Powder 3d printer

Tech Specs for the Fuse 1 SLS 3D Printer

Printer

Fuse 1

Fuse 1+ 30W

Technology

Selective Laser Sintering

Selective Laser Sintering

Build Volume (W x D x H)

165 × 165 × 300 mm

6.5 x 6.5 x11.8 in

165 × 165 × 300 mm

6.5 x 6.5 x11.8 in

Layer Thickness

110 microns

0.004 in

110 microns

0.004 in

Laser Type

Ytterbium Fiber 10W

Ytterbium Fiber 30W

Laser Spot Size (FWHM)

200 microns

0.0079 in

247 microns

0.0097 in

Build Chamber

Modular, compatible with Fuse 1 generation printers and Fuse Sift

Modular, compatible with Fuse 1 generation printers and Fuse Sift

Technology

Selective Laser Sintering

Selective Laser Sintering

Build Volume (W × D × H)

16.5 x 16.5 x 30 cm

6.5 x 6.5 x 11. 8 in

16.5 x 16.5 x 30 cm

6.5 x 6.5 x 11.8 in

Layer Thickness (Axis Resolution)

110 microns

0.004 in

110 microns

0.004 in

Hopper Capacity

17.8 Liters

14.5 Liters

Dimensions

68.5 x 64.5 x 106.5 cm

27 x 25.4 x 41.9 in

68.5 x 64.5 x 106.5 cm

27 x 25.4 x 41.9 in

Supports

No supports

No supports

Design/CAD Specifications

Minimum Access Dimensions (W × D × H)

125.5 × 149.5 × 187 cm

49.4 × 59.0 × 73.6 in

125.5 × 149.5 × 187 cm

49.4 × 59.0 × 73.6 in

Printer Dimensions (W × D × H)

64.5 × 68.5 × 107 cm (165.5 cm with stand)

25.4 × 27 × 42 in (65.0 in with stand)

64.5 × 68.5 × 107 cm (165.5 cm with stand)

25.4 × 27 × 42 in (65.0 in with stand)

Recommended Operating Footprint (W × D × H)

145.5 × 149.5 × 167.5 cm (49.4 × 59 × 66 in) to allow access to the front and sides of the printer.

145.5 × 149.5 × 167.5 cm (49.4 × 59 × 66 in) to allow access to the front and sides of the printer.

Stand Dimensions (W × D × H)

59.6 x 60 x 58.4 cm

23.5 × 23.6 × 23 in

59.6 x 60 x 58.4 cm

23.5 × 23.6 × 23 in

Weight

114 kg (without build chamber or powder)

251.3 lb (without build chamber or powder)

120 kg (without build chamber or powder)

265 pounds (without build chamber or powder)

Startup Time

< 60 minutes

< 60 minutes

Operating Environment

18 – 28 ºC

68 – 82 ºF

18 – 28 ºC

68 – 82 ºF

Internal Temperature

Up to 200 ºC

Up to 392 ºF

Up to 200 ºC

Up to 392 ºF

Temperature Control

Quartz tube heating elements

Positive temperature coefficient (PTC) cartridges

Quartz Tube Heating Elements

Resistive Air Heater

Air Handling

Pressure-controlled two-stage filtration

(Replaceable HEPA and carbon mediums)

Interface to external inert gas supply

Pressure controlled two-stage filtration

(Replaceable HEPA and carbon mediums)

Power Requirements

EU: 230 VAC, 7. 5 A (dedicated circuit)

5 A (dedicated circuit)

US: 120 VAC, 15 A (dedicated circuit)

EU: 230 VAC, 7.5 A (dedicated circuit)

US: 120 VAC, 15 A (dedicated circuit)

Galvanometers

Formlabs Custom

Formlabs Custom 2nd Generation

Laser Specifications

Ytterbium Fiber

IEC 60825-1: 2014 certified

1070 nm wavelength

Maximum 10 Watts

4.01 mrad beam divergence (nominal, full angle)

Ytterbium Fiber

IEC 60825-1: 2014 certified

1070 nm wavelength

Maximum 30 Watts

3.24 mrad beam divergence (nominal, full angle)

Laser Spot Size (FWHM)

200 microns

.0079 in

247 microns

.0097 in

Radiation Information

The Fuse 1 is a Class 1 Laser product. Accessible radiation is within Class 1 limits.

The Fuse 1+ 30W is a Class 1 Laser product. Accessible radiation is within Class 1 limits.

Connectivity

Wi-Fi (2. 4GHz + 5GHz)

4GHz + 5GHz)

Ethernet (1000 Mbit)

USB 2.0

Wi-Fi (2.4GHz + 5GHz)

Ethernet (1000 Mbit)

USB 2.0

Printer Control

10.1” interactive touchscreen

1280 × 800 resolution

10.1” interactive touchscreen

1280 × 800 resolution

Alerts

Touchscreen alerts and tracking

SMS/email via Dashboard

Live video feed with computer vision

Proactive maintenance alerts

Touchscreen alerts and tracking

SMS/email via Dashboard

Live video feed with computer vision

Proactive maintenance alerts

Print Preparation

PreForm Desktop Software

PreForm Desktop Software

System Requirements

Windows 7 (64-bit) and up

Mac OS X 10.12 and up

OpenGL 2.1

4 GB RAM (8 GB recommended)

Windows 7 (64-bit) and up

Mac OS X 10.12 and up

OpenGL 2.1

4 GB RAM (8 GB recommended)

Hardware Requirements

Fuse 1 generation 3D printer

Fuse 1 generation 3D printer

File Types

. STL or .OBJ

STL or .OBJ

FORM file output

.STL or .OBJ

FORM file output

hardware selection and technology guide

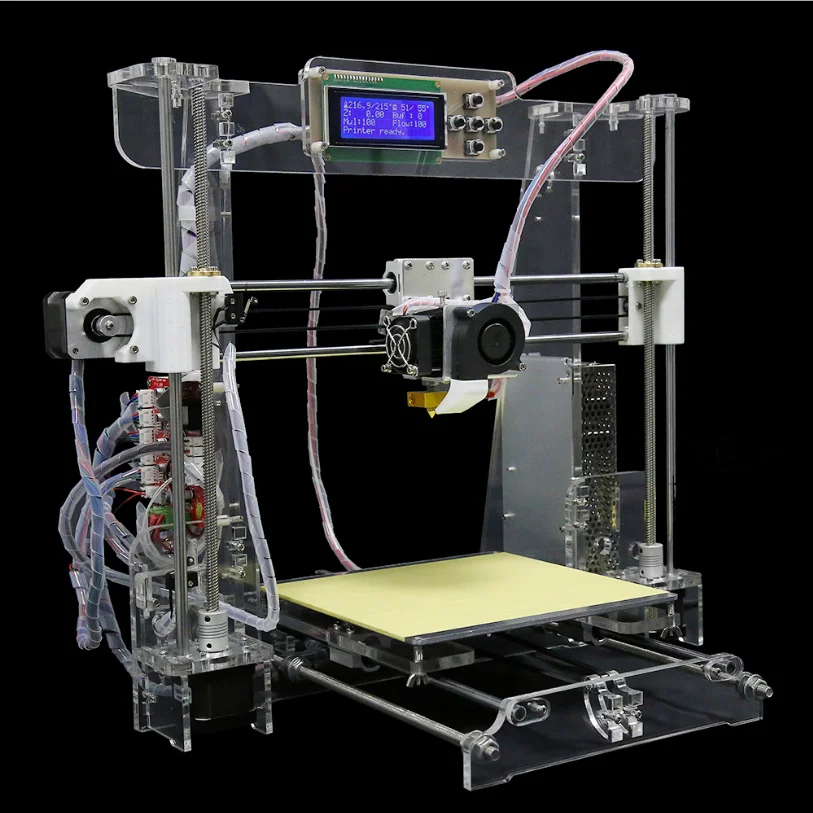

What desktop SLS 3D printers are available on the market?

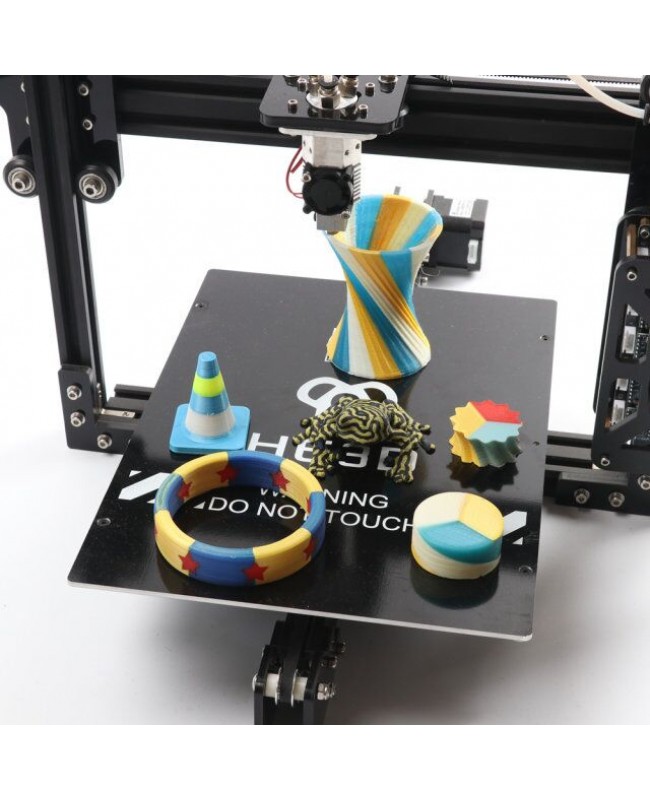

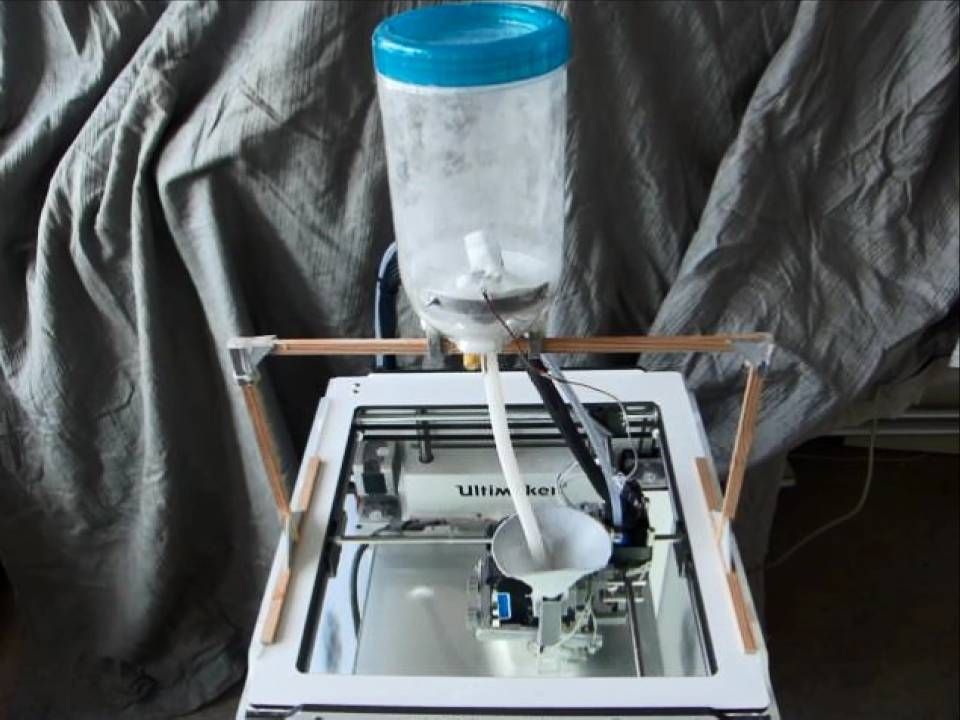

SLS (Selective Laser Sintering) is a 3D printing technology that uses a laser beam to sinter powdered material. This technique enables the 3D printing of detailed functional parts and prototypes.

Five to ten years ago, SLS technology was exclusive to large, industrial additive manufacturing systems. In recent years, a more compact SLS 3D printer niche has been slowly emerging, with lower prices and office-friendly formats.

Starting at around $6,000, these benchtop or desktop SLS 3D printers enable SMEs to access accurate and advanced in-house prototyping without having to rely on external 3D printing services. They are able to print with powder materials such as Nylon, TPE, and other thermoplastics.

In this guide, we take a closer look at which desktop SLS printers are available on the market from brands like Sintratec, Sinterit, and Formlabs.

The best desktop SLS printers for professionals

| Brand | Product | Build size | Country | Price Approximate starting prices based on supplier-provided information and public data. Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …). | |

|---|---|---|---|---|---|

| Sintratec | Sintratec Kit | 110 × 110 × 110 mm4.33 × 4.33 × 4.33 in | – | $ 5,9994 990 €5,321 £894,187 ¥ | Quote |

| Natural Robotics | VIT SLS | 250 × 250 × 300 mm9.84 × 9.84 × 11.81 in | Spain | $ 12,90011 000 €11,443 £1,922,822 ¥ | Quote |

| Sinterit | Lisa | 150 × 200 × 150 mm5.91 × 7.87 × 5.91 in | – | $ 12,9957 990 €11,527 £1,936,983 ¥ | Quote |

| Sinterit | Lisa Pro This product has been reviewed by our team. | 150 × 200 × 260 mm5.91 × 7.87 × 10.24 in | – | $ 17,99011 990 €15,958 £2,681,517 ¥ | Quote |

| Formlabs | Fuse 1 | 165 × 165 × 320 mm6.5 × 6.5 × 12.6 in | – | $ 18,49918 499 €16,409 £2,757,387 ¥ | Quote |

| RED ROCK 3D | RED ROCK | 180 × 180 × 180 mm7.09 × 7.09 × 7.09 in | – | upon request | Quote |

Expand to see more specs

The products in the table are ranked by price (low to high).

| Brand | Product | Build size | Country | Price Approximate starting prices based on supplier-provided information and public data. Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …). | |

|---|---|---|---|---|---|

| Sintratec | Sintratec Kit | 110 × 110 × 110 mm4.33 × 4.33 × 4.33 in | – | $ 5,9994 990 €5,321 £894,187 ¥ | Get a quote |

| Natural Robotics | VIT SLS | 250 × 250 × 300 mm9. 84 × 9.84 × 11.81 in 84 × 9.84 × 11.81 in | Spain | $ 12,90011 000 €11,443 £1,922,822 ¥ | Get a quote |

| Sinterit | Lisa | 150 × 200 × 150 mm5.91 × 7.87 × 5.91 in | – | $ 12,9957 990 €11,527 £1,936,983 ¥ | Get a quote |

| Sinterit | Lisa Pro This product has been reviewed by our team. | 150 × 200 × 260 mm5.91 × 7.87 × 10.24 in | – | $ 17,99011 990 €15,958 £2,681,517 ¥ | Get a quote |

| Formlabs | Fuse 1 | 165 × 165 × 320 mm6.5 × 6.5 × 12.6 in | – | $ 18,49918 499 €16,409 £2,757,387 ¥ | Get a quote |

| RED ROCK 3D | RED ROCK | 180 × 180 × 180 mm7.09 × 7.09 × 7.09 in | – | upon request | Get a quote |

What is SLS (Selective Laser Sintering) technology?

Up until early 2014, Carl Deckard from Structured Polymers held a patent on Selective Laser Sintering 3D printing technology. Selective Laser Sintering (SLS) is part of the Powder Bed Fusion family of 3D printing technologies.

Selective Laser Sintering (SLS) is part of the Powder Bed Fusion family of 3D printing technologies.

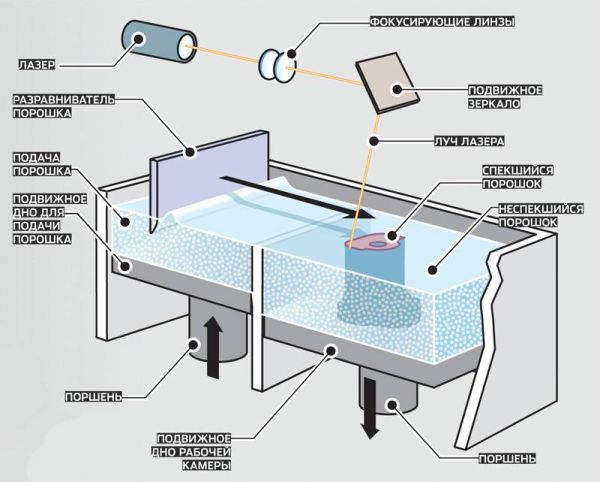

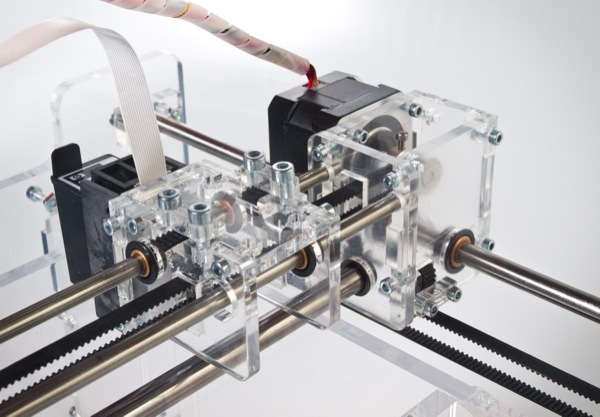

How does Selective Laser Sintering work?

This technology uses a laser to sinter powdered material. In other words, a powerful laser beam selectively melts and fuses tiny powder particles together.

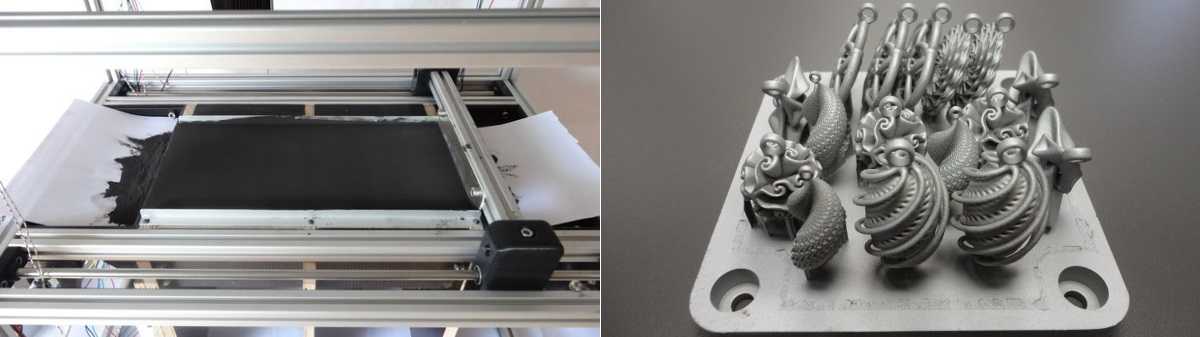

SLS 3D printing technology. Source: SculpteoOnce a layer is finished, more powder is rolled and spread onto the print bed. The process repeats itself layer after layer. The excess powder stays in the powder bed, thus automatically providing support for the object and its intricacies (though supports are still needed when it comes to metal 3D printing).

When the 3D printing process is finished and the powder bed has cooled down, the objects can be removed. The excess powder material is then to be brushed off to reveal the final part. Aside from powder removal, the parts require little to no post-processing for basic applications.

Overview of the best desktop SLS printers

The Sinterit Lisa is a plug-and-play desktop SLS 3D printer made by Polish manufacturer Sinterit. It is one of the most affordable SLS 3D printers actually available on the market.

It is one of the most affordable SLS 3D printers actually available on the market.

This 3D printer offers a relatively large build volume for a desktop 3D printer, and even more so for an SLS 3D printer in this price range. With the Lisa it is possible to 3D print flexible material (Flexa Black/Grey) or rigid, strong material (PA12).

Contact manufacturer Get a quote Add to comparison

In comparison with the regular Lisa, the Lisa Pro boasts various upgrades and features. For starters, the Pro version is equipped with a Nitrogen chamber, for wider material compatibility.

The Lisa Pro SLS printer also provides a bigger print volume as well as a larger touchscreen than the Lisa.

Our review at Sinterit headquarters: Sinterit Lisa Pro review

Contact manufacturer Get a quote Add to comparison

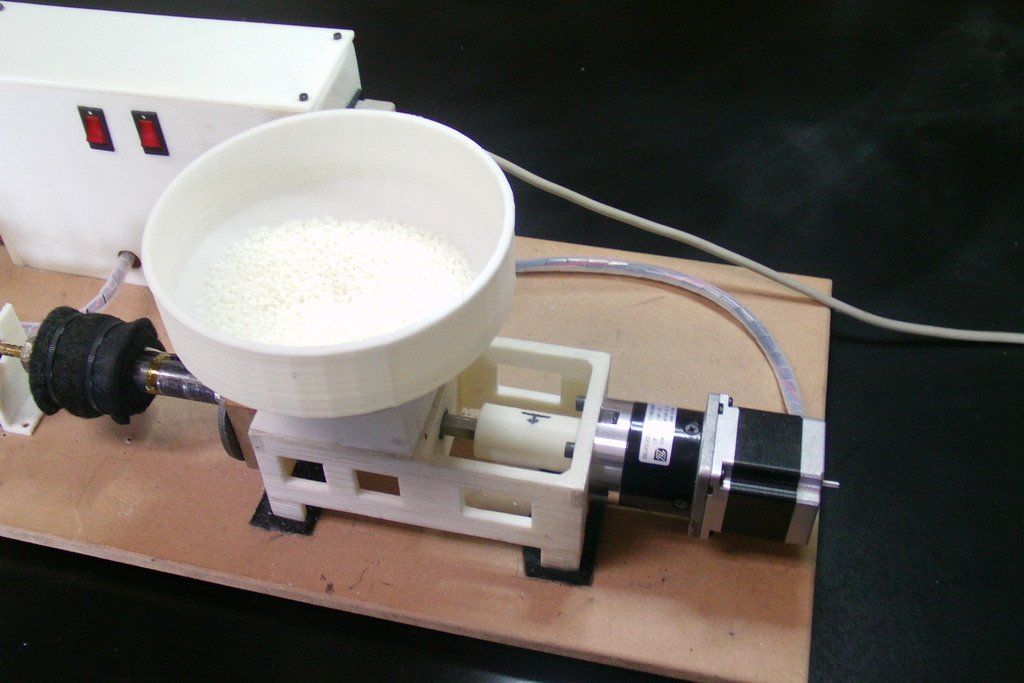

The Sintratec Kit started out as an Indiegogo crowdfunding campaign in 2014. It is one of the most affordable SLS 3D printers available today.

The Kit requires around four days of assembly. Users can freely adjust the laser’s height, speed, and temperature in order to try out different materials.

Users can freely adjust the laser’s height, speed, and temperature in order to try out different materials.

Contact manufacturer Get a quote Add to comparison

Formlabs, originally an SLA 3D printer manufacturer, introduced their first SLS 3D printer – the Fuse 1 – mid 2017. It is officially available since January 2021.

The printer works with Formlab’s PreForm software, and features two separate build chambers. This enables users to immediately launch a second build once the first job is complete.

After the printing process, the chamber can be directly placed as-is in the Fuse Sift, an all-in-one sieving machine that collects unused powder and prepares it for future builds by mixing it with fresh powder. The Fuse 1 can work with up to 70% of recycled powder, so each new build only requires 30% of fresh material (which costs around $100/kg).

Contact manufacturer Get a quote Add to comparison

Note: Natural Robotics launched the VIT SLS via Kickstarter in 2017. As of January 2021, some backers are stating that they still haven’t received their printers, although the company claims to be shipping products.

As of January 2021, some backers are stating that they still haven’t received their printers, although the company claims to be shipping products.

The VIT SLS offers a relatively large build volume compared to the other 3D printers in this range.

Contact manufacturer Get a quote Add to comparison

Note: This 3D printer is only available in a limited geographical region.

RED ROCK 3D is a new 3D printer manufacturer from Russia. Its RED ROCK SLS 3D printer offers a relatively large build volume compared to most of the other desktop SLS 3D printers in this selection.

Little information about this SLS 3D printer is available on the RED ROCK 3D website, which hasn’t been updated in a while (as of January 2021).

Contact manufacturer Get a quote Add to comparison

Compact industrial-grade SLS 3D printers: our picks

The following printers are larger than the benchtop SLS printers from our main selection but are still relatively compact considering the usual size of industrial SLS systems.

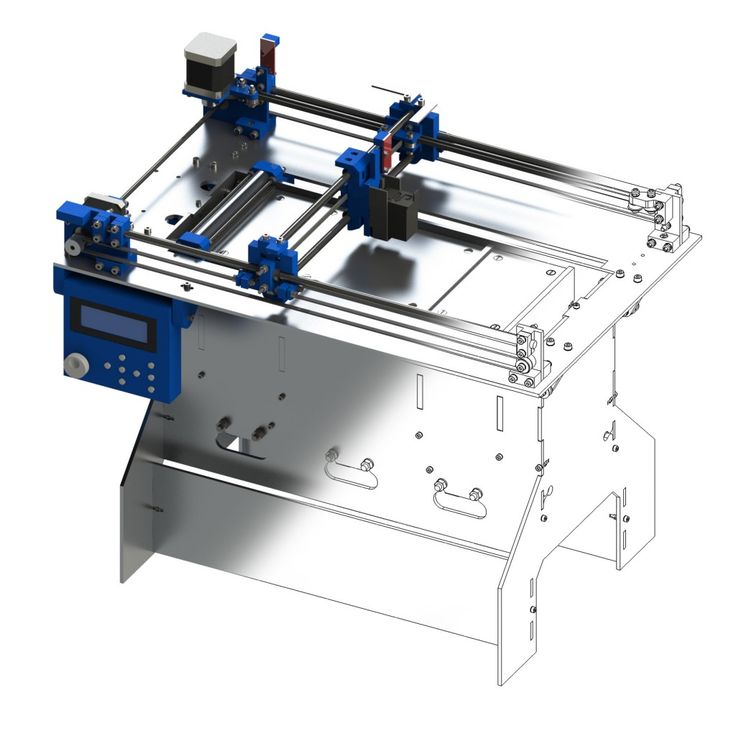

The Sintratec S2 is an all-in-one modular and scalable SLS 3D printing system with an onboard camera and large, intuitive touchscreen. It integrates a material preparation module as well as a depowdering station for semi-automatic workflows.

Optional stations include a blasting station, vortex unit, and a polishing station, enabling easier part post-processing.

Contact manufacturer Get a quote Add to comparison

The SnowWhite 2 features a powerful CO₂ laser that is able to sinter a range of materials including PA 12, PA 11, and TPU, as well as powder loaded with carbon or glass fiber or even aluminum.

All unused powder can be recycled. The printer can be powered up in ten minutes and the minimum amount of powder required to start a print is 300g.

Contact manufacturer Get a quote Add to comparison

XYZprinting’s range of products is one of the industry’s most diverse in terms of technology, suiting both consumers and businesses.

The MfgPro230 xS is an open-source system, meaning that its powerful 30W CO2 can print with any powder that’s available on the market. Hence, users can experiment with different types of Nylons and TPU materials, and even light-colored ones, which is not the case with entry-level SLS printers.

Hence, users can experiment with different types of Nylons and TPU materials, and even light-colored ones, which is not the case with entry-level SLS printers.

Contact manufacturer Get a quote Add to comparison

Released in 2020, the Gravity SLS 3D printer by Swedish manufacturer Wematter is the most recent printer in our selection. The printer features integrated powder recycling and easy material handling with user-friendly packaging.

Wematter’s cloud-based slicing software automatically optimizes the build area, packing parts efficiently and as close together as possible thanks to advanced algorithms.

Contact manufacturer Get a quote Add to comparison

Benefits and limits of SLS 3D printing

Main benefits of SLS 3D printing

No need for support: 3D printing complex and functional parts

Since unused powder remains in the powder bed, it naturally acts as support for the following sintered layers. This support, which is present all over, allows the 3D printing of very complex and/or functional parts and prototypes.

This support, which is present all over, allows the 3D printing of very complex and/or functional parts and prototypes.

It’s also possible to 3D print objects within objects, also known as nesting. This is not possible with other 3D printing technologies such as FFF and FDM (extrusion) or SLA and DLP (resins).

Multiple layers of parts to be 3D printed with SLS technology. Source: SinteritWaste reduction

It is possible to re-use powder that has not been sintered. This significantly reduces material waste and costs compared to other 3D printing techniques. Also, no material is wasted on support structures.

Main limitations of powder SLS 3D printing

Just like any technology, SLS 3D printing has its downsides.

Porosity/rough surface

SLS 3D printed objects are porous, though it is possible to apply sealant to alter their sandy, granular-like surfaces.

Expensive material

The price for one kilogram of PA12 powder can range from around $55 to about $180.

Logistics and post-processing

Due to the volatile nature of powder, extra caution is required when handling the material and taking the final 3D print out of the powder bed. The prints must be depowdered; either manually, which is time-consuming, or with a dedicated powder removal solution.

SLS vs FDM vs SLA

SLS vs FDM (FFF)

Compared to Fused Filament Fabrication, SLS can:

- achieve higher quality prints

- provide thinner layers and wall thicknesses

- generate complex 3D prints without the need for support

However, Selective Laser Sintering 3D printers offer much less material choice (and colors).

SLS vs SLA

Compared to stereolithography 3D printing technology, Selective Laser sintering offers:

- thinner wall thicknesses

- complex 3D prints without support structures

That being said, SLS 3D prints have rougher surfaces than SLA 3D prints.

SLS 3D printing: what materials are available?

Main desktop SLS 3D printing powders

Most desktop SLS 3D printers use Polyamide (PA) powdered material, also known as Nylon. The main PA powders available on the market are:

- Nylon PA12

- Nylon PA11

Then, there are composite or “charged” powders, meaning that different materials are mixed with PA. The most common are the following:

- Alumide: PA mixed with aluminum (shiny, metallic appearance)

- Carbonamide: PA reinforced with carbon fiber (stiff and lightweight)

- Nylon 3200: PA filled with glass (more chemical and heat resistant than PA12)

There is also PEBA 2031, a flexible, rubbery, and resistant plastic powder. Some manufacturers produce elastic 3D printing powders (such as Sinterit’s Flexa Black and Flexa Grey) to 3D print shock absorbers, clothing parts, bellows, etc.

Nylon SLS 3D printing material

Nylon, or Polyamide (PA), is the most common powdered material used by SLS 3D printers. It boasts many interesting characteristics:

- Lightweight: Polyamide is a lightweight 3D printing material.

- Robust: this material can bear loads or be used for mechanical parts.

- Flexible: Nylon can bend and come back to its original form.

- Resistance: PA offers good heat and chemical resistance.

Manufacturers generally sell their own, branded powder material.

SLS 3D printing in general

Desktop SLS printers are limited to plastics when it comes to material choice. However, when using larger, more expensive powder industrial 3D printers, it is possible to 3D print metal powder. Some industrial SLS 3D printers are also able to 3D print ceramics.

3d powder printing | Powder 3D printers

Today, 3D printing has received active development. Many different devices have been created that can create three-dimensional objects. Moreover, various technologies and materials are used for printing, including metal.

Many different devices have been created that can create three-dimensional objects. Moreover, various technologies and materials are used for printing, including metal.

What are 3D powder printers?

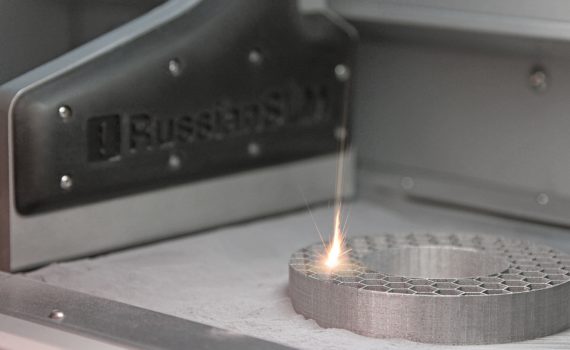

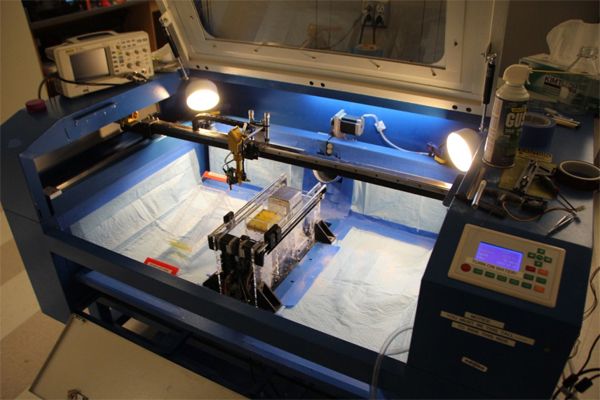

3D powder printers are devices that, under the action of a laser, bind metal powder particles, creating a product in layers.

Metal 3D printing is a huge investment. The price of printers can reach several hundred thousand dollars. If you add to this the cost of maintenance and service, consumables, training and salaries, you get an impressive amount.

However, the high cost is offset by the economy of the processes. For example, in the aviation industry, up to 90% of raw materials go to waste. In the case of 3D printing, this figure will be no more than 5%. The unused powder is sieved, a new one is added to it and reused for printing.

The advantage of powder 3D printing is the ability to create products from any known alloys. In addition to the generally accepted metal compounds, there is a wide base of special alloys, products from which are made for specific customer tasks.

Purpose

About 20 tested alloys are already used in additive technology. For example, tool, stainless, heat-resistant, aluminum, titanium, etc. Such opportunities bring 3D printing to a new level, expanding its scope.

Powder printing applications:

- aerospace industry;

- large and small machine building;

- oil and gas extraction;

- electrical engineering;

- medicine and dentistry;

- food industry;

- experimental work.

Technologies

All 3D printers are divided into several main categories according to the printing method:

- 3DP - three-dimensional inkjet printing.

- SLM - selective melting of metal powder. In this case, the powder is melted by a laser to a liquid state.

- SLS and DMLS - metal sintering. Here, the temperatures are not so high, so the powder particles simply sinter, sticking together.

Popular 3D powder printers

Today, there are several companies that specialize in the production of 3D powder printers. The most popular models are shown below.

The most popular models are shown below.

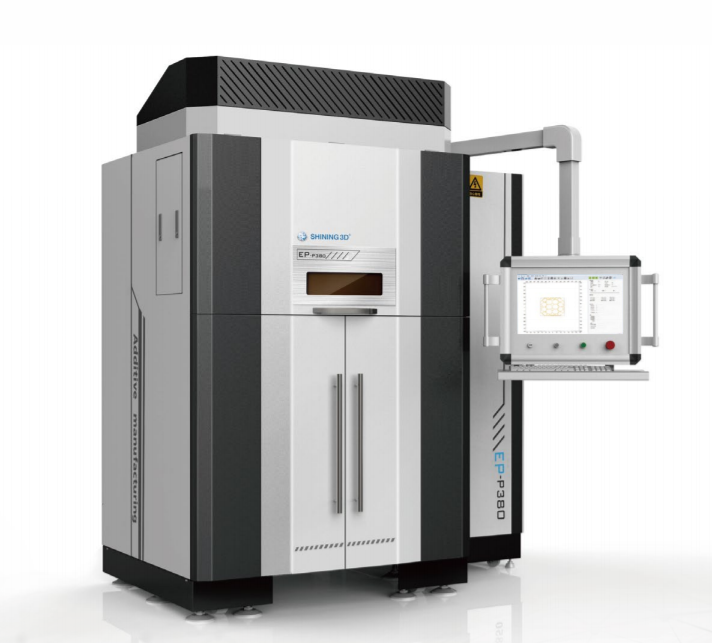

EP-M100T

Industrial 3D printer manufactured by Shining 3D. Works on the basis of SLM technology and is intended for the implementation of individual metal structures. This printer will be relevant for the production of crowns, abutments, bridges and clasp prostheses. It can also be used in jewelry.

The device supports printing with fine powders, such as nickel, cobalt and chromium alloys, copper, titanium.

Model advantages:

- One layer only 0.15-0.05 mm thick. This allows you to create high-precision models.

- Built-in software that allows you to control the parameters and workflow.

- Can be controlled by mobile phone.

- Automatic supply and circulation of inert gas.

- Multifunctional security system.

- Compact size that allows you to install the printer even in a small space.

- Low power consumption - 1 kW of energy.

Up to 110 crowns can be placed on the working platform. During the day, this printer is able to work out 3 cycles, that is, to produce up to 330 products.

During the day, this printer is able to work out 3 cycles, that is, to produce up to 330 products.

Mid2019

Mid2019 is a highly detailed printer with a minimum print layer of just 0.1mm. The height of the manufactured parts is up to 220 mm.

Advantages of the model:

- The operator does not need special training, because there is already a configured program for 3D printing, where the optimal parameters are already set.

- Possibility to install a more powerful laser for higher productivity.

- Individually developed firmware designed to control the operation of components and systems of this particular printer.

- The presence of encoders allows you to stop and resume the printing process at any time.

- Remote monitoring capability.

FS301M

Farsoon FS 301M is a 3D printer based on SLM technology. It is considered one of the best in the world in terms of price and quality. At the request of the customer, it is equipped with two or one laser.

At the request of the customer, it is equipped with two or one laser.

The dual scan and calibration algorithm greatly improves the quality and speed of large part production. The printer has a special inert gas supply and filtration system.

The open platform makes it possible to use all materials available today. The operator can control the operation of the system, including the sintering algorithm, temperature, laser power, layer thickness.

Model advantages:

- High quality and performance. Allows mass production without sacrificing quality.

- Integrated powder loading station. This improves security and processing time.

- Small size. The dimensions of the device help to place it even in small production areas.

- Large printing table. Allows you to create large parts in 1 cycle.

3D Systems ProX DMP 300

This printer is equipped with DMP or DMLS direct printing technology. This machine is equipped with automatic loading and disposal of materials.

This technology also uses a laser, but it melts the powder to create the desired object. The metal powder is spread on the platform by means of a special roller or a coating mechanism.

Direct printed parts have high density: 95-98% versus 70% with SLS technology.

Important! Sealed powder loading and circulation keeps it free from contamination and makes the printing process safer for the operator.

Benefits of 3D Systems ProX DMP 300:

- increased working surface with the ability to adjust the thickness of the deposited layer;

- high performance DMP technology;

- sealed loading and disposal system;

- multifunction software.

Weaknesses:

- large;

- expensive.

Benefits of 3D printing:

- Ability to produce parts with complex geometries that cannot be reproduced with traditional methods.

- Parts have excellent physical properties. Almost all known alloys are available for processing.

Disadvantages:

- The production costs are very high, so powder printing is not suitable for making parts that can be made using traditional methods.

- The list of materials available today is small and limited to the most common alloys (titanium, aluminium, 316L, Inconel 718). Other powders can only be obtained for a huge amount of money.

- Limited area of application, which does not allow the manufacture of large products.

Metal powder 3D printing has significant potential in many industries. More and more companies and research organizations are adopting this technology. For example, such global brands as General Electric, Airbus, Boeing, Michelin. They have already moved from the production of piece products to mass production.

- March 21, 2021

- 2778

Get expert advice

Powder is not only washable, but also 3d printed

The choice of consumables for 3D printing today is extremely diverse. Moreover, this market segment is regularly filled with new samples suitable for working with various types of 3D printers. Powdered materials have for the most part firmly established themselves in additive manufacturing, especially on an industrial scale.

Moreover, this market segment is regularly filled with new samples suitable for working with various types of 3D printers. Powdered materials have for the most part firmly established themselves in additive manufacturing, especially on an industrial scale.

Powders for 3D printing - a variety of materials, research and development in the field of improving their properties

Powder materials, in fact, are rarely homogeneous in their composition. Powder 3D printing allows you to mix particles of different materials and thus obtain unique alloys with excellent mechanical, functional, and aesthetic properties. Research centers around the world are actively developing this direction of the industry.

Accordingly, it is not possible to give a precise definition of the group of powder materials, as well as to classify them according to functions or properties. Therefore, we will review the most common types of powder materials used for 3D printing.

● Ceramic powder. A finely dispersed granular mixture that allows printing products of various shades, textures, with different mechanical properties. The finished product requires firing and glazing.

A finely dispersed granular mixture that allows printing products of various shades, textures, with different mechanical properties. The finished product requires firing and glazing.

● Graphene is a monoatomic carbon modification of graphite with unique physical and chemical properties, the study of which is still at the very beginning. It is considered the material of the future.

● Metal powders - metal powders, mixtures of metals, mixtures of non-metals with metals.

● Cement polymers are powdered materials identical to concrete, capable of significantly improving the physical properties of polymers.

● Gypsum powder - 3D printing transforms this material into a convenient building material with various decorative and physical properties, such as an analogue of sandstone with optimized mechanical properties.

● Gypsum-based composite powder for use with 3D Systems Projet printers using Color Jet Printing technology

● Plaster is a powder mixture for a 3D construction printer that gives new qualities to facing surfaces.

● Stainless Steel - A mixture of steel powder and binders to print a strong metal material with high anti-corrosion properties.

● Thermoplastic powders - mixtures of plastics of different composition with a wide range of applications in the technologies of sintering and fusion of various materials. They differ in a wide variety of qualities, characteristics and properties.

Powder technologies and consumables

The most common powder technologies are: SLS - selective laser sintering; SLM - laser particle fusion; DMLS – direct laser sintering; CJP(3DP) technology of layer-by-layer production from gypsum composite. Selective sintering technology works with metals, polyamides and plastic powders. Fusion and direct laser sintering - for working with metal powders.

CJP(3DP) Gypsum based powder technology

Gypsum 3D printing technology, the essence of which is the layer-by-layer gluing and coloring of a composite powder based on gypsum or plastic, has a wide range of practical applications. For work, two components are used - the main and the binder. The first serves as the basis for the layers of the product, the second forms the product by painting and gluing the particles of the composite powder.

For work, two components are used - the main and the binder. The first serves as the basis for the layers of the product, the second forms the product by painting and gluing the particles of the composite powder.

This technology is used to create prototypes, presentation samples, architectural and other models, souvenirs, miniatures and much more. The advantage of the CJP method is low cost, no need for support material, high printing accuracy, the ability to create both monochrome and full-color products.

Properties of CJP printed products

High precision printing with gypsum powder allows you to build models with thin walls and various levels of surface complexity of the product. Printed prototypes are easily post-processed, during which they can be glued, sanded, painted, treated with fixatives, resin, wax.

Gypsum-based powder models are distinguished by their presentable appearance, colorfulness and high detailing. Due to these qualities, they are widely in demand for various demonstration purposes - educational, marketing, visualization, exhibition, scientific and others.

SLS - an additive method with more possibilities

This kind of powder 3d printing was patented in 1989. Its inventors are Dr. Carl Descartes and his students from the University of Austin in Texas. To date, there are two types of technology: sls-printing with metal powders and sls-printing with polyamide powders.

Finished products made from metal powders, after finishing, are visually almost indistinguishable from their originals created by traditional methods, such as casting. However, according to their physical characteristics, they can differ significantly. For example, lightness, durability.

Models made of plastic powder mixtures, characterized by increased impact resistance, wear resistance, isotropic properties and resistance to thermal and chemical influences. Plastic-based powders, for the most part, are engineering materials with high surface quality and detail.

Depending on the powder material used, the strength, duration, baking temperature may vary. The baking method also varies: the laser can act along the entire depth of the layers, or only along the boundaries between the layers.

The baking method also varies: the laser can act along the entire depth of the layers, or only along the boundaries between the layers.

Advantages of SLS technology:

● no need for support material;

● the process of manufacturing the product is faster, due to the lack of the need for complete melting of the particles;

● there is a possibility of simultaneous production of several products;

● it is possible to manufacture products of large sizes;

● high mechanical properties of products.

SLM, DMLS and other powder fusing technologies in a 3d printer

The original idea of the SLM method appeared in 1995 at the Fraunhofer Institute for Laser Research in Germany. Then, a number of scientists engaged in similar research joined forces and patented their technology. Around the same period, other research centers also patented their own identical SLM powder 3D printing methods, giving them different names.

For the production of parts from powdered alloys by 3D printing, methods such as SLM, DMLS, LaserCUSING, EBM, SLS are used. As for the similarity between SLS and SLM technologies, which are often confused, there are fundamental differences. In the first case, the particles are sintered together, in the second, they melt and turn into a high-rigidity framework.

As for the similarity between SLS and SLM technologies, which are often confused, there are fundamental differences. In the first case, the particles are sintered together, in the second, they melt and turn into a high-rigidity framework.

Electron beam fusion and its features

EBM is a technology in which an electron beam plays the role of a laser. This method is more complicated, but is considered the most convenient and effective for working with metal alloys, such as titanium. Products made from powders by electron beam melting have high strength, wear resistance, and are light in weight.

Benefits of 3D printing technologies for powder materials:

● the feasibility of any category of complexity of the geometry of products;

● high fidelity reproduction of copies;

● high strength characteristics;

● light weight;

● high thermal stability.

Industrial application of 3D powder printing products

Gypsum powder 3D printing is a promising way to produce products for industries such as:

● aircraft industry;

● astronautics;

● mechanical engineering;

● metallurgy;

● robotics;

● medicine;

● construction;

● jewelry;

● design;

● souvenir industry;

● prototyping;

● prototyping;

● sculpting;

● restoration work, museum exhibits….