Conveyor belt 3d printer open source

New Open Source Belt 3D Printer Project: TigTag3D « Fabbaloo

By Kerry Stevenson on January 21st, 2022 in news, printer

Tags: belt, github, open source, tigtag3d

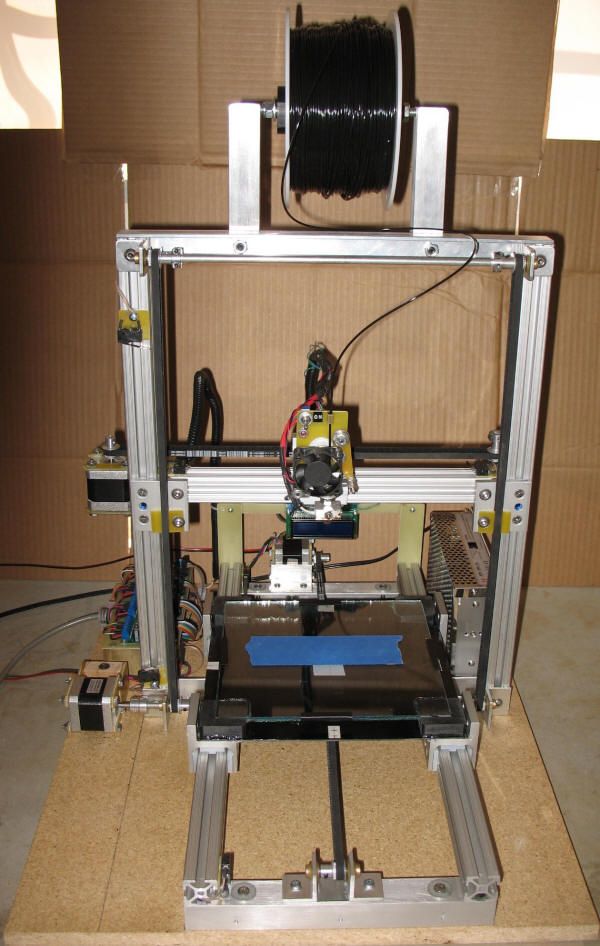

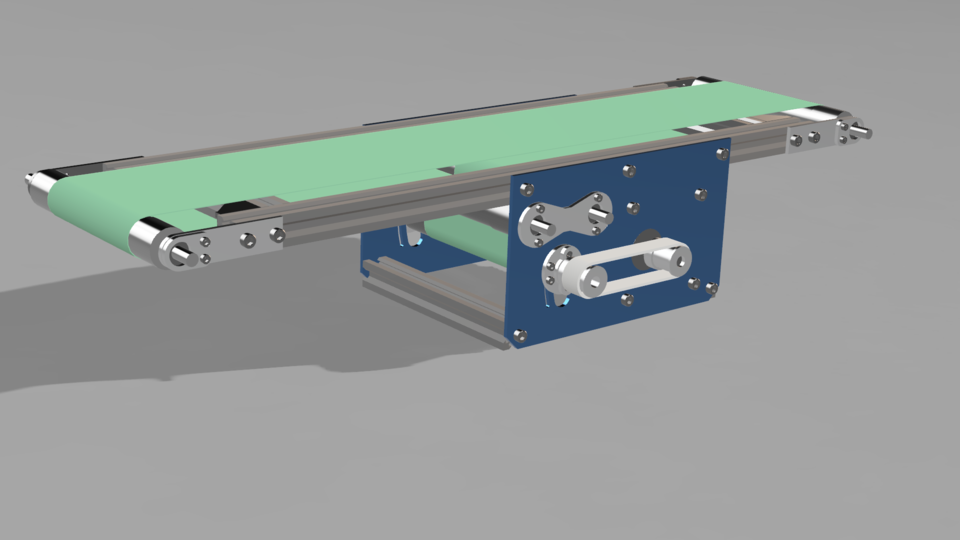

Concept rendering of the open source UE3 belt 3D printer [Source: TigTag3D]A new belt 3D printer design is available from an open source project.

“TigTag3D” is the name of the project. Their machine is a belt 3D printer design, which provides two key capabilities not available on “normal” 3D printers: belt 3D printers can produce very long parts, far longer than the size of the machine itself; alternatively, a belt 3D printer can continuously produce objects serially, as they just roll off the belt while more objects are being printed.

The belt concept was first proposed many years ago by a modification to the original MakerBot CupCake device, then later commercialized by Blackbelt. Since then there have been a couple of commercial options emerge, including White Knight, iFactory, Robot Factory, and most notably Creality’s CR-30 3DPrintMill.

As for open source belt 3D printer options, there has been only one of note until now, the White Knight, which has posted the design files on Thingiverse.

[UPDATE] It’s been brought to our attention by reader Len there is one more open source belt 3D printer project, “EnderLoop“, based on the Ender 3 platform. All information for that project is posted on Thingiverse. There is also another private group on Facebook, “The 45th Degree & ENDER BENDER Belt Printer Upgrade” attempting something similar for the Ender 3.

The new project, TigTak3D, offers GitHub-hosted design files downloadable by anyone interested in attempting a build. The current model is the UE3.

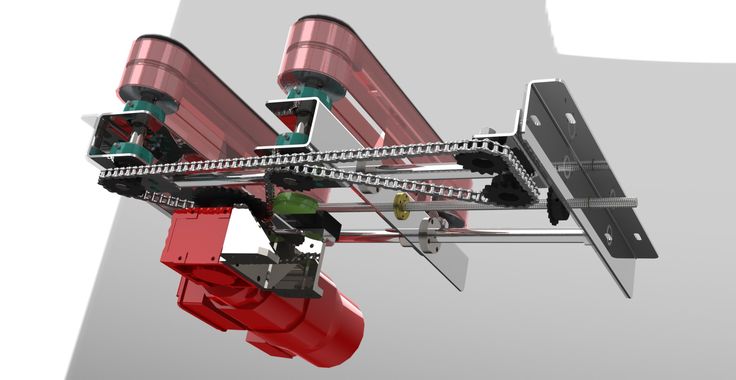

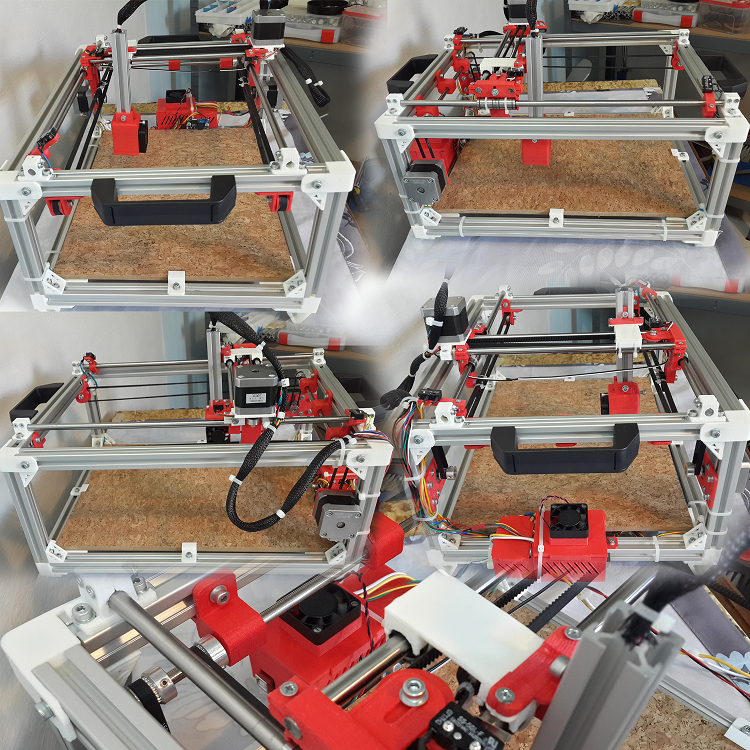

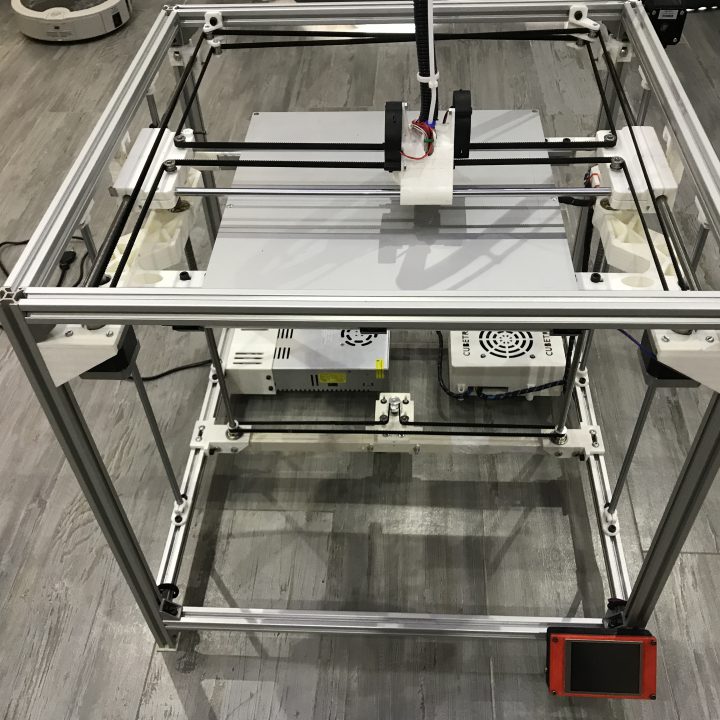

Is it only a concept? Not quite, there is evidence that it is being built, too:

Building the open source UE3 belt 3D printer [Source: TigTag3D]While the project is open source, it is a bit rough around the edges. There are a pile of STL 3D model files on their GitHub page, there is no open source license specified. Even more perplexing is that there is no readme files to explain anything. There is also no bill of materials to indicate what non-printed components might be required.

Even more perplexing is that there is no readme files to explain anything. There is also no bill of materials to indicate what non-printed components might be required.

A tweet from their account suggests that it is their “first time on GitHub”, having moved from Thingiverse.

There are several videos of the UE3 design in progress, here is the most recent edition:

Curiously, among the videos on their YouTube channel showing progress on the design is a promotional video for Zhuhai CTC Electronics Co. Ltd., a Chinese manufacturer of 3D printers for over ten years. This company produces a variety of equipment, ranging from inexpensive desktop units to industrial-sized options. I take it from this coincidence that the founders of this open source project might be somehow related to Zhuhai CTC Electronics.

In examining the UE3 design, it appears to be a feasible concept, albeit possibly a bit overbuilt. That’s actually a good thing, as it could make the motion system more stable and accurate.

There’s not much more known about the design, as it appears you’ll have to fill in the blanks for electronics, power and software to drive the machine.

One important omission is information about the main belt. This essential component should be sufficiently robust to withstand heat, cooling, repeated extrusions and other abuse. Someone building the UE3 would certainly benefit from having some advice about the nature of the belt and possible sources for purchase.

Concept rendering of the open source UE3 belt 3D printer [Source: TigTag3D]While this project might not be completely executable at this point, you should know that TigTag3D is very early, having posted their files only weeks ago. I suspect they could greatly benefit from additional contributors who could bring expertise and effort to the project.

I am also very interested to see another open source belt 3D printer project, as it might help drive the technology further forward. My opinion is that belt 3D printers should eventually become a standard, but they aren’t there yet. Open source experiments might lead the way there.

If you’re interested in belt 3D printers, this is a project you should follow.

Via TigTag3D GitHub

TwitterKerry Stevenson, aka "General Fabb" has written over 8,000 stories on 3D printing at Fabbaloo since he launched the venture in 2007, with an intention to promote and grow the incredible technology of 3D printing across the world. So far, it seems to be working!

View all of Kerry Stevenson's posts.

Conveyor Belt 3D Printer: Complete Buyer's Guide 2022

3D printing technology has come a long way in recent years and is still constantly evolving. One of the most recent innovations is the creation of the conveyor belt 3D printer.

Conveyor belt 3D printers, or just belt 3D printers, are a fairly new innovation designed to make 3D printing easier and more efficient, but aren’t very widely known yet. So what exactly are conveyor belt 3D printers, how do they work and what are they used for?

So what exactly are conveyor belt 3D printers, how do they work and what are they used for?

We answer those questions and more in this guide to conveyor belt 3D printing. Once we’ve explained what conveyor belt 3D printers are and how they’re beneficial, we’ll then review the top models on the market in case you’d like to buy one for yourself.

What is a Conveyor Belt 3D Printer?

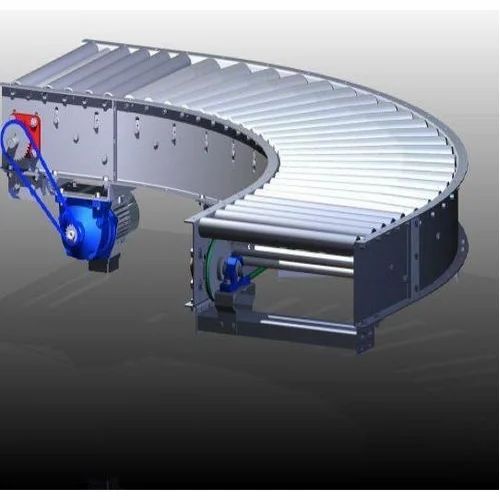

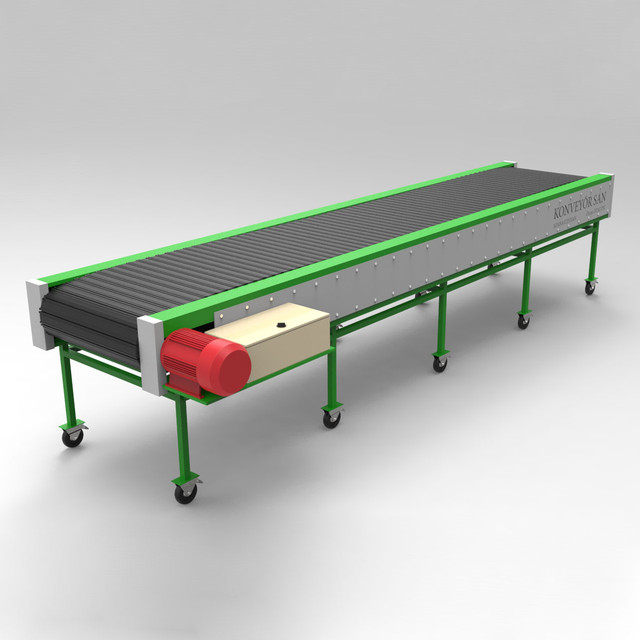

As the name suggests, a conveyor belt 3D printer uses a belt as a bed so that you can print continuously. This means you can easily mass-produce small models and print large parts that wouldn’t be possible, or would at least be a lot more difficult, with a regular 3D printer.

Conveyor belt 3D printing is still a relatively new technology that came about in 2017 when the Dutch company Blackbelt 3D released its first model. Several other companies have since followed suit in exploring conveyor belt 3D printing, although these types of printers are still currently restricted to just a few manufacturers.

Although these printers are more expensive than regular ones, they have intrigued many 3D printing enthusiasts, both hobbyists and professionals. So, how exactly do they work and in what kind of situations would a 3D printer belt suit you? Let’s find out.

How Does 3D Printer Belt Technology Work?

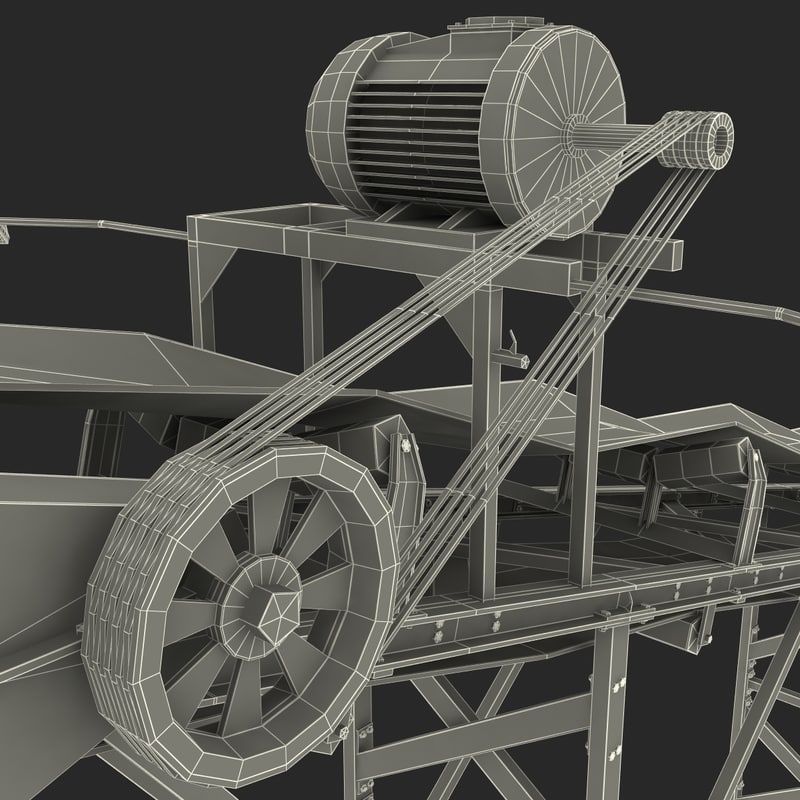

Conveyor belt 3D printers use fused deposition modeling (FDM) technology. This is where materials are fused together by melting them just past their glass transition temperatures and then layering them on top of each other to create an object.

However, they are different from other FDM printers, such as Cartesian, polar, Scara, and delta models, as they use tilted nozzles. Whereas a standard Cartesian frame has its top tilted sideways, 3D belt printers have a CoreXY gantry in which one side is tilted down. The angle is typically 45 degrees, although it can be smaller.

If you’re unsure what these mean, read: the main types of FDM 3D printer

In a 3D belt printer, the machine the X and Y axes are rotated at an angle rather than being parallel to the build plate. The Z-axis build plate itself is placed with a conveyor belt, meaning there is infinite build potential along the Z-axis.

The Z-axis build plate itself is placed with a conveyor belt, meaning there is infinite build potential along the Z-axis.

During printing, the belt pulls prints away from the nozzle. The hot end is suspended in the CoreXY gantry and travels within a titled XY plane, whereas the belt travels along the Z-axis, meaning it can in theory print objects of infinite length.

Of course, prints would eventually fall off the belt, but this can be avoided simply by having a support structure in place. If you have this, which could be anything from a beam at the printer’s height or a set of rollers in front of the bed, then you can print objects with no length restrictions.

Conveyor Belt 3D Printers Uses & Applications

The fact that a conveyor belt 3D printer can be used for continuous printing offers two main benefits – the ability to mass-produce small models and the ability to print extremely large models. This means they’re particularly well suited for semi-automated or fully automated production.

A 3D printer belt means the machine can automatically remove objects so that it can start the next job as soon as one part is done, massively increasing productivity. In terms of model size, this type of printer can print infinitely long objects in the Z direction, so you’re not limited by the size of the build platform like you are with regular printers.

These aren’t the only advantages, though. With a conveyor belt 3D printer, there’s no loss in average print speed, print removal is automatic and hassle-free, and it’s also possible to have a partially heated printing bed.

In most cases, conveyor belt 3D printers are best suited to professionals working in business and industry. This is due to the types of projects they’re best suited for, their size and their expense. That’s not to say that they’re not useful for serious hobbyists, but that they’re outside the scope of beginners and casual 3D printing hobbyists.

If you’re considering purchasing a conveyor belt 3D printer, it’s important to consider the limitations as well as the benefits. For example, in addition to the high prices and requirement of additional support structures, these types of printers print at relatively slow speeds, can’t print in ABS and some other materials, and you can’t have glass print beds.

For example, in addition to the high prices and requirement of additional support structures, these types of printers print at relatively slow speeds, can’t print in ABS and some other materials, and you can’t have glass print beds.

The Best Conveyor Belt 3D Printers to Buy

If you’ve read our guide and fancy buying a conveyor belt 3D printer for yourself, here are our recommended printers that you can purchase today.

3DSourced is reader-supported. When you buy through links on our site, we may earn an affiliate commission. Learn more

Creality CR30 – Overall Best Conveyor Belt 3D Printer

- Price: $1,049 — Available at Creality Store here / Available at Amazon here

The Creality CR30 is currently the best and most popular conveyor belt 3D printer on the market. This model has set the benchmark for this type of 3D printer.

For starters, it has an extremely stable CoreXY precision structure with isosceles right triangle support. This means the printer is very sturdy and robust, offering an overall very smooth experience.

This means the printer is very sturdy and robust, offering an overall very smooth experience.

The conveyor belt itself is made of wear-resistant nylon for durability, extending the working life and enabling the printer to work to a high level over long periods of time. It has strong adhesion, well-balanced conveyance, and offers simple removal of products, as it has a removable extension bracket to prevent models from falling during printing.

This belt 3D printer has an all-metal frame that’s designed to minimize vibrations from the Core-XY motion gantry for smoother, more stable printing. The nozzle can reach temperatures of 240°C, so it’s capable of printing a wide range of materials including TPU and PETG.

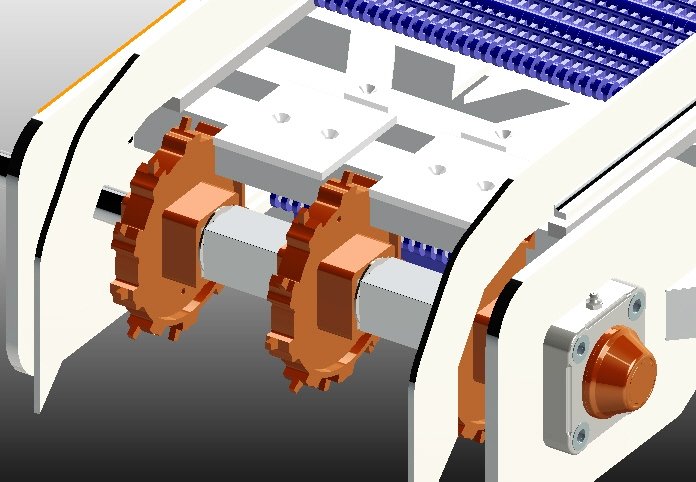

Thanks to the high-quality dual gear metal extrusion mechanism, as well as the 45 degrees slanting nozzle, this printer is capable of printing for over 200 hours at a time. The printing bed itself has a max temperature of 100°C, so it provides plenty of adhesion for printing polymer parts. You can easily level the bed using the knobs on the edges of the conveyor belt.

You can easily level the bed using the knobs on the edges of the conveyor belt.

Another really useful feature is the filament breakage detector. It has a smart sensor that suspends printing whenever the filament runs out or there is a breakage, and then printing resumes automatically after you have fed in the new filament.

This printer comes in four separate parts – the base, front, rear, and control panel – but it’s simple to set up and should only take half an hour or so to get started.

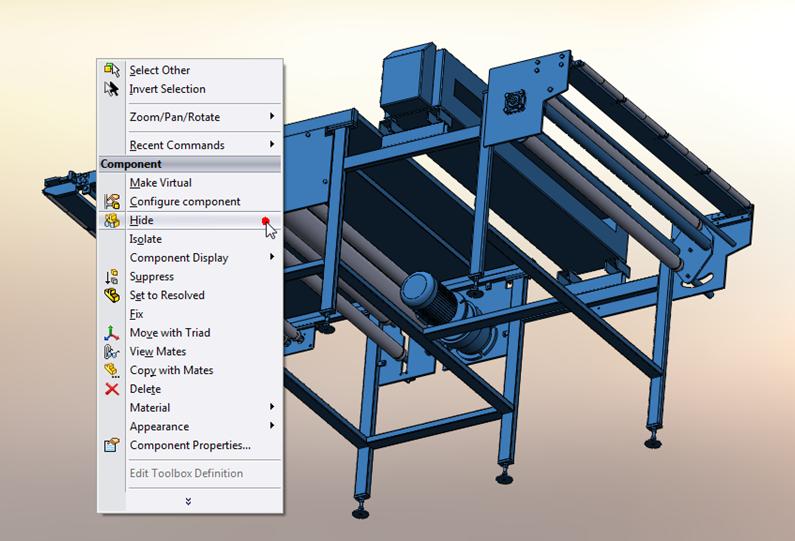

Finally, this 3D belt printer comes with the CrealityBelt slicer software included. With the software, you can slice a model of any length as well as multiple models in a line, and the package includes ready-made slicing profiles developed by Tom Jackson, a well-known slicer expert.

Blackbelt 3D – Excellent 3D Printer Belt for Industrial Settings

- Price: Upon enquiry

Blackbelt was the trailblazer of 3D belt printing with the release of its own model back in 2017, and it’s still one of the best on the market.

There are actually two purchasing options for the Blackjack 3D conveyor belt printer. You can choose the standalone version which consists of the printing platform with the controller and support construction, or you can go for the roller table version which has an extended support table capable of supporting prints of two meters.

You also have the option of adding a VarioDrive setup extension to your printer. It comes with a Bowden set up as standard, which works well with rigid materials. If you go for the VarioDrive setup, you’ll be able to print with a wide range of flexible materials, as well as nylon and carbon-filled filaments.

There is a choice of angles from 15 to 45 degrees, so you can adjust it based on your production needs. The belt is made from carbon fiber, so it’s lightweight yet incredibly durable.

While this is an exceptionally high-quality machine, it doesn’t come cheap. You have to request a quote from the company before you can get a firm price, but the average cost is around $10,000. The higher price means that this machine is best suited to business and industry, whereas the Creality machine is more open to hobbyists.

The higher price means that this machine is best suited to business and industry, whereas the Creality machine is more open to hobbyists.

Other Conveyor 3D Printer Belt Machines

While the Creality and Blackbelt machines are the best 3D belt printers on the market for both hobbyists and professionals, they’re not the only choices you have. Here are some other machines worth checking out if you’re looking to purchase a 3D belt printer.

Powerbelt3D Zero

- Price: around $500

This is another low price conveyor belt 3D printer that’s designed to make the technology more accessible to hobbyists. It’s certainly not as visually appealing as the Creality or Blackbelt machines, but it does have some benefits. For example, it has a semi-heated bet, an all-metal hot end, and it can print flexible filaments such as TPU.

You’ll need to request a quote if you want to buy the Powerbelt3D Zero.

iFactory One

- Price: $999

The iFactory One 3D printer belt was released around the same time as the Creality machine and has some nice features. The belt was made in conjunction with one of the world’s biggest belt manufacturers for optimum durability, the nozzle and other parts are custom made, and the drone also has Raspberry Pi, a webcam and the OctoPrint software built in.

The belt was made in conjunction with one of the world’s biggest belt manufacturers for optimum durability, the nozzle and other parts are custom made, and the drone also has Raspberry Pi, a webcam and the OctoPrint software built in.

This conveyor belt 3D printer will set you back $999.

The White Knight

- Cost: around $2,000

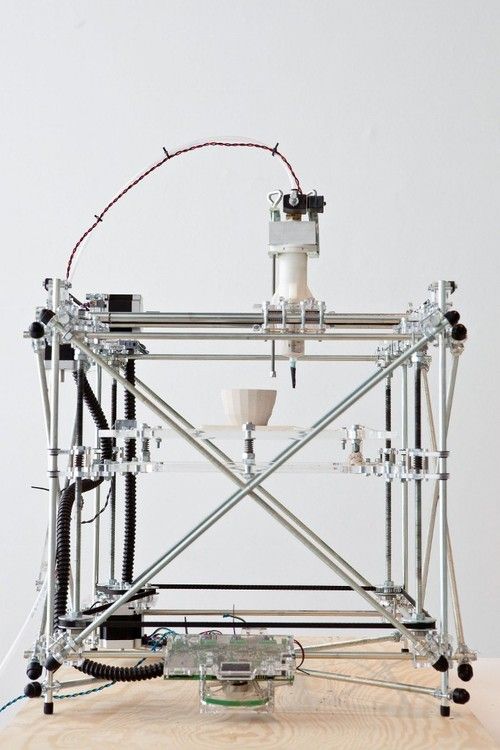

Whereas the printers we’ve profiled so far are complete models you can purchase as one, the White Knight is an open source DIY project in which you build the printer yourself. The total cost comes to around $2,000, and you don’t get the quality you get with the Creality or Blackbelt 3D printer belt machines. However, it’s certainly a fun and challenging project for 3D printing DIY enthusiasts and comes with a lot of community support.

Best Budget - Infinite-Z 3D Printer

Known for its quality desktop 3D printers and high market share in the 3D printing industry, Creality 3D launched the revolutionary Infinite-Z 3D printer, 3DPrintMill, on Kickstarter on November 19, 2020.

More information about the campaign: https://www.kickstarter.com/projects/3dprintmill/creality-infinite-z-axis-build-volume-printer-3dprintmill?ref=1dse7g

Simply put, 3DPrintMill is something between a traditional 3D printer and a conveyor belt. This means two things:

Continuous, maintenance-free printing of parts. The parts are 3D printed, the heated ribbon moves forward, the parts come off and fall into the tray. There is no need to constantly remove parts from a heated bed and start the printing process again. 3DPrintMill can turn a whole roll of plastic filament weighing 1, 5 or 10 kilograms into precisely sized plastic parts without any human control.

Very long 3D prints (theoretically "infinite" along the Z axis). By tilting the hot end 45 degrees, the back of the printed object slides out of the 3D printer while the front remains printed inside the printer. The longest 3DPrintMill print to date is a 20ft, 6m long bar all in one piece, machine-made at just 66cm long.

-

The 45° angle allows for longer passes than ever before. The maximum length of a structure is no longer an obstacle. The hot end is also adjustable to 15°, 25° and 35° with accessories.

-

Conveyor belt combined with 45° hot section for endless prints. The printed design will eventually come out of the belt. Users can leave the printer unattended until it finishes printing. All prints can be collected at the collection area at the end.

-

Silent 32-bit motherboard for the desired printing environment. Users no longer have to look for another way to eliminate engine noise.

-

Filament sensor. It is a necessary component for endless or repeated identical prints. It will pause printing if the filament runs out or breaks to prevent possible printing failure.

-

Proprietary 350 W power supply. It is able to provide sufficient power of the thermal layer. The heating layer is located at the back of the tape, next to the hot spot. The model cools by slowly moving away from the heated area and then detaches from the belt into the collection area.

3DPrintMill's unique triangular structure gives it perfectly balanced strength and superior rigidity. The moving belt allows the mass production of an identical object or purlins, which are usually located outside the building slab.

The 3DPrintMill triangular frame is built using a Core-XY structure that provides precision, speed and stability.

Creality will provide the special slicer version required to match the unique structure of this printer. It allows users to select the number of copies for a single part, or use the infinite Z-axis to create a long print.

This campaign was launched on Kickstarter at 12 noon on November 19 (GMT +8), 3DPrintMill is available for order from November 19 to December 19 on Kickstarter, shipping in March 2021. The regular retail price of 3DPrintMill is $999. You can save up to $461 with the flash sale. Super Early Birds also save up to $411. The sooner you join the program, the more benefits you will receive.

The regular retail price of 3DPrintMill is $999. You can save up to $461 with the flash sale. Super Early Birds also save up to $411. The sooner you join the program, the more benefits you will receive.

Special price per piece:

Urgent sale price - $538

Early Booking Price - $588

Early Booking Price - $688

Kickstarter Special Price - 738

Multipack Special Price:

2 pieces for $1363

3 pieces for 1998

3DPrintMill is the most affordable 3D printer -Z ever created. Similar strip printers currently on the market are for industrial use and cost about 10,000 euros.

3DPrintMill will be available at about 1/10 of our competitor's price. In addition, when buying on the Kickstarter platform, you can save up to 50%. It will not be available elsewhere until the Creality Kickstarter campaign completes all backer orders.

Creality was inspired by the open source design and collaborated with those who developed it. By combining these ideas with our hardware design team over the past few months, we have been able to create a configuration that is both high performance and low cost.

Creality releases this product at such an affordable price for the following reasons: Creality is a manufacturer and distributor, there are no intermediaries. Our products are distributed by word of mouth, which saves on advertising. We are grateful to all Creality users. We want to thank our users with this innovative and revolutionary product at the most affordable price on the occasion of Creality's 6th Anniversary.

Since its founding in 2014, Creality 3D has grown rapidly to become a well-known and trusted name in the 3D printing community. Creality 3D is headquartered in Shenzhen, with branch offices in Beijing, Shanghai, and Wuhan that include R&D, manufacturing, and after-sales divisions. With a total area of 30,000㎡ factory and research space, a team of more than 1,000 employees, and a sales volume of more than half a million 3D printers per year, our ability to meet production deadlines is guaranteed. Creality 3D is proud of its major R&D facility, the Creality 3D Printing Labs and Research Institute. It is this drive to innovate - to develop and improve open source designs - that led to the creation of 3DPrintMill.

It is this drive to innovate - to develop and improve open source designs - that led to the creation of 3DPrintMill.

The mission of Creality to enable thousands of families to enjoy the convenience that technology brings. 3DPrintMill is a powerful continuous printing and mass production 3D printer for your micro factory that really offers simple and very affordable 3D printing solutions.

For more information, please visit:.

- Official CREALITY website: https://www.creality.com

- Kickstarter campaign page: https://www.kickstarter.com/projects/3dprintmill/creality-infinite-z-axis-build- volume-printer-3dprintmill?ref=1dse7g

Source : CREALITY

This page has been translated using machine translation. Suggest the best translation

Previous

ShareNEXT

90,000 conveyor 3D printer from Creality enters the KickstarterNews

Subscribe to

Subscribe

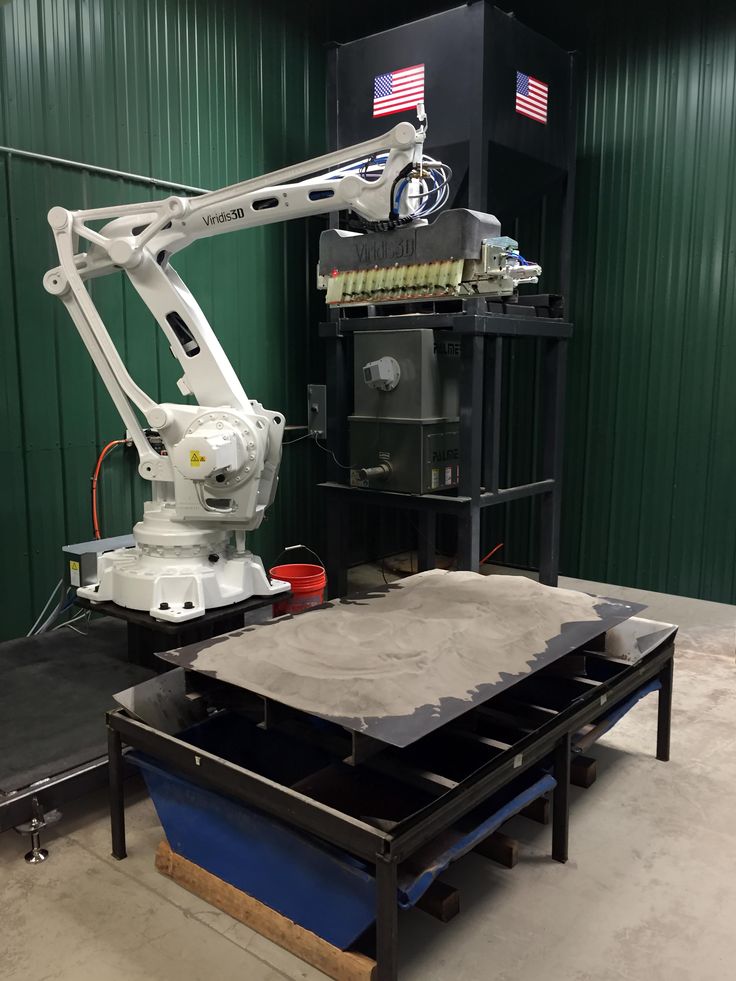

0101 with an unlimited plot area along the Z axis. The desktop additive system can be used for both 3D printing of oversized products and small-scale additive manufacturing.

The desktop additive system can be used for both 3D printing of oversized products and small-scale additive manufacturing.

This 3D printer has already been featured in several reviews under the designation CR-30. In the additive community, the idea of conveyor 3D printers has been floating around for a long time, at least twelve years, but commercial versions have only recently begun to appear: Blackbelt in 2017, Powerbelt Zero in 2019, from the open source versions, the White Knight project can be mentioned. Another promising option called Printrbelt was never brought to market due to the untimely demise of Printrbot.

It was only a matter of time before an analogue appeared in the assortment of leading Chinese manufacturers of 3D printers, and already on November 18, everyone will be able to apply for Creality's system, called 3DPrintMill. The development of our own version of a conveyor 3D printer was promoted by Naomi Wu (a.k.a. SexyCyborg), a DIYer familiar to our community members, who has been collaborating with Creality for a long time. Perhaps the main factor was the cost: the price range among the above offers is wide, reaching up to €12,500, and Creality offers a very affordable option: early Kickstarter campaign participants can place orders for as low as $538.

Perhaps the main factor was the cost: the price range among the above offers is wide, reaching up to €12,500, and Creality offers a very affordable option: early Kickstarter campaign participants can place orders for as low as $538.

As you can see in the illustrations, the distinguishing features of these 3D printers are the guides mounted at an angle of 45 ° to the surface along the X and Y axes, as well as the conveyor belt. You can get confused with the coordinate system, but imagine that a slightly skewed 3D printer is lying on its back - then the CoreXY kinematics are mounted on the portal with the appropriate coordinates, and the belt moves along the Z axis. The tilt of the portal, coupled with the translational movement of the belt, provides the ability to build parts in height without the need to rollback the entire model. In other words, this scheme allows you to print parts of theoretically unlimited length - just remember to attach the roller table and open the window.

Alternatively, this 3D printer can be used for in-line production, printing one part after another and allowing the models to separate themselves from the tape at the end and fall into a container. From an economic point of view, serial 3D printing will be justified as long as we are talking about relatively small batches of products, measured in hundreds or thousands of pieces.

Polylactide, PET-G, and TPU are listed as consumables, but there is a heated platform in the work area under the belt. The wear-resistant conveyor belt is made on a nylon base, apparently with the addition of carbon fibers. The system is calibrated at the factory, equipped with quiet drivers, a massive airflow with three fans is installed on the head. Additional features include a filament sensor, save and resume function, plus a card capture reader for offline operation. Frame made of aluminum profiles with V-shaped rollers and guides reinforced with corners. Given the unusual coordinate system, the preparation of machine code requires special software - for this purpose, the company offers a specialized slicer CrealityBelt.

Specifications of 3DPrintMill 3D printer (CR-30):

- Print technology: FDM

- Number of extruders: 1

- Construction area size: 200x170x∞ mm

- Printing accuracy: ±0.1 mm

- Nozzle diameter: 0.4 mm

- Layer thickness: 0.1-0.4 mm

- Hot end temperature: ≤240°C

- Heating temperature: ≤100°C

- Power consumption: 350W

- Power supply: AC 100-120V / 200-240V, DC 24V

- Consumables: PLA, PET-G, TPU

- Filament diameter: 1.75 mm

- Interface language: English

- Data transfer: USB, SD card

- Software: CrealityBelt Slicer

- Dimensions: 535x656x410 mm

- Weight: 16.5 kg (net), 20.5 kg (gross)

The start of accepting orders is scheduled for November 18, 19:00 Moscow time.

You can subscribe to the notification about the start of the campaign here.

FFF fdm CREALITY 3DPrintMill CR-30 conveyor

Follow author

Follow

Don't want

11

More interesting articles

5

Subscribe to the author

Subscribe

Don't want

Institute of Laser and Welding Technologies (ILIST) of St. Petersburg State Marine Tech...

Read more

four

Follow the author

Subscribe

Don't want

The new software is integrated into Eiger's proprietary cloud slicer and allows testing.