3D printing api

New API 3D Printing Standard Promotes Efficiency and Environmental Stewardship

WASHINGTON, August 23, 2022 – The American Petroleum Institute (API) today published a new standard on additive manufacturing (3D printing) for polymer-based components used in the natural gas and oil industry that will increase operating efficiency, ease supply chain issues and help reduce emissions.

“This new standard highlights the industry’s success in leveraging new technologies and innovations to improve operations while supporting sustainability efforts,” said API Vice President of Standards and Segment Services Alexa Burr. “Additive manufacturing can bring significant efficiency improvements that will help the industry meet the world’s demand for natural gas and oil.”

API Standard 20T, Additively Manufactured Polymer-Based Components for Use in the Petroleum and Natural Gas Industries, specifies requirements for qualification in the manufacturing process, production, marking and documentation of 3D printed polymer-based components used in the industry.

The standard also provides guidance on how to test and document the material properties for the 3D printing of polymer-based components and introduces three additive manufacturing specification levels that define technical, quality and qualification requirements.

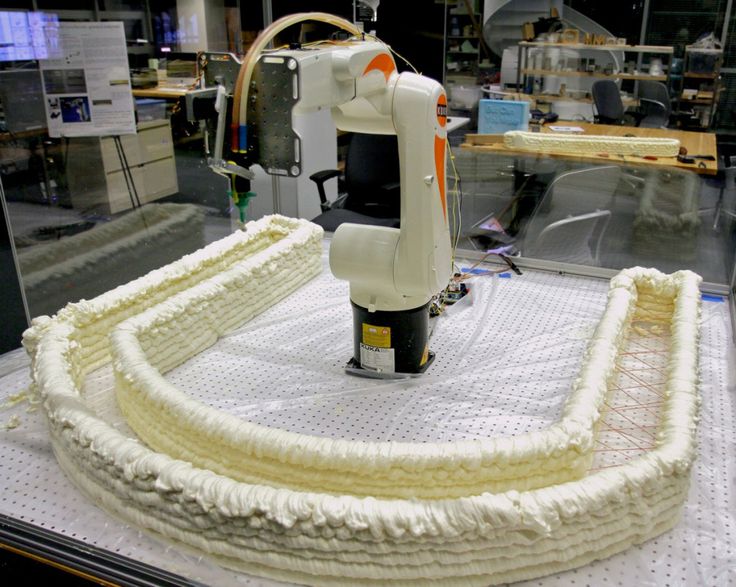

Additive manufacturing can help the natural gas and oil industry improve efficiency and productivity, cut lead times and supply chain stress, and streamline transportation and logistics because additive manufacturing takes place near the point of use.

Deploying 3D printing can help the industry reduce Scope 3 emissions when compared to traditional manufacturing, showing how innovation and technologies support API’s Climate Action Framework, which details the industry’s commitment to protect the environment by reducing greenhouse gas emissions.

20T is a complementary standard to the first edition of API Standard 20S, Additively Manufactured Metallic Components for Use in the Petroleum and Natural Gas Industries, published in late 2021. Focused on 3D printing of metallic components, 20S is first-of-its-kind for the industry and provides similar benefits as its sister standard on polymer-based components. A webinar covering both 20S and 20T has been scheduled for October 4, 2022. Registration information can be found here.

Focused on 3D printing of metallic components, 20S is first-of-its-kind for the industry and provides similar benefits as its sister standard on polymer-based components. A webinar covering both 20S and 20T has been scheduled for October 4, 2022. Registration information can be found here.

API represents all segments of America’s natural gas and oil industry, which supports more than 11 million U.S. jobs and is backed by a growing grassroots movement of millions of Americans. Our approximately 600 members produce, process and distribute the majority of the nation’s energy, and participate in API Energy Excellence®, which is accelerating environmental and safety progress by fostering new technologies and transparent reporting. API was formed in 1919 as a standards-setting organization and has developed more than 800 standards to enhance operational and environmental safety, efficiency and sustainability.

###

API's new 3D printing standard to help “strengthen the supply chain resiliency” of oil and gas firms

0Shares

The American Petroleum Institute (API) has unveiled a new standard that’s designed to drive the further adoption of additive manufacturing within the oil and gas sector.

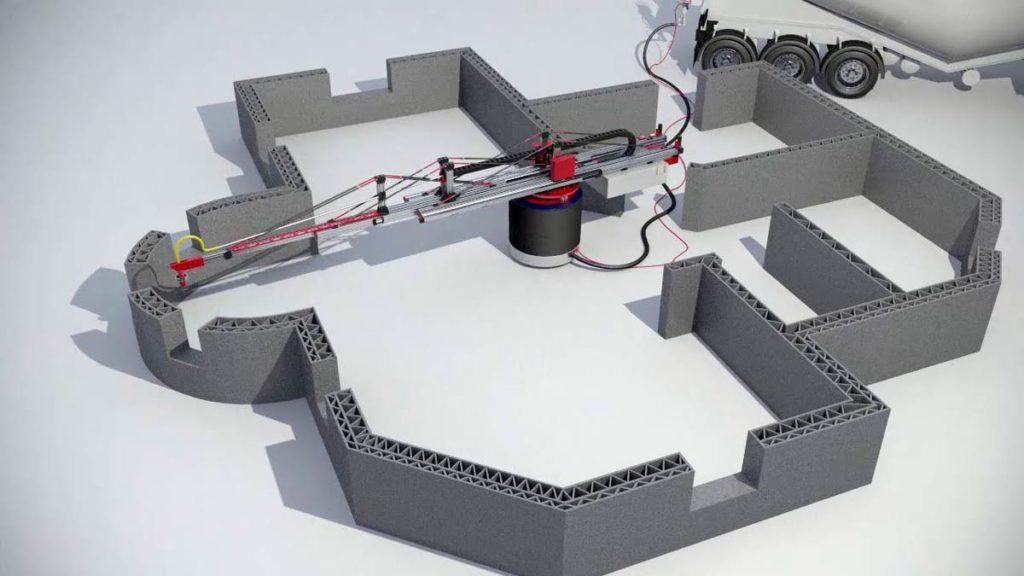

With the launch of ‘Standard (Std) 20S,’ the API has effectively introduced a three-tiered criteria, which sets out the technical, quality and qualification requirements for 3D printing end-use-ready rig parts. In practise, the group expects Std 20S to allow oil and gas firms to deploy the technology more consistently, in a way that reduces their carbon footprint and “strengthens their supply chain resiliency.”

“This new standard expands API’s best-in-class safety and efficiency requirements and supports cutting edge operations, helping producers to deploy new 3D printing technologies to meet rising global demand for natural gas and oil products,” said Alexa Burr, API’s VP of Segment Standards and Services for Global Industry Services.

A Linde hydrogen production facility. Photo via the API.Taking fossil fuel regulation global

Established more than 100 years ago, the API has nearly 600 members hailing from across the natural gas and oil industry, thus it claims to produce, process and distribute the majority of energy in the United States. The organization’s preeminent status has provided it with the clout needed to set standards for the sector, and it now has a catalogue of more than 700 of these, as well as best practices.

The organization’s preeminent status has provided it with the clout needed to set standards for the sector, and it now has a catalogue of more than 700 of these, as well as best practices.

Leveraging its accrued oil and gas expertise, the API issues guidance on everything from drill bit and material qualification, to ensuring site safety standards. In order to police these in practise, the organization has introduced ‘Monogram’ and ‘Individual Certification’ Programs, through which it carries out checks on firms’ compliance with certain standards, and recognizes those working closely to industry codes.

According to the API, many of its standards have been incorporated into U.S. federal law, and they’re “widely-cited by the international regulatory community.” As a result, the group has increasingly sought to go global with the ambition of improving “the safety and viability of the U.S. oil and gas industry,” and addressing the sector’s wider environmental challenges.

The API’s new standard is designed to make LPBF, DED and binder jet 3D printing easier for oil and gas part manufacturers to adopt. Photo via Cetim.

Photo via Cetim. Introducing ‘API Standard 20S’

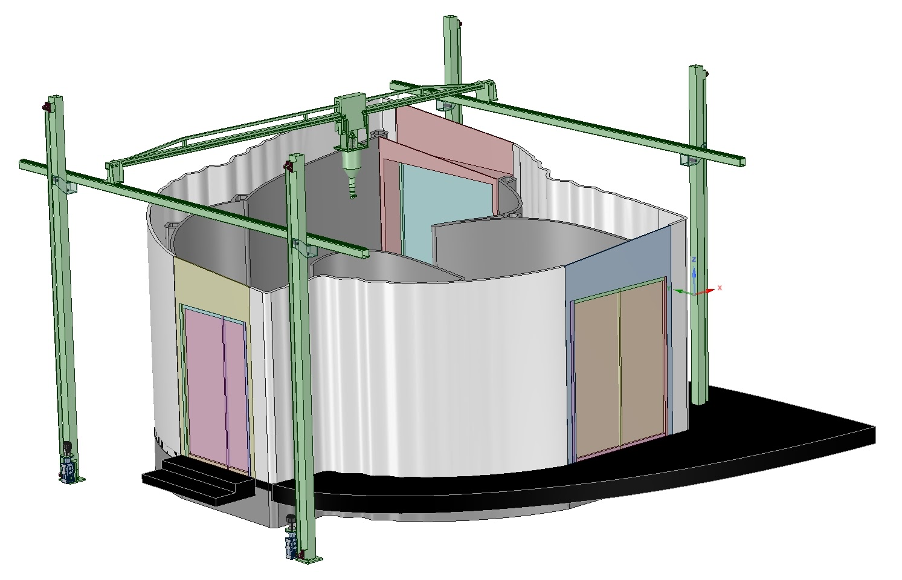

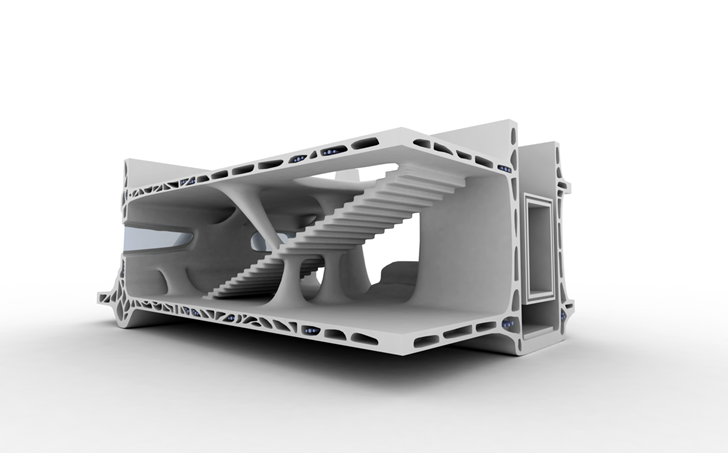

Launched in October 2021, API Standard 20S covers the production, marking and tracking of ‘Additively Manufactured Metallic Components for Use in the Petroleum and Natural Gas Industries.’ Specifically, the document introduces measures that oil and gas firms need to follow, if they want to manufacture fit-for-purpose powder bed fusion (PBF), directed energy deposition (DED) or binder jet 3D printed parts.

Standard 20S is essentially built around three additive manufacturing specification levels (AMSLs), which define the rising technical, quality and qualification requirements that need to be met to gain API ‘AMSL grades 1-3.’ However, to achieve this certification, oil and gas firms will also need to meet wider standards, around issues like training, inspection, equipment, material testing and quality control.

Once implemented, the API anticipates that its AMSLs will hasten the sector’s 3D printing adoption, and result in the roll-out of optimized parts that “drive efficiency, safety and technological advancements across all segments of the industry. ”

”

The organization also sees Standard 20S as a way of helping oil and gas firms reduce their supply chain dependency, while making progress towards the goals outlined in its Climate Action Framework. In a report published earlier this year, the API committed to working for a “lower-carbon future” via the “acceleration of technology and innovation,” thus it has now turned to AM in pursuit of these aims.

“Employing innovation is one of the many approaches that our industry is taking to reduce carbon emissions, as outlined in API’s Climate Action Framework,” added Burr. “The ability to deploy innovative technology and bring critical manufacturing closer to the point of use, reduces stress in the supply chain, while driving down Scope 3 emissions and maximizing production capability.”

Following the introduction of Standard 20S, the API says it’s now working on a similar set of guidelines for polymeric 3D printed parts, adding that its latest announcement “is only the beginning of the work that will be done in this space. ”

”

Those interested in finding out more about API Std 20S can purchase access to the document via the organization’s dedicated online store here.

Protolabs published a survey earlier this year highlighting how 3D printing can help oil and gas firms gain “environmental credibility.” Photo via Protolabs.AM’s oil and gas opportunity

Although the API describes its new standard as a “first-of-its-kind document,” it’s actually similar to those already developed by the likes of DNV GL, which has also identified the potential of 3D printing within the oil and gas sector.

As long ago as 2017, the company introduced its first classification guideline for oil, gas and maritime 3D printing, and it has since followed this up with a service specification document, designed to expedite the technology’s adoption. Having met these standards, part provider Protolabs gained ‘Qualification of Manufacturer’ certification, for its metal 3D printing offering from DNV GL in May 2021.

Said to be the first PBF manufacturer to meet DNV GL’s lofty standards, Protolabs was awarded qualification specifically for its Inconel 718 superalloy direct metal laser sintering (DMLS) offering. Using its technologies, the firm says it’s now possible to produce complex, ultra-resistant end-use rig parts, and the results of its ‘Decision Time’ survey indicate there’s a growing demand for AM within oil and gas too.

Elsewhere in the industry, energy services provider Hunting PLC has also indicated that it plans to begin 3D printing oil and gas components, following its acquisition of a stake in Cumberland Additive. While the firm hasn’t revealed exactly how it intends to deploy the technology, it says that its investment provides it with “new market opportunities,” in “sectors complementary to its core competencies.”

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows an offshore wind farm. Photo via Protolabs.

Tags Alexa Burr American Petroleum Institute Cumberland Additive Holdings DNV GL Hunting PLC Protolabs

Paul Hanaphy

Paul is a history and journalism graduate with a passion for finding the latest scoop in technology news.

Prototypster Launches API for Integration with Internet Services and Applications / Sudo Null IT News

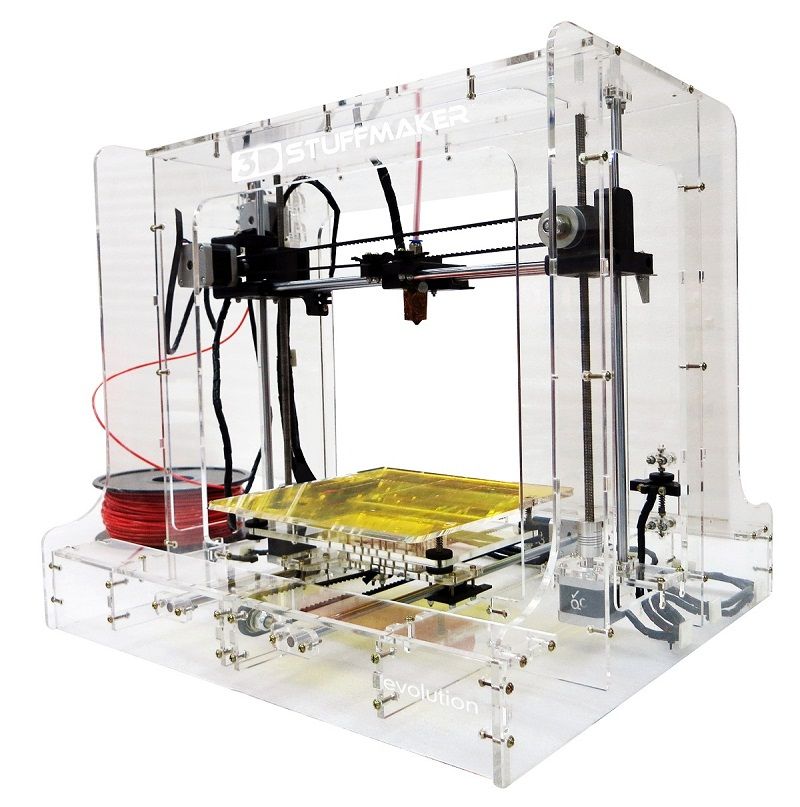

Hello Geek! We are the Prototipster company, one of the largest manufacturers of 3D printing products in the CIS. More recently, we have developed and opened an API that will allow you to integrate the order and payment for 3D printing of any product on any site.

API for 3D printing was not invented by us - it is actively used in the West. For example, the American company Shapeways, the manufacturer and seller of the world's largest range of 3D products, provides an API for partner sites and designers to create and sell their 3D models. Shapeways takes care of everything - from production to sale through the store and delivery: designers only have to create and design new ideas. nine0003

This is not the only company on the market, among the big ones we could mention Sculpteo and others, but they all have in common that they somehow do not work with our market. Of course, there are ways to order the delivery of any 3D product from the same Shapeways store to Russia, but this requires additional efforts from the buyer - more than just entering a delivery address and making a payment on the site.

In general, the Russian market is in need of similar solutions. And one of the first on it we present our own: API "Prototypester". nine0003

nine0003

What it does

Any business, one way or another interested in the production / sale of 3D printing products, can take advantage of our production facilities, our experience and expertise - everything, up to payment and delivery options through us.

You can work with us as a white label model for those companies that do not want their customers to know exactly where the production of their goods takes place - from their point of view, all processes will go inside your department: you yourself accept payment, and we'll even label the boxes with your logo before shipping. nine0003

Partial integration is also possible, when the user selects products on your site, and then goes to us to complete and pay for the order. This is a good option for start-up businesses without a legal entity or the ability to set up payment acceptance on their website. In this case, all a partner needs to sell their 3D products is a website with a product showcase connected to our API.

Where can this be applied?

3D printing is a serious business, %username% There are many uses for its products, and it's not just toys (although they are too). The Prototypster API can be embedded in off-the-shelf applications and on the Internet, such as galleries for viewing 3D models; Internet resources dedicated to game characters. The API is also useful in online 3D model builders, for example, designer jewelry, smartphone cases, etc. nine0003

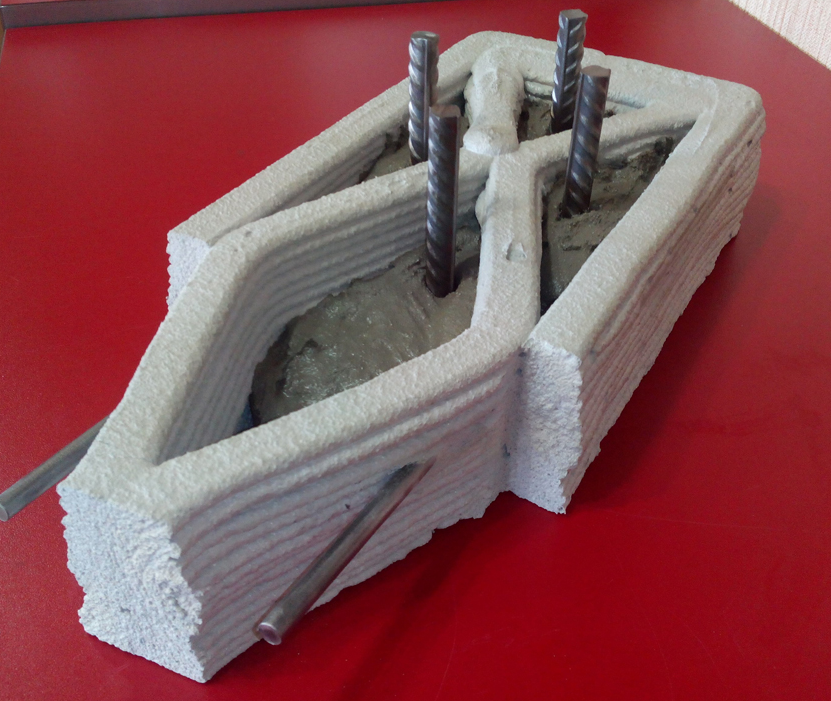

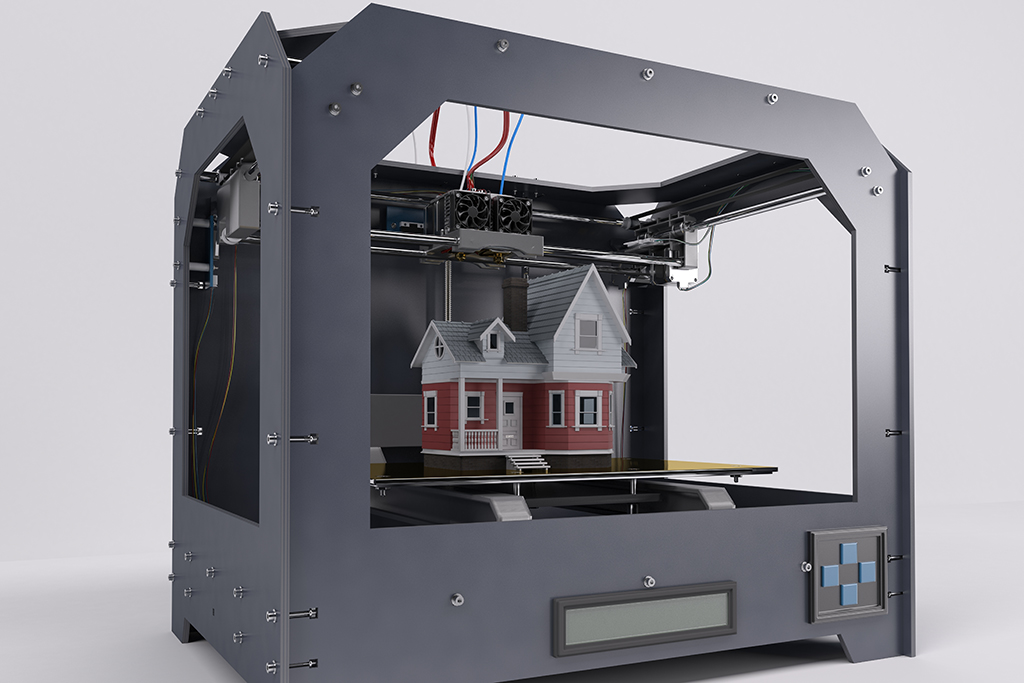

- For example, 3D printing is in demand in architecture — for example, models of future buildings.

- Special demand for 3D printing in jewelry - we are not talking about the actual printing of gold and platinum products, although this is also possible - using 3D printing, you can significantly simplify the casting process by creating waxes (casting molds) on a 3D printer .

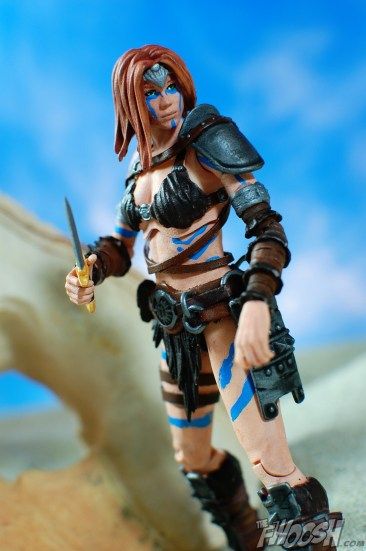

- Souvenirs: figurines with characters from favorite movies, comics, anime and games are very popular among fans. One of our partners and early adopters of the Prototypster API, globalgallery.

ru, produces great figurines of characters from popular games - they design models and sell them through their website, and we provide production and delivery. nine0030

ru, produces great figurines of characters from popular games - they design models and sell them through their website, and we provide production and delivery. nine0030 - Gadgets - 3D printing comes in many different forms, but designer cases for smartphones are one of the most popular.

- Prototyping industrial solutions - any design office can do engineering work for their client, and we will print and send him a prototype in the best possible way.

Of course, your business uses more than just 3D printing and our API. In principle, you don’t even need to have a business for this - just the idea of a product that can be printed on a 3D printer and that will be in demand. Any designer can bring his idea to life and turn his site into a 3D goods store - it's like the production of T-shirts with a designer print, only the designer in this case will earn money on each product produced according to his project. nine0003

For existing businesses, integrating 3D printing orders into their website and processes is a great opportunity to expand their horizons and even open up new directions. For our part, we offer a well-functioning production and delivery system.

For our part, we offer a well-functioning production and delivery system.

Product quality

Processes on our side are automated as much as possible. When you upload a model for 3D printing on the protoypster website, the in-house production program evaluates the feasibility of the submitted model. If the model is designed correctly, then the user will only have to select the desired production material from the twelve available, and then either place an order if he prints for himself, or send it to our store if the model is loaded for sale. Or both. nine0003

If the model is designed with errors, the system will automatically correct non-critical ones - the one who loaded the model may not even notice that there were problems. If the errors in the project are serious, the system will point them out to the uploader of the model. After that, all that remains is to start selling it - in our store or on any site connected to the Prototypster API. We organize printing, packaging (including the possibility of branding it with partner stickers, logos, etc. ) and delivery within the territory of at least Russia and the CIS. nine0003

) and delivery within the territory of at least Russia and the CIS. nine0003

Prototypster API connection

You or your programmer here: API documentation

In the following publications, we will tell you more about how it works, works and connects.

Join the community

One of the conditions for the development of the 3D printing market in Russia and the Russian Internet is a community of designers, engineers, etc. — people who are able to create new products for 3D printing — from phone cases to medical prostheses and satellite parts. To become a part of our community, you need to start by registering on our website and uploading your model. nine0003

We need ideas

Another factor in the development of the market will be the search for new ways to apply 3D printing. Have an idea how to use the Prototypester API in your business or create a new one with it? We are waiting for your comments.

Free 3D File API Booth・Object for Download and 3D Printing・Cults

Fidget cube 15 mm

Free

nine0071 Order 4 sphericonFree

Best 3D Printer Files in the Miscellaneous Category

6 Handles for 3D printed dental impression trays

10 €

Clarinet Mouthpiece 1.

0

0 Free

SUBMARINE HOLLAND S1 USA

9 €

nine0071 BoomboxFree

Cerebrix Human Skull

Free

Halloween decoration

3.13 €

Sheetov cistern

Free

EDC Flashlights Holder for Glasses ( Ball Jointed )

Free

Bestsellers in Miscellaneous category nine0081

SlingHAMMER - repeating crossbow pistol for steel balls 6mm 8mm 10mm or 12mm

12.50 €

MMPR Dragon Dagger

4.74 €

5 gnomes (without support)

2.49 €

4th planet Fighting pre-Olympic god

12 €

nine0071 CHRISTMAS TREE v21,50 €

Mate Qatar 2022 FIFA World Cup

10 € -fifty% 5 €

Gremlin rail 640 mm FPV

0,95 €

Wednesday item

3. 91 €

91 €

1,30 €

TING Addams

8.53 €

flexible volute

2 €

Key holder for middle finger

1 €

Brackets for shock absorbers and trx4m escalators

1,90 €

nine0071 ItsLitho "Pure" personalized Lithophane Christmas ball1,90 €

Christmas stitch

1.25 €

Charizard - pokemon with flexible articulation (seal in place, without supports)

3 €

Do you want to support Cults?

Do you like Cults and want to help us continue our journey on our own ? Please note that we are a small team of 3 people, so supporting us in maintaining activities and creating future developments is very easy.