Market bot 3d printer

3D Printing Software & Apps

Cloud-Powered 3D Printing

MAKERBOT CLOUDPRINT™

Print and monitor your project - from your browser straight to your MakerBot 3D Printer. Add the Print from CAD integration for your favorite CAD program and start a print in just two clicks.

PREPARE AND LAUNCH 3D PRINTS FROM ANYWHERE

Open a native CAD file in MakerBot Cloud, adjust your print settings, and start a print on your connected MakerBot 3D printer. No downloads or updates required.

Cloud-Powered 3D Printing

MAKERBOT CLOUDPRINT™

Print and monitor your project - from your browser straight to your MakerBot 3D Printer. Add the Print from CAD integration for your favorite CAD program and print in just two clicks.

PREPARE AND LAUNCH 3D PRINTS FROM ANYWHERE

Open a native CAD file in MakerBot Cloud, adjust your print settings, and start a print on your connected MakerBot 3D printer. No downloads or updates required.

Streamline Your 3D Printing

Discover, import, prepare, manage, monitor, and share your 3D prints. MakerBot’s software and apps optimize and streamline the 3D printing process for any workflow or environment.

Streamline Your 3D Printing

MAKERBOT 3D PRINTING

SOFTWARE + APPS

Discover, import, prepare, manage, monitor, and share your 3D prints. MakerBot’s software and apps optimize and streamline the 3D printing process for any workflow or environment.

Best-in-class 3D printing software

MAKERBOT PRINT

MakerBot Print is the best and easiest way to prepare, manage, monitor, and share your 3D print files. Enjoy the best of everything that 3D printing has to offer on your Mac, PC or in the Cloud.

PREPARE AND PREVIEW 3D PRINTS

Import design files and fine-tune settings for optimum results when printing.

IMPORT NATIVE CAD FILES

Streamline print preparation and file management with native CAD file support.

CLOUD-ENABLED 3D PRINTER MANAGEMENT

Control and monitor multiple 3D printers via live camera feeds and print status updates.

Best-in-class 3D printing software

MAKERBOT PRINT

MakerBot Print is the best and easiest way to prepare, manage, monitor, and share your 3D print files. Enjoy the best of everything that 3D printing has to offer on your Mac, PC or in the Cloud.

PREPARE AND PREVIEW 3D PRINTS

Import design files and fine-tune settings for optimum results when printing.

IMPORT NATIVE CAD FILES

Streamline print preparation and file management with native CAD file support.

CLOUD-ENABLED 3D PRINTER MANAGEMENT

Control and monitor multiple 3D printers via live camera feeds and print status updates.

Discover millions of free 3D printable Things

THINGIVERSE

Thingiverse is the world’s largest 3D printing community with over 1. 7 million 3D printable models. Browse all of the designs, remix them using Thingiverse apps, or share your work with the world!

7 million 3D printable models. Browse all of the designs, remix them using Thingiverse apps, or share your work with the world!

EXPLORE THINGIVERSE

Discover millions of free 3D printable Things

THINGIVERSE

Thingiverse is the world’s largest 3D printing community with over 1.7 million 3D printable models. Browse all of the designs, remix them using Thingiverse apps, or share your work with the world!

EXPLORE THINGIVERSE

Hundreds of free 3D printing lessons

THINGIVERSE EDUCATION

Thingiverse Education provides hundreds of free 3D printing lessons that make teaching with a 3D printer easier and more effective for a variety of grade levels and subjects. It also provides a community where educators can exchange best practices or remix projects.

EXPLORE THINGIVERSE EDUCATION

Hundreds of free 3D printing lessons

THINGIVERSE EDUCATION

Thingiverse Education provides hundreds of free 3D printing lessons that make teaching with a 3D printer easier and more effective for a variety of grade levels and subjects. It also provides a community where educators can exchange best practices or remix projects.

It also provides a community where educators can exchange best practices or remix projects.

EXPLORE THINGIVERSE EDUCATION

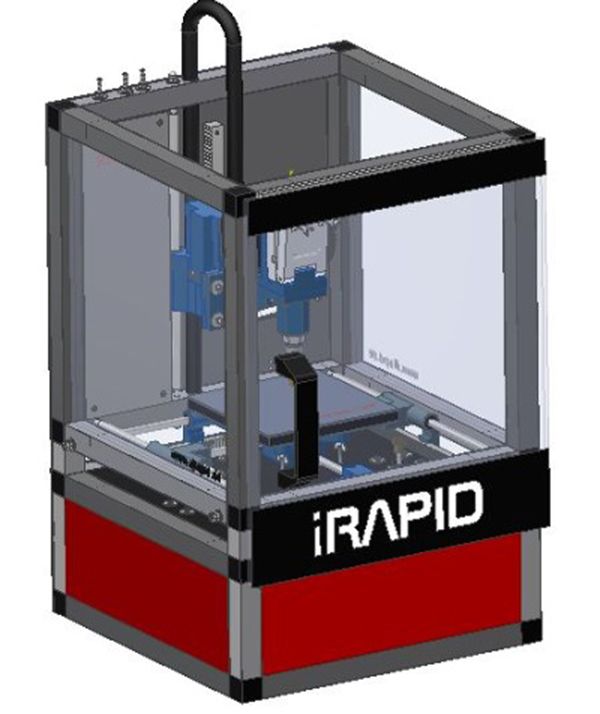

METHOD

INDUSTRIAL 3D PRINTING FOR EVERY ENGINEERNext-Generation desktop 3D printing platform that delivers manufacturing-grade parts with advanced engineering materials.

SKETCH CLASSROOM

THE IDEAL CLASSROOM SETUP

The most reliable classroom 3D printing setup, giving your students the access they need and setting you up for classroom success.

A manufacturing workstation

METHOD

Print real, production-grade ABS with a 100°C chamber—powered by Stratasys®.

SKETCH CLASSROOM

THE IDEAL CLASSROOM SETUP

The most reliable classroom 3D printing setup, giving your students the access they need and setting you up for classroom success.

Industry-Leading Quality

MAKERBOT 3D PRINTING MATERIALS

Materials optimized to give you the best results and highest quality with MakerBot 3D Printers.

MakerBot Replicator 5th Generation Review

3.3

See Price

MakerBot’s Replicator is among the top well-known 3D printers on the market. There are various different versions available, but it goes without saying that some are better than others. Today, we’ll be taking a closer look at one of the lesser-known models – the Replicator 5th Generation.

We’ll be keeping an eye out for any strengths or weaknesses this printer might have. Who knows – while it’s been replaced by the Replicator+, maybe it has benefits that later models don’t. You’ll have to read our full review below to find out.

| Filament Diameter | 1.75mm |

| Extruders | 1 |

| Supported Materials | PLA |

| Connectivity | USB, WiFi |

| Printing Speed | 150mm/s |

| Build Volume | 9. 92 in x 7.83 in x 5.9” 92 in x 7.83 in x 5.9” |

Table of ContentsShow

Design

It’s easy to be intimidated by the large, looming frame of the 5th Generation. However, it’s designed to be accessible and easy to use. Take the chassis, for instance. It’s built to accommodate an enclosure, in case you’re having difficulty maintaining a consistent temperature during a print.

Of course, because of the printer’s size, the build area looks relatively small. In actuality, it’s larger than most, except for when it comes to depth. Still, there’s a lot of potential here, especially if you’d like to print models larger than most 3D printers will allow.

Let’s be clear: this printer is probably too big for your desktop. It’s pretty clearly designed for professionals, so you’re really expected to have a designated printing area set up. Since the extruder can move up to 150mm/s, you can expect it to be a little louder than most, too.

Printing

Overall, the Replicator 5th Generation has average-to-good print quality. We were a little underwhelmed by the 0.5mm minimum layer size, but for general day-to-day printing, it’ll do just fine. The problem is that this printer is intended for experienced users, yet offers very little to draw these people in.

We were a little underwhelmed by the 0.5mm minimum layer size, but for general day-to-day printing, it’ll do just fine. The problem is that this printer is intended for experienced users, yet offers very little to draw these people in.

For instance, you’re limited to PLA filament. We’ve seen open-source, $200 printers that can handle more materials than this one, and for a company like MakerBot, that’s just embarrassing. Its speed might have helped redeem it, but 150mm per second hardly makes it the fastest printer around.

For what it’s worth, it does replicate models pretty well. Mechanical gears, for instance, rarely need any post-processing in order to work properly. That said, at this price, you really expect it to excel in some way, and that’s simply not the case.

Features

It’s not all bad, though. The LCD screen is an absolute joy to use, with clean, well-organized menus and a control dial to save space on the unit itself. There are even WiFi capabilities so you can print while away from the machine. There’s also the option to print from a USB stick, but not an SD card.

There’s also the option to print from a USB stick, but not an SD card.

We’d be remiss if we didn’t mention the smart extruder. The Replicator series claims to be the only range of printers with a hot-swappable extruder, meaning if one stops working, you don’t have to halt production. It’s also more reliable than traditional extruders, which can only be a good thing.

The print bed, unfortunately, isn’t heated. This means that you’ll be relying on tape or other sticky surfaces to keep your prints stable. We were pleased to see that there is an automatic leveling function, though, so you don’t have to waste time getting set up for a print every single time.

Cost

So far, the Replicator 5th Generation sounds decent for a mid-range printer. There’s an issue, though: it’s priced like a premium one. While it’s no longer available directly from MakerBot, it retails on third-party sites for around $2000. Even after a couple of years, this price stays too high to be viable.

On the plus side, PLA is about as cheap a filament as you can get. You can actually use a third-party filament, but you might have to download a user-created print mode in order to do so. It’s a bit of a shame: if users can build these on their own, MakerBot could easily have just included them as standard. Of course, this would hurt their bottom line, so they didn’t.

The Replicator 5th Generation really struggles to justify its high price. It has decent performance across the board, but nothing particularly stands out about it. If you’re a collector or 3D printing enthusiast, by all means, buy one, but most people can find something better at a lower price.

Support

MakerBot’s website has tutorials and support for all of its printers… except for the 5th Generation. If you need help, you can search for general information using keywords, or you can call them on the phone during office hours. There used to be email support, but we’ve heard reports that they no longer reply.

There’s a little confusion regarding this product’s warranty, too. In the user manual, it claims that the 5th Generation is covered by a limited warranty and links to the terms. However, while most other printers are referred to specifically, there’s no mention of this one. You should still qualify for some kind of third-party warranty, but it might be worth trying your luck regardless.

This simply isn’t good enough. Even for a model that’s no longer actively sold, users should know up front if they’re protected should something go wrong. While we can overlook this from smaller manufacturers, MakerBot has the money and legal resources to take better care of its legacy customers.

Not the MakerBot 3D printer that you want? Check our review about the MakerBot Replicator 2, this one might be the one that you’re looking for.

3D printers with different kinematics: comparison, pros and cons

Author: Vasily Kiselev, owner and managing director of Top 3D Group

There are many printing technologies for 3D printers: digital LED projection (DLP) , laser stereolithography (SLA), selective laser sintering (SLS), thermal sintering (SHS), etc. In this article, we talk about the features of FFF technology, about the printers that use it, and about its strengths and weaknesses.

In this article, we talk about the features of FFF technology, about the printers that use it, and about its strengths and weaknesses.

Introduction

Fused Filament Fabrication (Fused Filament Fabrication) printers, also known as Fused Deposition Modeling (FDM) printers. They are devices for creating three-dimensional objects, as the name implies, by layer-by-layer application of molten thermoplastic to the working surface. FFF printers are used for both commercial and home model printing.

Types of kinematics of 3D printers

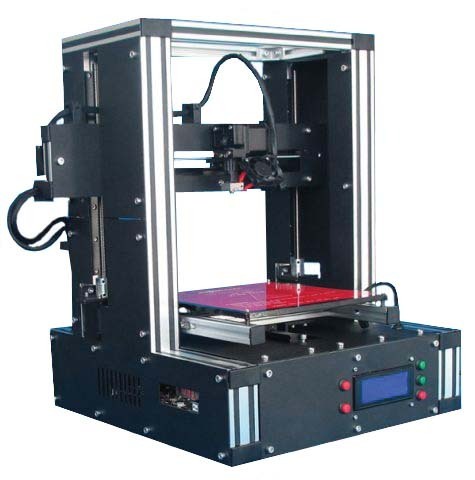

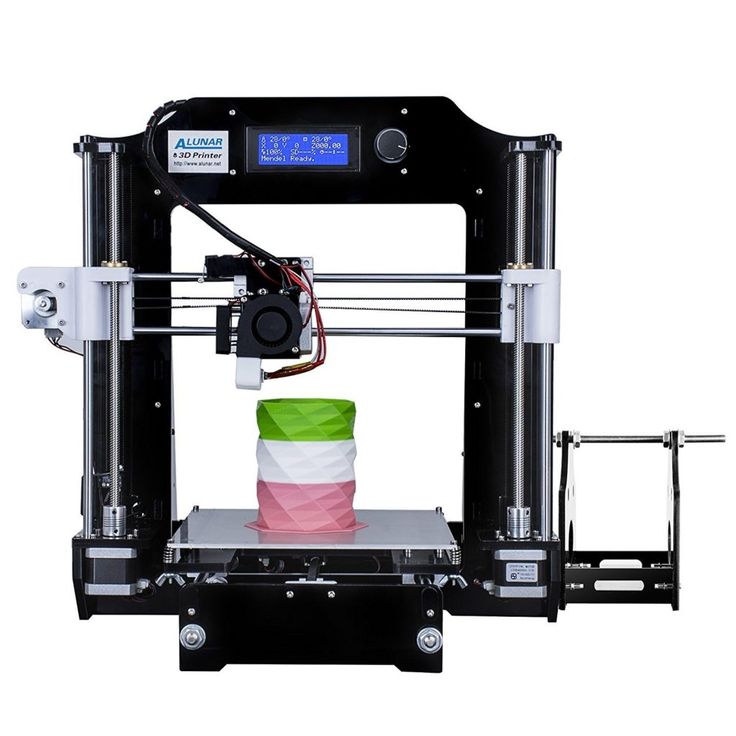

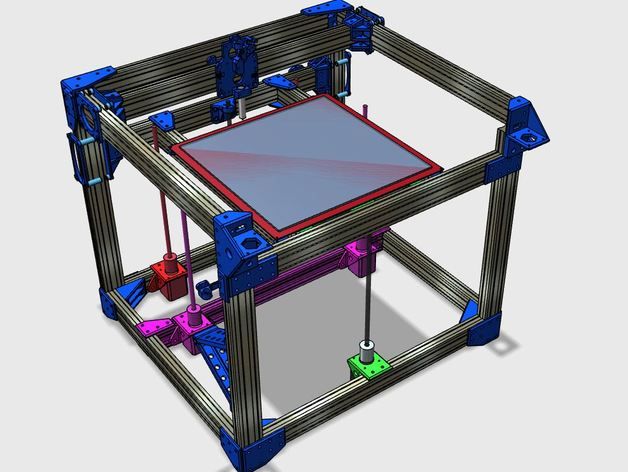

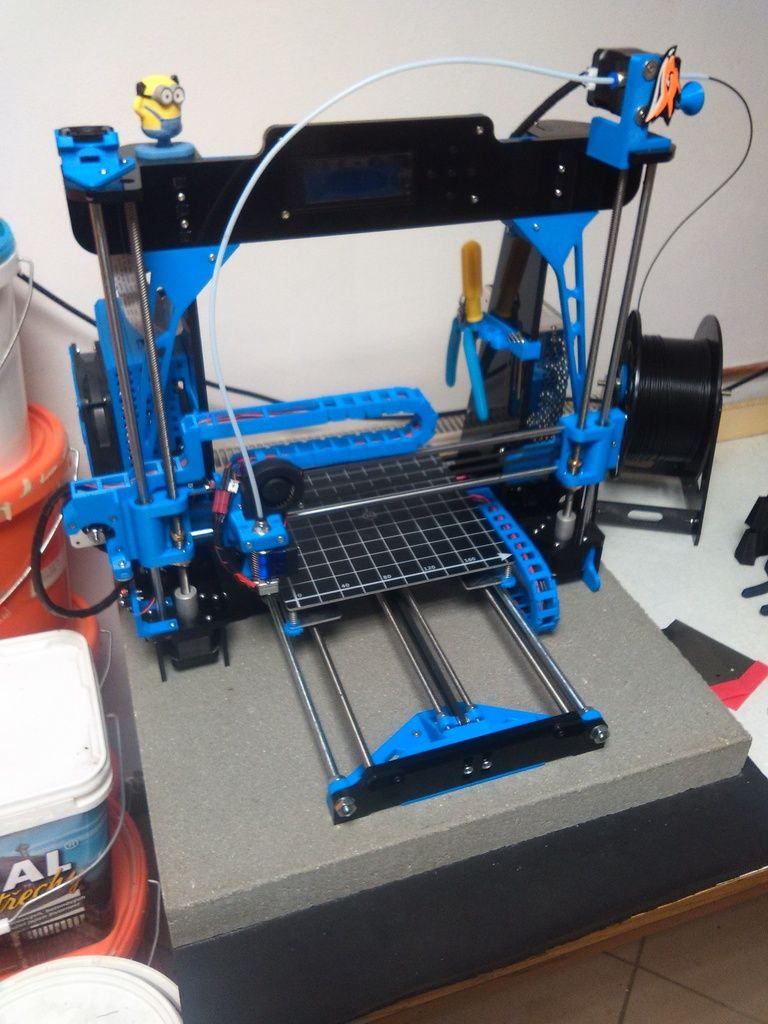

Each 3D printer has its own kinematic scheme, according to which the mechanical parts of the device are set in motion: platforms and extruders. Below we will look at four types of FDM 3D printer: Cartesian, Delta, Polar, and Robotic Arm.

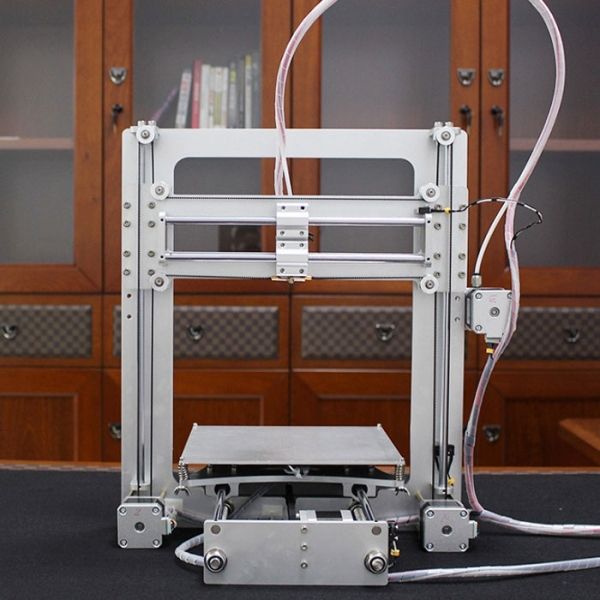

In the FFF / FDM 3D printer market, Cartesian kinematic devices are the most common. Based on the Cartesian coordinate system, this technology works on the basis of three axes - X, Y, Z. The movement of the mechanical parts of the device is carried out along one or more of them, i.e., the coordinates specified along the axes implement the pattern of movement and position of the print head relative to the platform .

Based on the Cartesian coordinate system, this technology works on the basis of three axes - X, Y, Z. The movement of the mechanical parts of the device is carried out along one or more of them, i.e., the coordinates specified along the axes implement the pattern of movement and position of the print head relative to the platform .

The number of options for moving the print head and platform is limited:

-

The platform moves along one of the horizontal axes - X or Y, the extruder moves along the other and in height.

-

The platform moves in height, along the Z axis, and the extruder moves in two planes, forward-backward and left-right.

-

The platform moves along one of the axes and in height, the extruder - along the other axis.

-

The platform is stationary, the extruder moves along all three axes.

-

Platform moves in XY axes, extruder moves in height.

The second scheme is the most common - when the platform for printing moves along the Z axis (up and down), and the extruder works in two dimensions, along the XY planes.

Advantages of Cartesian

Of all the types of FDM 3D printer kinematics, Cartesian ones show almost perfect results stability. FDM consumables are low cost and come in the widest range of colors and materials. Often, Cartesian 3D printers are used for commercial purposes - for printing on order and for the sale of household objects, souvenirs and jewelry.

Cartesian 3D printers have long and firmly established themselves in the lives of amateurs and professionals of 3D printing. Therefore, there are many thematic communities on the network with comprehensive information about the design of printers, working with them and creating models, from simple to complex.

Cartesian models can be decomposed for printing, allowing you to create 3D printed objects of any size, not limited by the printer. Many 3D printers come as a build kit. For beginners and those who do not want to understand the printer device, manufacturers supply ready-made devices. With them, you can print models almost after unpacking.

Many 3D printers come as a build kit. For beginners and those who do not want to understand the printer device, manufacturers supply ready-made devices. With them, you can print models almost after unpacking.

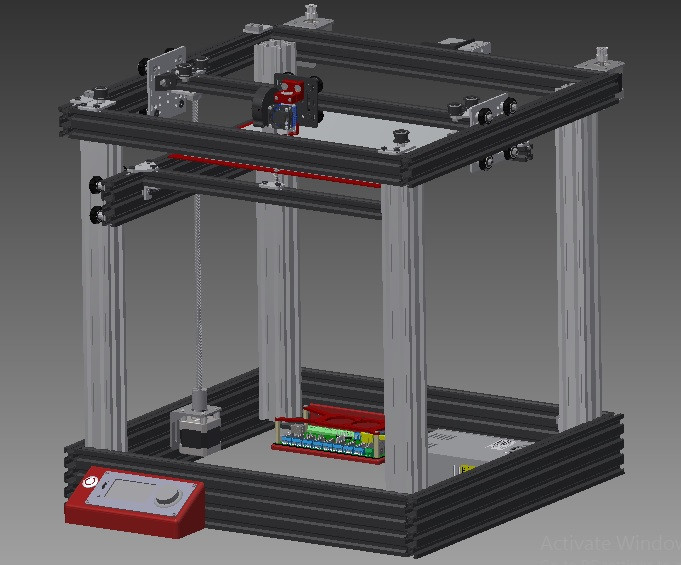

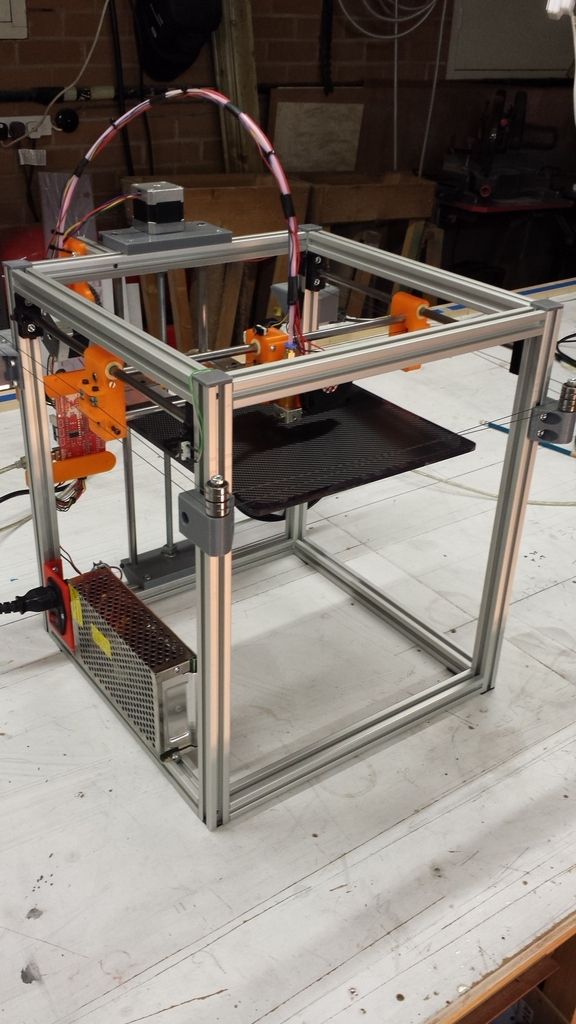

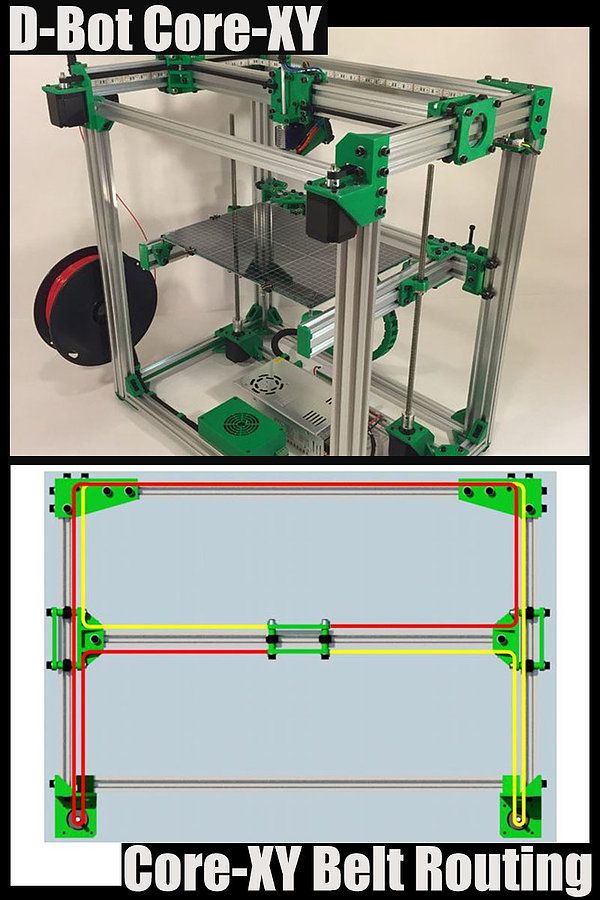

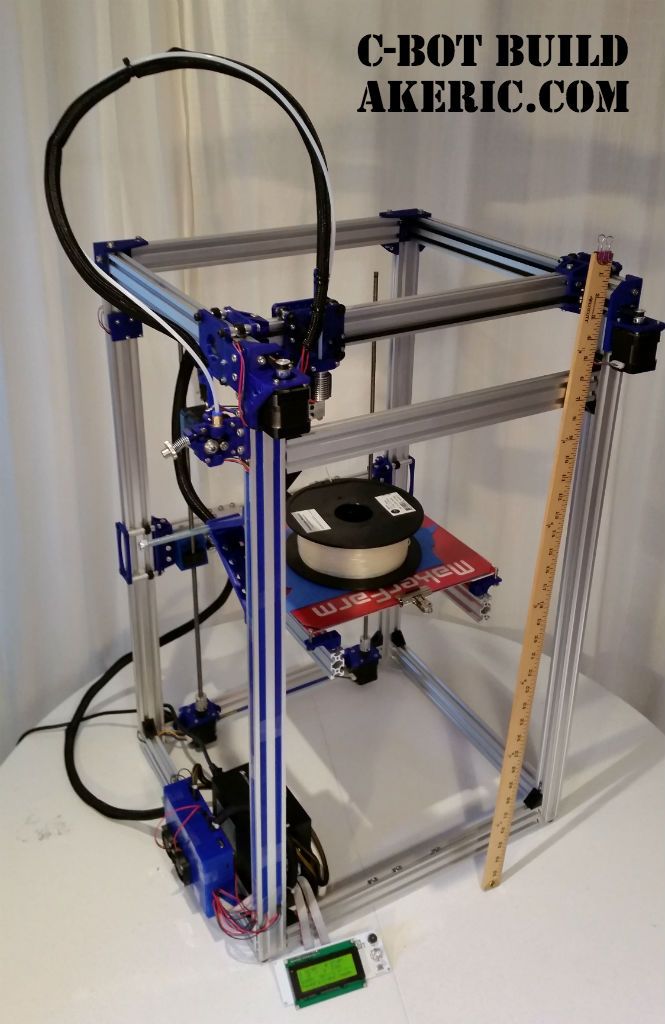

Variations of CoreXY and H-Bot Cartesian kinematics

These kinematics are common in commercial applications. Differ in original methods of positioning of an extruder. In both kinematics, the platform moves up and down.

Source : smoothieware.org

H-Bot 3D printer kinematics are based on similar mechanics but with a different belt drive. In this case, there is only one belt and it is stretched in a shape resembling the letter H (ash) circled around the contour, for which the scheme was called ash-bot.

Source : smoothieware. org .

org .

One example of such 3D printers is the Designer X PRO. This model is fast because thanks to the JetSwitch function, printing with 2 materials has become even faster (up to 5 seconds in normal mode and 250 ms in draft mode). And the newly designed print head with 1 micron accuracy, frame structure, precision mechanics and next-generation hardware platform will allow you to print high-quality models comparable to industrial products. Possesses function of the two-material press. The software has full control over the process, which minimizes errors and increases the productivity of the 3D printer.

Printing example:

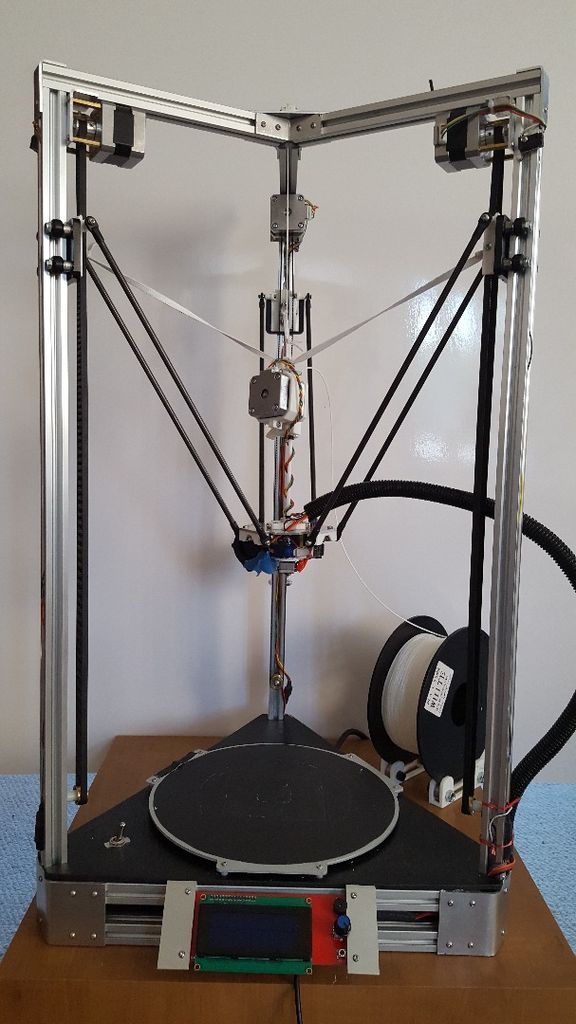

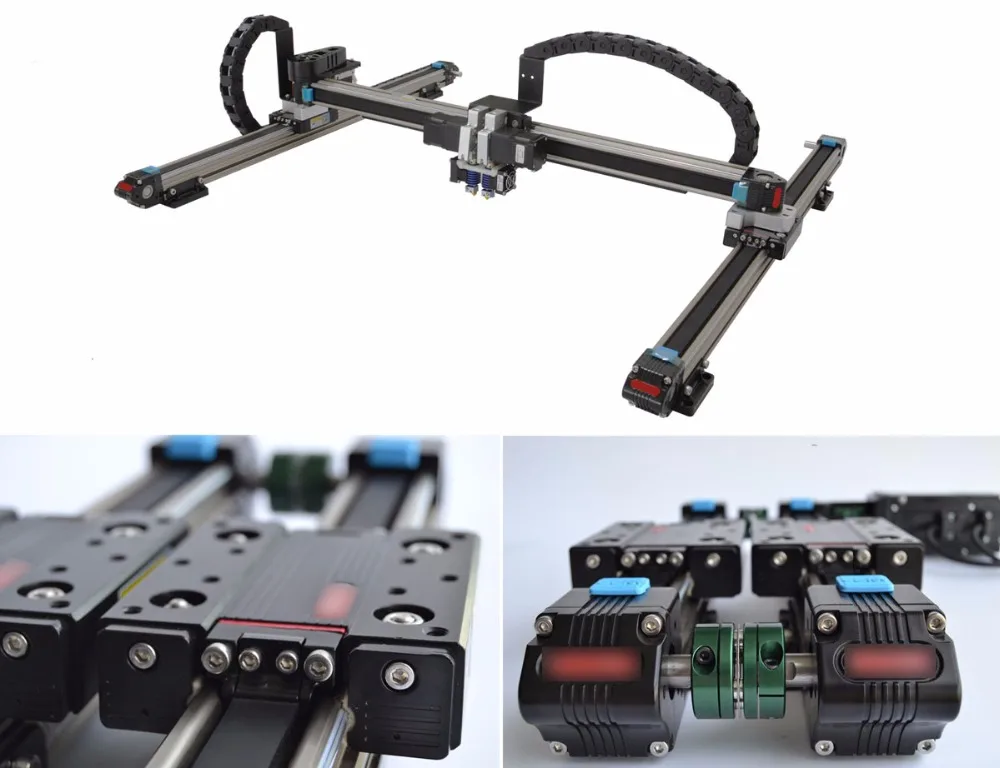

Delta printers Delta printers differ from Cartesian printers both externally and in the way they implement mechanics. The main difference lies in the way the extruder moves relative to the desktop. Delta kinematics, compared to Cartesian models, has a higher print speed, but less accuracy at the edges of the model. The reason is that all three attachment points are involved in the movement of the extruder, their motors work simultaneously, which leads to the accumulation of errors in the positioning of the coordinates. Other benefits: Small size. The design is high, but in length and width does not take up much space. No protruding parts. You can independently increase the rigidity of the frame and close the case. Possibility to build high vertical models. High price category. Difficult to self-assemble. It will be difficult for beginners to assemble the structure accurately enough, so it is recommended to use ready-made solutions that come assembled. The specifics of working with polar coordinates: less common software and more expensive electronics, because higher requirements for the processing power of the filling. One example of such a 3D printer is the Tevo Little monster. It is mainly used for commercial activities, design, advertising and educational purposes, and is also used as a home 3D printer. Differs in the high speed of the press and small dimensions. Works with many materials: PLA, ABS, Flexible PLA, HIPS, WOOD, PVA, Nylon. Print example: source: https://twitter.com/ A rather new but interesting kinematic polar scheme is introduced to the market by the company of the same name Polar. Source : http://www.purdue3dpc.org The platform of such 3D printers is round, rotates in a circle and moves along one horizontal axis, while the extruder moves only up and down. Imagine a turntable - the printer's printhead works like a pickup stylus moving across a record. The only difference is that here the “plate” not only rotates, but the “needle”, on the contrary, is limited in movement. Polar 3D printers allow you to create large objects while saving money through high energy efficiency. They still have low accuracy, but in the long run, perhaps the manufacturer will be able to solve this problem. Source : https://about. These 3D printers include the Polar 3D model. In this 3D printer, there is no heating of the print bed, which makes it difficult to use ABS. It has modest dimensions, good performance, but low accuracy compared to delta printers and models with a Cartesian coordinate system. The manufacturer recommends purchasing a model for educational purposes. Printing example: 3D printers with robotic arms Represents a design with a mechanical programmable arm-grip with a replaceable extruder. If we are talking about large industrial specimens (and there are also more compact ones), then, in addition to the functions of a manipulator and a 3D printer, such a robot can perform welding, milling, painting and other operations. Source : http://www. Although the mechanics of 3D printing with a robotic arm is mainly used in industry, there are models for individual use, with a wide range of functions. Dobot Magician Educational Robot Arm has many functions. It can draw, write, grab and move objects, perform laser engraving, etc. Work example: SCARA SCARA (Selective Compliance Articulated Robot Arm) - kinematics based on the movement of the working unit in a horizontal plane due to rotation in the joints of the lever mechanism. The devices built on this scheme are distinguished by very high accuracy and repeatability, much higher than that of traditional robotic manipulators, low noise and vibration levels, and compactness. If we talk about Cartesian and SCARA robots of comparable size and mass, then scara is usually not only more accurate, but also faster. At the same time, these devices are expensive, have limited rigidity in the XY axes, a smaller area of work and freedom of movement. An example of such kinematics is the Dobot M1 robotic arm. This is a compact desktop robot that combines the functions of a 3D printer and a manipulator. Actions are programmed through the software installed on the computer or a mobile application. It has interchangeable heads for printing, engraving, soldering and assembling. Work example: Source : https://thegadgetflow.com/ The advantages of 3D printers with a robotic arm are obvious - such a printer is not limited by the volume of the working chamber, which it does not have - with the same print area, the device itself takes up much less space. Source : https://spectrum.ieee.org/ The extruder can move not only in layers, as in desktop printers, but also along complex paths in three dimensions, and at different angles, which facilitates the process of creating complex structures. A definite plus is also the fact that these are usually universal designs, when replacing the extruder with other blocks, they perform many tasks. In terms of printing accuracy, manipulators will not compete with Cartesian 3D printers, but due to their versatility and large size, industrial robots are actively used in 3D printing in industrial environments, where they are almost indispensable. Miniature desktop robots are good primarily as a visual aid, as well as a hobby object or a tool for it. When choosing a device before buying, first of all, decide on the goal - why do you need a 3D printer? Business, work or play? The versatility of FFF/FDM 3D printers is that they are suitable for different applications. You can purchase a suitable device and consumables at https://top3dshop.ru, a retail division of Top 3D Group, a leading integrator of additive equipment in Russia. And also on the site: https://top3dshop.com, if you do not live in the CIS countries. List of sources used: What are the advantages of the FDM technology? - Professional 3D Printers // [Electronic resource]: dddrop.com - Electron. Dan. – dddrop.com – Access mode: https://www.dddrop.com/fdm-technology/ (date of access: 08/03/2019). Application of FDM three-dimensional printing technology in the digital manufacture of custom edentulous mandible trays // [Electronic resource] : Scientific Reports - Electron. Reconstruction and Development of a 3D Printer Using FDM Technology // [Electronic resource] : Procedia Engineering - Electron. Dan. – sciencedirect.com – Access mode: https://www.sciencedirect.com/science/article/pii/S1877705816311651 (Accessed: 08/03/2019). Catalog // [Electronic resource]: 3D Printers - Electron. Dan. – top3dshop.com – Access mode: https://top3dshop.com/3d-printers/ (Accessed: 08/03/2019). Catalog // [Electronic resource]: 3D Printers - Electron. Dan. – top3dshop.ru – Access mode: https://top3dshop.ru/kupit-3d-printer/ (date of access: 08/03/2019). 3D printing technologies, FFF printers, multi-kinematic 3D printers, laser stereolithography (SLA), selective laser sintering (SLS), thermal sintering (SHS), digital LED projection (DLP), H-Bot kinematics , Designer X PRO Content Many printer manufacturers had no idea that 3D printing would revolutionize advertising and the market today. And then the approach to work changed, and some inventors brought the 3d printer to sale in hardware stores. At first, customers didn't realize the benefits until they tried printing plastic posters and event posters. Application areas of unique printing are diverse: 3D technology has firmly established itself in the mass market of plastic products, children's toys and research institutes. Therefore, clients of a developed business have new opportunities in all spheres of human activity. Employees set certain parameters and dimensions of the future product, and then the product is printed from any material. However, light plastic is most often used for the convenience of the client. And the weight of the toy or new equipment is reduced due to the ease of processing elements. Simulation of complex fixtures and designs allows customers to correctly evaluate the multifaceted possibilities of a new printing technology. And lower prices make 3D printers more affordable for mass consumption. After all, it is really difficult to compete in a motley market. Especially with high competition and versatility of technology. Active exploitation of printers is observed in mechanical engineering and prototyping. All customers are aware of the future projects of new gadgets and electrical appliances. However, there are many checks, tests and promotional presentations required before a product is released. The acceleration of production processes helps the development of the economy and industrial production of medical, scientific and mechanical goods. The economy in terms of resources and precious time impresses customers, and increases innovation in the market. Design developments have become really in demand thanks to the development of research and medicine. The variety of applications of this seal goes off scale compared to conventional electronic devices. Design is used even in dentistry and medicine, and most of all in architecture and design. The creation of works of art begins with sketches or drawings, models or drawings. And in serious work it is necessary to apply new technologies. A great opportunity is the use of a 3d printer by professional artists, designers and architects. What is the purpose of the printing device: The industriousness of sculptors used to reach impossible limits. After all, each element of the future sculpture had to be done with his own hands. And this process cannot be called easy and fast. Therefore, creative people created works of creativity for too long, and each component took a lot of time and effort. And now, with the advent of amenities and special printers, activities have taken a rapid turn. Casting and painstaking work in the workshop are left behind, a bright future belongs to the artists. What art professionals will really need a printer for: The work of engineers and designers is greatly simplified by new gadgets. Devices accelerate industrial production many times, and it becomes much more pleasant for a person to do what he loves. One button saves the life of an employee who has many useful duties even without small details. What can be printed on a 3d printer: Research centers and clinics are equipped with modern equipment. And this is facilitated by new technologies for printing real parts of the medical field. It is enough to pass through the oral cavity scanner, and the prostheses are made automatically. Doctor visits are significantly reduced, and printers work well for a long time. And when the equipment breaks down, you can buy a new electrical appliance. Methods for making plaster models and unique prostheses have improved with the help of technology. And now the probability of inaccuracy and a crooked tooth is negligible, because the machine analyzes information from the scanner from several sides at once. 3D printing is proving to be a useful activity that saves the lives of many people from the deplorable consequences of doctors' mistakes. What can be done with a 3D printer: Printing machines allow experts to create finished products without wasting time. The whole process takes place automatically, and no doubt leads to positive results. Income can be obtained from large companies or individual orders of medium-sized consumers. Every entrepreneur who has 3d technology available seeks to earn and receive appropriate dividends. What stages of business implementation work with the help of printers: Attention! A business using 3D printers requires investment and time. Therefore, it is necessary to think over the scope of work in advance, take care of renting and advertising a new service center and negotiate with customers. A revolutionary printing device greatly increases the possibilities for self-realization of artists. Many designers and artists are able to realize themselves by creating 3-dimensional pictures on a computer. And if the owner has a home 3d printer, then you can easily start making money and get significant profit from an interesting activity. Modern modeling amazes the audience, creativity becomes a way to implement business projects. Please note! At home, volumetric printing is most in demand, because not everyone has such a printer nearby. Therefore, it is worth opening a group on a social network and selling images with finished goods to neighbors or townspeople. What can be done on a 3D printer: Customers are demanding better technology and more products available. Therefore, printer models have to be improved every season, and additional functions added to production. 3D printing allows you to make a wide variety of interior items. The possibilities are endless in terms of the choice of materials and the shape of the steel product. Amazing things or what can be printed on a 3D printer: Buyers can choose a souvenir of almost any size. And therein lies the advantage of an innovative technology for turning fantasies into reality. Jewelry made of gold, plastic parts, prototypes of body parts, action figures from video games and TV shows - the choice is varied enough to fulfill desires. Gradually, entrepreneurs fill the niche of 3D printing services, and competition is growing in proportion to the innovations in technology. In the near future, this device will work everywhere, and users will appreciate the profitable technology. This device will become a replacement for a conventional printer, and painstaking work with numerous errors will be left behind.

Advantages and disadvantages of delta bots

Polar 3D printers  As the name implies, printing uses a polar coordinate system - instead of the usual XYZ, the positioning of the extruder is set by radius and angle.

As the name implies, printing uses a polar coordinate system - instead of the usual XYZ, the positioning of the extruder is set by radius and angle.

Pros and cons of polar mechanics  polar3d.com/

polar3d.com/ 7

dubox.me/

dubox.me/

Analysis of robotic kinematic schemes

Conclusion  Whether you want to learn 3D printing and acquire a new hobby, live out your creative fantasies or start a business, there is a suitable machine for each of these goals, you just need to choose.

Whether you want to learn 3D printing and acquire a new hobby, live out your creative fantasies or start a business, there is a suitable machine for each of these goals, you just need to choose.

Dan. – nature.com – Access mode: https://www.nature.com/articles/srep19207 (Accessed: 08/03/2019).

Dan. – nature.com – Access mode: https://www.nature.com/articles/srep19207 (Accessed: 08/03/2019).

Tags:

3D printer application

After all, the technologies were relatively primitive, the devices could not be delivered to the broad masses of consumers.

After all, the technologies were relatively primitive, the devices could not be delivered to the broad masses of consumers. Application area of 3D printers

A three-dimensional model of a project or future product is printed on a special printer as a full-fledged material object.

A three-dimensional model of a project or future product is printed on a special printer as a full-fledged material object.  And this requires miniature product models in record time. 3D printing in this case is able to replace casting and machining, or rather, several months of hard work for people.

And this requires miniature product models in record time. 3D printing in this case is able to replace casting and machining, or rather, several months of hard work for people. Art

In general, it is best to use 3D technologies to create complex compositions. To do this, first of all, it is necessary to show imagination and imagination, tolerance for fashion trends and attentiveness when working with an electrical appliance.

In general, it is best to use 3D technologies to create complex compositions. To do this, first of all, it is necessary to show imagination and imagination, tolerance for fashion trends and attentiveness when working with an electrical appliance.

Industry

The disadvantages of modeling are visible at the initial stage, and specialists have the opportunity to correct the mistakes made in time.

The disadvantages of modeling are visible at the initial stage, and specialists have the opportunity to correct the mistakes made in time.

Medicine

And it is useful to purchase a 3D printer in order to develop prostheses or individual tooth substitutes. These devices are convenient for dentists, because it is better to get rid of long hours of manual work on the creation of crowns, prostheses and medical products for subsequent sale. Clients enjoy the comfort and convenience of the updated dental service.

And it is useful to purchase a 3D printer in order to develop prostheses or individual tooth substitutes. These devices are convenient for dentists, because it is better to get rid of long hours of manual work on the creation of crowns, prostheses and medical products for subsequent sale. Clients enjoy the comfort and convenience of the updated dental service.  And most customers appreciate the new equipment in the medical field.

And most customers appreciate the new equipment in the medical field.

3D printer and own business

3D printing business at home

Custom items made with 3D printer

Learn more