Polycarbonate 3d printing service

Polycarbonate 3D Printing | Get Custom 3D Prints Fast

Back

-

Materials

Materials by Service

Injection MoldingCNC Machining3D PrintingSheet Metal

Materials by Type

PlasticsMetalsElastomers

Related Links

Customer Supplied ResinsColors

Injection Molding Material Alternatives Guide

Struggling with thermoplastic material shortages? We created a detailed guide to resin substitutes for ABS, PC, PP, and other commonly molded thermoplastics.

Download

-

Resources

Design Tips Guides and Trend Reports Case Studies Design Aids Webinars and Trade Shows

Blog Videos FAQs Educators and Students Glossary

Industries Medical Aerospace Automotive Consumer Electronics Industrial Equipment

-

About Us

Who We Are Why Protolabs? Research and Development Cool Idea Award Partnerships Sustainability and Social Impact

Careers Investors Locations Press Procurement

Contact Us

Proto Labs, Inc.

5540 Pioneer Creek Dr.

Maple Plain, MN 55359

United StatesP: 877.479.3680

F: 763.479.2679

E: [email protected]Best-in-Class Online Quoting

After uploading your part design, you'll receive an online quote that includes manufacturing analysis to help improve part manufacturability. Within your quote, you can also adjust quantity and material and see price changes in real-time.

Learn More

Get a QuoteSign In

GET A QUOTE

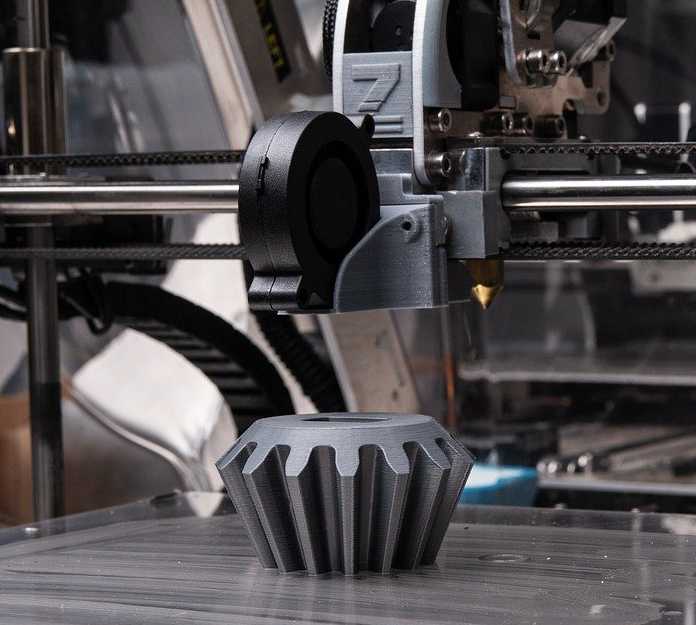

Polycarbonate is a versatile material choice that stiff parts with excellent heat deflection. Multiple polycarbonate-like materials are available through our stereolithography (SLA) process.

- PC-Like Translucent (Accura 60): High stiffness and functional transparency can be achieved with custom finishing

- PC-Like Advanced High Temp (Accura 5530): High elastic modulus, can be thermal cured for increased heat deflection as high as 482°F

- Ceramic-Like Advanced High Temp (PerFORM): Stiffest SLA material, can be thermal cured for increased heat deflection as high as 514°F

VIEW POLYCARBONATE 3D PRINTING MATERIALS >

Compare Polycarbonate Material Properties

- US

- Metric

| Material | Process | Color | Tensile Strength | Tensile Modulus | Elongation |

|---|---|---|---|---|---|

| PC-Like Translucent/Clear (Accura 60) | SLA | Translucent/Clear | 10. 8 ksi 8 ksi | 508 ksi | 7% |

| PC-Like Advanced High Temp (Accura 5530) | SLA | Translucent/Amber | 6.5 ksi | 566 ksi | 1.5% |

| Ceramic-Like Advanced High Temp (PerFORM) | SLA | White | 10.9 ksi | 1,523 ksi | 1% |

| Material | Process | Color | Tensile Strength | Tensile Modulus | Elongation |

|---|---|---|---|---|---|

| PC-Like Translucent/Clear (Accura 60) | SLA | Translucent/Clear | 74.4 MPa | 3,500 MPa | 7% |

| PC-Like Advanced High Temp (Accura 5530) | SLA | Translucent/Amber | 44.8 MPa | 3,900 MPa | 1.5% |

| Ceramic-Like Advanced High Temp (PerFORM) | SLA | White | 75.2 MPa | 10,500 MPa | 1% |

Applications for 3D-Printed Polycarbonate

Polycarbonate's high strength and transparent options makes it well suited for many applications such as:

- Electronic housings

- Medical devices

- Lighting components

- Electrical components

- Under-the-hood automotive parts

Related Resources

Selecting a Material for Stereolithography (SLA) 3D Printing

Compare materials for stereolithography with one another and with injection-molded plastics.

Read Design Tip

3D Printing Materials: Select the Right Plastic or Metal for Your 3D-Printed Part

Explore material properties available for plastic and metal 3D printing processes

Read Guide

How to 3D Print Clear and Translucent Plastic Parts

Explore options available for building and post-processing clear parts for 3D printing.

Read Blog

An Introduction to Stereolithography (SLA) 3D Printing

Stereolithography, a staple of 3D printing, can deliver complex prototypes quickly and accurately.

Read Design Tip

Polycarbonate 3D Printing | Quote and Applications

CapabilitiesCustom Online 3D Printing ServicePolycarbonate 3D Printing

Get instant online quotes on custom 3D printed polycarbonate parts. Free shipping on all US orders. ISO 9001:2015, ISO 13485 and AS9100D certified.

About Polycarbonate 3D Printing

Polycarbonate (PC) is a thermoplastic with excellent mechanical properties and some of the best temperature resistance of any common FDM 3D printing plastic. PC can be subjected to high levels of plastic deformation without breaking. It is useful for both end-use parts and functional prototypes in the medical and automotive industries.

Polycarbonate printing can be more difficult than other standard FDM plastics due to its high glass transition temperature. This means the print must be done at a far higher temperature than other standard plastics like PLA or ABS. PC is also a good electrical insulator wherein some grades of polycarbonate can be sterilized with various standard processes making it ideal for food or medical applications.

3D Printed Polycarbonate at a Glance

Application | Manufacturing tools and jigs, functional prototypes |

Advantages | High temperature resistance, electrically insulating, high tensile strength |

Disadvantages | Highly susceptible to scratching, hygroscopic |

Lead Time | 1 day |

Price | $ |

Minimum Feature Size | 0. |

Tolerances | Z plane: +/- 0.010” (0.254 mm) for the first inch, plus +/- 0.002” (0.0508 mm) for every inch thereafter. XY plane: +/- 0.004” (0.1016 mm) for the first inch, plus +/- 0.002” (0.0508 mm) for every inch thereafter. |

Layer Height | 0.010" (0.254 mm) for parts below 16" (406.4 mm) and 0.013" (0.330 mm) for parts above 16" (406.4 mm) |

Max Part Size | 24” x 36” x 36” (610 mm x 915 mm x 915 mm) |

FDM PC

Standard polycarbonate has excellent mechanical properties that far exceed those of other popular high-strength plastics like ABS. This makes polycarbonate ideal for functional prototypes and manufacturing tools as well as end-use parts.

FDM PC Properties

| Tensile Strength (MPa) | Elongation at Break (%) | Hardness (Rockwell) | Heat Deflection Temperature (℃) | Glass Transition (℃) |

|---|---|---|---|---|

Tensile Strength (MPa) 68 | Elongation at Break (%) 5 | Hardness (Rockwell) 115 | Heat Deflection Temperature (℃) 138 | Glass Transition (℃) 161 |

FDM PC-ABS

As the name suggests, PC-ABS plastic combines these two popular plastics to create a material that contains properties of both. It has the high strength and temperature resistance of polycarbonate while maintaining some of the flexibility of ABS. 3D printing in PC-ABS is ideal for end-use parts that need to be flexible and don’t need to focus on temperature resistance.

It has the high strength and temperature resistance of polycarbonate while maintaining some of the flexibility of ABS. 3D printing in PC-ABS is ideal for end-use parts that need to be flexible and don’t need to focus on temperature resistance.

FDM PC-ABS Properties

| Tensile Strength (MPa) | Elongation at Break (%) | Hardness (Rockwell) | Heat Deflection Temperature (°C) | Glass Transition (°C) |

|---|---|---|---|---|

Tensile Strength (MPa) 29 | Elongation at Break (%) 2 | Hardness (Rockwell) 110 | Heat Deflection Temperature (°C) 110 | Glass Transition (°C) 125 |

FDM PC-ISO

This version of PC is biocompatible under ISO 10993 USP class IV and can be either gamma- or EtO-sterilized. The ability to be sterilized, coupled with PC’s mechanical and thermal properties, makes this variant ideal for medical device prototyping and food packaging.

FDM PC-ISO Properties

| Tensile Strength (MPa) | Elongation at Break (%) | Flexural Strength (MPa) | Heat Deflection Temperature (°C) | Impact Strength Notched (J/m) |

|---|---|---|---|---|

Tensile Strength (MPa) 57 | Elongation at Break (%) 4 | Flexural Strength (MPa) 90 | Heat Deflection Temperature (°C) 133 | Impact Strength Notched (J/m) 86 |

Finishes

3D printing in PC using FDM technology does not typically give you many potential surface finishes. However, PC is available in black, white, or clear plastic. In addition to this, some basic surface finishes are listed below.

Standard: Support structures are removed and some light sanding is performed at the support locations. It must be understood that in general FDM creates a surface texture with visible layer stepping. If a completely smooth part is required right off the machine, other 3D printing technologies like SLS or HP Multi Jet Fusion should be considered.

Custom: Custom surface finishes like painting and additional sanding can be requested. Polycarbonate FDM parts react well to sanding, so excellent surface smoothness can be achieved.

Cost-saving Design Tips

DFM: FDM 3D printing in PC requires special considerations when designing parts. FDM constructs parts from the bottom up, so any large overhangs will require support. Large internal cavities are not ideal as support structures cannot be removed. This can, however, be overcome with special soluble supports. To gain the most benefit from the material when 3D printing in PC, parts should not be designed to have loads applied perpendicular to the print layers.

Material Choice: PC is a relatively low-cost plastic but is still more expensive than other commodity thermoplastics like PLA or ABS. It should only be used if the resulting part needs to be strong or resistant to high-temperature conditions.

Ready to 3D Print Polycarbonate Parts?

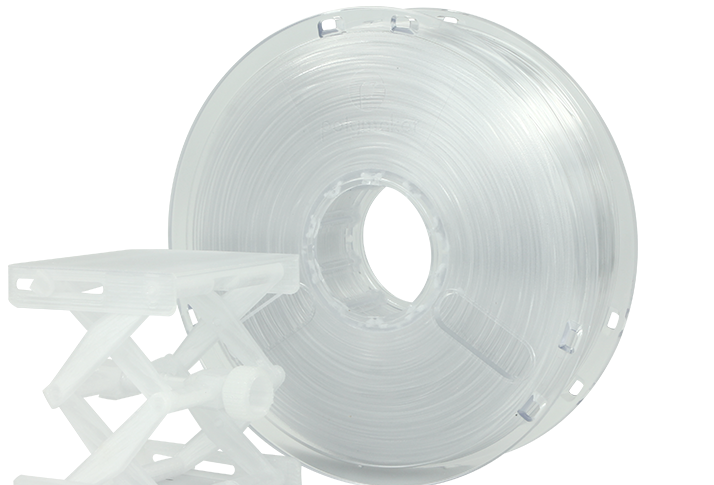

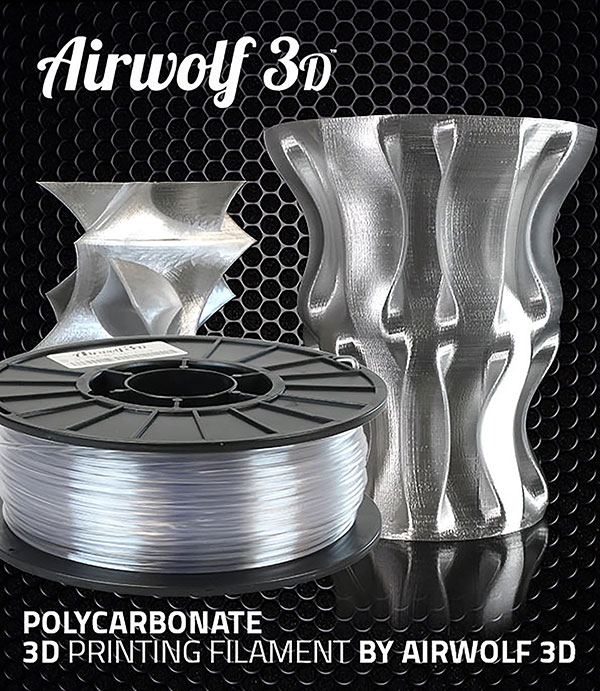

Polycarbonate for 3D printing

Description

Polycarbonate is a thermoplastic in honeycomb form widely used as a durable substitute for conventional glass. In addition, polycarbonate has found use as a material for the manufacture of CDs, contact lenses, protective equipment (for example, bicycle helmets or glasses). The combination of transparency of polycarbonate and high strength (about 250 times higher than ordinary glass) makes it possible to produce even bulletproof glass. nine0005

In addition, polycarbonate has found use as a material for the manufacture of CDs, contact lenses, protective equipment (for example, bicycle helmets or glasses). The combination of transparency of polycarbonate and high strength (about 250 times higher than ordinary glass) makes it possible to produce even bulletproof glass. nine0005

Another advantage of polycarbonate is its high resistance to high and low temperatures - from -40 to 120°C. In addition, polycarbonate is prone to attenuation when exposed to open flame, contributing to fire safety, and resistant to acids.

Among the disadvantages of polycarbonate, one can single out a rather high hygroscopicity. Thread spools are recommended to be stored in dry places, and preferably vacuum-packed. In addition, polycarbonate is somewhat vulnerable to ultraviolet light, which leads to loss of strength over time, and is vulnerable to attack by petroleum products and organic solvents. nine0009

3D printing application

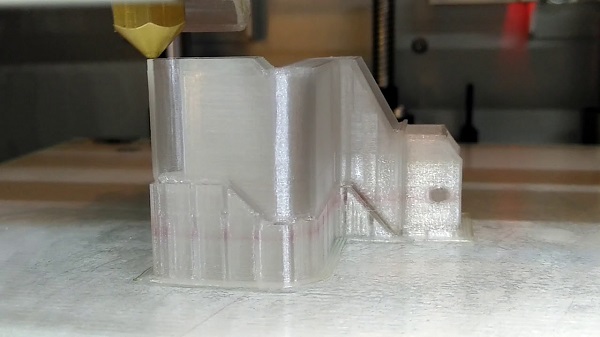

Polycarbonate printing example

Polycarbonate is rare in FDM printing due to certain technological difficulties, but is rapidly gaining popularity as technology improves.

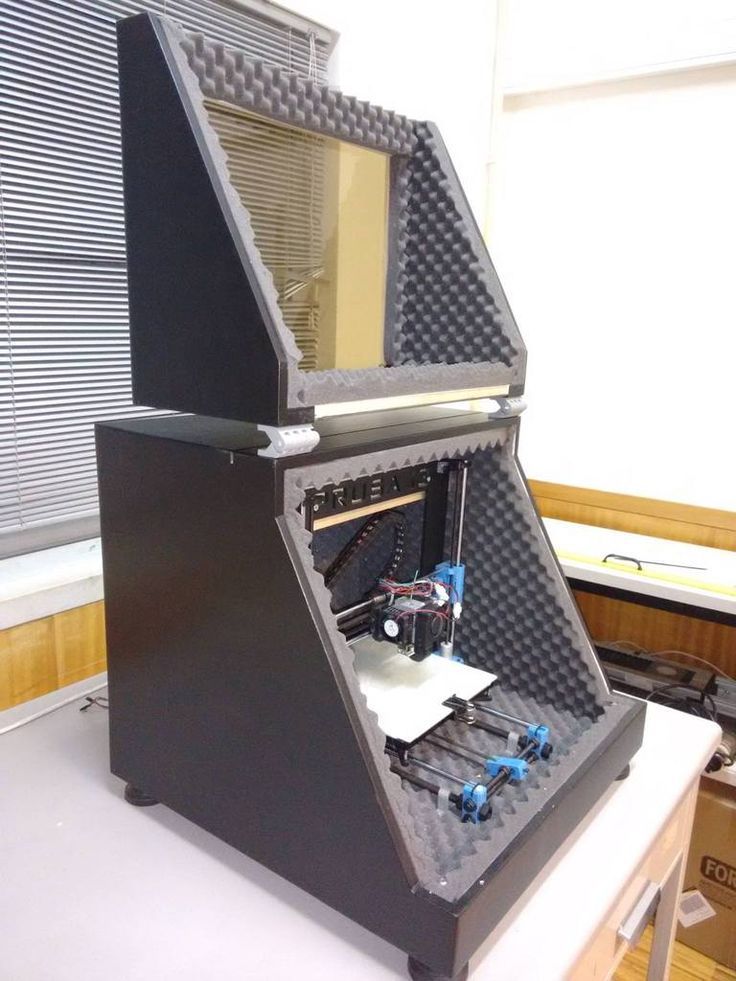

Polycarbonate requires a fairly high extrusion temperature in excess of 300°C when printing at high speed.

Due to its high hygroscopicity, it may be necessary to dry the consumable immediately before printing. nine0005

To do this, it is recommended to keep the thread for 8-10 hours at a temperature of 70°C.

Otherwise, water vapor may be released during extrusion, clouding of the material and increased shrinkage, which increases the risk of deformation.

Even dry polycarbonate will require the use of a heated worktable up to 90°C-120°C.

It is recommended to use a polyimide film (Kapton) for better adhesion of the first layer to the worktable surface. nine0005

Printing examples with dry and slightly damp polycarbonate

Finding the right balance of extrusion temperature and print speed will be required to maintain transparency and avoid nozzle clogging and cracking.

Printing at 30mm/s will require heat up to approximately 265˚C, 285˚C at 60mm/s, 300˚C at 80mm/s and over 305˚C at 120mm/s. The glass transition temperature of polycarbonate is about 150˚C.

The glass transition temperature of polycarbonate is about 150˚C.

Polycarbonate threads are available in standard diameters of 1.75mm and 3mm. nine0009

Polycarbonate Safety

Polycarbonate itself is safe, but the material typically uses BPA as the main raw material. Bisphenol A, in turn, is very toxic even in small volumes, up to the excitation of oncological diseases. Unfortunately, polycarbonates often contain residual Bisphenol A (albeit in extremely small amounts), which is released when heated. Accordingly, the use of polycarbonate products for storing hot food or drinks is not recommended. Limited bans on the use of polycarbonate in food packaging have already been introduced in Canada and the EU, and are being considered in the US. We recommend that you print in a well-ventilated area. nine0005

Go to the main page of the Encyclopedia of 3D Printing With the help of such a unique modern fixtures like a 3D printer.

Professional 3D printing services for the creation of any products are offered by the Technoplast manufacturing company. nine0005

Scope of application of three-dimensional printing

Modern technologies allow the use of this technique in almost all areas of modern life without exception. Therefore, orders for the manufacture of products using 3D printing come from various areas of production. In particular, 3D printing is used for:

- Creation of prototypes - experimental, trial, samples of new products being developed.

- Manufacture of souvenirs, elements of original decor. nine0060

- Production of medical equipment and even individual organs of the human body.

- Create tutorials and tutorials

Order a product consultation

Submit a request

Use a 3D printer in a foundry

You can also use 3D printing to create any injection mold. Unlike standard technology, when the shape of the finished master model is additionally painstakingly corrected by the master to the parameters specified by the program using milling finishing or manual grinding, this method is much more profitable, both in terms of time and labor. When manufacturing a mold by printing on a printer, in a few hours the desired product is completely ready, 100% corresponding to the parameters of a digital model created using 3D modeling. nine0005

When manufacturing a mold by printing on a printer, in a few hours the desired product is completely ready, 100% corresponding to the parameters of a digital model created using 3D modeling. nine0005

By choosing a 3D printing technique to create molds, the customer benefits from the following:

- Saves time and money. In addition to the fact that the forms are prepared much faster than with the standard method, the cost of their production is also more affordable.

- Has the ability to order molds of any shape and size. The printer can reproduce in reality an object of any degree of complexity.

Also, forms created in this way are much easier to improve and correct, if necessary,

Technologies and materials of modern 3D printing

There are several types of 3D printing.

FDM technology

The method involves the creation of a 3D object by layering a material, thermoplastic, melted in the print head of the printer used for printing. The method is characterized by relatively low cost, a wide choice of materials (ABS plastic, nylon, polycarbonate, polyethylene, etc. can be used), as well as high printing speed. nine0005

The method is characterized by relatively low cost, a wide choice of materials (ABS plastic, nylon, polycarbonate, polyethylene, etc. can be used), as well as high printing speed. nine0005

The disadvantages of the technique include the need to use props when creating parts with overhanging elements, as well as post-processing of the finished product, the impossibility of manufacturing large solid objects.

FDM technology is mainly used for prototyping parts and medium-sized objects.

SLS technology

The object is formed by layer-by-layer application of the powder sinter product. Nylon, resins, ceramics, glass, etc. can be used as the printing material. The product created in this way is highly durable, does not need a manufacturing process to use support. But this technique is more expensive than the above. In addition, the product that came out of the 3D printer has a rough surface and needs additional polishing. nine0005

The method is used most often for the manufacture of complex parts for mechanical engineering, as well as the production of small series of products for various industries.

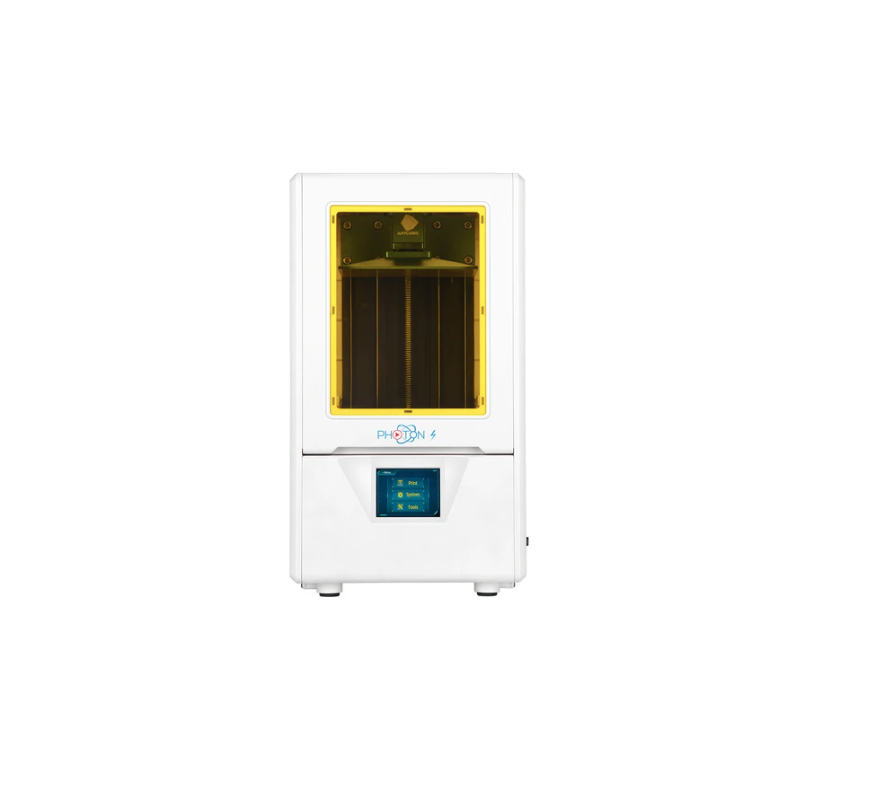

SLA or photopolymer technology

Products are made from a photopolymer that hardens under the influence of energy from an ultraviolet beam directed at it. The result is an impeccable quality part with high detail and a smooth surface (no need for additional grinding). The disadvantages of the technique include the high cost of materials and their limited choice, slow printing speed. nine0005

Stages of production of products by printing on a three-dimensional printer

- Provision by the client of a 3D model created using a 3D scanner or 3D modeling process. If you do not have a digitized version of the future product for printing, our employees will produce it themselves, based on the drawings, photographs or detailed description provided by you.

- Selection of 3D printing technology and material from which the object will be made.

- Drawing up an estimate of the order and its coordination with the customer. nine0060

- Printing a product - depending on the complexity, the process takes from half an hour to several days.

- Post-processing of the product that came out of the 3D printer (if necessary): the procedure includes grinding, painting, removal of supports.

Request a product consultation

Submit a request

Why choose 3D printing

Object production speed

3D printing allows you to create products in the shortest possible time - from 30 minutes to several days. When choosing the injection molding method, only preparatory work takes up to several months. nine0005

Choice of technology and material

In addition to choosing the right technology (FDM, SLA, etc.), the customer can also order a specific material. Most 3D printers print from plastic, but many modern models also work with wax, clay, wood, rubber, and other materials.

Creation of objects of any level of complexity

With the help of 3D printing, you can easily bring to life any, even the most complex and detailed object. By means of a 3D printer, they even now create prostheses and individual internal organs for patients. nine0005

nine0005

Simplicity and accessibility

3D printing does not require any special tools or equipment other than a 3D printer and a prepared digital model in STL format. Whereas with the injection molding technique, it is necessary to have a pre-prepared mold, injection molding machine, etc.Place an order for the manufacture of products by 3D printing in Technoplast!

Affordable prices for services

It is profitable to place an order for the manufacture of any product using the 3D printing method with us. After all, you communicate directly with the manufacturer and do not overpay for the services of third-party intermediaries, and we also provide individual discounts and can consider the possibility of payment by installments. Contact us!

Turnkey work

We provide not only services for printing products on 3D printers, but, if necessary, our company's employees can independently draw a digital version of the part for its further manufacture - you can order 3D modeling and scanning of an object from us with subsequent refinement. nine0005

nine0005

Application assistance

We provide professional advice, answer all your questions, help with the selection of suitable materials and technologies that will ensure the creation of high-quality products that meet all your needs.

High quality

We employ experienced employees who know absolutely everything about 3D printing and are able to perfectly apply their knowledge in practice, and the use of modern equipment and quality materials ensures that the products that you receive from us within the agreed time will be of high quality, durable and in accuracy that meets all your expectations. nine0005

Any number of

We accept orders for the production of three-dimensional printing both for single items and for mass production - we produce batches of goods up to 1000 pieces.Q&A

How much does 3D printing cost you?

The total cost of 3D printing depends on many factors, including the printing method and material, the complexity of the product being created, the number of applied layers, infill density, and the need for post-processing of the finished product.

010" (0.254 mm) for parts below 16" (406.4 mm) and 0.013" (0.330 mm) for parts above 16" (406.4 mm)

010" (0.254 mm) for parts below 16" (406.4 mm) and 0.013" (0.330 mm) for parts above 16" (406.4 mm)