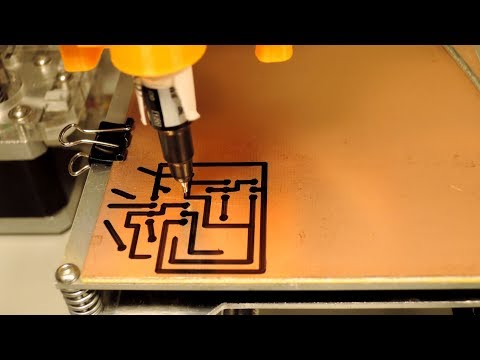

3D printed pcb mill

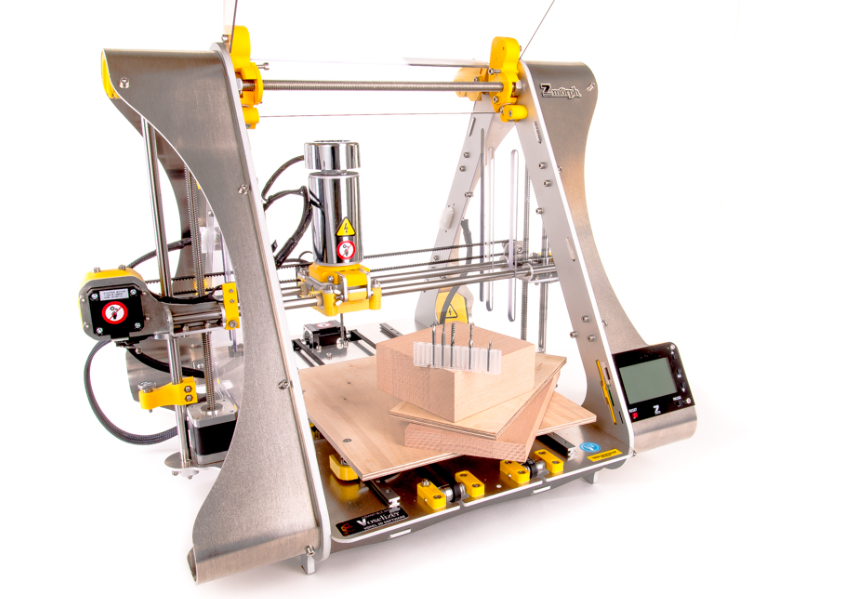

Is It a 3D Printer? Is It a PCB Mill? Is It Crowd Sourcing? Is it the Future?

0Shares

Embedded Projects GmbH, an online place for selling, buying, presenting and discussing embedded open source making projects (involving anything from Arduino to Linux to Microcontrollers of all kinds), is asking your opinion on going ahead with the construction of a particularly interesting project, as far as the 3D printing industry is concerned, that first appeared on Elektor Labs, an online community for sharing electronics projects (that also has its own magazine with a circulation of about 125,000 monthly copies).

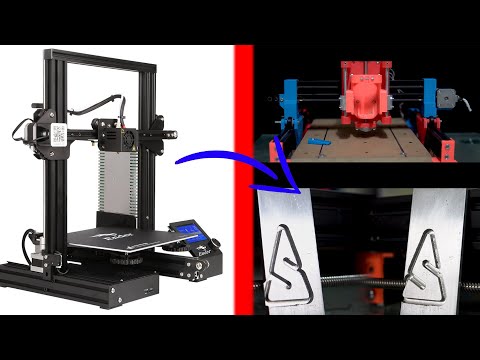

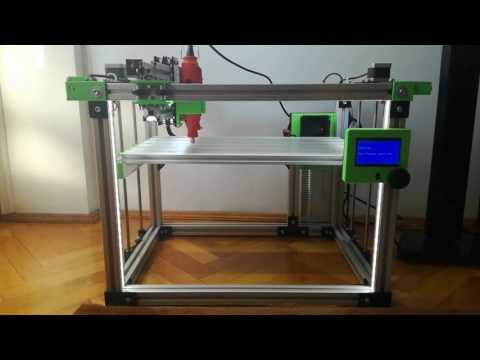

What Embedded Projects wants to know is whether you think that there is room in the market for a 3D printer with embedded Linux controls that can easily turn into a PCB (Printed Circuit Board) milling machine. To find out it posted this video (article continues below)

and a form in which it asks whether you would buy such a machine and how much you would be willing to pay for it. You also have the option to “beg” them not to build it, if you feel the market has already been saturated. Can this form of directly addressing the public through the web to assess demand be considered a new form of crowd sourcing, a sort of crowd-pre-sourcing?

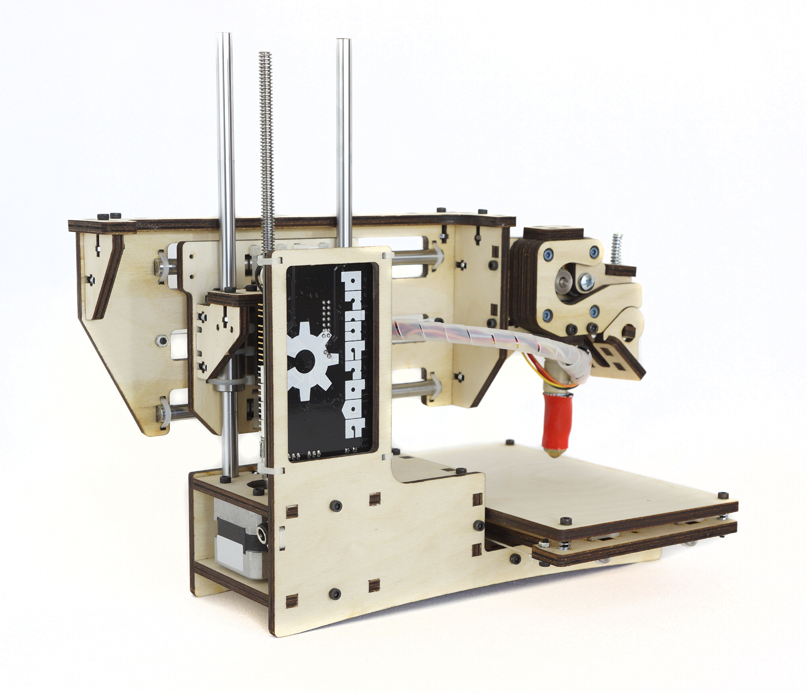

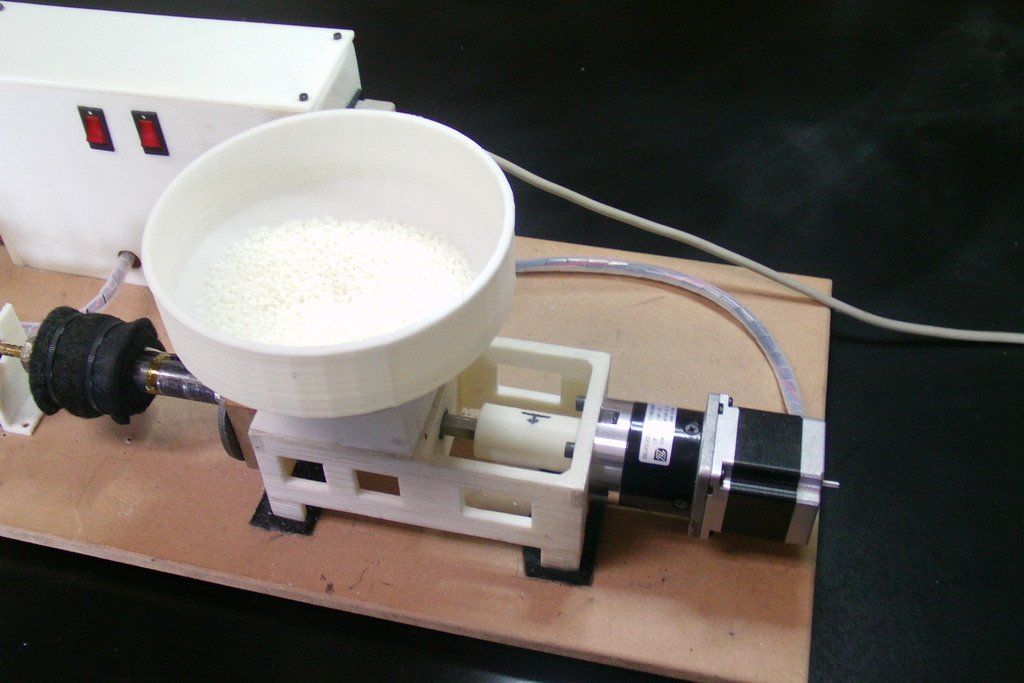

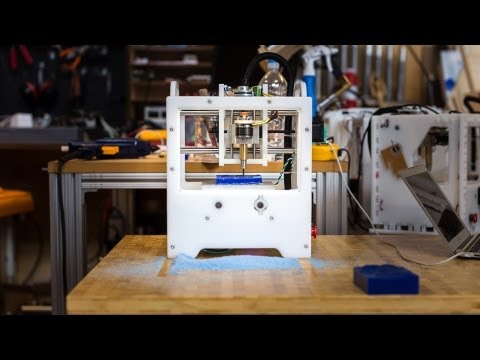

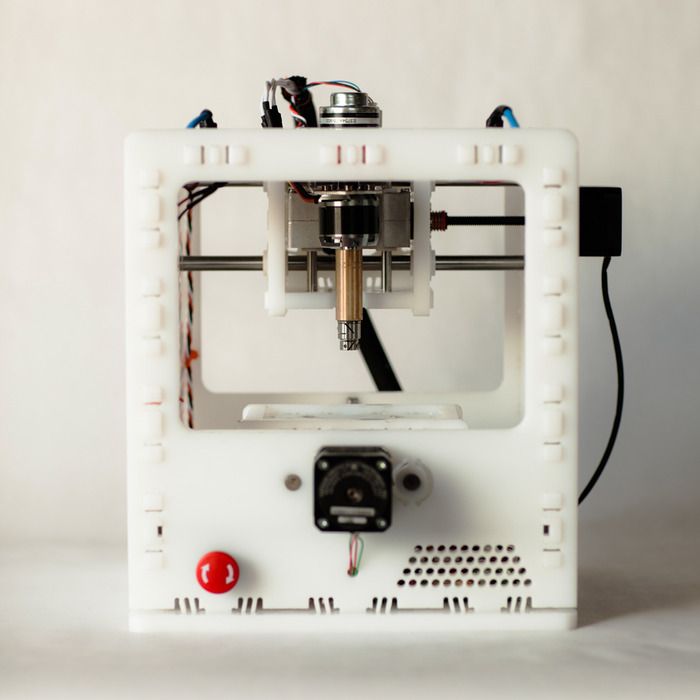

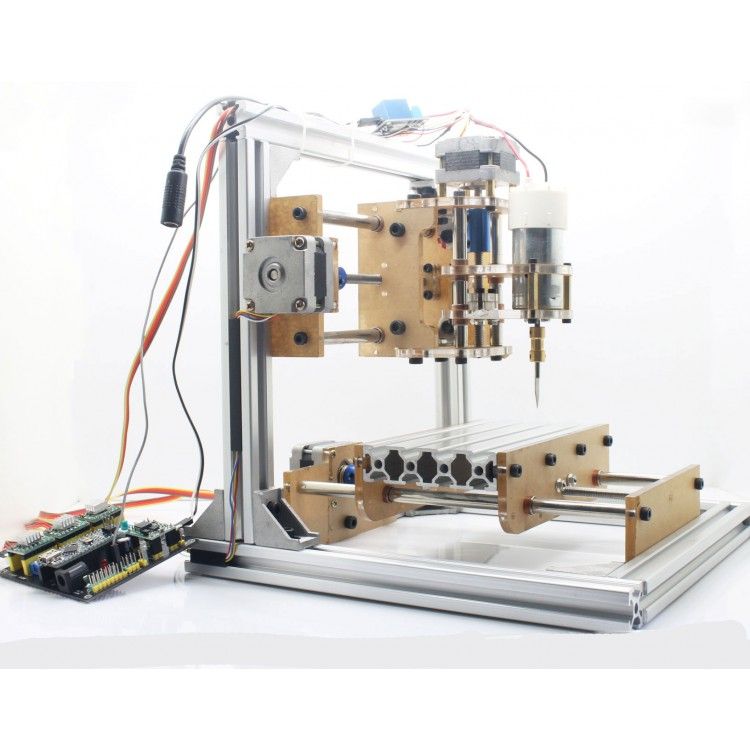

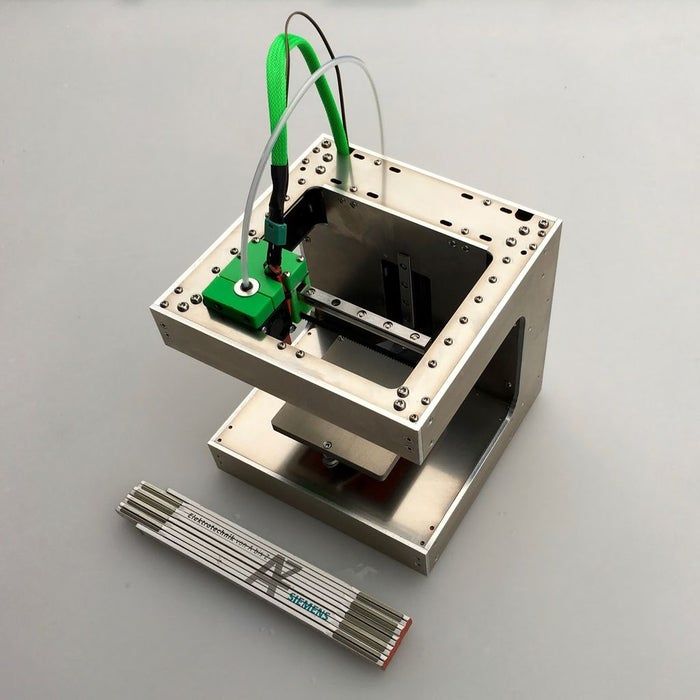

The machine, which is also a thesis project by Manuel Liebert, comes with a Linux board and custom software (including the G-code interpreter) and its controls are based on a simple Web interface: it is fully open source and doubles as a solid 3D FDM 3D printer with a wider range of Linux based controls and a precise platinum cutter for circuit boards.

The question it poses actually goes beyond the fact that it may have a market in and of itself but widens it to all multi-purpose (additive and subtractive) machines. Is there really a market for them? Some companies seem to think so, especially in direct metal 3D printing. An object may thus be assembled roughly and then its surface smoothed out with a milling machine, optimizing costs and time while reducing waste of materials.

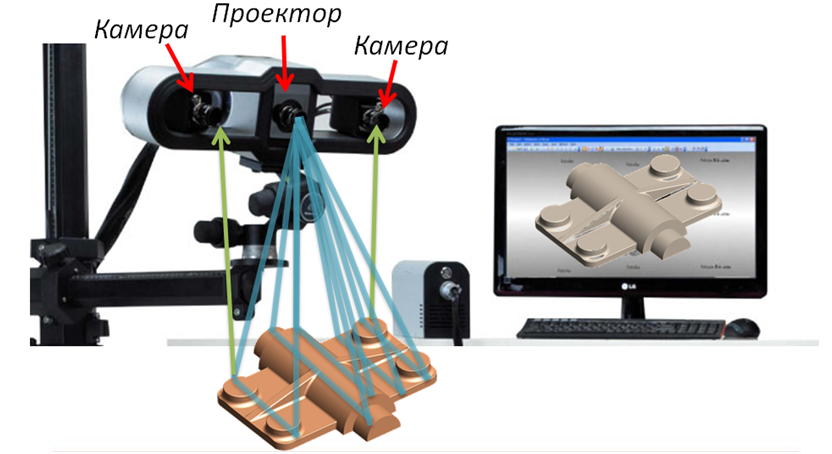

My friend Peter Musson, a London based silversmith/maker/artist that experiments with 3D printing on many levels, first showed me one such machine that he had built (not for sale). It has custom control software, it does 3D printing (with ceramic and metal pastes as well), CNC milling (I am not sure about PCB) and one more thing: it is also a 3D scanner of objects, all with the same mechanical arm. Is there a market for that as well?

Davide Sher

Davide was born in Milan, Italy and moved to New York at age 14, which is where he received his education, all the way to a BA. He moved back to Italy at 26 and began working as an editor for a trade magazine in the videogame industry. As the market shifted toward new business models Davide started working for YouTech, the first iPad native technology magazine in Italy, where he discovered the world of additive manufacturing and became extremely fascinated by its incredible potential. Davide has since started to work as a freelance journalist and collaborate with many of Italy’s main generalist publications such as Corriere della Sera, Panorama, Focus Italy and Wired Italy: many of his articles have revolved around the different applications of 3D printing.

3D Printer/CNC Mill Hybrid – Engineering Design Fair 2022

Project Category: Mechanical

Welcome! Come join us!

10:00 a.m. to 1:00 p.m. MDT

Zoom Link

About our project

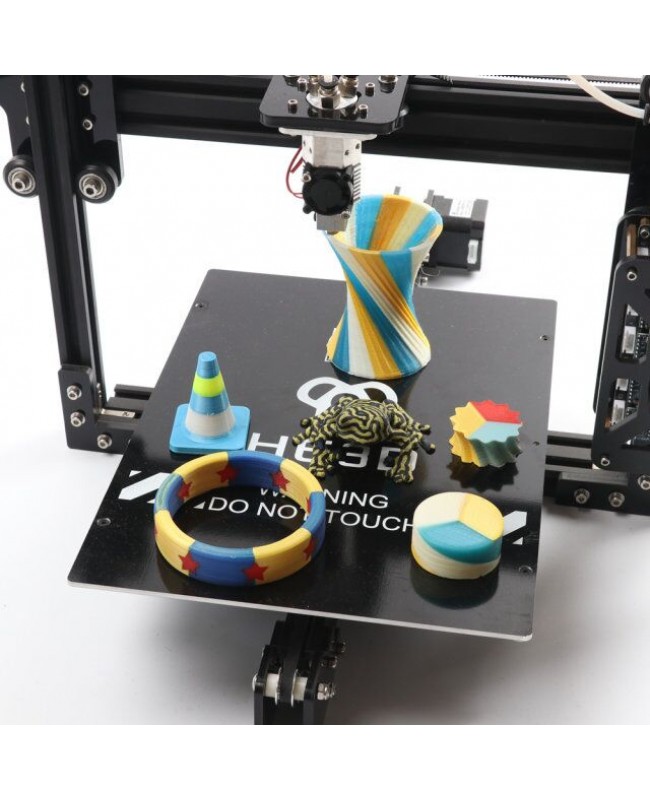

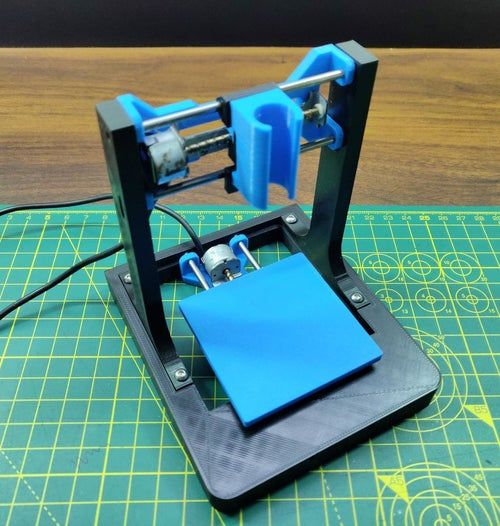

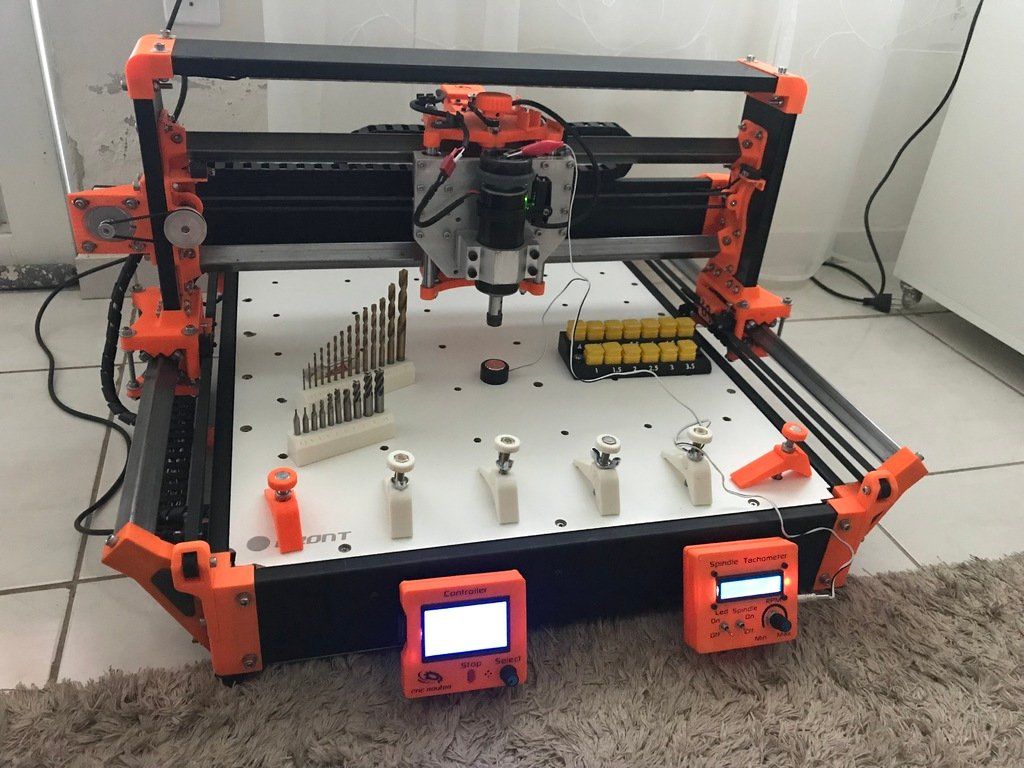

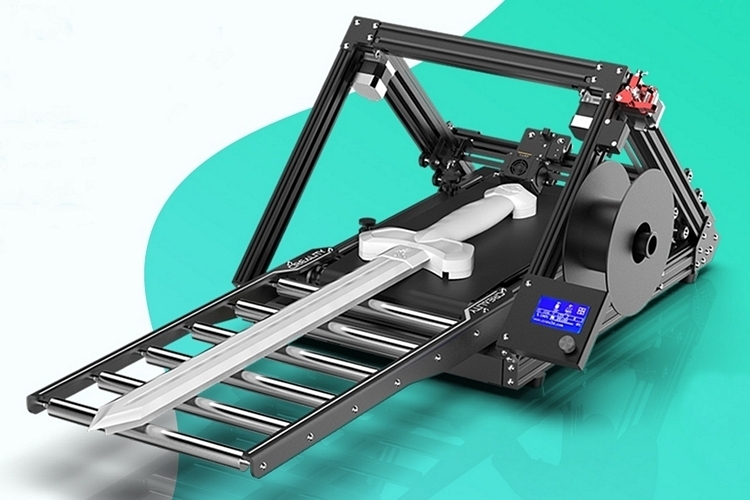

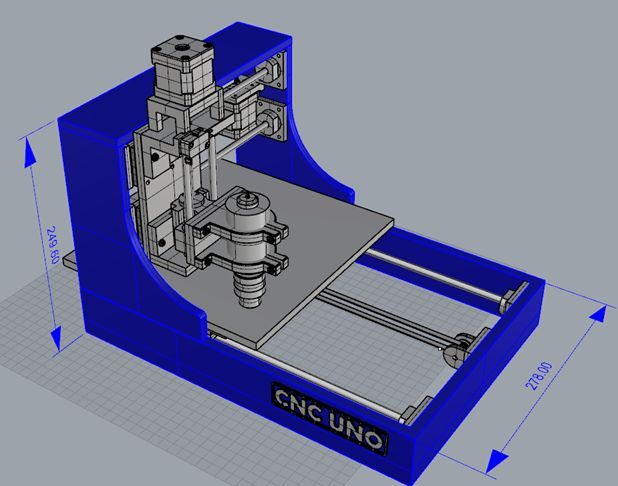

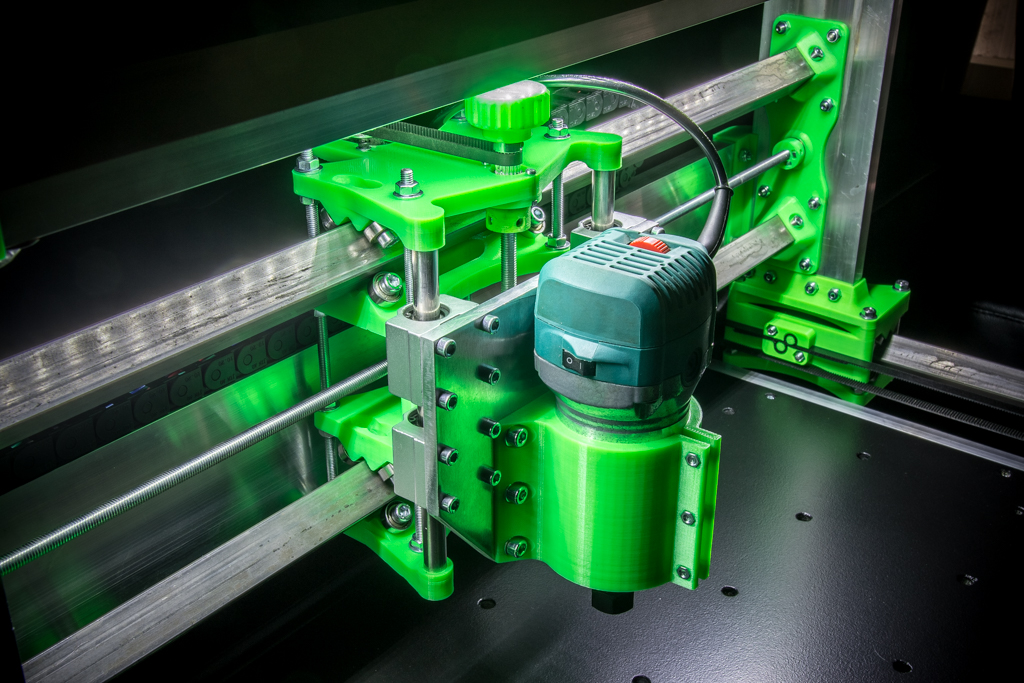

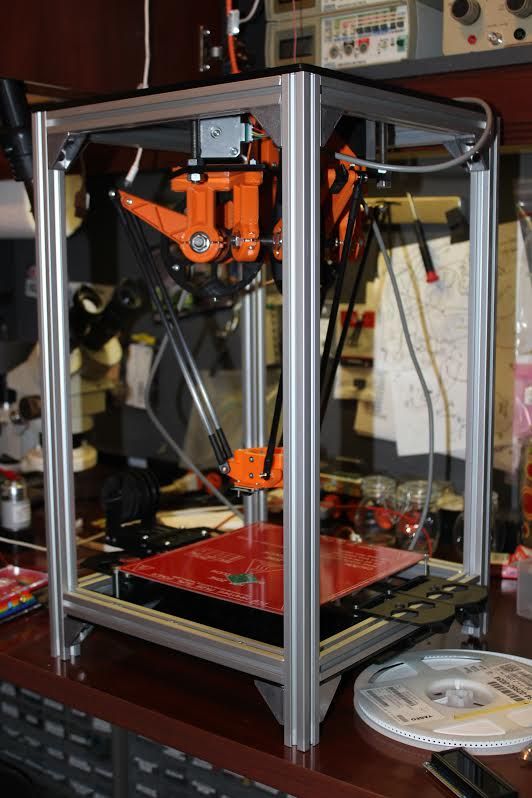

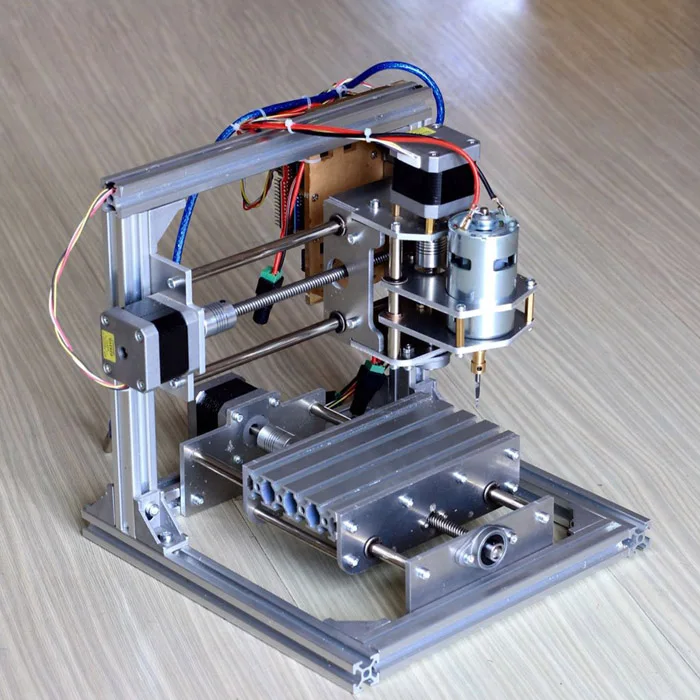

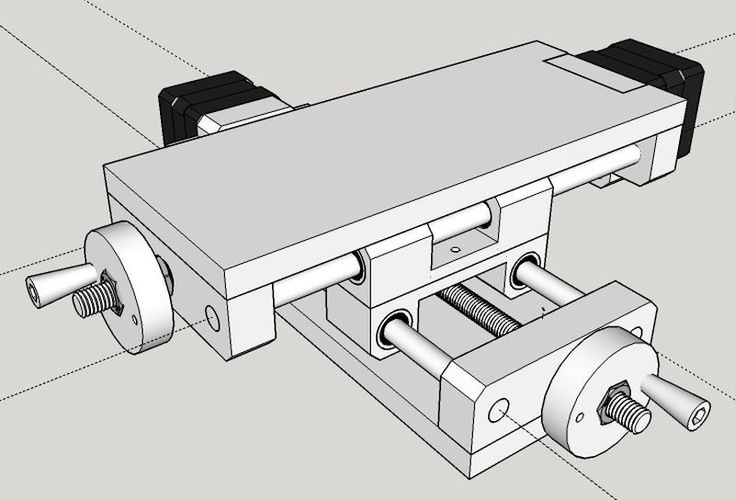

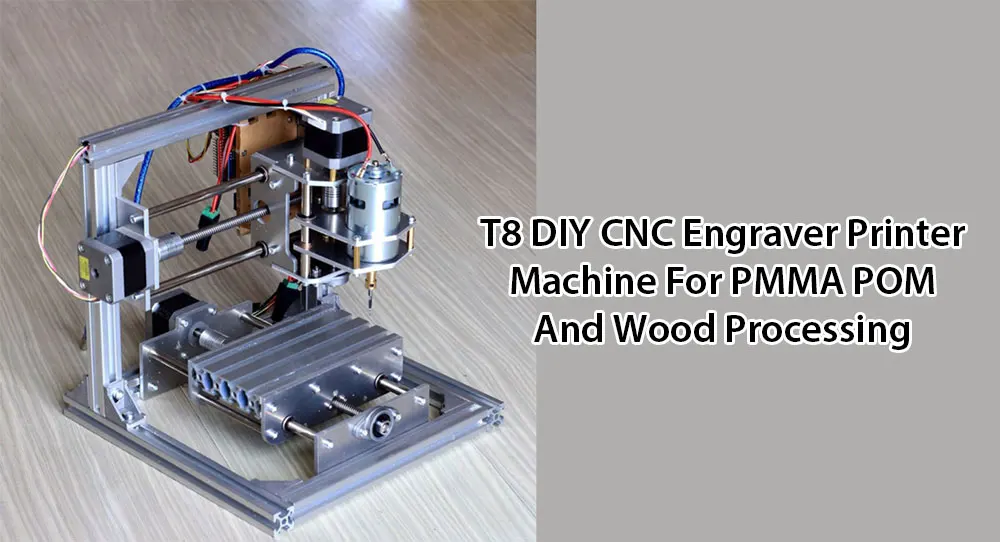

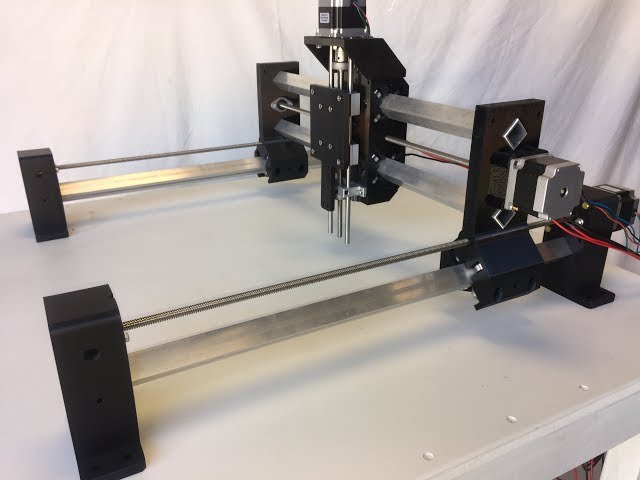

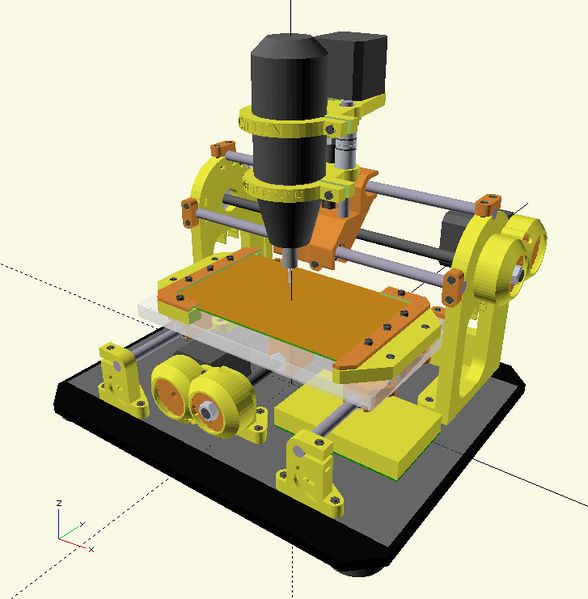

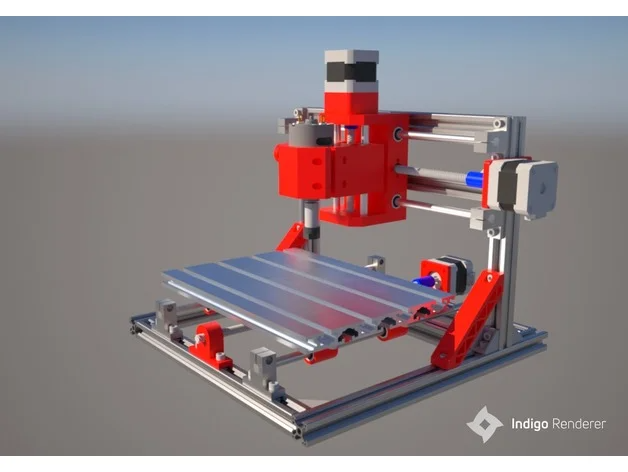

The KM 4-20 is a compact 3D printer & Computer Numerical Control (CNC) mill hybrid. As 3D printing technology becomes more prevalent, there is increasing demand to produce precise rapid prototypes with minimal post-processing. Traditionally, a 3D printer can reach a dimensional tolerance of 0.1mm with rough washboard-like surfaces, which limits the potential applications of 3D printed parts. CNC mills use rotary cutters to remove material, producing parts with a dimensional tolerance under 0.01mm, however this method wastes raw material and can be costly. Merging these two technologies allows the hybrid to rapidly produce accurate parts with enhanced surface finish while minimizing material waste.

The KM 4-20 works by 3D printing a part slightly oversized then milling it to its final dimensions. Our proprietary software allows a user the freedom to combine 3D printing and milling operations in any order suitable for their project. For example, if a project requires an inset bearing, the part can be 3D printed oversized and then cut down with the mill to the required size and smoothness. After the bearing is installed, it can be sealed into the part with additional 3D printing.

Our proprietary software allows a user the freedom to combine 3D printing and milling operations in any order suitable for their project. For example, if a project requires an inset bearing, the part can be 3D printed oversized and then cut down with the mill to the required size and smoothness. After the bearing is installed, it can be sealed into the part with additional 3D printing.

In industry, machine setup is a necessary but time consuming and cost prohibitive procedure for manufacturing single prototypes. In some cases, prototypes may require multiple setups to achieve final dimensions. The KM 4-20 was designed to minimize total setup time by reducing the number of setups required.

We invite you to find out more about the KM 4-20 and learn about its additional features to unleash your creativity.

View our Video

Meet our team members

Sean Mason

Sean is a journeyman machinist of over 15 years, with 10 years of direct experience with CNC milling machines and lathes. His expertise applies directly to the programming and setup of the KM 4-20. Sean’s interests are in CNC manufacturing, automation, and aviation.

His expertise applies directly to the programming and setup of the KM 4-20. Sean’s interests are in CNC manufacturing, automation, and aviation.

Rachel Jacyszyn

Rachel has a broad range of interests but has chosen to focus in the areas of mechatronics and consumer products. She has a creative streak and really enjoys the design aspect in product creation and presentation. Her background includes a prior degree in cellular biology and industry experience in research and development. She enjoys hobbies such as photography, backpacking, home-improvement, tinkering and videography.

Matt Moldenhauer

Matt’s areas of interest are manufacturing and automation. He has professional experience in the steel industry, where he developed a fascination with process optimization. In his free time you can find him hiking or working on his latest design project.

Graeme Kendall

Graeme has been involved with makerspaces and Calgary’s startup scene over the past 5 years. He has professional experience in the construction industry, where he developed a skillset for product and vendor selection. He applied this knowledge for component selection and integrating both CNC and 3D printing technologies for this project. He enjoys in his free time curling, classical literature and prototyping.

He has professional experience in the construction industry, where he developed a skillset for product and vendor selection. He applied this knowledge for component selection and integrating both CNC and 3D printing technologies for this project. He enjoys in his free time curling, classical literature and prototyping.

Ryen Kuiper

Ryen’s interests include programming, tinkering, and the minutiae of how things work. He coded the software tools developed for this project, and contributed to some of the theoretical analyses of the prototype. He also tried his hand at voiceover artistry for our introductory video!

Details about our design

| Printing Method | Fused Filament Deposition |

| 3D Printing Work Volume | 300 mm X 165 mm X 28.3 mm |

| Milling Work Volume | 300 mm X 180 mm X 45 mm |

| Print Tolerance | 0.1 mm |

| Mill Tolerance | 0.01 mm |

| Bed Temperature Range | 0 °C – 130 °C |

| Hotend Temperature Range | 0 °C – 240 °C |

| Maximum Spindle Speed | 20,000 RPM |

| File Transfer Method | USB/SD Card/Wi-Fi |

| File Format | . gcode gcode |

| Power Supply | 24 VDC, 15 A |

| Print Material | PLA, ABS |

| Filament Diameter | 1.75 mm |

| Weight | 10 kg |

| Dimensions | 483 mm X 318 mm X 406 mm |

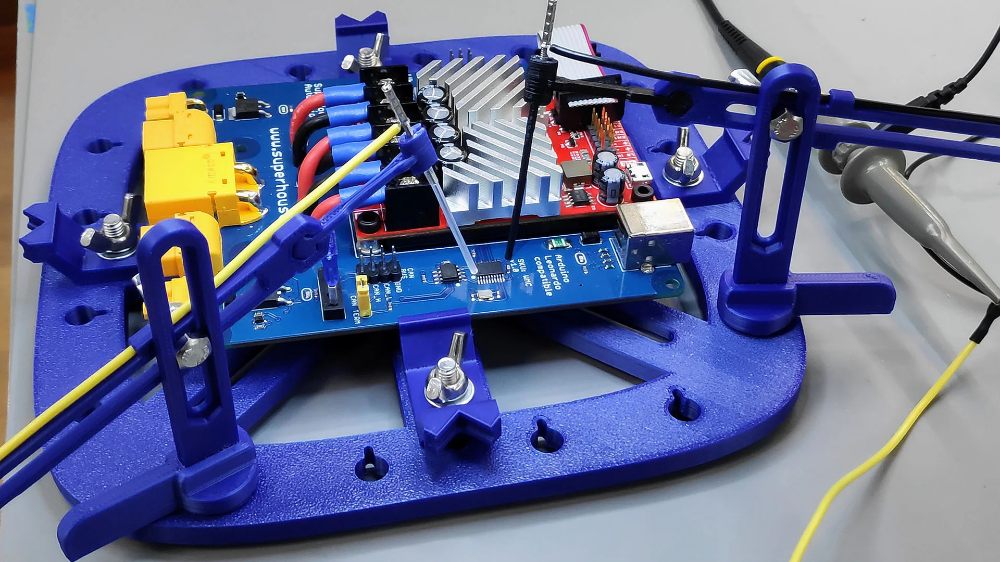

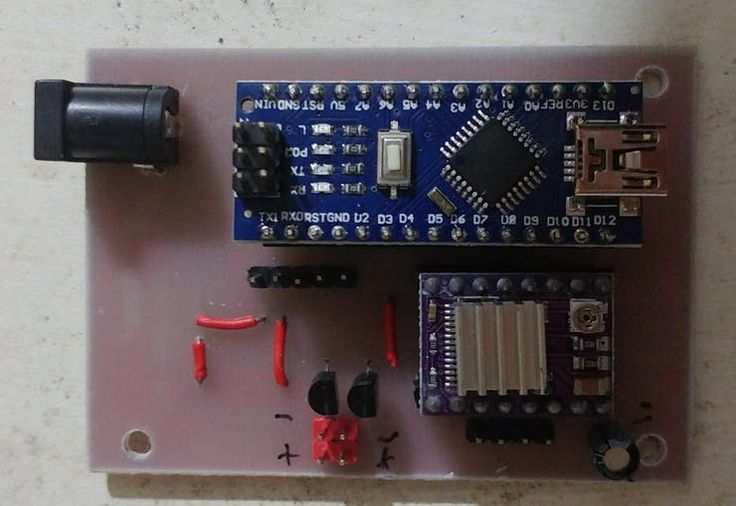

Closed-Loop Stepper Controllers

A common error in 3D printers is “layer shift”, in which an axis deviates from its programmed position due to external forces. The Bigtreetech® S42B control boards sense changes to a magnetic field to determine the exact position as the motors rotate, allowing the stepper motors to correct for external errors and ensure the tool is always in its desired position.

Touchscreen Interface

The KM 4-20 can operate without an external computer using an offline touchscreen controller. The Bigtreetech® TFT24 controller provides temperature, fan, and motor regulation. It also allows for direct G-Code input for the machine-specific functions like the printhead retracting system. Useful information is displayed such as current bed temperature, nozzle temperature, and fan settings.

Useful information is displayed such as current bed temperature, nozzle temperature, and fan settings.

Heated Bed with Manual Levelling

The working surface is a 240-Watt SIMAX 3D printer heated bed capable of reaching temperatures of 130 degrees Celsius. A thin sheet of polymer film is placed on top of the bed. The combination of the film and heat improves print adhesion so that the milling operations don’t need any additional fastening. Nylon screws and nuts thermally isolate the bed from the rest of the machine and allow for manual bed levelling.

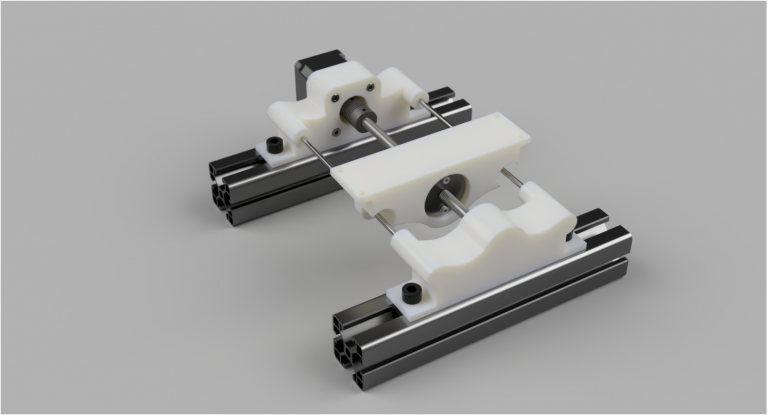

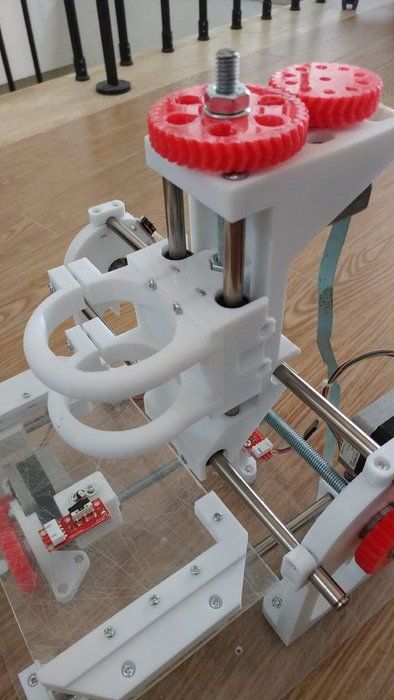

Retractable Printhead

The printhead is mounted to a four-bar linkage to allow for retraction during milling operations. The device is moved by a pair of servomotors which provide accurate position control. The motors transmit force through gears, which reduce the motor load and prolong their useful life.

Power Interruption Protection

In the event of a power interruption, a standard 3D printer stops in its current position and the print must be restarted. The KM 4-20 features a capacitor bank which allows the machine to continue operating through short-term power interruptions.

The KM 4-20 features a capacitor bank which allows the machine to continue operating through short-term power interruptions.

Angled Nozzle

The 3D printing head was angled to minimize the distance between the spindle and the nozzle, and maximize the work envelope.

The 3D printer nozzle is ground at an angle to ensure it is parallel to the print surface. This has the advantage of improved adhesion of extruded filament to the heated bed.

Emergency Stop

The KM 4-20 includes an emergency stop button that completely turns off power, bypassing the power loss protection. This button instantly stops motion and heating to prevent injury in an emergency. The button can also be positioned in the vicinity of the machine operator for a swift response.

Electronics Case

The electronics are housed in an insulated case, protecting them from debris and users from electrical shock.

Homing Switches

Axial limit switches were added to the frame to maintain dimensional repeatability by providing a reference point for printing and milling operations.

32-Bit Control Board

The main control board is a 32-bit Bigtreetech® SKR V1.3. This board provides multiple advantages including faster processing speed, higher quality, and expanded firmware compatibility. Another benefit is that it is “future proof”; it gives the option to add upgrades and more advanced components compared to commonly used 8-bit board.

Remote Monitoring

A Raspberry Pi™ paired with a webcam works to provide remote control and monitoring over Wi-Fi™. This means that the user does not need to be present to supervise the entire process, and files can be sent to the machine without needing to keep track of SD cards or USB cables. Additional functions are available as open-source add-ons to enable features such as time-lapse video recording and G-Code simulation.

Spool Holder

The spool holder was designed for commonly available filament spools. One arm is removable for easy loading and unloading of filament.

Spindle Motor

The upgraded spindle motor rotates up to 20,000 rpm, increasing the range of speeds and feeds for a variety of materials. The spindle speed range gives the user greater control over surface quality and cutting time.

The spindle speed range gives the user greater control over surface quality and cutting time.

The control board of the KM 4-20 uses Marlin© firmware, which was chosen for its versatility. Among its many features, Marlin© allows for temperature control of the hybrid’s heated bed and extrusion nozzle, preventing thermal instability and overheating during printing. It also recognizes an extended library of G-Code commands, which allows for precise raising and lowering of the printing assembly, and controlling the milling spindle speed.

Two MATLAB programs were written to process and sequence G-Code instructions that the KM 4-20 can execute: The first combines printing and milling instructions into one sequential process. The second is an error recovery program that takes the sequenced G-Code file, asks at what layer height a print failed, and mills away the failed layers of the part before allowing the print to resume from that point.

A flowchart laying out the basic operation procedures of the KM 4-20 is shown below. On a software-equipped PC, a user models a part and produces printing and milling G-Code files. The first MATLAB program sequences the files so they can be loaded into the KM 4-20. This sequencing process allows a user to print and mill their parts in the desired order, or independently. If there is a design change or a printing error, the recovery script can be executed.

On a software-equipped PC, a user models a part and produces printing and milling G-Code files. The first MATLAB program sequences the files so they can be loaded into the KM 4-20. This sequencing process allows a user to print and mill their parts in the desired order, or independently. If there is a design change or a printing error, the recovery script can be executed.

In the future we will develop an open-source G-Code modification program in Python™ so that it is accessible.

Print only

Mill only

Print & Mill

Linkage Material

The four-bar linkage was first verified with finite element analysis (FEA) in SolidWorks®. This revealed weak points at the corners of the square hole. The links were made and tested using four different materials: pine, oak, 3D printed plastic, and aluminum. The pine links broke upon assembly, and the oak links broke upon first usage. Both links broke at the expected weak points. The properties of the 3D printed links were insufficient to hold the print head rigid. Finally, aluminum links produced at an external fabrication shop were found to be the superior material choice.

Finally, aluminum links produced at an external fabrication shop were found to be the superior material choice.

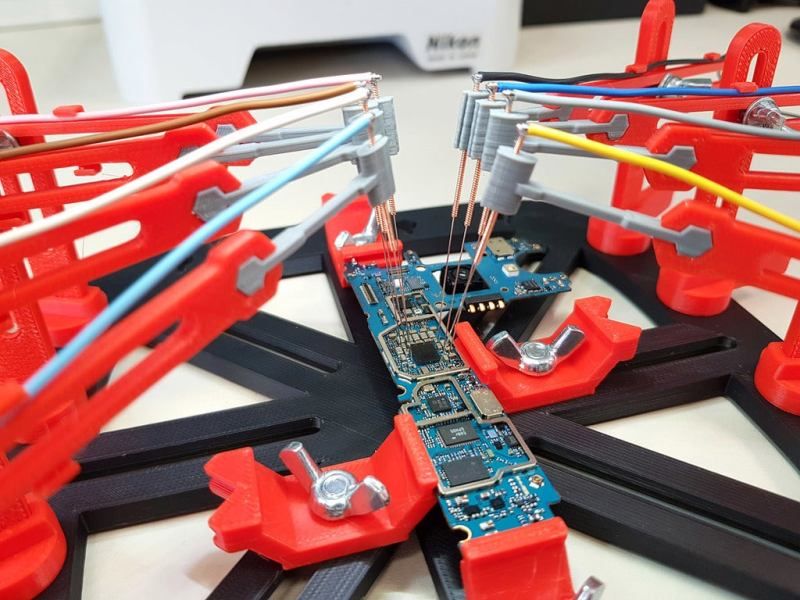

Test Parts

The sample parts verified the machine’s capabilities. The first part was a relatively simple drawer knob that involved a pause to embed a threaded component before resuming printing. The second part was a drone propeller with more complex geometry. For this part a fixture was printed to hold the propeller for milling both sides. With additional planning, this can be performed in one machine setup.

Closed-Loop Control

To test the closed-loop controllers, the machine head was programmed to move to a specific point within the work envelope while the lead screw was held stationary. Once the lead screw was released the head position was recorded using a dial indicator. As expected, the closed-loop controllers corrected for any difference in position.

Surface Finish

A surface finish analysis was conducted to find the most suitable speeds and feeds while still leaving a smooth surface. It was found that running the spindle at its maximum 10,000 RPM while using a 700 mm/min climb-milling feed rate, provided the best balance between cutting times and superior surface finishes.

It was found that running the spindle at its maximum 10,000 RPM while using a 700 mm/min climb-milling feed rate, provided the best balance between cutting times and superior surface finishes.

Tolerance

A tolerance analysis of 3D printers, the Genmitsu CNC, and the KM 4-20 was performed. We found that the 3D printers averaged a 0.17 mm error while the Genmitsu CNC averaged only 0.01 mm error. That’s 17X more accurate than a 3D printer. The KM 4-20 has an average accuracy of 0.02 mm — a significant improvement over existing 3D printers.

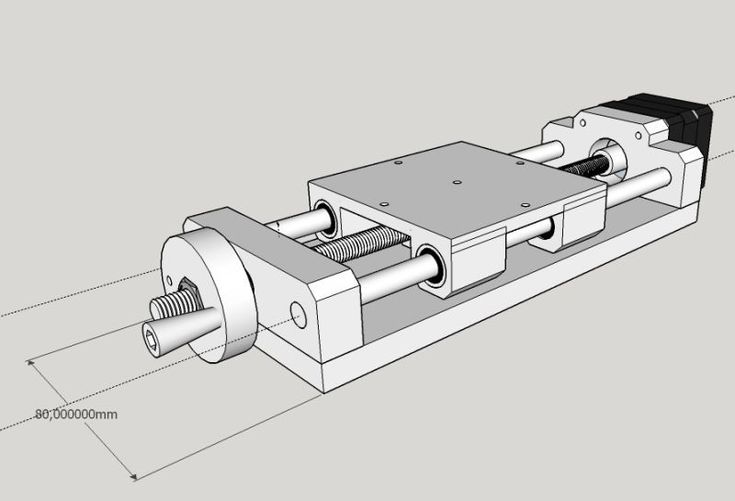

Larger X Guide Rods

After adding the mass of the printhead we found deflection at the centre of the 10mm rods that decreased accuracy. A kinematic analysis showed that increasing the rod diameter to 12 mm would restore accuracy. This would also require larger bearings.

Custom Bed Heater

Installing cartridge-style heaters directly into the t-slots on the machine bed with plastic inserts to fill the gaps would save the full vertical work volume and have improved adhesion.

Enclosure

To improve safety while reducing noise and cleanup, we recommend an enclosure. This would surround the machine to contain any removed material while preventing accidental spindle contact. Enclosures made specifically for the 3018 CNC are available, but it would be equally effective to make one out of clear acrylic.

Printer Component Upgrades

Higher quality printer components such as brand name stepper motors, additional cooling fans, heat-resistant electronics, and an automatic bed levelling system would improve 3D print quality.

The cost of these upgrades would total $192.00; since there is still room in the budget, these improvements are recommended.

Budget

The original project budget was $1000, and the project cost a total of $809.83. Adding the recommended upgrades would bring the total up to $1001.83 .

Schedule

| Task | Start Date | Completion Date |

|---|---|---|

| Research | 11 September, 2020 | 15 October, 2020 |

| Design and CAD | 11 September, 2020 | 10 December, 2020 |

| Mill Building | 26 September, 2020 | 1 December, 2020 |

| Initial Tolerance Testing | 29 September, 2020 | 30 December, 2020 |

| KM 4-20 Building | 25 January, 2021 | 4 April, 2021 |

| Product Analysis | 6 Feb, 2021 | 12 April, 2021 |

| Design Fair | 23 March, 2021 | 12 April, 2021 |

| Final Report | 23 March, 2021 | 14 April, 2021 |

Design Tools

Partners and mentors

Thank you to the ENME 502 instructors team, with a special thanks to lead instructor Dr. Simon Li and TA Danny Wong. Their advice and guidance was instrumental in the success of the project.

Simon Li and TA Danny Wong. Their advice and guidance was instrumental in the success of the project.

Thank you to All Metal Manufacturing for fabricating the aluminum linkages.

Our photo gallery

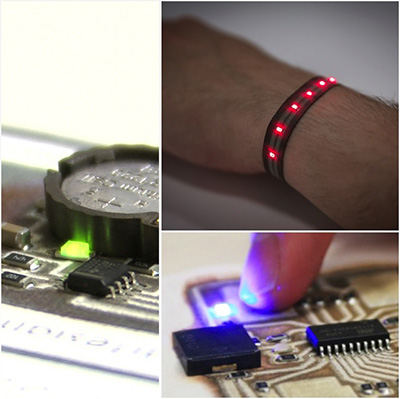

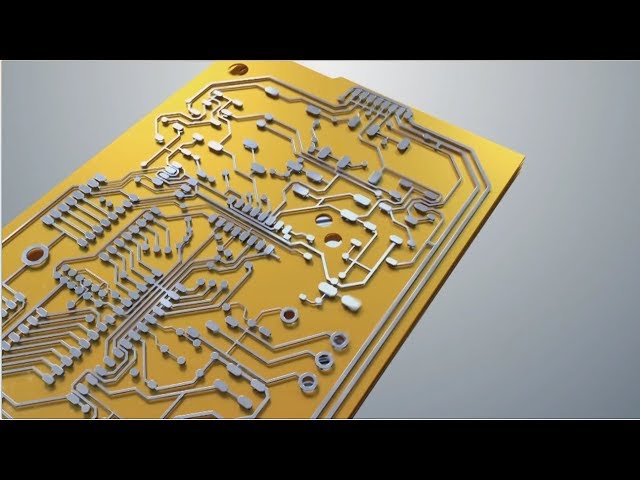

Printed circuit boards using a photopolymer 3D printer / Sudo Null IT News And in the last year or two, thanks to a strong reduction in cost, their photopolymer subspecies is also flourishing. Now such a printer is already available to almost everyone, and the number of their models on the market is multiplying every month.

Even when I just learned about the appearance of a new type of photopolymer printers a few years ago - in which the image of the layer for illumination is formed by an LCD, the thought flashed through me already then: "Hmm, what if we substitute a photoresist on a textolite?". But then it was a purely theoretical question - the prices for them were considerable, and the resolution and display area left much to be desired. However, today these printers can already boast of a decent resolution - from 30 microns per pixel, and a completely normal display area.

However, today these printers can already boast of a decent resolution - from 30 microns per pixel, and a completely normal display area.

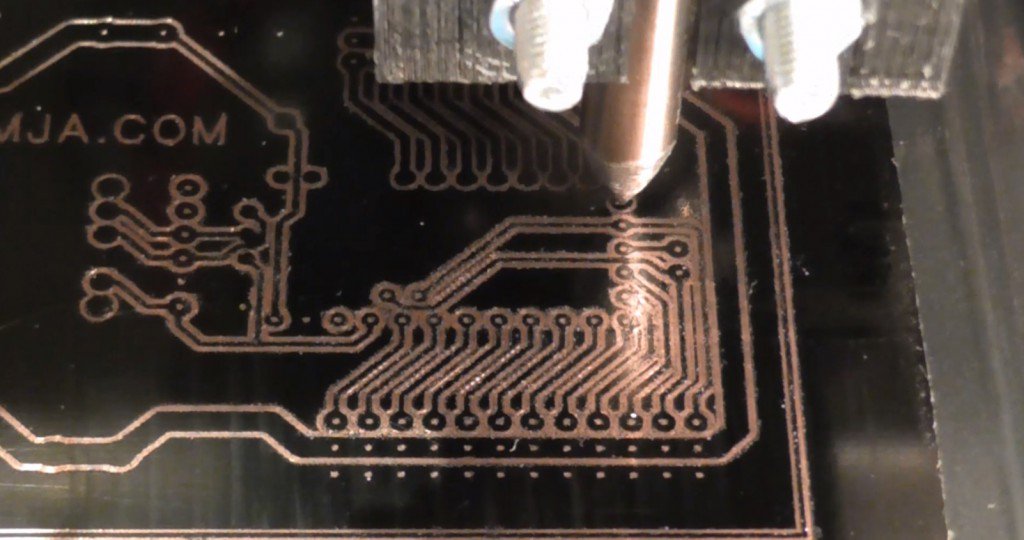

And as it turned out, with the help of an inexpensive modern photopolymer printer, it is quite possible to make boards with tracks / gaps from 0.15 mm.

I apologize in advance for such a voluminous graphomaniac, I myself did not expect that the note would get so fat...

I foresee the question "But why? In China, they will make normal boards with a mask and silk-screen printing for a penny!" I answer: now, most likely, there will be several iterations of finishing the board to a satisfactory state. I made a board - tested it - made corrections. And so several times. Waiting every time for 2-3 weeks from China is not an option :) But when the final design of the board is determined - then, of course, normal production in China or on Rezonit.

Now let's get down to business.

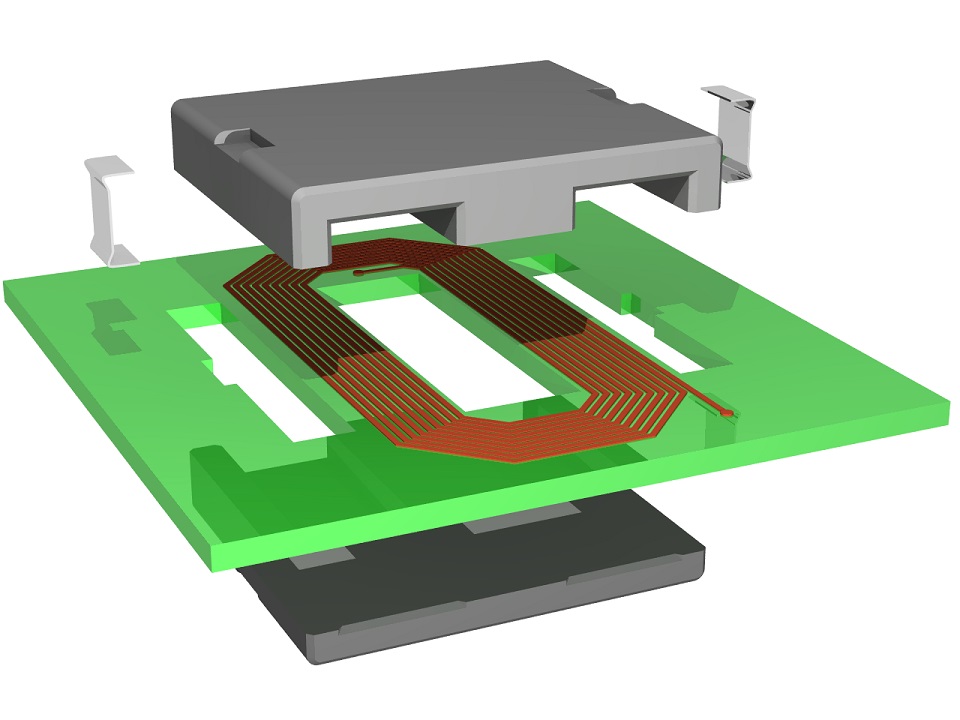

Who does not know - here is a brief principle of operation of such a printer The main part of such a printer is an LCD display. Below this display is a 405 nm UV source. Above the display is a bath of photopolymer, which has a thin transparent FEP film as a bottom. A platform is lowered into the bath, on which the model is “grown”. At the beginning of printing, the platform lowers to the height of one layer from the film, the image of the first layer is displayed on the display, and UV illumination is turned on for a specified time. Illumination, getting through the "open" pixels of the display and the film onto the photopolymer, hardens it, so a hardened layer is obtained. The first layer sticks to the platform. Then the illumination is turned off, the platform rises to the height of the next layer, the image of this layer is displayed on the display, and the illumination is turned on. The second layer is cured by welding with the previous layer. And this is repeated over and over until the entire model is printed.

Below this display is a 405 nm UV source. Above the display is a bath of photopolymer, which has a thin transparent FEP film as a bottom. A platform is lowered into the bath, on which the model is “grown”. At the beginning of printing, the platform lowers to the height of one layer from the film, the image of the first layer is displayed on the display, and UV illumination is turned on for a specified time. Illumination, getting through the "open" pixels of the display and the film onto the photopolymer, hardens it, so a hardened layer is obtained. The first layer sticks to the platform. Then the illumination is turned off, the platform rises to the height of the next layer, the image of this layer is displayed on the display, and the illumination is turned on. The second layer is cured by welding with the previous layer. And this is repeated over and over until the entire model is printed.

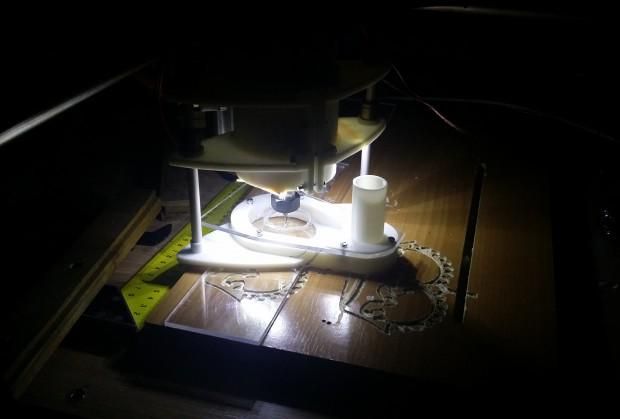

The idea to try to make a printed circuit board using such a printer came to me again about three years ago, when I bought myself an Anycubic Photon S printer. , then I just forgot about this idea, because and there was no need to make boards. But the other day, the need arose for the manufacture of several small boards, and with a high probability that as tests are made, changes will be made to these boards and it will be necessary to go through several iterations of "manufactured-checked-changed" in a short time. And the idea resurfaced.

, then I just forgot about this idea, because and there was no need to make boards. But the other day, the need arose for the manufacture of several small boards, and with a high probability that as tests are made, changes will be made to these boards and it will be necessary to go through several iterations of "manufactured-checked-changed" in a short time. And the idea resurfaced.

To be honest, I thought that by now the Internet would be filled with the results of such experiments, the idea lies on the surface :) But to my surprise I found that the Internet is almost completely silent on this issue. There are separate notes, but there is no integrity and completeness in them. That's why I decided to publish this post - maybe it will help someone go all the way faster than me, and with less rakes :)

Well, the most important thing is that you don't need film and you don't have to struggle with increasing the contrast of the template. You also do not need a separate UV source with a place for its installation. And, of course, it is stylish, fashionable, youthful.

And, of course, it is stylish, fashionable, youthful.

There are also disadvantages - the resolution of most modern 3D printers still does not cause much enthusiasm yet - the pixel size of all fluctuates around 0.05 mm. But this is already enough for confident manufacturing of boards with tracks from 0.2 mm and rather high chances of success with tracks from 0.15 mm. Due to the raster nature of such a template output, the position and size of elements on it can vary + -1 pixel, so I think it’s not even worth counting on tracks of 0.1 mm or less.

Let's go in order.

Task

It is necessary to make a printed circuit board at home using photoresist. Instead of templates and illumination lamps, use a photopolymer 3D printer that will serve both at the same time.

Let's divide the problem into separate steps-solutions for each moment.

-

Board development

-

Outputting layers in a printer-friendly format

-

Preparation of textolite with photoresist

-

Printer flare

-

Photoresist development, board etching

1.

PCB development

PCB development Well, there are no questions. Whoever prefers to work in what program - in that one makes boards. The main thing is that the program should be able to display the result in some commonly used form. The easiest way I've come up with is outputting board layers to gerber files that can be fed to an online service. But you can also output to PDF or images.

2. Converting the CAD output to a printer friendly

This is where the trouble begins. If almost all CADs can output to generally accepted formats - gerberas, DXF, printing to PDF, then 3D printer manufacturers so far categorically refuse to accept any file standard. Everyone is perverted as they can. The situation is largely saved by the fact that many manufacturers use motherboards from one Chinese company, Chitu Systems, in their printers. Thanks to this, many printers on such boards are able to understand one of the basic formats developed by the same company. And even often, if a file has some unique extension, then in fact it has the same basic format, just with a different extension. But it may differ in some details.

But it may differ in some details.

In any case, there is a free UVtools utility known among photopolymerists that can open files in one format and convert them to another format. It understands almost all formats on the market :)

I have tried two ways of preparing files with layers for the printer and I will describe both.

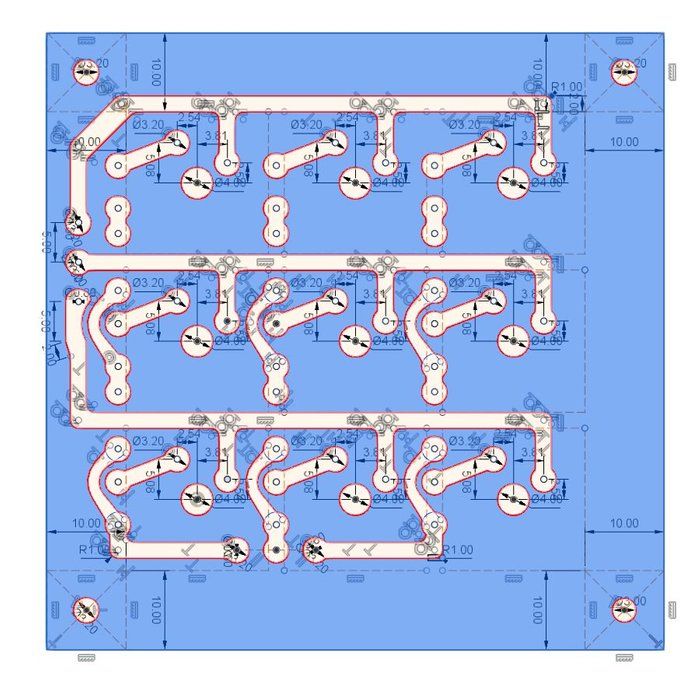

2.1 Gerber output and conversion to .photon

The .photon file format is understood by the old Anycubic printers - Photon and Photon S. This is exactly the case when the printer manufacturer took the format from Chitu and changed its extension. In the original, this is the Chituvian .cbddlp format, so you can safely change the extensions of these file types among themselves and the printers will devour them like native ones.

Since I have a printer that understands this format, this method suited me perfectly. The limitations of this method are that the printer must understand .photon or .cbddlp files and have a standard display for most non-monochrome printers with a resolution of 2560x1440 and a diagonal of 5. 5". manuals on how to do this for any CAD that can, in principle, mirror layers or not - it makes no difference, they can be mirrored in the utility during the conversion process.0003

5". manuals on how to do this for any CAD that can, in principle, mirror layers or not - it makes no difference, they can be mirrored in the utility during the conversion process.0003

Now open the online utility for converting gerber files - https://pcbprint.online/ and load the gerberas into it. By the way, this is a utility from a Russian developer who lives here.

It is easy to understand, although it does not contain any information or help. But here is a short guide:

For a single-sided boardUpload your gerbera in the main window with the "Upload file" button:

We made sure that everything is fine and the image meets expectations, if necessary, make a negative or mirror the image with the buttons in the top center, and press the button " Render layout":

Now press "Lauout" at the top right and get into another screen:

Here you first need to go to the settings (gear button at the top right) and there select the format of the output file "photon":

The time in "Exposition" can be left at default and change it to the desired one directly in the printer. But you can immediately put the right one if its value is already known :)

But you can immediately put the right one if its value is already known :)

Close the settings and return to the previous screen. Here the output image is on a black space showing the working field of the printer. The image can be moved, aligned. When everything suits, we first press "Render", and when the "Download result" button next to it becomes active, we also press it. And save the proposed .photon file to a convenient location on your computer :)

For double-sided boards, things are a little more complicated due to the need to match them. Therefore, it is necessary to know very exactly the position of the image displayed on the printer's display in order to place the board on the display very accurately in accordance with it.

I had several options for solving this issue, but in the end I decided on the simplest of them, which did not require any mechanical conductors. To do this, I still in CAD in a separate layer (it is possible in the border layer or in any other "unnecessary" layer) I draw a frame around the board with a line of 0. 15 mm and indented from the edges of the board by 0.25 mm. As a result, I get three gerberas - the top layer, the bottom layer and a separate empty frame.

15 mm and indented from the edges of the board by 0.25 mm. As a result, I get three gerberas - the top layer, the bottom layer and a separate empty frame.

I upload all three gerberas to the above site and then in a few steps I get three files for the printer.

Double-sided board in pcbprint.online/So, all three gerberas have been loaded. All of them are mixed together, but it's not scary:

Now hide the top and bottom layers, leaving only the frame (by clicking on the eyes in the names of the gerberas).

Click "Render layout" and go to the "Layout" screen with the button in the upper right corner. We see an empty frame, drag it to the desired position on the black field of the display, click "Render" and "Download". The first file for the printer is ready.

Switch back to the gerber screen with the "PCB comose" button. Redisplay the first layer (the frame layer still remains visible), mirror if necessary, and click "Render layout" again. Again we go to the output screen and now there are two pictures hanging on the display field - a separate frame and the first layer with a frame. The frame remained in the same place where we pulled it last time. And now our task is to exactly combine the frame of the first layer and the empty frame:

The frame remained in the same place where we pulled it last time. And now our task is to exactly combine the frame of the first layer and the empty frame:

Click "Increase" and combine in one of the corners. In this case, in no case should you move the empty frame that we set in the last step!

Combined, click "Render" and "Download", and we have a second file for the printer. Before returning to the gerbera screen, we delete the render layer with the frame, we should again have an empty frame. And now we return to the gerberas, hide the first layer and display the second one, look at the need to mirror, click "Render layout" and go to this screen again. In the same way, we combine the layer frame with an empty frame (which cannot be moved!), then "Render" and "Download".

Everything, all three necessary files for the printer are ready.

All this hemorrhoids allows you to generate for the printer files of an empty frame and layers with a frame in the same place on the printer display with high accuracy. The empty frame serves to aim the board, more on that below.

The empty frame serves to aim the board, more on that below.

If necessary, the resulting .photon files can be converted to the desired format using UVtools :)

2.2 Output layers to PDF or images

The second method is perhaps more confusing, but its great advantage is versatility, it is suitable for any printers, whose formats are supported by UVtools. I will describe it only in general terms, because. There are quite a lot of tools and specific ways to implement it, and everyone can choose them according to their preferences.

So, the goal of the first step is to get a picture with a size equal to the resolution of the printer's display, preferably in a lossless compression format. In this case, the image of the layer in the picture must correspond to the real size in the scale of the display.

If CAD allows you to output directly to the picture - great, output to it. If the resolution of the output image is configurable - specify the resolution of the printer display. It is elementary to calculate it - we divide the number of pixels across the width of the display by the width of the working area in mm and multiply the result by 25.4, we get the resolution in pixels per inch. If the resolution is not set, then set the image size as large as possible so that there are at least 15-20 pixels per 1 mm of the board.

It is elementary to calculate it - we divide the number of pixels across the width of the display by the width of the working area in mm and multiply the result by 25.4, we get the resolution in pixels per inch. If the resolution is not set, then set the image size as large as possible so that there are at least 15-20 pixels per 1 mm of the board.

If output to image in CAD is not available, then output to PDF. This PDF will need to be opened in another program and converted to an image. Photoshop, Corel, maybe other programs can do this... The requirements for image resolution are the same. For example, in Photoshop, when importing a PDF, you can immediately specify with what resolution to convert to an image. For example, for common displays with a resolution of 2560x1440 and a diagonal of 5.5 "the resolution is approximately 537.566 PPI (pixel size - 0.04725 mm).

The resulting image will need to be changed in some image editor, bringing its size to the resolution of the printer's display. In this case, the layer image must be scaled to the real one (taking into account the pixel size of the printer display) or saved without scaling if the PPI of the display was specified when importing the image.

In this case, the layer image must be scaled to the real one (taking into account the pixel size of the printer display) or saved without scaling if the PPI of the display was specified when importing the image.

UPD: in the comments @0x3f00 gave a link to his converter of PNG images to files for the .photon printer - https://github.com/0x3f00/PhotonCpp/releases/tag/v1.0.0 . There is also an instruction for using it just for the purpose of manufacturing boards - https://github.com/borelg/PhotonPCB.

2.3 There is another way, but it is very resource-intensive

You can output layers to PDF, then open this PDF in Corel, convert it, save it in DXF, extract a three-dimensional object from this DXF, which you can push into the printer's slicer.

Necessary transformations in the vector editor:

-

Connect all curves.

-

Convert outlines to objects.

-

Merge intersecting objects.

You can extract a three-dimensional object from DXF, for example, SolidWorks. Fusion360 also seems to be able to. Who else is capable of this - I honestly don't know, but in theory any CAD that can import DXF as a sketch.

Fusion360 also seems to be able to. Who else is capable of this - I honestly don't know, but in theory any CAD that can import DXF as a sketch.

Thus, for example, I made a model for determining the exposure time of the photoresist.

3. Preparation of textolite with photoresist

The Internet is simply littered with articles on this topic, but for the sake of integrity and for the sake of some specific points, I will also describe such well-known stages as the preparation and etching of textolite.

My first experience with such a fabrication was a couple of days ago with a domestic photoresist PF-VShch. Taking into account the last yesterday's experience, I categorically advise not to waste time on this photoresist, but immediately take a decent one - Ordyl Alpha 350(330) :) They say that Kolon is also decent, but I have not tried it. With Ordyl photoresist, the results are much more stable and accurate, it is easier to develop and adheres much better to the foil. And he can forgive those mistakes that will be critical for the PF-VSC. And what is important - it is sold in a bunch of places quite inexpensively.

And he can forgive those mistakes that will be critical for the PF-VSC. And what is important - it is sold in a bunch of places quite inexpensively.

3.1 Preparing the textolite

To begin with, the textolite should be smooth, very preferably with a smooth foil without scratches or dents. Otherwise, the chances of success are reduced.

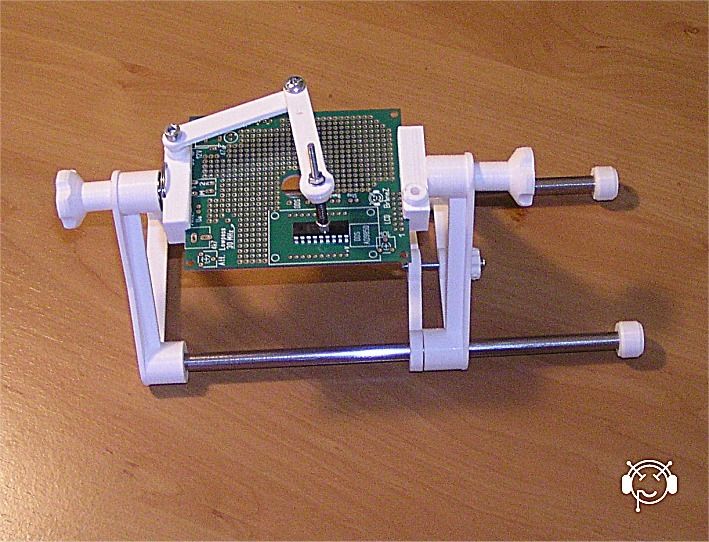

If a double-sided board is being made, then you need to immediately cut the board out of the PCB exactly to size. If there is any CNC router, then you can drill all the holes and cut along the contour in one installation, as I do. If not, then it is better to leave the drilling for later, when the board is etched.

After this, the textolite blank must be very carefully cleaned and degreased. This can be done with a kitchen abrasive sponge (but not used for washing dishes on which fats have already accumulated) and a scouring powder like Pemolux. Very carefully, slowly three every square millimeter of foil, without touching it with your fingers. In general, I categorically do not advise touching the foil with your fingers after the start of cleaning, there should not be the slightest even the faintest greasy spot on it. After cleaning, rinse thoroughly in running water, shake off excess water and allow to dry. I do not advise blotting or wiping with anything, because. grease can be applied, even from a new napkin.

In general, I categorically do not advise touching the foil with your fingers after the start of cleaning, there should not be the slightest even the faintest greasy spot on it. After cleaning, rinse thoroughly in running water, shake off excess water and allow to dry. I do not advise blotting or wiping with anything, because. grease can be applied, even from a new napkin.

3.2 Application of photoresist

Also a fairly common topic on the Internet, so I'll go over it briefly.

Photoresist usually comes in sheets or rolls. It consists of three layers - two protective films and the photoresist itself between them. A piece is cut off from the photoresist according to the size of the board + 5 mm in length and width, then a matte (polyethylene) protective film is removed from it.

the second, glossy (lavsan) must remain on it until the etching stage.

The easiest way to remove the film is with a piece of tape. It is glued with its edge to the corner of the photoresist and then folded back, pulling the protective film along with it.

After removing the matt film, the photoresist is applied to the edge of the board and smoothed along this edge with a finger. The rest of the photoresist is supported by weight, without tension, but in such a way that as little as possible of its area lies on the foil.

Please note that if the Ordyl photoresist falls on a well-prepared textolite, then it can firmly stick to it, and without bubbles it can no longer be rolled. You have to scrape it off and do it all over again. And PF-VShch can fall as much as you like - it definitely won't stick :)

Now the knurling itself. If you have a laminator, in which the textolite will crawl through the thickness, then it's just wonderful. We make an envelope-type strip of paper folded in half, put a textolite with a sticky edge of the photoresist in it, and serve this sandwich into a laminator heated to 100-110 degrees. At the same time, we continue to hold the photoresist so that it comes into contact with the textolite foil only directly at the inlet of the laminator.

That's all for Ordyl, for PF-VShch it will be harmless to roll a couple more times.

If there is no laminator, then smooth the photoresist to the textolite with your finger from edge to edge, gradually lowering it onto the textolite. The main thing is not to catch the bubbles. After all the photoresist lay on the foil, we take a hair dryer and heat the textolite to 70 degrees, after which we iron the entire photoresist once again.

After knurling, let the textolite with photoresist lie down for 15-20 minutes, or at least until they cool down to room temperature - according to the recommendation of the photoresist manufacturer.

And now everything is ready to highlight the layer pattern :)

4. Printer highlights

I want to warn you right away: looking directly into the glowing display of a photopolymer printer may not be very good for the eyes. Although not true UV (405 nm), the brightness is quite noticeable and can be harmful to the eyes. Therefore, I recommend using colored or tinted goggles. I think even sunscreen will do.

Therefore, I recommend using colored or tinted goggles. I think even sunscreen will do.

First, you need to remove the bath and platform from the printer, they are completely unnecessary for this business and even interfere. This completes the preparation of the printer :)

Lighting also has different options. If you have a one-sided board and the blank is larger than the size required for the board, then everything is simple - throw the file obtained at the preparation stage into the printer and, knowing the approximate place for displaying the image on the display, put a textolite with photoresist in this place. Then start printing the file and wait until it is completed. Everything, the photoresist is exposed, it is possible to develop.

If the workpiece is equal in size to the board being made and the error with the position of the workpiece on the display is unacceptable, then in this case it is necessary to remove the frame during preparation, as is the case for a double-sided board. Illumination also occurs using a frame, similar to a double-sided board, only without the second side and the second layer.

Illumination also occurs using a frame, similar to a double-sided board, only without the second side and the second layer.

So, the illumination of the double-sided board. We throw all three files into the printer - with a frame, with the first layer and with the second layer. We put the workpiece next to the printer in quick accessibility. If it is already pre-drilled, it will be useful to make sure that it lies in the correct position so that you can quickly take it and immediately put it on the display. To do this, we run a file with a layer planned for exposure, and compare the layer pattern on the display and the orientation of the board next to the printer.

Printing a file with one frame. As soon as the frame lights up on the printer display, we take the workpiece and put it approximately inside the frame. While the frame is being illuminated, we align the workpiece so that it is exactly in the frame, with the same indentation of the frame from the edges of the workpiece on all sides.

In the photo, I gave an example with a ready-made board, because I did not take pictures during the manufacturing process. Well, reflections interfere quite strongly, alas... But I think it's understandable :)

That's it, the position of the workpiece is verified, printing of the frame file can be interrupted or wait for it to finish. Without moving the workpiece, run the file with the first layer and wait for it to finish. We illuminate the second layer (the second side) in the same way - we launch the frame, place and align the workpiece, without moving it, we launch the second layer. Before this, just in case, you can make sure that the workpiece will lie in the correct orientation, as before the first layer.

If the workpiece is not completely flat and does not fit the entire area of the display, then you can press it down from above with some heavy flat piece of iron. You just need to make sure that this piece of iron does not interfere with the platform lever, which will go down with the start of printing - the printer thinks that this is a normal photopolymer print and you need to lower the platform to the bottom of the bath :)

Illumination time can be different from printer to printer . It depends on the power of the emitter, and on the optical illumination system, and on what type of display is worth - monochrome or RGB. Here already it is necessary to select each individually. For orientation, I can say that I got the best result with the Ordyl photoresist at an exposure time of about 90-110 seconds. With photoresist PF-VShch - about 10-13 minutes. Printer with paraled, illumination power slightly less than 50 watts.

It depends on the power of the emitter, and on the optical illumination system, and on what type of display is worth - monochrome or RGB. Here already it is necessary to select each individually. For orientation, I can say that I got the best result with the Ordyl photoresist at an exposure time of about 90-110 seconds. With photoresist PF-VShch - about 10-13 minutes. Printer with paraled, illumination power slightly less than 50 watts.

After exposure, the workpiece should be allowed to rest for 15 minutes - this is according to the recommendation of the photoresist manufacturer. Ordyl changes the color of the highlights quite noticeably, so it's pretty easy to control the highlights. Unfortunately, the photo did not convey it well, it can be seen better with the eyes.

5. Development, etching

Everything here is according to the recommendation of the photoresist manufacturer and according to the classics of the Internet.

All necessary chemicals were purchased inexpensively from Auchan. Even hydrogen peroxide 6% - this was a surprise for me, I had never seen it in hypermarkets before, and even in liter bottles.

Even hydrogen peroxide 6% - this was a surprise for me, I had never seen it in hypermarkets before, and even in liter bottles.

For one session you need:

-

Soda ash - 1.5 grams

-

Hydrogen peroxide - 150 ml for 3% (or 75 ml for 6% + 75 ml of water)

- citric acid

-

Salt - 7.5 grams

-

Alkali (caustic soda, sodium hydroxide) 5-7% - 100 ml

With the cheapness and ease of buying all the components around the corner, I am in favor of preparing a new solution for each board. Although the etching solution, as they say, is not stored anyway. A solution of soda ash noticeably "poorer" in the process of development. Unless caustic soda can be reused, but is it worth it to keep another bottle ...

Both Ordyl and PF-VSH appear in a weak solution of soda ash. For PF-VShch - 1-2%, for Ordyl - 0.8-1.2%. For Ordyl, we take 150 ml of water and dilute 1.5 grams of soda in it. The solution can be heated up to 30 degrees, this will speed up the development, but it is important not to overdo it, otherwise the illuminated areas may begin to be damaged.

Ordyl appears rather quickly. Already after 10-15 seconds, the illuminated pattern begins to become more and more contrasty, the unexposed areas gradually dissolve, become thinner and become paler.

To speed up the process, it is recommended to shake the bath so that the reaction products are washed off the surface of the workpiece. For this I adapted my old 3D printer, its table and shook and heated the bath with the solution during development and etching :) Two minutes passed before there were at least some signs that development had begun. In addition, if Ordyl does dissolve, then PF-VShch first swelled like gelatin and discolored, and only then began to slowly dissolve.

At the end of development, you can go over the boards with a hard paintbrush (or soft toothbrush) several times in different directions to help flush out any remaining photoresist from tight spots. Ordyl holds on tight, this procedure should not disrupt it, but with PF-VShch you need to be very gentle, even without a brush it strives to exfoliate on thin paths.

After etching, the workpiece must be rinsed in cold water so that the soda residues do not continue to attack the photoresist and so as not to clog the etching solution with them.

The result should be something like this, maybe even better :)

More detailsScale of the grid square - 0.2 mm:

The scale is the same. Here you can see the raster component of the illumination, the pixels stick out:

Etching was also done according to the traditional recipe, popular on the net:

It is better to heat the solution to 40-50 degrees, then the etching goes much faster. This is my first experience with this solution. I used to poison with ammonium perchlorate, and even earlier - with classic ferric chloride. To be honest, I can't really express how I feel about this solution. On the one hand, it poisons rather quickly, is transparent, does not get dirty, and is relatively safe. On the other hand, it seemed to me that it was easing quite a lot ... But maybe it just seemed, I haven’t been making boards for 10 years and I forgot how it all worked when the trees were big :)

After etching, the exposed photoresist must be removed from the workpiece, and this is done in caustic soda.

On my bottle of cleaner it says "at least 5% but not more than 15%" and it takes 5-8% to remove the photoresist. I diluted the product 1:1 with water and this solution did the job perfectly. The photoresist does not dissolve in it, it simply peels off the foil after 2-3 minutes and begins to float in tatters in the solution.

On my bottle of cleaner it says "at least 5% but not more than 15%" and it takes 5-8% to remove the photoresist. I diluted the product 1:1 with water and this solution did the job perfectly. The photoresist does not dissolve in it, it simply peels off the foil after 2-3 minutes and begins to float in tatters in the solution. After that, the board is thoroughly rinsed under the tap and... The board is ready!

Summary of my experience

Overall I am satisfied. I did not expect to get tracks / gaps of 0.1 mm and I did not get them. Here, the capabilities of the printer are severely limited (pixel size), and in general, good experience is needed for such results. But I was hoping to get at least 0.2 mm, and if I'm lucky, then 0.15 mm - and I got it. 0.2 mm confidently, 0.15 mm - well, so-so... If you try, you can achieve :)

There were some flaws - it was not pickled in some areas, and imperfect alignment of layers and holes. But neither is critical. As for the non-mordant - I think that I just hurried to take it out of the developer, I was afraid after PF-VShch that thin paths would begin to peel off.

Although in the reviews people write that it is quite difficult to re-develop this Ordyl, you need to try for this. Imperfect alignment of layers and holes is to be expected. From such a simple method of alignment, I expected an error of 0.1-0.2 mm, which I got, but it suits me.

Although in the reviews people write that it is quite difficult to re-develop this Ordyl, you need to try for this. Imperfect alignment of layers and holes is to be expected. From such a simple method of alignment, I expected an error of 0.1-0.2 mm, which I got, but it suits me. Thank you for reading.

And finally, a few photos of my results. Exposure time test, from 1 to 2 minutes. You can see the areas that are offset relative to the holes. 3D Printing Dremel・CultsPaint mixer Timbertech

0.62 €

Versatip stand insert for original Dremel case

Free

Soporte CNC Mototool TITAN

Free

Base for dremel3000

0.96 €

Universal Filament Filter

Free

dremel bench

2.

79 €

79 € Mini PCB Drill Press - M8 Rod Version

Free

My Dremel Organizer

Free

Dremel 3000 CNC Mount

Free

dremel drywall nozzle

Free

Protector dremel 3000

0,50 €

Cordless Dremel Clip Mount

Free

Dremel Modular Tool Stand

Free

Small dremel tool holder

Free

Dremel 9 Angle Adjustable Table Saw0030

Free

3D Printing CNC DIY - Dremel CNC Remix

Free

Dremel Mount for Bear Upgrade / Prusa MK3

Free

Dremel Small CNC PCB Mount

Free

Dremel Ball Sander

Free

Dremel depth gauge

2 €

Dremel

Chainsaw ManualFree

Dremel Holder

Free

Dust collector for CNC Dremel "CLIP ON

Free

Magnetic vice

1 €

PROXXON IBS/E Precision handle

Free

Dremel cutting discs with spark arresters

4,99 €

Boquilla Dremel 2.

35mm

35mm Free

Dremel Nail Board Mount

Free

Dremel Drill Press (Remix)

Free

Mini Lathe Stand - (Black And Decker, Dremel)

1.67 €

Vacuum sanding dust extractor

Free

Paint mixer attachment

Free

Dremel Flexible Shaft for Lathe

Free

Large and medium mills

0.96 €

MaduixaCNC Dremel tool holder

Free

dremel table

Free

Dremel Bit Holder - Holder

1 €

adapter dremel 3d20

0,56 €

Organizer for mini coffee grinder (coffee grinder)

Free

Dremel 8220 Screw adapter

Free

multifunctional blade that is suitable mainly for dremel

Free

dremel_skadis_ikea_holder

Free

MINI DRILL

2.

Learn more