Pcl 3d printing filament

Facilan™ PCL 100 Filament | 3D4Makers

Roll over image to zoom in Click on image to zoom

Save €-105.00

Facilan™SKU: FPCL1-0000-175-750-3D4M

3 reviews

Color: Natural

Natural

Diameter: 1.75mm

1.75mm

2.85mm

Weight: 750 gram

750 gram

2300 gram

Variant

Natural / 1.75mm / 750 gram - €105.00Natural / 1.75mm / 2300 gram - €289.95Natural / 2.85mm / 750 gram - €105.00Natural / 2.85mm / 2300 gram - €289.95

Facilan™ PCL 100 (Polycaprolactone) Filament

- Facilan™ PCL 100 it is perfect for high-value applications such as medical research.

- Our customers use our PCL for research into artificial trachea, smart materials, scaffolds for tissue engineering, bioabsorbable implants, drug-loaded implants and other cutting-edge applications.

- Facilan™ PCL 100 is used by many leading universities and research centers worldwide for bleeding edge work in bioprinting and patient specific medical research.

- Facilan™ PCL 100 is very flexible and tough with a glass transition temperature of -60 °C and a print temperature of around 120°C.

- Facilan™ PCL100 is polycaprolactone homopolymer with a molecular weight of 50000 g/mol.

- Facilan™ PCL100 is a semi-crystalline aliphatic biodegradable polyester with white final appearance.

- Filament produced by 3D4Makers is based on raw material produced in compliance with the European regulations EC No. 1935/2004 and EC No. 10/2011 concerning plastic materials and articles coming into contact with food.

- The material has an amazing adhesion between layers which results in great improvement of the impact resistance, strength, durability, and printability.

- Due to the low melting point, of Facilan™ PCL100 it can be reshaped after 3D printing in water with a temperature of 55 °C.

Recommended restrictions

Do not use in medical applications involving permanent implantation in the human body.

3D4Makers Polycaprolactone Facilan™ PCL 100 is one of the most extensively used bioprinting and medical 3D printing research materials worldwide.

Facilan™ PCL100 Material Properties

- Density: 1.1 g/cm³

- Tensile Strength: 45 MPa

- Elongation at Yield: 15 %

- Tensile Modulus: 350 MPa

- IZOD Impact Strength (notched): 8 kJ/m2

- Shore D Hardness: 46

- Heat Deflection Temperature (0,45 MPa): 57 °C

Print Settings

- Print Temperature: 130°C (130 to 170°C)

- Bed Temperature: 30-45°C

- Adhesion: Ultimaker Adhesion sheets, Avery Mailing labels L7567-25, PEI Sheets

- Print Speed: 10mm/s (10 - 30 mm/s)

- Mass flow: 120%

- Fan Speed: 100%

- Note: Add M302 S120 into the beginning of the g-code to allow cold extrusion, below 170°C

- Extra: Minimum Layer Time considerably +/- 60 sec minimum, highly dependent of model size and complexity and enabled Lift Head.

- Support: If PVA or breakaway Support = enabled; Support overhang angle = 0°; Enable Prime Tower = Enabled. Support with Facilan Ortho onto itself: not recommended

TDS

You can download the Technical Data Sheet for Facilan™ PCL 100 here.

MSDS

You can download the Material Safety Data Sheets for Facilan™ PCL100 here:

English

Spanish

French

Italian

German

Dutch

*The previous name of this product was PCL100

AmazonAmerican ExpressApple PayDiners ClubGiropayGoogle PayiDEALJCBMaestroMastercardPayPalPaySafeCardShop PaySOFORTVisa

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.

Country

NetherlandsGermanyItalyFrance---AfghanistanÅland IslandsAlbaniaAlgeriaAndorraAngolaAnguillaAntigua & BarbudaArgentinaArmeniaArubaAscension IslandAustraliaAustriaAzerbaijanBahamasBahrainBangladeshBarbadosBelarusBelgiumBelizeBeninBermudaBhutanBoliviaBosnia & HerzegovinaBotswanaBrazilBritish Indian Ocean TerritoryBritish Virgin IslandsBruneiBulgariaBurkina FasoBurundiCambodiaCameroonCanadaCape VerdeCaribbean NetherlandsCayman IslandsCentral African RepublicChadChileChinaChristmas IslandCocos (Keeling) IslandsColombiaComorosCongo - BrazzavilleCongo - KinshasaCook IslandsCosta RicaCroatiaCuraçaoCyprusCzechiaCôte d’IvoireDenmarkDjiboutiDominicaDominican RepublicEcuadorEgyptEl SalvadorEquatorial GuineaEritreaEstoniaEswatiniEthiopiaFalkland IslandsFaroe IslandsFijiFinlandFranceFrench GuianaFrench PolynesiaFrench Southern TerritoriesGabonGambiaGeorgiaGermanyGhanaGibraltarGreeceGreenlandGrenadaGuadeloupeGuatemalaGuernseyGuineaGuinea-BissauGuyanaHaitiHondurasHong Kong SARHungaryIcelandIndiaIndonesiaIraqIrelandIsle of ManIsraelItalyJamaicaJapanJerseyJordanKazakhstanKenyaKiribatiKosovoKuwaitKyrgyzstanLaosLatviaLebanonLesothoLiberiaLibyaLiechtensteinLithuaniaLuxembourgMacao SARMadagascarMalawiMalaysiaMaldivesMaliMaltaMartiniqueMauritaniaMauritiusMayotteMexicoMoldovaMonacoMongoliaMontenegroMontserratMoroccoMozambiqueMyanmar (Burma)NamibiaNauruNepalNetherlandsNew CaledoniaNew ZealandNicaraguaNigerNigeriaNiueNorfolk IslandNorth MacedoniaNorwayOmanPakistanPalestinian TerritoriesPanamaPapua New GuineaParaguayPeruPhilippinesPitcairn IslandsPolandPortugalQatarRéunionRomaniaRussiaRwandaSamoaSan MarinoSão Tomé & PríncipeSaudi ArabiaSenegalSerbiaSeychellesSierra LeoneSingaporeSint MaartenSlovakiaSloveniaSolomon IslandsSomaliaSouth AfricaSouth Georgia & South Sandwich IslandsSouth KoreaSouth SudanSpainSri LankaSt. BarthélemySt. HelenaSt. Kitts & NevisSt. LuciaSt. MartinSt. Pierre & MiquelonSt. Vincent & GrenadinesSudanSurinameSvalbard & Jan MayenSwedenSwitzerlandTaiwanTajikistanTanzaniaThailandTimor-LesteTogoTokelauTongaTrinidad & TobagoTristan da CunhaTunisiaTurkeyTurkmenistanTurks & Caicos IslandsTuvaluU.S. Outlying IslandsUgandaUkraineUnited Arab EmiratesUnited KingdomUnited StatesUruguayUzbekistanVanuatuVatican CityVenezuelaVietnamWallis & FutunaWestern SaharaYemenZambiaZimbabwe

BarthélemySt. HelenaSt. Kitts & NevisSt. LuciaSt. MartinSt. Pierre & MiquelonSt. Vincent & GrenadinesSudanSurinameSvalbard & Jan MayenSwedenSwitzerlandTaiwanTajikistanTanzaniaThailandTimor-LesteTogoTokelauTongaTrinidad & TobagoTristan da CunhaTunisiaTurkeyTurkmenistanTurks & Caicos IslandsTuvaluU.S. Outlying IslandsUgandaUkraineUnited Arab EmiratesUnited KingdomUnited StatesUruguayUzbekistanVanuatuVatican CityVenezuelaVietnamWallis & FutunaWestern SaharaYemenZambiaZimbabwe

Zip code

Returns

Our policy lasts 30 days. If 30 days have gone by since your purchase, unfortunately we can’t offer you a refund or exchange.

To be eligible for a return, your item must be unused and in the same condition that you received it. It must also be in the original packaging.

To complete your return, we require a receipt or proof of purchase.

Any item not in it's original condition, is damaged or missing parts for reasons not due to our error.

Any item that is returned more than 30 days after delivery

Refunds

Once your return is received and inspected, we will send you an email to notify you that we have received your returned item. We will also notify you of the approval or rejection of your refund.

If you are approved, then your refund will be processed, and a credit will automatically be applied to your credit card or original method of payment, within 14 days.

Late or missing refunds

If you haven’t received a refund yet, first check your bank account again.

Then contact your credit card company, it may take some time before your refund is officially posted.

Next contact your bank. There is often some processing time before a refund is posted.

If you’ve done all of this and you still have not received your refund yet, please contact us at [email protected].

Sale items

Only regular priced items may be refunded, unfortunately sale items cannot be refunded.

Exchanges

We only replace items if they are defective or damaged. If you need to exchange it for the same item, send us an email at [email protected] and send your item to: Oudeweg 91-95 Haarlem NL 2031CC.

If you need to exchange it for the same item, send us an email at [email protected] and send your item to: Oudeweg 91-95 Haarlem NL 2031CC.

Gifts

If the item was marked as a gift when purchased and shipped directly to you, you’ll receive a gift credit for the value of your return. Once the returned item is received, a gift certificate will be mailed to you.

If the item wasn’t marked as a gift when purchased, or the gift giver had the order shipped to themselves to give to you later, we will send a refund to the gift giver and he will find out about your return.

Shipping

To return your product, you should mail your product to: Waarderweg 56 Haarlem NL 2031BP

You will be responsible for paying for your own shipping costs for returning your item. Shipping costs are non-refundable. If you receive a refund, the cost of return shipping will be deducted from your refund.

Depending on where you live, the time it may take for your exchanged product to reach you, may vary.

If you are shipping an item over €75, you should consider using a trackable shipping service or purchasing shipping insurance. We don’t guarantee that we will receive your returned item.

PCL Low Temperature Filament - Natural - 1.75mm - 1 KG

€22,95 Save €-22,95

SKU: 12-D4-3647 Filaments.ca

Sold Out

Description

Low Price Guarantee

Shipping Policy

Returns & Exchange

Our PCL (Polycaprolactone) 3D filament is a very unique material that can well suited for many unusual applications.

PCL is also a safe & biodegradable plastic!

The main feature of PCL is that it has a very low melting temperature compared to usual 3D printing materials such as PLA, ABS etc.

Main Features of our PCL filament:

- PCL has a melting temperature of only 58°C ~ 60°C.

- It can be 3D printed at much lower and safer temperatures (70°C to 140°C) and does not require a heated bed.

- Objects can be re-shaped after printing to fit specific application by simply softening it in warm 60°C water (Example: re-shaping a river to fit through a whole).

- Once cooled, PCL is a very tough and impact resistant plastic.

- PCL has a glass transition temperature of -60°C which makes it tough, flexible and durable.

- Can be easily colored

- Great inter-layer adhesion

NET WEIGHT: 1 KG (2. 2 LB) 2 LB) |

PrintingTemperature: | Notes: |

| 70°C - 140°C |

|

We want to make sure that your shopping experience is truly worry-free, that's why we guarantee our everyday competitive prices & won't be beat on price!

We will beat any advertised price on identical or comparable products!

If you find an identical or comparable item currently offered for less at a local competitor's store or website (including shipping, handling and fees, if applicable) before you buy or within 30 days of your purchase we’ll beat that price by 10% of the difference. In addition, should our own price be reduced after your purchase, present us with your original receipt within 30 days of purchase and we will match the price and refund you the difference.

How to make a request:

Simply contact us by phone, email or live chat and show us confirmation of the price that you have found for less from a local competitor via a complete URL (web address) of the product page on the competitor's website or via flyer/print-out (including shipping, handling and other fees, if applicable).

The product you’re comparing must:

- Be priced in Canadian Dollars and include all fees, shipping costs, and other charges.

- Be sold and shipped by a retailer AND authorized dealer located within Canada.

- Be in stock, available for sale, and cannot be a limited time offer or available only in limited quantity.

- Not be lower priced due to an advertising error, misprint, or special sale price

Special sale prices are excluded from this offer, these include but not limited to the following:

VIP SALE, Black Friday, Friends and Family, Cyber Monday, Boxing Day/Week, special educational prices, restricted offers, mail order offers, rebates, coupons, premiums, free or bonus offers, Original Equipment Manufacturer (OEM) prices, open box products, close-outs, liquidations, discontinued, clearances, demos, refurbished items, open box items, financing offers and errors or misprints.

Also excluded are marketplace sellers on websites such as Amazon.ca or resellers such as eBay.ca as well as any sellers whose products are refurbished or liquidated.

Canada & International Shipping:

We ship Canada wide as well as internationally. We use Canada Post, UPS, Purolator, Canpar & FedEx for our shipping solutions. Large shipments, 50kg or more may be shipped by freight. Shipping costs are automatically calculated by the carrier during the checkout process. Any additional shipping charges incurred as a result of incorrect or incomplete address information as well as delivery refusal will be at the customer's expense.

All orders are shipped "Signature not required" unless otherwise requested (additional charges may apply).

All orders are shipped directly from our Mississauga, Ontario warehouse.

Please note that international shipments may incur additional charges such as brokerage, duties, taxes or other cross border related fees. These fees are NOT calculated during the checkout process, are NOT charged by Filaments.ca and are completely out of our control. It is important to note that Filaments.ca does NOT charge any additional fees beyond what is stated on the order invoice. Any cross-border related fees are the sole responsibility of the purchaser and are handled between the purchaser and the country the good being imported into, including any related agencies and/or customs brokerage companies.

These fees are NOT calculated during the checkout process, are NOT charged by Filaments.ca and are completely out of our control. It is important to note that Filaments.ca does NOT charge any additional fees beyond what is stated on the order invoice. Any cross-border related fees are the sole responsibility of the purchaser and are handled between the purchaser and the country the good being imported into, including any related agencies and/or customs brokerage companies.

Free Shipping:

We offer free shipping within Canada for orders totaling CAD$125 or more before tax. We also offer free shipping within the 48 contiguous United States for orders totaling CAD$200 or more before tax. To take advantage of this offer, please choose the free shipping option during the checkout process.

We reserve the right to choose the most economical shipping method. The shipping fee coverage for the free shipping option is limited to shipping services with charges up to CAD$50.

Free shipping does not apply to bulk or custom orders with discounted pricing.

FedEx Overnight:

Please note that our cut-off time for shipping overnight is 03:00 PM (Eastern Time). This means that if you choose FedEx Overnight as your shipping option, the order must be placed by 03:00 PM (Eastern Time) in order to get the order the next business day (FedEx overnight orders placed on a Friday will be delivered the following business day / Monday). It is important to follow this cut-off time in order to allow our warehouse time to prepare your order and still hand it over to FedEx on time for their overnight service.

Same Day Local Delivery:

Local delivery is available in the Greater Toronto Area. Please click here for more information.

Tracking Numbers:

As soon as your order is fulfilled, you will receive an email confirmation including your tracking number. Some shipping options such as envelopes or local deliveries may not have a tracking number.

Failed Deliveries:

Please note that in case of a refused delivery or if a shipment fails to be delivered to you because no one is home or available to receive the package, the courier WILL send the package back to us at OUR expense. When this happens, we will try to contact you and make further arrangements. These additional shipping charges incurred as well as charges to re-ship the package, will be forwarded to you, the customer. Therefore, please ensure that someone is always available to receive the package or pick it up from your local post office/courier facility before the courier ships it back to us.

Processing Time:

We strive to ship out orders as soon as same day for all orders placed by 2pm EST. Although depending on order specifications, it can take between 24 to 48 hours. Unexpected issues may further delay this process and will be communicated accordingly.

Out of Stock & "Sold Out" Products:

The inventory in our online store and the inventory in our warehouse are synced. When you purchase a product on our online store it means the product is already in stock and ready to ship. But on very rare occasions, technical issues might cause this sync to fail, and one or more of the products purchased might be out of stock. IF this happens, we will offer an alternative product or refund you for the out of stock item/s. Your order may be marked as "partially fulfilled", meaning we will immediately ship the items that are in stock and the rest will be shipped as soon as the item/s are back in stock.

When you purchase a product on our online store it means the product is already in stock and ready to ship. But on very rare occasions, technical issues might cause this sync to fail, and one or more of the products purchased might be out of stock. IF this happens, we will offer an alternative product or refund you for the out of stock item/s. Your order may be marked as "partially fulfilled", meaning we will immediately ship the items that are in stock and the rest will be shipped as soon as the item/s are back in stock.

Products marked as "Sold Out" or "Unavailable" are normally available again within 1-4 weeks. Feel free to check back or contact us for information about availability of specific products.

Order Pick Ups:

Customers in the Greater Toronto area are welcome to pickup orders at our Customer Pickup location in Mississauga. Please note that we require at least 1 business day notice for pickup orders. When placing an order online, simply choose the "PICKUP" option on the checkout page. After we process your order we will send you an additional email with details about the date and time your order will be ready to be picked up.

After we process your order we will send you an additional email with details about the date and time your order will be ready to be picked up.

Pickup Address:

7355 Torbram Rd.

Unit 15

Mississauga ON

L4T 3W3

Please have your ID ready to pick up your package.

Buy in Store:

Products can also be purchased directly at our Mississauga pickup location using credit, debit or cash.

Check our returns & exchange policy for information.

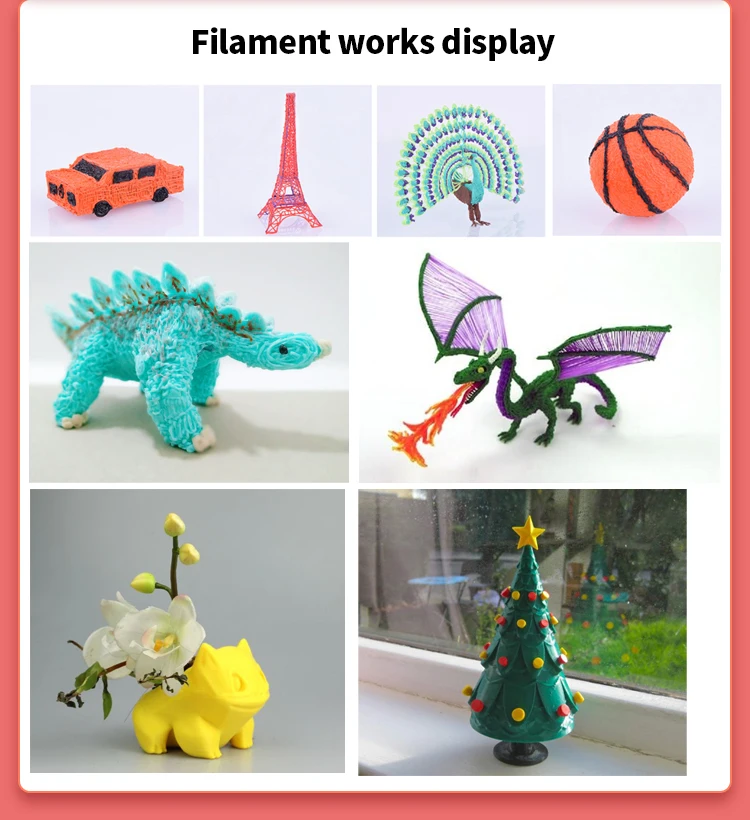

Differences and purpose of ABS, PLA and PCL plastics for 3D pens.

If you have already become the proud owner of a 3D pen, you have already found a small amount of plastic that comes with the pen. As a rule, these are several small coils of ABS or PLA plastic of different colors, the total length of which does not exceed 10 meters.

This introductory set is enough for a few 2D figures or one or two 3D figures, which means that it's time to start thinking about buying "working" sets of plastic for your 3D pen.

In this article we will look at the types of plastics that 3D pens work with and the types of plastic sets.

1. Types of plastic for 3D pens

Modern 3D pens work with several types of plastic, which differ in properties and have different purposes.

Not all pens are compatible with multiple types of plastic, as plastics have different melting points. You can find out what types of plastic your pen supports by reading the instructions for using the 3D pen.

Attention! Using the wrong type of plastic or choosing the wrong temperature mode can lead to breakage of the 3D pen and non-warranty repairs at the service center.

Most modern 3D pens of the second generation and above can work with two types of plastic - ABS and PLA, for this there is a special temperature switch in the design of the pen. Structurally, the switch can be made in the form of a display with buttons, a two-position toggle switch or an adjusting screw, while the adjustment is made using a small screwdriver supplied with the handle.

The most common type of plastic is ABS plastic.

ABS (acrylonitrile butadiene styrene) - this type of plastic is widely used for industrial purposes - parts and cases of household appliances and furniture, children's toys, sanitary ware and many other consumer goods are made from it.

ABS plastic has received such widespread use for a reason, it has advantages that allow it to be used everywhere:

- Can be dyed in various colors.

- Netoxicity under normal conditions

- Durability in the absence of direct sunlight and ultraviolet radiation [3]

- Resistance to alkalis and detergents

- Moisture resistance

- Oil resistance

- Heat resistance 103 ° C (up to 113 ° C (up to 113 ° C )

- Wide operating temperature range (-40°C to +90°C)

Figures and 3D models made using ABS 3D pen are strong and durable. They are absolutely non-toxic in domestic use - a child can play with them, swim, use in the sandbox - the plastic will withstand dirt, soapy water and other tests.

Important! Heating temperature of ABS plastic in a 3D pen - from 200 to 240 degrees. At this temperature, ABS releases acrylonitrile fumes, so prolonged handling of ABS should be done in a ventilated area or near a hood/open window.

ABS plastic must not be used in contact with hot food. At best, it can be used in contact with cold products. Contact with alcohol is unacceptable - the substances of alcohol and ABS plastic interact and release a harmful substance - styrene.

PLA (polylactide) - biodegradable, biocompatible, thermoplastic, polyester. The raw materials for production are annually renewable resources such as corn and sugar cane.

Used for the production of products with a short service life (food packaging, disposable tableware, bags, various containers), as well as in medicine, for the production of surgical sutures and pins.

PLA is safer than ABS when used at home. The melting temperature of PLA in a 3D pen is 173-180 degrees. When melting this type of plastic, no harmful substances are released, therefore, this type of plastic is recommended for a child to work with a 3D pen.

When melting this type of plastic, no harmful substances are released, therefore, this type of plastic is recommended for a child to work with a 3D pen.

PLA plastic decomposes in a few years, so it is not recommended to make long-term crafts from it. Toys and parts are best used indoors, away from direct sunlight.

Toys made of PLA plastic are afraid of water, high humidity, temperatures above 60 ° C - all these factors reduce the service life of the product.

When PLA decomposes, it is absolutely safe for children and does not cause any harm to the environment, as it does not emit harmful substances.

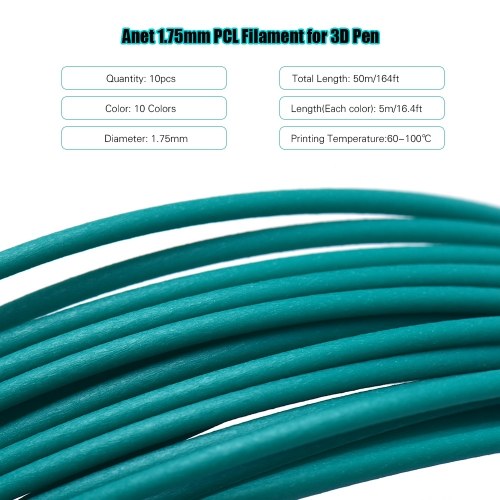

PCL (polycaprolactone) - biodegradable polyester with a low melting point (60-90 degrees)

For use in 3D pens, this plastic began to be used relatively recently. The price of this plastic is quite high compared to ABS and PLA plastics, so it has not won much popularity. But due to its properties, it has firmly occupied its niche in the market of plastics for 3D pens. The fact is that the low melting point of PCL plastic allows it to be used in 3D pens that operate from a built-in power source and do not require constant connection to a power outlet. This allows you to use to work outdoors, work without a power cord becomes easier and more convenient.

The fact is that the low melting point of PCL plastic allows it to be used in 3D pens that operate from a built-in power source and do not require constant connection to a power outlet. This allows you to use to work outdoors, work without a power cord becomes easier and more convenient.

In addition, the temperature of the nozzle and plastic at the outlet of the pen is no more than 50 degrees, which makes the pen safe to use even for the smallest children. The child will not get burned, even if he touches the nozzle with his hands or melts the plastic directly onto the skin.

Another interesting property of this plastic is that it becomes soft in hot water. This means that the figurine made of this plastic can be easily changed by heating it in water to a temperature of 60-70 degrees and giving it a new shape with your bare hands!

PCL plastic is a material that is safe for humans and the environment, has a wide color palette.

All these factors make it possible to recommend PCL for use in children.

Attention! Before buying PCL plastic, make sure that your pen supports printing with this material.

2. Choosing a set of plastic

The variety of plastic sets for 3D pen on the market can confuse the buyer or make it difficult for him to choose the right set. At first glance, all sets differ only in colors and footage. But not everything is so simple, some little things can spoil the impression when working with a 3D pen. Let's take a look at the 3D pen plastic kits on the market.

As a rule, all sets on the market can be characterized by the following properties:

- type of plastic

- color palette (number of colors). Usually there are from five to twenty colors in a set. It is worth noting that it is not uncommon for kit manufacturers to be cunning and call colors more “appetizing”: scarlet, aquamarine, rising sun, and similar names. In fact, these are ordinary colors - red, turquoise, blue, orange, etc. At best, you will get these colors slightly modified, indistinguishable at first glance from the standard colors.

At the same time, all these “new” colors do not complement the main color, but replace it. Therefore, in one set you will not find red and scarlet.

At the same time, all these “new” colors do not complement the main color, but replace it. Therefore, in one set you will not find red and scarlet. - total number of meters in the set

- weight of the set

- packing and size of the skeins. This characteristic is important when choosing a set, so you should carefully consider the choice. The fact is that in order to reduce the cost of producing a set, some manufacturers mix all the colors in one large skein. Such a set will have to be unraveled before you start working with it. This is guaranteed to take time and may spoil the child's first impression of working with a 3D pen. As a rule, such sets are sold in a closed box or an opaque bag.

- skein size. Large skeins of plastic can be inconvenient for storage and transportation. The small size of the skein is inconvenient when unwinding, twisting and intertwining during operation.

- skein binding method. Coils of plastic separated by colors can be fastened in several ways, the most common of which are:

- plastic clamp. The most common way to fasten a skein of plastic. For cutting, you will need sharp scissors or wire cutters. Cannot be reused. After use, the remaining skein must be fastened or put in a bag with the rest, resigned to the fact that they will get confused.

The most common way to fasten a skein of plastic. For cutting, you will need sharp scissors or wire cutters. Cannot be reused. After use, the remaining skein must be fastened or put in a bag with the rest, resigned to the fact that they will get confused.

- vacuum packed. Disposable packaging, scissors may be required to remove the skein.

- adhesive tape. The most convenient way to fasten a skein. Allows after use to fasten the skein back into the ring and fix it with adhesive tape again.

Sets of plastic produced by Orpheus, presented in our store, have an optimal coil diameter for work, the plastic does not twist or get tangled.

The use of special adhesive tape in Orpheus coils, which does not leave marks on the plastic, allows you to unwind the required amount of plastic without the use of additional items (scissors or wire cutters) and fasten the plastic remaining in the coil again. This increases convenience and leaves a pleasant impression of working with a 3D pen.

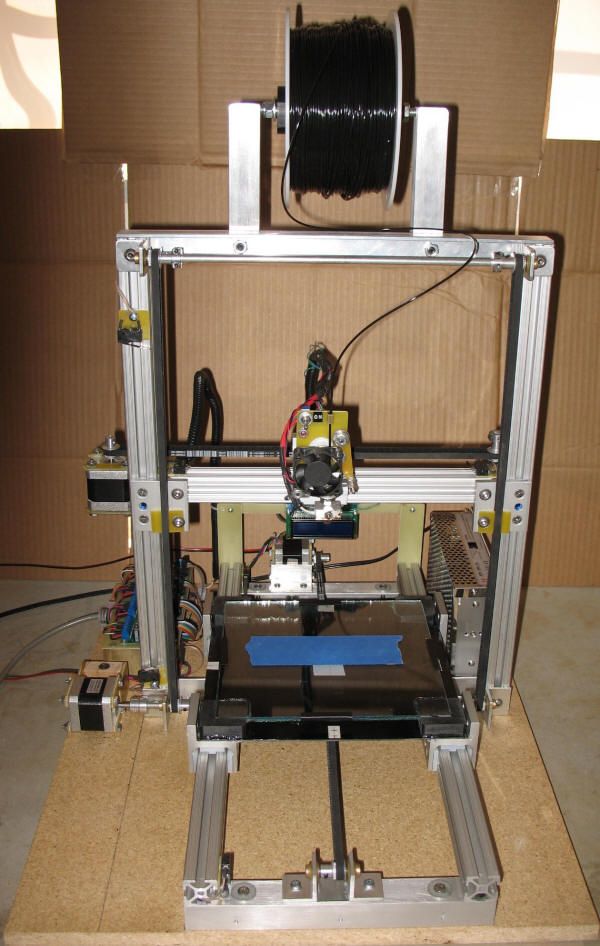

FDM/FFF consumables

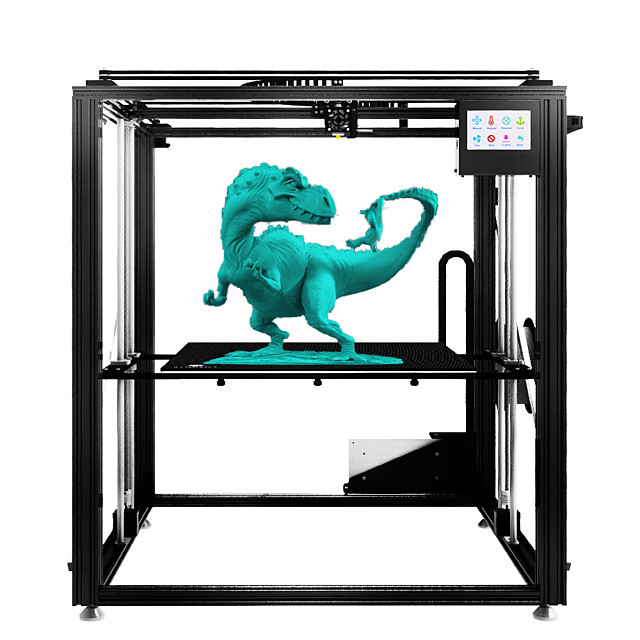

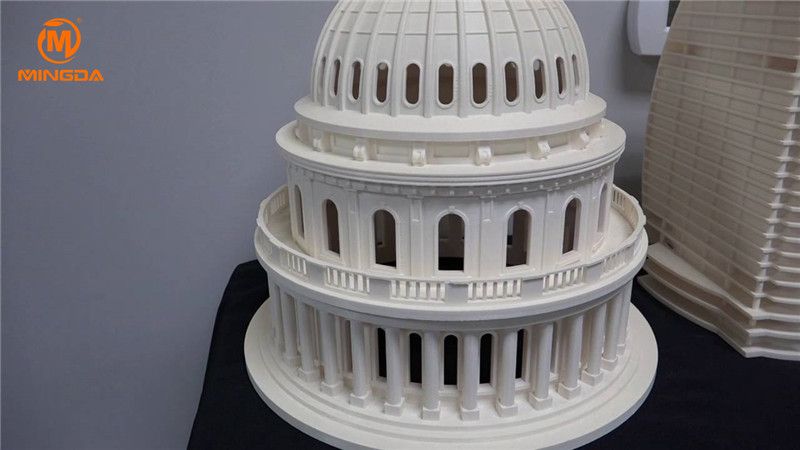

FFF technology has many advantages, including the relative simplicity of the design of printers and the affordability of both devices and consumables. Moreover, the range of materials is perhaps the widest among all available technologies. As a rule, thermoplastics are used for printing, but there are exceptions - composite materials containing various additives, but based, again, on thermoplastics. In this section, we will try to talk about the most widely used materials in more detail, starting with the most popular types.

- 1 Polylactide (PLA, PLA)

- 2 Acrylonitrile butadiene styrene (ABS)

- 3 Polyvinyl alcohol (PVA)

- 4 Nylon

- 5 Polycarbonate (PC)

- 6 High density polyethylene (HDPE)

- 7 Polypropylene (PP, PP)

- 8 Polycaprolactone (PCL)

- 9 Polyphenylsulfone (PPSU)

- 10 Polymethyl methacrylate (Acrylic, plexiglass, acrylic, PMMA)

- 11 Polyethylene terephthalate (PET, PET)

- 12 High impact polystyrene (HIPS)

- 13 Wood Simulators (LAYWOO-D3, BambooFill)

- 14 Sandstone Simulators (Laybrick)

- 15 Metal Simulators (BronzeFill)

Polylactide (PLA)

Polylactide is one of the most widely used thermoplastics due to several factors. Let's start with the fact that PLA is known for its environmental friendliness. This material is a lactic acid polymer, which makes PLA a completely biodegradable material. The raw materials for the production of polylactide are corn and sugar cane. At the same time, the environmental friendliness of polylactide causes its fragility. Plastic easily absorbs water and is relatively soft. As a rule, PLA models are not intended for functional use, but serve as designer models, souvenirs and toys. Few practical industrial applications include the production of food packaging, drug containers and surgical sutures, as well as use in bearings that do not carry high mechanical loads (for example, in modeling), which is possible due to the material's excellent slip coefficient.

Let's start with the fact that PLA is known for its environmental friendliness. This material is a lactic acid polymer, which makes PLA a completely biodegradable material. The raw materials for the production of polylactide are corn and sugar cane. At the same time, the environmental friendliness of polylactide causes its fragility. Plastic easily absorbs water and is relatively soft. As a rule, PLA models are not intended for functional use, but serve as designer models, souvenirs and toys. Few practical industrial applications include the production of food packaging, drug containers and surgical sutures, as well as use in bearings that do not carry high mechanical loads (for example, in modeling), which is possible due to the material's excellent slip coefficient.

One of the most important factors for 3D printing applications is the low melting point of only 170-180°C, which contributes to relatively low power consumption and the use of inexpensive brass and aluminum nozzles. As a rule, extrusion is carried out at 160-170°C. At the same time, PLA solidifies quite slowly (glass transition temperature is about 50°C), which should be taken into account when choosing a 3D printer. The best option is a device with an open case, a heated work platform (to avoid deformation of large models) and, preferably, additional fans to cool the fresh layers of the model.

As a rule, extrusion is carried out at 160-170°C. At the same time, PLA solidifies quite slowly (glass transition temperature is about 50°C), which should be taken into account when choosing a 3D printer. The best option is a device with an open case, a heated work platform (to avoid deformation of large models) and, preferably, additional fans to cool the fresh layers of the model.

PLA has low shrinkage, i.e. loss of volume on cooling, which helps prevent warping. However, shrinkage has a cumulative effect as the dimensions of printed models increase. In the latter case, the build platform may need to be heated to evenly cool the printed objects.

The cost of PLA is relatively low, which adds to the popularity of this material.

Acrylonitrile butadiene styrene (ABS)

ABS plastic is perhaps the most popular thermoplastic used in 3D printing, but not the most common. This contradiction is explained by certain technical difficulties that arise when printing ABS. The desire of craftsmen to use ABS is determined by the excellent mechanical properties, durability and low cost of this material. In the industry, ABS plastic is already widely used: the production of car parts, cases of various devices, containers, souvenirs, various household accessories, etc.

The desire of craftsmen to use ABS is determined by the excellent mechanical properties, durability and low cost of this material. In the industry, ABS plastic is already widely used: the production of car parts, cases of various devices, containers, souvenirs, various household accessories, etc.

ABS plastic is resistant to moisture, acids and oil, has a fairly high temperature resistance - from 90°C to 110°C. Unfortunately, some types of material are destroyed by direct sunlight, which somewhat limits the application. At the same time, ABS plastic is easy to paint, which allows you to apply protective coatings on non-mechanical elements.

Despite a relatively high glass transition temperature of around 100°C, ABS has a relatively low melting point. Actually, due to the amorphous nature of the material, ABS does not have a melting point, as such, but 180 ° C is considered an acceptable temperature for extrusion, which is on the same level as the above-described PLA. The lower temperature spread between extrusion and glass transition allows ABS to cure faster than PLA.

The lower temperature spread between extrusion and glass transition allows ABS to cure faster than PLA.

The main disadvantage of ABS plastic can be considered a high degree of shrinkage during cooling - the material can lose up to 0.8% of its volume. This effect can lead to significant deformations of the model, twisting of the first layers and cracking. To combat these unpleasant phenomena, two main solutions are used. First, heated work platforms are used to help reduce the temperature gradient between the lower and upper layers of the model. Secondly, ABS 3D printers often use closed housings and control of the background temperature of the working chamber. This makes it possible to maintain the temperature of the applied layers at a level just below the glass transition threshold, reducing the degree of shrinkage. Full cooling is carried out after receiving the finished model.

The relatively low stickiness of ABS may require additional bonding aids such as adhesive tape, polyimide film, or applying an acetone solution of the ABS to the platform just prior to printing. For more information on how to avoid warping, see How to Avoid Warping 3D Printed Models.

For more information on how to avoid warping, see How to Avoid Warping 3D Printed Models.

While ABS is not a health hazard at room temperature, heated plastic releases acrylonitrile fumes, a poisonous compound that can irritate mucous membranes and cause poisoning. Although the amount of Acrylonitrate produced in small scale printing is negligible, it is recommended that you print in a well ventilated area or use an exhaust hood. It is not recommended to use ABS plastic for the production of food containers and utensils (especially for storing hot food or alcoholic beverages) or toys for small children.

The good solubility of ABS in acetone is very useful as it allows large models to be produced piece by piece and glued together, greatly expanding the capabilities of inexpensive desktop printers.

Polyvinyl alcohol (PVA)

Polyvinyl alcohol is a material with unique properties and special applications. The main feature of PVA is its water solubility. 3D printers equipped with dual extruders have the ability to print models with PVA support structures. Upon completion of printing, the supports can be dissolved in water, leaving a finished model that does not require mechanical or chemical roughening. Similarly, PVA can be used to create water-soluble master patterns for molds and molds themselves.

The main feature of PVA is its water solubility. 3D printers equipped with dual extruders have the ability to print models with PVA support structures. Upon completion of printing, the supports can be dissolved in water, leaving a finished model that does not require mechanical or chemical roughening. Similarly, PVA can be used to create water-soluble master patterns for molds and molds themselves.

The mechanical properties of PVA are quite interesting. At low humidity, plastic has high tensile strength. With increasing humidity, strength decreases, but elasticity increases. The extrusion temperature is 160-175°C, which allows the use of PVA in printers designed for printing with ABS and PLA plastics.

Since the material easily absorbs moisture, it is recommended to store PVA plastic in dry packaging and, if necessary, dry before use. Drying can be done in a pottery kiln or an ordinary oven. As a rule, drying of standard coils takes 6-8 hours at a temperature of 60-80°C. Exceeding 220°C will cause the plastic to decompose, which should be taken into account when printing.

Exceeding 220°C will cause the plastic to decompose, which should be taken into account when printing.

Nylon

Nylon is attractive due to its high wear resistance and low coefficient of friction. Thus, nylon is often used to coat friction parts, which improves their performance and often allows them to function without lubrication. Following the widespread use of nylon in industry, additive manufacturing has also become interested in the material. Attempts to print with nylon have been made almost since the early days of FDM/FFF technology.

In reality, there are several types of nylon produced by different methods and with slightly different characteristics. The most famous is nylon-66, created by the American company DuPont in 1935. The second most popular option is nylon-6, developed by BASF to circumvent the DuPont patent. These two options are very similar. In terms of 3D printing, the main difference is the melting point: Nylon-6 melts at 220°C, while Nylon-66 melts at 265°C.

Many hobbyists prefer to use commercially available nylon threads such as trimmer wire. The diameter of such materials often corresponds to the diameter of standard FFF materials, which makes their use tempting. At the same time, these products are usually not pure nylon. In the case of trimmer rods, the material consists of nylon and fiberglass for an optimal combination of flexibility and rigidity.

Fiberglass has a high melting point and therefore printing with these materials is prone to high nozzle wear and plugging.

Recently there have been attempts to commercially develop nylon-based printing materials specifically for FDM/FFF applications, including Nylon-PA6 and Taulman 680. These grades are extrudable at 230-260°C.

Since nylon readily absorbs moisture, consumables should be stored vacuum-packed or at least in a container with water-absorbent materials. A sign of excessively damp media will be steam escaping from the nozzle during printing, which is not dangerous, but may degrade the quality of the model.

When printing with nylon, polyimide desktop coating is not recommended as the two materials fuse together. As a coating, you can use adhesive tape with wax impregnation (masking tape). The use of a heated bed will help reduce the possibility of deformation of the model, similar to printing with ABS plastic. Due to the low coefficient of friction of nylon, extruders with studded feeders should be used.

The nylon layers have excellent adhesion, which minimizes the chance of delamination of models.

Nylon is difficult to bond, making it difficult to print large multi-piece models. Alternatively, fusion of parts is possible.

Because nylon can release toxic fumes when heated, we recommend that you print in a well-ventilated area or use an exhaust fan.

Polycarbonate (PC)

Polycarbonates are attractive due to their high strength and toughness, as well as resistance to high and low temperatures.

The potential health risk of printing is worth noting: the toxic and potentially carcinogenic compound bisphenol A is often used as a raw material. .

The extrusion temperature depends on the printing speed to avoid cracking, but the minimum temperature at 30mm/sec can be considered as 265°C. When printing, the use of polyimide film is recommended for better adhesion to the desktop surface. The high susceptibility of polycarbonate to deformation requires the use of a heated platform and, if possible, a closed housing with heating of the working chamber.

Polycarbonate is highly hygroscopic (easily absorbs moisture), which requires storage in dry conditions to avoid the formation of bubbles in the applied layers. For extended printing in humid climates, even the print spool may need to be stored in a moisture-proof container.

High Density Polyethylene (HDPE)

Arguably the most common plastic in the world, polyethylene is relatively rare among 3D printed materials. The reason for this is the difficulty in layer-by-layer manufacturing of models.

The reason for this is the difficulty in layer-by-layer manufacturing of models.

Polyethylene melts easily (130-145°C) and hardens quickly (100-120°C), as a result of which the applied layers often do not have time to set. In addition, polyethylene is characterized by high shrinkage, which provokes the twisting of the first layers and the deformation of the models as a whole during uneven solidification. Printing with polyethylene requires the use of a heated platform and a working chamber with accurate temperature control to slow down the cooling of the applied layers. In addition, you will need to print at high speed.

Difficulties in use are more than offset by the cheapness and availability of this material. Recently, several devices have been developed for processing plastic waste from HDPE (bottles, food packaging, etc.) into standard filaments for printing on FDM/FFF printers. Examples are FilaBot and RecycleBot. Due to the simplicity of design, RecycleBot devices are often assembled by 3D craftsmen.

Melting polyethylene releases harmful vapors, so it is recommended to print in well ventilated areas.

Polypropylene (PP, PP)

Polypropylene is a widely used plastic used in the manufacture of packaging materials, utensils, syringes, pipes, etc. The material has a low specific gravity, is non-toxic, has good chemical resistance, is resistant to moisture and wear, and cheap enough. Among the disadvantages of polypropylene, one can note the vulnerability to temperatures below -5 ° C and to direct sunlight.

The main difficulty in printing with polypropylene is the high shrinkage of the material during cooling - up to 2.4%. For comparison, the shrinkage of the popular but already problematic ABS plastic reaches 0.8%. Although polypropylene adheres well to cold surfaces, it is recommended to print on a heated platform to avoid deformation of models. The minimum recommended extrusion temperature is 220°C.

Polypropylene printing filaments are sold by Orbi-Tech, German RepRap, Qingdao TSD Plastic. Stratasys has developed a polypropylene simulant optimized for 3D printing called Endur.

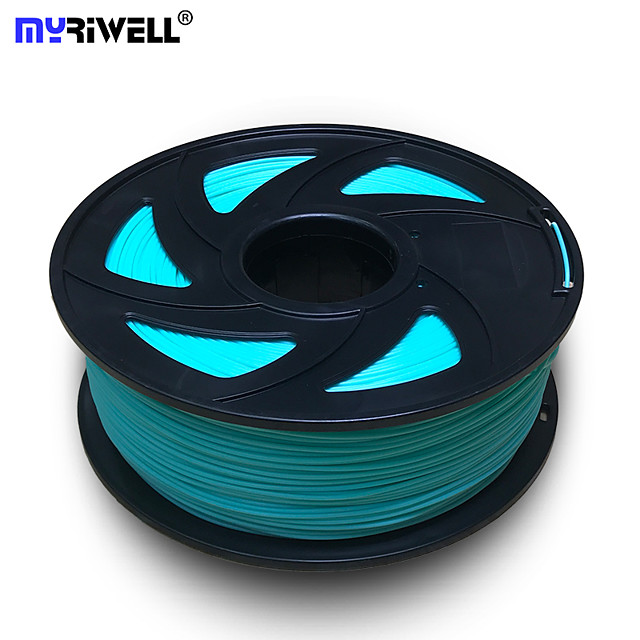

Polycaprolactone (PCL)

Polycaprolactone (aka Hand Moldable Plastic, Mold-Your-Own Grips, InstaMorph, Shapelock, Friendly Plastic, Polymorph, Polymorphus, Ecoformax) - biodegradable polyester, characterized by an extremely low melting point of about 60 ° C . In practice, this property creates certain problems in 3D printing, since not all 3D printers can be configured to work at such low temperatures. Heating polycaprolactone to the usual extrusion temperatures (about 200°C) causes a loss of mechanical properties and may lead to breakage of the extruder.

Polycaprolactone is non-toxic, making it suitable for use in the medical industry, and biodegradable. When ingested, polycaprolactone breaks down, which makes printing with this material safe. Due to the low melting point, there is no danger of burns when touching fresh models. The high plasticity of the material makes it possible to reuse.

Due to the low melting point, there is no danger of burns when touching fresh models. The high plasticity of the material makes it possible to reuse.

Polycaprolactone is of little use for creating functional mechanical models due to its viscosity (glass transition temperature is -60°C) and low heat resistance (melting point is 60°C). On the other hand, this material is perfect for the production of mock-ups and food containers.

The material sticks easily to the surface of even a cold working table and is easy to paint.

Polyphenylsulfone (PPSU)

Polyphenylsulfone is a high strength thermoplastic used extensively in the aviation industry. The material has excellent chemical and thermal stability and practically does not burn. Polyphenylsulfone is biologically inert, which makes it possible to use this material for the production of tableware and food containers. Operating temperature range is -50°С - 180°С. Plastic is resistant to solvents and fuels and lubricants.

Plastic is resistant to solvents and fuels and lubricants.

For all its merits, polyphenylsulfone is rarely used in 3D printing due to its high melting point, reaching 370°C. Such extrusion temperatures are beyond the power of most desktop printers, although printing is theoretically possible using ceramic nozzles. Currently, the only active user of the material is Stratasys, which offers industrial Fortus installations.

Polymethyl methacrylate (Acrylic, plexiglass, acrylic, PMMA)

Polymethyl methacrylate is a well-known organic glass. The material is durable, moisture resistant, environmentally friendly, easy to glue, plastic enough and resistant to direct sunlight.

Unfortunately, acrylic is not suitable for FDM/FFF printing for a number of reasons. Acrylic is poorly stored in the form of spools of thread, as constant mechanical stress leads to the gradual destruction of the material. To avoid bubbles, the print resolution must be high, with a precision almost impossible for home printers. Acrylic's rapid curing requires strict environmental control of the working chamber and high print speeds. Again, the print speeds of FDM/FFF printers are inversely related to print resolution, which exacerbates the problem.

Acrylic's rapid curing requires strict environmental control of the working chamber and high print speeds. Again, the print speeds of FDM/FFF printers are inversely related to print resolution, which exacerbates the problem.

However, attempts are being made to print with acrylic, and some of them are producing relatively positive results. However, when creating sufficiently strong models, it is not yet possible to avoid the formation of bubbles and achieve the usual transparency of the material. At the moment, the best results with acrylic are shown by another printing technology - multi-jet modeling (MJM) from 3D Systems. In this case, a photopolymer version of acrylic is used. Stratasys has also made significant progress using its own photopolymer acrylic simulant VeroClear on Objet Eden printers. It is hoped that the high demand for acrylic will lead to the emergence of composite materials based on polymethyl methacrylate, designed specifically for FDM/FFF printing.

Polyethylene terephthalate (PET, PET)

Polyethylene terephthalate - this complex name hides a material used for the production of plastic bottles and other food and medical containers.

The material has a high chemical resistance to acids, alkalis and organic solvents. The physical properties of PET are also impressive with high wear resistance and tolerance to a wide temperature range from -40°C to 75°C. Among other things, the material is easily machined.

Printing with PET is somewhat problematic due to the relatively high melting point of up to 260°C and significant cooling shrinkage of up to 2%. Using PET as a consumable requires approximately the same conditions as printing with ABS.

Achieving transparency of models requires rapid cooling to pass the glass transition threshold of 70°C - 80°C.

The material has become the focus of attention of 3D craftsmen using used containers as raw materials for home production of 3D printing consumables. Recycling devices such as FilaBot or RecycleBot are used to make threads.

High impact polystyrene (HIPS)

High impact polystyrene is widely used in industry for the production of various household products, building materials, disposable tableware, toys, medical instruments, etc.

When 3D printed, polystyrene exhibits physical properties very similar to the popular ABS plastic, making it an increasingly popular material among 3D crafters. The most attractive feature of polystyrene is the difference from ABS in terms of chemical properties: polystyrene is quite easily amenable to the organic solvent Limonen. Since Limonene has no effect on ABS plastic, it is possible to use polystyrene as a material for building soluble support structures, which is extremely useful when building complex, interlaced models with internal supports. Compared to the convenient, water-soluble polyvinyl alcohol (PVA) plastic, polystyrene compares favorably with relatively low cost and resistance to humid climates that make PVA difficult to work with.

Be aware that some ABS manufacturers mix slightly cheaper polystyrene into their consumables. Accordingly, models made from such materials can be dissolved in Limonene along with supporting structures.

When polystyrene is heated to extrusion temperature, toxic fumes can be released, so printing in a well-ventilated area is recommended.

Wood simulants (LAYWOO-D3, BambooFill)

LAYWOO-D3 is a recent development designed to print wood-like models. The material consists of 40% natural wood chips of microscopic size and 60% binder polymer. The LAYWOO-D3 is very easy to handle, being virtually warp-free and does not require the use of a heated platform. According to the manufacturers, the polymer is non-toxic and completely safe.

The unique material properties allow for different visual results when printing with different nozzle temperatures. The operating temperature range is 180°C-250°C. As the extrusion temperature increases, the shade of the material becomes progressively darker, allowing it to simulate different types of wood or annual rings.

Finished models are excellent for mechanical processing - grinding, drilling, etc. In addition, the products are easily painted, and unpainted models even have a characteristic woody smell.

Unfortunately, the cost of the material is almost four times higher than the price of popular materials such as PLA and ABS plastics. As popularity is projected to grow, the material should become more accessible.

As popularity is projected to grow, the material should become more accessible.

Alternative materials are currently being developed and tested, such as BambooFill from the Dutch company ColorFabb.

Sandstone simulants (Laybrick)

Composite material from the inventor Kai Parti, responsible for the revolutionary wood simulant LAYWOO-D3. This time, Kai set his sights on sandstone imitation, using a tried and tested method of mixing a binder with a filler, in this case mineral.

Laybrick allows you to produce objects with different surface textures. At low extrusion temperatures of the order of 165°C-190°C, the finished products have a smooth surface. Increasing the printing temperature makes the material rougher, up to a high degree of resemblance to natural sandstone at extrusion temperatures above 210°C.

The material is easy to work, does not require a heated work platform, does not show significant deformation when shrinking, and does not produce toxic fumes when heated. The only drawback can be considered a rather high cost of the material, which is largely due to limited production.

The only drawback can be considered a rather high cost of the material, which is largely due to limited production.

Metal Simulators (BronzeFill)

Metals have attracted additive manufacturing enthusiasts since the early days of 3D printing technology. Unfortunately, printing with pure metals and alloys causes a lot of difficulties that are insurmountable for most 3D printing methods. Fully functional metal products can only be produced using technologies such as SLS, DLMS or EBM, which require the use of industrial plants that cost hundreds of thousands of dollars. At the same time, metal imitators are successfully used in 3D inkjet printing (3DP), where products are formed from metal powders, the particles of which are held together by an applied binder material. In FDM/FFF printing, metal simulants are just emerging.

An interesting example is BronzeFill - in fact, a transparent PLA-plastic filled with bronze microparticles.