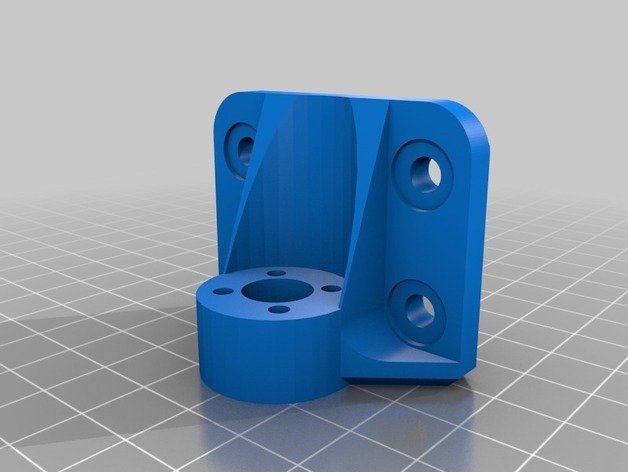

Order 3d printed part

Shapeways: 3D Printing Service Online

3D Printing Service

Create and customize. Streamline and save. Break down design barriers and scale your business with Shapeways 3D printing services.

Why 3D Printing?

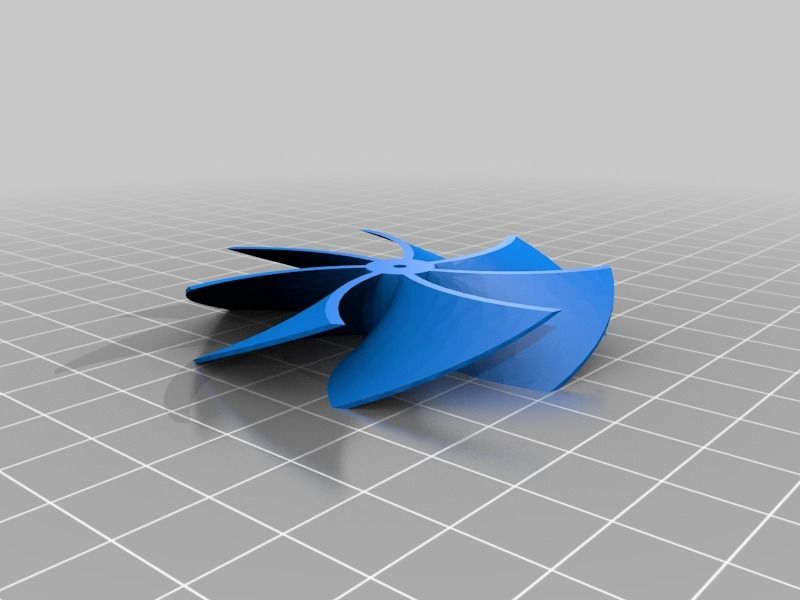

Reduce Assembly Time

Don’t waste time putting products together! Rely on 3D printing to make complex geometries that can be printed as one piece—or consolidated in one build.

Fast Turnaround

Working on a project for a customer that has to be just right? Get models back fast, and 3D print new iterations, if needed, for final feedback and production.

Reliable Quality

Proprietary processes, expert 3D printing operators, and inspections are our secrets to delivering exceptional, quality products every time.

Parts 3D Printed

3D Printing Technologies

Materials and Finishings

Countries Shipped

Customers Served

Cutting Edge Technologies

Manufacture high-quality products in over 90 of the best materials and finishes, from plastics to metals.

HP Multi-Jet Fusion

- Nylon 12 with a smooth and finished surface

- Exhibits incredible strength, durability and stiffness

- Supports complex geometries and thin features Learn More

ExOne Binder Jetting

- Steel infused with Bronze

- Supports large parts

- Strong metal with an industrial look and feel Learn More

Our Services

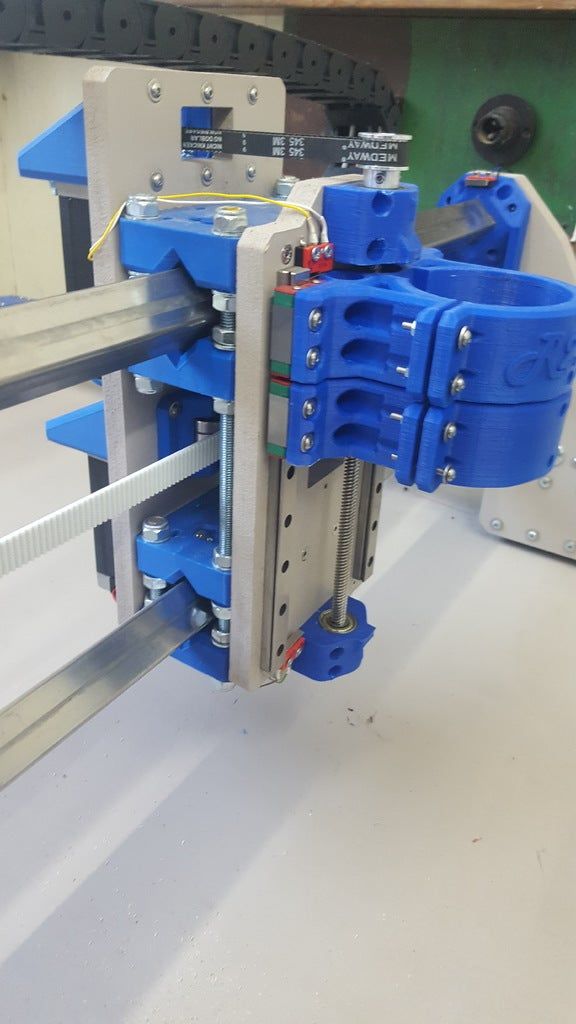

Production Parts

Upload customized models for 3D printing service—ensuring durability and strength in materials that result in end-use products meant to last. Learn More

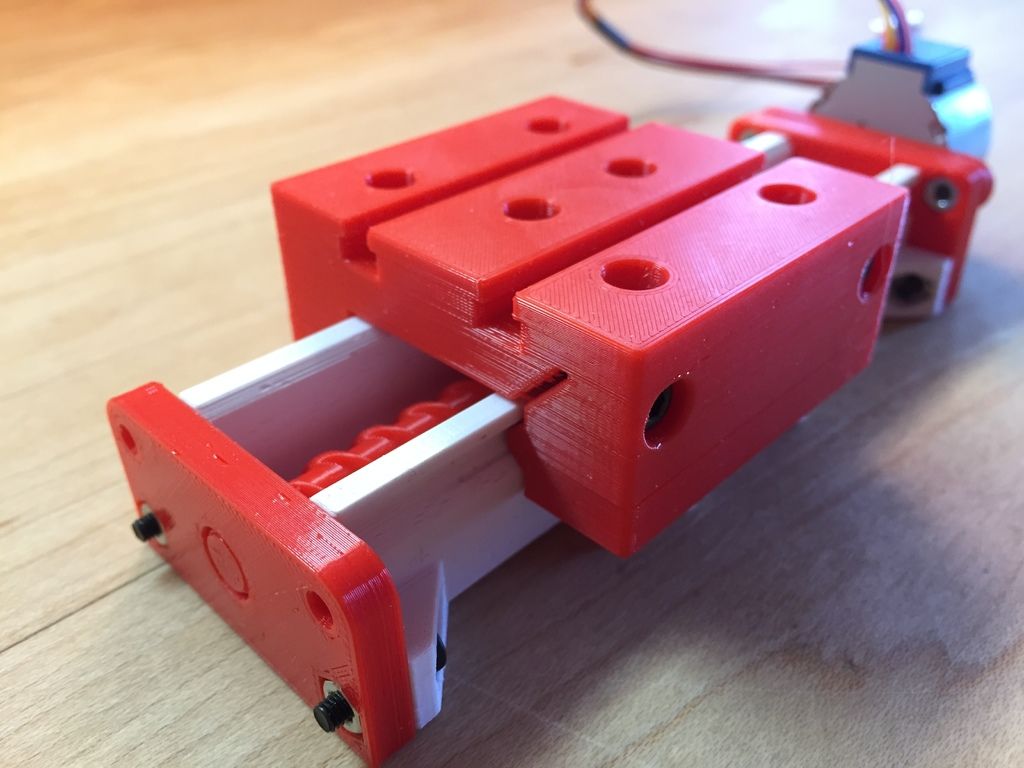

Rapid Prototyping

Take the guesswork out of product development with 3D printing services for high-performance models used in meetings, testing, and perfection of final parts. Learn More

Finishing

Whether designers prefer polishing, smoothing, dyeing–or a combination of finishing techniques–Shapeways 3D printing services can perfect those final touches with shine, gloss, and color. Learn More

Learn More

Professional Design Services

Bring your idea to life with 3D file design and optimization. Through our partnership with ZVerse, every customer has access to expert 3D Design solutions for any project need. Learn More

Rapid Prototyping

Our high quality printing enables you to assess factors such as ergonomics, usability, manufacturability, and material testing. Learn More

E-commerce Integrations

Launch your business through our marketplace by connecting to the Shapeways platform through our API, Shopify, or Etsy E-commerce Integrations. Learn More

Materials

Nylon 12 [Versatile Plastic]

Nylon 12 [Versatile Plastic] is a durable nylon plastic that can be used for a wide range of applications, both for prototyping and for end products. Printed using Selective Laser Sintering (SLS) 3D printing services, when thin, it's flexible enough for hinges and springs and when thick, strong enough for structural components. Learn More

Learn More

Accura 60

Accura 60 is a translucent and rigid acrylate-based plastic. Shapeways 3D prints this material using a large-format Stereolithography (SLA) printer capable of producing small to large parts with high resolution and detail as well as smooth surfaces with limited layer lines. Learn More

Stainless Steel 316L

Stainless Steel 316L is manufactured using ExOne’s ‘Triple Advanced Compaction Technology’ with Binder Jetting. Unlike our Steel that is infused with bronze, this material is a single alloy, composed of pure Stainless Steel. Learn More

Nylon 12

Nylon 12 (Versatile Plastic) is a durable nylon plastic that can be used for a wide range of applications, both for prototyping and for end products. Printed using Selective Laser Sintering (SLS), when thin, it's flexible enough for hinges and springs and when thick, strong enough for structural components. Learn More

Accura 60

Accura 60 is a translucent and rigid acrylate-based plastic. It is 3D printed using a large format stereolithography (SLA) printer capable of producing small to large parts with high resolution and detail as well as smooth surfaces with limited layer lines. Learn More

It is 3D printed using a large format stereolithography (SLA) printer capable of producing small to large parts with high resolution and detail as well as smooth surfaces with limited layer lines. Learn More

Stainless Steel 316L

Stainless Steel 316L is manufactured using ExOne’s "Triple Advanced Compaction Technology" with a binder jetting system. Unlike our Steel that is steel infused with bronze, this material is a single alloy, 100% Stainless steel 316L. Learn More

Testimonials

I like the ease of use in the Shapeways platform, being able to 3D print on-demand orders for the first time, and most of all–being able to scale my business. In the beginning years ago I basically had the change in my pocket and a credit line at my bank so I couldn’t order a ton of things, and you never know what’s going to sell.”

Steven Jaworski

Owner | Voytek Medical

During the process, we used Shapeways capabilities to 3D print many prototypes. That meant we had the option to iterate very quickly, print objects, and test them to see if they were working correctly in terms of complexity, or too much complexity. ”

”

Yonatan Assouline

Manager & Co-Founder | Flamingo Works

Shapeways was really great when we worked together before, which led us to reach out again. It’s been so helpful to talk with them about what we could do in every aspect of 3D printing and finishing, and it saved us a lot of time in experimentation.”

Nathan Lachenmyer

Director of Technology | Sitara Systems

I like the ease of use in the Shapeways platform, being able to 3D print on-demand orders for the first time, and most of all–being able to scale my business. In the beginning years ago I basically had the change in my pocket and a credit line at my bank so I couldn’t order a ton of things, and you never know what’s going to sell.”

Steven Jaworski

Owner | Voytek Medical

During the process, we used Shapeways capabilities to 3D print many prototypes. That meant we had the option to iterate very quickly, print objects, and test them to see if they were working correctly in terms of complexity, or too much complexity. ”

”

Yonatan Assouline

Manager & Co-Founder | Flamingo Works

Shapeways was really great when we worked together before, which led us to reach out again. It’s been so helpful to talk with them about what we could do in every aspect of 3D printing and finishing, and it saved us a lot of time in experimentation.”

Nathan Lachenmyer

Director of Technology | Sitara Systems

Previous Next

Recent Articles

Trusted by Businesses Around the World

Design, Upload, and 3D Print Your Files

Design, Upload, and 3D Print Your Files

3D print with Shapeways by creating complex products previously impossible with traditional manufacturing. Create sophisticated 3D printed ideas and designs, upload 3D print files, and expedite product development.

From sketch to the final 3D printed product, Shapeways allows you to choose advanced 3D printing materials, technology, and feedback for 3D print files. This ensures quality manufacturing for assembly and fit, functionality, and high-performance parts for applications like aerospace or medical.

This ensures quality manufacturing for assembly and fit, functionality, and high-performance parts for applications like aerospace or medical.

Upload a File

Contact Sales

Have a 3D File Ready?

Create your 3D model and upload the 3D print file to Shapeways. Don’t have a 3D file? Shapeways can help.

Shapeways 3D prints and post-process your product.

Your 3D print is shipped expediently and arrives ready to use!

Upload a Model to 3D Print

Whether you are uploading 3D models for jewelry or automotive parts, Shapeways instantly analyzes the 3D file for printability. While most 3D models are uploaded successfully, if an issue arises, Shapeways file fixers can help regenerate the 3D file or provide customized feedback. Inspections, proprietary processes, and expert 3D printing operators lead to exceptional products.

Explore Materials

Proper selection of 3D printing materials is key as they must be compatible with 3D printing technology and optimized for project requirements. From plastics to metal, Shapeways offers over 90 materials and finishes–and additive manufacturing services for any project.

From plastics to metal, Shapeways offers over 90 materials and finishes–and additive manufacturing services for any project.

3D Print Design Tips

While excellence in product development depends on optimized modeling, prototyping, and quality management, 3D printing design guidelines play a critical role in the outcome of every 3D printed part. Check out the following resources for assistance in taking your 3D design from concept to market.

Services for Your Business

- Use Shapeways 3D printing services to create complex 3D printed products for you.

- Receive 3D printed parts quickly, print new iterations, or rapid prototypes as needed.

- Rely on expert 3D printing operators and inspections for delivery of quality products.

- Choose from a range of additive manufacturing and traditional manufacturing options, designed to scale any business.

- Drop ship your 3D prints to over 130 countries.

Contact Sales

First Name*

Last Name*

Email*

Phone*

Company

Title

Country*

--None--AfghanistanAlbaniaAlgeriaAndorraAngolaAnguillaAntigua and BarbudaArgentinaArmeniaArubaAustraliaAustriaAzerbaijanBahamas, TheBahrainBangladeshBarbadosBelarusBelgiumBelizeBeninBermudaBhutanBoliviaBosnia and HerzegovinaBotswanaBrazilBruneiBulgariaBurkina FasoBurundiCambodiaCameroonCanadaCape VerdeCentral African RepublicChadChileChinaColombiaComorosCongo, Democratic Republic of theCongo, Republic of theCosta RicaCroatiaCyprusCzech RepublicDenmarkDjiboutiDominicaDominican RepublicEcuadorEgyptEl SalvadorEstoniaEthiopiaFaroe IslandsFijiFinlandFranceFrench GuianaFrench PolynesiaGabonGambia, TheGeorgiaGermanyGhanaGibraltarGreeceGreenlandGrenadaGuadaloupeGuamGuatemalaGuernseyGuineaGuinea-BissauGuyanaHaitiHondurasHong KongHungaryIcelandIndiaIndonesiaIraqIrelandIsraelItalyIvory CoastJamaicaJapanJerseyJordanKazakhstanKenyaKiribatiKorea, SouthKuwaitKyrgyzstanLaosLatviaLebanonLesothoLiberiaLibyaLiechtensteinLithuaniaLuxembourgMacauMacedoniaMadagascarMalawiMalaysiaMaldivesMaliMaltaMarshall IslandsMauritaniaMauritiusMexicoMicronesiaMoldovaMonacoMongoliaMontenegroMontserratMoroccoMozambiqueNamibiaNepalNetherlandsNetherlands AntillesNew CaledoniaNew ZealandNicaraguaNigerNigeriaNorfolk IslandNorthern Mariana IslandsNorth KoreaNorwayOmanPakistanPalauPalestinian TerritoryPanamaPapua New GuineaParaguayPeruPhilippinesPolandPortugalPuerto RicoQatarRomaniaRussiaRwandaSaint Kitts and NevisSaint LuciaSaint Vincent and the GrenadinesSamoaSan MarinoSaudi ArabiaSenegalSerbiaSeychellesSierra LeoneSingaporeSlovakiaSloveniaSolomon IslandsSouth AfricaSpainSri LankaSudanSurinameSvalbard and Jan MayenSwazilandSwedenSwitzerlandTaiwanTajikistanTanzaniaThailandTimor-LesteTogoTongaTrinidad and TobagoTunisiaTurkeyTurks and CaicosTuvaluUgandaUkraineUnited Arab EmiratesUnited KingdomUnited StatesUnited States Minor Outlying IslandsUruguayUzbekistanVanuatuVatican CityVenezuelaVietnamVirgin Islands (British)Virgin Islands (US)Wallis and FutunaYemenZambiaZimbabwe

How can we help?*

Choose an optionI'm interested in repeating ordersI'm interested in batch productionI want to design a one-time prototypeI'm new to 3D printing and need guidanceI’m interested in custom packagingOther/general questions

Description

By entering your email address, you grant Shapeways permission to send you messages about Shapeways and Shapeways services. You may unsubscribe from these messages at any time by using the unsubscribe link. Your information is protected by the Shapeways Privacy Statement.

You may unsubscribe from these messages at any time by using the unsubscribe link. Your information is protected by the Shapeways Privacy Statement.

Please check recaptcha box

3D printing of spare parts to replace imported parts

New Year - new sanctions, and this time serious ones. The mass withdrawal of foreign companies from the Russian market threatens with an acute shortage of spare parts in a number of industries. But there is good news: many components can be replaced with 3D printed counterparts, and in this article we will share a few illustrative examples.

In fact, the replacement of parts with 3D printed analogues and spare parts has long been practiced by many enterprises around the world - somewhere in an experimental manner, and somewhere in a planned manner.

Siemens Mobility Russia

For example, in 2020, Siemens Mobility purchased two industrial FDM 3D printers for its Russian division to print spare parts for the Sapsan high-speed trains running between Moscow and St. Petersburg. The reason for this decision was not even a shortage of components, but the timing of deliveries, the desire to simplify logistics and achieve 99 percent readiness of rolling stock.

Petersburg. The reason for this decision was not even a shortage of components, but the timing of deliveries, the desire to simplify logistics and achieve 99 percent readiness of rolling stock.

“These figures would be physically impossible to achieve by relying solely on external sourcing and traditional manufacturing methods, but 3D printers give us the ability to cost-effectively produce parts locally, thereby reducing the need to stock certain spare parts and tools. We have already seen the success of the Easy Sparovation Part program in Germany, where this technology has enabled Siemens Mobility to reduce time costs by up to 95% compared to traditional production methods. The delivery of an additional thirteen Velaro trains will require long-term maintenance of a large fleet with very tight time limits. Accordingly, 3D printing is an ideal addition to production facilities, providing flexibility in terms of in-house production and replacement of parts at any time, as needed,” explained Alexey Fedoseev, director of service support for the Russian division of Siemens Mobile.

2050.Additive Technologies

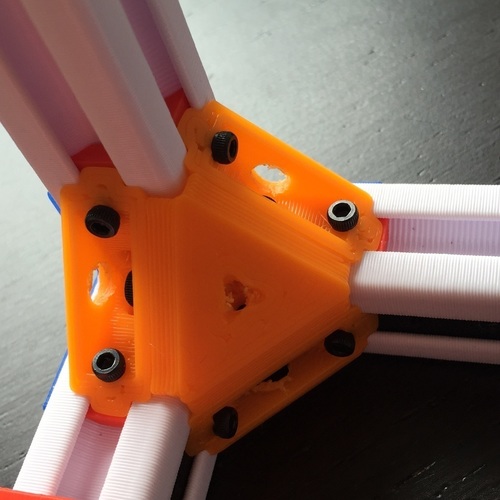

The Russian company 2050.Additive Technologies, which is part of the 2050.DIGITAL group, has gone the same way. In 2019, this enterprise undertook the creation of an entire factory for the production of parts for service locomotive depots and transport engineering enterprises, with the support of two industry partners - Transmashholding JSC and the LocoTech group of companies. The enterprise's capacities include several dozen 3D printers, mainly printing with polymer filaments.

Especially for the needs of the new plant 2050. DIGITAL has prepared a database with hundreds of 3D models of various parts created by reverse engineering using 3D scanning: buttons, handles, holders, bushings, fasteners, cabin interior elements and so on. The company calls this approach “seamless contact”: suppliers in the regions can select the necessary spare parts in the catalog and issue a command for 3D printing, quickly receiving the required components.

Abigo Medical

Is it possible to replace metal parts with plastic parts? Yes, you can. This is where refractory engineering thermoplastics such as polyetheretherketone (PEEK) come to the rescue. Due to its strength and temperature characteristics, this polymer is capable of replacing aluminum alloys, and besides, it is non-toxic, which is important, for example, in the medical or pharmaceutical industry.

Our next example is the Swedish pharmaceutical company Abigo Medical, which needed to urgently replace worn rollers on a packaging line. It took at least two months to deliver parts. As a result, the management decided to order branded parts, but at the same time quickly produce 3D-printed counterparts so as not to lose money due to long downtime. The matter was complicated by the fact that the temperature on the broken line fluctuates between 85-87 ° C, so the material had to be not only durable and non-toxic, but also heat-resistant, and here PEEK showed itself in all its glory.

“We expected the 3D printed rollers to last a week or two. By the time the original parts arrived, they had been running for nine weeks. The quality control department ordered that the homemade rollers be replaced with factory ones, but at that time the 3D printed PEEK parts were still in order and cost ten times cheaper than the original ones, ”said Abigo Medical technologist Linus Göhle.

CLAAS

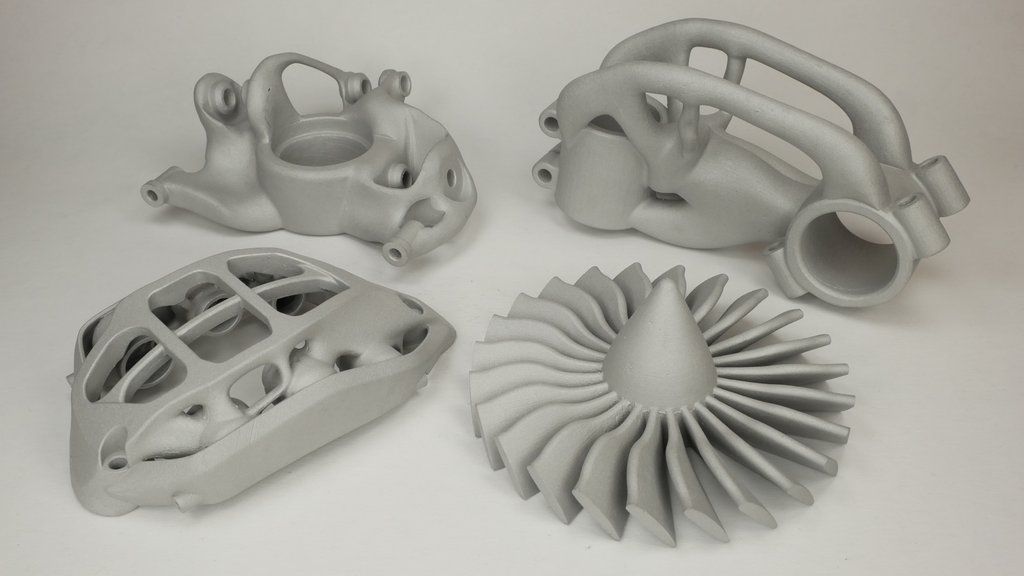

And this is an example from the Krasnodar Territory: a plant of the German machine-building company CLAAS, which produces agricultural machinery, operates here (or, at least, until recently). In 2020, the CLAAS design office took on the task of exploring the possibility of additive manufacturing of individual components and spare parts and immediately achieved interesting results.

One of the first prototypes was a 3D printed FDM-printed steering arm for the TERRA TRAC crawler chassis. The polymer 3D-printed part, with one hundred percent compliance with the original in terms of maximum load, came out six kilograms lighter, and this is nothing less than a 27 percent weight saving. The main point is that spare parts for old, no longer produced models, or rarely requested parts that are impractical to store in a warehouse, can be reproduced on a 3D printer, but they can be quickly printed - within a few hours.

The main point is that spare parts for old, no longer produced models, or rarely requested parts that are impractical to store in a warehouse, can be reproduced on a 3D printer, but they can be quickly printed - within a few hours.

Ford

Some companies generally prefer to rely on 3D printing not even spare parts, but original components. Of course, this doesn't always work. Additive manufacturing is mainly useful when it comes to the production of single or small-scale parts, and there are many such cases, for example, in the automotive industry.

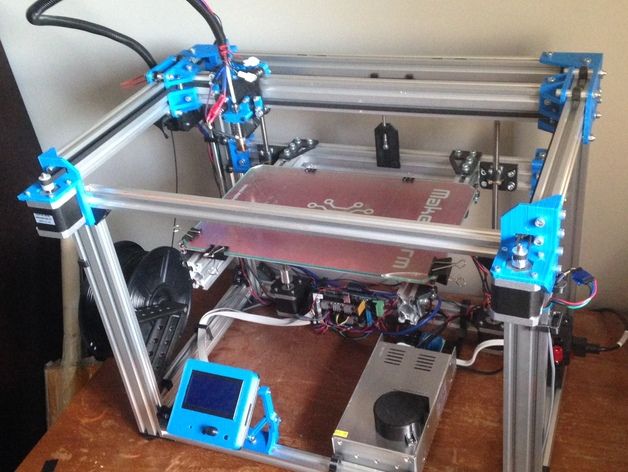

Ford has operated a purpose-built advanced manufacturing technology center in Detroit since 2018, equipped with more than two dozen 3D printers in technologies ranging from FDM/FFF to Selective Metal Powder Laser Sintering (DMLS).

In the same year, the center supplied the first mass-produced 3D printed parts - F-150 Raptor truck components for the Chinese market and the Ford Shelby Mustang GT 500 sports car. Why did the company decide to resort to additive manufacturing instead of casting? Simply because both of these models were planned to be produced in limited quantities, and the deployment of a foundry for the production of several thousand plastic parts turned out to be unprofitable. It turned out that it is faster and cheaper to print the required components with photopolymer resins without spending money on expensive casting equipment.

Why did the company decide to resort to additive manufacturing instead of casting? Simply because both of these models were planned to be produced in limited quantities, and the deployment of a foundry for the production of several thousand plastic parts turned out to be unprofitable. It turned out that it is faster and cheaper to print the required components with photopolymer resins without spending money on expensive casting equipment.

Best regards, REC3D team.

3D printing mold making

Desktop 3D printing molding allows engineers and designers to get more functionality out of a 3D printer beyond prototyping. Molding opens up a world of production materials and provides the opportunity to produce small batches and sample molds before using expensive

tools.

This booklet covers the following three mold making strategies: injection molding, high temperature molding and injection molded elastomers. Typically, molds are made from Formlabs clear resin, which is preferred for its transparency, although any standard resin can be used, and high temperature resin is ideal for processes with high temperature requirements. It should be noted that these processes are best suited for stereolithographic 3D printing (SLA) because the printed parts are isotropic and waterproof.

It should be noted that these processes are best suited for stereolithographic 3D printing (SLA) because the printed parts are isotropic and waterproof.

Prototyping and small-scale production with 3D printing tools

| Process | Equipment | Run time | Material cost (for example: 300 ml / cm3) |

| Do-it-yourself mold making and parts making | Mold 2 and injection molding machine | 5 to 24 hours (form print time) | Approximately $50 for High Temperature Resin |

| Outsourced SLA Form | injection molding machine | 3-5 days | Approximately $700 for back office printing on industrial SLAs |

| Outsourced metal mold | injection molding machine | 1-2 weeks | Approximately $6,400 for office desk, aluminum finish |

| Outsourced mold Creation and production | no - full outsourcing | 1-3 weeks | $4,000 to $15,000 depending on volume and materials |

Silicone molding and some desktop molds are available using Formlabs Standard Resins High Temp, which has the highest HDT at 0. 45 MPa for any 3D printed media currently on the market and allows print parts that can be used for high temperature forming such as thermoforming and injection molding of materials with higher melt temperatures

45 MPa for any 3D printed media currently on the market and allows print parts that can be used for high temperature forming such as thermoforming and injection molding of materials with higher melt temperatures

Injection molding

High-resolution SLA 3D printing on the Form 2 can be used to rapidly prototype inexpensive injection molds that can be used to make real parts from a wide variety of

thermoplastic materials. Injection molds can be used to test mold designs before manufacturing metal tooling or to produce low-volume parts

3D Printed Injection Molding covers injection molding using Formlabs clear resin printed molds. Following the release of Formlabs High Temperature Resin, designed to achieve higher heat resistance and stiffness, the booklet has been updated to describe the benefits of High Temperature Resin plates that are less likely to break due to thermal shock or temperature-related deformation

USB Device Enclosure Mold, 3D Printed on Form 2 High Temperature Resin

This mold contains a core, a cavity and two "gates" leading to the two halves of the enclosure. High temperature resin molds can be used to mold a wide range of thermoplastics without thermal stress or temperature-related deformation

High temperature resin molds can be used to mold a wide range of thermoplastics without thermal stress or temperature-related deformation

Formlabs High Temperature Resin can be used to injection mold a wide range of plastics.

3D printed mold tools reproduce the exact quality of the SLA print finish on the Form 2. Forms can be printed at 100 microns for faster prototyping or the recommended 50 microns for fine detail and smoothness

electronics molded in HDPE with a High Temp tool.

This shape of the USB case has been adjusted over three iterations to remove pits, entrapped air, and some shrinkage. Total cost of materials for prototyping this high temperature resin mold tool: $25

Thermoforms

Form 2 3D printed thermoformed dies are a fast and efficient way to create high quality vacuum formed parts for low volume production. Printed thermoformed dies can be used to make packaging prototypes, clean orthodontic retainers, and food-safe molds for chocolate confectionery.

Thermoforming dies experience less pressure than injection molds, but still reach high surface temperatures.

High temperature polymer resists deformation and surface degradation from the combined heat and pressure of thermoforming for most plastics. Standard resins may also be suitable for thermoforming with some low temperature plastics such as vinyl.

APPLICATION EXAMPLE

Formech thermoformed prototype packaging.

Thermoforming a thin sheet of polycarbonate over a high temperature polymer matrix produces a transparent piece by matching the geometry and detail of the matrix. Thermoformed packaging can be easily prototyped and incorporated into the design process along with 3D printed product prototypes, and all this is achievable on the Form 2. The printed matrix was used without additional processing and the need for UV curing. Texture is recommended in thermoforming design to prevent air trapping under the sheet - layer lines on the printed thermoforming die can be helpful in this regard.

TEMPERATURE CONTROL

High temperature polymer die cycle thermoforming

The die surface temperature reaches 130°C. The high temperature resin is highly resistant to deflection, whereas with standard resins you must allow the print matrix to cool between cycles, otherwise warping and degradation may occur.

If temperature rise becomes a limiting factor in molding efficiency, cooling channels are an effective way to remove heat from the print. When used in conjunction with an automated thermoforming machine, the water-cooled die can produce more parts with shorter cycle times.

Conformal water channels visible in the high temperature thermoforming die.

Thermoforming die surface temperature

Conformal cooling channels are easy to implement when designing for SLA 3D printing and print successfully without any internal supports to interfere with flow. After printing, the channels are flushed with uncured resin using isopropyl alcohol. The mold is connected to a pump and a source of cold water.

The mold is connected to a pump and a source of cold water.

Integrated water cooling as a strategy can also be applied to standard and rigid polymer parts to reduce heat dissipation when used in higher temperature environments.

Elastomer casting

Precision molds for most flexible elastomers, such as silicone and urethane rubbers, can be printed on the Form 2 using standard resin. The transparency of Clear Resin allows the material to be observed during the pouring or injection process. Flexible materials can be easily removed from rigid SLA printing plates, and applications from model production to functional molding can be obtained. Silicone molding can also be used to quickly replicate master prints, greatly reducing production time when multiple rigid parts and objects are needed.

APPLICATION EXAMPLE

Forms printed on Form 2 are used to create composite parts with advanced built-in features. Assembly subcomponents such as electronic, metal and SLA printed elements can be embedded and sealed in soft surface molds.

RightHand Robotics used the Form 2 to create the production blocks of their robotic gripper using urethane molding. The forms were printed in clear resin, with black resin inserts forming the internal structure.

The Form 2 printer allowed RightHand Robotics to move from prototypes to small-scale production without the need for expensive tooling. The rapid transition from original printed prototypes to production materials that have longer flex cycle life was done with 3D printed plates on the same Form 2 hardware they used for initial prototyping.

The first layer applied from RightHand Robotics' multi-stage process includes urethane compounds that can withstand multiple flex cycles while still providing the high elasticity needed to securely return the gripper to its open state.

The outer layer provides improved tactile grip and control, as well as sealing the sensor electronics with softer, lower durometer rubber.

SLA 3D printed parts can also be encapsulated inside molds to provide a rigid structure for flexible materials.