Used 3d printers for sale

Refurbished 3D Printers and Machines

MatterHackers refurbished 3D printers are fully functional printers that are certified and tested by the Pros here at HQ - plus, they come with a six-month warranty. These reconditioned, gently used 3D printers are the perfect source for makers, manufacturers, and educators that need high-quality 3D printers at an affordable price. Of course, all refurbished 3D printers come with lifetime support via email or phone. We realize that cost can be a factor for some buyers, that’s why we are excited to offer this option for everyone! Refurbished 3D printers come in two classifications; A Stock and B Stock. Don’t see the machine you are looking for? Check back often - we could be testing the affordable 3D printer of your dreams right now!

Guides & Articles

Tech Breakdown: Ultimaker S5 3D Printer Review

The Pros at MatterHackers break down and review all the new and improved tech in the first 3d printer from Ultimaker in their new 'S' line of products.

Tech Breakdown: Raise3D E2 3D Printer Review

The E2 is the first Raise3D 3D printer to feature independent dual extrusion for clean multi-material prints and duplicated print jobs.

Tech Breakdown: Lulzbot TAZ Workhorse 3D Printer Review

MatterHackers' pros take a look at why the Lulzbot TAZ Workhorse lives up to its name, making it a 3D printer to be reckoned with.

Tech Breakdown: Ultimaker S5 Pro Bundle Review

Building off the success of the Ultimaker S5, the Pro Bundle takes the printing experience to the next level.

Tech Breakdown: Ultimaker S3 3D Printer Review

A machine you can trust is absolutely essential for any professional, and the Ultimaker S3 passes with flying colors. Read on to see what makes it so reliable.

Tech Breakdown: Creality Ender 3 V2 Bundle 3D Printer Review

From the creators of the CR-10 and the ubiquitous Ender 3, the Ender 3 V2 improves on its predecessor in every way.

Tech Breakdown: BCN3D Epsilon W27 and W50 3D Printer Review

When you need to 3D print something big and in two materials, considering any of the BCN3D Epsilon 3D printers is a smart choice.

Tech Breakdown: Ultimaker 2+ Connect 3D Printer Review

The 3D printer that laid the foundation for Ultimaker gets spruced up and modernized. Let's take a look at the Ultimaker 2+ Connect and what makes it so special.

Tech Breakdown: Peopoly Phenom Resin 3D Printer Review

Building on the success of their other printers, Peopoly unveils the next edition to their resin 3D printer lineup.

Tech Breakdown: Craftbot FLOW 3D Printer Review

The latest line of 3D printers from the company known for their robust machines has a lot going on under the hood, read more to find out.

Tech Breakdown: Zmorph FAB All-In-One 3D Printer Review

The latest machine from Zmorph is more than just a 3D printer, it's a full-fledged workbench in one platform.

Tech Breakdown: BCN3D Sigma D25 3D Printer Review

BCN3D has done it again with the inaugural Sigma D25, the first entry into BCN3D's Desktop series of 3D printers and continuing their IDEX legacy.

Refurbished "A Stock" description:

- Fully functional printer, professionally inspected and tested

- Used, like new condition

- May contain minor cosmetic blemishes

- A nonessential item may be missing (thumb drive etc.)

- Comes with a 6 month warranty

Refurbished "B Stock" description:

- Fully functional printer, professionally inspected and tested

- Used, good condition

- May contain minor cosmetic blemishes

- May or may not include the original packaging

- Some nonessential items may be missing (filament, SD cards, etc.)

- Comes with a 6 month warranty

Used Industrial 3D Printers - CNCMachines.com

When you are searching for a used 3D printer for sale, youll notice a number of types of technologies with different names. To help you compare similar types of printers, below are five common technologies with their synonyms and similar technologies as you may find advertised on our used 3D printers catagory page:

To help you compare similar types of printers, below are five common technologies with their synonyms and similar technologies as you may find advertised on our used 3D printers catagory page:

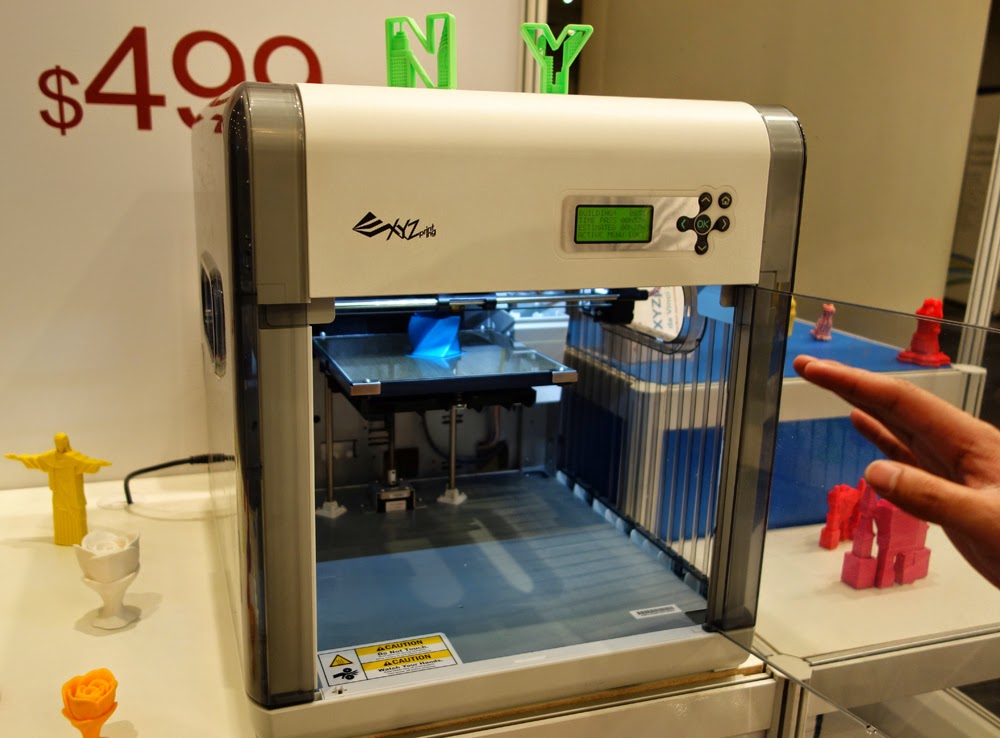

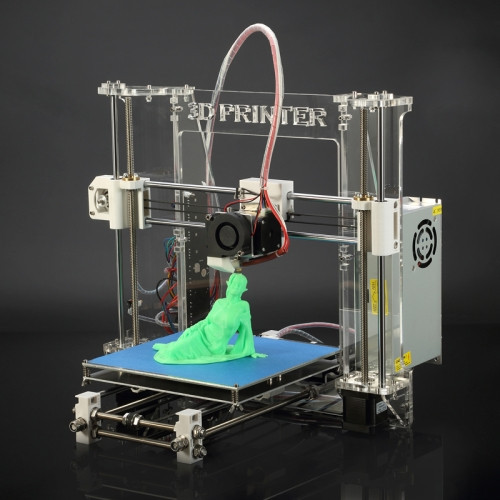

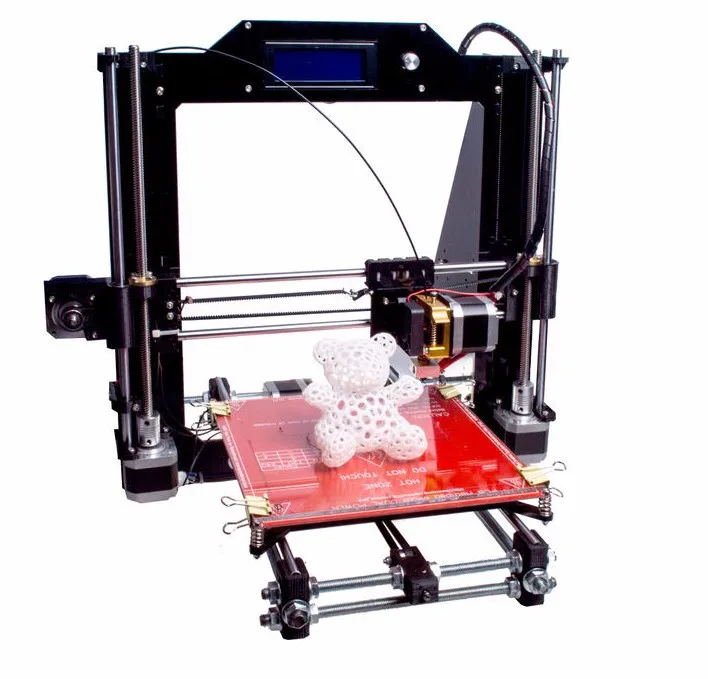

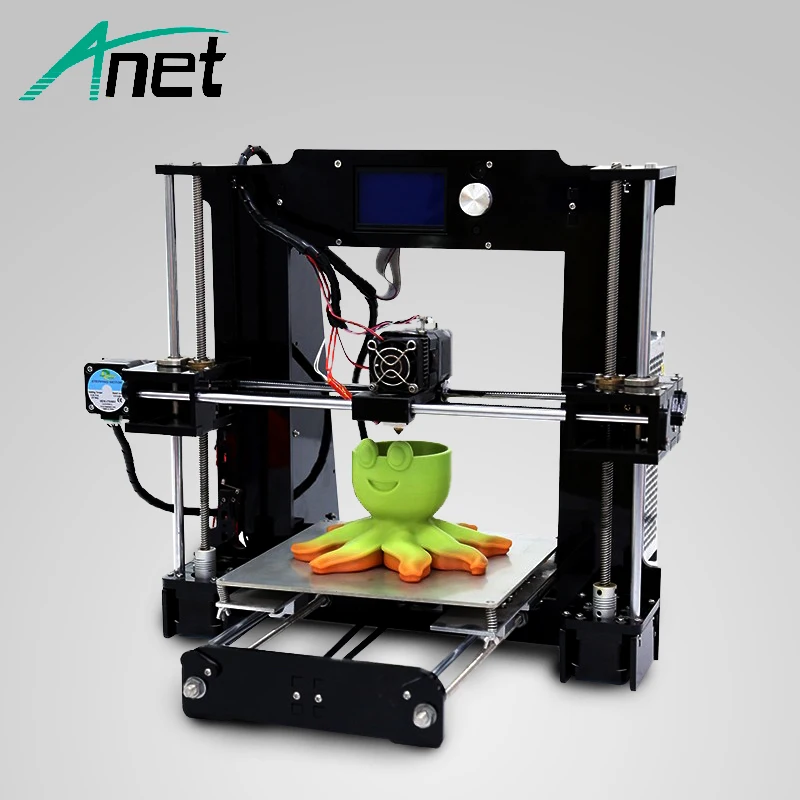

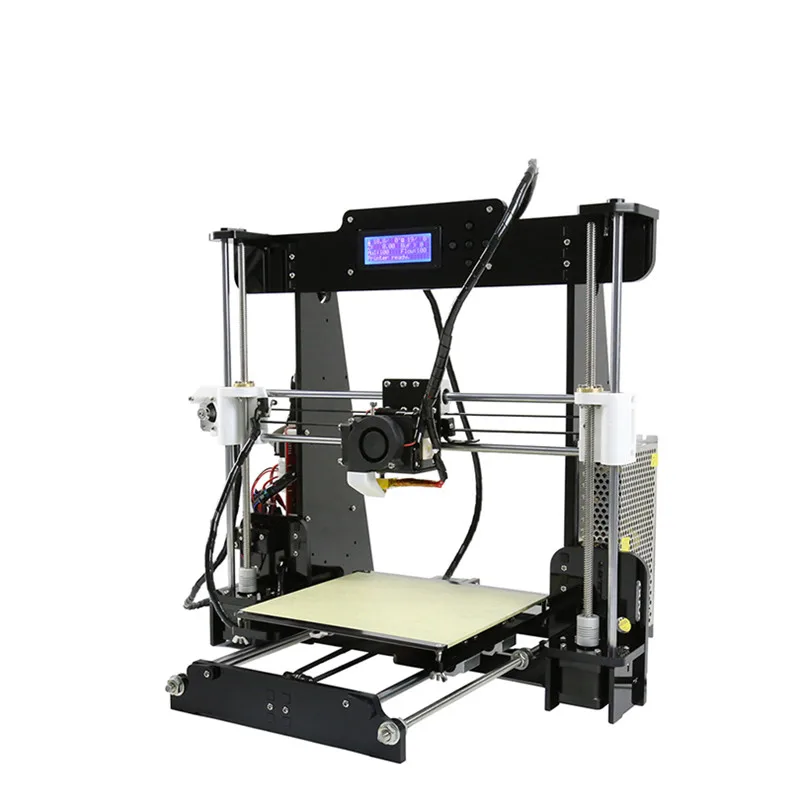

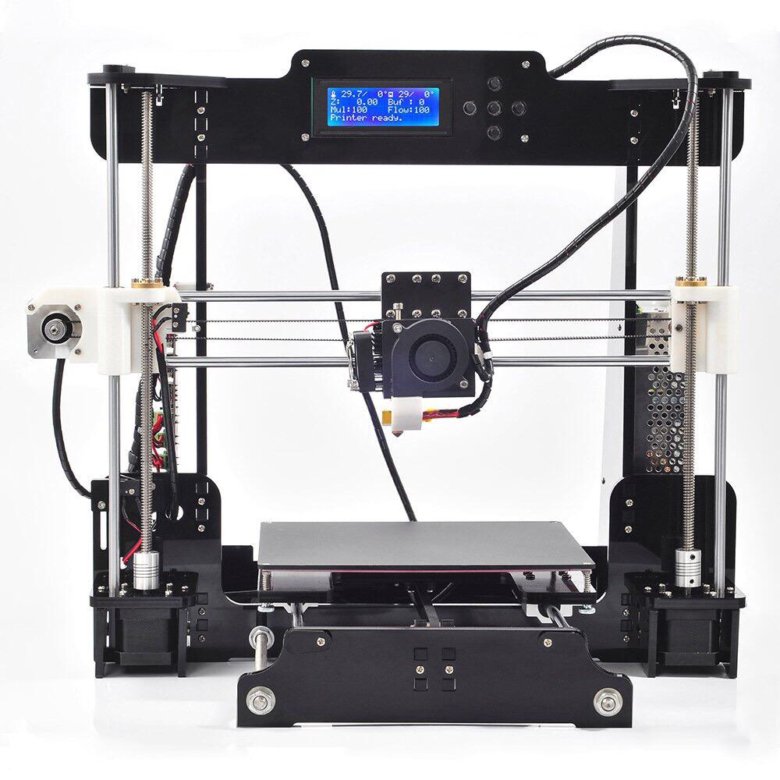

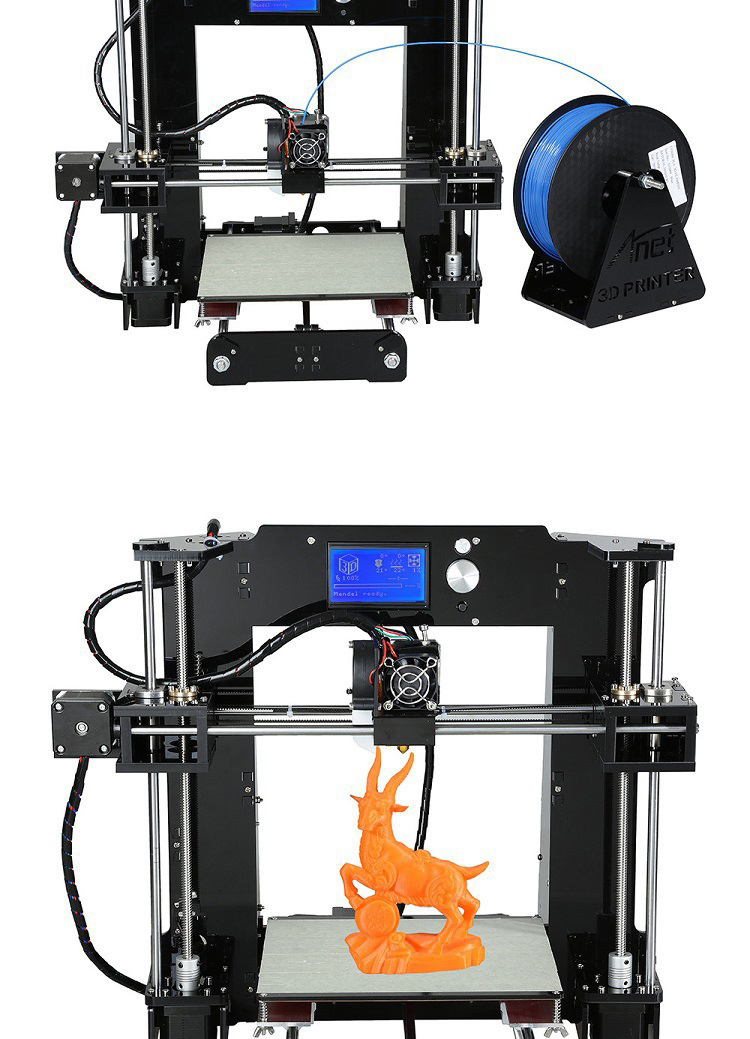

Fused Deposition Modeling

Similar Technologies/Names: (Fused deposition modeling (FDM)), fused filament fabrication, plastic jet printing, filament extrusion, fused filament deposition, and material deposition.

Fused deposition modeling is the most widely used form of 3D printing with models available at the consumer level as well as the industrial level. This technology builds parts layer-by-layer from the bottom up. It heats and extrudes a thermoplastic filament. Thermoplastics are available with special properties like toughness, translucence, biocompatibility, electrostatic dissipation, UV resistance, and high-heat deflection. The relative weakness of this technology is that you may have visible layer lines and the parts are weaker along the layer lines. Larger FDM machines require compressed air for high-performance plastics.

PolyJet Technology

Similar Technologies/Names: (PolyJet technology), multi-jet printing, photopolymer jetting

PolyJet 3D printers work similarly to a traditional inkjet printer, but instead of jetting ink onto paper, the print head jets liquid photopolymers onto a build tray. Each droplet is cured in a flash of UV light. This type of 3D printer can provide sharp precision, smooth surfaces, and very fine details. It can mix photopolymers in specific concentrations to many materials, even rubber, and human tissue. 3D printers with photopolymer jetting make amazing realism with a full gamut of colors.

Stereolithography (SL)

Similar Technologies/Names: (stereolithography), SLA, vat photopolymerization

A 3D printer with stereolithography (SL) technology is an excellent option for very tight tolerances and smooth surfaces. A UV laser cures and solidifies very fine layers of photopolymer in an open vat with this technology. Designers like this technology for quick build times for strong parts made of transparent, heat-resistant, moisture resistant materials. A relative weakness of this technology is UV sensitivity (parts are often painted for this reason) and extra post-curing steps. 3D printers of this type required dedicated manufacturing space with ventilation and a specialty multi-stage alcohol treatment.

Designers like this technology for quick build times for strong parts made of transparent, heat-resistant, moisture resistant materials. A relative weakness of this technology is UV sensitivity (parts are often painted for this reason) and extra post-curing steps. 3D printers of this type required dedicated manufacturing space with ventilation and a specialty multi-stage alcohol treatment.

Laser Sintering (LS)

Similar Technologies/Names: (laser sintering), selective laser sintering, SLS, power bed fusion

If you are looking for a 3D printer capable of building parts with good mechanical properties and extremely complex geometries like undercuts, thin walls or interior features, then finding a laser sintering 3D printer for sale might be your best bet. A laser sintering 3D printer uses a high-powered CO2 laser to melt and fuse powdered thermoplastics selectively. Parts made with this technology can be watertight, airtight and flame retardant since materials can hold excellent isotropic properties equally strong in all directions.

Metal Powder Bed Fusion (MPBF)

Similar Technologies/Names: (metal powder bed fusion), selective laser melting, metal laser melting, direct metal laser melting

MPBF is a type of 3D printing that makes it possible to produce complex geometries not possible with conventional metal manufacturing processes. It uses a precise high-wattage fiber laser that micro-welds powdered metals and alloys to form components similar to wrought counterparts. Strong and durable parts can be made with additive metals like Inconel, aluminum, stainless steel, and titanium. Its possible to make features like internal cavities, thin walls, undercuts and interlocking components which are difficult or impossible to make with machining. Usually, this selective laser melting 3D printing is used for prototypes, low-volume runs, or for parts that cannot be cast or machined.

Features of the operation of 3D printers and their use in practice

Many of the phenomena described in the science fiction works of Asimov, Clark or Verne have found their embodiment in reality. Nowadays, few people can be surprised by a cell phone, electric car or Skype, no matter the distance. However, there is a place for non-standard products today. We are talking about 3D printers.

Nowadays, few people can be surprised by a cell phone, electric car or Skype, no matter the distance. However, there is a place for non-standard products today. We are talking about 3D printers.

History of 3D printers

Chuck Hull is considered the founder of 3D printing. It was he who invented the first printer at 1984 year. The new technology was called "stereolithography" and was patented in 1986. The first device based on it was created in 1988 by 3D-Systems, founded by Chuck Hull. Already in 1993, Solidscape began mass production of inkjet-based 3D printers that could produce small parts with perfect surface quality. A major breakthrough was the creation of a device that can print three-dimensional objects in color. This happened in 2005 thanks to the efforts of Z Corp. Already in 2006, a printer appeared that could reproduce half of its own components. nine0003

What is a 3D printer and how does it work? He builds the final object by layering the material. The main elements of a 3D printer are the print head and the working platform.

The printhead is needed to apply the layers of material and form the object. It can only move in a horizontal plane. The working platform moves in the vertical direction. It is necessary to place the object. nine0003

The printhead is needed to apply the layers of material and form the object. It can only move in a horizontal plane. The working platform moves in the vertical direction. It is necessary to place the object. nine0003 Scheme of operation of the 3D printer

At the first stage of the device operation, its platform is in the upper position. Then the print head forms the bottom layer of the future product. After its application, the platform descends exactly to the thickness of the layer and the head applies the next one. This cycle is repeated until the required object is "grown". This is how a 3D printer works. The consumables can be metal clay, ceramic powder, plastic filament or photopolymer resin. nine0003

3D Printing Technologies

There are various 3D printing technologies that allow you to understand what can be printed on a 3D printer. One of the earliest and most common is stereolithography or SLA. It is based on the ability of a liquid photopolymer resin to harden under the influence of a laser beam. To build each subsequent layer, the working platform is immersed in a container with liquid resin by a layer size of 0.05-0.15 mm. After leveling the surface, its formation begins. The main advantage of stereolithography is its high precision. Due to this property, it is used to make prototypes of dental prostheses or jewelry. nine0003

To build each subsequent layer, the working platform is immersed in a container with liquid resin by a layer size of 0.05-0.15 mm. After leveling the surface, its formation begins. The main advantage of stereolithography is its high precision. Due to this property, it is used to make prototypes of dental prostheses or jewelry. nine0003

SLA technology

Digital LED projection or DLP is also based on liquid photopolymer resins. Only in this case, the printer projects the image of the entire layer of the object at the same time until the resin hardens. The technology is highly accurate, allowing it to be used in the manufacture of souvenirs or jewelry, as well as in dentistry.

Another known method is selective laser sintering or SLS. In this case, the formation of the final object occurs as a result of layer-by-layer sintering of particles of powdered material under the influence of a laser beam. This printing technology has become widespread due to the ability to produce parts of complex geometric shapes. These include art and even sports shoes. Sand or composite mixtures, metals and alloys, various polymers can be used as consumables. nine0003

These include art and even sports shoes. Sand or composite mixtures, metals and alloys, various polymers can be used as consumables. nine0003

SLS technology

Electron beam melting (or EBM) technology is based on the use of electron emitters for layer-by-layer melting of metal powder in an airless chamber. This method allows you to create parts of high strength and density. The final products are indistinguishable in mechanical properties from cast ones. With the help of EBM, medical implants, parts of rocket and jet engines, bearing elements of aircraft are made.

Another technology to note is 3D inkjet printing or 3DP. In this case, three-dimensional objects are created by layer-by-layer application of any powders, including sand mixtures, plastics, and even metals. Color printing is provided by the addition of dyes to the binder. The 3DP method makes it possible to manufacture products of complex geometric shapes that will not be subjected to mechanical stress in the future. With its help, souvenirs, jewelry or models are made. nine0003

With its help, souvenirs, jewelry or models are made. nine0003

Using 3D technologies in everyday life

Given the wide variety of consumables and technologies used, refilling 3D printers is a rather specific operation, but applicable to any device model. Currently, they are used in medical, construction, architectural, educational, jewelry and other fields. A device has been created that can build a full-fledged two-story house in just 20 hours. It is likely that in the near future the process of building construction will be simplified and accelerated as much as possible. 3D printers are also indispensable in medicine. They allow not only to produce strong and durable implants, but even human skin. These devices have become a real step into the future. nine0003

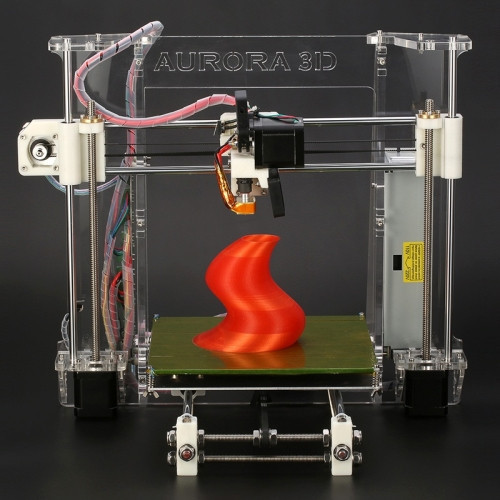

SkyOne 3D Printer

SkyOne 3D Printer

We offer a novelty in the world of three-dimensional technologies - SkyOne 3D printer MFP. Unlike most similar printers, SkyOne has advanced features that allow you to solve a wide range of tasks. SkyOne is universal coordinate a machine that has the ability to work as a 3D printer, engraver, CNC milling machine. Thanks to easily replaceable extruder and adaptive design of the 3d printer, it is possible to install a tool suitable for performing various tasks such as spindle, dispenser, vacuum gripper or pneumatic marker. nine0003

SkyOne is universal coordinate a machine that has the ability to work as a 3D printer, engraver, CNC milling machine. Thanks to easily replaceable extruder and adaptive design of the 3d printer, it is possible to install a tool suitable for performing various tasks such as spindle, dispenser, vacuum gripper or pneumatic marker. nine0003

The rapid development of additive technologies has led to the high popularity of 3D printing. Quality and beautiful 3d printing opens up great opportunities for us. 3D modeling and prototyping is the newest way receiving high-quality small-scale industrial products, three-dimensional images and figures. 3D printers are widely are used in design, construction and industry. A full copy of the future development saves time and means to avoid inaccuracies and errors. nine0003 SkyOne is a versatile and functional 3D printer.

nine0003 SkyOne is a versatile and functional 3D printer.

SkyOne Benefits

Multifunctionality. SkyOne 3d printer is also engraving and milling the machine.

Compact. Dimensions 275x250x400 mm with print area 140x190x200 mm.

High speed, fast preparation for printing. Coordinate machine quick release extruder, allows promptly prepare the printer for milling and engraving. nine0003

Rich equipment and a choice of one of two colors solutions.

In the 3dlaboratorio online store you can buy a SkyOne multifunctional 3D printer and all the necessary consumables materials at a bargain price. The basis of our company's activity is the production of high-quality three-dimensional printers and sale of consumables. We are also happy to offer you: nine0003

The basis of our company's activity is the production of high-quality three-dimensional printers and sale of consumables. We are also happy to offer you: nine0003

- Engraving sets.

- Durable and easy to machine plastics.

- Varnish for printing from the manufacturer.

- Training in the latest 3D technologies.

- Accessories for 3D printers.

- Prompt delivery of SkyOne 3D printer and accessories.

Having a high quality and fast 3D printer is only part of the success. Correct selection of consumables materials plays a key role in obtaining the desired result. When choosing, it is important to be guided by the properties and purpose plastics for printing. It is important to note that each plastic has individual properties and is suitable for certain areas of application. For example, PLA+ is a biodegradable plastic and is great for food, medical spheres, while FLEX is resistant to wear, neutral to oils and gasoline. nine0003

For example, PLA+ is a biodegradable plastic and is great for food, medical spheres, while FLEX is resistant to wear, neutral to oils and gasoline. nine0003

We invite you to free training in 3D printing. We teach our clients 3D technologies and share last achievements in a surprisingly interesting field. Free training is a great opportunity to join popular and rapidly growing field of 3D modeling.

Employees of our company will help you choose plastic for solving any problems. By working with us, you get the ability to organize a constant supply of high-quality accessories for printing at competitive prices. nine0003

Events

-

St. Petersburg 3D Printing Festival

Dear colleagues! We are pleased to announce the participation of SkyOne at the 3D Printing Festival in St.

Petersburg. Come, your Attention will be presented to practical examples of using a 3D printer - milling cutter. You will demonstrated how can be successfully printed and milled! The festival will take place on 9February 2019, from 10:00-19:00, at the address: Saint Petersburg, Congress Center "PetroCongress", st. Lodeynopolskaya, 5. See you!

Petersburg. Come, your Attention will be presented to practical examples of using a 3D printer - milling cutter. You will demonstrated how can be successfully printed and milled! The festival will take place on 9February 2019, from 10:00-19:00, at the address: Saint Petersburg, Congress Center "PetroCongress", st. Lodeynopolskaya, 5. See you! -

New company development - plastic dryer

3DLaboratorio presents a new innovative development - a dryer for plastic

nine0068 -

Participation in the exhibition "3D Print Expo"

We invite you to visit us at the exhibition "3D Print Expo" in Sokolniki, booth E17, 13 and 14 October.

-

Participation in the exhibition "Interplastica 2017"

January 24-27 HTW we invite you to visit our booth at the exhibition "Interplastica 2017". nine0003

-

Best Innovative Company 2016 Award

According to the results of the 3D Pint Expo, the HTW team received an award "Best Innovative company 2016" for own development - 3D printer / engraver / router SkyOne.