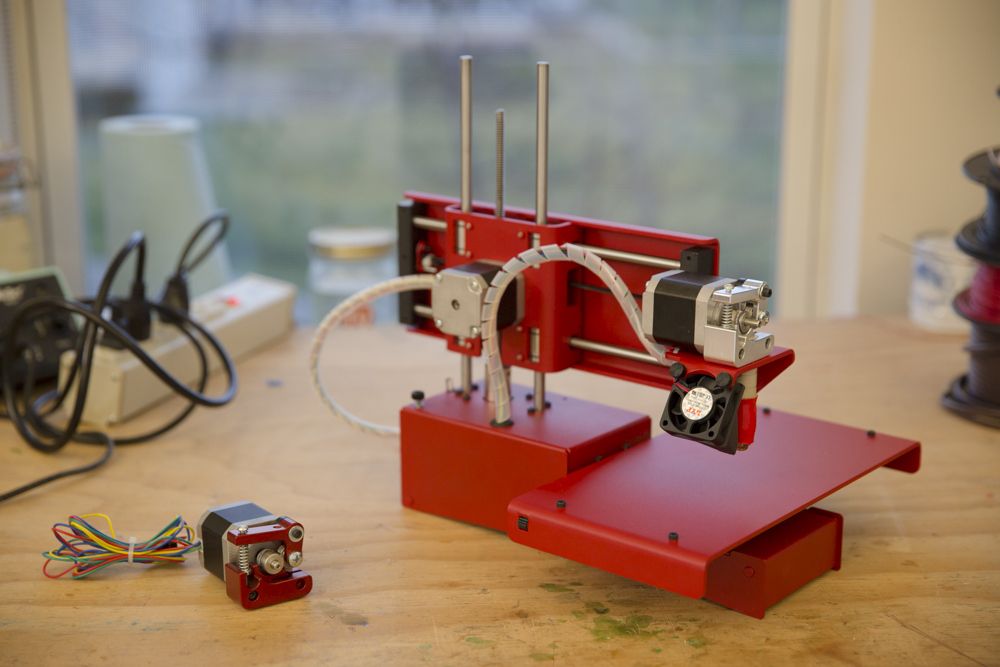

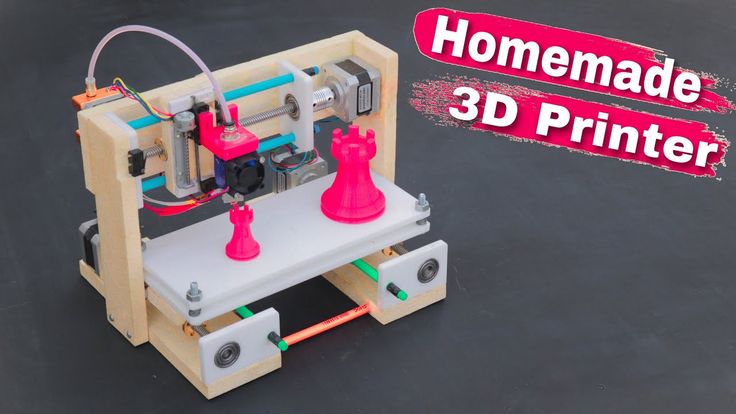

Homemade diy 3d printer

The 10 Best DIY 3D Printer Kits 2022 (Starting at $150!)

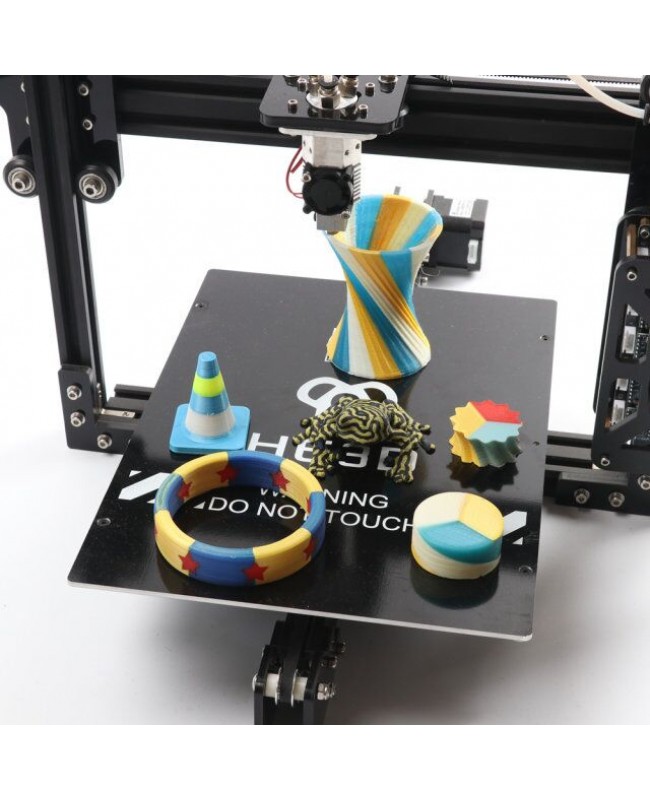

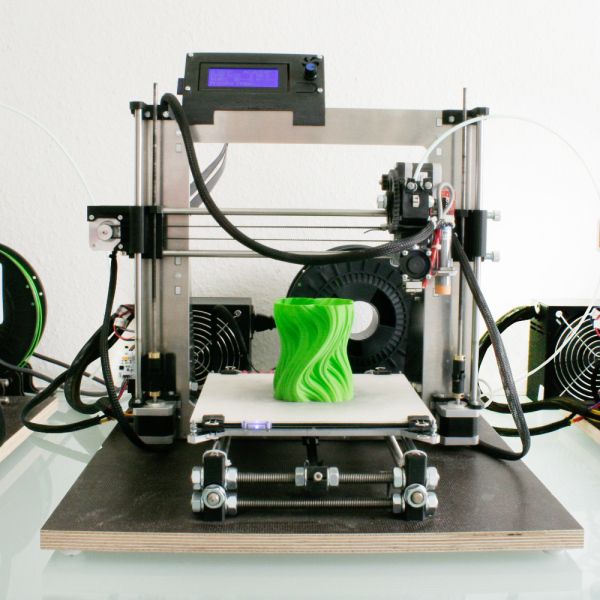

Increasingly, makers are turning away from desktop FDM 3D printers, preferring to buy a cheap 3D printer kit and build their own DIY 3D printer from scratch. Some of these are RepRap 3D printer kits, and some are specially designed kits.

The 3D printer kit revolution has reduced prices, led to a number of key breakthroughs, and has made 3D printing more accessible than ever before.

Great Ender 3 Alternative

Amazon here

Best Budget 3D Printer

Amazon here

Best 3D Printer Kit Overall

Buy pre-assembled here

These 3D printer kits can take just a few minutes to assemble, or take hours or even days. They can also vary greatly in price, print accuracy, maximum build and print speed. Some even use technologies other than fused deposition modeling — you can now buy DIY SLS 3D printers and SLA 3D printers.

| 3D printer kit name and brand | Build Volume (mm) | Price | Where to purchase for best price | Alternative Purchase Option |

|---|---|---|---|---|

| Creality Ender 3 | 220 x 220 x 250 | $189 | Creality Store here | Amazon here |

| Prusa Mini | 180 x 180 x 180 | $399 | Prusa Store here | |

| Creality Ender 3 V2 | 220 x 220 x 250 | $279 | Creality Store here | Amazon here |

| Creality Ender 5 | 220 x 220 x 300 | $349 | Amazon here | |

| Flsun QQ-S | 255 x 255 x 360 | $369 | Amazon here | |

| Tronxy X5SA Pro | 330 x 330 x 400 | $399 | Amazon here | |

| Anycubic Vyper | 245 x 245 x 260 | $429 | Anycubic here | Amazon here |

| Creality CR-10 / V3 | 300 x 300 x 400 | $369 / $459 | Creality here | Amazon here |

| Prusa i3 MK3S | 250 x 210 x 210 | $749 / $999 | Kit available available on Prusa Store here | Fully assembled on Prusa Store here |

| Peopoly Moai | 130 x 130 x 180 | $1,295 | Matterhackers here |

Advantages of DIY 3D printers

- Open source: Most homemade 3D printers are also open source 3D printers, meaning they can be tinkered with, upgraded, and modded freely with the creators’ permission. Many Creality, Prusa and Anet printers are open source, as well as desktop 3D printers like BCN3D and Ultimaker printers.

- Open build areas: 3D printer kits rarely feature closed chambers or enclosures as standard. This would affect the printing of filaments like Nylon or PEEK, but is less of an issue for standard filaments like PLA or PETG.

- Easily upgradable parts: DIY 3D printer owners are frequently switching out parts, such as nozzles, hot ends and extruders for better quality parts.

- Lower price: For the quality and size, you get a better deal if you build your own 3D printer.

- Larger build volume: The open build area means that you can have a larger 3D printer build area for the same size, neglecting the need for an enclosing frame.

Therefore, low cost kits like the Creality CR-10 can have huge build volumes.

Therefore, low cost kits like the Creality CR-10 can have huge build volumes.

Build your own 3D printer: what makes a good DIY 3D printer?

We used several criteria to determine which 3D printer kit made it into our ranking:

- Cheap DIY 3D printer kits: We only included FDM 3D printer kits under $1,500. The printers are listed in price order, cheapest first.

- Print quality

- It it easy to build your own 3D printer: Not everyone is a technology wizard. Therefore, any kit that can be assembled quickly, easily, and is simple to operate, is at an advantage.

The best 3D printer kits

3DSourced is reader-supported. When you buy through links on our site, we may earn an affiliate commission. Learn more

1. Creality Ender 3

- Price: $189 — Available on Creality Store here / Available on Amazon here

- Build volume: 220 x 220 x 250 mm

The original Ender 3 is still one of the most popular 3D printer kits in the world, more than three years after it was originally released. The low price, great build area, and reliability have cemented the Ender 3 as one of the best 3D printer kits around.

The low price, great build area, and reliability have cemented the Ender 3 as one of the best 3D printer kits around.

The reliability is a major selling point in such a cheap 3D printer kit. Whereas most DIY printers in this price range are plagued by issues caused by low-quality parts, the Ender 3 is dependable and consistent, partly due to its upgraded extruder to prevent clogging or poor extrusion.

The resume printing function is useful if you’re prone to power cuts or want to print for several days straight and don’t want to risk a huge ruined print, and the Ender 3 is fairly quick to assemble, and shouldn’t take more than an hour or so.

However, it doesn’t feature auto-leveling — you’ll need to install a BLTouch or similar kit for that.

Best Budget 3D Printer

Creality Ender 3 3D Printer

The best budget 3D printer kit around - and the best-selling, too. If you have the budget, pick up the V2 or V2 Neo version, or even the Ender 3 S1 if you prefer a direct drive extruder.

Creality hereAmazon here

We earn a commission if you make a purchase, at no additional cost to you.

2. Prusa Mini — Great Prusa 3D printer kit

- Price: $399 — Available on Prusa Store here

- Print volume: 180 x 180 x 180 mm

- Print speed: up to 200mm/s

The Mini 3D printer version of the wildly successful Prusa MK3S, the Mini retains the 0.05mm layer precision and can still calibrate itself, but costs less than half of the i3 MK3S. With the Mini, you can build your own 3D printer — and one with Prusa-level reliability! — for just $349.

It’s more compact, with a smaller build volume, and features removable spring steel sheets that make removing finished prints extremely easy — just flex the build plate and prints will come off with ease.

The extruder cannot reach the same temperatures during printing as the MK3S, though you can still print a number of tougher filaments like ABS, PETG, ASA and flexible filaments. The Mini retains the fast 200mm/s max printing speed, and can be upgraded to feature a filament sensor.

The Mini retains the fast 200mm/s max printing speed, and can be upgraded to feature a filament sensor.

Overall, it’s another reliable 3D printer by the trusted Prusa brand who have proven over the years that their printers are some of the best 3D printer kits around. If you have the money, go for the MK3S, but for those on a budget, the Mini does a great job.

Best Mini 3D Printer Kit

3. Creality Ender 3 V2 — Best DIY 3D Printer Under $300

- Price: $279 — Available on Creality Store here / Available on Amazon here

- Build volume: 220 x 220 x 250 mm

Building on the success of the Ender 3 and improving and fixing its few flaws, the Ender 3 V2, while the same size build volume, is a much enhanced DIY 3D printer.

The upgraded motherboard makes the printer quieter than ever, and the extra power makes for a much more stable and precise printing experience.

Read more: the quiet 3D printer buyer’s guide

The upgraded extruder is also a great touch. It’s easier to load and feed filament into via the rotary knob, ideal for PLA and flexible filaments. The large 4.3-inch screen makes the interface more intuitive, and the Ender 3 V2 is really easy to use overall.

It’s easier to load and feed filament into via the rotary knob, ideal for PLA and flexible filaments. The large 4.3-inch screen makes the interface more intuitive, and the Ender 3 V2 is really easy to use overall.

Another extra is the carborundum glass platform, which can heat up faster than ever and improves adhesion so you can be sure of a great first layer. Overall, if you have the extra $100 to spare, consider going for the Ender 3 V2 over the original.

Top Pick

Creality Ender 3 V2

$279.99

Upgraded version of the original Ender 3 with a number of key quality-of-life improvements.

Creality Store hereAmazon here

We earn a commission if you make a purchase, at no additional cost to you.

4. Creality Ender 5 — The Best DIY 3D printer under $500

- Price: $349 — Available on Amazon here

- Print volume: 220 x 220 x 300 mm

Another Creality kit, the Ender 5 is another great 3D printer you can build at home. The Ender 5 is $100 more expensive, but boasts a number of improvements that make the extra money seem worth it.

The Ender 5 is $100 more expensive, but boasts a number of improvements that make the extra money seem worth it.

Firstly, it can print taller prints than the Ender 3 — 300 mm high rather than 250 — important if you print tall structures like tall vases or monument 3D models. The structure is also stronger, having adopted a cube shape like the Tronxy X5SA which helps with stability, reducing vibrations or movements from external events, and improving part surface finish and quality.

Moreover, the minimum layer height of 50 microns is extraordinary for such a cheap machine. Review after review repeats how crisp the surface finish of their prints look with the Ender 5, so it’s fair to say the Ender 5 is a smash hit.

- For an extra $50 you can upgrade to the Ender 5 Pro printer kit, at $399. It’s available to buy here.

Note: while the Ender 5 can be tweaked to increase print speed without a noticeable loss in print quality, we recommend you don’t get too extravagant with this. Stick with 60 mm/s or below for models with intricate parts — it’s worth a bit of extra printing time to guarantee crisp prints.

Stick with 60 mm/s or below for models with intricate parts — it’s worth a bit of extra printing time to guarantee crisp prints.

5. FLSUN QQ-S — Great Delta DIY 3D printer

- Price: $369 — Available on Amazon worldwide here

- Print volume: 255 x 255 x 360 mm

- Print speed: up to 300mm/s

One of the best DIY delta 3D printer machines out there, the Flsun QQ-S features notable improvements on the original Flsun QQ. It comes 90% assembled, so though technically still a 3D printer kit it will take under an hour to get up and running.

- We were lucky enough to test the FLSUN QQ-S, make sure to also check out our FLSUN QQ-S review.

Not only does it have a fantastic build volume for the price — especially the ability to print tall parts! — but it also comes with an upgraded lattice glass print bed, allowing for faster heating up to 100C in under 5 minutes, less warping and better adhesion during 3D printing. This is perfect for materials such as ABS filament, which are known to warp significantly under the wrong conditions.

Another advantage that beginners will enjoy is that as delta 3D printers don’t move the print bed — the print head does all the moving — the printer only needs to be auto-leveled once. It comes with a titan extruder, and can print with common printing materials like PLA and ABS, PVA, and HIPS for supports, as well as wood-filled filaments and flexible filaments.

It’s accurate, too, able to print at up to 50 microns. Overall, it’s a fantastic delta 3D printer kit that prints accurately, and super fast — it even made it into our fastest 3D printer ranking. It’s also one of the easiest DIY 3D printers to build, coming almost fully assembled — you just need to attach the gears and rods to hold the structure up, and then attach the extruder and filament holder.

Best Delta 3D Printer Kit

FLSUN QQ-S-PRO Pre-assembled Delta 3D Printer

$399.00

Amazon here

We earn a commission if you make a purchase, at no additional cost to you.

12/13/2022 07:15 pm GMT

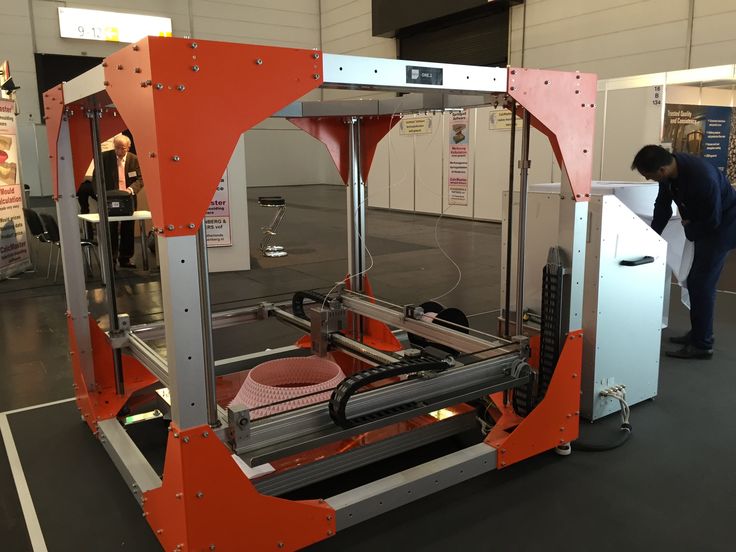

6. Tronxy X5SA Pro — Huge Self-Assemble 3D printer

- Price: $399 — Available on Amazon here

- Build volume: 330 x 330 x 400 mm

Kit 3D printer kings Tronxy showed humility and dedication to improve the X5SA Pro, fixing a number of small issues that affected the original. The X5SA Pro addresses the X-axis issues and has made it more stable, and upgraded the materials forming the printer kit’s structure. Now on the X5SA Pro, most of the printer is made from aluminum and is heavier and more stable, reducing vibrations and generally improving print performance.

As for the X5SA’s specs, it’s a large 3D printer DIY kit with similar printing sizes to the Creality CR-10, and boasts a 330 x 330 x 400 build volume. It claims increased precision vs the original Tronxy X5SA, and has a maximum accuracy of 125 microns. It’s impressive, reliable and one of the best cheap 3D printers you can get with such a large size — so those with big 3D printing ideas will enjoy both this and the Creality CR-10.

It’s impressive, reliable and one of the best cheap 3D printers you can get with such a large size — so those with big 3D printing ideas will enjoy both this and the Creality CR-10.

It’ll probably take you around four hours to build this printer kit, but it’ll be worth it once you start printing!

Big 3D Printer Kit

TRONXY X5SA PRO 3D Printer with Glass Bed Upgrade

Amazon here

We earn a commission if you make a purchase, at no additional cost to you.

7. Anycubic Vyper

- Price: $429 — Available on Anycubic store here / Available on Amazon here

- Build volume: 245 x 245 x 245 mm

A key feature on the Anycubic Vyper missing from many printers in this price range is that the Vyper self-levels. This is a huge relief for busy makers who would rather not re-level their printer every few prints, and who just want to get to the fun part — printing! The 16-point bed leveling process accounts for differences between the nozzle and bed and can be done in just one click.

The 32-bit motherboard is beefed up compared to previous Anycubic 3D printer kits, offering silent printing and improved stability. We tested the Anycubic Vyper and found it to be consistent in printing, easy to operate with the 4.3-inch touchscreen, and it was incredibly easy to assemble — we built it in 10-15 minutes.

The new PEI spring steel magnetic print bed can be lifted off the platform easily for easy removal of your finished parts, and is designed to be scratch and heat resistant and to work well with standard filaments such as PLA, ABS, PETG, and TPU.

The Vyper also features an innovative new two-fan dual cooling system, cooling down parts quicker and enabling faster printing without causing errors — the Vyper can comfortably print at 100mm/s.

Great Ender 3 Alternative

8. Creality CR-10 / V3

- Price: $369 / $459 — Available on Amazon here / Available on Creality Store here

- Print volume: 300 x 300 x 400 mm

The Creality CR-10 has a passionate group of supporters who hail it as the best DIY 3D printer kit in its price range. Manufactured by Creality, the CR-10 is a fantastic 3D printer build kit that can be built within 45 minutes.

Manufactured by Creality, the CR-10 is a fantastic 3D printer build kit that can be built within 45 minutes.

The Creality CR-10 has an accuracy and print volume which is competitive with printers 5 times more expensive. With it’s minimum layer thickness of 0.05mm and fantastic 300 x 300 x 400 mm build volume, the Creality CR-10 is a great printer for just $370. It’s easy to use, making it the perfect 3D printer for beginners.

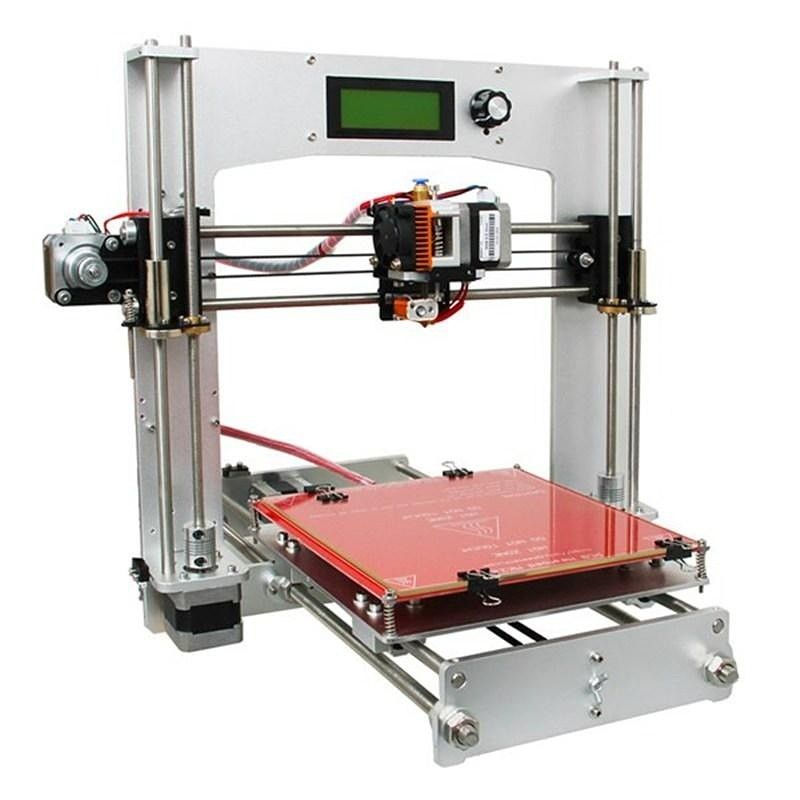

9. Prusa i3 MK3S — best 3D printer kit

- Price: $749 as a kit — Available on the Prusa store here / $999 fully assembled — Available on the Prusa store here

- Build volume: 250 x 210 x 210 mm

The Prusa i3 is known as the undeniable king of DIY 3D printer kits. These RepRap kits are fantastic, sporting an impressive print volume of 250 x 210 x 210 mm, and being able to print at speeds up to 200mm/s! It’s also accurate, durable and a complete workhorse, with layer heights from 0. 05 mm and a bendable print surface to make removing finished prints as easy as possible.

05 mm and a bendable print surface to make removing finished prints as easy as possible.

Accessible via USB stick or by SD card, the Prusa i3 MK3 kits are designed to be simple to use as well as effective. With layer resolutions up to 50 microns, the Prusa i3 homemade 3D printer is so effective that it outperforms far more expensive 3D printers. It can print tougher filaments than more expensive printers too, with a Bondtech extruder that can reach temperatures of up to 300C, making printing Polycarbonate, ABS, Nylon, and other difficult filaments no problem.

Additionally, you can print up to 5 colors simultaneously with your Prusa if you purchase their multi-material upgrade kit, costing $300. This makes colorful model printing a breeze, and opens up for far more extravagant printing projects.

The Prusa, with Multi Material Upgrade kit, allowing it to print multiple colors simultaneously. We explain this in our color 3D printer guide.- With a Multi Material Upgrade kit, it can also print multiple colors.

We explain more in our color 3D printer buyer’s guide.

We explain more in our color 3D printer buyer’s guide. - You can buy the Multi Material Upgrade Kit 2.0 here.

You can choose to either assemble the kit yourself or buy the printer pre-assembled, though this costs a few hundred dollars more. Overall, the Prusa remains the undisputed king of DIY 3D printer kits, with its competitors needing to do a lot of catching up to dethrone it.

Best 3D Printer Kit Overall

Original Prusa i3 MK3S+ kit

The best 3D printer kit of all time. If you have $1,000, this is some of the best value you can get.

Buy as a kit hereBuy pre-assembled here

We earn a commission if you make a purchase, at no additional cost to you.

10. Peopoly Moai SLA Kit — Homemade resin 3D printer kit

- Price: $1,295 — Available on Matterhackers here

- Build volume: 130 x 130 x 180 mm

The only resin 3D printer featured in our 3D printer kit guide, the Peopoly Moai is an incredible feat of engineering. It’s huge, offers incredible accuracy and precision, and best of all, you can build your own 3D printer at home from scratch.

It’s huge, offers incredible accuracy and precision, and best of all, you can build your own 3D printer at home from scratch.

For those looking for an effective SLA 3D printer, and who do not want to pay full price, the Moai kit could be the perfect printer for you. It is so accurate that it can mechanically print up to an astonishing 5-micron layer height, according to Peopoly, though you’ll likely never reach this accuracy because you won’t need to, nor would most resins or models accommodate this.

Featuring a 70-micron laser spot size, once you’ve built this homemade 3D printer you’ll be ready to create resin molds for 3D printed jewelry, dental models, engineering pieces, as well as prototypes for rapid prototyping or fun characters if you use the Moai as a 3D printer for miniatures.

The Peopoly Moai is open to use third-party resins, for those who want to save money on lower-cost resins and are fine with the slight quality drop-off. The printer itself however does not come with any resin, so you’ll need to purchase that with the kit. It is only to be expected that the Moai will take some time to assemble, as resin 3D printers are more complex than their FDM 3D printer counterparts, but most makers will be able to build their own 3D printer within 4 hours.

It is only to be expected that the Moai will take some time to assemble, as resin 3D printers are more complex than their FDM 3D printer counterparts, but most makers will be able to build their own 3D printer within 4 hours.

Best DIY Resin Printer

Creality Ender 3 3D Printer sale

Home Collections Ender 3 DIY 3D Printers Kit | 8.66x8.66x9.84inch | Resume Printing Function$ USD

$ USD

35 Reviews Pricing Not Include Tax

Ship From

United StatesCanadaCzech RepublicAustraliaUnited KingdomChina

Model-1

Ender-3 NEOEnder-3

Ship to

It is expected to arrive within and will cost $ USD to ship

This item can't be shipped to this Country/Region

Bundles

Quantity

28 Available

Add To Cart Buy It Now

Continue To Shopping View Cart

People who bought this item also bought

Official Creality Ender 3 3D Printer Fully Open Source with Resume Printing

- Easy and Quick Assembly: It comes with several assembled parts, you only need about 2 hours to assemble 20 nuts well.

- Advanced Extruder Technology: Upgraded extruder greatly reduces plugging risk and bad extrusion; V-Shape with POM wheels makes it move noiseless, smoothly, and durable.

- Safety Protected Power Supply: Only needs 5 minutes for the hotbed to reach 110℃.

- It is a great project for middle school and high school-aged students. The perfect gift to spark a lifelong love for science and engineering, and provide a deeper understanding of machinery and robotics.

Creality Ender 3:Complete beginner's guide to 3D printing - Assembly, tour, slicing, levelling and first prints

CR Touch Install Guide - From 3D Printscape

Why Most People Choose Ender 3 3D Printer

From 2018 till now, the Ender-3 model has remained in the "Best Selling". Although we are launching new Ender-3V2, Ender-3S1. So why do many choose Ender 3?

Although we are launching new Ender-3V2, Ender-3S1. So why do many choose Ender 3?

1. In terms of price: the price is lower than 200, stable printing quality and 220*220 printing size, supports different filament materials

2. In terms of performance: support resume printing, 5mins rapid heating, reliable power supply

3. Upgrade convenience: ender 3 direct drive, cr touch auto leveling kit, touch screen , tempered glass bed and more. There's do much you can do with it

4. Who chose him: News for 3d printing, 3d printing enthusiast; for DIY makers, for education... Customer

Ender 3' S FAQ:

Filament did not stick on the hotbed?

For newcomers, this is the most common problem. Do not worry, you can solve it easily. Generally,the distance between the nozzle and platform is too far or near. So rotary the knob under the platform to adjust the distance between the nozzle and platform again,at a piece of A4 paper distance or less).

Creality Ender 3 Bed Leveling – All You Need to Know

Any structure needs a strong foundation. The same is true for 3D-printed objects. Leveling the bed on your Creality Ender 3 will ensure that that all-important first layer is solid...

How to level Creality Creality Ender 3?

Move the nozzle so that it’s positioned over the left corner of the bed. A half-inch or so from both sides is a good location.

Slide the paper between the nozzle and the bed. If it doesn’t fit, drop the corner until it does.

Once the paper is able to slide under the nozzle, very slowly raise the corner with the adjuster. Remember: Clockwise moves the bed up. As you do this, gently slide the paper back and forth. The moment you feel even the slightest resistance to your moving the paper, stop turning the knob. That corner is (almost) ready to go.

Do the same for the other three corners of the build plate. Always advance the hot end to a new corner slowly. This will prevent damage to the build plate in case the nozzle starts to drag. If this occurs, simply lower the next corner (before starting the leveling process) to make some room.

If this occurs, simply lower the next corner (before starting the leveling process) to make some room.

After you’ve adjusted each corner once, go back and check the four corners again. You may have to do further adjustments to get all four correct.

Article: Creality Ender 3 Bed Leveling – All You Need to Know.

Download

Download

Download

Download

Download

Download

Download

Download

Download

Customer Reviews

Based on 35 reviews

77%

(27)

17%

(6)

Write A Review

Ask A Question

Reviews (35) Questions (5)$ USD

$ USD

ADD TO CART BUY IT NOW

Write a review

Ask a Question

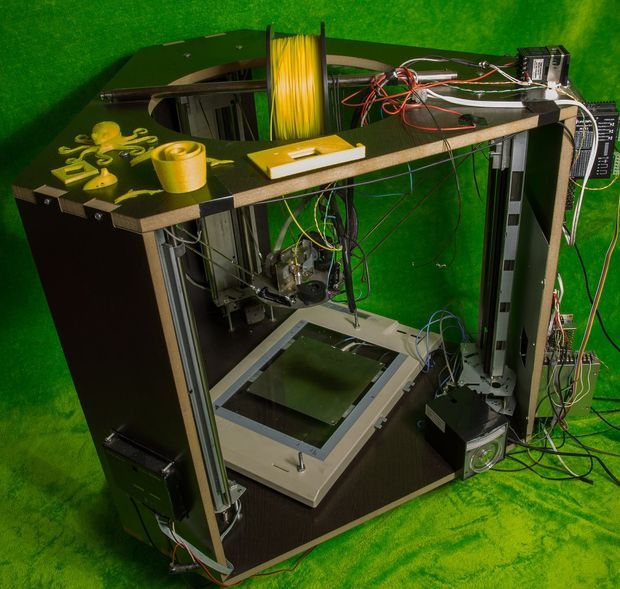

Homemade metal 3D printer, but something went wrong / Sudo Null IT News

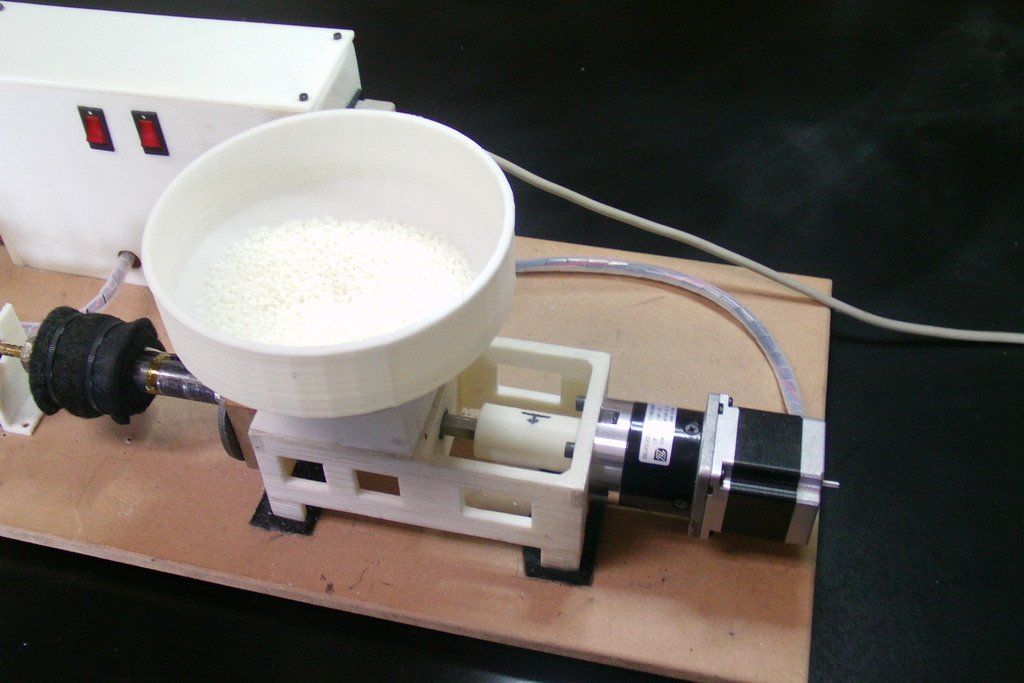

Hello everyone, my name is Sergey. In this article, we will talk about 3D printing with metal, more precisely, about my attempt to implement 3D printing with metal.

In this article, we will talk about 3D printing with metal, more precisely, about my attempt to implement 3D printing with metal.

Very often, people who are interested in or engaged in any activity, no matter what, stumble upon something completely new and previously unknown to them, something that can help develop/improve their main activity. A similar situation happened to me.

Surfing the expanses of your Internet, I came across a wonderful technology for vacuum deposition of metals on various materials. On Habré there is an interesting article about this technology. In addition, on many other resources it was said that the evaporated metal moves towards the target in a straight line.

Many resources0003

And then I thought, what if I spray metal in the place I need, gradually increasing the thickness? I looked for information about whether someone did this - I did not find it.

Registered on a forum where sprayers gather together and began to disturb them with questions like: is it possible to build up a “film” with a thickness of 1 or more millimeters. To which I caught a lot of misunderstanding what it was for, but received a positive answer.

General information received, you can begin to prepare for experiments.

It is known from various articles and documents that a vacuum of no more than 10⁻² Pa is required. For comparison, the order of magnitude - the pressure that gives a household vacuum pump (Value and others) - about 4 Pa (measured value), i.e. pressure is 400 times greater than necessary. How to deal with it and what to do? To achieve low pressures, turbomolecular vacuum pumps are used, they work in parallel with the foreline pump and, literally by molecules, capture the remaining air from the chamber. The process is not fast. The pump looks like this.

We installed a pump, it pumps out air and everything seems to be fine, but how to find out the pressure? For this I chose an ionization vacuum gauge.

In fact, nothing else is needed, except for the chamber and evaporator. I did not find a ready-made affordable (in terms of finances) camera, therefore, I decided to make my own. It is of a small volume (about 8-10 liters) in order for the air to be pumped out faster. Usually, the chambers have a spherical shape, in my case it is, on the contrary, elongated, in order to be able to set the “target” (the place where the metal is deposited) at different distances from the evaporator. In addition, the camera has a lot of flanges for connecting all kinds of inputs/outputs and sensors. I modeled the camera in a well-known CAD program, drew drawings and transferred it to production.

Current leads and conductors I made from a brass bar and a brass rod, bought on the local market. (Juno, who is from St. Petersburg).

In the photo below, a tungsten boat is fixed between two conductors.

The bottom part looks like this. The photo shows the cooling tubes of the current leads. Subsequently, I abandoned them, due to the simplification of the system.

Subsequently, I abandoned them, due to the simplification of the system.

Assembling the camera did not take much effort and complexity. It is much more difficult to achieve vacuum retention in this chamber. To do this, I polished the flanges and all mating surfaces to avoid the slightest leakage through the rubber seal (in the photo below, I processed only the top flange).

As it turned out later, the weld is not airtight at all (meaning for low vacuum). I, out of inexperience, assumed that by pumping a pressure of 300 kPa into the chamber and immersing it in a bath of water, I would carefully find all the leaks and eliminate them. Yes, at the first stage I did just that, but the pressure in the chamber did not fall below 10-2 Pa, there were leaks. Interestingly, before the start of the test, at a pressure in the chamber of 300 kPa, bubbles emerged from the welds with an intensity of approximately 1 bubble (diameter 2-3 mm) in 30-40 seconds. And those were big losses that I eliminated. But what to do with minimal vacuum losses that cannot be tracked in "kitchen" conditions?

But what to do with minimal vacuum losses that cannot be tracked in "kitchen" conditions?

The solution was close. To do this, all you need is a mass spectrometer.

The idea is simple – the investigated chamber or container is connected to the vacuum chamber of the spectrometer. Air is pumped out, on the graph they look for extraneous peaks of any gases. After that, helium is supplied locally, to the places of possible leakage. It is helium, because its penetrating power is higher and the helium peak can be easily tracked on the spectrum. As soon as helium enters the chamber through a micro-hole, it is immediately visible on the spectrum.

I drove twice and looked for leaks twice. Now the chamber with the installed pump is hermetic and it is possible to carry out experiments further, having previously assembled all the components of the system on the rack.

General view of the incredible installation.

Starting up the plant and checking it comes down to maintaining the lowest possible pressure. The foreline pump is started first.

The foreline pump is started first.

The pressure after the operation of the foreline pump can be seen in the picture below.

After the pressure is established (does not change). You can launch "heavy artillery" - a turbomolecular pump. It reduces the pressure by another 3 orders of magnitude.

The time has come for experiments, what I have been going for so long and what I have been waiting for so long.

First experiment.

Place a small amount of silver into the boat fixed between the conductors. Above the boat I install a steam conduit - a soldered tin cylinder, which, as I thought, should limit the spread of metal through the chamber. Above the steam conduit there is a lid with a hole of 2 mm, behind the lid there is a target on which the metal should condense. It is a pity that there are no photos left, but the vacuum chamber was completely dusty. There was not a single place where there was no applied layer of metal. In the photo below, it’s not a different planet at all, but silver sprayed onto the inner surface of the wall.

In the photo below, it’s not a different planet at all, but silver sprayed onto the inner surface of the wall.

Second experiment.

I thought it was because of the large gaps between the boat and the steam line. The solution was born immediately and quickly. I took two boats and combined them so that a shell was obtained. I placed silver inside, and cut a hole with a diameter of 2 mm in the upper half.

And he began to heat up the whole thing. But, I did not take into account the rigidity of the boats and the rigidity of the current leads. The shells parted a little and a gap formed between them, through which steam also flew in all directions.

As a result - spraying in the entire volume of the chamber. In the photo below there is a viewing window, the boat in which was slightly above half, but the window was completely dusty.

Third experiment.

After a little thought and grief, I thought that the container with the evaporated metal should be airtight and with only one outlet, but how and what to make it. From tungsten - very expensive and difficult to process. The way out has been found! Graphite is an excellent material for making a crucible, let's call it that. On the ad site, I found an ad for the sale of graphite bars from the contact whiskers of a trolleybus, cut out a bar with a hole in the center and made a cover for it. In the photo below - just a bar with a hole for the material (without a cover).

From tungsten - very expensive and difficult to process. The way out has been found! Graphite is an excellent material for making a crucible, let's call it that. On the ad site, I found an ad for the sale of graphite bars from the contact whiskers of a trolleybus, cut out a bar with a hole in the center and made a cover for it. In the photo below - just a bar with a hole for the material (without a cover).

And in this photo already in the chamber with the lid installed (the hole in the lid is 1 mm in diameter).

Under the spoiler are a few photos with a short period of time, from which you can see how dusty the viewing window is.

Loss of transparency

It is obvious that in this case, too, there was no success, to my great regret. All three experiments were carried out with a gradual increase in temperature from the state when evaporation does not occur.

A small video in which the information is presented in a slightly different way, in a different form and volume.

Video link

www.youtube.com/watch?v=4yWQOWIG1qw

Unfortunately, it was not possible to get what was intended, but, on the other hand, invaluable experience was gained in the design and manufacture of vacuum equipment. Most of this experience I have shared with you and I would be very grateful if you express your opinion on this issue.

Thank you all and good luck.

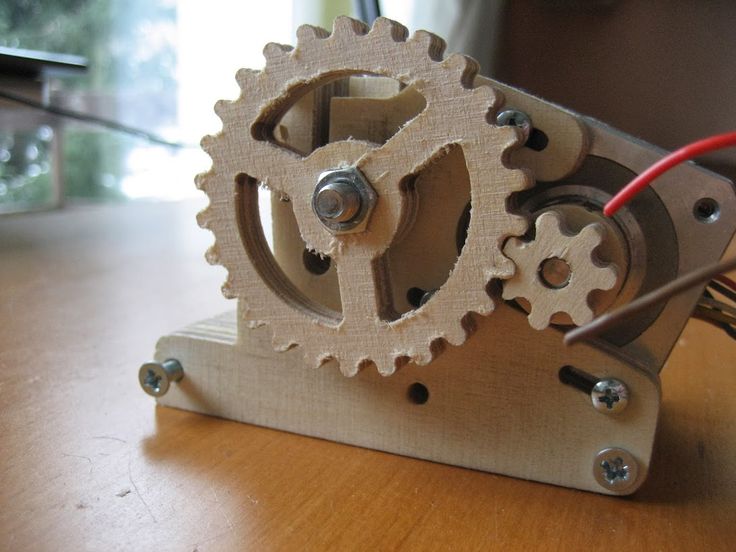

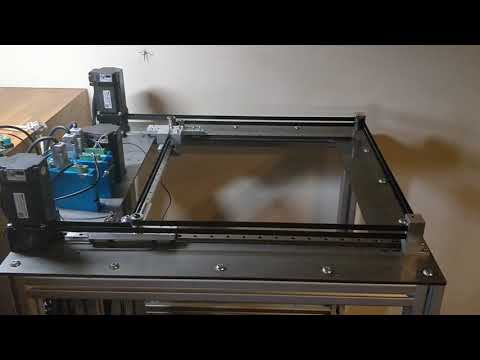

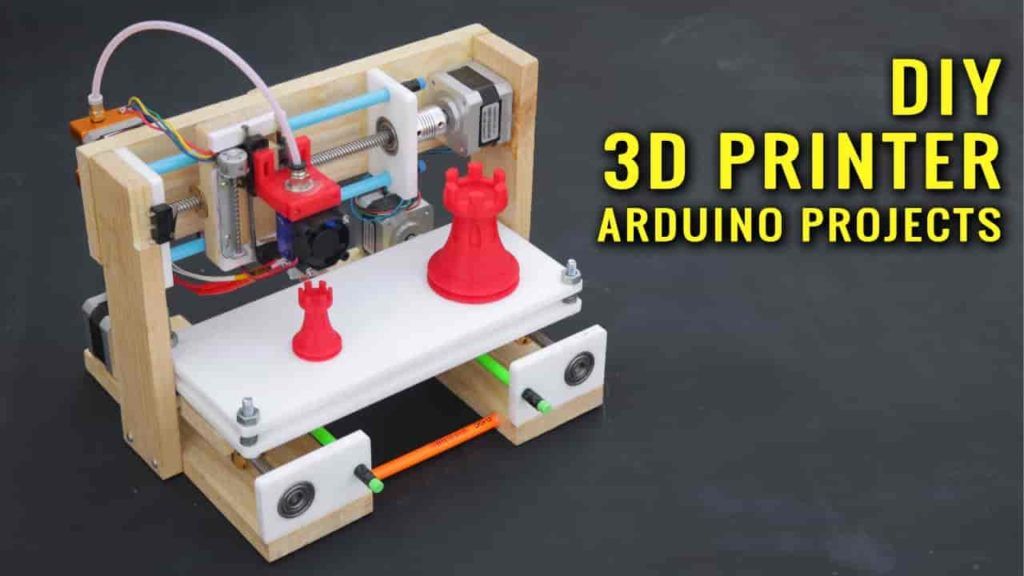

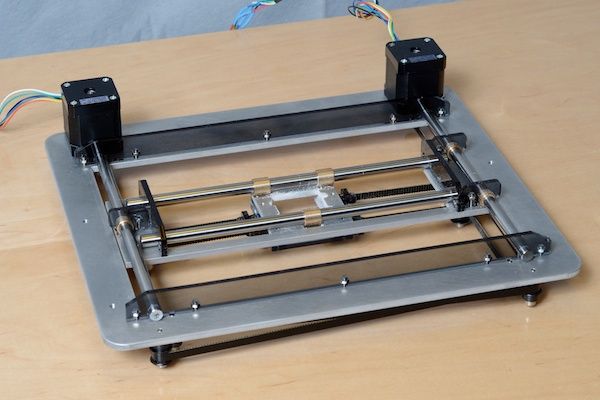

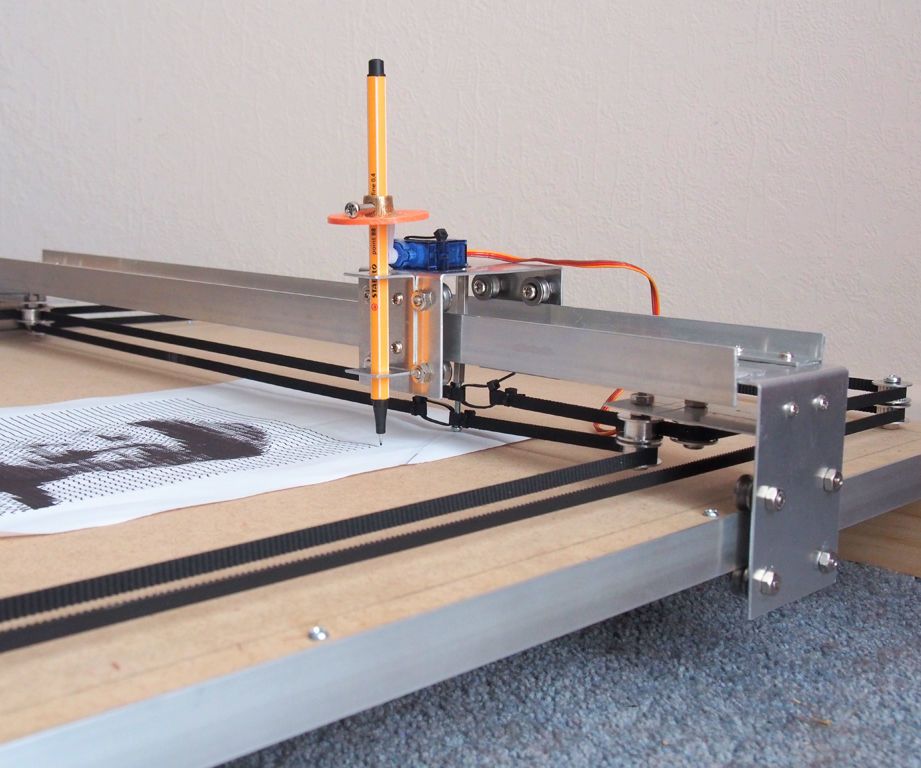

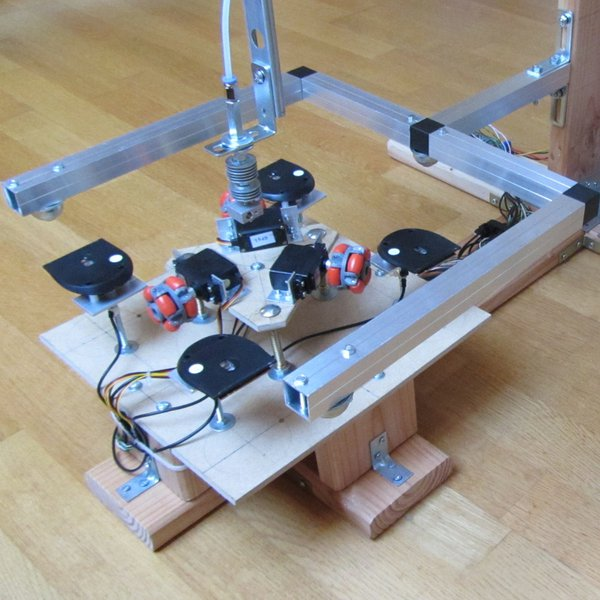

DIY 3D printer from an inkjet printer

How to assemble a 3D printer from parts from an inkjet printer?

3D printer is a high-tech and expensive device. If you buy a cheap device, you may encounter poor-quality assembly, fragile components and a short uptime. Having in stock unnecessary, decommissioned, failed inkjet printers and scanners, you can assemble a printing device from their parts to create three-dimensional models.

Do-it-yourself 3D printer from an inkjet printer

If the cost of the device is the leading factor in choosing a device for printing 3D objects, it is worth assembling a 3D printer yourself. According to user reviews, cheap models of 3D printed devices made in China have the main drawback - the low quality of components. In particular, guides are the weak point of Chinese devices. These elements are subjected to significant stress, and if they are of poor quality, they can be deformed under the action of tension belts.

According to user reviews, cheap models of 3D printed devices made in China have the main drawback - the low quality of components. In particular, guides are the weak point of Chinese devices. These elements are subjected to significant stress, and if they are of poor quality, they can be deformed under the action of tension belts.

Important! In older document printers, the rails are made of hardened steel. They do not bend even with considerable effort. Such details will be an ideal alternative to regular Chinese ones.

By dismantling unnecessary office devices, you can get a set of spare parts necessary for assembling a 3D printer and save a lot on the purchase of components. These are:

- printer head slide assembly;

- timing belts;

- mechanical or optical limit switches;

- power supply;

- stepper motors and drivers with controllers and other parts.

Attention! Inexpensive inkjet printers were mostly equipped not with stepper motors, but with DC motors with an encoder.

Theoretically, they can be used in the assembly of a 3D apparatus by redesigning the latter. Stepper motors are usually extracted from scanners.

But the advantage of DC-motors should be noted: they consume electricity only during movement, while stepper motors are constantly supplied with power.

Accessories such as hot end, extruder and control board will have to be purchased. The frame is assembled from improvised materials - plywood, steel corners or parts of the cases of disassembled copiers.

A self-assembled printer will be much cheaper than factory counterparts, but at the same time, it will be of higher quality than budget models presented on the market by Chinese manufacturers.

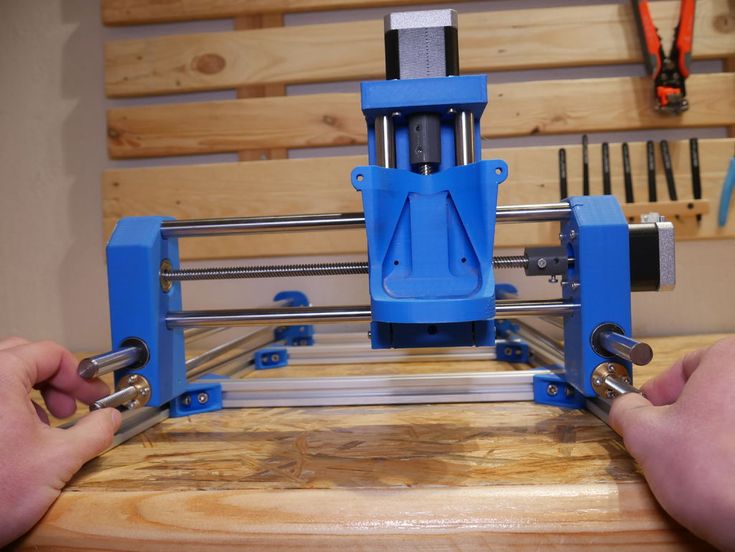

How to make a 3D printer from an inkjet printer: step-by-step instructions

To work on assembling a printer from donor components, you will need a set of tools and materials:

- hacksaw, drill - to make the case;

- soldering iron and solder - for mounting electrical cables;

- screwdrivers and hex set - for assembling components;

- pliers;

- multimeter tester - for checking the electrical circuit;

- screws and nuts;

- cable ties;

- electrical tape.

Attention! Knowledge of electronics and engineering is a plus.

Accessories:

- steel rails;

- timing belts;

- micro stepper motors;

- stepper motor drivers;

- extruder and hotend;

- optical sensors - limit switches-microswitches;

- power supply;

- connection cables;

- electronic control board and microcontroller based on Arduino;

- LCD display;

- desktop glass;

- frame parts.

Next, you will need to stock up on a fair amount of patience and pedantry - assembly requires careful observance of all instructions.

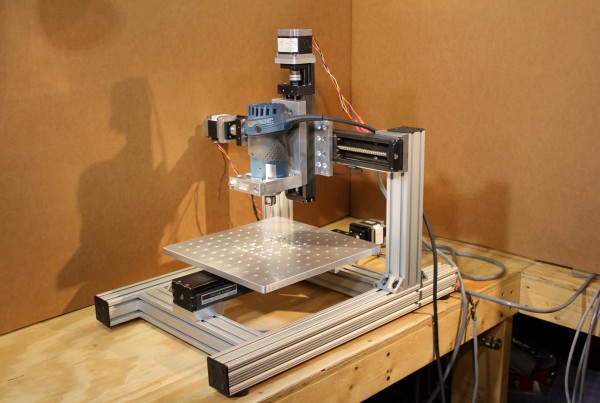

Assembly process

- Frame fabrication and painting.

- Mounting the X and Y frame axes and fixing the stepper motors to them. The extruder will move along the X axis, the Y axis is needed to move the platform.

- Installing the Z axis support rod.

- Attaching the extruder.

- Connection of heating elements, cables, power supply.

- Mounting of electronic elements: boards, microcontroller, LCD display.

After assembling and testing the electrical circuits, install the software. At the last stage, the working table, the X, Y, Z axes, the temperature of the heating elements and the filament pulling speed are calibrated.

Important! After starting the printer, print a test model. It will show all the flaws in the assembly and settings.

Mistakes and how to avoid them

Printer performance depends on the quality of the installation. But it is not always possible to eliminate errors when assembling the device.

- One of the serious mistakes that is often made when assembling the printer with your own hands is the incorrect installation of the frame elements. Even a slight misalignment of the corners will cause jamming when the carriages move.

The geometry of the mating parts must be maintained as accurately as possible.

The geometry of the mating parts must be maintained as accurately as possible.

If the body is made of plywood, it is recommended to cut its elements on a CNC laser machine. When assembling a frame from metal corners, it is necessary to control the mating angles of the parts at each stage. - The second common problem is the backlash of the frame elements. In this situation, print quality cannot be achieved. There should be no gaps between the parts. They occur either when the fasteners are loosely tightened, or if the frame elements are poorly prepared, that is, the dimensions are incorrectly maintained.

- If the electrical wiring connectors are not of good quality, there will be constant power outages. And the installation of short wires will cause them to break. The length of the wiring must match the dimensions of the frame, taking into account moving parts. It is necessary to check the tightness of the connection of the connectors, thereby minimizing the risk of disconnecting individual components and mechanisms from the power supply.

Quality control of the assembly at each stage, checking all connections and geometry of structural elements will help to avoid problems.

That's interesting! The article discussed how to assemble an FDM printer from improvised materials and parts left after dismantling office equipment. And an engineer from the Netherlands assembled a powder-type 3D printer based on an inkjet printer. As a filament, he used gypsum, sand, metal powder, and filled the cartridge with a binder. Otherwise, the technology is similar to laser layer-by-layer sintering.

Assembling a 3D printer with your own hands is not at all such a simple action as it seems at first glance. But lower financial costs and higher quality components compared to budget models from China make it expedient to manufacture a printing apparatus on your own. And given that a significant part of the parts will be recovered from the old inkjet printer and copier, this will further reduce the cost of producing a homemade 3D printer.