3D print petg temperature

Ideal Bed Temp & Print Settings – Clever Creations

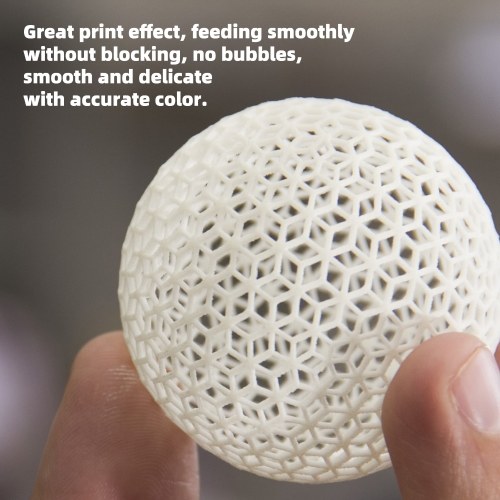

To 3D print well with PETG filament, you need a nozzle temperature between 210°C and 250°C, a heated bed temperature between 70°C and 80°C, and a print speed of 60mm/s or less. Set the cooling fan speed at 0% for the first few layers and then on for the rest of the print if needed.

Ready to start printing with PETG filament but aren’t sure what settings to use for the best results? We have you covered! PETG is a material growing in popularity with the 3D printing community. Even so, some of its settings are very different from other materials, so it can be confusing to make the switch.

In this guide, we’ll look at the best print settings for PETG and the pros and cons of printing with this material. We’ll also cover when you should and shouldn’t print with PETG and how to troubleshoot some of the basic issues that arise with PETG.

What Is PETG Filament?

Polyethylene terephthalate glycol (PETG) is a polyester-based thermoplastic often used in 3D printing for its durability and ease of use. PETG plastic is a slightly modified form of the PET plastics commonly found in food packaging. However, PET by itself is too brittle for 3D printing. Bonding glycol (G) to its polymers adds better flexibility and impact resistance.

PETG is a popular choice for food packaging, food containers, and industrial manufacturing. It has become more and more common in 3D printing over the last few years as a general catch-all filament choice as well.

Many filaments, like ABS and PLA, have well-known properties and behaviors. But PETG is still relatively new to the 3D printing community and thus unexplored territory for many users.

What Is PETG Filament Best Used for?

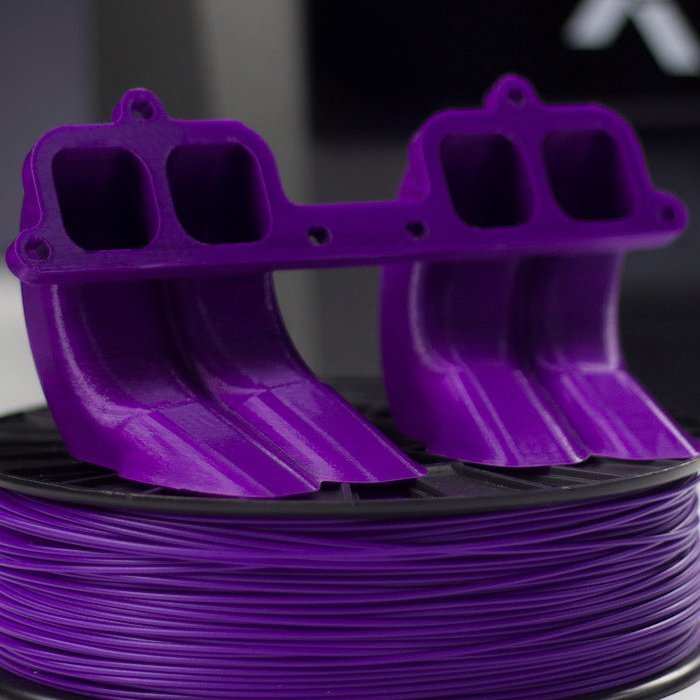

PETG filament is a great choice for industrial parts that need heat and/or impact resistance. Since PETG is slightly soft, it is slightly flexible and impact resistant. That, paired with its high tensile strength, makes it ideal for parts that need high mechanical resistance.

Its high UV and heat resistance make PETG an excellent choice for items meant to be outdoors as well since the sun’s rays won’t degrade it. Even the heat in a hot car won’t melt it, unlike what happens to PLA filament.

Even the heat in a hot car won’t melt it, unlike what happens to PLA filament.

PETG filament is ideal for projects that don’t need much post-processing. It has a high chemical resistance and it does not smooth with chemicals. Acetone smoothing, a popular technique for ABS, does not work with PETG.

PETG is also too soft to sand properly and doesn’t adhere well to things like paints. Either print your models in the right PETG filament color, or print them in PLA or ABS if you need to paint your 3D printed models.

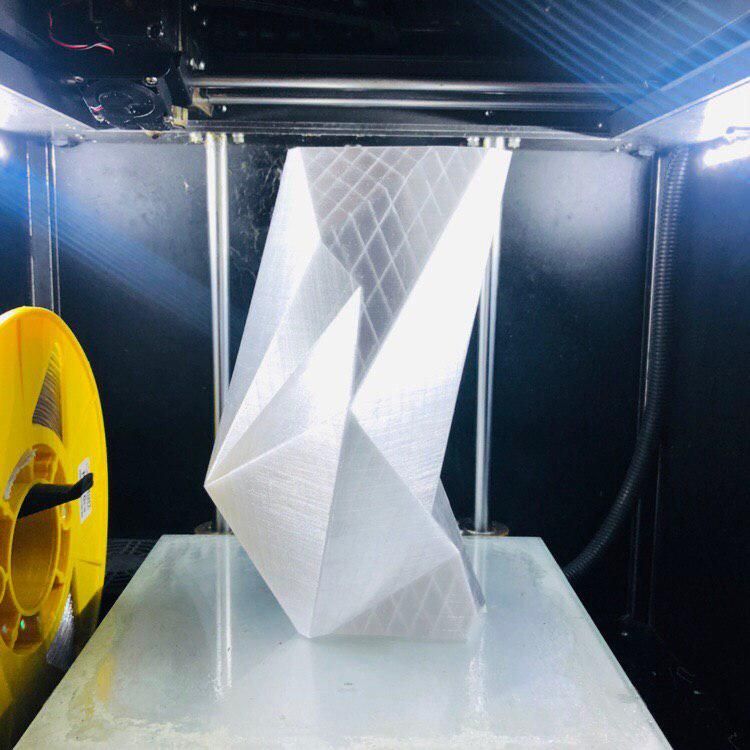

Image: Makkuro via Printables

PETG Print Temp: What Print and Bed Temperature Should You Use?

One of the reasons PETG filament is a popular choice for 3D printing enthusiasts is because it offers similar temperature resistance to ABS but at a lower printing temperature. The ideal PETG print temp is usually somewhere between 210°C and 250°C depending on the brand.

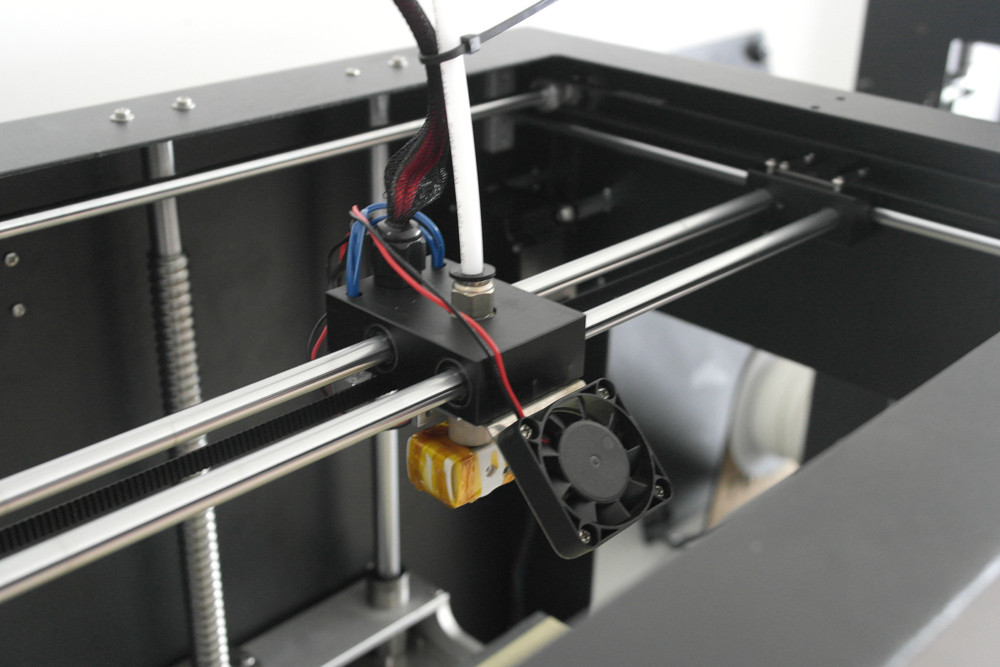

This means some PETG filaments work with a nozzle temperature similar to or the same as PLA. This is good news because it means that you don’t necessarily need an all-metal hot end on your 3D printer to print with PETG.

This is good news because it means that you don’t necessarily need an all-metal hot end on your 3D printer to print with PETG.

PETG does need a heated bed to print properly. However, the bed temperature is also usually set to a lower temp than other high-temperature filaments like ABS. Most PETG filament brands require a bed temperature between 70°C and 80°C to keep the first layer from warping.

For large PETG prints, you might also want to use a 3D printer enclosure or enclosed 3D printer. This will help to keep the heat inside the 3D printer and prevent your PETG prints from warping. Even the best PETG filament can be difficult to print if the environment is too cold and drafty.

What Speed Should I Print PETG at?

PETG usually prints best at a print speed between 40mm/s and 60mm/s. PETG is known for problems with stringing, so some users try to use a higher printing speed to correct this. However, high printing speed can seriously impact the overall quality of your print, so we don’t recommend exceeding a print speed of 60mm/s.

If you are having significant problems with PETG stringing, there are other settings you can and should try changing first to correct it.

What Are the Best Retraction Settings for PETG Filament?

PETG is known for stringing and oozing. As such, good retraction settings are a must to ensure you get a clean print from your PETG filament. Retraction speed and distance are the two settings you will want to pay the most attention to.

Retraction speed is how quickly the 3D printer retracts the filament further into the nozzle when traveling between points. For PETG, a good retraction speed to start with is 25mm/s for most printers and filament brands.

Retraction distance is how far the 3D printer retracts the filament into the nozzle when traveling from one point to another. Retraction distance settings usually vary depending on the type of extruder your printer has. Bowden extruders need greater retraction for PETG and work best between 3-7mm. Direct-drive extruders usually need about 2-4mm.

Both these settings can vary from one machine to another (or one filament brand to another). If you notice issues with your print quality, you may need to try out different speeds and distances until you find the right one.

Does PETG Need Cooling?

PETG filament technically does not require a cooling fan to print, There are some situations where you might choose to use cooling to get certain results. Using the cooling fan while printing PETG gives the print a smoother surface finish but makes the print weaker. No cooling fan allows for better layer adhesion (thus stronger prints), but your 3D print won’t look as nice.

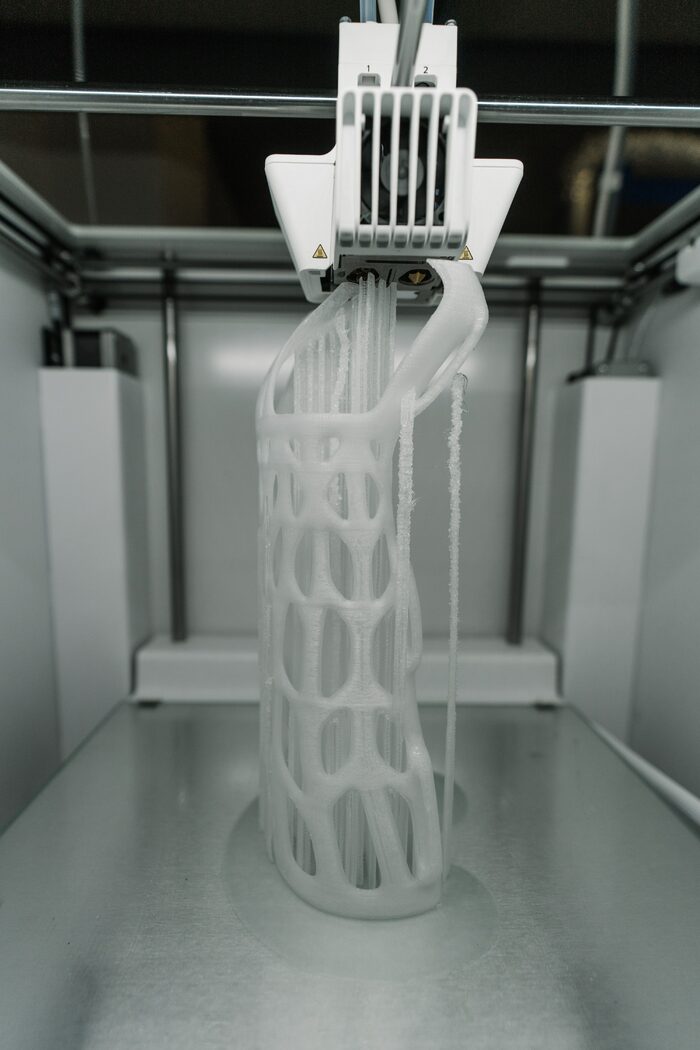

Some instances when you should opt to use cooling with PETG are on bridges and overhangs. These structures aren’t able to hold their shape long enough to cool on their own. Using the cooling fan at 70-80% fan speed on those sections prevents drooping.

Thin models with short layer times could also benefit from the cooling fan since they may not be fully dry before the printer starts laying down the next layer on top of them. In these cases, you should usually set your cooling fan to 20-50% fan speed to ensure a quicker dry time.

In these cases, you should usually set your cooling fan to 20-50% fan speed to ensure a quicker dry time.

You should keep cooling completely off while your print is first starting, however. You want a few layers of material built up between your first layer and the fan to make sure the initial layer stays up to temp and adheres well to the build plate.

How to Store PETG

PETG is very sensitive to moisture, so it needs to be stored properly to maximize the life of your filament. PETG will absorb moisture from the humidity in the air. Since PETG breaks down in water, the quality and structural integrity of your filament will slowly degrade over time.

Wet filament is also hard on your nozzle and extruder, so keeping your PETG dry can help you avoid costly or time-consuming repairs. If you are looking to make money with your 3D printer, this is a key aspect to pay attention to.

PETG should be stored in an airtight container with desiccant. Using a filament dry box is also helpful in removing moisture from PETG and prolonging its shelf life.

What Is PETG’s Glass Transition Temperature?

PETG’s glass transition temperature—the point at which PETG turns from a hard solid to a soft, rubbery state—is approximately 80°C. This makes it a much better choice than PLA for prints that need to withstand higher temperatures since PLA’s glass transition temp is about 60°C.

It is not, however, quite as good as ABS for heat resistance, since ABS’s glass transition temperature tends to be around 100°C to 110°C.

Recommended:

PETG vs ABS: Which Filament Should You Use?

Recommended:

PETG vs PLA Filament: Which is Best for 3D Printing?

Recommended PETG BrandsPolymakerPolymaker is a high-quality filament manufacturer that makes two different lines of PETG filaments: the PolyLite and PolyMax PETG filament lines. They both have a print temperature of around 230°C.

This makes it possible to 3D print them without an all-metal hot end. Instead, you can also use a PTFE-lined hot end.

This type of hot end is less expensive and easier to replace than an all-metal hot end, but it doesn’t have as wide of a temperature range. It can only safely reach up to 240°C. With Polymaker PETG, this is not a problem.

Polymaker uses Pantone color shading for their filaments, which is helpful for color consistency. PETG does not bond well to paints, so you want to make sure that the color you are printing in is the one you want.

The PolyMax is slightly stronger than the PolyLite. PolyMax only comes in two colors, however, making PolyLite the preferred line for non-industrial prints.

Polymaker PETG Filament 1.75mm, 1kg Strong PETG Translucent Red...

1,048 Reviews

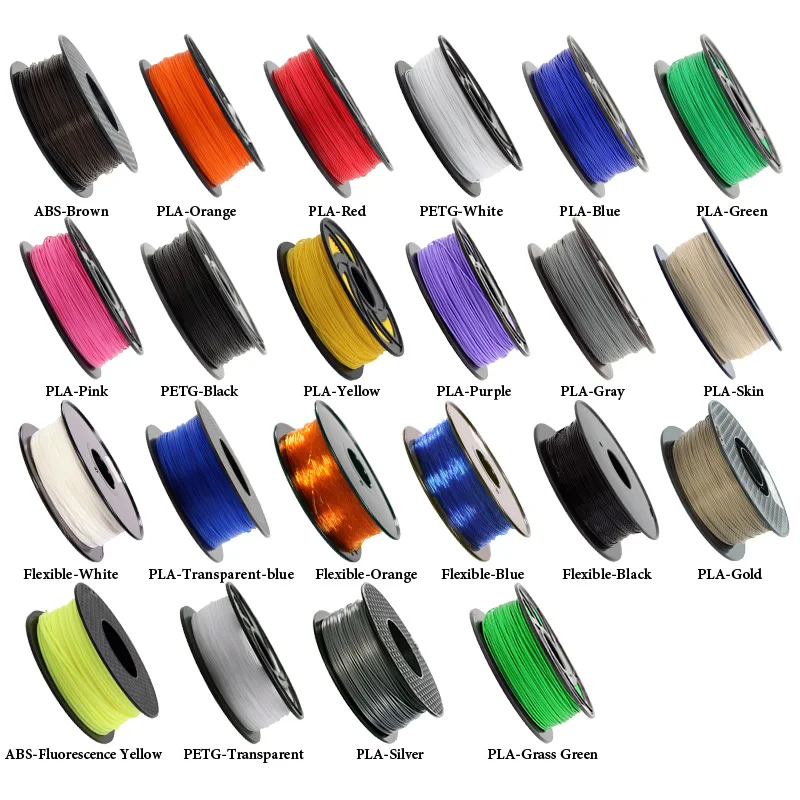

Check Price HatchboxHatchbox is an affordable filament brand that offers an impressive array of colors for their PETG filament line, including transparent, opaque, and novelty shades like glow in the dark. It has a higher nozzle temperature range than Polymaker with 230°C-260°C, so it is best for printers with an all-metal hot end.

The thing that differentiates Hatchbox from other PETG filament brands is the fact that you can print it without a heated bed. This is due mostly to its superior layer adhesion, making warping in your 3D prints less likely.

HATCHBOX PETG 3D Printer Filament, Dimensional Accuracy +/- 0.03 mm, 1...

Check Price Advantages3D printing with PETG filament has many advantages. This is why a growing number of 3D printing enthusiasts have started to use it as their everyday general printing material. PETG has a printability similar to PLA, but with the durability of other high-temp filaments. Essentially giving it the best of both worlds.

PETG’s biggest advantage is that it is easy to 3D print with. While it has a slightly higher printing temperature than PLA, it still prints much cooler than other high-temperature filaments. It also has fantastic first-layer adhesion. As long as you get the first few layers right, you will have few issues with warping and curling on small-to-medium-sized prints.

Unlike when working with flexible filaments, like TPU, you won’t need a direct extruder for printing PETG. A Bowden extruder will perform just as well, even though you will likely spend more time fine-tuning the retraction distance.

PETG is durable and strong in many ways. It has a typical temperature resistance of about 80°C-85°C, which is significantly higher than PLA’s 60°C resistance.

Its polymers are somewhat soft, giving it some flexibility. This is part of what gives it its impact resistance. It is also UV resistant, chemical resistant, and has excellent tensile strength, making it a relatively strong 3D printer filament.

PETG prints with a glossy surface that looks quite striking on most models. It also has very little odor or 3D printing fumes, so it isn’t as toxic as some of the other filament choices like ABS and Nylon.

Disadvantages

As with anything, PETG also has some disadvantages for 3D printing. While its pros usually outweigh its cons, it is important to know both so you can know when to avoid using PETG for your project.

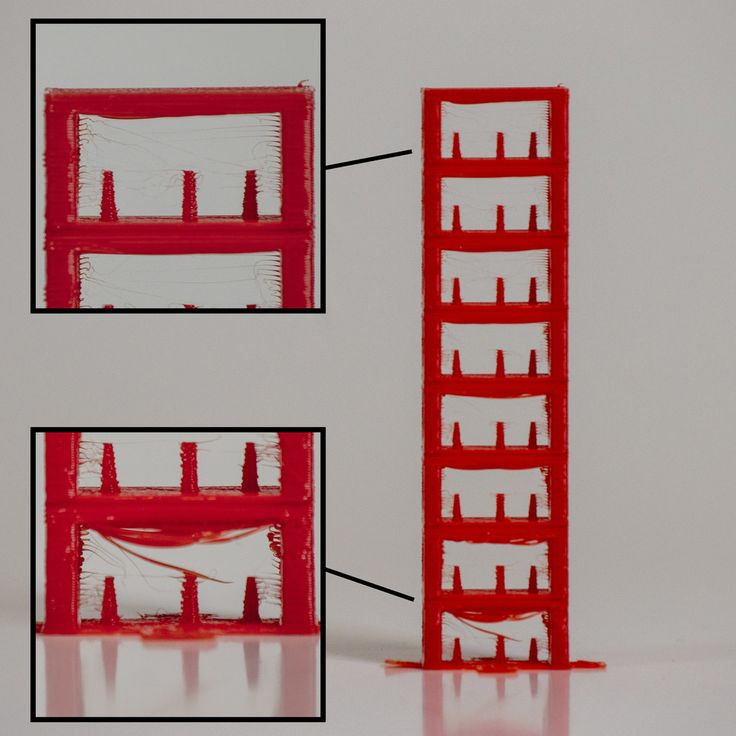

As we’ve already mentioned a few times, PETG stringing is a significant problem users can face when they print PETG. This comes down to your print settings, so once you dial in your printer’s settings, you can significantly decrease the amount of stringing you’ll see in your 3D prints.

PETG also tends to perform poorly with bridges and overhangs. It takes time to cool down, which often leads to bridges or overhangs on a print to start drooping. The fix for this is using the cooling fan to dry the layers more quickly, but that can compromise the layer adhesion and overall strength of the print.

While great bed adhesion is generally considered a good thing, PETG filaments sometimes have layer adhesion that is a little too good in its first layer. PETG prints can sometimes get stuck to the print bed when the nozzle is too close to the print bed. Some users may even be unable to remove the print from their PEI build plates altogether.

Supports are also difficult to remove. PETG’s great layer adhesion means the supports stick well to the prints. Some filament manufacturers make PETG that is compatible with certain water-soluble dissolving supports, but you typically need a dual extruder 3D printer for that. It’s usually better to just opt for a different material when possible for prints with a lot of support structures.

PETG’s great layer adhesion means the supports stick well to the prints. Some filament manufacturers make PETG that is compatible with certain water-soluble dissolving supports, but you typically need a dual extruder 3D printer for that. It’s usually better to just opt for a different material when possible for prints with a lot of support structures.

Troubleshooting

Poor Bed Adhesion and Warping

As we mentioned before, PETG usually has great first-layer adhesion. Even so, some factors can make it difficult for PETG to stick to the print bed or come unstuck later on in the printing process.

Uneven Print Bed

Like most 3D printing filaments, PETG does not stick well to an uneven print bed. When the bed isn’t level, some parts of the print are extruded from too far away to make enough contact with the build plate on the first layer. If you’re having issues with your print curling or warping, leveling your build plate should be your first step in trying to figure out the problem.

Just remember that PETG needs slightly more clearance between the print head and build plate than other 3D printing materials. Otherwise, the print can become stuck to the bed and damage your build surfaces.

Dirty Print Bed

If you haven’t cleaned your printer’s bed lately, it is likely coated with thin layers of debris, dust, and stuck-on filament. This build-up can keep your first layer from getting a good grip on the build plate. If you notice your PETG warping or curling up from the bed and changing the bed temp doesn’t fix it, try cleaning it.

Each type of print bed needs a slightly different approach for cleaning. Glass build plates need to be wiped down with some Windex and a clean cloth. PEI build plate surfaces come clean with a quick sanding using a fine-grit piece of sandpaper. If you use adhesives like hair spray or glue stick on your build surfaces, remember that you will need to clean them more often.

Too Much Cooling

If you are using the cooling fan while you print PETG, you might be causing your layers to cool too quickly. PETG has a very low shrinkage rate compared to ABS, but it does still contract slightly when it cools. Rapid cooling increases your shrinkage and doesn’t give your print enough time to properly adhere to the plate.

PETG has a very low shrinkage rate compared to ABS, but it does still contract slightly when it cools. Rapid cooling increases your shrinkage and doesn’t give your print enough time to properly adhere to the plate.

The easiest way to fix this issue is to turn off cooling for the first layers (or completely, depending on your print.) If you need to use some cooling, print your first few layers with the cooling fan set to 0% and raise the fan speed after. This will ensure that the fan doesn’t affect your initial layers directly, so they have a better chance of keeping temp until the print finishes.

Cold Print Bed

Image: Amos491 via Printables

Another possible reason your PETG isn’t sticking is that the heated bed temperature is too low. When the heated print bed isn’t set to the correct temp, the extruded PETG material cools too quickly and shrinks slightly in size. This causes the print to come unstuck from the printer’s bed, making the edges curl up.

Fixing this issue comes down to figuring out what bed temp works best with your 3D printer and the PETG brand you’re using. Try doing a series of test prints in which you print the same object several times with the bed temperature increasing in increments of 5°C for each one. Use the manufacturer’s recommended range at first, but don’t be afraid to go slightly outside of it if that is what your specific printer needs.

Try doing a series of test prints in which you print the same object several times with the bed temperature increasing in increments of 5°C for each one. Use the manufacturer’s recommended range at first, but don’t be afraid to go slightly outside of it if that is what your specific printer needs.

Blobs and Zits

Blobs and zits are a common occurrence with PETG filament and they are most often caused by over extrusion. Blobs usually happen when the printer has to pause for a moment to start the next layer and oozes out a bit of extra material onto the print. However, they can happen at any point in the layer if the printer tries to push out more material than is needed.

This is one of the trickier issues to fix because over extrusion can be caused by several different things. Lowering your extruder flow rate, raising your retraction settings, and lowering your nozzle temperature can all help with blobs and zits. You may have to change these settings several times until you find the right setting for your machine.

Stringing

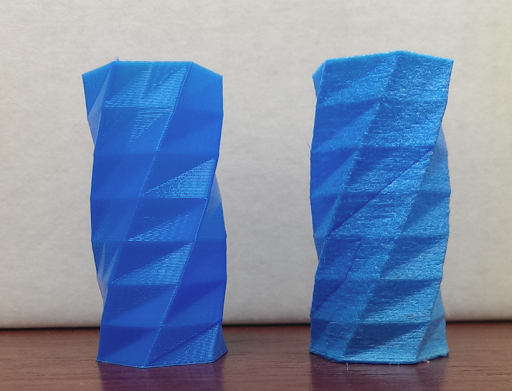

Image: Wemperor via Thingiverse

Stringing is one of PETG filament’s most common issues. Having your printing temperature set too high, using the wrong retraction settings, or having your travel speed set too low are all reasons you might be noticing more stringing than usual. Fixing these print settings in your slicer software should significantly decrease the amount of stringing you encounter.

If you want to learn more about solutions to PETG stringing, you can check out our dedicated article on the topic.

Recommended:

9 Easy Fixes for PETG Stringing & Blobs

PETG Print Stuck to Print Bed

We mentioned early that PETG’s adhesion properties are sometimes a little too good, and prints can become stuck to the build surface. The most common reason for this is having too little space between the bed and nozzle, causing too much material to be pressed onto the bed.

PETG needs slightly more room between layers than other 3D printing materials, so you need to relevel your bed before switching to PETG to make sure you have left more nozzle distance than for other materials.

To remove a stuck print, try adding heat by turning on your heated bed and using a strong scraper to slowly pry it off. That is usually sufficient for removing any stuck-on prints.

Nozzle Collides with Part

Like we said above, PETG needs extra room on the early layers than other 3D printing materials. When you put too much material down, it not only raises the print, it also causes poor bed adhesion. The print lifts off the bed slightly and into the nozzle. Raising your Z offset slightly is an easy way to fix this issue.

Frequently Asked Questions

Do you need an all-metal hot end to print PETG?

No, you don’t necessarily need an all-metal hot end to print PETG. However, if your PETG filament requires a print temperature above 240°C, then you’ll need an all-metal hot end to maintain that temperature.

An all metal hot end is also generally more durable than a plastic one. If you’re looking for a hot end that will last longer and be able to handle higher temperatures, then going with an all-metal option is a good idea.

Is PETG hard to print?

One of the easiest filaments to print, barring PLA. PETG has a high glass transition temperature, but it doesn’t warp as much as ABS and is less likely to deform after cooling. It also has good mechanical properties.

At what temperature does PETG soften?

PETG starts to soften around 80 degrees Celsius. This means that if you’re going to be using it in an application where the temperature is likely to exceed this, you’ll need to take precautions to make sure it doesn’t melt.

How do I get PETG to stick to the print bed?

Most brands of PETG will stick to a heated bed when printing. The recommended printing temperature for the bed is around 80-85°C. If you don’t have success getting PETG to stick to a plain glass surface, you can try applying blue painter’s tape or a thin layer of Magigoo or glue stick to the print surface.

Magigoo MO2016 All-in-One 3D Printer Adhesive Glue, Reduces Warping...

Check PriceIs PETG toxic when heated?

PETG is less toxic than other filaments when heated, making it a good choice for those looking for a safe option. However, it is still recommended that you work in a well-ventilated area and avoid breathing in the fumes.

However, it is still recommended that you work in a well-ventilated area and avoid breathing in the fumes.

What layer height is best for PETG?

No less than 0.2mm. PETG is a great material for 3D printing and has many advantages over other materials, but it can be tricky to get good results with thin layers. Stick to 0.2mm and higher to ensure good print quality and avoid extruder jams.

Can any 3D printer use PETG?

It depends on the specific brand of PETG and your 3D printer. Some printers can use PETG without any modifications, but other printers might require an all-metal hotend to print successfully. Before trying to print with PETG, always check with the manufacturer of both the PETG filament and your printer to make sure their nozzle temperatures are compatible.

How do you keep PETG from sticking to the nozzle?

To keep PETG from sticking to the nozzle, you can do a couple of things. Mainly, make sure to do a nozzle cleaning so that it is free of any debris. You can also make sure that you are using a good quality PETG filament with low levels of contaminants.

You can also make sure that you are using a good quality PETG filament with low levels of contaminants.

Final Thoughts

PETG is a fantastic 3D printing material for several reasons. Many 3D printing enthusiasts have replaced PLA with PETG as their everyday filament. It has great ease of use, tensile strength, and layer adhesion. It also has impact resistance, heat resistance, and chemical resistance.

While it can be difficult to dial in your 3D printer’s settings at first, once you find the right ones for your machine, PETG is a dream to work with.

Do you print with PETG filament already? What settings do you use to get the best results? Let us know in the comments!

How to 3D Print PETG Filament Like a Pro – Ultimate Guide & FAQ – 3D Printerly

When it comes to 3D printing with PETG, it does take some knowledge and practice to get good quality models. It’s not too difficult when you follow the right methods, so I decided to write this article to show users how to get good-looking PETG prints.

To 3D print PETG, you should use a printing temperature between 235-250°C and a bed temperature between 70-100°C for the best results. Your cooling fan should be at 100%, with a print speed of 40-60mm/s. Also, PETG absorbs moisture easily so, keep it dry in an airtight container when not in use.

This article is a simple yet in-depth guide on how to 3D print PETG filament just like the pros do, so stick around to see how it’s done and get your questions answered.

What is PETG Filament?

PETG or Polyethylene Terephthalate Glycol, is a popular thermoplastic polyester. PETG is different from the popular PET plastics. It is a glycol-modified variant of PET which leads to greater strength, impact resistance, and heat resistance. Common products made from PETG are water bottles and food containers.

It is widely used in different manufacturing industries due to its excellent formability, chemical resistance, high strength, and other excellent physical properties.

As a 3D printing filament, PETG is fast becoming the filament of choice for most 3D printing enthusiasts. This is because PETG prints display high strength, they are less prone to warping, and they have smooth and glossy surface finishes.

Also, PETG filament does not produce toxic odors like other thermoplastic filaments during printing. Furthermore, it is ductile, waterproof, and displays very little shrinkage, which makes it ideal for flat surfaces and models with low tolerances.

What Printing & Bed Temperature Should You Print PETG?

Printing temperatures for PETG filaments usually fall within the 235°C to 250°C range. Temperatures hotter or cooler than this can lead to stringing, blocked nozzles, over extrusion, etc. A heated bed isn’t necessary for small PETG prints, but for larger flat prints, a heated bed at 70-100°C is ideal.

Print temperatures can vary within the ranges given above for different brands of filaments. For the best results, always use the temperature values supplied by the filament manufacturers and adjust the settings if needed.

Here are some of the popular filaments on the market and their printing temperatures.

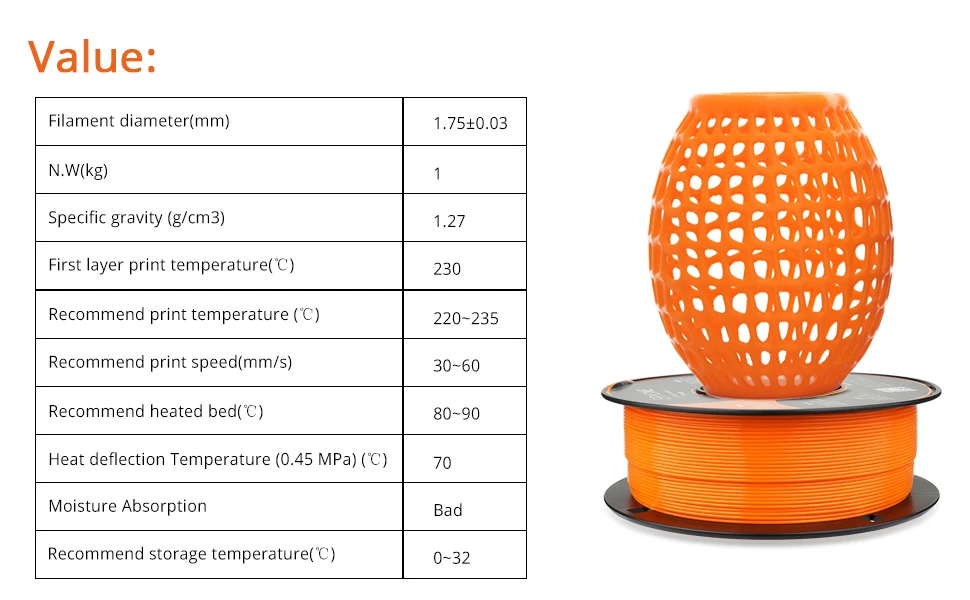

- Recommended Extrusion/Nozzle Temp: 230°C – 250°C

- Heated Bed Temp: 80°C – 90°

- Recommended Extrusion/Nozzle Temperature: 230°C – 260°C

- Heated Bed Temp: 80°C – 100°C

- Recommended Extrusion/Nozzle Temperature 220°C – 250°C

- Heated Bed Temp: 70°C – 80°C

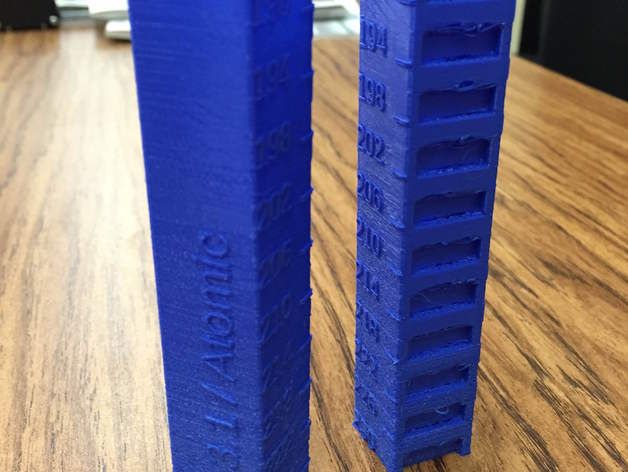

Another less glamorous way you can determine the ideal temperature for your filament is through old-fashioned trial and error. Calibration prints like the temperature tower can help in figuring out the proper settings for the filament.

Here’s how you can print one using Cura.

What Print Speed Should I Use for PETG Filament?

The final quality of the PETG model heavily depends on the print speed. Most users and manufacturers recommend a printing speed between 30 and 60mm/s for the best results.

Most users and manufacturers recommend a printing speed between 30 and 60mm/s for the best results.

Printing too fast above the recommended speed can lead to low-quality prints with many defects. So, it’s better to put a cap on the maximum printing speed to get quality prints.

On the other end of the spectrum, printing at a slow pace is good for first-layer adhesion and great print quality. However, below a certain point, slow printing speeds can also lead to print defects like stringing and oozing.

Lastly, one thing to note is that the optimal printing speed can vary between printers and filament brands. To get the best results, you should probably experiment with the settings to find the sweet spot.

Also, the printing speed should factor in the type of model being printed. For models with curved or complex geometries, a lower printing speed will probably be better.

Does PETG Need Cooling?

PETG filament does not necessarily need part cooling, but the cooling helps immensely with the final model quality. Your rate of cooling should be high to reduce print defects and stringing, while low cooling (30-50%) is better for strength due to better layer adhesion from previous layers melting into each other.

Your rate of cooling should be high to reduce print defects and stringing, while low cooling (30-50%) is better for strength due to better layer adhesion from previous layers melting into each other.

When deciding a cooling rate, you should choose one based on the purpose of the final part. The rate of cooling determines how well or beautiful the final model turns out.

When the cooling rate is high (70-100%), it helps to eliminate print defects and stringing, and the model’s details are rendered in great detail.

So, when deciding the cooling rate to use, you have to balance between aesthetic and functional value. Parts cooled faster will have a better surface finish and look, but they will not be as strong and durable as those done with lesser cooling.

Note: It’s good practice to print the first few layers without cooling to enhance first layer adhesion.

What Are the Best PETG Retraction Settings?

Retraction settings for PETG are very different from those for other filaments. This is because PETG prints at a relatively high temperature so, the material flow is very hard to stop and control.

The optimal retraction speed for PETG is relatively low, around 35-40mm/s, for both Bowden and Direct Drive extruders. The optimal retraction distance is between 5-7mm for Bowden extruders and 2-4mm for direct-drive extruders. Good retraction settings can help to avoid stringing, nozzle clogs and jams, etc.

To get the exact settings for your printer, you can experiment using a retraction tower to see what works best. You can check out how to do that in the video below.

Best Cura PETG Settings for 3D Printing

Ultimaker Cura is one of the most popular slicing software out there. Many users like and use it because of the number of features and functionality it offers at every user’s favorite price point, Free.

To slice and print your PETG 3D model using Cura, you’ll need the correct material settings for PETG. Luckily, the Cura software comes with a default material profile for printing PETG.

Here’s how you can activate it:

Step 1: Open the Cura software and click on the Material drop-down menu in the top toolbar.

Step 2: Click on the button to the right of the “Material” icon.

Step 3: In the menu that appears, hover your cursor over ‘Generic” and choose “PETG” from the menu.

Step 4: You can choose the type of print quality you want in terms of layer height. You can choose between:

You can choose between:

- Standard Quality (0.12mm)

- Dynamic Quality (0.16mm)

- Super Quality (0.2mm)

- Low Quality (0.28mm)

Step 5: You can check out the default print settings on the main interface. You can also tweak or customize any value you want.

Using the default profile can be a time-saver for some. But in case you want to get straight into printing, you can use these custom settings. These settings have been tried and vetted by many 3D printing enthusiasts as the optimal settings for printing PETG.

Let’s have a look at them.

Best Cura PETG Settings

- Nozzle Temperature: 235-250°C

- Bed Temperature: 70-100°C

- Print Speed: 40-60mm/s

- Initial Layer Print Speed: 20mm/s

- Retraction Distance: 6mm (Bowden setups), 2-3mm (direct drive setups)

- Retraction Speed: 40-45mm/s

- Combing: “Not in Skin” or “Within Infill”

- Cooling Fan Speed: 0-50% for strength, 50-100% for quality

- Initial Layer Cooling Speed: 0%

- Build Plate Adhesion: Raft or Brim

Is PETG Filament Toxic & Safe to 3D Print Indoor?

No, PETG filament is non-toxic, and it can be printed safely indoors. Also, it doesn’t even emit any smell when it is printing. Just make sure your 3D printing area is well ventilated to avoid a buildup of nanoparticles in the air. These particles can cause eye and throat irritations.

Also, it doesn’t even emit any smell when it is printing. Just make sure your 3D printing area is well ventilated to avoid a buildup of nanoparticles in the air. These particles can cause eye and throat irritations.

Is PETG Heat Resistant? What Temperature Can PETG Withstand?

PETG has decent heat resistance properties, especially when compared to most other filaments. It can resist temperatures up to its glass transition temperature, which is around 80-85⁰C. It handily beats out filaments like PLA in this respect, but it displays less heat resistance than ABS.

However, it is more UV resistant than both of them, making it the perfect choice for outdoor applications.

Can You 3D Print PETG on a Glass Bed?

Yes, you can print PETG on a glass bed. PETG adheres well to the glass surface. Sometimes, it can even stick too well to the glass surface, making it hard to remove. In some extreme cases, removing it can even take out chunks of the glass plate.

To help you avoid this, I’ll cover how to safely remove PETG prints from a glass bed in a later section.

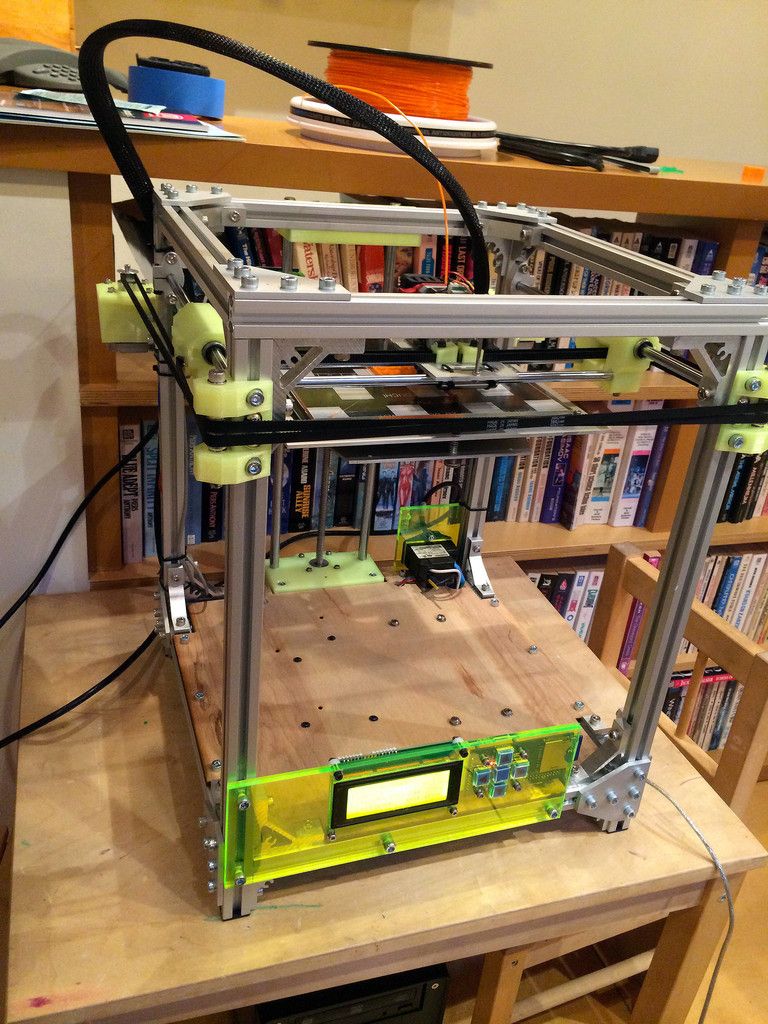

Can You 3D Print PETG Without a Heated Bed or Enclosure?

You can 3D print PETG without a heated bed, but it is recommended to have an active heated bed for the best results. A heated bed helps reduce the chances of your PETG prints warping and curling around the edges. It also gives much better first layer adhesion, which is the main foundation of all 3D prints.

How to Fix PETG Not Sticking to the Bed – Improve Bed Adhesion

Several issues can cause poor first layer adhesion when printing PETG. It can be due to problems in the printer’s set up like a dirty and poorly leveled print bed, print settings, or even poor filament quality.

To fix these, let’s run through a couple of solutions that will get your printer up and running in no time.

- Make sure your print bed is clean and free from debris and leftover print materials.

- Buy quality filament and ensure you keep it in a dry place where it cannot absorb moisture. PETG filament is hygroscopic, and moisture can ruin it.

- Make sure you level the print bed properly, leaving an appropriate Z- offset of 0.2 to 0.3mm between the bed and the nozzle. You can use three slices of paper or a thick card to get the distance right.

- To help the first layer adhere well to the bed, you can use glue sticks, hairspray, or printer tape. Some users even combine some of them to get better results.

- Turn off fan cooling, turn down the speed, and print the first layer slowly while using a heated bed.

- Check the nozzle and the print bed’s temperature to make sure they are within the range specified by the manufacturer. It’s usually between 210⁰C to 260⁰C for the hot end and 70⁰C to 90⁰C for the bed.

How to Fix PETG Stuck to Glass Bed

To fix PETG filament stuck to a glass bed, you can try alternating between hot and cold environments to loosen the material by heating the bed up or putting the glass bed in your freezer. You shouldn’t directly print PETG on a glass bed, but rather coat the bed with a layer of glue, hairspray or blue painter’s tape.

You shouldn’t directly print PETG on a glass bed, but rather coat the bed with a layer of glue, hairspray or blue painter’s tape.

These coatings provide a coating that makes it easier to remove prints. A properly leveled bed that doesn’t have the nozzle squishing onto the bed should fix the issue. PETG should be laid down from a higher height than PLA for this reason.

If your nozzle’s first layer goes deep onto the print bed, you are likely to see your PETG print getting really stuck to the print bed.

You can also try reheating the print bed, or you can pry the print off with a flat tool like a spatula. Try not to use excessive force with the spatula to avoid damaging the glass bed.

How to Fix PETG Stringing

The main methods to fix stringing in PETG prints is to increase retraction speed & distance, increase travel speeds, and decrease your nozzle temperature. PETG is prone to stringing, so you want to test your retraction settings by using a retraction tower. Use travel speeds of 200-250mm/s, depending on your printer.

Use travel speeds of 200-250mm/s, depending on your printer.

Stringing is a big issue most users face when printing with PETG. The good news is that it can be avoided by modifying a few settings.

The first setting to modify would be the retraction settings. Try increasing the retraction distance gradually in 1mm increments until the stringing stops. Also, reduce the minimum travel distance too.

Secondly, increase the printer’s travel speed in 10-20mm/s intervals until you find the sweet spot. This reduces the time the printer takes to move from one point to another, giving the nozzle less time to ooze.

Lastly, if all these aren’t working, try reducing the nozzle temperature. The reduced temperature means that less molten filament will be available in the nozzle to ooze.

How Do You Smooth PETG 3D Prints?

There are several ways you can smooth your PETG print. Here are some of them:

- Sanding: You can erase the layer lines and other imperfections from your 3D print using sandpaper.

It’s best to use a circular motion when sanding to avoid creating new directional layer lines on the model. Also, when sanding, start with coarse sandpaper and finish off with the finer sandpaper for the best results.

It’s best to use a circular motion when sanding to avoid creating new directional layer lines on the model. Also, when sanding, start with coarse sandpaper and finish off with the finer sandpaper for the best results. - Polishing: You can also smooth your 3D prints by applying a polishing compound like wax or a metal polish. The polish helps fill in the microscopic layer lines and gaps. Also, if it’s done right, it gives the 3D print a smooth mirror-like finish.

- Heat Treatment: It involves using a heat gun to smooth out the print’s surface. The heat gun melts a thin layer of the print’s outer surface to fill in the layer lines. This is done continuously until the print is finally smooth.

Is PETG Flexible?

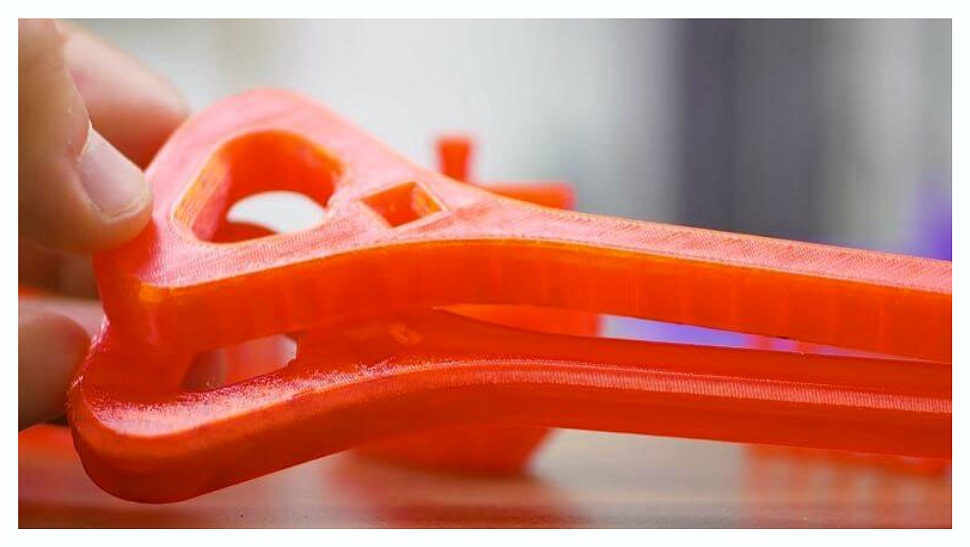

Although PETG is not as flexible as filaments like TPU, it still displays impressive tensile strength, which makes it virtually unbreakable in the layer direction. It is also more durable, impact-resistant, and flexible than ABS or PLA.

What is the Best PETG Filament?

There are several PETG filaments on the market for buyers to choose from. Out of these, there are some filaments users generally flock to because they offer great quality at a decent price.

These filaments are:

Here are some of the popular filaments on the market and their printing temperatures.

- Overture PETG

- Hatchbox PETG

- TecBears PETG

Overture PETG

Overture PETG is one of the most popular brands of PETG you can get out there, with over 8,000 reviews and a rating of 4.5/5.0 at time of writing. Many reviews mention how it is an amazing filament, especially for the low and competitive price.

This filament comes in several colors that you can use for any 3D printing projects and even comes with a 200 x 200mm build surface.

It has characteristics such as:

- Clog free & bubble free

- Less tangles and easy to use

- Cost-effective

- Wide range of compatibility

- Safe & odorless

- Little shrinkage

- High impact strength

- Has a little shine and spark to it

- 100% satisfaction guarantee

Get yourself a spool of Overture PETG from Amazon today.

Hatchbox PETG

Hatchbox PETG is a well-respected brand of PETG that works for plenty of users and comes in over 30 different colors. It has a dimensional accuracy of +/- 0.03mm which significantly reduces clogging and print failures.

PETG is a great alternative to PLA and ABS since it has amazing toughness and stiffness, while still being relatively lightweight. This Hatchbox PETG is good at resisting moisture absorption, gives good adhesion and is even safe for the environment.

You can trust in the quality and reliability of this filament. It comes vacuum-sealed with desiccant for the ideal quality that produces successful 3D prints.

You can find a spool of Hatchbox PETG from Amazon.

TecBears PETG

Another great PETG filament that many users are happy with is the TecBears PETG filament. It has high purity and low shrinkage so you can get the best dimensional accuracy with your 3D models. You’ll get some excellent layer bonding with this filament.

Each spool of filament is dried for 24 hours before they package it up with a vacuum-sealed packaging, along with the desiccants to keep it dry. They make sure it is mechanically wound up with strict manual examination, to guarantee a smooth 3D printing experience.

It has an even better dimensional accuracy than the Hatchbox PETG at +/- 0.02mm, making it a high quality and consistent filament to use in your 3D printer. They recommend a nozzle temperature of 220-250°C and a bed temperature of 70-80°C.

Get yourself a spool of TecBears PETG from Amazon today.

Well, we’ve reached the end of the article. I hope I’ve been able to answer all your questions about PETG. Remember, don’t be scared to experiment and find your perfect settings.

Good luck printing!

material overview, 3D print settings and troubleshooting tips

Polyethylene terephthalate glycol (PETG, PETG) is a wear-resistant thermoplastic from the polyester class, characterized by very high strength and a wide temperature range of application (from -40°C to +70°C). The letter G in the name means that the material has been modified with glycol to prevent crystallization and maintain transparency when cooled.

The letter G in the name means that the material has been modified with glycol to prevent crystallization and maintain transparency when cooled.

General characteristics of REC Relax based on PETG 92

Main advantages of PETG (REC Relax):

- High rigidity and hardness;

- Resistant to dilute acids and alkalis, salt solutions, soaps, oils, alcohols, aliphatic hydrocarbons;

- Good sterilization with alcohols;

- Easily processed;

- Resistance to external adverse climatic factors;

- Odorless 3D printing;

- High intercoat adhesion, low shrinkage, high platform adhesion, facilitating 3D printing

Simply put, the advantages of the material outweigh the disadvantages, and making PETG products with the right 3D printing settings is no problem. Therefore, our material was called Relax.

Therefore, our material was called Relax.

With better toughness than acrylic and lower cost than polycarbonate, PETG is popular in a variety of industries and is often the choice for complex products.

Applications for include the production of both prototypes and final products: instrument cases, protective covers, containers for various purposes, machine parts, children's toys, functional outdoor products and much more.

The softening point of PETG is 80°C, lower than ABS (105°C) but higher than PLA (55°C). In most climates, this allows PETG products to be used outdoors without being deformed by solar heat.

PETG (REC Relax) 3D Print Settings

- Extrusion temperature. The standard temperature for PETG 3D printing from different manufacturers varies between 215-245°C. Do not exceed 250°C printing temperature as this may damage the PTFE tube. It is also worth avoiding exceeding the permissible temperature due to the possible leakage of plastic from the nozzle and the formation of cobwebs or threads (the so-called "snot") on the product.

- Table temperature. Standard table temperature is 60-80°C. The opinions of both manufacturers and users differ: some recommend setting 20°C, others 90°C. Our recommendation: A standard table temperature of 60-80°C is sufficient for good adhesion.

- Retract. PETG does not like high speeds due to its softness, therefore, on most 3D printers with a Bowden filament supply system (with a separate installation of a hot end and a pusher mechanism connected by a long tube), it is desirable to set the retract speed at 25 mm/s, and the retract length - in the range of 6-7 mm. When using extruders with direct filament feed (with a hot end and a push mechanism in one assembly), a retract in the range of 3-4 mm is allowed.

- Cooling. In most cases, cooling of printed products is not required, but if your model has a large number of overhanging elements, it is advisable to turn on the blower.

- Speed.

PETG is quite sensitive to speed settings. If the material is laid too fast, the material will not have time to melt, which can lead to skipping extruder steps and even skipping layers. Increasing the extrusion temperature will not help much in this case. Too slow mode, on the contrary, can lead to the appearance of "snot" and deformation of parts. For 0.4 mm nozzle. we recommend setting the speed of PETG 3D printing at 50-55 mm/s, and when building the first layer and outer contours, do not exceed 25 mm/s.

PETG is quite sensitive to speed settings. If the material is laid too fast, the material will not have time to melt, which can lead to skipping extruder steps and even skipping layers. Increasing the extrusion temperature will not help much in this case. Too slow mode, on the contrary, can lead to the appearance of "snot" and deformation of parts. For 0.4 mm nozzle. we recommend setting the speed of PETG 3D printing at 50-55 mm/s, and when building the first layer and outer contours, do not exceed 25 mm/s. - Table adhesion. PETG adheres very strongly to glass and other materials without additional adhesives. Moreover, due to excessive adhesion, pieces of glass may come off when the printed models are peeled off.

To avoid chipping, it is recommended to apply glue or tape to the glass, and to set the correct gap between the glass and the nozzle. While ABS and PLA require a minimum gap between the glass and the nozzle, many recommendations for PETG require a slightly larger gap.

Post-processing PETG

The material can be easily machined, such as sanding or drilling. Dichloroethane or dichloromethane can be used to smooth surfaces, give gloss or glue individual parts. Do not forget that these solvents are very toxic and volatile, and therefore require safety precautions. PETG is difficult to paint, but if desired, the material can be treated with a primer and then painted.

Storage PETG ( REC Relax )

PETG is quite hygroscopic and storage depends on the climatic conditions of your area. If you use plastic in a humid climate, then the material may absorb moisture from the air if not stored properly. To avoid excessive moisture accumulation, the material should be stored in a cool, dry place. The dew point for safe storage of PETG plastic must be below zero. The simplest and at the same time very effective way is to store the filament in sealed bags with silica gel. Our coils are supplied in a vacuum package, but after opening the coil can be placed in a regular or vacuum Zip bag of a suitable size with a bag of desiccant inside, after squeezing or pumping out more air from the bag. You can also use rigid airtight boxes or simply tightly closed containers with silica gel for storage. You can read an article about plastic storage here.

Our coils are supplied in a vacuum package, but after opening the coil can be placed in a regular or vacuum Zip bag of a suitable size with a bag of desiccant inside, after squeezing or pumping out more air from the bag. You can also use rigid airtight boxes or simply tightly closed containers with silica gel for storage. You can read an article about plastic storage here.

Dry PETG ( REC Relax )

The best option is not to allow the filament to absorb moisture at all, but in practice this is almost impossible. So, before 3D printing, it is advisable to play it safe and dry the plastic.

How do you know if plastic is damp? 3D printing may be accompanied by characteristic clicks of bursting bubbles, the laying may be uneven, and all kinds of defects may appear on the surfaces of products. All this, as a rule, is accompanied by a decrease in interlayer adhesion, and often by a change in the mechanical properties of the material itself, for example, strength. The more moisture in the plastic, the more it loses strength during 3D printing, and if there is a lot of moisture, then it becomes already visible to the naked eye (skips, bubbles, and so on), while the strength drops dramatically.

The more moisture in the plastic, the more it loses strength during 3D printing, and if there is a lot of moisture, then it becomes already visible to the naked eye (skips, bubbles, and so on), while the strength drops dramatically.

PETG can be dried in several ways. The most popular ones are drying in an electric oven, a fruit dryer, a specialized dryer for filament, in a closed chamber of a 3D printer. Many users even dry plastics on radiators. Professional 3D printing studios and large productions usually use specialized drying cabinets.

We recommend using specialized plastic dryers for 3D printing or fruit dryers for drying the filament, as a cheaper option. The REC-branded coils themselves are made from impact-resistant polycarbonate that can withstand continuous heating up to 130°C.

Our tests PETG ( REC Relax )

We take our filament production very seriously and conduct many tests to check the quality of the materials we produce. Test results are available via the links below.

Test results are available via the links below.

Test:

Charpy impact strength

Bending

Tearing along layers

Tearing across layers

Compression

SanEpidem

*All tests were performed on 3D printed samples with a layer thickness of 0.2 mm.

Safety PETG

All 3D printing materials produced by our company have safety certificates. The safety certificate for REC Relax (PETG) can be found at this link.

Optimal temperatures for 3D printing PLA, PETG, Nylon and TPU plastics

3DPrintStory 3D printing process Optimal temperatures for 3D printing with PLA, PETG, Nylon and TPU plastics

Although almost all 3D printing materials are thermoplastics, each has its own temperature requirements. The specificity arises from the fact that individual fibers differ greatly from each other in chemical composition. Some, like PLA, are made from starches, while others, like ABS, are oil-based.

The specificity arises from the fact that individual fibers differ greatly from each other in chemical composition. Some, like PLA, are made from starches, while others, like ABS, are oil-based.

The chemical composition of a thermoplastic directly affects its glass transition temperature, the temperature at which the material changes from a brittle filament to an elastic substance that can be extruded. It is this temperature that must be maintained for high-quality 3D printing. And since each material has a different glass transition temperature, each plastic must be used for 3D printing at a different extruder temperature.

In addition to a specific extrusion temperature, some materials require a specific hot bed temperature. When some fibers cool, they shrink and deform. The heated bed allows these plastics to cool more slowly during extrusion so that bending is minimized.

The heated layer also provides additional adhesion, ensuring that the first layer adheres well and the part does not separate from the base during 3D printing.

So 3D printing temperature is a very important parameter that differs depending on the material that is used.

Recommended temperature for 3D printing PLA plastic

PLA is the most popular plastic in the world today. One of the reasons is undemanding to the conditions of 3D printing.

PLA prints best around 210°C, although it is very versatile and can work at 180 to 230°C. It doesn't require a heated bed to print, but if your 3D printer has one, set the bed temperature somewhere between 20 and 60° C.

When printing with PLA, make sure the cooling fans are on. PLA produces the best results when cooled properly.

Overall, PLA is very easy to use and doesn't require much drumming to be successful.

Recommended temperature for 3D printing with ABS

Until recently, ABS was the most widely used material for 3D printing. Then ABS lost to PLA in the battle for the lead. The main reason is the great difficulty during 3D printing.

ABS requires a slightly higher temperature to print successfully. The recommended nozzle temperature is between 210 and 250°C. A heated table with a set temperature between 80 and 110°C is required. This is because the ABS shrinks as it cools, and if the model cools too quickly, it deforms. For the same reason, the cooling fans must be turned off when printing ABS.

Recommended temperature for 3D printing PETG plastic

PETG is a relative newcomer to the 3D printing media market, combining many aspects of PLA and ABS.

It requires very high nozzle temperatures of 220 to 250°C. However, unlike ABS, PETG does not require a heated bed.

PETG prints best with blue masking tape on the table. Without it, the table must be heated to 50-75°C so that the extruded material will adhere well to the table on the first layer. And because this material doesn't flex like ABS, cooling fans can be turned on during 3D printing.

Although PETG is not as easy to use as PLA, it is much less demanding than ABS and is now the top of the list in popularity.

Recommended temperature for 3D printing Nylon with plastic

Nylon is another popular and interesting material, although it is more difficult to work with.

It requires a higher temperature than any of the other materials on the current list: 240 to 260° C is recommended. Required table temperature is 70 to 100° C. However, the glue stick layer is very important because Nylon suffers from adhesion quality problems first layer.

Nylon should not be printed with cooling fans as this will cause layer adhesion problems.

This material is also very hygroscopic, meaning it absorbs moisture from the air very actively. This significantly reduces the quality of 3D printing, so the nylon must be dried before printing or a quality thermal box must be used.

Nylon can be problematic at first, but once you learn how to print properly with this material, it will cover many of your questions and needs.

Recommended temperature for 3D printing TPU plastic

The flexible materials known as TPU are an unusual and sometimes very useful material, but very difficult to work with.