability to regulate firearms

The Liberator pistol made quite a stir. The design of this weapon includes one single metal element - the striker, which can be used as an ordinary nail. All other design elements can be printed. The design of the pistol has been released to the public.

The design of the pistol has been released to the public.

Finally, the development of FDM 3D printing allows the development of an entire industry of 3D design and print-on-demand. 3D boutiques are already becoming commonplace in many countries. The further spread of FDM printing technology could lead to a restructuring of the global economy: as home production grows, the demand for finished products will fall in parallel with the growth in demand for consumables. Chemical producers, retail chains and transport companies will have to adapt to a new business model based on local production. nine0028

Go to the main page of the Encyclopedia of 3D Printing

Kinematics of 3D printers: what are the best types

Kinematics of 3D printers - which device to choose?

The print quality of a 3D printer and how it works depends on several factors. One of the important indicators is kinematics. This article discusses its main types and their features.

This article discusses its main types and their features.

- What is the kinematics of 3D printers?

- Types and types of kinematics

What is the kinematics of 3D printers?

Each 3D printer has its own kinematics. Models are equipped with a platform and an extruder. These parts move in a certain direction relative to each other. Kinematics in such a device means the scheme along which the extruder and platform move.

Types and types

There are five types of 3D printer kinematics. The principle of operation of the device and the method of processing the workpiece depend on their features. nine0028

Cartesian 3D printers

The most common are 3D printers with Cartesian kinematics. They are based on the Cartesian coordinate system, they work in the X, Y and Z axes. They set the coordinates by which the print head changes position relative to the platform. The printhead has limitations in terms of movement in three axes.

- The extruder moves up when the platform moves in the horizontal X or Y axis.

- The platform moves up in the Z axis, the extruder can move in the horizontal directions at this moment. nine0004

- The platform moves along one of the axes in height, the extruder rises along the other axis.

- The platform is static and does not move, the extruder moves in all three axes.

- The extruder moves along the coordinates in height, and the platform moves along the X and Y axes.

The most common options during operation are the first and second.

Cartesian kinematics has a number of advantages.

- This is a simple motion pattern suitable for hobby printing. Many budget models work on its basis. nine0004

- The printer can be produced in any dimensions, if necessary, it is upgraded.

- Consumables are freely available. Users are offered a large number of materials and colors.

- The printers can be shipped unassembled.

This feature allows beginners in the world of 3D printing to understand the principle of the mechanism.

This feature allows beginners in the world of 3D printing to understand the principle of the mechanism. - Devices based on the Cartesian system, suitable for mass production of parts. They are designed to create blanks of different sizes. nine0004

Among the shortcomings of printers built on the principle of three coordinate systems, two factors stand out:

- models are bulky, after assembly they take up a lot of space on the desktop;

- The print speed is slow.

Cartesian kinematic printers suitable for hobby printing. They help beginners understand the process of work and learn how to create models.

Example of printing on a device with Cartesian kinematics.

Varieties of Cartesian kinematics CoreXY and H-Bot

CoreXY has two feed belts, while H-Bot has only one, but it is long - this is the main difference between the two varieties. The common feature in these devices based on Cartesian kinematics is that the platform moves only along the Z axis. The horizontal X and Y axes are moved by a pair of motors mounted on the frame.

The horizontal X and Y axes are moved by a pair of motors mounted on the frame.

Two motors are responsible for the movement along the horizontal axes, one for the vertical ones. Such kinematics is common not only in amateur printers, but also in professional ones. nine0028

CoreXY and H-Bot based 3D printers are more expensive than conventional Cartesian models. For the production of their cases, a metal alloy or composite materials are used. Rail guides unleash the potential of high-quality printing. This kinematics allows you to achieve good detail with fast printing.

The advantages of CoreXY and H-Bot are:

- high print speed;

- quality detailing of models; nine0004

- professional use.

But not without drawbacks:

- H-Bot is not implemented on steel shafts;

- the belt tension must be constantly monitored to avoid play;

- high cost of instruments;

- belts can wear out quickly if they rub against neighboring objects during operation, this factor must be taken into account during operation;

- the pulleys on which the belts move must be located strictly perpendicular to each other.

nine0004

nine0004

Cartesian kinematic printers are widely used in various industries. They are distinguished by high print detail, a durable metal case, and high-quality components.

Help! Cartesian kinematics allows you to create detailed objects at high speed.

Delta Printers

Delta kinematic printers differ from their competitors in a number of ways. The table remains stationary, and three fixed axes are used to move the print head at once. In such devices, there is no division into the X, Y and Z axis. To move the carriage sideways, you need to lower one axis, and raise the rest. nine0028

Help! In the production of 3D printers, the Delta kinematics has not yet found wide distribution. This is a promising direction, which is currently being developed by developers.

Already existing delta printers offer the following advantages.

- Small dimensions.

Devices do not take up much space on the desktop, they are tall, but not wide.

Devices do not take up much space on the desktop, they are tall, but not wide. - High print speed. Models can process 300–400 mm/s.

- A new approach to the production of blanks. The equipment does not print using the same technology as Cartesian. It is interesting to watch the process of processing the model.

Deltas also have a few disadvantages.

- Calibration complexity. A lens is formed on the printed surface, due to which it is impossible to fully calibrate the printing process. This is the main factor slowing down the mass introduction of kinematics.

- Poor accuracy. High print speeds sacrifice accuracy. All axes perform small movements, errors occur. nine0004

- Computing power requirement. Deltas are equipped with 32-bit boards, which is why they do not support interaction with 8-bit systems.

- The frame must be rigid. This is necessary to avoid backlash, deviations and distortions.

- Not all extruders will fit.

Deltas have weight restrictions, so direct type extruders are not allowed.

Deltas have weight restrictions, so direct type extruders are not allowed.

Printing accuracy remains high.

On deltas, you can build high-quality vertical models, even with large dimensions. There are no protruding parts on the body, which allows you to independently increase its rigidity. nine0028

Polar

The polar kinematic scheme is represented by only one company - Polar. The essence of this technology lies in the fact that it does not have positioning along the X, Y and Z axes. The position of the extruder is set by the angle and radius. The platform of polar 3D printers is round in shape, it moves only along the horizontal axis and only rotates in a circle. The extruder moves up and down.

The advantages of 3D printers based on polar kinematics are:

- the ability to create large objects;

- high energy efficiency;

- material savings;

- small dimensions.

But there are also disadvantages:

- low printing accuracy, which was started by Polar representatives;

- platform does not warm up during operation;

- material handling restrictions - ABS plastic cannot be processed.

Polar printers are inferior in print accuracy to Cartesian and Delta printers. The manufacturer recommends using such models for educational purposes; they are not yet suitable for professional printing. nine0028

Printing example shows that accuracy cannot be achieved. All features are blurred, the figure lacks sharpness and clarity.

With robotic arms

Printers with robotic arms are a design with a mechanically programmable extruder gripper arm. This is a multifunctional robot: it can carry out welding, painting, milling, etc.

The extruder can move in different directions: in layers, along complex paths in three dimensions, at different angles. Thanks to this set of functions, it is possible to create complex designs. nine0028

The main advantages are:

- versatility: the device can perform several types of tasks when replacing the extruder;

- are suitable for industrial applications: you can print large objects with almost no size restrictions.

But there are also disadvantages:

- low accuracy: such equipment is inferior to Cartesian kinematics;

- large size: devices take up a lot of space on the work surface. nine0004

These models are not suitable for professional 3D printing. They can be considered as an object for a hobby or a tool for it. For industrial purposes, such devices work only when high precision in the execution of parts is unimportant.

SCARA

SCARA (Selective Compliance Articulated Robot Arm) is a kinematics based on horizontal rotation of the platform. The movement is achieved by the articulation of the linkage mechanism.

These devices are highly accurate and repeatable, while operating with a minimum of noise and vibration. SCARA also surpassed the Cartesian models in terms of processing detail: the difference is that the former work noticeably faster. nine0028

Advantages of such kinematics:

- print accuracy;

- high workpiece processing speed;

- small dimensions and weight.

But there are also disadvantages:

- stiffness restrictions in the area of the X and Y axes;

- high cost;

- is not the widest area of use.

SCARA kinematic devices are devices that combine the functions of a 3D printer and a manipulator. Device actions are programmed through software or an installed mobile application. nine0028

The choice of kinematics for 3D printers depends on the requirements for technology and application.

- Cartesian models remain the most common. They combine high accuracy, good speed, small dimensions. They can be used for amateur 3D printing. They work in a Cartesian coordinate system, the platform and the extruder move along the X, Y, Z axes.

- CoreXY and H-Bot are varieties of Cartesian kinematics. They are highly detailed blanks, suitable for professional use. Their disadvantage is the complexity in the process of operation. The user must constantly ensure that the belts do not come into contact with foreign objects and are well tensioned.

Learn more