Defense 3d printing

The Best Uses for Additive Manufacturing in Defense

Published on June 30, 2022 by Clemens M.

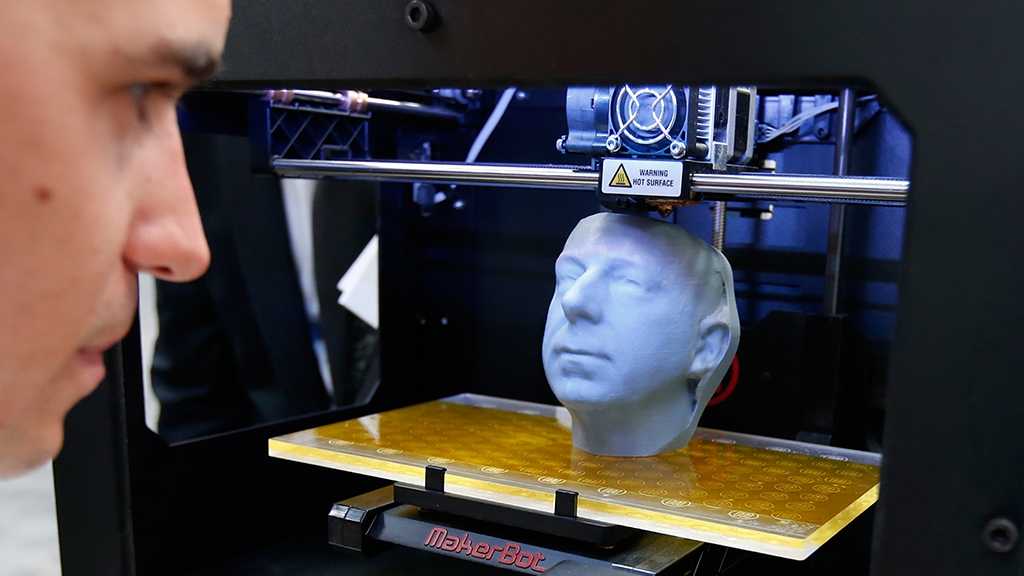

Additive manufacturing is widely used in many sectors including maritime, aerospace, and automotive. It should come as no surprise then, that it is also being increasingly adopted by the defense sector worldwide. In fact, the military 3D printing sector is expected to be worth $1.7 billion by 2027, showing the importance the technologies have. Considering that in the military speed, lighter weights, and lower costs are all paramount, additive manufacturing certainly has a role to play. We took a closer look at some of the most interesting applications for additive manufacturing in the defense sector, listed below in no particular order.

The Largest Metal 3D Printer Was Commissioned by the US Military

The U.S. military is so convinced of the benefits of additive manufacturing that last year, they announced that they would even be building the world’s largest metal 3D printer. The U.S. DEVCOM Army Ground Vehicle Systems Center is working to build the printer with the help of ASTRO America, Ingersoll Machine Tool, Siemens, and MELD Manufacturing at Rock Island Arsenal – Joint Manufacturing and Technology Center. The printer will be part of the Jointless Hull Project with the end mission being to print monolithic (one-piece) hulls for combat vehicles. When it was announced, it was estimated that the project would take around 14 months and the end printer would be capable of printing metal parts that are 30 feet long, 20 feet wide, and 12 feet high. Though we have had no recent news on it, it is likely that the project will be finished in the near future.

A 3D Printed Runway for the US Air Force

Another application in the military and defense sector comes from ITAMCO (Indiana Technology and Manufacturing Companies), which has developed a runway for military expeditionary airfields using additive manufacturing. These runway mats are an essential component of Expeditionary Airfields (EAF). Their function is to be implemented on weaker ground surfaces to allow military aircraft to land and take off. Before that, a portable runway made of aluminum planks was used, but as it became outdated, the army needed to find an innovative solution. The M290 3D printer from the German company EOS was used to create a much lighter and more durable model for the U.S. Air Force’s military equipment.

Their function is to be implemented on weaker ground surfaces to allow military aircraft to land and take off. Before that, a portable runway made of aluminum planks was used, but as it became outdated, the army needed to find an innovative solution. The M290 3D printer from the German company EOS was used to create a much lighter and more durable model for the U.S. Air Force’s military equipment.

ExOne and Its Military Pods, an Innovative Application for Additive Manufacturing in Defense

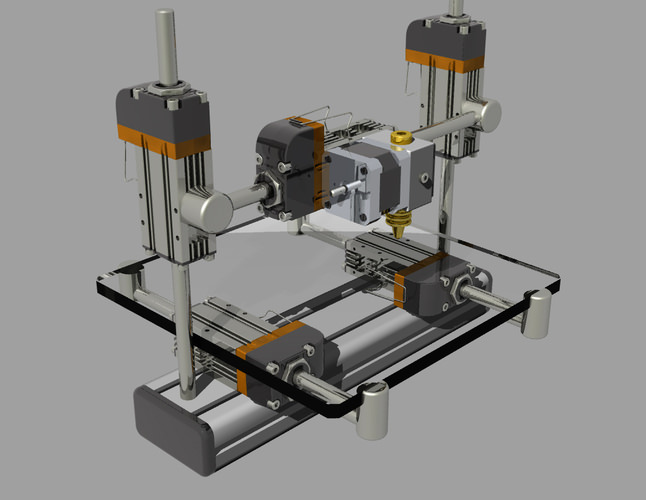

With the goal of accelerating the development of strong and robust 3D printed factory pods, ExOne got involved in the realization of this task after working with several partners. Specifically, it involved a Defense Logistics Agency (DLA) contract, which was valued at $1.6 million. For the process, ExOne’s Binderjet technology was used for military use due to its speed, flexibility of materials, and ease of use to best meet the critical needs of the military. The 3D printer, designed specifically for the military, is said to be capable of binder jetting more than 20 metal, ceramic and other powder materials – in addition, the unique housing and other features are said to make it perfect for a military-grade product.

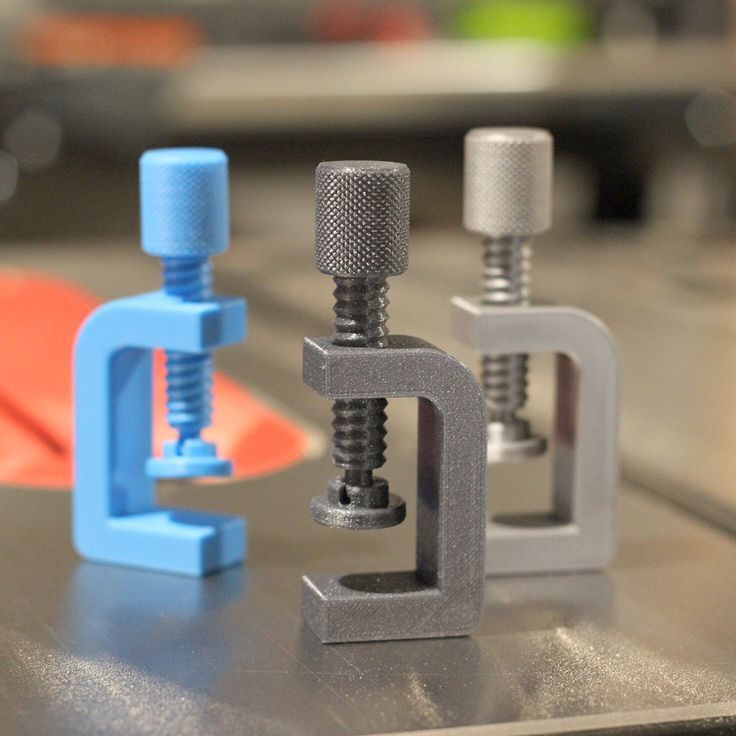

The U.S. Navy is Increasingly Turning to 3D Printed Tools

The U.S. Navy is also taking advantage of additive manufacturing. Marines have discovered the ability to produce innovative tools for their vehicle maintenance thanks to 3D printing. Specifically, this involves the Marine Corps System Command working with the Supply Battalion and industry partners to produce additively manufactured jigs for removing steering wheels from metal – a common problem that often needs to be solved in Navy vehicle maintenance! With the benefits of reduced maintenance time and increased readiness, additive manufacturing benefits greatly, especially considering that the actual wait time for such parts is around 25 days.

The U.S. Army’s Partnership With The University of South Florida

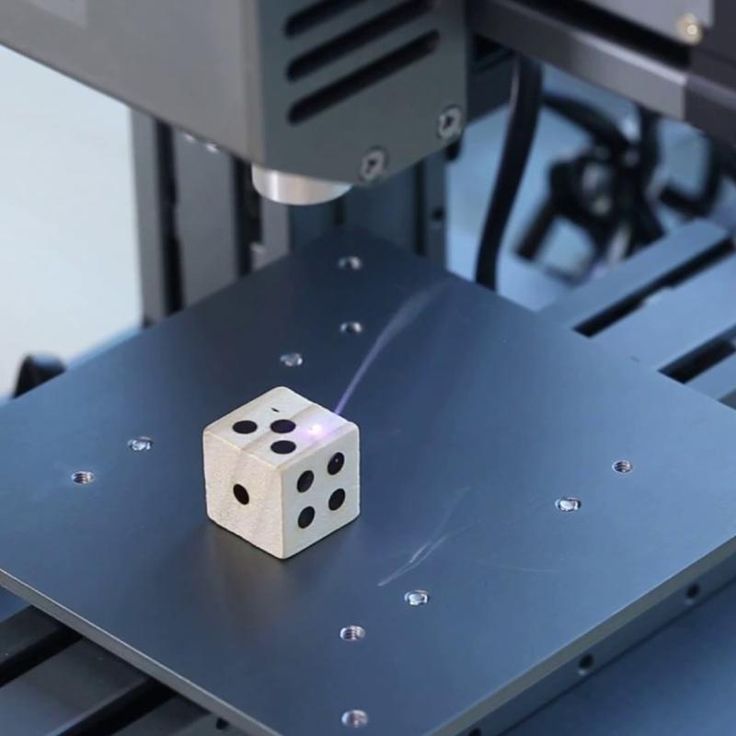

While the U.S. Army regularly collaborates with companies to slowly adopt technology, U.S. troops are also partnering with some universities. Recently, scientists from the University of Central Florida succeeded in 3D printing a magnesium alloy, called WE43. It is no coincidence that researchers have turned to this material. American soldiers are forced to carry extremely heavy bags and equipment, so it is now necessary to relieve them of this weight. And with the help of WE43 and the powder laser fusion process, the US Army and the University of Central Florida may have found the solution.

It is no coincidence that researchers have turned to this material. American soldiers are forced to carry extremely heavy bags and equipment, so it is now necessary to relieve them of this weight. And with the help of WE43 and the powder laser fusion process, the US Army and the University of Central Florida may have found the solution.

A Ship’s Propeller Made With Additive Manufacturing Shows Progress in the French Defense Sector

For several years now, the renowned French company Naval Group has been using 3D printing to meet a variety of needs. In 2021, thanks to additive manufacturing and more specifically to the WAAM (Wire Arc Additive Manufacturing) process, Naval Group has 3D printed a propeller. Composed of five 200 kg blades, the propeller was then fitted to the Andromeda, a mine-hunting ship. The teams behind the project explain that by using the technology they have drastically reduced the construction time and minimized the number of materials used.

The Spanish Air Force Upgrades Its Processes With 3D Printing

Additive manufacturing provides properties of hardness, strength, and lightness in the manufactured parts. Thanks to internal fiber reinforcement, various tooling and final parts have been developed, capable of withstanding the demanding performance conditions required in a context where the components are very highly stressed, and where there can be no margin for error. In Madrid, the head of the Spanish Air Force’s helicopter workshop says that nowadays, for every part’s requirements, additive manufacturing is always valued and traditional manufacturing is avoided. Some of the parts worth mentioning are, for example, a leak control measuring tool for the helicopter’s landing gear or a customized key for the helicopter’s main rotor.

General Lattice And Its Helmets For The U.S. Army

3D design software company General Lattice and the U.S. Army have signed a contract to improve the impact absorption of the Army’s combat helmet through 3D printing and advanced lattice geometries. For this project, the company developed a set of predictive modeling tools to design and generate materials for the helmet. To improve soldier protection in the field and the likelihood of survival after suffering a head impact, the 3D printed materials will be tested in real-world environments to validate the performance requirements of the Developmental Command Soldier Center.

For this project, the company developed a set of predictive modeling tools to design and generate materials for the helmet. To improve soldier protection in the field and the likelihood of survival after suffering a head impact, the 3D printed materials will be tested in real-world environments to validate the performance requirements of the Developmental Command Soldier Center.

Spare Parts in an Operational Armored Vehicle

The Australian Army has used metal additive manufacturing, and in particular, solutions developed by SPEE3D, in order to design a dozen spare parts for one of its armored vehicles. These parts have been tested and certified for use in the field and certified for field use, improving the agility of the Australian Army. Among the printed components include, for example, a wheel cover that was created in just 29 minutes, with an overall cost of 100 Australian dollars. The machine used in this case is the WarpSPEE3D, which has a print volume of 1000 x 700 mm and a speed of 1 kilo per minute. By turning to additive manufacturing the army is able to reduce the downtime of its armored vehicles and thus better respond to emergency situations.

By turning to additive manufacturing the army is able to reduce the downtime of its armored vehicles and thus better respond to emergency situations.

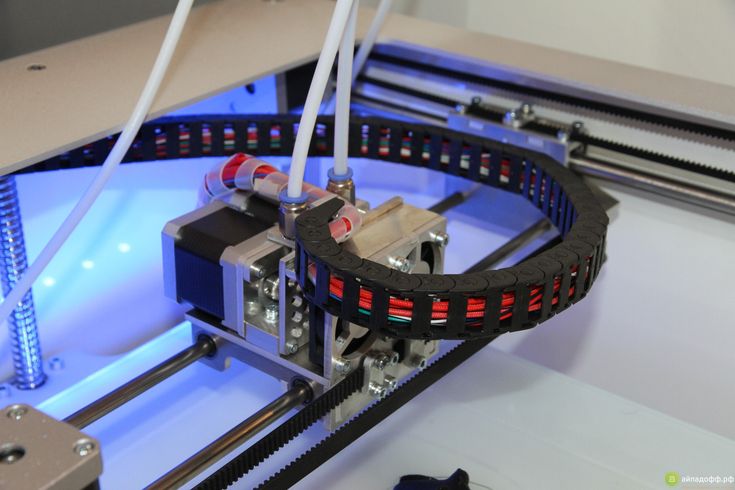

The U.S. Navy and Additive Manufacturing for the Defense Sector

The U.S. Navy has been conducting several additive manufacturing projects for many years now. The goal is to improve the agility and efficiency of the teams going on missions in the middle of the ocean, especially when it comes to manufacturing spare parts. That’s why the Naval Postgraduate School (NPS) invested in Xerox’s ElemX metal machine. It uses it to design spare parts for its submarines and ships, as well as tooling. This allows the company to have a much shorter supply chain and to manufacture custom components. NPS is not alone in launching 3D printing projects in the maritime field. Indeed, the company MatterHackers has signed a 5-year contract with the US Navy to provide all the 3D equipment it would need, as well as training sessions and maintenance. MatterHackers helped the Navy deploy Ultimaker S5 3D printers to design custom parts and other applications.

Indeed, the company MatterHackers has signed a 5-year contract with the US Navy to provide all the 3D equipment it would need, as well as training sessions and maintenance. MatterHackers helped the Navy deploy Ultimaker S5 3D printers to design custom parts and other applications.

The Future Energetics Project, 3D Printing in the UK Defense Sector

The Future Energetics Project from the UK works in the areas of research, explosives testing, novel energetics fabrication, explosion modeling, chemical synthesis, thermal characterization, and hazard testing. The goals of the project are to create new energetic materials and diagnostic methods to validate new materials. Additive manufacturing will be used to develop new explosive formulations. This offers numerous benefits to potential users, including reduced storage and transportation costs and improved performance. Charges can be precisely tailored to requirements and manufactured in novel and intricate designs, which would have been unthinkable before. The manufacturing process uses a LabRAM resonant acoustic mixer, which uses acoustic energy instead of physical blades to mix materials, making the process safer. The 3D printing project is currently still in the testing phase.

The manufacturing process uses a LabRAM resonant acoustic mixer, which uses acoustic energy instead of physical blades to mix materials, making the process safer. The 3D printing project is currently still in the testing phase.

Astro America Has Developed a 3D-Printed Combat Vehicle Hull

The Applied Science & Technology Research Organization, also known as ASTRO America, has been selected by the U.S. Army for the Jointless Hull Project. This program is supported by the U.S. Department of Defense’s beneficiary Institute for Manufacturing Innovation and is part of an effort to use 3D printing to develop and deliver a hull tool for combat vehicles. They hope to reduce manufacturing time and lower production costs while reducing the weight of the vehicle and increasing its performance and survivability.

3D Printed Barracks Helps the US Military Create Sturdy Lodging Anywhere

The 3D construction company ICON is already known for doing projects involving the military. For this particular one, the Austin-based company partnered with the Texas Military Department, Logan Architecture, and Fort Structures to create the largest 3D-printed structure in North America: training barracks at the Camp Swift Training Center in Bastrop, Texas. Using ICON’s Vulcan construction system, which is a tablet-operated robotic printer that works with cement-based material, the collaboration of companies and the military managed to build the first 3D-printed barracks for soldiers to live in. The final construction consists of a 3,800 sq.-ft building that is able to shelter up to 72 soldiers or airmen and prepare for their next missions!

For this particular one, the Austin-based company partnered with the Texas Military Department, Logan Architecture, and Fort Structures to create the largest 3D-printed structure in North America: training barracks at the Camp Swift Training Center in Bastrop, Texas. Using ICON’s Vulcan construction system, which is a tablet-operated robotic printer that works with cement-based material, the collaboration of companies and the military managed to build the first 3D-printed barracks for soldiers to live in. The final construction consists of a 3,800 sq.-ft building that is able to shelter up to 72 soldiers or airmen and prepare for their next missions!

3D Printed Submarine Hull, Taking Additive Manufacturing Undersea for Better Defense

Over the years, the defense sector found ways to apply 3D printing in many areas – On the ground, in the air, and at sea. With this latest project, the US army is literally diving into a 3D printing relatively unknown area: Under the sea. For this new endeavor, Oak Ridge National Laboratory (ORNL) partnered with the U.S. Navy’s Disruptive Technology Lab to help create a 3D-printed submarine hull, the first in military history. By using ORNL’s FDM Big Area Additive Manufacturing (BAAM) technology, the team produced a 30-foot concept hull with 6 carbon fiber composite material sections, which was produced faster and cheaper than it would have been using traditional manufacturing methods. Although still in testing, the signs are good that there will be more 3D-printed submarines diving through the oceans soon.

For this new endeavor, Oak Ridge National Laboratory (ORNL) partnered with the U.S. Navy’s Disruptive Technology Lab to help create a 3D-printed submarine hull, the first in military history. By using ORNL’s FDM Big Area Additive Manufacturing (BAAM) technology, the team produced a 30-foot concept hull with 6 carbon fiber composite material sections, which was produced faster and cheaper than it would have been using traditional manufacturing methods. Although still in testing, the signs are good that there will be more 3D-printed submarines diving through the oceans soon.

What do you think of these examples of applications for additive manufacturing in the defense sector? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

Military Looks for Novel Ways to Employ 3D Printing

Project ICON is developing the technology to 3D print buildings and other large structures.

Project ICON photo

In April, the Army signed a contract for its “Jointless Hull Project,” which has an ambitious goal of developing a 3D metal printer so large that it can create a military truck exterior in one giant piece.

“The mission is to develop a large-scale tool capable of producing single, jointless combat vehicle hulls at a near net size of 30-foot-by-20-foot-by-12 foot in size,” Larry “LJ” Holmes, principal investigator at ASTRO America, the nonprofit that is working with the Army to develop the massive 3D printer, said in a statement.

Additive manufacturing — also known as 3D printing — has been in development for decades and the U.S. military branches and the defense industrial base have both integrated the advanced manufacturing technique in their processes.

However, in January the Defense Department’s Joint Defense Manufacturing Council, the office of the deputy director for strategic technology protection and exploitation and the office of the undersecretary of defense for research and engineering released the Pentagon’s first additive manufacturing strategy.

The document described five goals for the technology: integrate it into the Pentagon and the defense industrial base; promote agile use; develop best practices and proficiency; secure workflows; and support collaboration across services and the federal government.

Meanwhile, a variety of 3D printing programs are proceeding throughout the military.

Aaron LaLonde, additive manufacturing subject matter expert at Army Combat Capabilities Development Command’s Ground Vehicle Systems Center — one of the participants in the Jointless Hull Project — said the manufacturing process will ultimately aid warfighters. “This project will scale the benefits of metal additive manufacturing to a size range that will allow the benefits of the technology to be realized on larger system scale parts and enable next-generation vehicle performance,” he said in a statement.

The Army project is one of many ways the armed services are using additive manufacturing to innovate and make supply chains more resilient.

Proponents say additive manufacturing has the potential to save the Defense Department a substantial amount of money in a time when budgets are being squeezed and sustainment costs are stacking up.

Benjamin Leever, technical director in the manufacturing and industrial technologies division at the Air Force Research Laboratory, said the service has reduced sustainment costs by printing tools and fixturing needed for equipment maintenance.

Low-cost tooling saves money and time without adding additional resources to certify the product, he said.

“We’ve demonstrated that we can impact processes and save millions of dollars a year,” he said at a panel in March hosted by media outlet Defense One.

Because interest from defense contractors is high, the Air Force is working on accelerating the airworthiness certification process for components manufactured by 3D printers, he noted.

Texas Air National Guard Lt. Col. Alex Goldberg, joint technology acquisition innovation officer at the Defense Innovation Unit, added that costs can be high for components that are no longer commonly made.

“You hear these stories of $10,000 for a relatively trivial part,” he said. “The incentive for the actual manufacturer to be able to produce that part is at a level to make it worth their time.”

Additive manufacturing can help the services save funds, officials say. One of the Army’s largest efforts includes reviewing weapons systems parts to see which ones could be recreated with 3D printing — particularly those found in legacy systems, Maj. Gen. K. Todd Royar, commanding general of Army Aviation and Missile Command, told reporters in December.

Goldberg said 3D printing reduces the logistical burden on manufacturers because it increases their ability to distribute on demand at the point of need.

“In the next real conflict, we’re going to have to think of ways to be able to move and be more flexible,” he said.

Goldberg pointed to the Marine Corps’ partnership with the Defense Innovation Unit — Project ICON — to develop the technology to 3D print buildings and other large structures like bridges as an example of what will move the technology forward and spark innovation.

The advanced technology could be game-changing in a natural disaster setting, he noted.

The military could “in a humanitarian crisis be able to leave that infrastructure behind to give a foothold for that [affected] nation-state to be able to climb out of whatever disaster that may be,” he said.

While some peer competitors are outspending the U.S. military in research and development, the Pentagon can leverage advanced manufacturing among other emerging technologies to keep pace, he said.

The COVID-19 pandemic has highlighted the manufacturing competition with adversary China, in particular. President Joe Biden signed an “Executive Order on America’s Supply Chains” in February to explore vulnerabilities that caused a shortage of semiconductors, commonly known as chips.

In 2020, the United States also struggled to procure personal protective equipment, while China dominated exports.

The proliferation of 3D printing technology in the defense industry could mean “actually being able to bring manufacturing back to the United States and be able to create parts and technology and capabilities that previously had just been too costly to do,” Goldberg said.

Meanwhile, federal government policy has also moved to support additive manufacturing. John Wilczynski, executive director at technology accelerator America Makes, said the Biden administration’s executive order to study supply chains could raise awareness about the technology’s advantages in emergencies.

America Makes is an additive manufacturing accelerator managed and operated by the National Center for Defense Manufacturing and Machining.

“Additive is a technology, along with others, that could put us in a position where we have the ability to respond more quickly [to] whatever that might be, whether it’s a crisis or supply chain breakdown,” he said in an interview.

While 3D printing has come a long way, Leever noted that it still needs to overcome consistency and confidence issues. When one part is manufactured, the technology is not advanced enough to guarantee that the same part will be printed exactly the same way at another printer. Additionally, humidity and composition can affect how parts can turn out in different locations.

The commercial and defense industries should be developing printers that can recognize conditions and adjust printing as necessary or find a way to more closely integrate monitoring into the printing process, Leever said.

The private sector has traditionally played a large role in developing the technology. Companies were responsible for approximately 90 percent of all 3D printing patents from 2015 to 2019, according to a Congressional Research Service report, “3D Printing: Overview, Impacts, and the Federal Role.”

Wilczynski noted that a lack of data availability and accessibility also reduces confidence in additive manufacturing.

“It is not insignificant, in terms of time or money, to generate enough data to have confidence in the process in material,” he said. “That has historically not been something that most want to make available to the rest of the community.”

If manufacturers were more willing to share information, it would reduce costs to implement the technology, he said.

Meanwhile, the Army Research Laboratory is looking to expand the materials that can be 3D printed. Brandon McWilliams, the technical lead for metals additive manufacturing, said the service is putting effort toward “really being able to take advantage of the manufacturing freedom that additive presents.”

Next-generation high strength metal alloys and lightweight metal alloys are some of the materials the Army is looking into 3D printing to meet potential performance requirements, he said.

Additionally, the Army has prioritized tracking and standardizing quality by implementing a “digital thread,” he noted. Instead of tracking the engineering of parts through drawings, the service is transitioning to 3D computer aided design, or CAD, models.

Through a digital system, engineers can more easily pinpoint where materials for the product came from, how it was manufactured, what supply chain it came from and what parameters were used to print it.

“That’s really starting to get at defining criticality,” McWilliams said.

Additive manufacturing is an opportunity to learn from the Army’s costly sustainment mistakes, he said. The service wants to work more closely with commercial industry to acquire cutting edge technology, but it needs to position itself to be able to manufacture its own replacement parts.

“They still make it, but we’re going to own the technical data ... so we don’t run into this problem in the future where we’re trying to reverse engineer 40-year-old parts to try and make it again,” McWilliams said.

The Jointless Hull Project is one of the first initiatives aimed at helping the Army take control of its own manufacturing. The service built its own 3D printing hub at Rock Island Arsenal, Illinois, where the project will kick off. The facility reached initial operating capability in 2019 and will be fully operational this year.

The project is organized through LIFT, the Detroit-based, Defense Department-supported National Manufacturing Innovation Institute.

Nigel Francis, the organization’s CEO and executive director, said getting technology to warfighters as quickly as possibly is part of its mandate.

“Developing the ‘jointless hull’ is also aligned with our mission of driving American manufacturing into the future by connecting materials to processes and to the systems involved,” he said.

Topics: Emerging Technologies

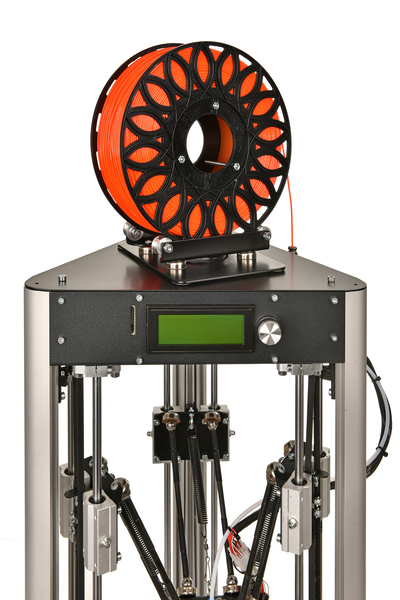

3D printers in military service - big overview

Overview: 3D printers in military service.

Source: https://all3dp.com/

The military industry has always been at the forefront of progress: many inventions either began their life as military or dual-use products, or, in the very first years after their appearance, were involved in this area . In this age of digital technology, this fate has not escaped 3D printing.

3D printers are actively used by military contractors and direct employees of all branches of the military.

In this article, we will talk about the use of 3D printing in the military-industrial complex around the world: from providing military equipment with spare parts, to operational printing of drones and buildings anywhere in the world.

In Russia,

JSC "Federal Research and Production Center "Titan-Barricades", which develops missile systems and military vehicles, has bought and uses in prototyping a kit based on an XJRP SPS450B 3D printer. The kit consists of two devices: directly a 3D printer with a large print area, working on SLA technology, and a polymer curing chamber.

| XJRP SPS450B 3D Prototyping Kit. |

| Source: http://pechat3d.ru/ |

The 3D printer is planned to be used to create miniatures of future parts, cases or mechanism assemblies. The first product made on this 3D printer was a prototype wheel with a tread.

Ilyushin specialists plan to produce some simple parts for the Il-112V military transport aircraft using 3D printing.

| Model of the Il-112V transport aircraft. |

| Source: © ITAR-TASS |

Together with specialists from the Voronezh Aircraft Plant (VASO), PJSC Il specialists use 3D-printed parts as test samples, which will be replaced with originals made by the classical method before departure. But in the future, it is planned to master the printing of simple components that will be installed on mass-produced aircraft.

But in the future, it is planned to master the printing of simple components that will be installed on mass-produced aircraft.

Pavel Chernikov, First Deputy General Director of PJSC Il, said: “The IL-112V is being created from scratch, and many parts and components need to be improved during installation on the aircraft. We started using a 3D printer to see how right or wrong our calculations were. Such technologies make it possible not to interrupt the finalization of finished products, which, in turn, significantly reduces the installation time of equipment and reduces the cost of the production process.”

Research and Production Corporation "Uralvagonzavod" named after F. E. Dzerzhinsky purchased a 3D printer S-Max manufactured by ExOne.

| ExOne S-Max 3D printer. |

| Source: http://3dtoday.ru/ |

This printer is designed for making sand molds. Molds are used for casting metal blanks. As the deputy chief metallurgist of NPK Uralvagonzavod said: “We will no longer have to manufacture expensive foundry equipment for experimental, new products and complex castings of small series. It will be enough for a designer to develop a 3D model of the required casting, according to which, also in 3D, the mold is made. The finished cores will go to the foundry. In addition, they can be transported to solve the problems of the corporation over any distance."

As the deputy chief metallurgist of NPK Uralvagonzavod said: “We will no longer have to manufacture expensive foundry equipment for experimental, new products and complex castings of small series. It will be enough for a designer to develop a 3D model of the required casting, according to which, also in 3D, the mold is made. The finished cores will go to the foundry. In addition, they can be transported to solve the problems of the corporation over any distance."

| A sand mold produced by the S-Max 3D printer, used for casting metal blanks. |

| Source: http://3dtoday.ru/ |

This is not the first professional 3D printing system that Uralvagonzavod uses. In 2015, the company purchased a Fortus 400mc 3D printer manufactured by Stratasys Corporation. This printer is used in the production of parts for the T-14 "Armata" tank and other vehicles manufactured by Uralvagonzavod.

| Tank T-14 ("Object 148") on the platform "Armata". |

| Source: OAO NPK Uralvagonzavod |

Representatives of the enterprise note that the introduction of 3D printing saves time and production resources. It is not required to spend forces on turning metal samples. If a part doesn't fit, it's easier to reprint it than remake it.

Russian Helicopters Holding, according to its CEO Andrey Boginsky, plans to 3D print about a hundred parts for rotorcraft by 2020.

| Andrey Boginsky. |

| Source: © Yuri Smityuk/TASS |

In 2018-2019, it is planned to conduct a series of bench tests in order to obtain all the necessary certificates for printed parts by mid-2020. In total, it is planned to test about a hundred parts and assemblies.

Compared to traditional parts, 3D-printed parts are lighter and their production will be deployed at the Kazan Helicopter Plant. As a result of the use of parts obtained by 3D printing, the holding plans to reduce the cost of products.

As a result of the use of parts obtained by 3D printing, the holding plans to reduce the cost of products.

In the world

The road of army 3D printing is not paved with roses. When we hear about cool 3D printed military projects, we have to consider some of the challenges that come with doing them.

| Soldiers get acquainted with FORTUS. |

| Source: https://all3dp.com/ |

Quality certification problem. Many things that the army is supposed to produce using 3D printing are designed for harsh operating conditions, they are subject to high requirements for compliance with dimensions, geometry and quality, and an unsuccessfully printed part can lead not only to monetary losses, but also to the death of soldiers . This issue will most likely be resolved by certification of the 3D printers themselves.

Insufficient printing speed for the army. Even the most expensive 3D printer is not fast enough. There are also issues of privacy/security, copyright, and many other little things that are not obvious at first glance.

Even the most expensive 3D printer is not fast enough. There are also issues of privacy/security, copyright, and many other little things that are not obvious at first glance.

While these issues are being addressed, the US Department of the Navy has decided to host a 3D printing hackathon. 12 organizations were invited to participate, which showed their developments in the field of 3D printing for the Navy. According to the participants, fully or partially printed inventions: “Allow to improve the ability to maintain combat readiness.”

One of the new and memorable developments was the four-legged transporter robot (MeRlin). It turned out to be quite compact and can run, jump and walk up and down stairs. Three-dimensional printing made it possible to create, right in the supporting frame of the robot, a hydraulic manifold that serves to transfer energy to the robot drives. Those interested in robotics will find Merlin similar to the transport robots of Boston Dynamics.

| The device of the robot MERLIN (Merlin). |

| Source: https://all3dp.com/ |

Aviation

A 3D-printed drone was launched from one of the British Royal Navy ships at sea, HMS Mersey. The device was created in collaboration with the University of Southampton.

| Launch of a 3D printed drone. |

| Source: https://all3dp.com/ |

Body made of nylon, laser sintered. With a wingspan of one and a half meters, the drone weighs only three kilograms. The main task of this project was to create a small drone for exploring the surroundings, which can be quickly printed on board the ship.

The drone, named SULSA, was equipped with a small video camera. Management was carried out by researchers from Southampton using video cameras. The flight, with a range of 500 meters, lasted only a few minutes, but proved that 3D printed drones could be launched from the sea.

| The route of the SULSA drone during a test flight. |

| Source: https://www.southampton.ac.uk/ |

3D printing solves the problem of ship capacity by allowing equipment to be printed at sea as needed. The only thing you need to have on board to print a drone is a 3D printer and a supply of nylon, which is disproportionately cheaper than a case made using traditional technologies, and takes up much less space.

The only drawback is the print speed, but it is expected to improve in the near future. Engineers from the American Army Research Laboratory (ARL) are trying to fight this shortcoming. They are developing drones that can be made within a day. Engineers are building drones that can be used to assist soldiers in communication, delivery, and aerial surveillance.

Eric Sopero demonstrates his drone to US military personnel. |

| Source: https://all3dp.com/ |

Drones are made using off-the-shelf motors and propellers, but their body is almost entirely 3D printed. The maximum speed of the drone is 55 miles per hour. Drones can either be controlled by the operator from the remote control or operate in a completely autonomous mode. Work continues to reduce noise and increase flight range, maneuverability and payload.

The US Army is partnering with the Marine Corps to develop an unmanned vehicle parts catalog that can be downloaded to an employee's tablet. The software of this catalog allows you to order or 3D print a product directly from it.

| American soldier with a drone. |

| Source: https://all3dp.com/ |

In addition to experiments with drones, 3D printing is also used in “big” aviation.

For example, the US Air Force has announced that it will 3D print toilet seats for military transport aircraft. The announcement comes after a scandal erupted when it was reported that each toilet seat cost the Air Force $10,000 to replace.

The announcement comes after a scandal erupted when it was reported that each toilet seat cost the Air Force $10,000 to replace.

| Airplane seat for $10,000. |

| Source: https://all3dp.com/ |

The public, which already believed that the government did not always save on military spending, was extremely outraged. After an investigation initiated by one of the senators, the military department announced that it would print toilet seats on 3D printers.

Why is the toilet lid so expensive? These covers were mass-produced by Lockheed Martin, and in 2001 this giant of the military industry stopped their production. In addition, the military department explained that the C-5 toilet seat is not only a cover, but also part of the lavatory wall, which is designed to protect the body of the aircraft from corrosion that can be caused by urine.

According to the manufacturer, its high cost is due to the need to suspend the production of other goods. In the case of independent production of the Air Force, the spare part will cost only $300.

In the case of independent production of the Air Force, the spare part will cost only $300.

The manufacturer now claims that the US Air Force does not own the copyright to this cap. It is not known how this lawsuit will end, but the Air Force says that they will no longer buy this spare part, because they can make it themselves much cheaper.

As stated by the department: “The use of 3D printing allows us to create parts that are no longer being produced, resulting in significant cost savings.”

| C-5 transport aircraft. |

| Source: https://all3dp.com/ |

Another example of 3D printing was demonstrated by the Maryland Marines. Using 3D modeling and 3D printing, they made a $70,000 F-35 fighter jet part for just 9 cents. The Marines were assisted by Sam Pratt, a mechanical engineer in the design office of the Carderock Additive Technology Factory.

Sam revealed that he was with a support platoon in South Korea teaching CLB-31 Marines how to design 3D models and how to use 3D printing. His main task was to test the performance of 3D printers on marine vessels. He also taught employees how to use Solidworks CAD.

His main task was to test the performance of 3D printers on marine vessels. He also taught employees how to use Solidworks CAD.

| Sam Pratt talks to the Marines about 3D printing. |

| Source: https://all3dp.com/ |

When there was a problem printing a part needed to repair an F-35, a Marine officer offered to team up to cooperate. It turned out that the employees had already developed this part, but could not find the right dimensions. The fact is that they used a hobby-grade 3D printer and the free 3D editor Blender - Blender is ideal for implementing art projects, but it is difficult to create engineering products in it.

| American Marine at the 3D printer. |

| Source: https://all3dp.com/ |

Pratt helped with modeling and printing issues, the part was printed in PET-G.

Currently there are about 90 parts for ground vehicles that are approved for 3D printing in the military, you can download one of these parts and print it.

Large manufacturers are also moving forward and mastering 3D printing technologies. Thus, the giant of the aviation and military industry Lockheed Martin is actively investing in 3D printing.

Lockheed Martin uses 3D printing in its manufacturing processes, with over a hundred 3D printers in its arsenal for prototyping, tooling and printing finished products.

There are several reasons why Lockheed Martin uses 3D printing:

- Reducing the time of production of products - up to 80%;

- Reducing the weight of parts - up to 40%;

- Proven reliability of parts in difficult conditions;

- The most important thing is the possibility of an additional increase in production in the near future.

For example, it takes 18 to 20 months to manufacture fuel tanks for spacecraft using traditional technologies. The production of such a tank by 3D printing takes two weeks. In this case, a better uniformity of the structure of the tank elements is achieved. The tanks are manufactured using a Sciaky printer using EBAM (Electron Beam Direct Manufacturing) technology, in which a bar of metal material is heated by an electron beam.

The production of such a tank by 3D printing takes two weeks. In this case, a better uniformity of the structure of the tank elements is achieved. The tanks are manufactured using a Sciaky printer using EBAM (Electron Beam Direct Manufacturing) technology, in which a bar of metal material is heated by an electron beam.

| Lockheed Martin uses 3D printing in its manufacturing processes. |

| Source: https://all3dp.com/ |

Lockheed Martin's 3D printed products have already passed the lab testing stage and are in active use. Some of them travel around our solar system: the Jupiter-exploring Juno satellite has eight 3D-printed brackets, and the Orion spacecraft uses printed high-pressure valves.

Fleet

South Korea is 3D printing loudspeaker grilles for aircraft carriers. Shipping these gratings from Europe took up to seven months and cost $612 each. The printed part is made in 4-5 hours and costs about $35. Printing parts reduces their cost and production time, and localization of production reduces dependence on foreign supplies, which may be delayed or become unavailable for various reasons.

Printing parts reduces their cost and production time, and localization of production reduces dependence on foreign supplies, which may be delayed or become unavailable for various reasons.

General Electric has contracted with the US Navy to develop software for rapid 3D printing of spare parts for ships, aircraft and other critical military installations. The contract, worth nine billion dollars, is designed for four years and provides for the creation of technology "digital duplicates" - a complex of software, base models and hardware. This technology will be used both for those spare parts that are no longer manufactured, and for new parts of ships and aircraft.

| Concept Laser M2 3D printer printing with metal powder. |

| Source: https://all3dp.com/ |

The project is being implemented in two stages: at the first stage, software and hardware parts will be developed, at the second stage they will be combined into a complex capable of quickly creating the necessary products using laser metal melting technology (DMLM).

Ammunition and small arms

The US Army has designed and 3D printed a fully functional grenade launcher called "R.A.M.B.O". The development of the grenade launcher took about six months. He fires 3D printed grenades

| R.A.M.B.O. grenade launcher |

| Source: https://all3dp.com/ |

The grenade launcher consists of 50 parts, all of which, with the exception of springs and hardware, are printed on a 3D printer.

| 3D printed parts of the R.A.M.B.O. |

| Source: https://all3dp.com/ |

R.A.M.B.O. demonstrated characteristics similar to the M203 underbarrel grenade launcher made in the traditional way.

A US Marine team is 3D printing and testing small explosive containers that can be used on the battlefield.

3D printed container for explosives. |

| Source: https://all3dp.com/ |

The development of small arms began in the private sector, with the most primitive pistols. On the Internet, you can find drawings of products such as the sensational Liberator. The first 3D printed pistol was printed on a professional Stratasys Dimension SST printer. The gun is chambered for 9 caliber rounds.mm and is charged during assembly.

| A gun whose main components are made of plastic and printed using a 3D printer. Frame: YouTube. |

| Source: YouTube |

The very possibility of obtaining weapons using 3D printing so excited the public that the drawings of the "Liberator" were withdrawn from public access, and the United States introduced a ban on 3D-printed weapons.

Solid Concepts has created a replica of the .45 Browning M1911 pistol, the Solid Concepts 1911 DMLS, using selective metal laser sintering. The first sample withstood 50 shots, later ones are capable of firing 600 shots without visible damage.

The first sample withstood 50 shots, later ones are capable of firing 600 shots without visible damage.

| A working replica of a .45 Browning pistol M1911 - Solid Concepts 1911 DMLS, made by selective metal laser sintering. |

| Source: Solid Concepts Inc |

Recently, the ban on the distribution of 3D printed weapons was lifted by a court decision. So, it is now possible to print weapons in the USA, with some restrictions: they can be no more than 50 mm in caliber and models cannot be freely available. This ban was easily circumvented by Defense Distributed, which posted models of their rifle for sale on one of the online services.

| M4 rifle from Defense Distributed. |

| Source: https://depositphotos.com/ |

“Our models are not in the public domain because customers pay money for them,” a company spokesman said.

Uniforms and protection

The Vatican decided to use 3D printing technology for the production of traditional Swiss Guard headdresses.

| Swiss Guard. |

| Source: https://all3dp.com/ |

The Swiss Guard is the personal bodyguard of the Pope. From time immemorial, their form was made of metal, but now they have decided to keep up with the times. A 3D printed helmet will be significantly cheaper and, more importantly, lighter.

| 3D printed helmet prototype. |

| Source: https://all3dp.com/ |

The helmets are made of PVC and bear the coat of arms of Pope Julius II, who founded the Swiss Guard in 1506.

The US military turned to the creators of the Iron Man costume, a movie character, for help in creating uniforms for the soldier of the future. The military commissioned Legacy Effects to develop and print the prototype components for the TALOS Special Outfit Kit.

The military commissioned Legacy Effects to develop and print the prototype components for the TALOS Special Outfit Kit.

TALOS will contain a cooling system to maintain a comfortable temperature in the suit, a tactical display and an integrated exoskeleton.

| The concept of the uniform of the future - a set of special uniforms TALOS. |

| Source: http://3dprintingindustry.com/ |

The studio team will join the large team already working on the project, which includes bioengineers, combat veterans and technologists.

Building

The US Army Research Engineering Team printed a large building in just 21 hours. The area of the building is 47.5 square meters. The barrack-style building is the result of a three-year US Army Construction Engineering Research (ACES) program with a laboratory in Champagne, Illinois.

3D printed barracks. |

| Source: https://all3dp.com/ |

Such a short construction time means that such temporary structures will become more affordable with the development of 3D printing. These buildings can be used as housing for refugees or temporary housing in case of natural disasters.

| The process of building a 3D printer. |

| Source: https://all3dp.com/ |

The building looks like an ordinary house, but in the future such buildings can be given any look. Such buildings are also more energy efficient than traditional ones - they require less energy for heating and cooling.

ACES cuts the amount of building materials used in half. Reducing the need for labor is 62%, compared with the construction of plywood structures.

Laying concrete mix with a construction 3D printer. |

| Source: https://all3dp.com/ |

ACES allows buildings to be printed using local materials.

Self-Sufficiency

A collaboration between the US Army Research Laboratory and the Marine Corps has led to the development of a technology to produce 3D printed PET filament from plastic waste such as water bottles.

According to the military, water bottles and plastic packaging are the most common litter on the battlefield. Both US and allied forces produce large amounts of this waste, and the ability to recycle it will reduce the cost of transporting raw materials. The filament obtained from recycled materials, provided that it is properly cleaned and dried, is completely equivalent in tensile strength to its analogue from primary raw materials.

| Joint work of employees of the Research Laboratory of the US Army and the Marine Corps. |

Source: https://all3dp. com/ com/ |

A plant is being developed, housed in a standard shipping container, that will allow the production of filament from waste.

The US Army is also developing food printers. Their advantages are obvious:

- the possibility of reducing the cost of food, compared with the traditional delivery of rations from abroad;

- the possibility of compiling an individual menu, in accordance with the preferences of each soldier;

- the possibility of individual balancing of the diet, depending on the dietary needs of each soldier.

The printer, like classic 3D printers, stacks components in layers.

| 3D printed food. |

| Source: https://all3dp.com/ |

The printer uses the ultrasonic agglomeration method to 3D print small snacks.

Electronics

Researchers at the University of Massachusetts Lowell have developed a new way to 3D print conductive components for radar systems. They have created a new type of ink that allows radars to be made using 3D printing.

They have created a new type of ink that allows radars to be made using 3D printing.

| Electronic components obtained by 3D printing. |

| Source: https://all3dp.com/ |

The development was sponsored by Raytheon, one of the defense industry companies.

According to the developers: “The use of this technology makes it possible to obtain cheaper and more versatile systems than those obtained by classical methods. This technology has obvious advantages in the military sphere, but it can also be used in civilian industry, for example, in the production of weather stations or unmanned vehicles. The main problem was obtaining ink with desired properties, capable of working with high-frequency radiation.”

| Applying ink to a plastic plate. |

| Source: https://all3dp.com/ |

The 3D printer is equipped with two heads with different operating principles. One applies the ink by spraying, the second fixes them by microvibration. Radar system components such as a voltage controlled capacitor (varicap), phase shifter (for electronic control of phase array radar systems) and frequency filters can be manufactured using this technology.

One applies the ink by spraying, the second fixes them by microvibration. Radar system components such as a voltage controlled capacitor (varicap), phase shifter (for electronic control of phase array radar systems) and frequency filters can be manufactured using this technology.

The ink material is based on nanoparticles that can be injected into molten plastic and then solidify with it, creating conductive structures.

The US Air Force Research Laboratory teamed up with American Semiconductor to create a silicon-polymer memory chip.

Using 3D printing technology, they have developed a new ultra-flexible chip with built-in sensors.

| Dan Berrigan holding the new flexible chip. |

| Source: https://all3dp.com/ |

According to American Semiconductor, the thickness of the silicon wafer is 2000 angstroms. This tiny chip can measure humidity levels, temperature, muscle fatigue, and so on. This makes it ideal for use in new technologies for monitoring the well-being of wounded soldiers or the elderly.

This makes it ideal for use in new technologies for monitoring the well-being of wounded soldiers or the elderly.

Flexible electronics technology is being developed not only by research laboratories, but also by industry giants.

Apple, Boeing and the Massachusetts Institute of Technology formed an alliance to collaborate with the US Department of Defense in the field of flexible electronics.

The goal of the alliance is to have high quality flexible electronics by 2020.

The Department of Defense plans to provide a consortium called the FlexTech Alliance with $75 million over 5 years and raise $96 million in additional funding.

| Smart clothes. |

| Source: https://all3dp.com/ |

The consortium includes 96 companies, 11 specialized laboratories, 42 universities and 14 state and regional organizations. The key partners of the consortium are Apple, Boeing, General Electric, General Motors, Lockheed Martin, Motorola Mobility, Qualcomm and many others. Partner universities include Cornell, Harvard, Stanford, New York University and the Massachusetts Institute of Technology.

Partner universities include Cornell, Harvard, Stanford, New York University and the Massachusetts Institute of Technology.

Practical applications will be primarily focused on military targets, such as uniforms with vital sign monitors. Pressure sensors can also be installed on vehicles to monitor deformation in key areas.

The civilian application of such microcircuits will help athletes control body function and improve performance, and people suffering from cardiovascular disease, control and prevent seizures. This technology will allow hospitals to monitor their patients en masse.

Concepts or Looking Ahead

British scientists and engineers are working on growing military drones using chemical technology.

| Hydroponic chemputter. |

| Source: https://all3dp.com/ |

Military developers explore all possible and impossible technologies. In this case, they are working on a "chemcomputer". “Chemputer” is a registered trademark of BAE Systems. The technology is being developed by Professor Lee Cronin of the University of Glasgow and is a 3D printing of biomaterial drones and aircraft.

In this case, they are working on a "chemcomputer". “Chemputer” is a registered trademark of BAE Systems. The technology is being developed by Professor Lee Cronin of the University of Glasgow and is a 3D printing of biomaterial drones and aircraft.

Unlike classic 3D printers, a chemputter performs chemical reactions at the molecular level, creating everything from electronics to wings.

| Drone prototypes. |

| Source: https://all3dp.com/ |

While British scientists are inventing new technologies in printing for the military department, simple makers are creating weapons of the future using conventional 3D printers.

So, David Wirth created a hand railgun in his workshop.

| David Wirth with his railgun. |

| Source: https://all3dp.com/ |

Possibly inspired by the computer game Quake, he created this weapon using CAD, a 3D printer and an Arduino platform. The railgun can use aluminum or graphite bullets as ammunition, firing them at a speed of 250 m/s. The design is based on six huge capacitors, which, with a total weight of about nine kilograms, store more than 1800 joules of energy for each shot. The railgun also consists of batteries, two parallel contact rails and a pneumatic ammunition supply system.

The railgun can use aluminum or graphite bullets as ammunition, firing them at a speed of 250 m/s. The design is based on six huge capacitors, which, with a total weight of about nine kilograms, store more than 1800 joules of energy for each shot. The railgun also consists of batteries, two parallel contact rails and a pneumatic ammunition supply system.

| Diagram of a railgun by David Wirth. |

| Source: https://all3dp.com/ |

Conclusion

3D printing technology is increasingly used in the military. The main role in its promotion is played by the need to reduce costs. On-site 3D printing of parts helps to solve the problems of logistics and supply, allowing you to save time and money on delivery, which is important for the army and aviation, and even more so for the navy - it is impossible to foresee ashore and take with you everything that you might need, and delivery boarding at sea is expensive.

We have cited only a small part of the military cases as examples - it is impossible to describe in one article all the prospects for the use of 3D printing in the military industry. And most of the solutions used by the military in production are also relevant for the civilian sector.

You can buy a 3D printer for production in Top 3D Shop — our experts will help you choose the best equipment for solving any tasks.

. 112V, corporation "Uralvagonzavod", 3D printer S-Max

News

NewsSearch by name:

The international cooperation Youth policy The science Science and education News of the Ministry Education

Search by date:

2020 2021 2022

reset filter

6

October

Russia strengthens cooperation in the field of education with the countries of the Caspian region

Round table "Law and scientific diplomacy for the sustainable development of the Caspian region" brought together more than 30 participants from Russia, Azerbaijan, Iran, Kazakhstan and Turkmenistan. The event was chaired by Deputy Minister of Science and Higher Education of the Russian Federation Natalya Bocharova as part of the Second Caspian Economic Forum, which took place in Moscow on October 5–6.

The event was chaired by Deputy Minister of Science and Higher Education of the Russian Federation Natalya Bocharova as part of the Second Caspian Economic Forum, which took place in Moscow on October 5–6.

International cooperation

6

October

69 regions joined the implementation of the federal project "Platform of University Technological Entrepreneurship"

69 regions joined the implementation of the federal project "Platform of University Technological Entrepreneurship". This was announced by Deputy Prime Minister Dmitry Chernyshenko.

Ministry News

6

October

Scientists have come close to solving the main problem of cryonics

The study of water, its states and forms is one of the important tasks of science. Molecular dynamics analysis of water in the state of amorphous ice was carried out by scientists from the Moscow Institute of Physics and Technology (MIPT). Amorphous ice is practically not found on Earth, but is the most common form of H 2 O in the Universe (included in interstellar dust and comet nuclei). His research is very relevant in cryonics - the technology of preservation using deep cooling. In order for the cell to come to life after freezing, it is necessary that the water does not crystallize, but remains in the amorphous phase.

Amorphous ice is practically not found on Earth, but is the most common form of H 2 O in the Universe (included in interstellar dust and comet nuclei). His research is very relevant in cryonics - the technology of preservation using deep cooling. In order for the cell to come to life after freezing, it is necessary that the water does not crystallize, but remains in the amorphous phase.

Science

6

October

“Women: School of Mentoring”: the final of the first season and the start of new tracks

The results of the first season of the project of the Russian Ministry of Education and Science “Women: School of Mentoring” were summed up at the Central House of Scientists. At the solemn meeting, the brightest projects prepared by the students together with their famous mentors were presented. Three new tracks were also launched, which will be released in the second season of the project.

Ministry News

5

October

Valery Falkov visited a new educational cluster at the Gubkin Russian State University of Oil and Gas

LUKOIL center. The Minister of Science and Higher Education of the Russian Federation, Valery Falkov, got acquainted with the new training program, and also examined the modern classrooms and the site of the training ground at the university.

The Minister of Science and Higher Education of the Russian Federation, Valery Falkov, got acquainted with the new training program, and also examined the modern classrooms and the site of the training ground at the university.

Ministry News

5

October

In 2023, the construction of world-class campuses will start in the Chelyabinsk and Nizhny Novgorod regions

The first concession agreements for the implementation of projects to create world-class campuses in the Chelyabinsk and Nizhny Novgorod regions were signed. By 2024, it is planned to launch the first accommodation facilities for about two thousand students.

Ministry News

5

October

Pacific State University was headed by the winner of the superfinal of the Leaders of Russia competition

Acting Rector of the Pacific State University (TOGU) Yuri Marfin at a meeting with the Governor of the Khabarovsk Territory Mikhail Degtyarev was introduced by State Secretary - Deputy Minister of Science and Higher Education of the Russian Federation Petr Kucherenko.