Polypropylene 3d printing

Ultimate Materials Guide - 3D Printing with Polypropylene

Overview

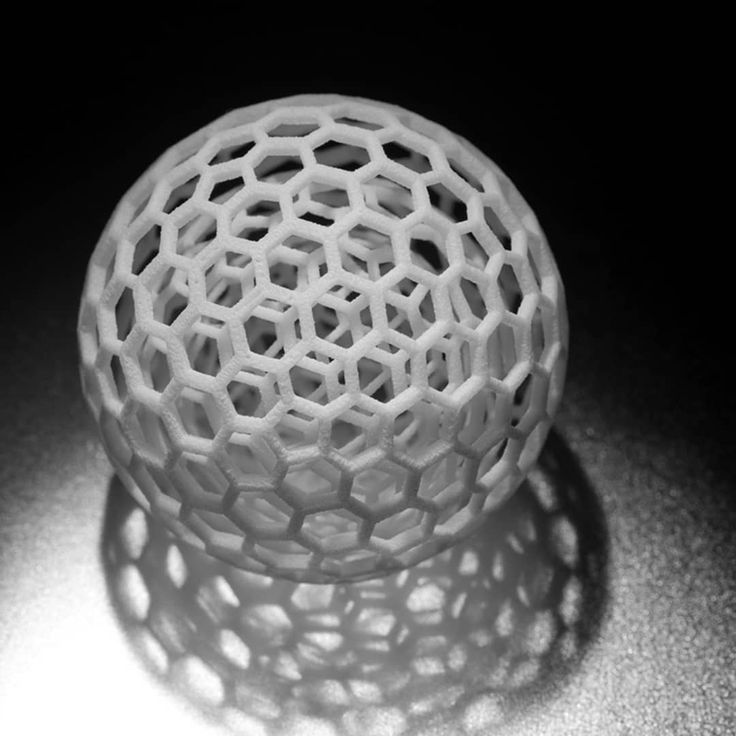

Polypropylene is a semi-rigid and lightweight material that is commonly used in storage and packaging applications. The semi-crystalline structure of the material causes the 3D printed parts to heavily warp upon cooling, making it challenging to 3D print. Polypropylene is tough and has a good fatigue resistance making it ideal for low strength applications like living hinges, straps, leashes, etc. A few manufacturers have even created polypropylene blends that have improved toughness making it suitable for practical use. The tips in this article will cover all the different types of polypropylene filaments available for 3D printing.

- Good impact and fatigue resistance

- Good heat resistance

- Smooth surface finish

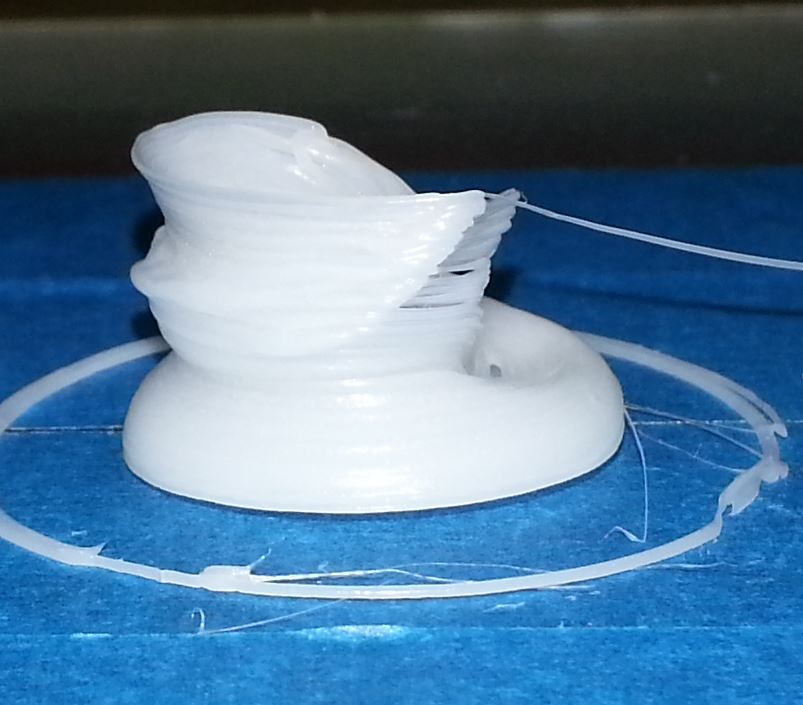

- Heavy warping

- Low strength

- Difficult to adhere to bed and other adhesives

- Expensive

Hardware Requirements

Before 3D printing with Polypropylene make sure your 3D printer meets the hardware requirements listed below to ensure the best print quality.

Bed

Temperature: 85-100 °C

Heated Bed Required

Enclosure Recommended

Build Surface

Packing Tape

Polypropylene Sheet

Extruder

Temperature: 220-250 °C

No special hotend required

Cooling

Part Cooling Fan Required

Best Practices

These tips will help you reduce the chances of common 3D printing issues associated with Polypropylene such as warping and poor bed adhesion.

Choosing the Right Build Surface

Finding a good build surface can be very challenging when you need to print with Polypropylene. The low surface energy of polypropylene makes it extremely difficult to get good bed adhesion even with heated beds. We have found that polypropylene adheres well only to itself. Thankfully, packaging tape is a readily available surface that is also Polypropylene based, so it can be a great option. A thick strip of packing tape along with a heated bed can greatly improve the success of your first layer with this material. Some packing tapes melt around 90 ºC so it is important to keep the heated bed at a temperature slightly less than the melting point of the tape.

Some packing tapes melt around 90 ºC so it is important to keep the heated bed at a temperature slightly less than the melting point of the tape.

Use Rafts to Protect the Base Layer

Polypropylene prints can sometimes bond too well to the packaging tape on the surface of your bed, which makes it hard to separate the tape from the finished part once the print is complete. This happens because the high temperature of the heated bed allows the tape and the part to slightly fuse together. To avoid this, consider using a raft for your prints. The raft will act as an interface between the hot build surface and the bottom of your part. Once the print is complete, the raft can be discarded, so even if it partially fuses to the tape, this will not affect the final part. Version 4.0 of Simplify3D added several new features that use less time, less material, and create rafts that are far easier to remove, so consider giving this option a try if you are having trouble with the parts bonding to the tape.

Using a Heated Chamber or Enclosure

Having a good build surface may not be enough to prevent printing issues. Since we know that Polypropylene can warp quite heavily, it helps to have an enclosure of some sort to trap the heat around the print. Using a printer that has a heated chamber will help eliminate warping. Temperatures of 45-60 °C for a heated chamber will usually work well. Having a standard enclosure can also significantly control warping when used with the heated bed, since the bed will help heat the air around the part, which is contained by the enclosure. However, be careful to control the heated bed temperature to avoid damaging the packaging tape as mentioned above.

Pro-Tips

- Although Polypropylene can print well at low temperatures, printing at slightly higher temperatures in the range of 240 ºC can help with adhesion between layers to create a stronger part.

- Consider using a lower temperature for the first few layers of your print to prevent the part from fusing to the build surface.

Get Started with Polypropylene

Now that you understand some of the unique characteristics of this material, you are ready to try your first print. We’ve included a few ideas below to help you get started.

Common Applications

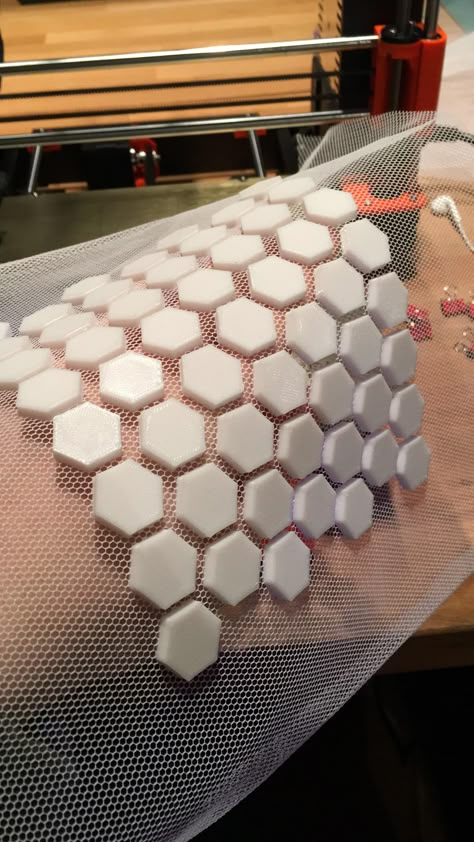

- Living hinges

- Storage containers

- Watch Straps

Sample Projects

- Pebble Watch Strap

- Travel Bottle

- Parts box

Popular Brands

- Ultimaker Polypropylene

- GizmoDorks Polypropylene

- Verbatim Polypropylene

How to Succeed When 3D Printing with Polypropylene Filament

Successfully produce 3D printed parts out of polypropylene filament with these tips on achieving stronger bed adhesion and minimizing shrinkage.

MatterHackers

July 22, 2022

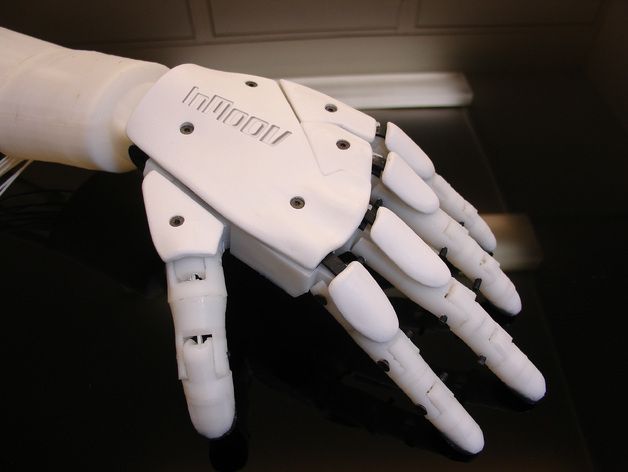

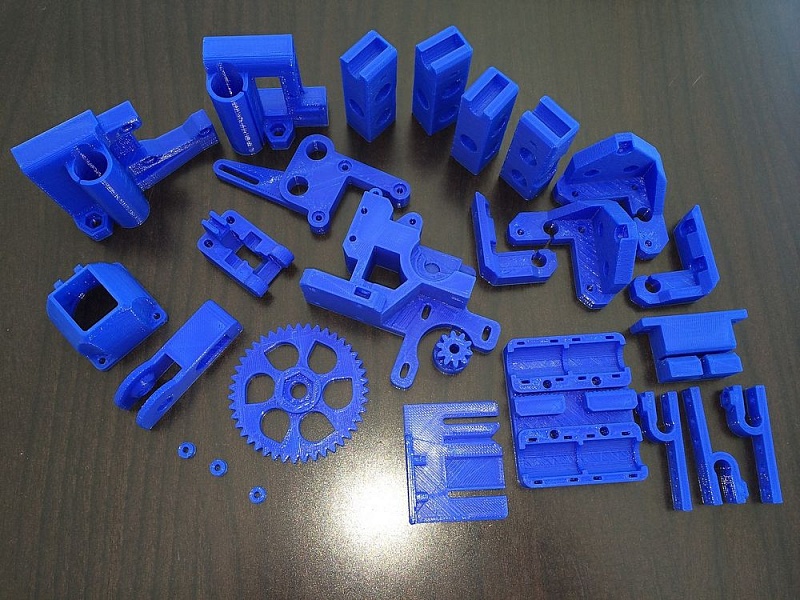

Polypropylene (PP) is a popular semi-rigid polymer material used to produce many common consumer products due to its superb mechanical properties. Suitable for a variety of applications, examples of everyday use cases can be found in the form of squeezable bottles, flip-top mint containers, car bumpers, toys, and so much more. Positive features associated with polypropylene include its robust resistance to chemicals, fatigue, high-temperature, and impact. This thermoplastic material is made up of hydrophobic molecules (molecules physically resistant to water), making it ideal for products that heavily rely on protection from moisture. With these qualities in mind, its no wonder polypropylene has caught the attention of 3D printing enthusiasts for prototyping purposes and even ready-to-use functional parts.

Positive features associated with polypropylene include its robust resistance to chemicals, fatigue, high-temperature, and impact. This thermoplastic material is made up of hydrophobic molecules (molecules physically resistant to water), making it ideal for products that heavily rely on protection from moisture. With these qualities in mind, its no wonder polypropylene has caught the attention of 3D printing enthusiasts for prototyping purposes and even ready-to-use functional parts.

Polypropylene, polypropylene blends, and OBC filament are fantastic materials to produce prototypes that are durable and functional.

TABLE OF CONTENTS- Polypropylene As a 3D Printer Filament

- 3D Printing With Polypropylene

- Checklist for Success: Use the Right Tools

- Hotend Recommendations

- Print Bed Recommendations

- Enclosure Recommendations

- How to Avoid Warping and Shrinkage

- Recommended Polypropylene Print Settings On LayerLock Build Surface

- Ready, Set, Print!

POLYPROPYLENE AS A 3D PRINTER FILAMENT

While not as commonly available as filaments such as PLA, ABS or PETG, polypropylene is slowly expanding its variety and availability in the market, and becoming more affordable for consumers. Hobbyists can expand their printing options as PP is a great practical option for producing prototypes that are lightweight, have water-tight tolerances, and are extremely durable. You will find that these qualities make this material especially ideal for prototyping household plastic containers. While this thermoplastic is technically both safe for microwaves and food contact, we do NOT recommend using prints made with Fused Deposition Modeling (FDM) 3D printers to store consumable food and liquids due to the porous nature of FDM 3D printing and possible cross-contamination when extruding this filament out of hardware that has not been labeled food-safe. Nonetheless, polypropylene is still a fantastic option for producing prototypes such as mechanical parts and containers with living hinges to store physical objects and liquids not intended for consumption.

Hobbyists can expand their printing options as PP is a great practical option for producing prototypes that are lightweight, have water-tight tolerances, and are extremely durable. You will find that these qualities make this material especially ideal for prototyping household plastic containers. While this thermoplastic is technically both safe for microwaves and food contact, we do NOT recommend using prints made with Fused Deposition Modeling (FDM) 3D printers to store consumable food and liquids due to the porous nature of FDM 3D printing and possible cross-contamination when extruding this filament out of hardware that has not been labeled food-safe. Nonetheless, polypropylene is still a fantastic option for producing prototypes such as mechanical parts and containers with living hinges to store physical objects and liquids not intended for consumption.

Have a product idea that will be made out of polypropylene? Produce your prototypes with its end-use material right from your workspace.

Producing parts with this material admittedly require a bit more finetuning compared to other filaments such as the fan-favorite PLA. That's where this handy how-to succeed guide comes in! All the tips and tricks we've uncovered from MatterHackers' engineers can be found here, so any hobbyist interested in expanding their 3D printing options can increase their chances of success. One crucial thing makers should be aware of is that this thermoplastic has a semi-crystalline structure that causes it to potentially warp and shrink upon cooling. Users must pay closer attention to settings that they may not normally consider in comparison to standard filaments like PLA. To avoid warping and shrinkage, check out the tips below on how to successfully produce polypropylene prints.

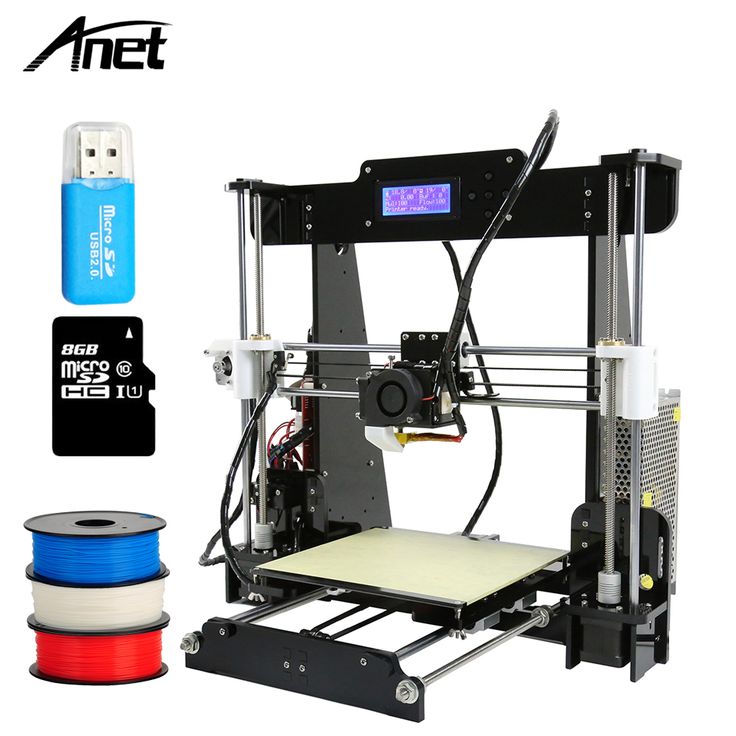

CHECKLIST FOR SUCCESS: USE THE RIGHT TOOLSThe first key to success is making sure you have the right tools. That means having the right 3D printer and accessories. With polypropylene, only a couple of upgrades are recommended if they do not already come stock with your machine. FDM printers that have the electrical hardware to print with polypropylene include (but are not limited to) the Pulse 3D Printer, Raise3D Pro2, LulzBot TAZ 6, and Ultimaker S5.

With polypropylene, only a couple of upgrades are recommended if they do not already come stock with your machine. FDM printers that have the electrical hardware to print with polypropylene include (but are not limited to) the Pulse 3D Printer, Raise3D Pro2, LulzBot TAZ 6, and Ultimaker S5.

Here at MatterHackers, we carry a wide variety of 3D printers that are ready to print advanced materials right out of the box.

Not sure if your 3D printer can safely extrude polypropylene? See if your 3D printer meets the following recommendations listed below.

HOTEND RECOMMENDATIONS- If printing a polypropylene with no special blends of other polymers and/or fibers (ex: SmartMaterials Polypropylene, Ultimaker Polypropylene), no special hotend is necessary.

- If printing a polypropylene with a special blend of abrasive fibers (ex: X-Strand or BASF's Black PPGF [Polypropylene Glass Fiber] 30), a hotend that safely operates at temperatures of up to 300°C is highly recommended.

- Universal hotends we recommend for this capability include (but are not limited to) E3D's V6 All-Metal Hotend, Slice Engineering's Mosquito All-Metal Hotend, and Micro-Swiss All-Metal Hotend.

- An abrasive resistant nozzle is highly recommended when printing with abrasive fibers such as carbon and glass. These materials will wear out non-abrasive nozzles quickly, which will cause inconsistent extrusions during the printing process.

- Abrasive resistant nozzles we recommend include (but are not limited to) Olsson Ruby Nozzles, Nozzle X, and any hardened steel or vanadium nozzles.

Whether you need a hotend that prints at 250°C or 300°C, MatterHackers has a variety of reliable extruder options that cater to your specific print needs.

PRINT BED RECOMMENDATIONS- A heated bed that can safely operate at temperatures of up to 100°C is required.

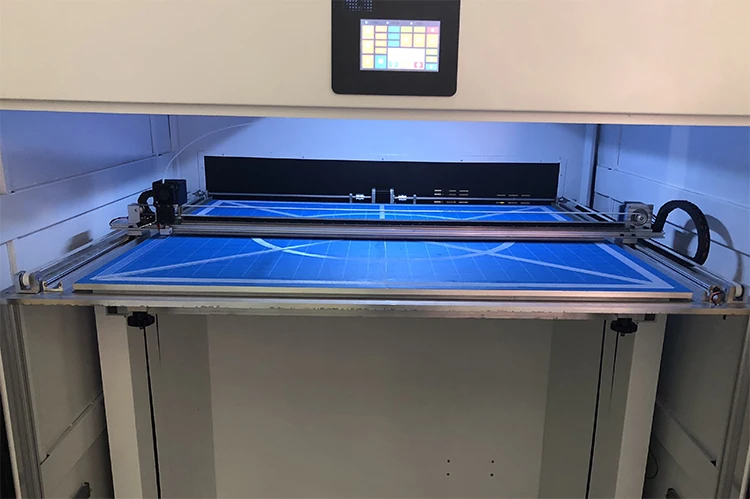

- LayerLock Build Surface for Polypropylene is the build surface we've seen produce the most consistent, successful results.

Designed to succeed with polypropylene, certain polypropylene blends, and OBC filament, LayerLock Build Surface sheets provide the strong adhesion necessary to keep prints from warping. We highly recommend LayerLock Build Surface as it is available in medium to large sheets that can be cut to size for your print bed.

Designed to succeed with polypropylene, certain polypropylene blends, and OBC filament, LayerLock Build Surface sheets provide the strong adhesion necessary to keep prints from warping. We highly recommend LayerLock Build Surface as it is available in medium to large sheets that can be cut to size for your print bed. - Packing tape is a possible alternative you can find around the house and in most stores. However, please note that it does require multiple strips of tape that must be carefully laid down (no creases or air bubbles), must be replaced more frequently, and may come with a few limitations (depending on what type of filament you are printing with). Also, confirm that the packing tape is made out of polypropylene as any other packing tape will not work.

Achieve the strong bed adhesion you need to succeed with polypropylene using LayerLock Build Surface and bed adhesion solutions for PP.

ENCLOSURE RECOMMENDATIONS- Only required if printing in an area that is cold or where the temperature is inconsistent.

View the wide variety of 3D printer enclosures available here.

View the wide variety of 3D printer enclosures available here.

Enclosures are fantastic 3D printer accessories for maintaining consistent, warm temperatures, which is critical when producing parts out of advanced materials in a cold or windy environment.

HOW TO AVOID WARPING AND SHRINKAGEFilaments that warp and/or shrink during 3D printing are nothing new among the current line of thermoplastics available on the market for both professionals and everyday hobbyists. Each type of material has its own special set of print settings and conditions it needs to succeed such as flexibles (TPU, TPE) benefiting from a PrintDry for quality print results and nylon/nylon-based materials like NylonX and NylonG heavily benefiting from both a PrintDry and LayerLock Garolite Build Surface for maximum print success. For polypropylene, a LayerLock Build Surface and polypropylene bed adhesion solution will maximize your success when 3D printing with this material. Depending on the temperature conditions of your workspace, an enclosure may also be recommended.

Depending on the temperature conditions of your workspace, an enclosure may also be recommended.

Whether it's PP, PPFG, or OBC filament, LayerLock Build Surface for Polypropylene will provide the bed adhesion necessary to prevent warping.

Achieving a strong bond between the first layer of your print and the heated bed's build surface is crucial for successfully avoiding warping. Like other filaments, printing too close can cause your part to stick too well to the bed and printing too high can lead to the material not sticking. What steps can you take to get that ideal first layer?

- Choose the right build surface.

- Level your bed.

- Set your nozzle at the appropriate height.

LayerLock Build Surface for Polypropylene has provided the most consistent results based on the continuous testing our engineers have been performing for months. Polypropylene has a strong tendency to warp as it tends to be extremely limited to what it likes to stick to and be sensitive to temperature. This thermoplastic loves sticking to our LayerLock Build Surface so you can rest easy knowing that first layer will stay firmly adhered to the build surface during the entire duration of the print. For easy removal post-printing, we recommend combining LayerLock with a bed adhesion solution specifically designed for polypropylene before the start of your print.

This thermoplastic loves sticking to our LayerLock Build Surface so you can rest easy knowing that first layer will stay firmly adhered to the build surface during the entire duration of the print. For easy removal post-printing, we recommend combining LayerLock with a bed adhesion solution specifically designed for polypropylene before the start of your print.

A successful first layer is necessary for an overall successful print. Make sure to use the right build surface that is compatible with polypropylene.

Before you start printing on any new bed surface, always remember to level your bed and calibrate your nozzle height to adjust for the print bed's height difference. With LayerLock Build Surface, it is essential to achieve the correct layer height because extruding too low may cause your print to fuse to the bed surface. When adjusting layer height, we always recommend starting higher than you normally would because that prevents the possibility of having your print fuse to the bed. A great starting point would be beginning a test print at a 1mm height away from the bed surface and working your way down. Optimal nozzle height is achieved when you see the filament extruded on the bed with a width of about 1 mm.

A great starting point would be beginning a test print at a 1mm height away from the bed surface and working your way down. Optimal nozzle height is achieved when you see the filament extruded on the bed with a width of about 1 mm.

When finding the right distance between the nozzle and print bed during polypropylene extrusion, we suggest baby-stepping on a test print to safely achieve that ideal layer height.

As for shrinkage during 3D printing, that shouldn't be an issue when following our recommended print settings below on a LayerLock Build Surface for Polypropylene in a room with consistent room temperature. Our engineers have been performing these tests on our open-frame Pulse 3D Printers and have been successfully producing polypropylene parts! However, if you are limited to printing in a room below 70°C or an area with air conditioning, we highly recommend using a 3D printer enclosure to ensure your parts are being produced in a consistently warm environment. Cold air can easily cause your parts to cool too fast during printing which can lead to cracks in your prints, leaving them unusable in the end. If you don't have an enclosure and are not located in a consistently warm environment, check out our catalog of 3D printer enclosures and enclosure kits. Follow our recommended settings below with our recommended 3D printer accessories and you will be closer to polypropylene 3D printing success!

Cold air can easily cause your parts to cool too fast during printing which can lead to cracks in your prints, leaving them unusable in the end. If you don't have an enclosure and are not located in a consistently warm environment, check out our catalog of 3D printer enclosures and enclosure kits. Follow our recommended settings below with our recommended 3D printer accessories and you will be closer to polypropylene 3D printing success!

Need a 3D printer that prints polypropylene? Check out our Pulse XE 3D Printer we used to successfully achieve consistent results.

RECOMMENDED POLYPROPYLENE PRINT SETTINGS ON LAYERLOCK BUILD SURFACE:- Extruder Temperature:

- 210°C - 230°C (SmartMaterials SmartFil Polypropylene, Ultimaker Polypropylene)

- 250°C - 280°C (X-Strand GF30-PP, BASF Black PPGF 30)

- Bed Temperature: 50°C - 80°C bed

- Bed Adhesion Solution: Magigoo Bed Adhesion for Polypropylene or SmartMaterials SmartStick

- Layer Height - Relative to the brand and type of polypropylene filament being printed

- To find the ideal layer height, start 1mm above the print bed and baby step down until your extruded filament looks to be about 1mm in width.

- To find the ideal layer height, start 1mm above the print bed and baby step down until your extruded filament looks to be about 1mm in width.

- Print Speed: 30 - 50mm/s

- Brim: 25 - 35mm

- Raft - May be useful for parts with a very large surface area; otherwise not necessary

- Layer Cooling Fan - May be needed when layer time is below 20 seconds; otherwise not recommended

We hope these tips help you succeed with 3D printing polypropylene! With this thermoplastic found in many common household products, PP is the perfect end-use material for prototyping straight from your workbench. If you have any further questions, feel free to hop on our forum filled with helpful posts and fellow enthusiasts working together to create a smooth, enjoyable 3D printing experience.

Happy Printing!

Successfully produce functional end-use products with LayerLock Build Surface for Polypropylene.

3D printing with polypropylene in Moscow at an affordable price

Flexible and impact-resistant prototypes for a wide variety of industries

A non-toxic plastic that is widely used in structural elements, household items, packaging and containers due to its high resistance to deformation and bending. The material is waterproof, heat resistant and has excellent flexural strength and is completely food safe.

The material is waterproof, heat resistant and has excellent flexural strength and is completely food safe.

If you need to order a 3D plastic printing service, you can contact our specialists using the link below.

Order service

- Equipment

- Tasks

- Industries

- manufacture of medical instruments

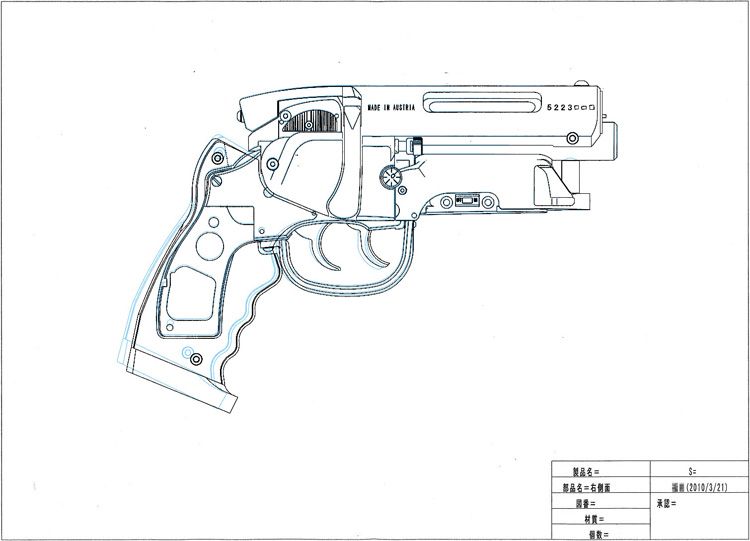

- rapid prototyping

- printing of cases of technical devices and mechanisms

- manufacture of packaging, containers and miscellaneous articles in contact with foodstuffs

-

Engineering

-

Automotive

-

Medicine

Polypropylene is the second most common polymer in the world. Printing with PP plastic is used when it is necessary to obtain a product with the following characteristics: flexibility, non-toxicity, impact and temperature resistance, resistance to oils and organic solvents.

It is a durable and flexible synthetic material that meets the requirements of 3D printing technology. It is based on propylene subjected to polymerization using catalysts that determine the structure and properties of the material. Available in the form of powder or granules, it can be colored and unpainted.

Where PP plastic is used

3D printing with PP plastic is a good way to make a variety of items and parts that a person needs.

Today PP products are used in industry, everyday life, construction, mechanical engineering. In terms of characteristics, the material successfully competes with PPA. Resin printing is a suitable technology for the production of parts in direct contact with food, life sciences, and bending resistant elements.

The most common polypropylene products:

- gas and water pipes;

- rigid and flexible packaging, cases and containers;

- furniture;

- plastic disposable and reusable tableware;

- buckets, basins, lids, caps;

- cases of household appliances and office equipment;

- car parts;

- toys;

- medical instruments and articles: - disposable syringes, pipettes, test tubes, containers for tablets, containers for samples;

- nonwovens;

- electrical insulating materials.

PP types

Manufacturers produce several types of polypropylene that can be used for printing with PP plastic. Differences in structure and composition determine its properties and characteristics: strength, ductility, melting point. The most common:

- Homopolymers. Consist of a semi-crystalline (with a well-organized structure) polypropylene monomer (low molecular weight substance involved in the polymerization reaction). Synthetic plastic with this composition is characterized by high specific strength (including when interacting with aggressive chemical compounds), rigidity and good bending strength. To connect it, you can use welding. Products made of such plastic are used in areas that involve a significant load: auto parts, pressure pipes, electrical engineering. However, when exposed to low temperatures, the homopolymer becomes more brittle.

- Block copolymers. Propylene monomers alternate with ethylene monomers.

The addition of ethylene can be 5–15% of the total composition. The links are in the correct order. The material is resistant to impacts and low temperatures, easy to process. At the same time, in order to increase the wear resistance of parts made of block copolymers, various modifiers are introduced into the composition. Therefore, PP is suitable for the manufacture of equipment cases, containers, furniture, utensils, as well as packaging of goods that are stored frozen.

The addition of ethylene can be 5–15% of the total composition. The links are in the correct order. The material is resistant to impacts and low temperatures, easy to process. At the same time, in order to increase the wear resistance of parts made of block copolymers, various modifiers are introduced into the composition. Therefore, PP is suitable for the manufacture of equipment cases, containers, furniture, utensils, as well as packaging of goods that are stored frozen.

Homopolymers and block copolymers are similar in properties. Melting takes place at temperatures in the range of 135-170 ° C, which is why 3D printing with polypropylene can not be performed on all printers. - Irregular copolymers. The difference in the structure of a substance is that it contains randomly arranged comonomer units. The attachment of the monomer to the chain is not affected by specific parameters and conditions. The second element included during copolymerization can be a small amount of ethylene (no more than 1–7%).

Random copolymers are more flexible and require lower temperatures to melt.

Random copolymers are more flexible and require lower temperatures to melt.

3D printer requirements

Printing PP plastic is more difficult than other types of polymers, since polypropylene deforms when heated and cooled rapidly. When printing with plastic, it is necessary to follow the technology of heating and cooling. This is the main problem that arises when printing with polypropylene.

To avoid shrinkage, the printer must be equipped with a special closed chamber that maintains high temperatures. A heated platform helps to avoid too rapid cooling.

Requirements for a 3D printer:

- heating plate to 85–100°C;

- extruder temperature 220–250°C;

- closed heat chamber.

Such parameters are necessary to carry out 3D printing with PP plastic without shrinkage and increase the strength of the product due to adhesion.

Printing using PP today is possible in Moscow and other cities.

Advantages and disadvantages of polypropylene

Polypropylene is one of the versatile modern plastics. Options for the polymerization process allow you to achieve different characteristics, change its texture.

Advantages:

- high strength - withstands heavy loads, shocks;

- lightness;

- flexibility - does not collapse during deformations, bends;

- waterproof;

- heat resistance - food contact acceptable, will not melt or release harmful substances when exposed to hot water and in microwave ovens.

Flaws:

- highly flammable;

- does not tolerate UV light well;

- is difficult to glue;

- has low frost resistance;

- is not compatible with chlorinated solvents;

- oxidizes.

Polypropylene chemical properties

PP is a semi-crystalline hydrocarbon polymer. Only strong oxidizing agents significantly affect it: nitric fuming acid, halogens. Even concentrated sulfuric acid and hydrogen peroxide do little damage.

Even concentrated sulfuric acid and hydrogen peroxide do little damage.

Plastics may swell slightly in organic solvents and dissolve in aromatic hydrocarbons.

Such plastic is resistant to dilute acids, oils, alcohol, alkalis.

Toxicity

The material is non-toxic, decomposes only under the influence of very high temperatures, does not dissolve in hot water.

Mechanical properties

PP is the least dense of all plastics, yet it is hard, heat-resistant and non-corrosive.

iQB Technologies is a Russian distributor of 3D printers for polypropylene printing from the Italian manufacturer Sharebot. We deliver printers and other ordered equipment in Moscow and other cities of Russia, as well as to the CIS countries.

In addition to 3D printers, we also offer custom 3D printing. We offer it at a bargain price, and our team of 20 experts will advise you on all your questions. We will announce the exact price of the service after the terms, scope of work and other details about the ordered object are known.

Glass-Filled Polypropylene

Nova PP-GF 3D Printer Filament, 550 g, on spool

Based on polypropylene reinforced with short glass fibres. Does not absorb water, does not need drying, has excellent chemical resistance. Supplied in coils

1650

p.

| Buy |

| Information |

Filament for Nova PP-GF 3D printer, 550 g

Based on polypropylene reinforced with short glass fibers. Does not absorb water, does not need drying, has excellent chemical resistance. Supplied in skeins.

1600

| Buy |

| Information |

Filament in a skein for Nova PP-GF 3D printer, 250 g

Based on polypropylene reinforced with short glass fiber. Does not absorb water, does not need drying, has excellent chemical resistance. Supplied in skeins.

Does not absorb water, does not need drying, has excellent chemical resistance. Supplied in skeins.

| Buy |

| Information |

Filament for Nova PP-GF 3D printer, 50 g

Based on polypropylene reinforced with short glass fiber. Does not absorb water, does not need drying, has excellent chemical resistance. Supplied in test rolls.

| Buy |

| information |

Filament for Nova PP-GF30 3D printer, 600 g

Based on polypropylene with a high content of short glass fibers 0.4-0.6mm. The material is tough and durable. Tensile strength and stiffness are 1.5 times greater than Nova PP-GF. Supplied in coils.

1620

1950

| Buy |

| Information |

Filament for Nova PP-GF30 3D printer, 600 g

Based on polypropylene with a high content of short glass fibers 0. 4-0.6 mm. The material is tough and durable. Tensile strength and stiffness are 1.5 times greater than Nova PP-GF. Supplied in skeins.

4-0.6 mm. The material is tough and durable. Tensile strength and stiffness are 1.5 times greater than Nova PP-GF. Supplied in skeins.

1900

| Buy |

| information |

Filament in a skein for Nova PP-GF30 3D printer, 250 g

Based on polypropylene with a high content of short glass fibers 0.4-0.6 mm. The material is tough and durable. Tensile strength and stiffness are 1.5 times greater than Nova PP-GF. Supplied in skeins.

| Buy |

| information |

Filament in a skein for Nova PP-GF30 3D printer, 50 g

Based on polypropylene with a high content of short glass fibers 0.4-0.6 mm. The material is tough and durable. Tensile strength and stiffness are 1.5 times greater than Nova PP-GF. Supplied in test rolls.

| Buy |

| information |

Nova PP 3D printer filament, 530 g

Pure polypropylene filament of a specially selected brand for printing. Two colors The material is flexible, impact resistant, chemical resistant and suitable for food use. Supplied in coils.

Two colors The material is flexible, impact resistant, chemical resistant and suitable for food use. Supplied in coils.

1650

| Buy |

| Information |

Filament for Nova PP 3D printer, 530 g

Pure polypropylene filament of a specially selected grade for printing. Two colors The material is flexible, impact resistant, chemical resistant and suitable for food use. Supplied in skeins.

1600

| Buy |

| info |

Nova PP 3D Printer Filament, 250 g

Pure polypropylene filament of a specially selected brand for printing. Two colors The material is flexible, impact resistant, chemical resistant and suitable for food use. Supplied in skeins.

| Buy |

| information |

Test skein filament for Nova PP 3D printer, 50 g

Pure polypropylene filament of a specially selected brand for printing.