Polyjet 3d printing wiki

3D printing - Wiki | Golden

3D printing, also known as additive manufacturing or additive layer manufacturing, is the construction of a three-dimensional object from a digital 3D model. The name additive manufacturing comes from the differentiation of 3D printing, which adds material layers upon each other to build an object, from the more traditional process of subtractive manufacturing, which removes material through milling, machining, carving, and shaping to create an object.

Traditionally, subtractive manufacturing has been used for high production volume manufacturing, while additive manufacturing has been reserved for prototyping and rapid tooling. However, the increased cost-effectiveness of additive manufacturing, the reduction of material waste, and the increased mainstream adoption of 3D printing systems has increased the use of additive manufacturing systems. These, along with the increased precision, repeatability, and material range of 3D printing, have increased the use of the technology for higher volume production.

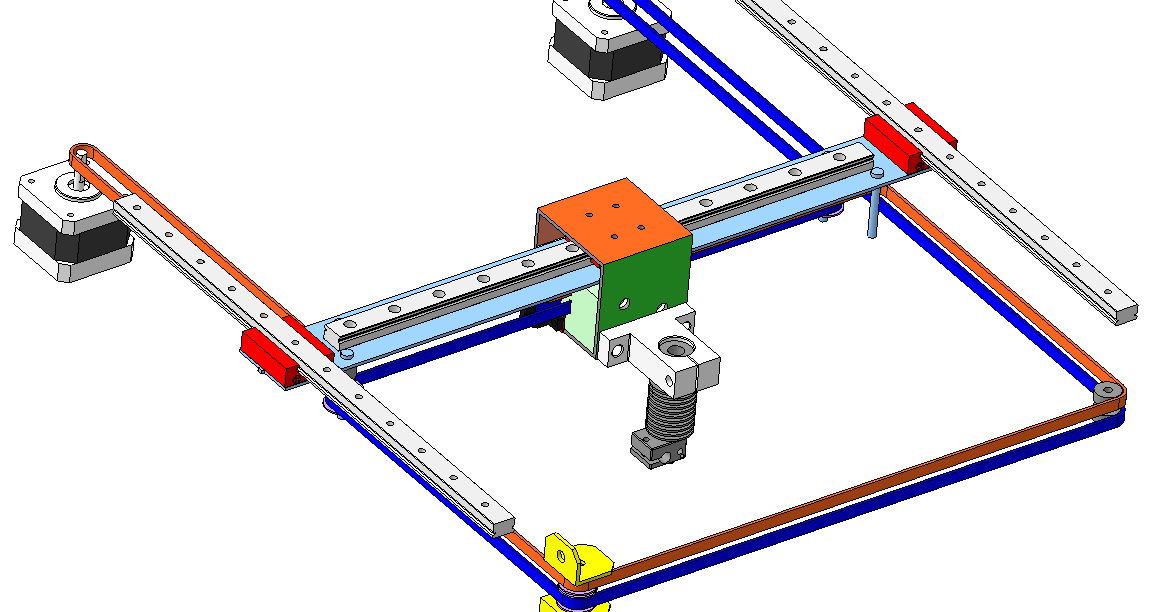

In the case of most 3D printers, a user creates a design using computer aided design software or by scanning an object to print. Software translates the design into the printed layers and framework for the machine to follow. The plan is sent to the printer, which begins creating the object. The materials capable of being printed include polymers, metals, ceramics, foams, gels, and biomaterials.

Processes

Material extrusion

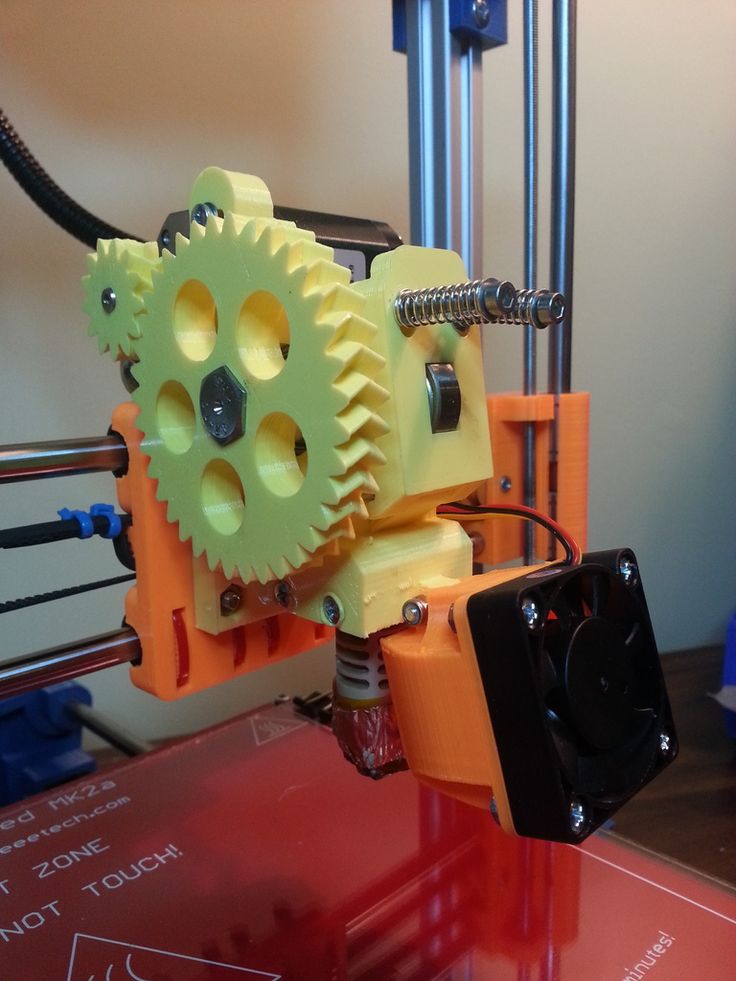

Material extrusion printing, or fused filament fabrication, also known by the trademarked term "fused deposition modeling," is a 3D printing process using a continuous filament of a thermoplastic material. Through this method, filament is fed through a moving, heated printer extruder head and deposited on a growing work. Printers using this method use a computer to control the printed shape. And printers of this type layer the printed object one horizontal layer at a time before making a small vertical move to start the next layer. The extruder head speed can be controlled to start and stop deposition in order to form an interrupted plane without stringing or dribbling between sections. Fused filament fabrication is the more popular printing process (by number of machines) for hobbyist-grade 3D printing.

The extruder head speed can be controlled to start and stop deposition in order to form an interrupted plane without stringing or dribbling between sections. Fused filament fabrication is the more popular printing process (by number of machines) for hobbyist-grade 3D printing.

The fused deposition modeling technique was developed by S. Scott Crump, the co-founder of Stratasys, in 1988. The patent on the technology expired in 2009 and presented the beginning of people using the type of printing without paying rights to Stratasys. This allowed commercial, hobbyist, and open-source 3D printer applications to grow.

The materials capable of being extruded by fused filament fabrication machines include thermoplastics, such as acrylonitrile butadiene styrene (ABS), polylactic acid (PLA), high-impact polystyrene (HIPS), thermoplastic polyurethane (TPU), and aliphatic polyamides (nylon).

Stereolithography (SLA)

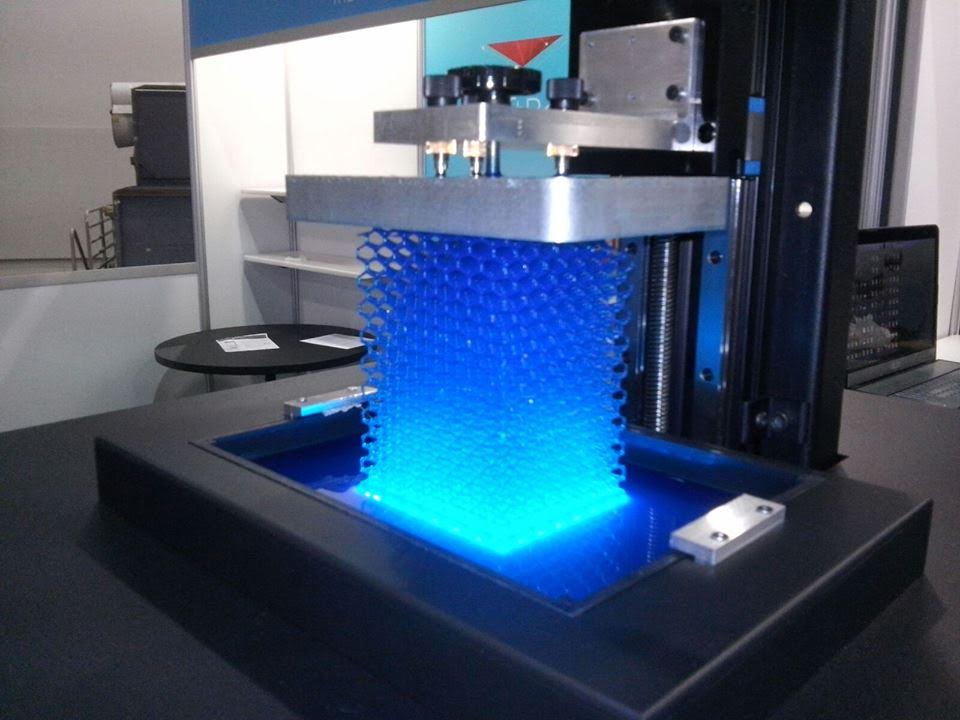

Stereolithography (SLA), also known as optical fabrication, photo-solidification, VAT photopolymerisation, or resin printing, is a 3D printing technology that prints parts in a layer-by-layer fashion using photochemical processes. SLA uses light to cause chemical monomers and oligomers to cross-link and form polymers that, in turn, make the body of a three-dimensional solid. The process is fast and can produce almost any design, but can be cost prohibitive. The main fields of application include products in development, medical models, and computer hardware.

SLA uses light to cause chemical monomers and oligomers to cross-link and form polymers that, in turn, make the body of a three-dimensional solid. The process is fast and can produce almost any design, but can be cost prohibitive. The main fields of application include products in development, medical models, and computer hardware.

The materials used in SLA printing are referred to as resins and are thermoset polymers. These resin materials can be soft or hard, filled with secondary materials such as glass and ceramic, or imbued with mechanical properties such as heat deflection or impact resistance. In the post-process of SLA manufacturing, parts need to be removed from a support structure, and alcohol and water rinses are used to remove excess resin. At times, post processing can include scrubbing to remove additional material, and some processes use ultraviolet light for a post-cure process.

Stereolithography was first developed in the early 1980s by Hideo Kodama, who used ultraviolet light to cure photosensitive polymers. French inventors Alain Le Mehaute, Oliver de Witte, and Jean Claude Andre filed an early patent for technology that was later abandoned. The final patent, which gave the process the name "stereolithography," was filed by Chuck Hull in 1984 and granted in 1986. Chuck Hull later founded 3D Systems to commercialize the patented technology.

French inventors Alain Le Mehaute, Oliver de Witte, and Jean Claude Andre filed an early patent for technology that was later abandoned. The final patent, which gave the process the name "stereolithography," was filed by Chuck Hull in 1984 and granted in 1986. Chuck Hull later founded 3D Systems to commercialize the patented technology.

Powder bed fusion

The powder bed fusion manufacturing process includes the printing techniques of direct metal laser sintering, electron beam melting, selective heat sintering (SLS), selective heat sintering, and selective laser melting (SLM). All methods use either a laser or an electron beam to melt and fuse material powder together. The methods involve spreading the powder material over previous layers, using either a roller or a blade while a hopper or reservoir provides fresh material supply. In all methods, a layer, typically 0.1 millimeters thick, of material is built over the platform and the laser or electron beam fuses new material in layers or cross-sections. Materials capable of being used in powder bed fusion manufacturing processes include nylon, stainless steel, titanium, aluminum, cobalt chrome, steel, and copper.

Materials capable of being used in powder bed fusion manufacturing processes include nylon, stainless steel, titanium, aluminum, cobalt chrome, steel, and copper.

In direct metal laser sintering, metal powders are sintered layer by layer with a range of metals available.

In electron beam melting (EBM), layers are fused using an electron beam to melt metal powders. In the EBM process, a vacuum is required with a pressure of 1×10-5 mba, and electromagnetic coils are used to control the beam. The EBM process also produces better strength properties due to even temperature during fusion. These strength properties with the high quality and finish of the product suits it to manufacturing of parts for aerospace and medical applications.

In selective laser sintering (SLS), machines are made up of three components: a heat source, a method to control the heat source, and a mechanism to add new layers of materials. The SLS process requires no additional support structure for the product being printed. In the SLS chamber, nitrogen is often used to maximize the oxidation and end quality of the model. A cool-down period is also required to ensure high tolerance and quality of fusion. Some SLS machines monitor the temperatures layer by layer and adapt the power to improve quality. SLS processes use plastic powders, rather than metal powders used in direct metal laser sintering.

The SLS process requires no additional support structure for the product being printed. In the SLS chamber, nitrogen is often used to maximize the oxidation and end quality of the model. A cool-down period is also required to ensure high tolerance and quality of fusion. Some SLS machines monitor the temperatures layer by layer and adapt the power to improve quality. SLS processes use plastic powders, rather than metal powders used in direct metal laser sintering.

Selective heat sintering uses a heated thermal printhead to fuse powder material. Layers are added with a roller between fusion of layers. The use of a thermal printhead reduces the heat and power levels required for printing. Selective heat sintering systems use thermoplastic powders and require support materials in the process of printing. The process is often used to create concepts prototypes rather than structural components.

Selective laser melting (SLM) is similar to selective laser sintering, except it is faster while requiring the use of an inert gas and requiring higher energy use with poor overall energy efficiency. Through the process, a roller or blade is used to spread new layers of powder over previous layers. In cases when a blade is used, the blade is often vibrated to encourage a more even distribution of powder.

Through the process, a roller or blade is used to spread new layers of powder over previous layers. In cases when a blade is used, the blade is often vibrated to encourage a more even distribution of powder.

Material jetting

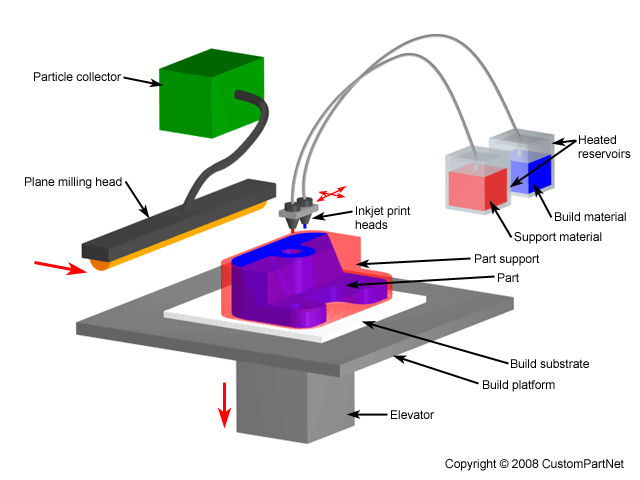

Material jetting, also known as multi-jet modeling, creates objects in a similar method to an inkjet printer. The process uses droplets to build a material on a support structure, while ultraviolight light or heat cures the droplets to create a 3D object. In the technique, droplets are selectively deposited on an X, Y, and Z axis controlled by computer and based on computer-aided designs. Common materials used in material jetting machines include polymers and waxes, due to their viscous nature that can form droplets. Overall, the materials suitable for use in material jetting machines are limited. And the parts printed through material jetting printers are mainly suitable for non-functional prototypes, as the printed parts often have poor mechanical properties.

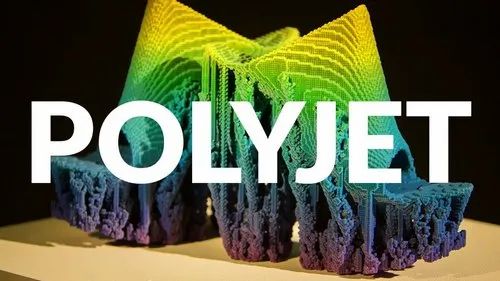

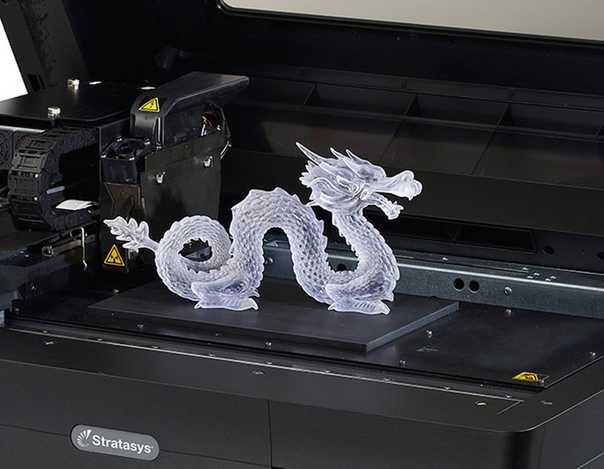

The types of material jetting technologies include PolyJet technology, NanoParticle Jetting, and Drop On Demand. PolyJet technology jets thin layers of photopolymer material onto a build tray, in which each layer is cured by ultraviolet light. PolyJet technology was the first material jetting technology introduced. The PolyJet process was developed by Object and was later bought by Stratasys.

NanoParticle jetting technology was developed by XJet and uses a dispersion methodology to deposit solid nanopoarticles suspended in a liquid and jetted onto the build tray. In the system, two printheads and thousands of nozzles spray ultrafine drops that both build and support materials onto the build trays, while high temperature in the build area evaporates the liquid jacket around the nanoparticles. The remaining nanoparticles are sintered and the support material is removed, with a thin and smooth surfaced product capable of fine details remaining.

Drop on demand (DOD) technology is a process typically used for viscous materials, and consists of deposits tiny dots of material instead of continuous lines. The printers consist of two heads for each build and support material and are often used for make wax patterns for investment casting. In the printing process, wax material is printed in layers with the support material automatically laid down and eliminating the need for designers to create support structures. The finished part is placed in a liquid bath which dissolves the support material away.

Binder Jetting

Binder jetting is a manufacturing technique in which a binding liquid is selectively deposited to join powder material to form a 3D part. The process does not require heat during the printing process. Exon, an early developer of the binder jetting technique, uses furan binder, silicate binder, phenolic binder, and aqueous-based binder for their binder jetting printers. Regardless of binder, the process of a binder jetting printer sees the application of a layer of material powder, followed by a printhead depositing the binder adhesive on the powder where required until a 3D model is finished. The unbound powder remains until it is removed.

Regardless of binder, the process of a binder jetting printer sees the application of a layer of material powder, followed by a printhead depositing the binder adhesive on the powder where required until a 3D model is finished. The unbound powder remains until it is removed.

Binder jetting processes can manufacture in a range of different colors and in a range of metal, polymers, and ceramics. The two-material process allows for many different binder-powder combinations with various mechanical properties. However, often, through the use of specific binder materials, binder jetting printed materials are not always suitable for use as structural parts.

Sheet Lamination

Sheet lamination is a process of building a 3D object by stacking and laminating thin sheets of material. The lamination method can be bonding, ultrasonic welding, or brazing while a final shape is achieved through laser cutting or CNC machining. Sheet lamination produces parts with the least additive resolution compared to other additive manufacturing processes; however, it is a low cost and offers fast manufacturing times from easily available low-cost material.

The materials involved in sheet lamination include paper, plastic, metal, and woven fiber composites. Forming methods include CNC milling, laser cutting, and aqua blasting. And the lamination techniques include adhesive bonding, thermal bonding, and ultrasonic welding. The process either follows a form then bond process, in which sheet material is cut into shape and then bonded layer on layer to create a 3D object. Or it follows a bond then form process, in which the material layers are bonded and then cut into the desired shape. Sheet lamination types, each offering some kind of variation of the above methods, can be categorized into seven types:

- Laminated object manufacturing (LOM)

- Selective lamination composite object manufacturing (SLCOM)

- Plastic sheet lamination (PSL)

- Computer-aided manufacturing of laminated engineering materials (CAM-LEM)

- Selective deposition lamination (SDL)

- Composite based additive manufacturing (CBAM)

- Ultrasonic additive manufacturing (UAM)

Directed Energy Deposition

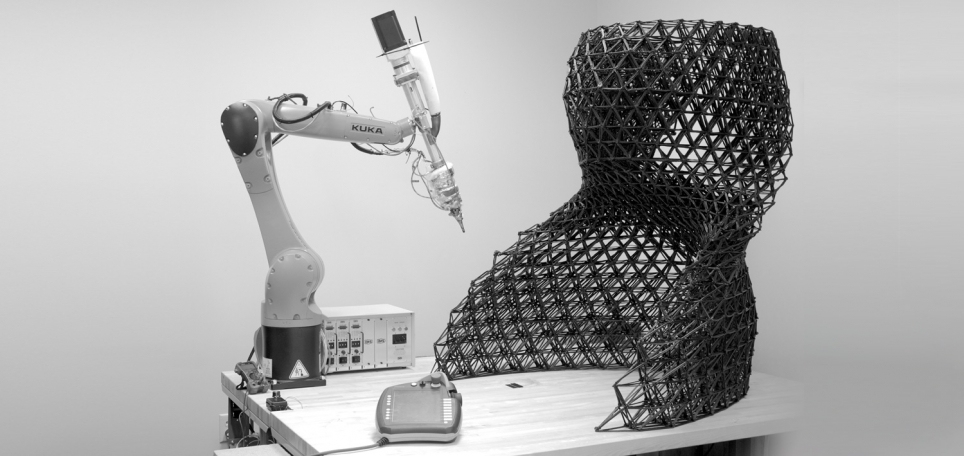

Directed energy deposition is an additive manufacturing process that forms 3D objects by melting material as it is deposited using focused thermal energy such as laser, electron beam, or plasma. Both energy source and the material feed nozzle are manipulated using a gantry system or robotic arm. Due to the nature of direct energy deposition, even though it is possible to create 3D objects from scratch, the process is generally used for adding to an existing part or repairing existing parts. Direct energy deposition systems are used in hybrid manufacturing, in which a substrate bed is moved to create complex shapes.

Both energy source and the material feed nozzle are manipulated using a gantry system or robotic arm. Due to the nature of direct energy deposition, even though it is possible to create 3D objects from scratch, the process is generally used for adding to an existing part or repairing existing parts. Direct energy deposition systems are used in hybrid manufacturing, in which a substrate bed is moved to create complex shapes.

Direct energy deposition systems can be used to make metal, ceramic, and polymer parts, although they are primarily used to make metal parts. The types of systems include laser-based systems, such as Optomec's laser engineering net shape system, which uses a laser as the main energy source. An electron beam based system, such as Sciaky's electron beam additive manufacturing system, uses electron beams to melt the powdered material feedstock. And the plasma or electric arc based system, such as Wire's arc additive manufacturing process use electric arcs to melt wire.

The suitable materials for direct energy deposition systems include niobium, titanium and titanium alloys, inconel, stainless steels, hastelloy, aluminum alloy, tantalum, zinc alloy, tungsten, and copper-nickel alloys. Direct energy deposition systems are used in industries such as aerospace, defense, oil and gas, and the marine industry.

Applications

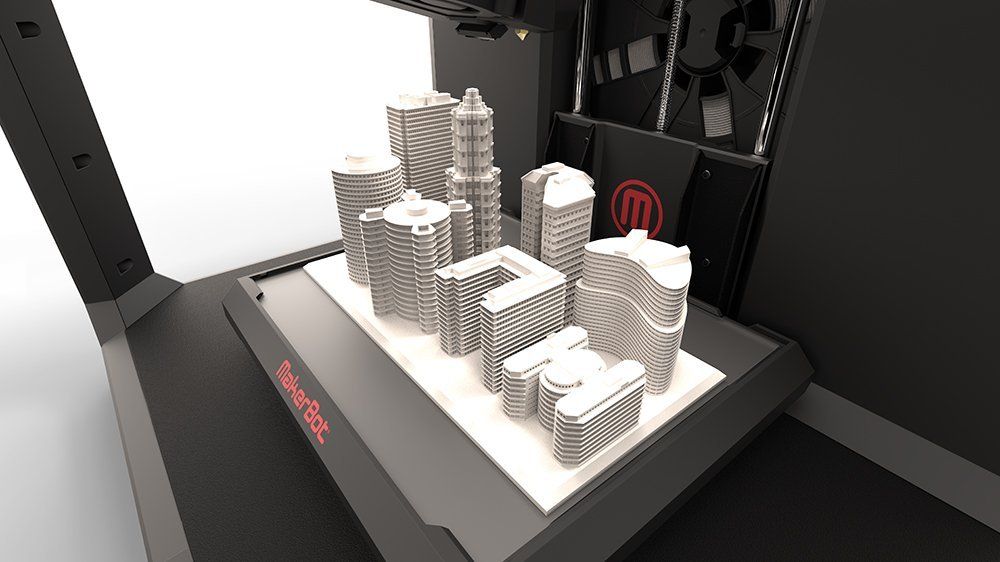

The applications for 3D printing are various across industries and for hobbyist uses with the introduction of lower cost printing technology.

Housing

3D printing is being explored as a construction method that reduces the costs of on-site construction and time-to-build of a home. The application of 3D printing in home construction has been explored as an affordable housing solution for urban areas.

3D printing companies in housing industry

Aerospace

Additive manufacturing systems are capable of producing lightweight parts with complex geometric designs useful for the aerospace industry. In 2013, NASA tested SLM-printed rocket injector during a hot fire test generating 20,000 pounds of thrust. In 2015, the FAA cleared 3D-printed parts for use in commercial jet engines. In the 2017 Paris Air Show, the Boeing 787 displayed FAA-certified structural parts fabricated from 3D printing of titanium wire.

In 2013, NASA tested SLM-printed rocket injector during a hot fire test generating 20,000 pounds of thrust. In 2015, the FAA cleared 3D-printed parts for use in commercial jet engines. In the 2017 Paris Air Show, the Boeing 787 displayed FAA-certified structural parts fabricated from 3D printing of titanium wire.

3D printing companies in aerospace industry

Automotive

The automotive industry has used 3D printing processes for rapid prototyping. As manufacturing techniques have advanced, 3D printing has been used for developing automotive parts. This includes the McLaren Formula 1 racing team using 3D printed parts in their race cars, including a rear wing replacement that took ten days to produce using 3D printers, instead of the five weeks subtractive manufacturing can take. In 2014, Koenigsegg, Swedish supercar manufacturer, used 3D printing for many components. Most of the manufacturing processes extend to the bodywork and related elements, but do not extend to the powertrain.

Healthcare

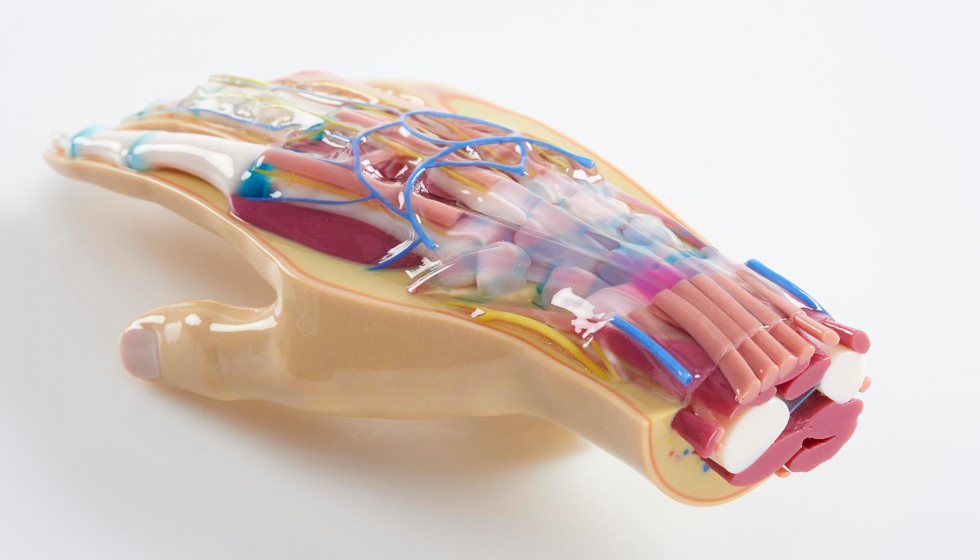

Additive manufacturing has been used in the healthcare industry to produce medical items and prosthetics. This has included medical device manufacturing company Stryker using additive manufacturing technology to create surgical implants for patients suffering from bone cancer. A clinical study done by the New York University School of Medicine is looking into the use of patient-specific, multi-colored kidney cancer models and whether they can effectively assist surgeons with pre-operative assessments.

There have been studies into the viability of 3D bio-printing for use in tissue engineering applications, including the printing of organs and body parts. In the process, layers of living cells are deposited onto a gel medium or sugar matrix to build a three-dimensional structure, including vascular systems. In May 2018, a 3D printing system was used for a kidney transplant to save a three-year-old boy.

In the pharmaceutical industry, 3D printing systems are being used by researchers as a new way to develop formulations of materials and compounds not possible with conventional techniques such as tableting or cast-molding. One of the possible uses of 3D printing in pharmaceuticals is to print personalized dosages to better target patient needs.

One of the possible uses of 3D printing in pharmaceuticals is to print personalized dosages to better target patient needs.

3D printing companies in healthcare industry

Clothing

In the clothing and fashion industry, designers and manufacturers have experimented with 3D printed clothing items, including Nike using 3D printing to prototype and manufacture their 2012 Vapor Laser Talon football shoes and New Balance 3D manufacturing custom-fit shoes for athletes.

Shoes

In 3D printing for shoes, the additive manufacturing techniques offers a chance for creators and designers in the fashion industry to create designs and collections with shapes or designs that could be otherwise unable to create in subtractive manufacturing methods. As well, there are many projects launching to develop new speakers, futuristic lightweight footwear, and customer printed shoes for specific athletes.

Food

Additive manufacturing systems, or analogues, are also being used in the manufacturing of food. The foods printed have included chocolate, candy, crackers, pasta, and pizza. NASA has pursued research into the technology to reduce food waste and design foods to fit astronauts' dietary needs. And in 2018, Giuseppe Scionti developed technology to generate fibrous plant-based meat analogues using a custom-built 3D bioprinter.

The foods printed have included chocolate, candy, crackers, pasta, and pizza. NASA has pursued research into the technology to reduce food waste and design foods to fit astronauts' dietary needs. And in 2018, Giuseppe Scionti developed technology to generate fibrous plant-based meat analogues using a custom-built 3D bioprinter.

Often 3D printing in foods describes an additive manufacturing process, such as an automated pizza vending machine that is capable of extruding dough, topping the dough with tomato sauce and cheese, and sending that to an oven. Food can, especially in the case of viscous foods, be printed fairly easily. 3D printing has been used for decorating and deserts where the accuracy of the printer can create complex designs. However, in the case of other types of food, 3D printing can be more restrictive. As well, in the case of 3D printing new or novel foods, the technology is further behind its peers, as the technology can be prohibitively expensive and often is not scalable.

Firearms

Additive manufacturing has been used in the firearms industry to offer a new manufacturing method for established companies, and has produced possibilities for the do-it-yourself manufacturing of firearms.

All 3D printing companies

Guide to Resin 3D Printers

There are many 3D printing processes on the market. Getting familiar with the nuances of each helps to clarify what you can expect from final prints to ultimately decide which technology is suitable for your particular application.

Stereolithography (SLA) and digital light processing (DLP) 3D printing are the two most common processes for resin 3D printing. Resin printers are popular for producing high-accuracy, isotropic, and watertight prototypes and parts in a range of advanced materials with fine features and smooth surface finish.

While these technologies were once complex and cost-prohibitive, today’s small-format desktop SLA and DLP resin 3D printers produce industrial-quality parts at an affordable price point and with unmatched versatility thanks to a wide range of materials.

Both processes work by selectively exposing liquid resin to a light source—SLA a laser, DLP a projector—to form very thin solid layers of plastic that stack up to create a solid object. While very similar in principle, the two technologies can produce significantly varying outputs.

In this in-depth guide, we walk through the details of the two resin 3D printing processes and explore how they compare in terms of resolution, accuracy, build volume, speed, workflow, and more.

Sample part

See and feel Formlabs quality firsthand. We’ll ship a free sample part to your office.

Request a Free Sample Part

Desktop SLA 3D printers contain a resin tank with a transparent base and non-stick surface, which serves as a substrate for the liquid resin to cure against, allowing for the gentle detachment of newly-formed layers.

The printing process starts as the build platform descends into a resin tank, leaving space equal to the layer height in between the build platform, or the last completed layer, and the bottom of the tank. A laser points at two mirror galvanometers, which direct the light to the correct coordinates on a series of mirrors, focusing the light upward through the bottom of the tank and curing a layer of resin.

A laser points at two mirror galvanometers, which direct the light to the correct coordinates on a series of mirrors, focusing the light upward through the bottom of the tank and curing a layer of resin.

The cured layer then gets separated from the bottom of the tank and the build platform moves up to let fresh resin flow beneath. The process repeats until the print is complete.

Low Force Stereolithography (LFS) technology, used by the Form 3+ and Form 3L, is the next phase in SLA 3D printing.

In LFS 3D printers, the optics are enclosed in a Light Processing Unit (LPU). Within the LPU, a galvanometer positions the high-density laser beam in the Y direction, passes it through a spatial filter, and directs it to a fold mirror and parabolic mirror to consistently deliver the beam perpendicular to the build plane and ensure accurate, repeatable prints.

As the LPU moves in the X direction, the printed part is gently peeled away from the flexible bottom of the tank, which drastically reduces the forces exerted on parts during the print process.

LFS 3D printing drastically reduces the forces exerted on parts during the print process, using a flexible tank and linear illumination to deliver incredible surface quality and print accuracy.

This advanced form of stereolithography delivers vastly improved surface quality and print accuracy. Lower print forces also allow for light-touch support structures that tear away with ease, and the process opens up a wide range of possibilities for future development of advanced, production-ready materials.

White Paper

Looking for a 3D printer to realize your 3D models in high resolution? Download our white paper to learn how SLA printing works and why it's the most popular 3D printing process for creating models with incredible details.

Download the White Paper

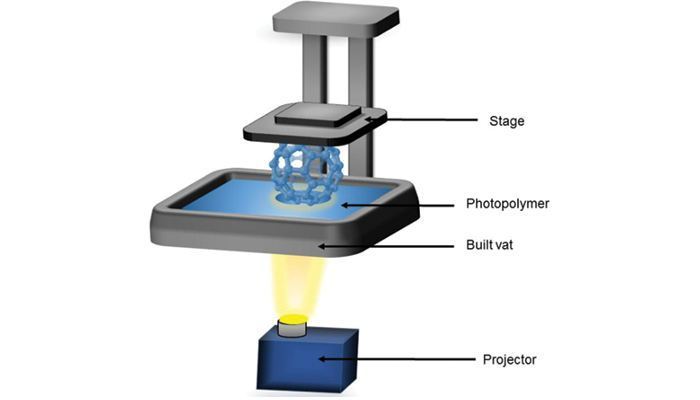

Just like their SLA counterparts, desktop DLP 3D printers are built around a resin tank with transparent bottom and a build platform that descends into a resin tank to create parts upside down, layer by layer.

The difference is the light source. DLP 3D printers use a digital projector screen to flash an image of a layer across the entire platform, curing all points simultaneously.

The light is reflected on a Digital Micromirror Device (DMD), a dynamic mask consisting of microscopic-size mirrors laid out in a matrix on a semiconductor chip. Rapidly toggling these tiny mirrors between lens(es) that direct the light towards the bottom of the tank or a heat sink defines the coordinates where the liquid resin cures within the given layer.

Because the projector is a digital screen, the image of each layer is composed of square pixels, resulting in a three-dimensional layer formed from small rectangular cubes called voxels.

Resolution shows up more often than any other value in 3D printer spec sheets, but it’s also a common ground for confusion. The basic units of the SLA and DLP processes are different shapes, making it difficult to compare the different machines by numerical specifications alone.

In 3D printing, there are three dimensions to consider: the two planar 2D dimensions (X and Y) and the third vertical Z dimension that makes 3D printing.

Z resolution is defined by the layer thicknesses a 3D printer can produce. Resin 3D printers like SLA and DLP offer some of the finest Z resolutions—thinnest layers—of all 3D printing processes and users can normally choose from a range of layer height options between 25-300 microns, allowing designers to strike a balance between detail and speed.

In DLP 3D printing, XY resolution is defined by the pixel size, the smallest feature the projector can reproduce within a single layer. This depends on the resolution of the projector, the most common being full HD (1080p), and its distance from the optical window. As a result, most desktop DLP 3D printers have a fixed XY resolution, generally between 35 to 100 microns.

For SLA 3D printers, XY resolution is a combination of the laser’s spot size and the increments by which the laser beam can be controlled. For example, the Form 3 LFS 3D printer features a laser with an 85 micron spot size, but because of the constant line scanning process, the laser can move in smaller increments and the printer can consistently deliver parts with 25 micron XY resolution.

For example, the Form 3 LFS 3D printer features a laser with an 85 micron spot size, but because of the constant line scanning process, the laser can move in smaller increments and the printer can consistently deliver parts with 25 micron XY resolution.

However, resolution in itself is often just a vanity metric. It offers some indication, but it doesn’t necessarily correlate directly with accuracy, precision, and print quality.

Learn more about resolution in 3D printing in our in-depth guide.

Because 3D printing is an additive process, each layer introduces an opportunity for inaccuracy, and the process by which layers are formed affects the level of precision, defined as the repeatability of the accuracy of each layer. Accuracy and precision depend on many different factors: 3D printing process, materials, software settings, post-processing, and more.

In general, both SLA and DLP resin 3D printers are among the most accurate and precise 3D printing processes. Differences in accuracy and precision are often better explained by the differences between machines by various manufacturers than differences between the technologies themselves.

Differences in accuracy and precision are often better explained by the differences between machines by various manufacturers than differences between the technologies themselves.

For example, entry-level SLA or DLP printers might use off-the-shelf projectors, lasers, or galvanometers, and their manufacturers will try to get the best performance possible out of these parts. Professional SLA and DLP 3D printers, like the Formlabs Form 3, feature a custom optical system adapted to the specifications required by professional customer applications.

Accuracy and precision are crucial for parts like dental splints (left) and surgical guides (right).

Calibration is also crucial. With DLP projectors, manufacturers need to deal with the non-uniform light distribution on the build plane and optical distortion of the lenses—meaning that pixels in the middle are not the same size or shape as pixels on the edges. SLA 3D printers use the same light source for every part of the print, which means it’s uniform by definition, but they still require extensive calibration to account for distortions.

Even a 3D printer with the highest quality components and degree of calibration can produce widely varying results depending on the material. Different resins require optimized material settings to perform as intended, which might not be available for off-the-shelf materials or resins that are not thoroughly tested with a specific 3D printer model.

The takeaway? Accuracy and precision are almost impossible to understand from the technical specifications alone. Ultimately, the best way to evaluate a 3D printer is to inspect real parts or ask the manufacturer to create a test print of one of your own designs.

With DLP 3D printers, there’s a direct trade-off between resolution and build volume. The resolution depends on the projector, which defines the number of pixels/voxels available. If one moves the projector closer to the optical window, the pixels get smaller, which increases the resolution, but limits the available build area.

Some manufacturers stack multiple projectors next to each other or use a high-definition 4K projector to increase the build volume, but this leads to substantially higher costs that often price these machines out of the desktop market.

As a result, DLP 3D printers are generally optimized for specific use cases. Some have a smaller build volume and offer high resolution to produce small, detailed pieces like jewelry, while others can produce bigger parts but at a lower resolution.

The stereolithography process is inherently more scalable, since an SLA 3D printer’s build volume is completely independent of the resolution of the print. A single print can be any size and any resolution at any location within the build area. This makes it possible to 3D print large parts at high resolution or a large batch of detailed small parts to increase throughput with the same machine.

The other main barrier to increasing build volume in both SLA and DLP 3D printers is the peel force. When printing larger parts, the forces exerted on the parts increase exponentially as a cured layer separates from the tank.

In LFS 3D printing, the flexible film at the base of the resin tank gently peels away as the build platform pulls the part up, significantly reducing the stress on the part. This unique feature has made it possible to substantially increase the build volume for the first accessible large format SLA 3D printer, the Form 3L.

This unique feature has made it possible to substantially increase the build volume for the first accessible large format SLA 3D printer, the Form 3L.

The Form 3L is the first affordable large format SLA 3D printer with a build volume of 30 cm x 33.5 cm x 20 cm.

Webinar

Want to learn more about the Form 3L and Form 3BL ecosystem, and the new large format post-processing machines?

In this demo, Kyle and Chris will expain how to navigate the Form 3L end-to-end workflow, including post-processing.

Watch Now

SLA and DLP resin 3D printers both known for creating parts with the smoothest surface finish of all 3D printing processes. When we describe the differences, in most cases these are only visible on tiny parts or highly detailed models.

Because objects are made of layers in 3D printing, 3D prints often have visible, horizontal layer lines. However, because DLP renders images using rectangular voxels, there is also an effect of vertical voxel lines.

DLP 3D printers render images using rectangular voxels, which causes an effect of vertical voxel lines. In this image, see the vertical voxel lines as they appear naturally on the left, and then outlined to more easily identify on the right.

Because the unit is rectangular, voxels also have an effect on curved edges. Think of building a round shape out of LEGO bricks—the edges will appear stepped on both the Z axis and the X-Y plane.

The rectangular shape of voxels makes curved edges appear stepped. Removing the appearance of voxel and layer lines requires post-processing, such as sanding.

In LFS 3D printing, layer lines are close to invisible. As a result, surface roughness is reduced, which ultimately leads to smooth surfaces, and for clear materials, more translucent parts.

When thinking about speed in 3D printing, it’s important to consider not just raw print speed, but also throughput.

Raw print speed for SLA and DLP resin 3D printers is comparable in general. As the projector exposes each entire layer all at once, print speed in DLP 3D printing is uniform and depends only on the height of the build, whereas, SLA 3D printers draw out each part with a laser. As a rule of thumb, this results in SLA 3D printers being comparable or faster when printing small or medium-size single parts, while DLP 3D printers are faster to print large, fully dense prints, or builds with multiple parts that fill up much of the platform.

As the projector exposes each entire layer all at once, print speed in DLP 3D printing is uniform and depends only on the height of the build, whereas, SLA 3D printers draw out each part with a laser. As a rule of thumb, this results in SLA 3D printers being comparable or faster when printing small or medium-size single parts, while DLP 3D printers are faster to print large, fully dense prints, or builds with multiple parts that fill up much of the platform.

But once again, it’s worth considering the trade-off between resolution and build volume for DLP printers. A small DLP 3D printer can print a small part or a (small) batch of smaller parts fast, at high resolution, but the build volume limits the part size and the throughput. A different machine with a larger build volume can print larger parts or a batch of smaller parts faster, but at a lower resolution than SLA.

SLA 3D printers can produce all of these options in one machine and offer the user the freedom to decide whether she wants to optimize for resolution, speed, or throughput.

SLA 3D printers offer a larger build volume, allowing users to batch parts and print overnight to increase throughput.

Speed can also depend on the material choice. Printing four times faster than Formlabs standard materials, Draft Resin fast-printing resin that is ideal for initial prototypes, rapid iterations, as well as dental and orthodontic models. From fast print initiation speeds to minimal support removal, wash, and cure times, Draft Resin has an optimized workflow to truly maximize efficiency.

100 microns | 200 microns |

|---|---|

100 microns | 200 microns |

|---|---|

100 microns | 200 microns |

|---|---|

Interactive

Try our interactive ROI tool to see how much time and cost you can save when 3D printing on Formlabs 3D printers.

Calculate Your Savings

Just like with accuracy and precision, the workflow and available materials differ more from machine to machine than technology to technology.

Most SLA and DLP 3D printers are “plug and play,” with easily swappable build platforms and resin tanks. Some more advanced models also come with a cartridge system to automatically refill the tank with liquid resin, which requires less attention and facilitates printing overnight.

Some printers come with proprietary software to prepare 3D models for printing, such as PreForm for Formlabs SLA 3D printers, while other manufacturers offer off-the-shelf solutions. Features differ by software tool, for example, PreForm offers one-click print setup, powerful manual controls to optimize support density and size, adaptive layer thickness, or functions to save material and time. Luckily, the software can be easy to download and test before purchasing a 3D printer.

Resin 3D printers offer a variety of materials for a wide range of applications.

One of the most significant benefits of resin 3D printing is the variety of materials that make it possible to create parts for diverse applications. Resins can feature a wide range of formulation configurations: materials can be soft or hard, heavily filled with secondary materials like glass and ceramic, or imbued with mechanical properties like high heat deflection temperature or impact resistance.

However, the range of supported material options depend on the 3D printer model, so we recommend inquiring with the manufacturer before purchase.

Parts printed with both SLA and DLP technologies require post-processing after printing. First, the parts need to be washed in a solvent to remove excess resin. Some functional materials like engineering or biocompatible parts also require post-curing. For SLA 3D printers, Formlabs offers solutions to automate these steps, saving time and effort.

At last, 3D printed parts printed on supports require these structures to be removed, a manual process that is similar for both SLA and DLP 3D printers. LFS 3D printing simplifies this step by offering light-touch support structures that use very small touchpoints to enable easy removal with minimal support marks left behind.

LFS 3D printing simplifies this step by offering light-touch support structures that use very small touchpoints to enable easy removal with minimal support marks left behind.

Interactive

Need some help figuring out which 3D printing material you should choose? Our new interactive material wizard helps you make the right material decisions based on your application and the properties you care the most about from our growing library of resins.

Recommend Me a Material

After sorting out the differences in technology and outcomes, we hope it’s much easier to select a resin 3D printer that best matches your workflow and output needs.

To explore the next generation of SLA 3D printing, learn more about the Form 3 and Form 3L LFS 3D printers.

Curious to see the quality firsthand? Order a sample part shipped to your office.

Request a Free Sample Part

PolyJet 3D printing technology

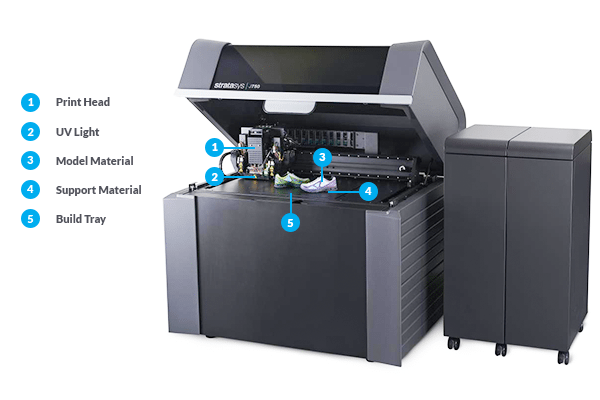

PolyJet is a 3D printing technology based on the layer-by-layer curing of a liquid photopolymer material under the influence of ultraviolet radiation. Used in Stratasys 3D printers.

Used in Stratasys 3D printers.

- Principle of work

- Advantages

- Examples of print

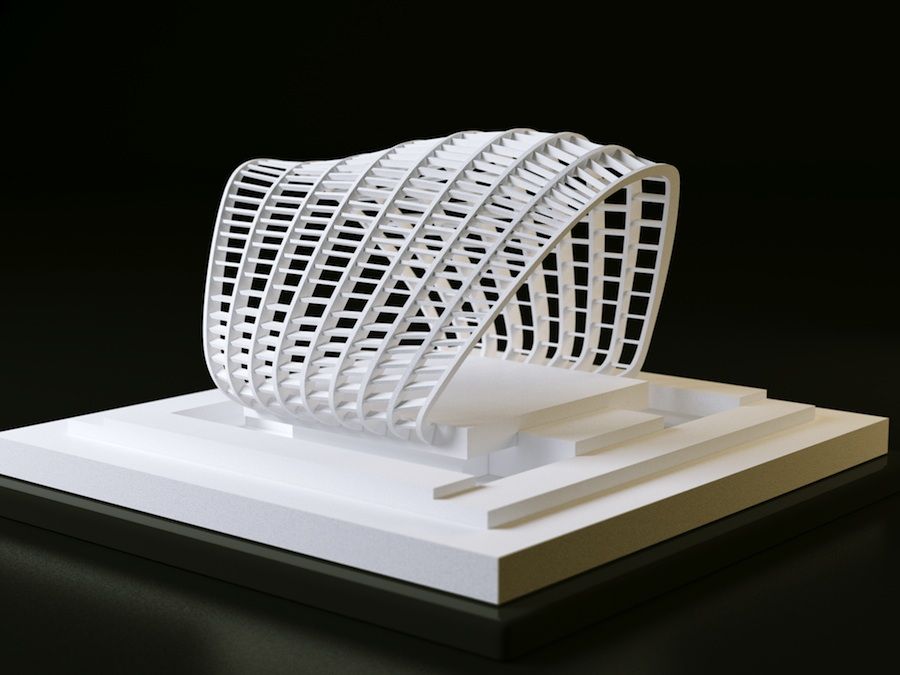

- Selection0002 What is better to print: product prototypes, test models, burnt-out master models, silicone casting samples.

Advantages: high surface quality, accuracy, construction speed, washable support.

Alternative: MJM technology (also based on UV illumination of photopolymer material).

What is better to print: product prototypes, test models, burnt master models, silicone casting samples. nine0003

Advantages: high surface quality, accuracy, construction speed, washable support.

Alternative: MJM technology (also based on UV illumination of photopolymer material).

How it works

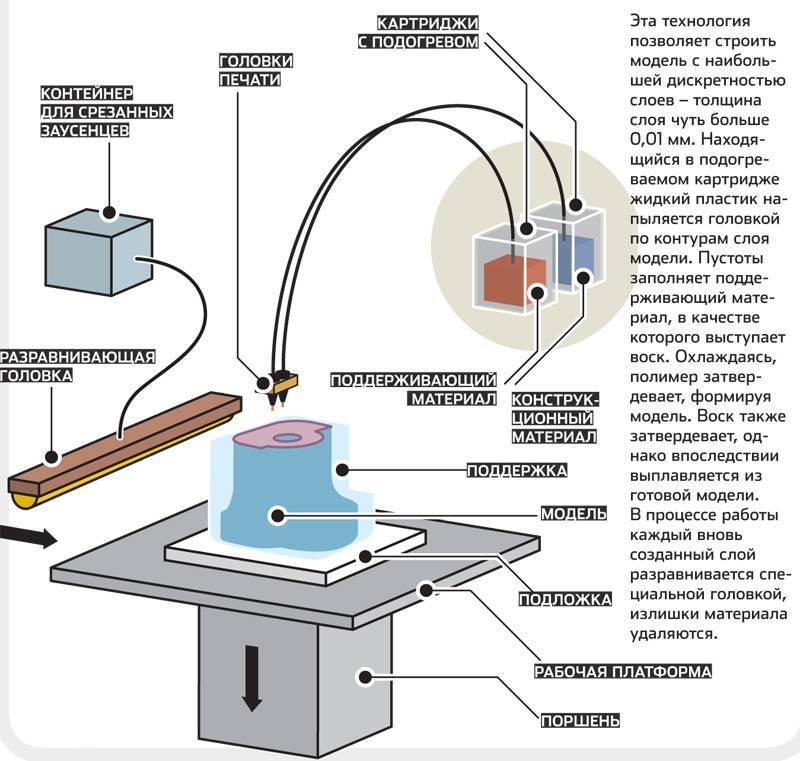

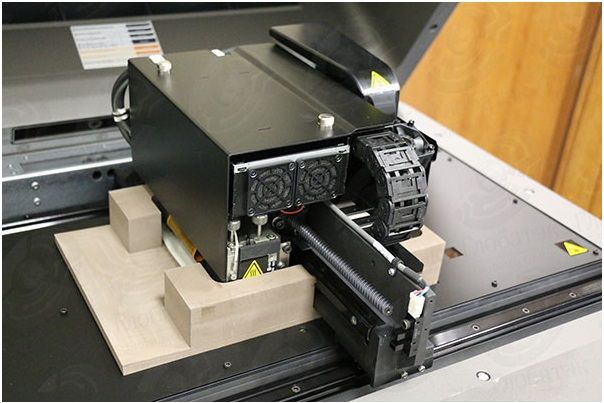

The 3D printer print unit sprays the model material and support material in thin layers (16/30 µm) according to the data of the 3D mathematical model.

Each layer is polymerized by ultraviolet light immediately after application. The result is an object that does not require any additional surface treatment. A model printed using PolyJet technology can be used immediately after the printing process is completed. nine0003

Each layer is polymerized by ultraviolet light immediately after application. The result is an object that does not require any additional surface treatment. A model printed using PolyJet technology can be used immediately after the printing process is completed. nine0003 How it works

The 3D printer print unit sprays the model material and support material in thin layers (16/30 µm) according to the data of the 3D mathematical model. Each layer is polymerized by ultraviolet light immediately after application. The result is an object that does not require any additional surface treatment. A model printed using PolyJet technology can be used immediately after the printing process is completed.

Technology Benefits

Accuracy and detail of finished products

PolyJet technology provides a high accuracy of construction in 0.02-0.085 mm for objects up to 50 mm in size. For objects larger than 50 mm, the construction accuracy varies from 0.

1 to 0.2 mm. Printing accuracy depends on the geometry of the model, the parameters of its construction and orientation, as well as the material used.

1 to 0.2 mm. Printing accuracy depends on the geometry of the model, the parameters of its construction and orientation, as well as the material used. Large selection of materials with different properties

PolyJet grown objects have different properties depending on the material used. Materials differ from each other in mechanical, thermal, electrical and chemical characteristics. The FullCure line of PolyJet printing media offers a choice of rigid, flexible, translucent, transparent, and certified biocompatible media. nine0003

Soluble support material

In the process of building complex products, various cavities, overhanging structures are often present. To prevent their collapse, all voids under such elements are filled with a special material - support material. In addition, such material serves as additional insurance when printing thin walls and complex structures. FullCure705 Support is a versatile model support material that can be easily removed with water in an ObjetWaterJet flush station.

nine0003

nine0003 Benefits of Technology

Accuracy and Finished Product Details

PolyJet technology delivers high build accuracy of 0.02-0.085 mm for objects up to 50 mm in size. For objects larger than 50 mm, the construction accuracy varies from 0.1 to 0.2 mm. Printing accuracy depends on the geometry of the model, the parameters of its construction and orientation, as well as the material used.

Large selection of materials with different properties

PolyJet grown objects have different properties depending on the material used. Materials differ from each other in mechanical, thermal, electrical and chemical characteristics. The FullCure line of PolyJet printing media offers a choice of rigid, flexible, translucent, transparent, and certified biocompatible media. nine0003

Soluble support material

In the process of building complex products, various cavities, overhanging structures are often present.

To prevent their collapse, all voids under such elements are filled with a special material - support material. In addition, such material serves as additional insurance when printing thin walls and complex structures. FullCure705 Support is a versatile model support material that can be easily removed with water in an ObjetWaterJet flush station. nine0003

To prevent their collapse, all voids under such elements are filled with a special material - support material. In addition, such material serves as additional insurance when printing thin walls and complex structures. FullCure705 Support is a versatile model support material that can be easily removed with water in an ObjetWaterJet flush station. nine0003 What is PolyJet 3D printing technology

PolyJet 3D printing is similar to conventional inkjet printing. But instead of spraying ink onto the paper surface, 3D printers like PolyJet spray liquid photopolymer plastic layer by layer on a special internal platform. Then the plastic hardens under the influence of an ultraviolet lamp. Layers are layered one on top of the other, and, as a result, a three-dimensional model or prototype is obtained. The hardened model can be picked up and used immediately, without resorting to additional processing. In addition to certain materials for modeling, the 3D printer uses a gel-like support material designed specifically to reinforce long protrusions and complex geometric elements.

It is easily removed by hand or washed off with water. PolyJet 3D printing technology is ideal for rapid prototyping due to a number of advantages, which include: excellent quality, speed, high accuracy and a wide range of materials used. Based on PolyJet technology, Stratasys' Objet Connex 3D printers are the only additive modeling systems that allow 3D printing to use different materials to produce a single 3D model in a single workflow. nine0003

It is easily removed by hand or washed off with water. PolyJet 3D printing technology is ideal for rapid prototyping due to a number of advantages, which include: excellent quality, speed, high accuracy and a wide range of materials used. Based on PolyJet technology, Stratasys' Objet Connex 3D printers are the only additive modeling systems that allow 3D printing to use different materials to produce a single 3D model in a single workflow. nine0003 The only multi-material 3D printing technology

Objet Connex 3D printers are equipped with a unique technology that allows you to use several materials during prototyping at once in one work cycle. That is, you can use several base materials in the manufacture of one prototype and even create combined materials by mixing base materials. Such combinations will provide exactly the physical properties you require. With over 100 different base materials and their combinations, from hard to rubbery, from opaque to completely transparent, a superlative degree of realism can be achieved.

Learn more