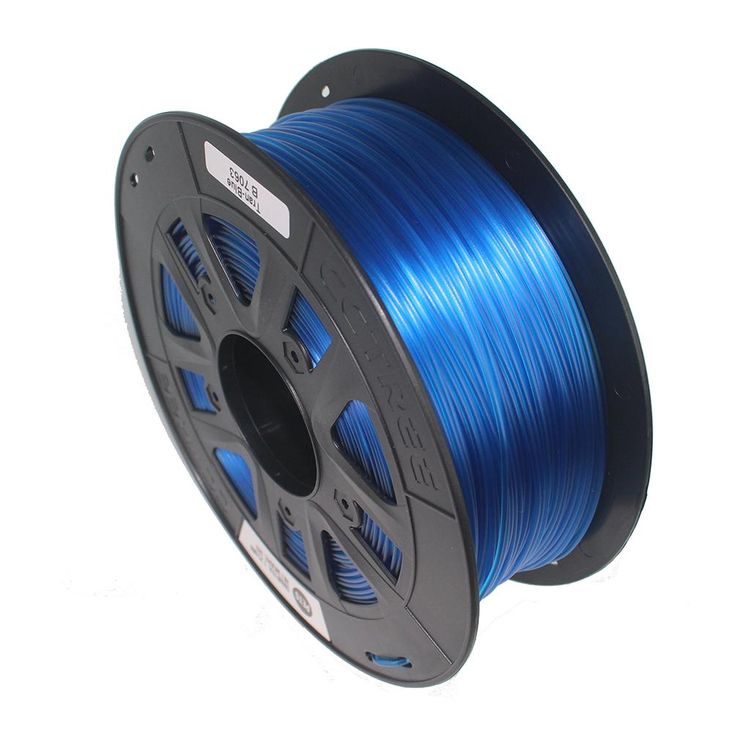

Petg 3d printer filament

How to Succeed when 3D Printing with PETG Filament

This in-depth guide provides everything you need to succeed when printing with PETG filament. Embrace the fantastic properties of durable and easy to print, PETG filament!

Updated on November 2, 2022

by

MatterHackers

PETG has become a very popular 3D printing material thanks to it's ease of printing, mechanical strength, thermal resistance, and incredible color options thanks to natural PETG being so clear. There are a few things to know before getting started, like the need for an all-metal hotend and the necessity of well-tuned retraction, so we've put all our PETG expertise into this article so you can get out of the gates strong and start making amazing PETG 3D prints today. Let's get into it!

What is PETG Plastic?

PETG is an extremely common polymers used today that you likely encounter without even realizing it. Basically any clear plastic bottle is going to be made of PET (Polyethylene Terephthalate) or PETG (Polyethylene Terephthalate with a glycol modifier) and in fact many consumer 3D printers utilize PETG or some derivative to makeup their 3D printed structural components. When used as a 3D printing filament, PETG has found its home as the more accessible "durable 3D printing filament" due to its relatively stable 3D printing properties that make it easy to print and yet capable of being in low-heat or high-strength environments.

You’ll often see references to PETG in one of the following forms: PET, PETG, PETT, and many others. This can make it seem like these are many different filaments when in reality they are just slight variations in the formula to create a material that is more translucent, stronger, or more flexible. In terms of print settings, across all these variants they will be approximately the same, with some minor tweaks here and there to reduce stringing or improve layer adhesion.

If you're used to printing with PLA, then you might not have considered a unique attribute of PETG: that it's ductile. Where PLA may be able to withstand more force without breaking, when it hits the threshold where it'll break it is very sudden and without warning. In contrast, PETG will bend a little before it breaks, so you can see a failure before it happens. It's the different of printing a PETG shelf bracket that's starting to droop and a PLA shelf bracket that dumps your books onto your desk and monitors.

With PETG you can also take that ductility and use it in the design of some purposefully flexible geometry. Snap fit enclosures, where small tabs bend out of the way and snap into a channel once a lid is fully pressed in place, are a beautiful opportunity to utilize PETG. Or you can design a part that needs to rigidly hold something else without being too difficult to insert, like a bearing holder on a 3D printer part.

PETG 3D printing filament is a great material for functional prototypes and end-use parts.

Hardware Requirements

Hotends

There are many variations to the PETG formula, which makes specifying one temperature to print at a difficult claim. Some have additives that bring their printing temperature significantly lower while others bring the temperature significantly higher. Essentially, start with 245°C and play around with 5°C higher or lower to find the ideal print quality for you.

Some 3D printers utilize a PTFE (teflon) lined hotend as it is easier to manufacture than a hotend that is all-metal from the heatsink to the nozzle. PETG's printing temperature is right at the threshold of the temperature that PTFE begins to degrade, so some 3D printers might be able to get away with lower-temperature PETG filaments that have an ideal temperature at 240°C or less. For the most part, PETG does require an all-metal hotend to be able to tune your filament to its fullest, as in while you may have successful prints at 240°C, you don't achieve full strength until 255°C.

In general, PETG is non-abrasive, but once you start playing with additives it becomes a case-by-case basis. Sparkly filament isn't abrasive despite having non-PETG material in it, but it's common to add carbon-fiber to increase the stiffness and strength of the finished 3D prints, which is extremely abrasive. An easy way to avoid these concerns is to swap over to an Olsson Ruby nozzle or a Nozzle X when you want to use these materials.

Layer cooling is only occasionally necessary. This does depend on the 3D models actually being printed, as moderately sized models can be printed without cooling and come out beautifully, but tall and thin models with short layer times may need some gentle cooling to hold its shape. 50% is the maximum you will need for extreme overhangs or short layers, otherwise you are free to leave the fan off for the best layer adhesion possible.

E3D v6 All-metal Hotend

Bed Requirements

For the best chance of success, you will want to make sure you have a heated bed set to 65°C. Some PETG is more warp-prone than others, so higher temperatures may be required to give them enough adhesion to the bed. If you're having difficulty, bump the temperature up by 5°C at a time until adhesion improves.

Some PETG is more warp-prone than others, so higher temperatures may be required to give them enough adhesion to the bed. If you're having difficulty, bump the temperature up by 5°C at a time until adhesion improves.

As for the bed surface itself, you have quite a few options to work with, keeping in mind that it's not an exhaustive list, just the big players. Let's take a look at each surface individually:

- LayerLock Powder-Coated PEI - A textured, flexible build surface that can add a unique look to your 3D prints. Make sure you already have a magnetic system in place for this to work properly and keep it clean with the highest percentage isopropyl alcohol you can find. You may need to "smoosh" the first layer a bit more than you're used to to get it to stick, but once it is cooled it usually pops off without touching it.

- LayerLock Garolite - While it is the ideal surface for 3D printing with nylon, LayerLock Garolite is still quite versatile and can be used to support PETG 3D printing.

You will want to use any of the adhesives listed below to get additional bed adhesion to lock down your PETG 3D prints. A little roughing up with some high-grit sandpaper can also refresh your garolite and give it more bite for your 3D prints to hold onto.

You will want to use any of the adhesives listed below to get additional bed adhesion to lock down your PETG 3D prints. A little roughing up with some high-grit sandpaper can also refresh your garolite and give it more bite for your 3D prints to hold onto. - Glass - If you want a glossy smooth bottom to your 3D prints, this is the way to go. You will want to use an adhesive of some sort though (check the list below) as a release agent as some users have torn chunks of glass out of their bed as it adheres to their clean PETG print's first layer.

- BuildTak - An adhesive sheet you can apply directly to your 3D printer's bed or on top of a Flexplate. No adhesive solution necessary, simply wait for your bed to cool and use a BuildTak spatula or twist the Flexplate to remove your print. A word of caution though, as printing too close to the BuildTak can permanently bond the two together and tear chunks of it off your printer's bed.

- BuildTak PEI - An adhesive sheet you can apply directly to your 3D printer's bed or on top of a Flexplate.

Basically magic. Sticks solid when hot and pops off with a gentle tap when cool. You may need to bump the temperature up slightly to get enough adhesion to stick (near 70°C should be plenty). A thin smear of an adhesive is highly recommended to prevent the PETG from permanently bonding to the PEI.

Basically magic. Sticks solid when hot and pops off with a gentle tap when cool. You may need to bump the temperature up slightly to get enough adhesion to stick (near 70°C should be plenty). A thin smear of an adhesive is highly recommended to prevent the PETG from permanently bonding to the PEI. - GeckoTek - An adhesive sheet you can apply directly to your 3D printer's bed or on top of a Flexplate. Available in both a hot and cold variant to better suit the capabilities that your 3D printer has.

- Wham Bam PEX - An entire flexible bed system adhered to the 3D printer's bed. A strong magnet keeps the spring steel with an adhesive sheet of PEX applied to it secured to the printer's bed during the print, but can be easily removed and flexed to pop your print off.

There are always new and exciting methods for bed adhesion being developed, so it's important to have a good grasp on what each method is best used for. You can check out our 3D Printing Essentials article about bed surfaces to fully understand the pros and cons of every bed surface you might come across while 3D printing.

In addition to build surface upgrades, there are also a wide variety of 3D printer adhesives that you can apply to your 3D printer's bed to get a great first layer. These adhesives are specifically developed for the 3D printing industry, so you can trust they have been tested to be tried and true 3D printer adhesives. Here are the best 3D printer adhesives that you can use to get the best first layer for PETG filament:

- Stick Stick 3D printer adhesive

- Magigoo 3D printer adhesive

- 3DGloop! 3D printer adhesive

Most 3D printer bed adhesives have the same instructions for use: apply a thin layer to the build surface where your actively 3D printing. Then, wait for your part to cool before removing - waiting for your 3D printed part to cool makes it much easier to remove, and certain adhesives will sometimes even "pop" the part off the bed once cooled.

High quality PRO Series PETG 3D printing filament is the top choice for when you need reliable printing for every project.

Changing Your PETG 3D Printing Filament

When switching between two PETG spools and colors:

- While the extruder is cold set the heat to 245°C and wait for it to heat up.

- When you reach 245°C, release tension on the extruder (by either squeezing the tension release, flipping a latch, or completely unscrewing the adjustable tensioner), and quickly, but consistently pull on the filament to remove it from the hotend without breaking.

- Continue releasing tension on the extruder and insert the new filament until it reaches the nozzle.

- Run the new color through the extruder until it runs clean and the new color is all that is coming out of the extruder. If you are switching from a dark color (such as black) to a light color (like white or natural) run a while longer to be sure you don't have any dark contamination. Without this step it's possible to be a couple layers in and have the last bit of filament finally purge out.

Getting the First Layer of Your PETG 3D Printed Part Right

The first layer is the most important part of any print - it sets the foundation that the entire print builds on. You can check out the in-depth article on how to get a perfect first layer here, or for a brief summary of what to consider below are the few things you need to do to get the first layer to stick well.

You can check out the in-depth article on how to get a perfect first layer here, or for a brief summary of what to consider below are the few things you need to do to get the first layer to stick well.

- You need the print bed to be level.

- You need the nozzle to be the correct distance from the bed at the start of the 3D print.

- You need a good base material for your PETG to adhere to.

Below is a video from MatterHackers' 3D Printing Essentials series that will help guide you in the right direction for getting a stellar first layer. In this video, we'll walk you through the steps mentioned above in detail so you can succeed when 3D printing with PETG filament.

Difficult When Wet

There are 3D printing materials which are hygroscopic, which means it will actively absorb moisture from the air. This is a factor that you can't change in the material, so a hygroscopic material left out for long enough will reach saturation until it can no longer absorb water. Thankfully this is a fully reversible process without any material degradation. Best practices before 3D printing with any PETG filament is to thoroughly dry it out with a PrintDry PRO for several hours (or overnight if you have the time) and print with it immediately. Unless you live somewhere extremely humid without any temperature controls, your spool of PETG should be dry enough for use for several weeks before needing to be dried back out again.

Thankfully this is a fully reversible process without any material degradation. Best practices before 3D printing with any PETG filament is to thoroughly dry it out with a PrintDry PRO for several hours (or overnight if you have the time) and print with it immediately. Unless you live somewhere extremely humid without any temperature controls, your spool of PETG should be dry enough for use for several weeks before needing to be dried back out again.

Wet 3D printing filament doesn't just impact the appearance of your 3D print, but breaks down the molecular chains and creates a significantly weaker 3D print, which is why it's so important to make sure your filament is dry. Check out our in-depth article on how moisture affects your filament, and how you can successfully dry your 3D filament here.

PETG 3D Printing filament is a durable and easy-to-print materials making it great for functional, end-use parts.

What to do When Things go Wrong When Using PETG 3D Printing Filament - PETG Filament Troubleshooting

There are a few key things to check when your prints aren't working. But before we look at solutions we need to have a brief description of your symptoms.

But before we look at solutions we need to have a brief description of your symptoms.

"I can't tell if my printing temperature is right "What to Look for if you are having trouble getting your PETG filament temperature right:

- If the temperature is too high

PETG tends to get stringier the higher you take the temperature. Small cobweb like strings will web between different parts of the 3D print until it eventually balls up and sticks to your nozzle, heater block, or wall of your progressing 3D print. As long as you are confident that your filament is dry and you are still encountering stringing, lower the temperature by 5°C and see if that improves the situation. If not, you may just need to adjust your retraction settings for this slightly more flowy PETG. - If the temperature is too cold

You will either see that the filament is not sticking to the previous layer or that less filament is being extruded than necessary. You will get a part that is not strong and can be pulled apart easily or visually has many small voids along its walls where filament couldn't be extruded well enough. In either case, you should increase the temperature by 5°C and try again until you get consistent extrusion and layers that fully adhere to each other.

In either case, you should increase the temperature by 5°C and try again until you get consistent extrusion and layers that fully adhere to each other.

"I can't get the first layer to stick."

- Make sure the nozzle is at the right height.

Check out the 3D printing Essentials: Bed Leveling for what to look for in an ideal first layer. PETG, contrary to almost every other material, actually prefers to be "laid down" onto the surface rather than smeared into it. Raise your nozzle from your bed ever so slightly so it's not as squished as usual. - Make sure the print bed is level.

Check out the 3D printing Essentials: Bed Leveling for best practices when leveling your bed. If part of the bed is too far from the nozzle and the other part of the bed is too close, filament can drag around and create compounding problems.

"The part has bad internal layers and top surfaces."

- Check the temperatures.

Make sure you’re printing at the right temperature and that your bed is the right temperature. Too cold on either of these and there won't be enough adhesion between the two surfaces. - Check the filament tension.

Too loose and the extruder gears won't have the bite they need to push the filament around, too tight and filament can be deformed and not extrude reliably. - Clean the filament drive gear (if it looks clogged).

If you had a print fail where the job continued but no filament was being extruded, then the drive gear likely chewed a spot in the filament and filled its teeth with filament, reducing its overall grip.

"The outside edges of my parts have lots of little bumps on them."

- Make sure your printer is getting enough data.

If printing from a computer, ensure that the computer is not too busy to feed the printer commands. If the printer is pausing it is usually due to the printer being too busy.

- Print from SD card.

You can get around this by printing from an SD card. Sometimes this means you lose the ability to control the printer from your PC, but its a guaranteed way to remove your PC's hardware capabilities from the equation. - Source better PETG.

We have found that the quality of your print material can have a big impact on the quality of your part. Getting better PETG can help you get better parts. However, don't be too quick to assume the problem is in your PETG. With the right settings and patience hobbyists have succeeded in printing all sorts of materials many of which have very low viscosity and inconsistency. You should be able to get at least usable parts even with some lower quality filament. - Your retraction settings need tuning.

If your retractions settings aren't set right, your printer could be overextruding after each retraction leaving little bumps at the location where it started extruding again. Play with the "extra restart distance" and see if that helps.

Play with the "extra restart distance" and see if that helps. - Your filament is wet.

Many filaments can absorb water from the air and PETG is one of the most notorious. Because PETG is hygroscopic, you need to dry your spool before using it, which can easily be done using a PrintDry PRO to pull the moisture out of your filament. When not in use, you can also use silica gel packets to prevent your spool from reabsorbing water, but these packets won't pull moisture that is already present in the filament.

"Tall sections of my prints look melted or squished together."

- Print more than one part at a time.

By adding more parts to the build plate you are increasing the overall cross sectional area of each layer, giving more time for the separate objects to cool than if they were printed on their own. Since you can't use too much layer cooling without losing layer adhesion, adding more parts to the build plate is a suitable solution.

"My printer will not put out any material."

- Make sure your hot end is getting hot.

Check that the hot end is heating at all. If it is not you need to have your printer serviced. It is likely that you have a loose connection or your electronics have been fried (assuming the printer is still connected and responding to your host software :). - Clean the drive gear and adjust tension.

The first thing we are going to do is clean the filament touching drive gear and ensure that we have proper tension against the filament. Usually improper tension or a clogged drive gear will make the print look more like the picture we have for low temperature filament, but it sometimes does prevent extrusion all together. Clean the pinch wheel with a wire brush, and make sure your tension is good and solid (too much can also prevent extrusion and is more common with direct drives [the motor is directly connected to the drive gear] but less common with geared drives).

- Remove the current filament.

It may be that you have a small particle in your extruder tip jamming the plastic. Use the change filament technique described above to pull out any particles that are in the extruder tip. - Check for and remove jams between the extruder and hot end.

This is the most extreme type of problem because now it is time to take things apart. Sometimes heat can creep up the filament in the extruder and cause a bulge that then cools and prevents any further extrusion. This is usually at the junction between the extruder and hot end. Take off the extruder and remove all the PETG you can (you may need the hot end hot (80c-100c) to get all the material out. If you can't get out all the filament by pulling it out you may need to try and drive it down through the hot end. We usually use a small allen wrench. If this fails you can try and drill out the extruder or hot end but you may need to replace parts. Be sure to take precautions against being shocked or burned. If you are not qualified to do this work find someone who is, rather than risk injury.

If you are not qualified to do this work find someone who is, rather than risk injury.

Thank you for reading How To Succeed When Printing In PETG.

Happy Printing! - MatterHackers

P.S. Check out our Filament Comparison Guide to get the scoop on all the latest and greatest filaments! Or browse the MatterHackers Store for all your filament needs.

Article Tags

- 3D Printing

- Firmware

- 3D Design

- MatterControl

- Press Releases

- Small Business

- Automotive

- E3D

- Jewelry Making

- Engineering

- Entertainment Industry

- MatterControl Touch

- ESD Materials

- NylonX

- BCN3D

- Open Source

- Crafty Pen

- Digital Fabrication Anatomy

- How To

- Hardware and Upgrades

- Tips and Tricks

- Weekend Builds

- Top Ten

- Education

- Tech Breakdown

- Women in 3D Printing

- Project Ideas

- Advanced Materials

- Reference

- Vacuum Forming

- Pulse Dual Extrusion

- Product Spotlight

- Aerospace

- Jobs

- Military & Government

- Multi-Tool Machines

- Getting Started

- Healthcare

- How To Succeed With Any 3D Printing Material

- Creality3D

- Architecture

- 3D Printer Reviews

- Hacker of the Month

Related Products

View all related productsFree US Shipping* – Atomic Filament

Atomic Filament Brand Shirt - Light Gray

$ 995

CARBON FIBER Extreme Black PETG PRO

115 reviews$ 4999

Deep Black Opaque PETG PRO

41 reviews$ 3299

Bright White Opaque PETG PRO

26 reviews$ 3299

Gun Metal Gray Opaque PETG PRO

12 reviews$ 3299

Crystal Clear / Natural PETG PRO

16 reviews$ 3299

CARBON FIBER Nuclear Nylon v3

33 reviews$ 4999

Table Top Ball Bearing Spool Holder

10 reviews$ 999

Majestic Brown PETG PRO

2 reviews$ 3499

True Gold v2 PETG PRO

3 reviews$ 3299

Light Gray PETG PRO

6 reviews$ 3299

Dark Cherry Red PETG PRO

26 reviews$ 3299

Marble v2 PETG PRO

21 reviews$ 3299

Perfect Red Opaque PETG PRO

8 reviews$ 3299

Metallic Silver v2 PETG PRO

10 reviews$ 3299

Gemstone Ruby Red Translucent PETG PRO

15 reviews$ 3299

Royal Blue Opaque PETG PRO

9 reviews$ 3299

Starry Night Translucent v3 PETG PRO

15 reviews$ 3299

Neon Green UV Reactive Opaque PETG PRO

15 reviews$ 3299

Aqua Translucent PETG PRO

10 reviews$ 3299

Magigoo 3D Print Bed Adhesive

16 reviews$ 1995

Neon Orange UV Reactive Opaque PETG PRO

15 reviews$ 3299

Perfect Orange Opaque PETG PRO

6 reviews$ 3299

Sapphire Blue Translucent PETG PRO

5 reviews$ 3299

Dark Cherry CARBON FIBER Extreme PETG PRO

15 reviews$ 4999

Emerald Green Translucent PETG PRO

13 reviews$ 3299

Extreme JET Black PETG PRO

18 reviews$ 3499

Dark Blue CARBON FIBER Extreme PETG PRO

12 reviews$ 4999

Neon Yellow UV Reactive Opaque PETG PRO

7 reviews$ 3299

Hot Pink Opaque PETG PRO

7 reviews$ 3299

Translucent Fluorescent Neon Green PETG - UV REACTIVE

6 reviews$ 3299

Olive Drab Green PETG PRO

11 reviews$ 3299

Smoke Blue CARBON FIBER Extreme PETG PRO

17 reviews$ 4999

Cosmic Graphite PETG PRO v2

8 reviews$ 3299

Pearlescent Blue Opaque PETG PRO

2 reviews$ 3299

Khaki PETG PRO

6 reviews$ 3299

Rose Gold Metallic Translucent PETG PRO

4 reviews$ 3299

Perfect Yellow PETG PRO

1 review$ 3299

Perfect Purple PETG PRO

3 reviews$ 3299

Perfect Blue Opaque PETG PRO

2 reviews$ 3299

Stone Gray CARBON FIBER Extreme PETG PRO

5 reviews$ 4999

Atomic Filament Brand Shirt - Dark Navy

5 reviews$ 995

Mysterious Abyss v2 Pearl PETG PRO

9 reviews$ 3299

Gray PETG PRO

1 review$ 3299

Golden Blood Diamond Translucent PETG PRO

7 reviews$ 3599

Pine Green PETG PRO

3 reviews$ 3299

Bronze Metallic PETG PRO

3 reviews$ 3299

Turquoise PETG PRO

$ 3299

Amethyst Violet Gemstone Translucent v2 PETG PRO

2 reviews$ 3299

Black Marble PETG PRO

1 review$ 3299

How to succeed with PETG filament - 3d-club.

ru

ru Strong and easy to print, PETG filament is the most used and is ready to withstand heavy loads. This detailed guide contains some tips and tricks on how to get started and understand the fantastic properties of this material.

PETG is polyethylene terephthalate glycol, which is one of the most common polymers. As a 3D printing filament, PETG plastic has proven its value as a durable material that is easy to use. Figuratively speaking, it combines the most useful characteristics of ABS (rigidity and mechanical properties for functional parts) and the ease of printing of PLA.

What is PETG plastic?

You will often see references to PETG in one or more of the following forms: PET, PETE, PETP, PET-P, PETG, GPET, PETT, and others. This can be confusing for those who are trying to understand the differences between the two.

PETG is the general form used for 3D filament. The G stands for glycol-finished PET, and this makes the polymer clearer and less brittle than pure PET. Pure PET is rarely used for 3D printing. PETE, PETP, PETT and PET-P are modified versions of PET (called copolyesters), but by far the most common material used in 3D printing is PETG.

Pure PET is rarely used for 3D printing. PETE, PETP, PETT and PET-P are modified versions of PET (called copolyesters), but by far the most common material used in 3D printing is PETG.

In this article, PETG will be used as a generic term.

Looking for quality PETG filament

Poor quality PETG or PETG that is not dry enough will not print properly, which can cause problems and waste of time.

PETG is hygroscopic, which means it will actively absorb moisture from the air. For this reason, PETG plastic should be stored in a cool, dry place and dried if exposed to moist air for too long. It is better to spend more time drying the thread than to leave it wet.

Printing wet PETG can lead to hydrolysis which will change the material at the molecular level, making it much weaker than it would be dry.

Vacuum packs and desiccants ensure that the filament is exposed to the least amount of moisture.

If the package loses its seal, the desiccant will help to cope with the amount of moisture entering the package.

Using the right 3D printer

PETG printing has certain requirements, some printers may not meet these requirements.

To print PETG, your printer must be equipped with a heater that can reach at least 235°C. You should be able to reach 265°C, but sometimes 235°C is enough. Keep in mind that each coil is unique and may require slightly higher or lower temperatures.

Printing with PETG filament

Normal extrusion of PETG can be achieved in the temperature range of 230-265°C. If the temperature is higher, then the material will simply flow out like paste from a pen, and if the temperature is lower, the material will get stuck and delaminate. Because the exact thermal properties vary from spool to spool, you can experiment with any filament you buy to determine the best temperature for printing.

Correct first layer

As with any type of filament, getting a good first layer is essential to successful printing. Without a good first layer, you will probably need to reprint the element.

We have experimented with several different bed types and adhesion methods and the best ones are listed below.

Blue Ribbon Printing

Blue Ribbon is the best printing surface for PETG plastic. In addition to improving the quality of adhesion, you can remove the part right along with the tape. PETG adheres very well to most surfaces, to the point of tearing pieces out of them or bonding to them permanently. Blue ribbon printing gives you the ability to remove any detail without damaging the printable surface.

Printing on glass

The glass is very smooth, giving the printed part a glossy finish. We find that hairspray on a heated bed (50-60°C) works best on bare glass. Some users have reported that PETG adhered so well to their glass bed that pieces were torn out of it. Print on glass with care.

Other printable surfaces

BuildTak underlay works well with PETG filament. It also works with PLA and ABS without the need to change substrates. Of course it wears out over time, but the adhesion to plastic is very good.

Of course it wears out over time, but the adhesion to plastic is very good.

PEI print surfaces are great for most other filaments and work very well with PETG. Too good. It sometimes rips out pieces of PEI as it bonds strongly to the surface.

Getting the right temperature

Keep track of how much filament isn't where it should be. PETG plastic can bleed through, so watch out for filament that gets stuck on the nozzle. Sometimes drops of PETG filament will stick to the nozzle and then cling to a part of the print where it shouldn't be. If this happens, it will cool and harden, which can be hazardous to the nozzle. The result is usually layer shifting, which can be detrimental to the print.

Change filament

To PETG

When changing filament from something else to PETG, you need to heat the printhead at least to the temperature needed to melt the previous filament by pushing the rod up the temperature until the PETG melts

Once the previous filament stops coming out of the nozzle, PETG is ready to print.

WITH PETG

When changing from PETG filament to another filament, you need to heat the print head to at least the melting temperature of PETG or slightly hotter. After you feed a new filament, you can adjust the print head temperature to match the melting temperature of that filament.

Part design for PETG

PETG has a shrinkage factor of less than 0.01 cm, printing large parts is not a problem if the print surface is well aligned.

The use of supports can be easily done with PETG plastic, but a larger air gap may be required for easy removal of the supports.

Diagnostics

Several issues may arise during PETG printing. Below is an overview of some of the most common PETG filament printing problems and steps you can take to fix them:

The first layer does not stick to the bed.

If the thread just drags all over:

- Make sure you have the correct bed surface for PETG:

1) the blue tape is not heated or treated with glue.

2) glass treated with adhesive.

- Make sure you are printing at the correct extrusion and bed temperatures.

230-265°C extrusion temperature. Bed temperature 70-90°C

- Make sure the printed bed is level.

- Check that the extruder is at the correct height, and if it is not, then:

1) Adjust the Z-axis offset of the extruder.

2) Adjust the printer limit switch (if equipped).

Check ambient temperature. If it is too cold, it will negatively affect the print.

Part has poor infill and top layers.

When the filament, during infill and/or top layers, rolls up behind the nozzle:

- Check that the extrusion temperature is not too low.

- Slow down the print speed by 10-20%, either with or without raising the temperature. Speed and temperature are directly related to obtaining good extrusion.

- Check thread tension.

Printed edges are defective.

Defects on the outside of printed parts can occur for various reasons.

If the printer slows down when connected to a computer:

- Make sure the computer is not too busy to issue printer commands. Running applications other than printer management software at the same time as printing will use up some of the computer's memory. If other programs use enough memory, it is not available for printer communication and printing may suffer.

- Print from SD card. On some printers, you can print files from an SD card. This often helps to run more smoothly.

If the floss bubbles when exiting the nozzle:

- Dry the floss. Wet filament will hydrolyze as it melts and will be significantly weaker than dry printed filament.

The quality of your print directly depends on the quality of the thread. Some hobbyists have succeeded in printing good parts from lower quality filament.

High areas of prints appear melted or flattened together.

- Turn on the cooling fans.

- Reduce temperature and speed.

- Print more than one part to give the layers time to cool.

Use a small fan. If the printer does not have a built-in fan, you can use a small desktop fan. Just make sure the fan is not cooling the print head.

Part of the part rolls off the bed.

Although this does not happen with PETG in the same way as with some other threads (eg ABS), deformation can occur and destroy the perfect print.

If this occurs, use more bed adhesive (depending on your bed surface). 2-3 layers of adhesive material on the backing are usually sufficient.

Avoid uneven application of adhesive material or extremely thick adhesive layers, which can interfere with printing.

PETG plastic for 3D printer

Diameter:

Select Diameter1,752.85

Net Weight:

Select Net Weight: 750100025005000

White (RAL 9003) Green Grey Blue Yellow Red Natural Black Red transparent Blue transparent Green transparent golden transparent White Natural Color from range

-

1kg

-

Hit 1kg

Properties

During polymerization, a second glycol tail is added to PET (the name is derived from the abbreviated phrase polyethylene terephthalate-glycol). Thanks to this component, the material acquires increased impact resistance and durability, does not transmit ultraviolet light, and is suitable for sterilization and processing.

Thanks to this component, the material acquires increased impact resistance and durability, does not transmit ultraviolet light, and is suitable for sterilization and processing.

This material is also optimal for professional 3D printing. It combines the best properties of other materials: as easy to work as PLA, as strong, durable and heat resistant as ABS. The material is environmentally friendly and does not emit foreign odors during printing: this quality is especially important for those who work at home or in small industrial premises.

Due to its high wear resistance, it is suitable for the manufacture of a wide variety of parts, including various bushings, joints or gears that are not subjected to too much stress. The material is resistant to the aggressive effects of many chemicals and has a low percentage of shrinkage. Due to this, parts made of this material are practically not deformed, as is often the case when working with ABS plastic.

Natural plastic has no color. For printing, its variations are released in various translucent shades: yellow, pink, blue and others. Parts made from this material have a characteristic luster.

For printing, its variations are released in various translucent shades: yellow, pink, blue and others. Parts made from this material have a characteristic luster.

Specifications

| Vicat Softening Point | 84 °C |

| Operating temperature | -40°C to +70°C |

| Modulus of elasticity, 1mm/min | 1900 MPa |

| Elongation at break | 7% |

| Bending stress at maximum load | 54 MPa |

| Density | 1.24 g/cm3 |

| Melt Flow Index | 11g/10min |

3D printer settings for printing

| Print temperature | 230-245 °C |

| Platform temperature | 20-80°C |

| Nozzle | 0.2mm, 0.3mm, 0.4mm |

| Printer body | Any |

| Print speed | 40-80 mm/s |

| Airflow | Possible |

| Rollback speed | 20-80 mm/s |

| Rollback distance | 1-3 mm |

| Chamber temperature | 60°C |

Material drying

| Drying temperature | 80 °C |

| Drying time | 1-2 hours |

Storage

Material does not require special storage conditions.