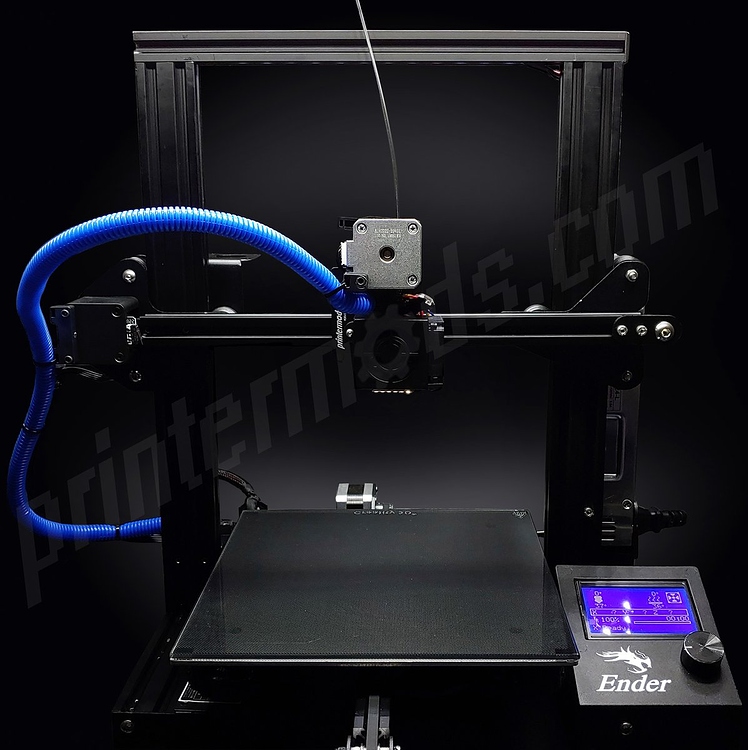

Ender 3 pro upgrades 3d print

3D Printer Review: Creality Ender 3 V2, Good for Beginners?

Odin(

180

)

0

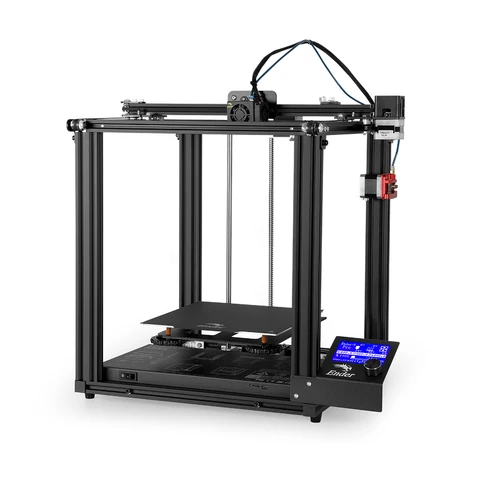

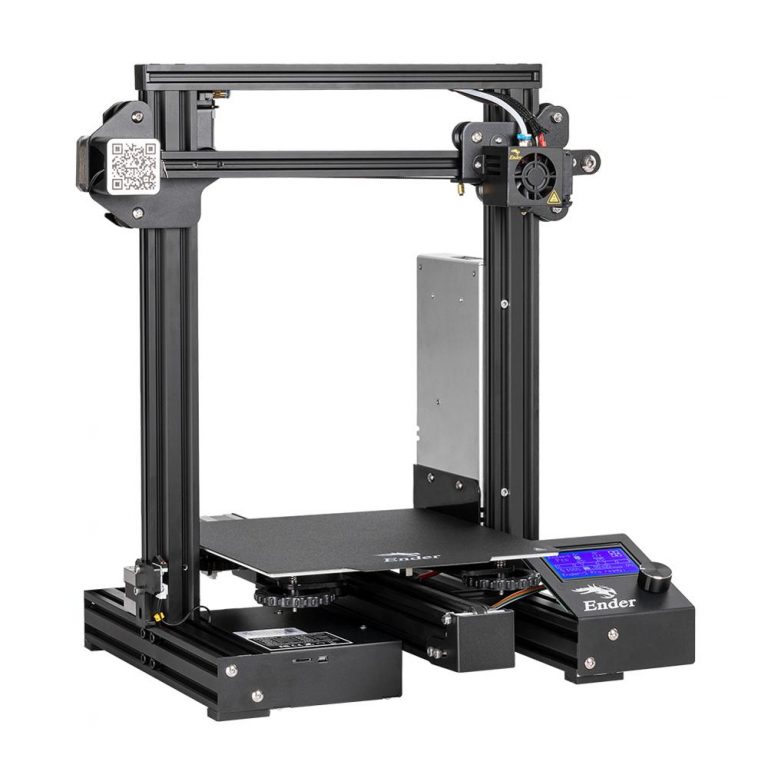

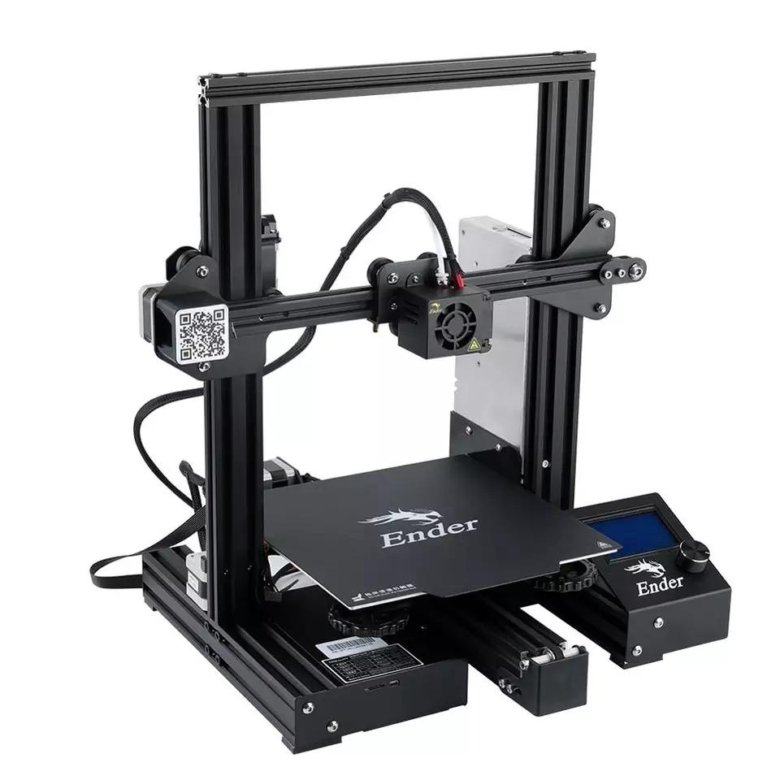

The Ender 3 V2 is an improved version of the Ender 3, showing Creality’s continued efforts at expanding this bedrock model in their impressive 3D printer line-up. Without a doubt, Creality still laps the competition when it comes to a heavily modifiable 3D printer, offering a platform from which a dedicated enthusiast could go far on the wings of their imagination.

However, beginners to the world of 3D printing might find the basic nature of the Ender 3 V2 intimidated and complicated. The Ender 3 V2 lacks some helpful advanced features and comes at an advanced state of disassembly, requiring a fair amount of work to get ready to actually start printing.

There are pluses and minuses to this printer for a beginner, depending on your use-case, your proclivity to DIY projects, and your desire to have a hands-on experience with your printer.

The TLDR is: get this if you want to learn the ins and outs of 3D printing, and your printer, from the ground up. Grab something more expensive with more included features if you’re mainly just hoping for a good 3D printing experience out of the box.

| Creality Ender 3 V2 3D Printer | × | 1 |

Howchoo is reader-supported. As an Amazon Associate, we may earn a small affiliate commission at no cost to you when you buy through our links.

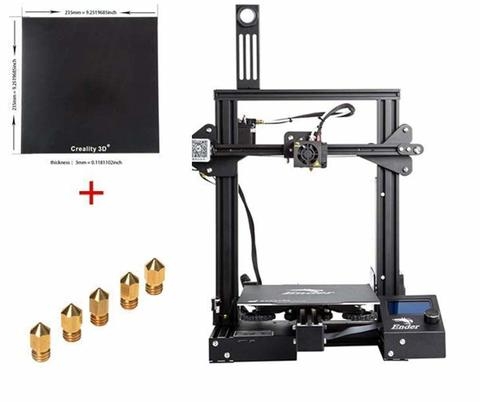

Specifications of the Ender 3 V2

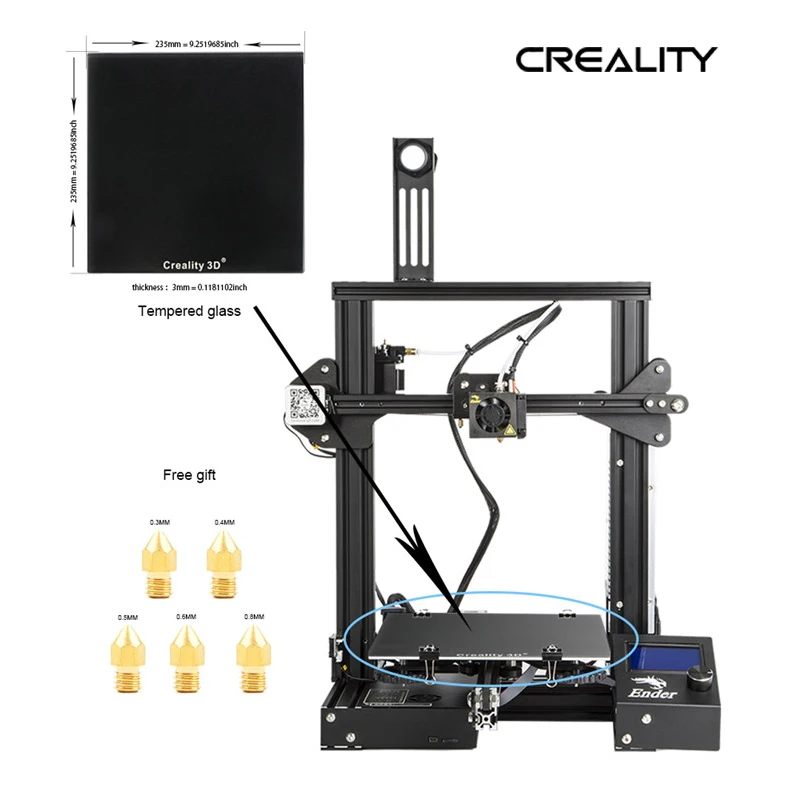

The Ender 3 V2 is an FDM printer, which stands for “Fused Deposition Modeling.” This type of printer works by printing thin layers of plastic one atop another to create or “build up” an object. The Ender 3 V2 follows the original Ender 3 in maintaining great specifications for a low price, offering a 220 × 220 × 250 mm (8.6 × 8.6 × 10 in) build area, tempered glass build plate, and can handle ABS, PLA, TPU, among other filament types.

The Ender 3 V2 follows the original Ender 3 in maintaining great specifications for a low price, offering a 220 × 220 × 250 mm (8.6 × 8.6 × 10 in) build area, tempered glass build plate, and can handle ABS, PLA, TPU, among other filament types.

It’s a sturdy little printer, too. Though it only weighs 17.6 pounds in its unmodified form, its all-metal body means that it sits well and doesn’t wobble, improving the build quality of your prints. That metal frame also comes in handy when you do want to start modifying it, offering a huge range of attachment point possibilities and easy access to the printer’s internal electronics.

Ender 3 V2: ease of assembly

As I showcased in my set-up guide for the Ender 3 V2, this printer is fairly easy to assemble if you take your time and follow the steps from beginning to end. I repeatedly found references to multi-hour complexity for assembling the Ender 3 V2 when I first started researching it, but my own experience putting it together showed that it could be finished and ready for testing in just 2 hours.

That said, I fancy myself a relatively technically minded person, I have a degree of orderliness and patience, and I’m a big guy capable of easily manipulating the 18-pound printer without any difficulty. I absolutely found points in the assembly process where someone without those qualities, someone easily made anxious by poor instruction manuals, or someone generally uninterested in DIY projects, would have a hard time.

I recommend the Ender 3 V2 specifically for those people who like a bit of a challenge, want to teach themselves all about the intricacies of how a 3D printer works, and who are excited about the prospect of upgrading their Ender 3 V2 in the future.

Upgrading your Ender 3 V2

Upgrading the Ender 3 V2, as it was with the original Ender 3, is almost half the point of purchasing it. This printer, at its base state, is basic. It offers, out of the box, a powerful platform capable of turning out good prints, but where the real magic happens is inside the process of printing your own parts and using those parts to upgrade the printer’s look and functionality.

There is a massive range of potential modifications to make to the Ender 3 V2, some of which are relatively simple and cosmetic, others which will require soldering skill, knowledge of electrical circuitry, and the patience to experiment (and possibly mess things up in the process).

You can absolutely take your basic Ender 3 V2 and turn it into a powerhouse 3D printer capable of matching pre-assembled printers that come at a much higher total price-point, but doing so is going to itself be a long-running DIY project that will challenge you to acquire and practice a wide range of skills beyond simply learning how to use a Slicer program.

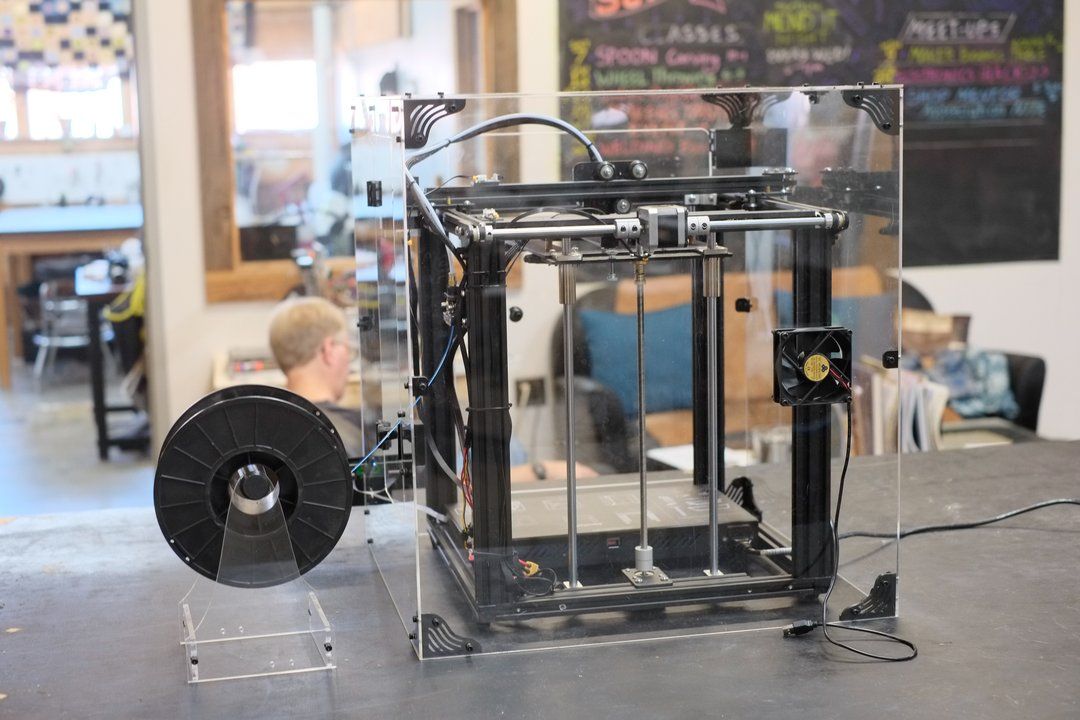

You can purchase upgrades, like an enclosure, stepper motor dampeners, and a whole new controller board. You can even purchase a Raspberry Pi mini computer and enhance the Ender 3 V2 with wireless compatibility and other awesome features.

You can also print your own modifications, like cable chains, custom enhancements for storage and filament unspooling, and even editions that allow your 3D printer to take on other functions, like turning it into a stability platform for macrophotography. With the range of options nearly limitless, and the printer’s initial cost so low, it starts to become easier to see why the Ender 3 V2 remains a dominant name in the 3D printing market.

With the range of options nearly limitless, and the printer’s initial cost so low, it starts to become easier to see why the Ender 3 V2 remains a dominant name in the 3D printing market.

Getting the Ender 3 V2 is a great choice for beginners who already know they love DIY experiences. But it might also be good for people who are hesitant about DIY work, too. Getting the Ender 3 V2 means you will need to teach yourself all the basics of how to use a 3D printer and how one functions, from the ground up. As you slowly start adding modifications to the printer, your skills will level up, and pretty soon you’ll find yourself capable of doing neat things like soldering in your own specialized power pack, or upgrading the circuit board with wicked Raspberry Pi integrations. If you go the quick and easy route of buying a printer that already does it all, you might miss out on learning some awesome skills and tricks. This might be the perfect opportunity to challenge yourself!

Functionality of the Ender 3 V2

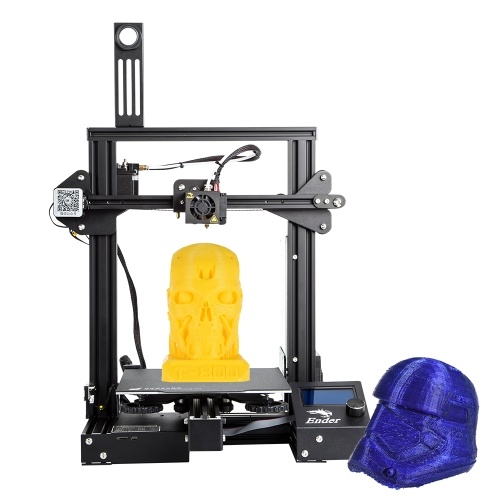

The reason we get a 3D printer is to, well, 3D print things. So, how well does the Ender 3 V2 actually perform in real-world conditions? Admirably, as it just so happens, even when you use it completely stock, sans modifications.

So, how well does the Ender 3 V2 actually perform in real-world conditions? Admirably, as it just so happens, even when you use it completely stock, sans modifications.

The Ender 3 V2 can handle a large variety of models, and it produces them with reasonable clarity. You will start to find problems emerging with longer, bigger prints, however. This is due to how easily the stock Ender 3 V2 loses its build platform level. At the very least, you’ll find yourself manually re-leveling your build plate after every print. But you might also find bigger prints getting a bit wonky, especially if your Ender 3 V2 was already a little off-level when you started printing. Upgrades can solve this, but that requires time, expense, and the sheer desire to DIY.

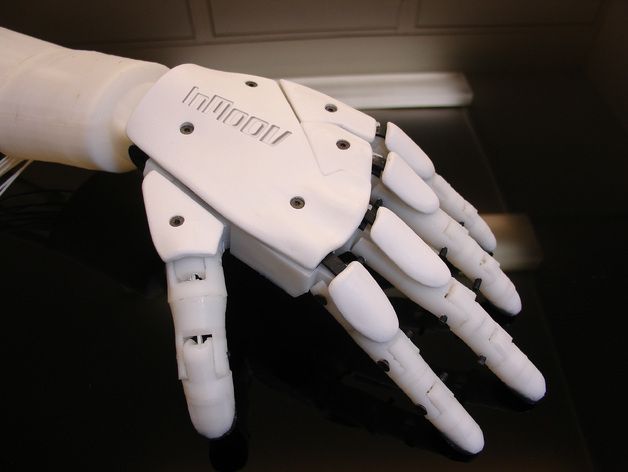

The Ender 3 V2 cannot create extremely high-definition minis (FDM printers in general aren’t great at this sort of work, you want to go for a resin printer instead), but I found that reasonable role-playing game mini figurines could be printed using its stock settings.

You can also print larger items, like a Boba Fett helmet for cosplay purposes, if you print the large model in pieces and then assemble it later using glue or heat.

The TLDR of it is: yes, the Ender 3 V2 works respectably well out of the box, but it’s still going to require some DIY and a more hands-on approach than printers with a few more automated and quality of life features built in. If you love going the DIY route, grab this printer right now. If you prefer to focus on learning how to slice models and just want your printer to work with a button press, I reccomend checking out the Anycubic Kobra Plus, which has become my go-to daily printer.

Ender 3 V2: price comparison

When considering which 3D printer to buy, especially as a beginner to the hobby, it’s important to think about the cost-to-benefit ratio.

A more expensive printer might have numerous features that will make your quality of life as a beginner easier from the get-go. However, starting out with a cheaper printer like the Ender 3 V2 might allow you to still produce cool prints, but can help you spend money on upgrading your printer more slowly, thus lowering the total coast and spreading that cost out over months or even years.

However, starting out with a cheaper printer like the Ender 3 V2 might allow you to still produce cool prints, but can help you spend money on upgrading your printer more slowly, thus lowering the total coast and spreading that cost out over months or even years.

The Ender 3 V2

If you have a sub-$300 budget, the Ender 3 is probably the best way to go. Know that you’re going to have a steeper learning curve and a more basic experience, but keep in mind that your ultimate goals should be to slowly upgrade this printer into a 3D printing beast. You’ll learn as you go, and you’ll become a 3D printing wiz in no time.

The Anycubic Kobra Plus

The Anycubic Kobra Plus

My go-to recommendation if you care more about getting straight into printing and will read up on the fine points of the machinery behind it all as you go. This puppy comes with auto-leveling built in, and a whole host of other quality of life features that will make your experience fun basically right out of the box.

Elegoo Mars 3

Elegoo Mars 3

If you want a printer that can handle fine detail, you need to go the route of a resin printer. The Elegoo Mars 3 is a 4K printer in a low-ish price range, offering good build volume for the cost. Resin printing comes with its own massive learning curve that’s totally different from what you’ll find with an FDM printer, but the quality of your prints is going to astound you.

NEXT UP

jtjones1988(

1

)

30 minutes

In this guide, I will remove the stock Ender-3 motherboard and install a BIGTREETECH SKR mini-E3. The process is the same for both the 1.2 and 2.0 versions of the motherboard.

Continue reading

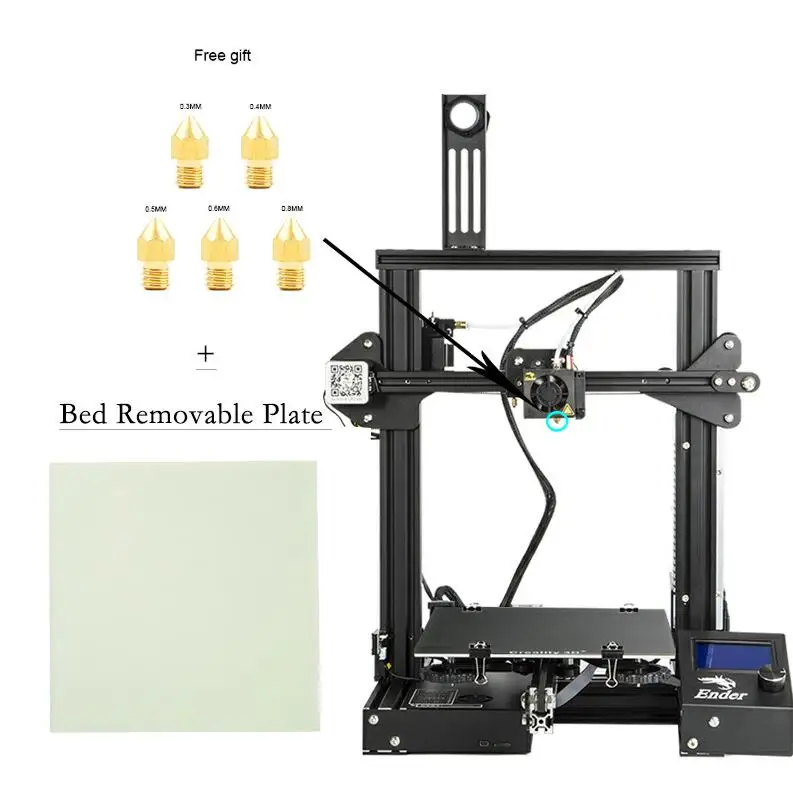

The Best Creality Ender 3/Pro Upgrades and Mods – Creality 3D

The Ender 3 is an amazing 3D printer. For the money, it's hard to find one that will give you better prints right out of the box. However, it's far from perfect.

For the money, it's hard to find one that will give you better prints right out of the box. However, it's far from perfect.

In this guide, I'll show you the top must-have upgrades and mods for the Ender 3 and Ender 3 Pro—both 3D-printable and purchased upgrades/mods.

A note on this guide:

In researching this guide, I found a lot of others with massive lists containing every upgrade and mod under the sun—unfortunately, many of those upgrades are pointless wastes of time and money. So, in this guide, I'll cut through the BS and cover the most impactful items that will give you better prints while also improving your overall printing experience.

- Upgrades and mods to 3D print

- Silent mainboard v1.1.5

- MeanWell power supply (PSU) upgrade

- Glass print bed

- BLTouch auto-leveling sensor

- LED strip

- Bed springs

- Metal feeder assembly

- Stepper motor dampers

- Direct Drive Extruder

- Firmware upgrade

Below are the top 3D-printable Ender 3 mods and upgrades you can perform. Tons of other printable mods exist, but this is the core list that will give you the best bang for your print time.

Tons of other printable mods exist, but this is the core list that will give you the best bang for your print time.

Board fan guard

Before you print anything else, print this mod. The location of the mainboard fan is directly beneath the build plate, meaning bits of filament can fall in and damage the fan or board. The model is available on Thingiverse.

Filament guide

This filament guide holds the filament away from the feeder, allowing for a more consistent feed rate and less skipping. It snaps directly into the side of the upper support.

Cable chain

This cable chain is a must-have for preventing dangerous cable snags when the bed moves along the Y-axis.

Display PCB cover

This simple screen cover protects your Ender 3 display's PCB (printed circuit board) from damage.

Bowden tube fitting fix

If your Bowden tube has popped out of place or if you're having print quality issues, you might want to print these pressure fitting shims that will prevent your Bowden tubes from shifting or popping out during printing.

Beeper silencer

You've probably noticed how loud the Ender 3 beeps when navigating the menu interface. This beep can level villages and knock satellites out of orbit. This 10-minute print mutes the beep quite a bit, getting rid of that annoyance and protecting our countrysides and space assets.

If you're using a 3D printer enclosure, I recommend printing these mods using ABS or PETG filament; ambient enclosure temperatures can cause PLA to warp and deform over time.

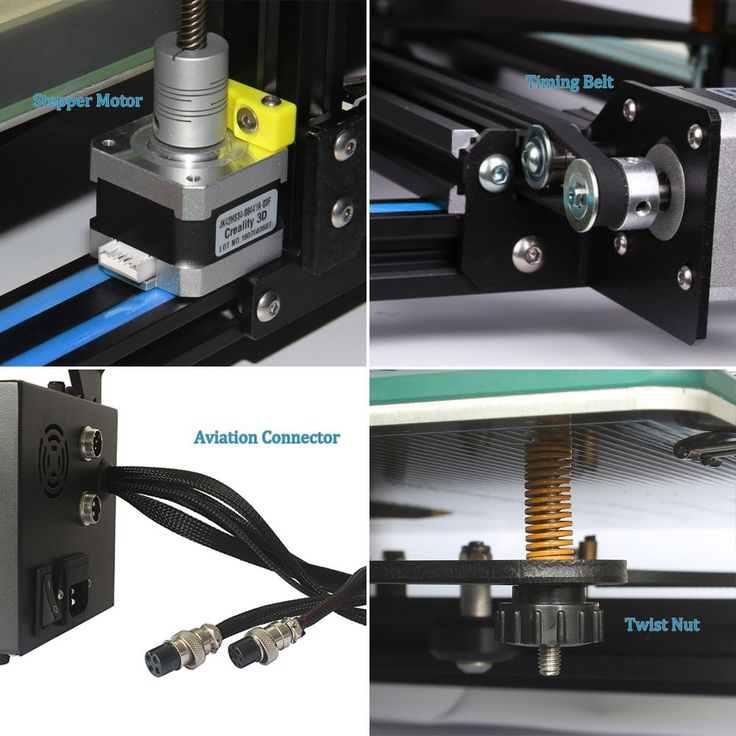

There are two main sources of noise on your printer: 1) fans, and 2) the drivers (chips) that run your stepper motors. The "whirring" noise you associate with printing is caused by the cheap stepper motor drivers used on the stock Ender 3 board.

Enter the Creality Silent Mainboard (v1.1.5). This board directly replaces your existing Ender 3 mainboard, upgrading your printer to the silent TMC2208 stepper motor drivers. This is the biggest "sound" upgrade you can make. It reduces your printer's noise from approximately 48dB to 36dB, with the remaining sound coming from the Ender 3's fans (which can also be upgraded to quieter fans).

If I had to choose a single upgrade from this guide (other than OctoPrint), it would be this one. Combined with the MeanWell PSU upgrade also mentioned in this guide, I often forget my printer is running since it now generates so little noise.

Of course, in addition to decreasing noise, this board and its upgraded stepper motor drivers improve the quality of your prints.

There are several reasons to upgrade your Ender 3 to a MeanWell PSU including noise, safety, and even reducing bed-leveling issues.

Noise

Compared to the stock PSU whose fan runs continuously, the MeanWell PSU only runs when it needs to—usually less than 20% of the time. This means a much quieter printer, especially when paired with the silent board upgrade. This reason alone made the upgrade worth it to me. I work in the same room as my printer, so noise is a huge issue.

Safety

MeanWell PSUs use higher quality components than the cheap stock unit, providing cleaner power with fewer of the electrical spikes and sags that could pose a safety hazard.

Reduce auto-bed-leveling issues

If you're using an auto-leveling sensor such as the BLTouch or EZABL, the MeanWell PSU's consistent, clean power reduces issues related to power ripples and grounding.

Form factor

The MeanWell PSU is noticeably thinner than the stock unit, which is handy if you're using an enclosure and need to relocate it.

Which one to buy (and where)

The MeanWell LRS-3500-25 PSU is the correct 24V MeanWell power supply for the Ender 3, and this upgrade takes about 20 minutes to perform, excluding PSU housing print time.

There are tons of different build plate surfaces out there: metal, magnetic, BuildTak, painter's tape, and tons more. But after printing for many years on several different printers, I've always had the best experience with glass.

Glass beds are supremely flat, fixing the all-too-common "warped Ender 3 bed" issue that many of us experience. Glass beds also save on prep time, are easy to clean, and offer effortless print removal with a semi-glossy print finish.

Choosing a bed

I wrote a comprehensive guide to 3D printing on a glass bed if you'd like to dive into the details. tl;dr; Choose a thin borosilicate glass bed, and adhere it directly to the existing build plate using small binder clips. This 235x235mm glass bed is the one I recommend for the Ender 3.

Bed leveling the Ender series 3D printers is key to the perfect first layer and overall print quality. Unfortunately, it's also one of the most annoying "chores" in 3D printing. Just when things are going well, you realize you forgot to relevel your bed and things look terrible.

But what if a simple sensor, installed in just 45 minutes, could automatically level your bed for you every time? That's what BLTouch does.

How BLTouch works

BLTouch uses a small probe to build a mesh of points at the beginning of each print to determine exactly how unlevel (or warped) your bed is, and in which directions. It then takes that into account when performing a print, altering each GCODE instruction as needed to account for the imperfect build surface.

The process

Here's a breakdown of what goes into this upgrade:

Hardware: The probe mounts next to your print head assembly and connects to the existing Ender 3 mainboard.

Software: A slight firmware modification is needed to allow BLTouch to work.

Slicer/OctoPrint: You'll need to insert a few lines into your slicer (and OctoPrint, if equipped) so that each GCODE file you generate will include some BLTouch instructions at the top.

This Instructables guide does a good job of explaining how to do this on the CR-10, though the process is similar for the Ender 3.

Which one to buy (and where)

I recommend this BLTouch sensor (V3.1 or newer) since older versions won't work with newer Marlin firmware.

Proper print illumination allows you to identify issues with your prints early—it's also nice to be able to see what's happening clearly. There are tons of methods for adding an LED strip to your 3D printer. I prefer one that places the light source as high as possible in order to illuminate the entire print bed, not just the current print area.

I wrote a comprehensive guide on adding an LED strip to your 3D printer, featuring the Ender 3 specifically. Using the method outlined there, you can even power your LED strip directly from your Ender 3 by regulating the voltage using this buck converter in conjunction with this XT60 splitter cable.

Your bed springs might seem like an insignificant part of your 3D printer, but they're actually quite important to bed leveling and stability.

The stock Ender 3 bed springs are terrible and can lead to print issues and frequent bed leveling. These issues are largely caused by:

The cheap metal used to manufacture the springs, and

The rounded design of the springs themselves

In fact, if you compare the stock and upgraded springs side by side, you can see only the upgraded ones feature a flat surface on the top and bottom. This leads to less shifting compared to the stock springs.

Upgraded Ender 3 springs take minutes to install and mean less frequent bed leveling between prints. This upgrade costs about $10, making it one of the least expensive Ender 3 upgrades out there.

This upgrade costs about $10, making it one of the least expensive Ender 3 upgrades out there.

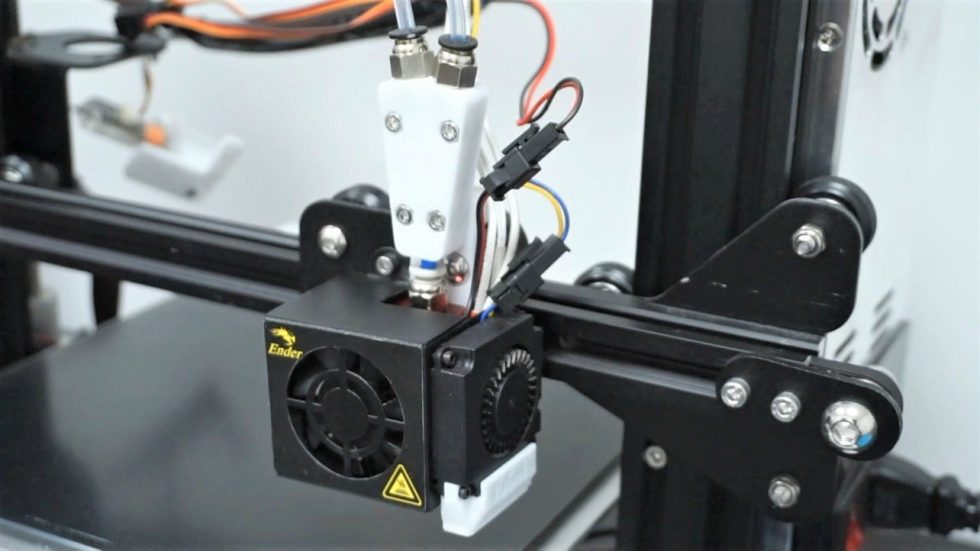

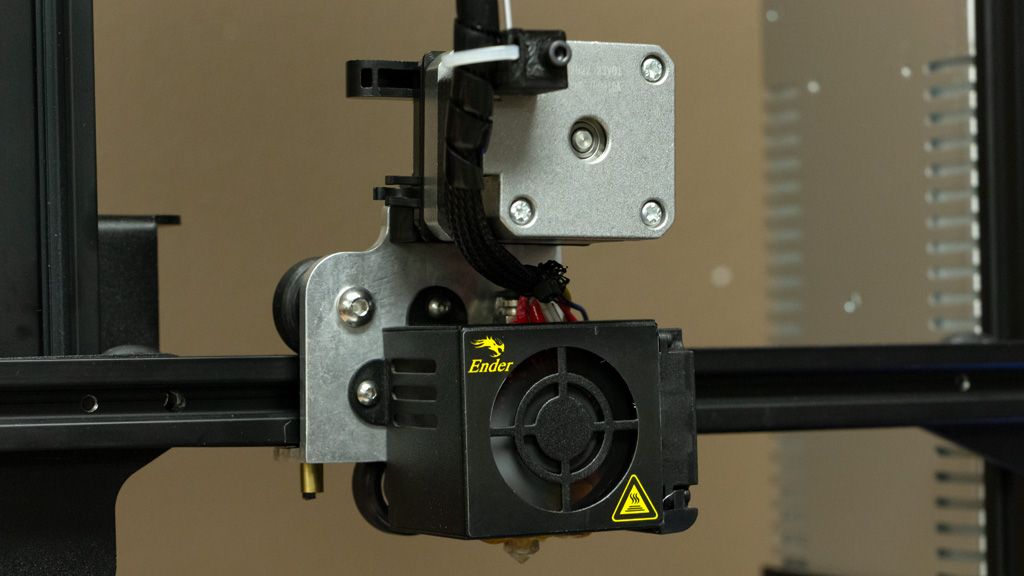

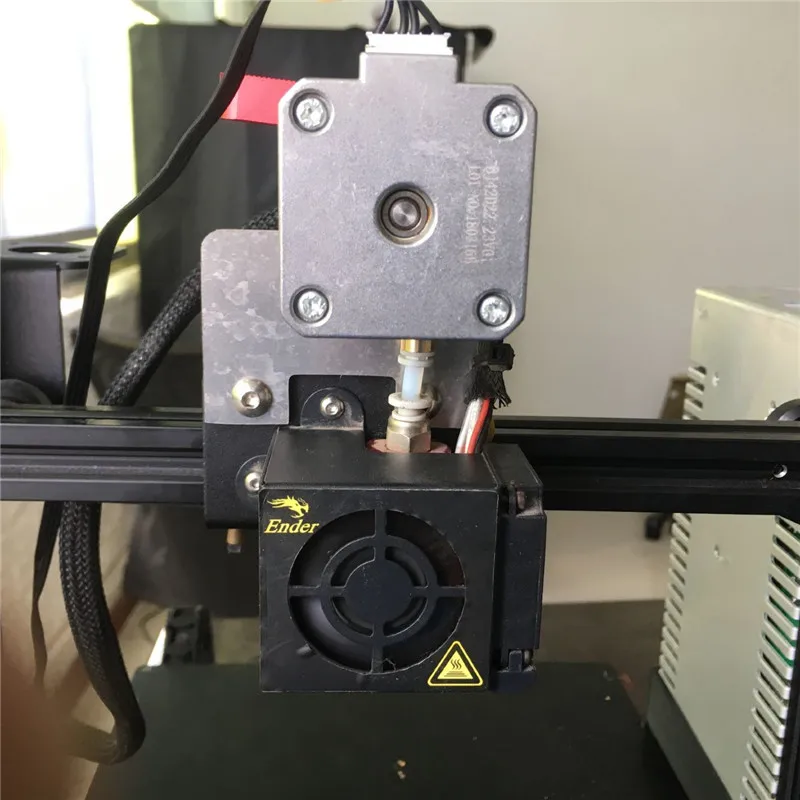

The plastic metal feeder assembly on the Ender 3 leaves something to be desired, and improper tension can even cause feeder gear skips, leaving gaps in the layers of your print. Installing an all-metal feeder assembly such as this one will add durability and stability to your printer.

Yet another noise mod—adding these dampers to your X- and Y-axis stepper motors decreases the noise they generate by 5-10dB. This is a simple, inexpensive mod with a measurable noise reduction impact.

- All-metal case, sturdy and wearable

- Direct extruding, more precise feed-in

- Compatible with more filament. such as TPU, PLA, ABS, etc

- Easy to install and use

- Suitable for Ender-3 Series

- Output voltage: 24V

Get the latest Firmware

SOURCE: howchoo.com

(Resolved) Ender 3 V2 Updates and Additions

creality-ender-3

I'm new to 3D printing. I'm about to get an Ender 3 V2, but before I do, I'd appreciate some advice on what to get as upgrades/add-ons for it. I'm not sure what I need for V2 as most of the sites are for the original Ender 3 so I don't know if V2 already has this update/addons or not compared to the original. I'd rather get all the upgrades/addons and Ender 3 V2 at the same time to save on shipping and everything else.

I'm about to get an Ender 3 V2, but before I do, I'd appreciate some advice on what to get as upgrades/add-ons for it. I'm not sure what I need for V2 as most of the sites are for the original Ender 3 so I don't know if V2 already has this update/addons or not compared to the original. I'd rather get all the upgrades/addons and Ender 3 V2 at the same time to save on shipping and everything else.

Pretty much the only update/addons I've ever seen is the auto leveling table.

If someone can help a newbie with 3D printers, that would be great!

@stealthrt, ±

In my research, the biggest differences between the original and V2 are as follows:

- Tempered carborundum glass table

- HD color screen instead of the old LCD character display

- Upgraded, 32-bit, self-evolving, “silent” motherboard

- Ability to resume printing after a power failure

- XY tensioner

- Manual filament feed

- Tool kit built into the base of the printer

For more information, you can check all3dp and Creality websites for more information.

Next, there are several YouTube videos on updates/additions that you can do:

- Firmware update

- Double Gear Extruder

- Table springs

- Another update for table glass

- Octopi

There are a few extras that you can print yourself once you get your printer (some of which are not included with the Ender 3 V2). Of course, you will have to decide which ones you want to add. Here are just a few of them:

- First 24 updates on my Ender 3 Pro

- Ender 3 Pro Updates

- Ender 3 Updates

I would suggest, like others, that you first get the printer and take it for a "test drive". Once you see its capabilities and if, again, IF something needs to be fixed/updated/upgraded, then do what your budget allows. And be sure to do extensive research, ask questions on the forums and here, and most importantly, have fun!

(Sorry, I don't have enough reputation to create more links.)

. @ agarza

@ agarza

▲ 5

IMHO it's probably best to get the printer as is first. This way you can get familiar with the printer and 3D printing in general before being overwhelmed by all the extra introduced variables from your updates.

The new model already has many features that were considered upgrades on the old model, and you can already get very good results.

Upgrading the printer is part of the 3D printing hobby and you'll probably never be done with it :)

. @ Rik

▲ 2

The first things I bought for my V2 within the first week of its release was a magnetic flex type plate as the prints were a pain in the ass to get them off the glass and update aluminum extruder. I didn't use the double gear because, frankly, I didn't pay attention to it at the time. however, the aluminum set has a more positive feeding feel compared to the stock plastic. I just felt like I was going to break my arm if I tried harder than I should have, whereas having an aluminum arm feels better. Also, maybe a BLTouch alignment sensor so you can fix things easier than with a piece of paper, but that's really all I can offer at the moment. I've been using my phone quite a lot lately and enjoying it as is. I realize this post is over a couple months old, but I just saw it and thought I'd contribute if you haven't made your purchase(s) yet.

I just felt like I was going to break my arm if I tried harder than I should have, whereas having an aluminum arm feels better. Also, maybe a BLTouch alignment sensor so you can fix things easier than with a piece of paper, but that's really all I can offer at the moment. I've been using my phone quite a lot lately and enjoying it as is. I realize this post is over a couple months old, but I just saw it and thought I'd contribute if you haven't made your purchase(s) yet.

, @ Milton

▲ 0

I have an Ender 3 v2 and haven't updated anything other than a firmware update. The first thing I suggest is to update the firmware and change the hotend to an all-metal one. This will allow you to print at higher temperatures, and the addition of a BLTouch for automatic table leveling will make your life a little easier.

, @ hfjim super

▲ 0

Agree with the approach of using V2 as is. Watch some YouTube videos about initial setup and calibration. Determine the type of printing you will be doing and determine where it falls short. This will be the driver of what you want to start updating from.

Watch some YouTube videos about initial setup and calibration. Determine the type of printing you will be doing and determine where it falls short. This will be the driver of what you want to start updating from.

Updates I have made to date:

BLTouch Table springs (should have come with BLTouch spacers) Borosilicate glass printing table (OEM tempered glass table has been shaped into a cup in the middle) Bowden tube (lower friction) X-axle belt (original crushed) All fans for extra reliability Filament guide

Between calibration and the above updates, I consistently print dimensionally accurate parts. But your situation may change as quality and tolerances change in economical parts. Would highly recommend the V2 though as the prints out of the box were much better than the quality of the draft.

, @ matt.warfield

▲ 0

According to my information, you don't need to upgrade your 3D printer, but some of the following steps to keep in mind to make your Ender 3 print better:

- Level the table.

- Set nozzle height.

- Try different build plates for different effects.

- Keep it in the sweet spot for your table temperature.

- Printer setup and maintenance is a priority.

, @ Tommy Digal

setup, customization and firmware update process

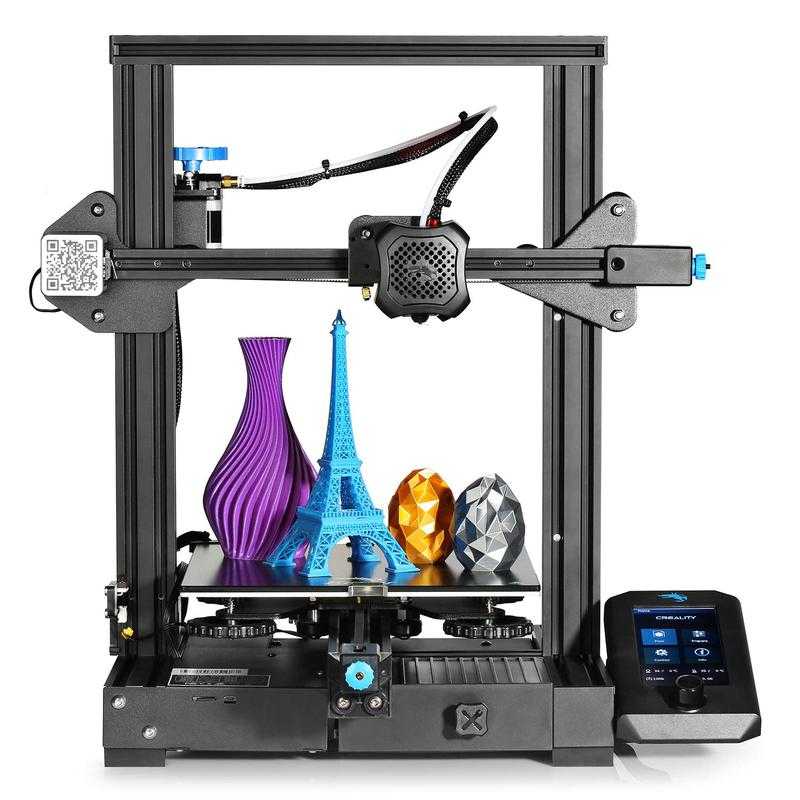

Creality Ender 3 Pro is a budget Chinese 3D printer. The device became the company's bestseller, with 200,000 models sold in 2018. The equipment prints blanks using FDM technology.

Creality Ender 3 Pro Review

Creality Ender 3 Pro comes in a DIY format: the user needs to assemble the frame and connect all the necessary nodes. Each detail is marked, beginners will not have difficulty. The model comes with a user manual detailing the assembly steps.

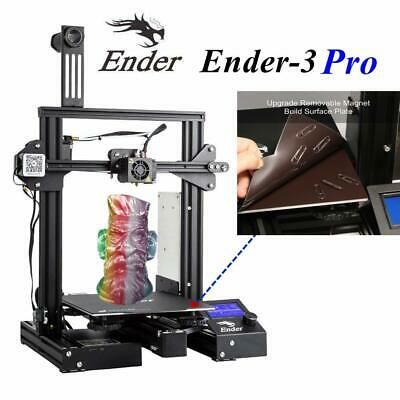

Creality Ender 3 Pro is an upgraded version of the popular Creality Ender 3. There are three main differences between the printers.

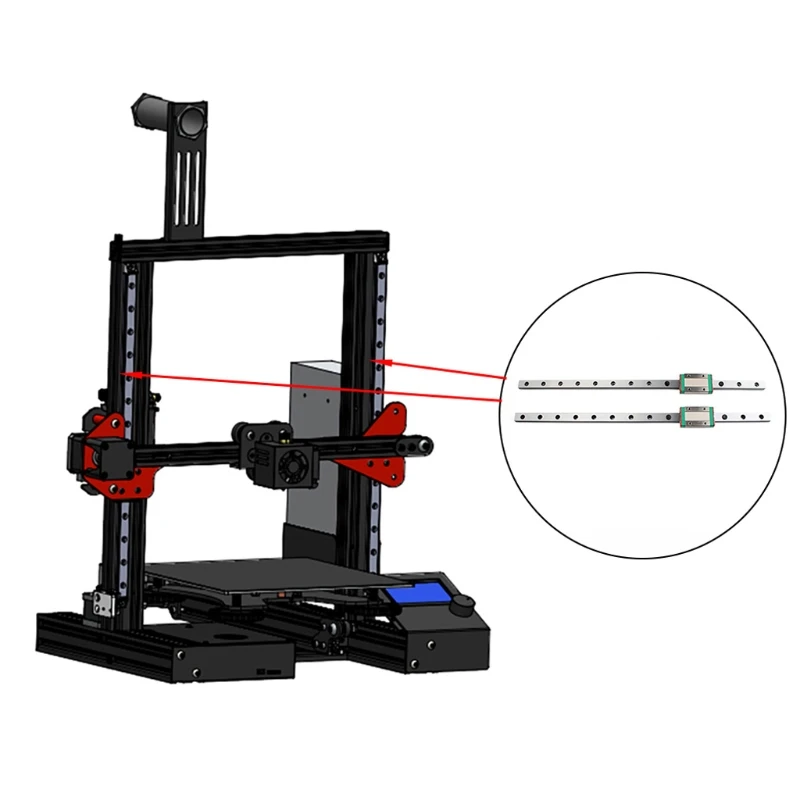

- Mechanical data. The Pro version uses a 40×40 aluminum profile to create a rigid Y-axis extrusion. This measure improves print stability. Improved guide wheels are installed, which improve the stability of work.

- There are rubberized feet at the bottom of the case. This allows you to reduce the noise level during operation. The printer is securely fixed to the surface, which reduces vibration.

- Brand new magnetic printing surface. The C-Mag magnetic backing is removable and flexible, it allows you to quickly unstick the printout from the desktop after the printer has finished working. The panel is textured, the first layer adheres well - this is important for detailed processing.

The frame of the Creality Ender 3 Pro is made of aluminum profiles. This adds rigidity and strength to the device. One screw is mounted on the left, it is responsible for the functioning of the Z axis. The model has a large heated table, which allows you to process several types of plastic.

The print chamber measures 220 x 220 x 250 mm and is suitable for medium size workpieces. It is equipped with a small monochrome LCD display and a rotary switch to control and monitor the printing process.

Chamber fully open. This is a good option for those who would like to get acquainted with the principle of operation of the extruder and consider the mechanism of 3D printing.

Description

The Creality Ender 3 Pro 3D Printer is a Chinese design that incorporates cutting-edge concepts and precision printing requirements. Works using standard Cura software. The slicer is distinguished by a multifunctional menu in which each setting item is signed. The user can choose the necessary characteristics independently.

Equipped with Meanwell power supply for stable operation and high performance. This part allows you to achieve a constant supply of electricity from the network to the device.

Aluminum V-rails ensure smooth and silent movement of the extruder along the axes. Wear-resistant rollers are installed, sliding freely during operation.

Wear-resistant rollers are installed, sliding freely during operation.

Advantages and disadvantages of

Creality Ender 3 Pro has the following advantages.

- Magnetic work surface.

There is a magnetic sticker on the platen. It provides better adhesion than glue or a textured surface. This property is especially important for working out the first layer. It is detailed and smooth.

The finished model can be removed effortlessly. It is enough to pry it with a spatula, it will move away from the surface itself.

- Patented extruder MK-10.

New technology reduces clogging and improves extrusion.

- Fast heating of the platform surface.

Platform warms up to 110°C in 5 minutes. This is facilitated by the updated UL power supply system: the device works without interruption.

- Ability to resume operation after an emergency shutdown.

If the 3D printer has a power failure or a filament supply failure while the 3D printer is running, the user will be able to resume work from the point they stopped. The device saves progress, to continue printing, you need to select the appropriate item in the menu on the external display.

The device saves progress, to continue printing, you need to select the appropriate item in the menu on the external display.

- Y-axis mounting slots are CNC machined.

They provide precise positioning and a high level of workpiece processing.

- Simple calibration.

There is a large nut under the platen. To manually calibrate the level of the table, it is necessary to rotate it in the desired direction and monitor the position of the working platform.

- Narrow filament channel.

User can work with flexible threads.

- Modernizable.

To improve print quality, control overheating of the extruder, and fine-tune the unit is upgradeable.

- Equipped with USB and Micro SD card slots.

The user can download the projects created in the slicer directly to the device, start work through the monochrome display installed on the external part.

- Compact.

The volume of the print chamber allows you to work with medium-sized workpieces. But at the same time, the device does not take up much space on the desktop.

The Creality Ender 3 Pro also has a few drawbacks.

- Magnetic base not suitable for all materials.

- Adhesion aids may be required to improve adhesion.

- The Autodesk Kickstarter test system showed that fine flow control in the printer is poorly implemented. The device cannot print objects with high detail. If there are spikes on the surface, then in the workpiece they may be of irregular shape.

- Z alignment does not work correctly. This negatively affects the development of layers.

- Fragile filament causes problems during operation. It is damaged and processed incorrectly, the finished model is different from the one that was created in the slicer.

Help! Creality Ender 3 Pro belongs to the budget class of 3D printing equipment.

It has become an improved version of its predecessor.

Creality Ender 3 Pro

The device is supplied as follows.

- 3D printer disassembled;

- hex wrench set;

- power cable;

- PLA for proof printing;

- spatula and wire cutters;

- SD card and USB adapter for SD card;

- nozzle cleaning wire;

- replacement nozzle;

- fixing kit;

- cable tie kit;

- screwdriver;

- user manual in Russian;

- warranty card.

The manual describes in detail how to build a DIY printer. For the convenience of users, there are color codes and inscriptions that help to assemble the device. Experienced assembly will take 10 minutes, beginners - about 30 minutes or an hour.

Print quality and product examples

The manufacturer suggests that you start with a test print. A three-dimensional model of a dog is supplied as a sample.

The workpiece is fuzzy. Eyebrows and eyes lack detail, the user will have to manually clean up the flaws of the printer.

Eyebrows and eyes lack detail, the user will have to manually clean up the flaws of the printer.

Piglet also failed. The left side is covered with potholes, a notch appeared between the ears. The ears are processed in different ways, the patch is without details, lubricated.

During the printing process, the problem of filament breakage may occur, as users write about in the reviews. An example is a model of a toy boat.

The device could not print the top part. The preparation was left unfinished.

A set of simple geometric products, the printer prints well after correcting the shortcomings in the settings. The surface is smooth, the filament is fed evenly without interruption.

With the correct setting and correcting of defects in the positioning of the table, the printed models come out clear.

Details of its structure are visible on the body of the dragon: scales and fangs are printed, all spikes are of different lengths and are at different levels.

Geometric patterns print well after adjusting the extruder. The layers are uniform, without gaps.

WOOD prints parts with moving parts.

An Autodesk Kickstarter issue occurs during printing of spikes. On the turtle on the right, this is clearly visible: filament threads are visible on the surface, there is not enough smoothness and clarity.

The gaps in the man's torso are made hollow, as it was created in the slicer. There are no filament threads and fuzzy printed edges. An identical problem occurred when printing a figure with spiers.

Tips came out fuzzy. They are of different heights and thicknesses. The lower part is processed without significant remarks.

What types of plastics does he use?

Creality Ender 3 Pro can print on the following plastics:

- ABS;

- TPU;

- WOOD;

- PLA;

- PETG.

The platform warms up to 110 °C, which allows you to work with different types of plastic.

Upgrade

You can upgrade yourself to improve print accuracy, improve user experience, and eliminate minor imperfections.

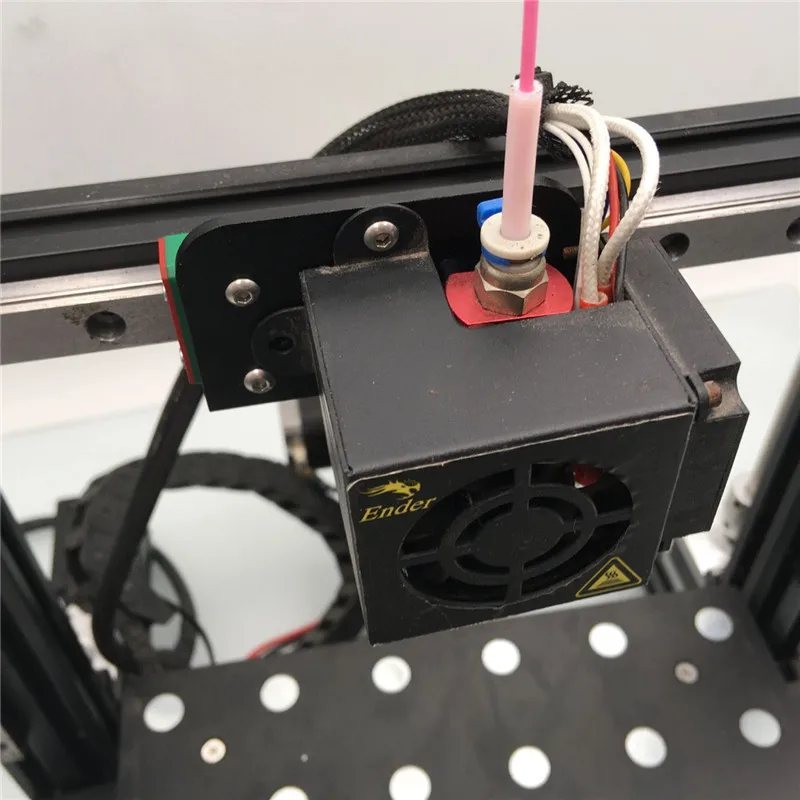

- Extruder replacement.

The plastic filament feeder is unstable. This leads to defects during printing, the printer does not print details, makes the layers fuzzy. The plastic mechanism backlash, before work, the screw must be tightened tightly. Due to the constant control of the screw, the pressure roller may jam, which will lead to uneven processing of the layers.

Users experiencing this issue are advised to replace the filament feed mechanism before use. A compact self-printing version is suitable: it can be used with a standard roller, a feed gear and a spring with the ability to adjust the clamping force.

- Cooling system

One of the common problems with Creality printers is the poor performance of the cooling system. If this deficiency is not corrected, the print quality will deteriorate. The thermal barrier overheats, the plastic softens, the extruder does not process all the necessary zones.

The thermal barrier overheats, the plastic softens, the extruder does not process all the necessary zones.

Fans must be replaced immediately to avoid overheating and defects in finished blanks. They should be 40 x 40 x 20 mm in size and with a potential of 24 V. A powerful cooling system is necessary to work with PLA plastic.

It is also recommended to replace the cooling system of the board. If it overheats during operation, the drivers may stop working, defects are found on the blanks during printing. A suitable fan model is with dimensions of 70 × 70 × 15 mm. For installation, you must first print a new cover with a suitable size or increase the airflow hole.

It is also recommended to install a dust filter. It is not included in the kit. It can be printed on a printer or purchased at a store.

Initial Setup and Setup Instructions

Creality Ender 3 Pro DIY Model. The user needs to assemble it himself and prepare it for work. To do this, the kit includes a Russian-language user manual. It describes the process of assembling the equipment step by step and with illustrations.

It describes the process of assembling the equipment step by step and with illustrations.

- Mounting the axle guides.

Before screwing in the vertical guides, check the play on the table rollers. Tighten the eccentrics with the key from the kit, do not press them hard, so as not to accelerate wear.

Insert the rails into the lower part of the frame, screw into the end with a pair of screws M 5 × 45. To do this, use the hexagon that is included in the kit. It is important to observe the distance from the edge of the rail to the frame hole, as indicated in the instructions.

- Shield and power supply assembly.

To mount the screen, take M 5 × 8 screws from the kit. Screw the display obliquely into the end part of the profile. The power supply is fixed with M 4 × 20 screws to the vertical rails.

- Installation of the limit switch on the axle.

Take a small fee from the Z-limit package. It is screwed with plastic guides to the necessary protrusions. Screw the board, connect with a wire marked "Z" to the control unit.

It is screwed with plastic guides to the necessary protrusions. Screw the board, connect with a wire marked "Z" to the control unit.

- Installing the motor on the axle.

The part for fastening the motor to the frame is made of durable plastic and is already attached to the motor. The task of the user is to screw it to the frame and connect it to the designated wire. After that, you need to insert the trapezoidal screw into the coupling and tighten it.

- X-axis assembly.

The X-axis is supplied almost completely assembled. It is necessary to fix the guide, on which then install the carriage with the hotend. There are holes on the body plates through which you need to tighten the screws to secure the rail. Finally install the fitting for the extruder.

- Carriage installation with hotend.

Take a plate with three rollers, a pair of M 4 × 16 screws and a carriage with a hot end, which must be adjusted after being installed on the rail. Tighten the screws so that the carriage does not wobble, but do not compress them too much.

Tighten the screws so that the carriage does not wobble, but do not compress them too much.

- Install the belt on the X-axis.

In order for the carriage with the hot end to move along the axis, you need to mount the belt. The kit comes with a part of the required length, copper plates are installed at the ends. Pass it through the holes indicated in the instructions, on the other hand, install the tensioner. Fix the belt in the carriage by inserting the aglet into the slot.

- Installing the tensioner on the X-axis belt.

This is the last stage of the X-axis assembly. Insert the tensioner from the end of the guide, slightly tension the belt without creating maximum tension. Secure the tensioner with swivel T-nuts - they are inserted into the channel and tightened with screws. Do not screw them in to the limit.

- Installing the X-axis on vertical rails.

For mounting, slide the axle onto the vertical rails. Loosen the axial fasteners so that the screw enters the trapezium. They should move slightly. Lower the axle.

Loosen the axial fasteners so that the screw enters the trapezium. They should move slightly. Lower the axle.

- Top rail fastener.

Take the remaining rail and 4 screws M 5 × 25, screw them in and install the end caps on the end of the rails.

- Mounting the spool holder.

Attach the metal holder with screws to the location indicated in the instructions.

- Wiring.

All connectors and wires are marked, some of them are connected during the assembly of the printer. Complexity may arise at the stage of connecting the screen. The connector is on the right when looking at the device from the side of the board.

It remains to connect the motor connectors on the X axis, the limit switch on the X axis and the extruder. The printer will be ready for use after calibration.

The height of the table must be adjusted before use. If it is not set, the printing process will not start or will fail.

Check the setting of the Z-axis limit switch, set it in such a position that the limit switch is pressed when the X-beam is lowered. The nozzle should not rest against the table; a small margin should be left in the springs to adjust the height. This is necessary so that the nozzle does not rest against the table during calibration.

Turn on the printer, select the "AutoHome" item in the menu, the carriages will move to the zero mark. Turn on the heating of the extruder to 200° and the table to 50°. After everything warms up, start adjusting.

Disable steppers in the menu (select "Disable steppers"). This allows you to adjust the position of the carriages along the X and Y axis manually. The Z axis does not need to be touched, it is already at the required point. Move the carriage with your hands over the entire surface of the table, starting from the corners. Raise and lower the table with rollers installed from below. It is necessary to ensure that the nozzle touches the table at all points butt.

Firmware for Creality Ender 3 Pro

In order for the 3D printer to work correctly, the user needs to install an updated firmware version. You can download the required Marlin software here. Before you start, you also need to install the Arduino IDE to edit the firmware. You can download from the official website by following the link.

Attention! Choose the latest version of the Arduino IDE as older ones may not work with the updated Marlin.

- Go to the "Marlin" folder, open the Marlin.ino file through the Arduino IDE program.

- A field for editing printer settings opens.

- Go to "Configuration.h".

- Search for "Ender 3 Pro".

- Uncomment the initialization line (remove "//" before the device name).

- Uncomment the "define DISABLE BOOT" line. This will speed up the boot process of the device by disabling the splash screen on the screen.

- Change the printer name in the "define USER_PRINTER_NAME" field.

Uncomment and type "Ender 3 Pro".

Uncomment and type "Ender 3 Pro". - Automatic calibration settings do not need to be changed.

- Go to "Tools", select "Sanguino" in the "Board" field, replace the programmer with Arduino as ISP. Click on Download Bootloader. Wait for the process to complete.

- Restart printer.

Creality Ender 3 Pro is ready to go.

Conclusion

The Creality Ender 3 Pro is a budget open chamber 3D printer. It is equipped with the possibility of additional changes: the user can install a new extruder, dust filter and replace the cooling system with a more powerful one.

- The model is completed with a magnetic table. This increases adhesion and makes it easy to remove finished products with a spatula.

- The front panel has a monochrome display and a switch to control the printing process.

- There is a function to restore work from the last point after a crash.

- Works with several types of plastic: TPU, WOOD, PLA, PETG.

Learn more