Voltes v 3d print

Free STL file Voltes V

Mecha King Kong

€17.40

ARTICULATED DRAGONLORD (not Dragonzord) - NO SUPPORT

€17.40

Transformable Valkrii

€19.90

Jinbao Not Bruticus Upgrade Kit G1 Ver

€3.88

Deathpunch (Not Mazinger Z)

€17.40

ARTICULATED SPACE DEFENDER (Not Astro Megazord) - NO SUPPORT

€17.40

Guardian Angel

€22.40

KO TFC Uranos Upgrade Kit IDW Ver

€3.86

Best 3D printer files of the Game category

Pumpkin Halloween Without Stands

€1. 20

RC Bat Plane Quadcopter

Free

The Commander

Free

Snowball making terminal device

Free

Drinking trough Playmobil toy horse

Free

Armored Articulated Dragon

€2.87

Simple Toy Robot Arm 5DoF

Free

Geared Star

€4.50

Best sellers of the category Game

Beaky Boyz Builder: PF_MK-Six

€11.86

Nintendo Switch Crystal Dock - Classic and OLED version

€3.13

FLEXIBLE CHRISTMAS SNOWMAN

€2.60

Lion Foo

€5. 50

50

Snake and Rattlesnake

€3.79

Chopper Motorcycle Print-In-Place

€1

RC 1/10 Dodge Challenger

€7.50

Enourmous Imperial Heavy Tank

€10

Derelict damaged space ship compatible kill team into the dark or boarding action games

€13.92 -50% €6.96

SM Healer Conversion Kit

€6

Fotiann Wildmen

€9.49

Catafrac Heavy Armoured Warriors - Limbs Pack

€1.85

Voidwalker Exosuits Truescale

€14. 84

84

Jarl

€6.64

Flexi Flying Unicorn

€1.77

CRAMER Truggy RC 4x4 Full 3D Printed

€7.50

Would you like to support Cults?

You like Cults and you want to help us continue the adventure independently? Please note that we are a small team of 3 people, therefore it is very simple to support us to maintain the activity and create future developments. Here are 4 solutions accessible to all:

ADVERTISING: Disable your AdBlock banner blocker and click on our banner ads.

AFFILIATION: Make your purchases online by clicking on our affiliate links here Amazon.

DONATE: If you want, you can make a donation via PayPal.

WORD OF MOUTH: Invite your friends to come, discover the platform and the magnificent 3D files shared by the community!

3D file Voltes V - MaxLab Version・3D printer model to download・Cults

Mospeada MaxLab Cyclone

€9. 49

49

VF-1 Super Veritech ( Macross - Robotech )

€22.19

Legioss - Robotech Alpha - MaxLab Version

€9.49

Gerwalk VF-1S - Macross Robotech Static Figure

€5.97

Interceptor MVT12 - MaxLab

€7.59

Optimus Prime Orenstein Memory ( with Trailer )

€17.09

Grendizer - Goldrake - MaxLab Version

€9.49

SoundWave - MaxLab Version

€9.49

Best 3D printer files of the Game category

Gloomhaven Captain of the Guard

Free

New Chess Piece is a Game Changer - Introducing the 'Earl'

Free

SnowMan Angry/Happy!

€3. 60

60

warzone logo

€0.70

Playmobil Pirates Chest

Free

Retro Sci-fi Rocket

Free

Support for Nintendo Game Boy Color

€1.45

Best sellers of the category Game

Catafrac Heavy Armoured Warriors - Civil War Wargear Pack

€2.50

Flexi Flying Unicorn

€1.77

Enourmous Imperial Heavy Tank

€10

NEKHRON LOKHUST DESTROYERS

€3

Derelict damaged space ship compatible kill team into the dark or boarding action games

€13.92 -50% €6. 96

96

Voidwalker Exosuits Truescale

€14.84

Nice Flexi Dragon

€1.77

Beaky Boyz Builder: PF_MK-Six

€11.86

Jarl

€6.64

Articulated Snowman

€2.84

Octopus 2.0

€3.79

Dirt Bike

€1.40

RC 1/10 Dodge Challenger

€7.50

Catafrac Heavy Armoured Warriors - Limbs Pack

€1.85

USS EnterSurprise - Print-in-place Playset Container for Tiny F14 Jet Fighters

€3.79

FLEXIBLE CHRISTMAS SNOWMAN

€2. 60

60

Would you like to support Cults?

You like Cults and you want to help us continue the adventure independently? Please note that we are a small team of 3 people, therefore it is very simple to support us to maintain the activity and create future developments. Here are 4 solutions accessible to all:

ADVERTISING: Disable your AdBlock banner blocker and click on our banner ads.

AFFILIATION: Make your purchases online by clicking on our affiliate links here Amazon.

DONATE: If you want, you can make a donation via PayPal.

WORD OF MOUTH: Invite your friends to come, discover the platform and the magnificent 3D files shared by the community!

Medical 3D printer overview

Use of 3D printing in medicine

Source: docwirenews. com

com

3D printing has been used in medicine since the early 2000s, when this technology was first used to make dental implants. Since then, the use of 3D printing in medicine has expanded significantly, with doctors around the world describing ways to use 3D printing to produce ears, skeletal parts, airways, jawbones, eye parts, cell cultures, stem cells, blood vessels and vasculature, tissues and organs, new dosage forms and much more.

Source: zortrax.com

Using files with models for 3D printing provides an opportunity for the exchange of work among researchers. Instead of trying to reproduce the parameters described in scientific journals, doctors can use and modify ready-made 3D models. To this end, in 2014, the National Institutes of Health established the 3dprint.nih.gov exchange to facilitate the exchange of open source 3D models for medical and anatomical devices, custom equipment, and mock-ups of proteins, viruses, and bacteria.

Source: 3dprint.com

Modern medical use of 3D printing can be divided into several broad categories: tissue and organ fabrication, prostheses, implants and anatomical models, instrument printing, and pharmaceutical research.

Top five uses for 3D printing in medicine

Operational preparation and student education

Source: 3dprint.com

Taking into account individual differences and features of the anatomy of a particular human body, 3D printed models can be used to prepare surgical operations. Having a doctor have a tangible model of a particular patient's organ, made, for example, based on the results of CT (computed tomography) for study or to simulate an operation, significantly reduces the risk of medical errors.

Source: openbiomedical.org

The use of 3D models for training surgeons and students is preferable to training on cadavers, as it does not create problems in terms of availability and cost of objects. Cadavers often lack appropriate pathology, so they are more suitable for anatomy lessons than for presenting a patient with a disorder appropriate to the topic under study. With the help of 3D printing, it is possible to create a model of any organ with any known pathology.

Source: ncbi.nlm.nih.gov

two-dimensional images.

Bioprinting of tissues and organs

Source: hbr.org

Bioprinting is one of the many types of 3D printing used in the medical field. Instead of printing using plastic or metal, bioprinters use a syringe dispenser to apply bioink (layers of living cells or a structuring base for them) to create artificial living tissue. In addition to being used as an alternative to donor tissues, such tissue constructs or organoids can be used for medical research.

In addition to being used as an alternative to donor tissues, such tissue constructs or organoids can be used for medical research.

Source: press.ginkgo3d.com

Although 3D bioprinting systems can be laser, inkjet, or extrusion, inkjet bioprinting is the most common. Multiple printheads can be used to accommodate different types of cells (organ-specific, blood vessel cells, muscle tissue), which is a major challenge in the fabrication of heterocellular tissues and organs. 3D printing with biological materials can be used to regenerate tissues, and in the future, organs, directly on the patient.

Printing Surgical Instruments

Volt Grip Details, Source: bitegroup.nl

Today's surgeons are trying to perform operations with as little trauma to the patient as possible, so they very often require a personalized instrument. The use of 3D printing makes it possible to create such tools within hours.

The use of 3D printing makes it possible to create such tools within hours.

Volt capture model visualization, Source: bitegroup.nl

Now the doctor can independently modify the finished model, giving it the necessary size and shape for convenience and efficiency. Dentists can now create, for example, individual guides right in front of the patient, eliminating the possibility of damage to healthy teeth during prosthetics.

About the clamp Volt, from the photos above, read further in the section “Examples of use”.

Here's how students at Duke University in Durham, North Carolina create tools using metal 3D printing.

"Printing" drugs

Source: mdpi.com

3D printing technologies are already being used in pharmaceutical research and personalized medicine, and their scope is constantly expanding. 3D printing enables precise dose control of drugs and the production of dosage forms with complex drug release profiles and prolonged action. Now pharmacists can analyze a patient's pharmacogenetic profile and other characteristics such as age, weight, or gender to determine the optimal dose and sequence of medications. If necessary, the dose may be adjusted, depending on the clinical response. With 3D printing, it is possible to produce personalized medicines in completely new formulations, such as tablets containing multiple active ingredients, either as a single mixture or as complex multi-layered tablets.

3D printing enables precise dose control of drugs and the production of dosage forms with complex drug release profiles and prolonged action. Now pharmacists can analyze a patient's pharmacogenetic profile and other characteristics such as age, weight, or gender to determine the optimal dose and sequence of medications. If necessary, the dose may be adjusted, depending on the clinical response. With 3D printing, it is possible to produce personalized medicines in completely new formulations, such as tablets containing multiple active ingredients, either as a single mixture or as complex multi-layered tablets.

Prosthetics and Dentistry

Source: eos.info

3D printing has been successfully used in medicine for the manufacture of complex custom prostheses or surgical implants. Implants and prostheses of any possible geometry can be made by converting X-ray, MRI or CT images into a 3D printable model using special software.

The rapid production of custom implants and prostheses solves a pressing problem in orthopedics, where standard implants often do not fit the patient. This is also true in neurosurgery: skulls are individually shaped, so it is difficult to standardize a cranial implant. Previously, surgeons had to use various tools to modify and fit implants, sometimes right during the operation. The use of 3D printers makes this procedure unnecessary. Additive technologies are especially in demand when it is necessary to urgently manufacture implants.

A real revolution in dentistry came with the advent of 3D technology.

Source: hypowerfuel.com

First, complete and accurate 3D scanning of the oral cavity is now possible. Secondly, the use of 3D printing has made it possible to create prostheses that absolutely fit the anatomy of the patient, without the need for a long and unpleasant fit. The radical reduction in the share of manual labor in the manufacture of prostheses or veneers has reduced the required tolerances in production, expanded the list of materials used and increased patient satisfaction with the results of the doctor's work.

The radical reduction in the share of manual labor in the manufacture of prostheses or veneers has reduced the required tolerances in production, expanded the list of materials used and increased patient satisfaction with the results of the doctor's work.

Application examples

Printing a model of the heart of a four-year-old patient, Zortrax M200 3D printer

In the photo: the assembled heart model. Source: zortrax.com

At the Medical University of Gdansk (Poland) to prepare for an operation to treat a complex congenital heart disease (Fallot's tetrad - malfunction of the pulmonary artery heart valve) in a four-year-old patient, specialists from the Department of Pediatric Cardiology and Congenital Heart Diseases , together with colleagues from the Department of Cardiac Surgery and Radiology, used the Zortrax M200 3D printer.

Photo: artificial pulmonary valve. Source: zortrax.com

The modern method of treatment consists in inserting a catheter through the femoral vein, through which an artificial valve is fed to the heart for implantation. This is a very complex operation that requires the doctor to have detailed knowledge of the individual characteristics of the patient's anatomy.

In the photo: a model of the heart during printing. Source: zortrax.com

Until now, doctors could only rely on a 3D model on a computer screen created from CT and MRI images, and such a reconstruction is not always enough to get a complete picture of the real organ and possible complications .

Source: zortrax.com

Having a highly detailed tactile model of a patient's living organ in preparation for surgery can be critical to its success. Even experienced surgeons have appreciated the potential of the new technology. Previously, it was difficult to notice individual features and deformations, now it has become tangible and accessible for closer study.

Previously, it was difficult to notice individual features and deformations, now it has become tangible and accessible for closer study.

The model was printed within 24 hours. The Z-ULTRAT material was used to print the heart, and the Z-GLASS material was used to print the vessels. After a successful operation, the model was transferred to the University for student training.

Artificial corneas made on the Nano master SMP-III 3D bioprinter

Source: europepmc.org

In South Korea, about 2000 patients are waiting for corneal donation, and the waiting time for surgery is an average of six years. For patients who cannot find a suitable donor, it is possible to implant artificial corneas consisting of recombinant collagen and synthetic polymers. Unfortunately, they often do not take root and are not completely transparent. This is due to the special structure of the cornea in the form of lattice collagen fibrils, which has not yet been able to be reproduced. A team of researchers from Pohang University of Science and Technology and Kungpuk National University School of Medicine in South Korea have developed a method to 3D print an artificial cornea using patient tissue material.

A team of researchers from Pohang University of Science and Technology and Kungpuk National University School of Medicine in South Korea have developed a method to 3D print an artificial cornea using patient tissue material.

Source: ithl.co.kr

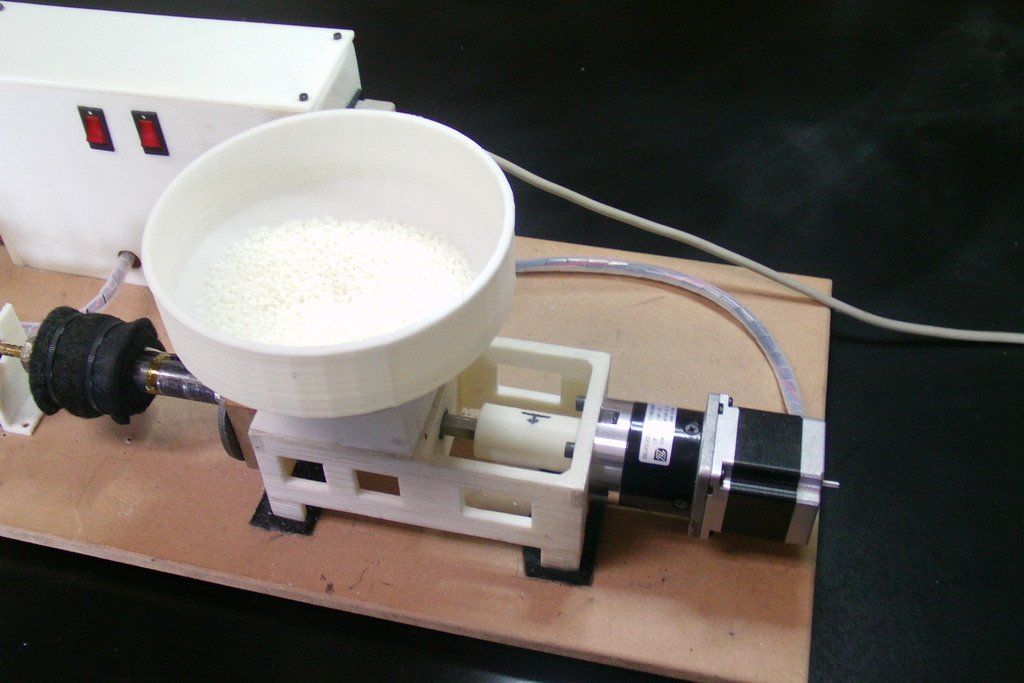

3D bioprinter with Nano master SMP-III microextrusion system, Musashi Engineering, Tokyo, Japan, with the following parameters:

-

print speed 130mm/min;

-

extrusion speed 0.0024 mm/s;

-

nozzle diameter 0.29 mm;

-

print temperature 4 °C.

The printed and biomaterial-filled cornea was then cultured in an incubator at 37 °C for four weeks.

Source: europepmc. org

org

A 3D-printed artificial cornea made from decellularized corneal stroma and patient stem cells can completely replace a donor cornea in eye surgery. Since such a cornea is made up of materials derived from the patient's own tissues, it is completely compatible. Cellular 3D printing technology replicates the natural microenvironment of the eye, resulting in transparency similar to that of the human cornea.

Pohang University of Science and Technology Professor Jina Jang said:

"We are confident that this technology will restore vision to many patients suffering from corneal diseases."

Wake Forest Institute for Regenerative Medicine, mobile 3D printer for treating extensive wounds

the place of the damaged. In addition to the fact that this method is additionally traumatic for the victim, in some cases there may not be any healthy skin left on the body for use. Wake Forest School of Medicine has developed a printer that can print skin cells grown from patient tissue directly onto a wound.

Wake Forest School of Medicine has developed a printer that can print skin cells grown from patient tissue directly onto a wound.

Source: 3dnatives.com

The ZScanner Z700 handheld 3D scanner is used to determine the size and depth of a wound. Based on this information, the 3D printer prints subcutaneous, dermal and epidermal skin cells at appropriate depths to completely cover the wound.

Source: 3dnatives.com

The 3D bioprinting system developed by scientists consists of a three-axis moving print head with eight 260 micron diameter nozzles with independent dispensers. Specifically for this device, the researchers created a bioink consisting of autologous dermal fibroblasts and epidermal keratinocytes in a hydrogel carrier.

Bite

Volt Bipolar Surgical Forceps for Laparoscopic Surgery stop bleeding during surgery. It was created for use in minimally invasive (sparing) surgery in 2016 and successfully tested on pig liver.

It was created for use in minimally invasive (sparing) surgery in 2016 and successfully tested on pig liver.

Source: bitegroup.nl

The design of the device allows easy adjustment of the shaft and tip geometry depending on the patient's anatomy and surgical requirements. Maneuverable shank - ±65° for lateral movements and ±85° up and down. Flexural stiffness of 4.0 N/mm for connection 1 and 4.4 N/mm for connection 2, significantly higher than previously available guided tools. The tip consists of two 3D printed titanium movable jaws with an opening angle of up to 170°. The instrument is connected to an Erbe electrosurgical unit and is able to successfully coagulate tissue at a temperature of 75 °C, reached in 5 seconds.

Conclusion

Source: intermercados.com.br

The use of additive technologies in medicine is expanding so rapidly that it is more like a revolution in healthcare. The use of 3D printing in medicine enables the individualization of medical devices, medicines and equipment, increases cost efficiency and productivity, reduces waiting times for patients and improves the availability of medical care.

The use of 3D printing in medicine enables the individualization of medical devices, medicines and equipment, increases cost efficiency and productivity, reduces waiting times for patients and improves the availability of medical care.

Source

Tags:

3D printing in medicine, dental implants, 3D printing for ear production, 3D printed models, Surgical instrument printing, Drug printing, Prosthetics and dentistry , Zortrax M20 3D printer

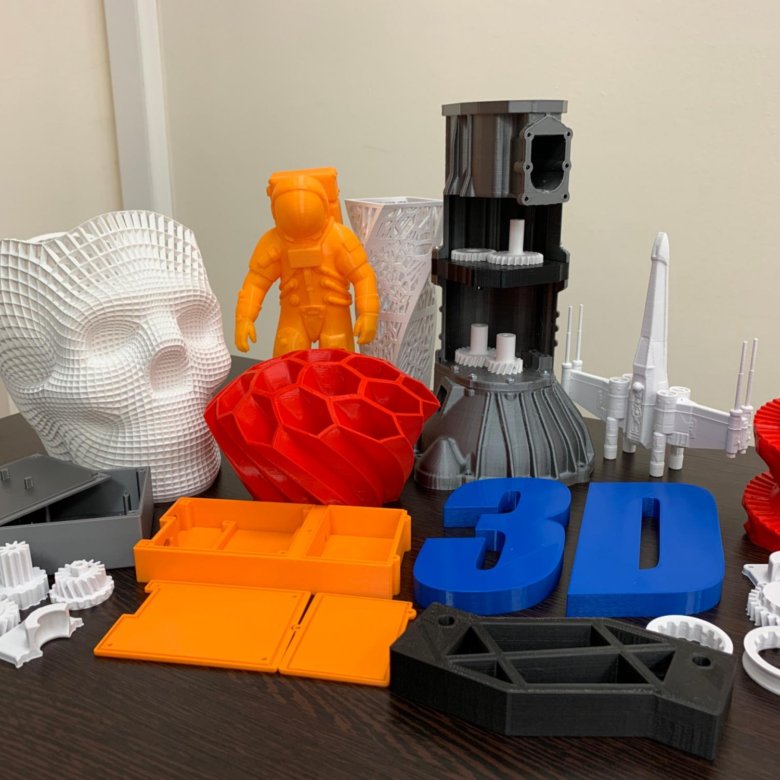

10 industries that 3D printing is starting to change

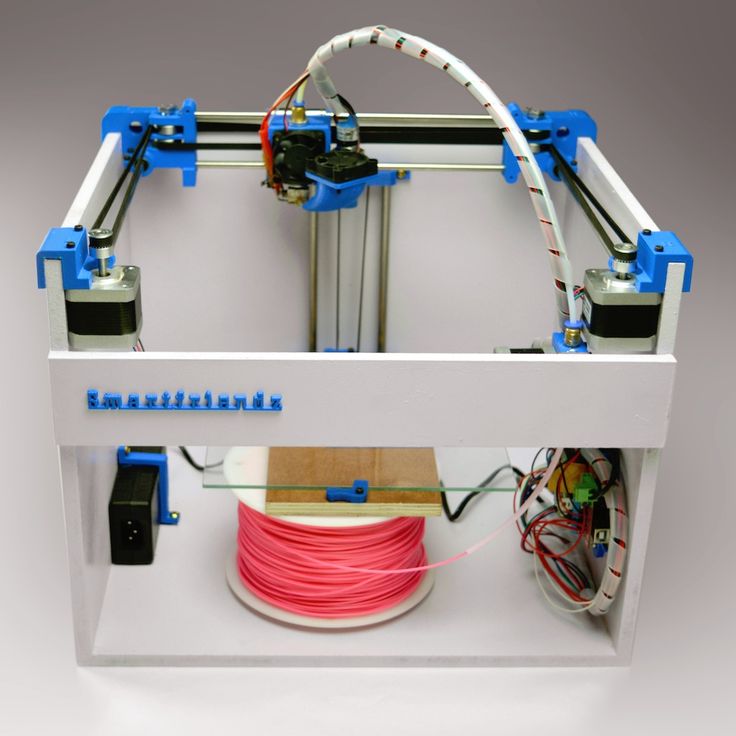

3D printing has come a long way from printing small prototype buildings out of plastic. Today, 3D printing is fulfilling its potential in a range of industries, from aerospace to apparel and footwear.

This technology not only allows you to create items with incredible precision, but also saves money.

Today, there are many materials that allow you to make a wide variety of objects using 3D printing.

Below we describe the industries in which this technology is applied.

1. Aerospace

In the aerospace industry, everything must be made with high precision. Precision plays a very important role here in the execution of every space mission, and the industry itself is extremely important for the development of mankind.

3D printing has already begun to change the industry, it is used to replace many parts that have become too expensive to produce. In addition, the technology is used to test prototypes.

ULTEM 9085 is a thermoplastic commonly used in aircraft construction that can be melted down and used in 3D printing.

2. Architecture

3D printing technology saves time in building construction.

With this technology, printing houses is as fast as printing documents.

And when creating a design, you can share it with other users by placing an object in the database.

3.

Food

Food

While 3D printing doesn't save lives, it could change the way we think about food.

Nevertheless, experts note that in the future humanity will face a shortage of food, it is already becoming increasingly difficult to feed the growing population of the planet.

However, science is looking for ways to grow meat and use alternative materials to produce food.

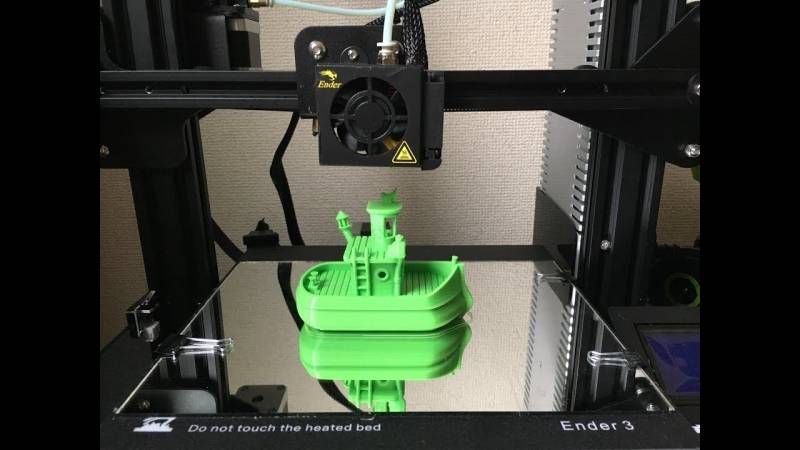

4. Product design

Technology allows you to design something on a computer, then print it in an hour, test it, find flaws, redesign, print a second prototype - and all this takes only half a day.

Previously, concepts were produced, but now 3D printing technology makes it possible to get closer to an almost identical product representation in a very short amount of time.

5. Medicine

3D printing plays an important role in almost every aspect of medicine. When it comes to prototyping, technology allows you to create ready-made models that will cost less and take less time to create, and these will be ready-made models that are completely usable.

Clarity and precision allows you to print ultra-fine lines that allow you to create the smallest tools.

In addition, 3D printing technology makes it possible to recreate parts of the human body using various materials. Scientists are constantly working to create new materials and textures.

6. Dentistry

Making dental models is very useful, but it is not always possible to make them taking into account the individual characteristics of a person.

3D printing technology allows you to make exact copies of a patient's teeth to replace them, or crowns that can last longer.

Objet Digital is a dedicated 3D printer designed for use in the field of dentistry.

He uses materials that are very similar in structure to bone to print teeth.

7. Construction

In Dubai, 3D printing is an increasingly common way to construct buildings. Cazza, a 3D printed construction company, plans to build the world's first 3D printed skyscraper.

They created special machines that can build buildings from the bottom up.

Companies around the world have expressed interest in such machines.

In addition, this method of building construction leaves less debris. During construction, environmentally friendly materials can be used.

8. Agriculture

It may seem strange to use this technology in agriculture, but it is true. Many farms need specialized tools, which cost between $8,000 and $12,000 and can take months to complete.

PLA, or polylactic acid, is a material that is used for 3D printing and costs $0.25 per 1.5 cu. m. This can significantly save money and time for farmers who are looking to upgrade their machines.

9. Making clothes and shoes

So far, 3D printed clothes have not entered the mass market, but the idea of such clothes has been developed since 2013.

The idea is that in the future, customers can print clothes, which suits their individual sizes.