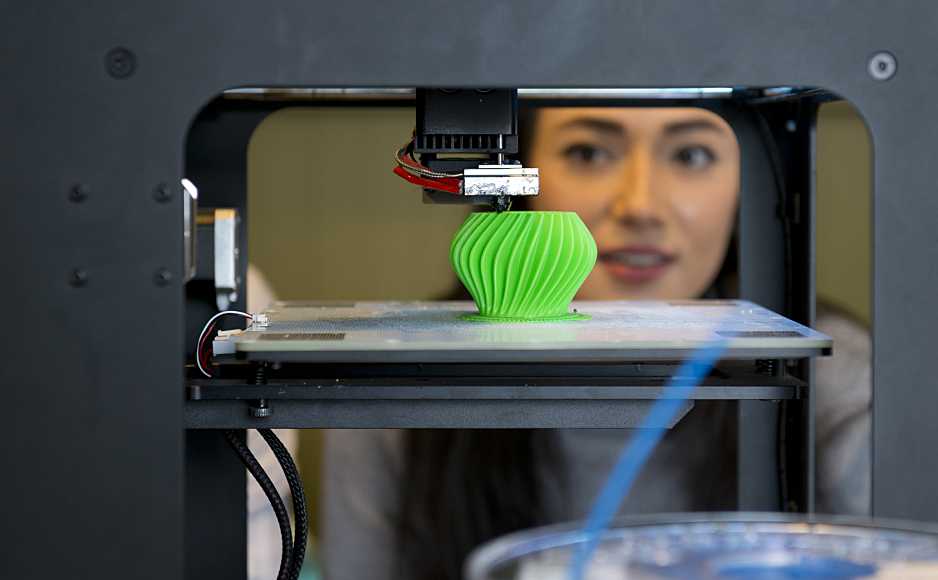

Plexiglass 3d printer

Can You 3D Print Clear Plastic

Many consumer products, from cell phone cases to kitchen appliances, use transparency to help with both functionality and appearance. But unlike other materials traditionally used in prototyping – foam, clay, fabric – fully transparent materials can be difficult to manipulate.

Now that 3D printing has been identified as a solution for design problems, you might be wondering if you can 3D print transparent materials the same way you can print opaque plastics and photopolymers.

The short answer? Yes!

Multi-material 3D printing technology makes creating custom translucent and transparent parts easier than ever. Read on to find out more about transparent materials, how 3D printing them works, and possible applications.

What's the difference between transparent, translucent, and opaque materials?

Opaque materials entirely block the passage of light, meaning nothing can be seen through them. The majority of materials, like colored plastics, wood, and metal, are opaque.

Translucent or semi-transparent materials allow some passage of light, but you usually can’t see clear shapes through them. Examples of common translucent materials include wax paper, sheer fabric, and frosted glass.

Transparent materials allow enough light to pass through so that objects on the other side of the material can be seen clearly. Clear glass, water, and cellophane are all examples of common transparent materials.

Designers use all of these types of materials – and every opacity in between – for product development. Certain applications may require semi-transparent materials, while others might need fully transparent components.

How can you 3D print transparent materials?

As with most 3D printing methods, it truly depends on the application. For rough prototypes or tooling, one option is FDM technology and transparent filament. With extensive sanding and/or coating, a degree of translucence can be achieved.

With extensive sanding and/or coating, a degree of translucence can be achieved.

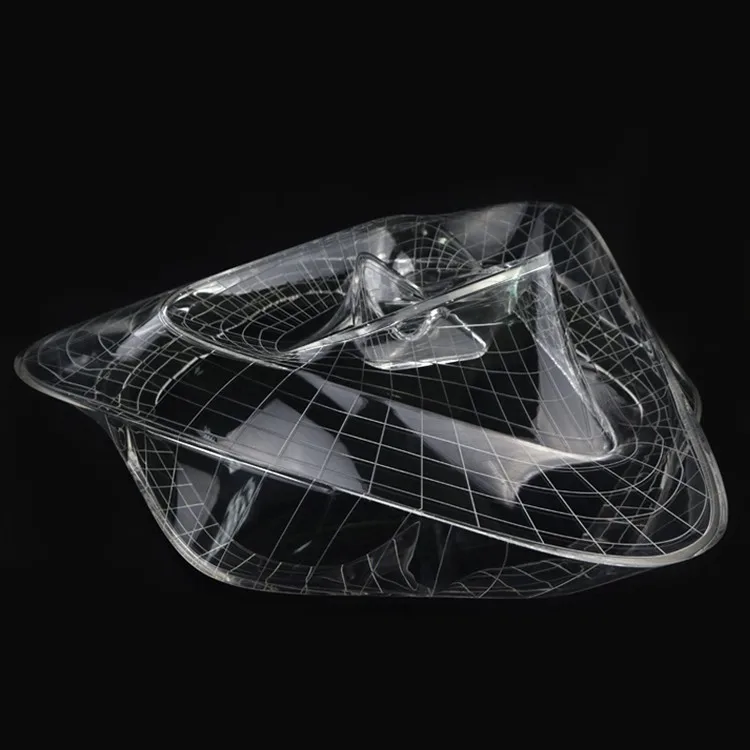

However, for high-fidelity models or final use parts, a smooth finish and true transparency may be required. Photopolymer materials like Stratasys VeroClear™ and VeroUltraClear™ are engineered for a smooth finish and high light transmission for excellent clarity.

Can you 3D print acrylic?

PMMA, also known as acrylic, is a transparent thermoplastic often used as a more durable alternative to glass. For 3D printing, VeroClear and VeroUltraClear simulate the physical properties of acrylic, and can be combined with thousands of opaque color options for a full range of colored transparencies.

VeroClear offers similar mechanical properties to acrylic, with good strength, stiffness, and impact resistance. VeroUltraClear provides excellent, improved clarity and a lower yellow index for truly transparent parts.

3D printed fish.

What are practical applications for transparent materials?

Consumer products.

For consumer products, the applications for 3D printed transparent materials are endless.

Incorporate transparency into prototypes for cosmetics packaging, kitchen products, and food and beverage containers. Tinted transparent components help build up model realism, helping designers see their ideas become reality.

Medical devices.

For models that need to simulate glass or clear polymers for eyewear, VeroClear and VeroUltraClear are ideal choices. Nidek Technologies, an Italian company specializing in ophthalmology R&D, used VeroClear to prototype a special new optic device.

Medical models.

For surgical training or preparation, anatomical models with transparent components or walls are useful when studying complex anatomies like vascular systems. Clear 3D printed materials allow the creation of custom, transparent geometries, opening up a range of possibilities for medical research and patient care.

3D printing clear plastics can provide a whole new way of designing, whether for consumer products or medical research. With the ability to create fully custom transparent parts, you can create models that show internal mechanisms, accurately represent a final product, or allow for functional, real-world testing.

To learn more about what you could do with transparent 3D printing, visit the material pages for VeroClear and VeroUltraClear.

Plexiglass best 3D printer models・Cults

Plexiglass Airbox for Peugeot 206

€5

Monoprice Mini Delta Plex Sides

Free

Cover for Ultimaker 2 and 2+

€4.04

Lightning box

€1.50

connectors for plexiglass box

Free

Plexiglass Protector

Free

FlashForge Creator Pro - Enclosure Brackets

Free

Panel Door Glass inset Holder

Free

Broken Laptop to All-in-One Desktop Conversion

Free

Plexiglass sight cover

€1. 30

30

Magnetic Latch For 2020 Extrusion

Free

2020 Alignment Tool for Acrylic

Free

Display Riser Legs

Free

JeSc HyperCube Plateau clamps v2.0

Free

Cubicle Covid Bracket

Free

Photographic plate stand (5,4,3,2 or 1 mm) - Socle pour plaque photo

Free

Off-set Lift-Off Hinge

Free

ENCLOSED CRAFTBOT- FULL ENCLOSURE

Free

Printable Prusa i3 Frame Parts for Laser-cut (6mm) Frames

Free

TP-Link Archer C5 holder bracket

Free

Door Handle _ Türgriff verstellbar Plexiglas

Free

Simple Edge Bracket

Free

Pineapple RGB Arduino light

€50

Plexiglas covid support

Free

Ultimaker hinges for front door - 1 piece printed

Free

MP Mini Delta Plexiglass Mounts

Free

WallClock "Floating Numerals" cnc

Free

Bread Basket "Flower" cnc/laser

Free

SquircleStool cnc

Free

Clock Face "VeneeredPMMA" cnc

Free

"Waveguide" Bedside Reading Lamp cnc

Free

joiners for 3/16 plexiglass

€1. 01

01

Tinyboy 2 Replica

Free

Enclosure Mounting Hardware for Replicator 2

Free

Base plate for photo plate 1,2,3,4 or 5 mm thick

Free

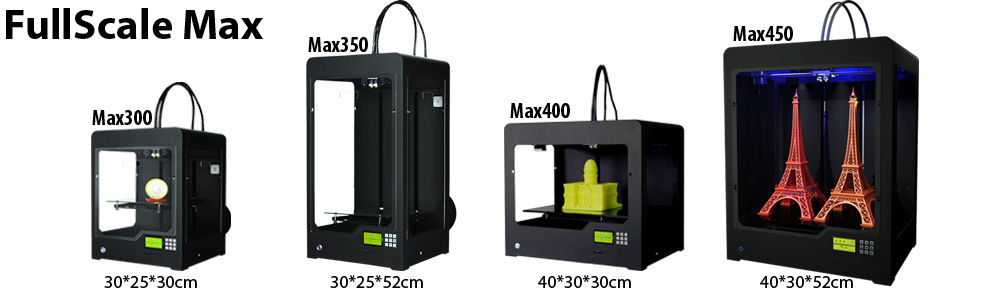

Thermal cabinet (box) for 3D printers

In the world of rapid development of 3D printers, all kinds of applications for them are also rapidly gaining momentum, one of these is thermal box. The main difficulty of FDM printing on 3D printers that do not have a closed or semi-closed housing is the preservation of thermal climate. Thus, many enterprising users resort to the use of thermal cabinets.

Shakf is any structural shell for a 3D printer that allows you to maintain temperature conditions. Simply put, it is a box to store heat and prevent external factors from changing the printing conditions. The shell helps the 3D printer stabilize the printable area, neutralize external factors and prevent warping. Such chambers are especially important for printing ABS plastic.

Such chambers are especially important for printing ABS plastic.

There are many ways and different materials used for cabinets. They may have one or more doors, some models are acrylic, others are metal. And there are also models designed for a specific 3D printer. Although this makes them more reliable, it also increases the price, often provided by the companies themselves as optional accessories for a 3D printer.

They are available from online stores such as Amazon and Ebay. But it is possible to find this device in the form of printable files, on sites such as thingiverse. While some are kits, others may require users to print additional latches or locks. Some kits are as easy as using a hex driver to tighten screws, while others have to be glued or drilled.

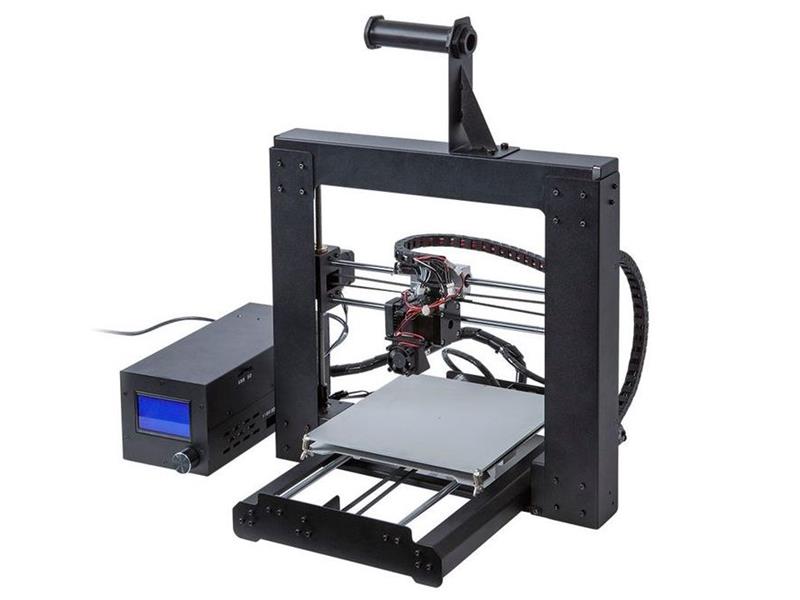

Simple DIY 3D Printer

This is the cheapest option. A simple DIY case will certainly help, but it has to be done right. For example, the picture above uses acrylic boxes. It consists of 2 boxes fastened together and reconfigured with a cutting wheel.

It consists of 2 boxes fastened together and reconfigured with a cutting wheel.

When making this box, remember that you need to run wires, and it is also important to provide enough space for the 3D printer to move in all 3 axes. The shape should also allow for easy loading and unloading of the filament. In addition, consideration must be given to how best to set up the 3D printer to correct values such as table alignment and jamming in case of printing errors.

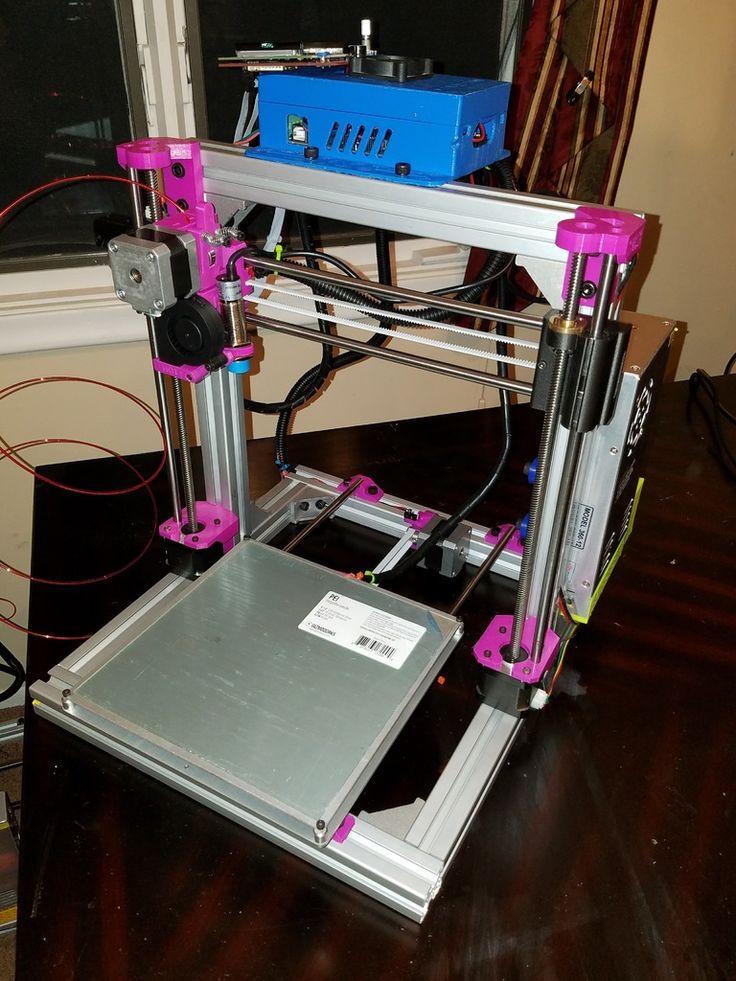

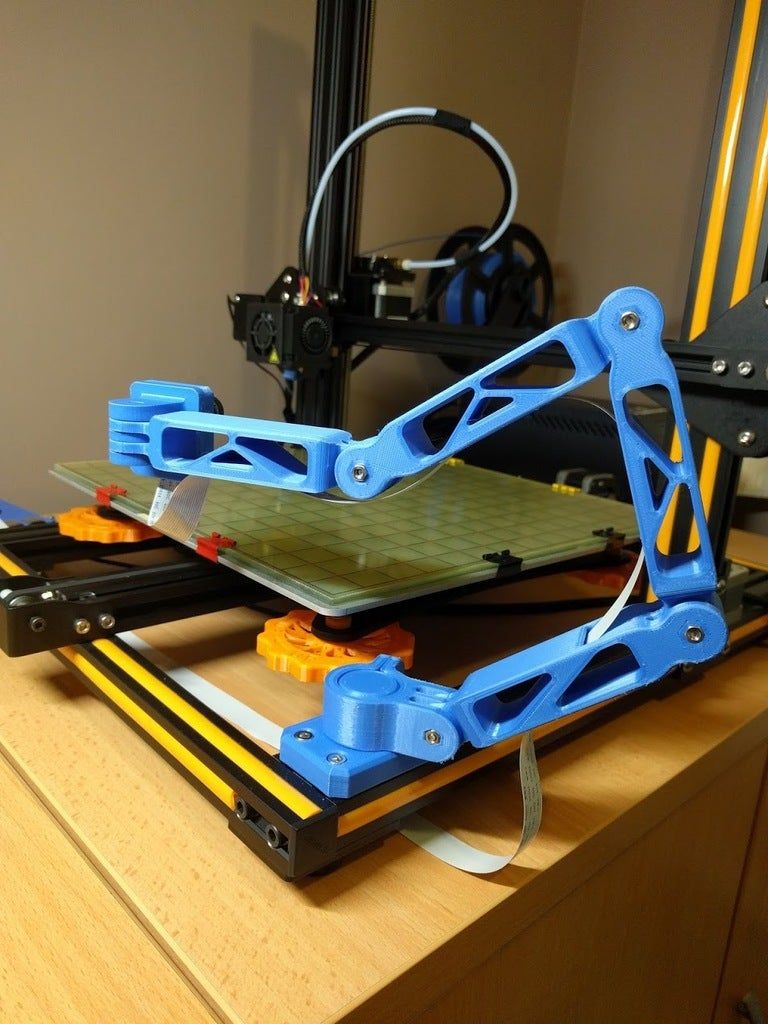

Complex DIY 3D Devices

The figure above shows a relatively complex system. It uses a metal frame with various printed parts. It has a complex anatomy and is carefully positioned according to the 3D printer. This particular sample costs just under $400. This may sound expensive, but it is a very complex system with a heat sensor and very specific materials.

The advantage of a DIY shell is that it can fit your 3D printer. The system shown above also appears to be more robust, and the configuration makes it easier to calibrate the 3D printer.

Other examples of simple products:

Instructables has many examples, but one of the best is Schlem. It consists of a series of plexiglass panels connected by hinged corners and ABS. Connecting parts are made of ABS.

Robert Soyak created a great cabinet using a simple frame with a bunch of ingredients, including 10x10mm slats, small hinges, a couple of screw latches, a handful of small corner brackets, and 6 meters of window duct tape. It consists of acrylic panels, hinges, lock nuts and screw latches, as well as room for a fan and additional electronics.

If wood is your preference, GrabCad has a tutorial on how to build this device. Originally built by a user named Jonathan, the hotbox is a sleek and functional device. It's like the LeapFrog Bolt front panel is warped in the middle.

Hotbox is suitable for any 3D printer that does not exceed 26x26x24. It has a removable hood, LEDs for lighting - space for a cooling fan. An internal 72W power supply is required to power the fan and LEDs. It takes quite a bit of work to create a hotbox, but it's certainly one of the most impressive skins out there.

An internal 72W power supply is required to power the fan and LEDs. It takes quite a bit of work to create a hotbox, but it's certainly one of the most impressive skins out there.

Of course, if you save on buying the 3D printer itself, but want to get

high-quality printing you will need such a miracle cabinet, but maybe you should immediately buy a 3D printer, with a closed or semi-closed case and don’t think about it anymore, especially since the price is not much different.

5 reasons why a shroud is a must for any 3D printer

How can temperature affect 3D printing?

Maintaining a stable temperature during printing can be ensured by using a special casing designed to protect the printed product from a sudden drop in temperature. Changes in room temperature can be caused by factors such as drafts or air currents from air conditioners. What are the benefits of this solution and how does it affect the 3D printing process?

ABS model printed on 3DGence INDUSTRY F340

3D printing with technical materials

Using a shroud with a 3D printer is often necessary to ensure a proper 3D printing process. The most advanced technical materials, such as ABS and polypropylene (PP), require strict conditions under which the subsequent layers of the model are created.

The most advanced technical materials, such as ABS and polypropylene (PP), require strict conditions under which the subsequent layers of the model are created.

Why is it necessary to use a professional casing when working with structural materials? Do you still have doubts?

5 reasons why a shroud is a must have for any 3D printer

1. Proper layering of material

- Using a shroud provides more durable prints.

2. Minimize shrinkage of workpiece material

- The ability to obtain high-precision parts, preventing product deformation from internal stresses.

3. Creation of an isolated workplace

- Isolation of the working area from external sources of cold air. Temperature differences can adversely affect the final appearance of the printed element.

4. Increased safety of use

- Securely guards hot printheads and other moving parts.

5. Reducing the noise level of a running 3D printer

– Possibility to limit noise from the device in the workplace.

In the photo: on the left - a model made on a 3D printer from ABS material. Significant cracks are visible on this 3D printed product. In this case, the user did not use a special casing that can protect the printed product from external factors. The photo on the right shows the same model that was printed on the 3DGence DOUBLE P255 printer. During this 3D printing process, a special casing was used. In this case, the printed 3D model meets all design requirements.

3DGence DOUBLE P255 printer with new print cover

The basic package of the 3DGence DOUBLE P255 printer includes a casing, an accessory that allows you to better control the 3D printing process. The case allows you to print from materials such as ABS or PP. Proper heating conditions are essential when working with these materials due to their very high shrinkage sensitivity.

For some users, printing with ABS material can be more difficult due to issues such as cracking when exposed to high temperatures or delamination of the model when exposed to a hot fuser. However, ABS is one of the most popular materials used in the 3D printing industry, so it's important to learn how to 3D print with this material.

However, ABS is one of the most popular materials used in the 3D printing industry, so it's important to learn how to 3D print with this material.

I have personally tested the print quality of ABS and PP, so I can confirm that the quality of products printed using the new shroud designed specifically for the 3DGence DOUBLE P255 printer is much better.

Andrzej Kukuła, President of the Management Board, 3DGence

R&D printed cover

The new casing, developed by 3DGence R&D engineers, consists of elements made of plexiglass and connected with clips and magnets. The entire structure rests firmly on the printer, and the quality of the components used ensures ideal conditions inside the camera.

Installing a special cover on the 3DGence DOUBLEP255 printer

High precision 3D printing

The casing of the 3DGence DOUBLE P255 printer guarantees high accuracy of the created model.