3D printed jacket

3D Printing Goes Ready to Wear as Danit Peleg's Bomber Jacket Becomes the First Commercially Available 3D Printed Garment - 3DPrint.com

The only fashion shows I’ve ever attended have featured 3D printed collections, with talented designers turning to 3D printing to create wearable art ready to walk down the runway at RAPID. While an additive manufacturing tradeshow isn’t necessarily the go-to place for fashion in general, the shows have been standing room-only the last two years. In 2016, designer Danit Peleg was among those showcasing a collection at RAPID, and it was the first chance I’d personally had to see her designs in person. And now, we all have the opportunity to do much more than just see her 3D printed looks on the runway as she is offering a customized, 3D printed bomber style jacket as the first commercially available 3D printed garment that’s available for purchase right now.

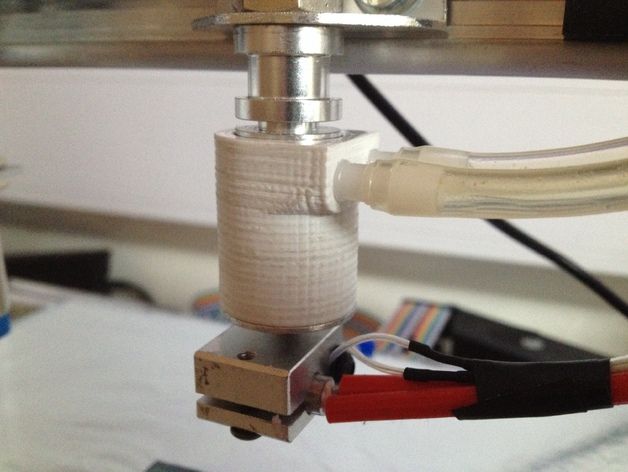

Peleg, a talented young designer out of Israel, shot to prominence in fashion with the unveiling of her 2015 collection of clothes 3D printed at home in what she saw as a vision for the future of fashion. That collection hit the runway at RAPID 2016, showing off the ease of movement possible in the cleverly designed plastic garments; you can see the entire collection, and the designer, walk together in the first 30 seconds of part two of the video I took of last year’s fashion show (and see individual pieces shown in part one here):

Key to Peleg’s vision of 3D printed fashion is that the clothes actually be wearable, not just high-fashion. Last September, that wearability was in focus when Peleg designed a dress ready for the samba — and that’s just what happened when Paralympic snowboarder Amy Purdy wore a completely 3D printed dress for a choreographed dance with a massive robot at the Paralympic opening ceremony in Rio 2016. Fashion becomes much more accessible when it’s something you can actually imagine wearing in real life.

While my current lack of plans to dance with robotic arms (plans I am willing to make at any time, mind you) precludes my immediate need for a performance-ready dress like that made for Purdy, and I can’t see running for groceries in, say, the fairly see-through striped skirt I love so much from Peleg’s 2015 collection, that vision changes when I consider her new commercially available jacket.

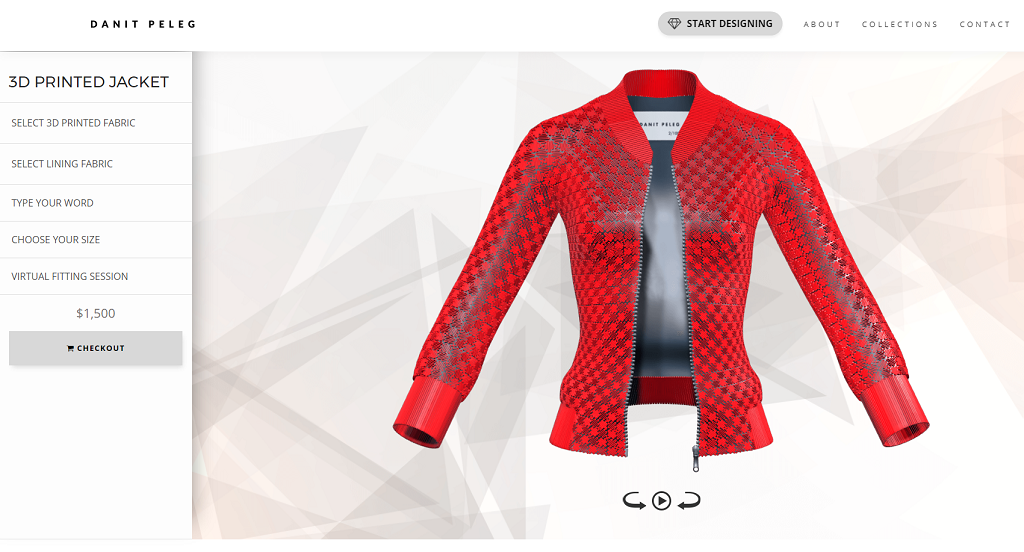

The jacket is fully customizable and is available now to order. Limited to a run of 100 personalized jackets, Peleg is remaining pragmatic about the approach to commercializing, avoiding the all-too-common trap of over-promising and under-delivering by keeping to a set run edition. Each jacket, she explains, takes 100 hours to 3D print and create to custom order.

Peleg explains the vision behind the jacket here:

In designing a custom jacket, a user is walked through several steps of creation. Unique to the person in control of the digital design, jackets can be customized by choosing:

- 3D printed fabric color

- Lining fabric

- A word emblazoned across the back (up to five characters)

- Size

All this is followed up with a virtual fitting session to ensure the piece looks just as you like; instructions for fit will be sent via email through iPhone or other platforms. I customized a jacket in about five minutes; the process is quite straightforward.

“Own a part of history. This is the first ready-to-wear 3D printed jacket available to purchase online. It takes more than 100 hours to print and assemble. It’s printed in Spain and assembled and shipped from Tel Aviv. It’s a first step in the journey to a 3D printed world. Thanks to this revolutionary technology, every piece is unique, made to measure with your own customizations and its production process produces zero waste,” the jacket’s site explains.

“The jacket is printed with a flexible, rubber-like material and has a silky fabric lining that makes it super comfortable to wear. This is a limited edition of 100 jackets. Your jacket’s serial number will be 3D printed on its label and it will be shipped in a premium box.”

The jacket I designed (3DP4E), trying to keep to something a bit TARDIS blue. Please note there are now less than two shopping months until my birthday.

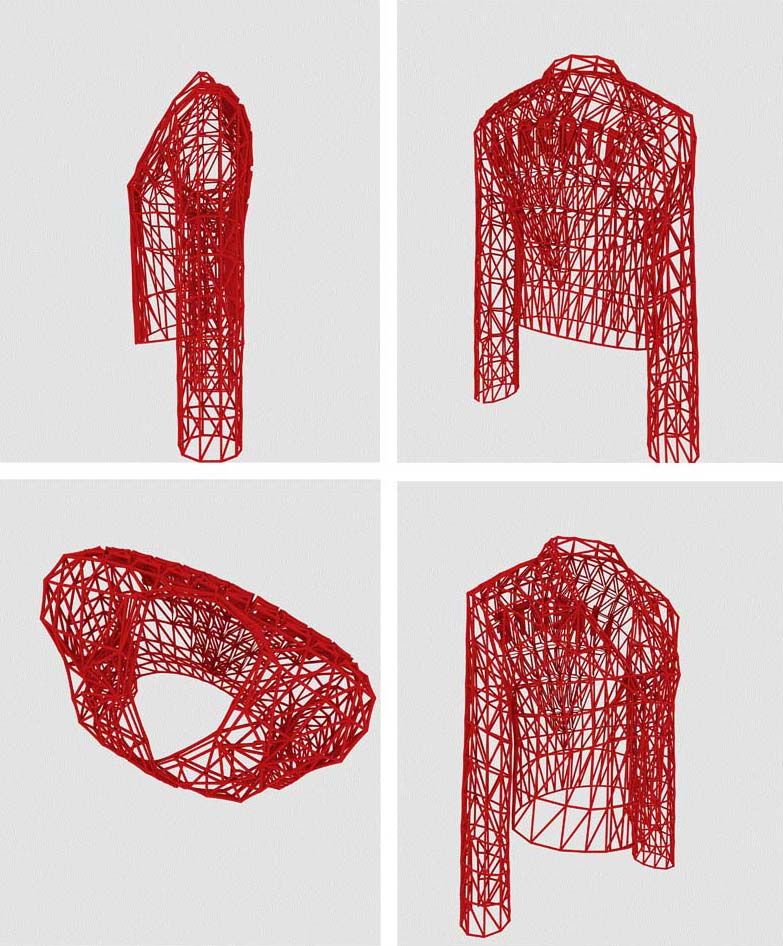

Peleg worked again with creative collaborative partner Gerber Technologies, using their AccuMark 3D and YuniquePLM, to bring this jacket to life.

“With each collection, Gerber has helped me streamline my workflow to accelerate the 3D printed design process. My vision of the future is that you will buy your 3D print file and print your clothes at home or at a designated store,” Peleg said of her work.

She has been working with Gerber for a few years now, having begun the partnership during her senior project at Shenkar College of Engineering and Design.

“We are excited to help Danit bring 3D printed garments to the market and be a part of this incredible journey. Our creative partnership has helped define a workflow in AccuMark 3D for the benefit of our customers who will transform the industry in the coming years,” said Elizabeth King, Vice President of Digital Solutions, Community and Eco-System at Gerber Technology.

The bomber jacket is part of Peleg’s ‘The Birth of Venus’ collection, inspired by Botticelli’s famous painting of the same name. Available here, the jacket retails for $1,500. Peleg also provides washing/care instructions for 3D printed garments (a washing machine is a big no-no for 3D printed wear, remember).

Peleg also provides washing/care instructions for 3D printed garments (a washing machine is a big no-no for 3D printed wear, remember).

Share your thoughts in the Danit Peleg forum at 3DPB.com.

[All images: Danit Peleg]

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: 3d print jacket • 3d printed clothes • 3d printed fashion • 3d printed fashion design • 3d printed garments • Accumark • commercial launch • danit peleg • Gerber Technology

Please enable JavaScript to view the comments powered by Disqus.

What are the best projects?

3D Learning Hub

See all categories

Contents:

- Introduction

- Fashion and 3D printing: 3D printed fashion is the new revolution

- What are the best 3D printed clothes projects?

- 3D printing footwear

- 3D printed jewelry

- 3D printed bags

- Evolution of 3D printed clothes: What is the future of fashion?

Introduction

Fashion and 3D printing: 3D printed fashion is the new revolution

3D printing for the design aspect

Additive manufacturing is interesting for fashion as it allows to work more easily on fashion designs and to create amazing things for the fashion industry such as garments, ornaments, and meshes.

This technology is really giving a lot of freedom to the designers in terms of geometry. It is, for example, possible to create intricate designs for various projects inside the fashion industry. From shoes and accessories to 3D printed dresses, the fashion industry starts to embrace the full potential of 3D printing and to develop interesting objects.

Some of the garments developed thanks to 3D printing technology would have been too complex and expensive to create with another manufacturing method.

New considerations for the fashion industry

Sustainable manufacturing and eco-friendly products

There is obviously an evolution in the way that we are thinking about fashion and clothes manufacturing. New aspects are now taken into account and now, the reasons why designers are choosing 3D printing are changing: it is becoming important to use 3D printing for sustainable and eco-friendly purposes.

For instance, textiles are part of the waste problem around the world, that is why a lot of elements of the manufacturing process need to be rethought in order to be more eco-friendly. Using 3D printing allows to reduce waste, you only need to use the amount of material that is needed to create your project.

Using 3D printing allows to reduce waste, you only need to use the amount of material that is needed to create your project.

It is also a way to use some recycled materials for the manufacturing process. Adidas created a 3D printed midsole for one of its sneakers, made with recycled plastic found in the ocean. Creating new materials and using plastic in a more responsible way are new reasons to use 3D printing for fashion companies, and even for big brands such as Adidas.

3D printing comfortable clothes

The use of 3D printing to create clothes is evolving. It first has been used to create extremely complex and impressive pieces. The use of 3D printing in this sector was a way to push the boundaries of the fashion world to create outstanding projects, that were visually impressive.

Now some designers are more interested in using 3D printing to develop collections of regular clothes, using additive manufacturing as a traditional manufacturing method. They are not only using 3D printing for the design benefits but as an advantageous manufacturing method to create customizable and comfortable clothes. Additive manufacturing is a great way for all industries to improve their manufacturing process. It is allowing them to work on their prototypes with faster and cheaper methods, but also to produce customizable products in the end. These two elements are quite important in the fashion industry.

Additive manufacturing is a great way for all industries to improve their manufacturing process. It is allowing them to work on their prototypes with faster and cheaper methods, but also to produce customizable products in the end. These two elements are quite important in the fashion industry.

While using 3D printing, we can notice more freedom on the customization side. Indeed, additive manufacturing is the perfect technique for mass customization. We know that customization can be an expensive process in the fashion industry. Producing garments and accessories made to measure are made possible thanks to 3D printing.

3D printing could also totally help to create clothes adapted to the movement of all bodies! 3D printing is not only a manufacturing method for haute couture creations anymore.

What are the best 3D printed clothes projects?

The Spider Dress

The Spider Dress of Anouk Wipprecht has mechanical arms that extend and retract as a response to external stimuli when people approach. The wearer’s own breath will help to signal the defense posture of the robotic arms. The dress is fully 3D printed with the Selective Laser Sintering technology.

The wearer’s own breath will help to signal the defense posture of the robotic arms. The dress is fully 3D printed with the Selective Laser Sintering technology.

The Spider Dress

3D printing regular clothes

The idea of Julia Daviy is to use 3D printing to create biodegradable fashion, believing that we can change the way we produce clothes!

Her collection included 3D printed dresses and tops. Most of the time, the 3D printed clothes made by designers are not easy to wear. But it is not the case with the clothes 3D printed by Julia Daviy. She is really thinking about 3D printing as a new method to create garments without wasting a lot of textiles, and avoid the mass-production aspect.

credit: https://www.3dprint.com/212640/julia-daviy-3d-printing/

Multicolor 3D printing for garments

This dress is a piece made by the American designer Travis Fitch, with 30 different sections. It has been printed with a colorful multi-material. The material is flexible in order to respond to the movements of the body. The 3D printing process is a good way to give life to objects with really complex designs and to make them wearable as traditional garments.

The 3D printing process is a good way to give life to objects with really complex designs and to make them wearable as traditional garments.

The use of color on this project is quite unique, 3D printing projects in the fashion world are often monochrome, and are not as colorful. This technique offers new possibilities as multicolor 3D printing is not often used in these kinds of projects.

credit: https://3dprintingindustry.com/news/3d-printed-dress-debuts-new-york-fashion-week-95736/

3D print knits

Ministry of supply developed a 3D printed knit blazer, a sustainable way to create garments that will last longer! The 3D printing process and the work on the 3D designs that they are creating are allowing to make pieces more adapted to the body and to its movements.

Their goal is to develop an agile supply-chain and create on-demand products that are more comfortable and durable. Their 3D printing technology is an eco-friendly method to create knits, and they are noticing a reduction of 35% regarding material waste.

New generation of 3D printed clothes collections

Danit Peleg is a designer who decided to create a fashion collection that she entirely 3D printed by herself. By doing that, she shows that 3D printers are great tools, allowing to rethink the manufacturing process of the fashion industry. The collection took her 2 000 hours to print completely.

https://www.3ders.org/articles/20150724-danit-peleg-3d-prints-entire-ready-to-wear-fashion-collection-at-home.html

Her goal? To create comfortable clothes that she could wear herself. Once again, we see the will of designers to create wearable 3D printed clothes.

3D printing, still useful to give life to outstanding designs

Alexis Walsh is a talented designer who created an impressive dress 3D printed using Selective Laser Sintering. The dress has 400 tiles assembled by hand. Here, 3D printing has been used to develop the design of the dress. It took at least six months to the designer to develop this impressive garment using 3D printing.

The 3D printed comfortable dress

We were talking previously about more comfortable clothes. Dresses made by designers are not what we can call comfortable, as it is not their primary goal. But do you know about the Kinematic dress? By 3D scanning her model, Jessica Rosenkrantz created a dress perfectly fitting her body.

By using this innovative manufacturing technique, the designer wanted to show a new approach of manufacturing for her fashion collection. Moreover, 3D printing is perfect to make several iterations for these kinds of dress, to be sure that they respond correctly to the movements of the model.

http://www.youfab.info/2015/youfab-award-ceremony-1.html

3D printing costume

It is now possible to use additive manufacturing to create costumes for the film industry, but also for video games. You might have heard about Sculpteo’s collaboration with Ubisoft for their Just Dance 2020 video game! The goal here was to create a lightweight costume, with an ambitious design but that shouldn’t hinder the dancer’s performance.

Get more info about this great project in the following video:

3D printed fashion for men

We can see that most of these creations are dresses or tops, intended for women. But what about men?

There is actually the 3D printed tie developed by Viptie 3D. This company is more focused on the mass customization aspect of 3D printing technology. They want to join luxury and high tech to create ties and bowties, as unique products for their customers.

3D printing footwear

More than garments, additive manufacturing is revolutionizing the footwear industry. Some important brands such as Adidas are making the most of additive manufacturing to develop impressive projects.

Adidas and the Futurecraft 4D

Adidas actually launched its Futurecraft 4D project: they create shoes with a midsole created in partnership with Carbon 3D, using a new process called Digital Light Synthesis (formerly known as CLIP). Thanks to digital light synthesis, oxygen-permeable optics, and liquid resin, this process can produce durable and resistant polymeric goods.

Thanks to digital light synthesis, oxygen-permeable optics, and liquid resin, this process can produce durable and resistant polymeric goods.

Using additive manufacturing in the footwear industry allows working on new designs to improve a previous product, for example. That is precisely what happened with this project, Adidas created an impressive midsole using a lattice structure!

This project is also showing an interesting aspect of the use of additive manufacturing. Indeed, these shoes are not only produced using 3D technology, but they are mass-produced using 3D printing! We can say that Carbon and Adidas are taking additive manufacturing a step further with this project.

Olivier Van Herpt developing the fully 3D printed shoe

For the moment, 3D printing is mainly used in the footwear industry to 3D print midsoles, which offers, once again, to get custom made products, adapted to any morphology. But is it even possible to 3D print an entire shoe? Designer Olivier Van Herpt is using 3D scans and 3D printing to create new shoe structures, making them unique, lightweight and really resistant. These 3D printed shoes guarantee you the perfect fit.

These 3D printed shoes guarantee you the perfect fit.

3D printed jewelry

3D printed jewelry is now becoming more and more common. 3D printing is a perfect method to launch a jewelry business, for both prototyping and production, additive manufacturing can be used to improve your product and process on many different levels! At Sculpteo, we offer great 3D printing technologies, suitable for the creation of your jewelry parts.

It’s possible to use metal 3D printing, with technologies such as Lost Wax Casting, and different materials such as Brass, Sterling Silver, or Bronze. These precious metals can be beneficial for your projects. Resin and plastic 3D printing can also be used for jewelry projects, Selective Laser Sintering or Polyjet technologies can be useful to create accurate parts.

If you don’t want to produce your jewelry using additive manufacturing, keep in mind that this technology can be used to create your jewelry molds. An interesting use of additive manufacturing is the creation of master 3D printed molds for your parts!

The Nervous System collection

This collection of rings, bracelet and necklaces called Nervous System is made with nature-inspired designs, structures that it would have been impossible to create without 3D printing. These jewelry parts are created using the Lost-Wax Casting process!

These jewelry parts are created using the Lost-Wax Casting process!

ABL’s 3D printed watch

Is it possible to 3D print a watch? ABL “Atelier le Brézéguet” is a french brand from Toulouse. This company is specialized in watches and used our 3D printing service to produce the black rings, on the top and the bottom of the watch. These parts are 3D printed using polyamide material.

3D printed bags

Accessories such as bags can also be produced using 3D technology. For example, the Italian brand XYZ Bag created a 3D printed handbag collection called “DADA”. These bags are customizable, thanks to the use of 3D printing.

Regarding the designs, 3D printing is offering great advantages for the development of bag projects: it is actually offering the possibility to play with geometries and try new things. Working on different structures, like implementing lattices, can be an effective solution to get lightweight but resistants bags!

Evolution of 3D printed clothes: What is the future of fashion?

Some companies are developing new techniques and new 3D printing materials such as Ministry of Supply who used a new method to create knit garments. We can notice that some extraordinary 3D printed designs made for fashion shows are still present as the 3D printing technology is still really convenient to manufacture these unique pieces. But 3D printing tends to be more and more used to create clothes that anybody could wear. Indeed, now that we saw that the 3D printing technology is able to create intricate geometries for garments, comfort is becoming the key to new 3D printed fashion projects.

We can notice that some extraordinary 3D printed designs made for fashion shows are still present as the 3D printing technology is still really convenient to manufacture these unique pieces. But 3D printing tends to be more and more used to create clothes that anybody could wear. Indeed, now that we saw that the 3D printing technology is able to create intricate geometries for garments, comfort is becoming the key to new 3D printed fashion projects.

There is also a growth regarding the use of different 3D printing materials and techniques. In the future, metal 3D printing could be implemented to create some ornaments, but also laser cutting techniques! There are a lot of benefits and possibilities for designers who want to approach the laser cutting and 3D printing industry.

We can also see that the eco-friendly aspects offered by 3D printing are becoming quite important, as, for instance, recycled plastic and biodegradable materials can be used to 3D print some fashion parts. Soon, it could even be possible to use natural materials. Last but not least, we notice that the fashion industry is trying to push the boundaries of 3D printing, but is also implementing other great technologies such as electronics. It is now possible to 3D print smart fabrics, and more of these outstanding projects might be unveiled in the upcoming years!

Soon, it could even be possible to use natural materials. Last but not least, we notice that the fashion industry is trying to push the boundaries of 3D printing, but is also implementing other great technologies such as electronics. It is now possible to 3D print smart fabrics, and more of these outstanding projects might be unveiled in the upcoming years!

If you have a 3D printing idea and want to bring it to life right now, we can help you to choose the perfect CAD software for your fashion project, thanks to this blog post. Then, you will be able to upload your 3D models on our online 3D printing service.

Related Topics

- Return to Top

Get the latest 3D printing news delivered right to your inbox

Subscribe to our weekly newsletter to hear about the latest 3D printing technologies, applications, materials, and software.

characteristics, photos and customer reviews

1 056 ₽The product is not available now, see similar

Go to the storeThe product is no longer sold, see similar

Link copied, share it

Or send via social networks

This product is currently not available, but there are similar and similar

The price has increased by 181 ₽

More expensive than average, significantlyReliability of the seller is unknown

JIUZHE Store

- The seller does not have enough completed orders or reviews to evaluate the reliability of the seller stand collar high quality casual coat

0ratings

0orders

0% reliability

Seller SPEMIX Tactical Coolman Store

To StoreGo to Store

1654 – 1666 kr

New 2019 YASUGUOJI Autumn Fashion Floral Print Jacket Men's Stand Collar Slim Fit Casual Jackets Streetwear Ribbed Sleeve Zip Jackets

0ratings

000006 Reliable 000006 73%Seller Chinese Bao's Industrial Co.

Ltd.

Ltd. Go to StoreGo to Store

353.44 – 452.18 ₽

2019 Fashion Men's Jackets Coat Autumn Winter Zip Casual Fleece Coat Stand Collar Bomber Jacket Fashion Men's Windproof Outerwear

0 OTOCHOK

0 PrOSS

Reliability -51 %

Seller Insland Store

In the store to store

Found 43 similar goods

9000 -7 9000 % 9000 % 1 134 -1 334 ₽Male jacket -jacket -jacket -jacket -jacket -jacket -jacket -jacket -jacket -jacket -jacket -jacket -kurt mantlconx, solid color stand-up collar casual jacket, fall 2019

0

1

stand-up collar and coat, s-5xl axp215

0

1

The reliability of the seller is 89 %

-0.

9000 % 2

2 2 478 ₽

African male baseball jacket, an ankara coat, men's jackets with a standing collar, to order, dashiki, jacket -bomb with a print with a print , dropshipping

0

1

Reliability of the seller 27%

814.47 – 1 633 ₽

Bomber jacket for men; season spring-autumn; casual plain baseball jacket with zipper; pilot jacket with stand-up collar; men's fashion street outerwear; coat; 5xl

1

0

The reliability of the seller 89 %

9000 -6 9000 %Equal data

1 423 ₽

Men -sided jackets military bomber Air form jacket two ways of wearing a coat fashionable everyday clothing with a hard -resistant

collar0

0

Seller Reliability 0%

282.61 – 439.24 ₽

Men's zip-up jackets, autumn-winter casual fleece coat, stand-up collar bomber jacket, fashionable men's outerwear, fitted and slim fit

0

1

The reliability of the seller 21%

545.

48-666.70 ₽

48-666.70 ₽ 2019 Fashion male jackets of coats Winter on a zipper everyday fleece coat jacket-bomb with a stand-up male windshield

9000 84

Reliability of the seller 62%

-3

%

730.03 – 1 009 ₽

Jacket with a zipper with a stand-up collar and long sleeves for men and women

2

1

Seller Reliability 85%

2 236 ₽

Floral print casual jacket for men 2020 new stand-up collar baseball jacket for men flower and butterfly printed bomber jacket for men

11

Reliability of the seller 89%

-2

%

1 902 ₽

, men's coat

0

0

The reliability of the seller 53 %

9000 -2 9000 %980.

63-1,361 ₽

63-1,361 ₽ Autumn-casual everyday jacket-bomber, male fashion jacket, warm jacket, fitted everyday coat jacket-bomber-bomber-bomber-bomber With a hardware collar

5

3

The reliability of the seller is 89 %

-4

%

2 827 ₽

African baseball jacket of Ankara, a long coat, a men's jacket with a hardware collar, a jacket-bomber with custom dashiki print dropshipping

1

1

Reliability of the seller 27% perfect gift

0

0

Reliability of the seller 9% hop, spring-autumn

0

0

The reliability of the seller is 19 %

9000 -15%

1 054-1,449 ₽

Male everyday baseball jacket, an autumn bomb jacket with a print in the back, men's autumn jacket on a zipper with a collar stand-up, European size, not Asia

1

1

Reliability of the seller 89%

3 139 – 3 210 ₽

worn jackets

0

0

The reliability of the seller 61%

862.

82 ₽

82 ₽ Women's/men's jacket Doom Eternal with a 3D print, Fashion Street clothing, 2019

0

0

The reliability of the seller 89 %

-22

%

1 089 – 1 157 ₽

Davydaisy men's jacket autumn social dress slim plain jackets with zippers with stand-up collar casual bomber jacket work men's business coats dct-018

0

0

The reliability of the seller 89 %

9000 -7 9000 %2 178 -2 451 ₽

mantlconx Male jackets and coat Men's jacket Autumn -winter jacket for lightning with side pockets men's clothing 2021 coats 2021 coats men's

0

0

Seller Reliability 72%

2 522 ₽

Men's African style baseball jacket, ankara street coat, men's stand-up collar custom-made bomber jacket with print

0

0

The reliability of the seller is 27 %

9000 -7bomber jacket, men's coat for autumn and winter

1

2

Reliability of the seller 89% military style jacket, men's wear

0

1

The reliability of the seller 56 %

-0.

9000 % 8

8 3 632-3 768 ₽

Male base jacket, a long jacket, men's bomber jacket with a street style in

street style.4

1

Reliability of the seller 27%

1 263 – 1 818 ₽

Men's bomber jacket with a stand-up collar, cotton, with a zipper, casual fashion fitted, baseball outerwear, spring-autumn

0

0

Reliability of the seller 68%

-3

% Spring-Ashen 2021

0

2

The seller’s reliability 72 %

-5

9000 %3 472 ₽

Wipper with a hardware collar, a male bomb jacket, street clothing, baseball jacket, baseball jacket, baseball jacket tactical coat

1

1

The reliability of the seller is 89 %

9000 -3Spring-Ashen

1

0

The reliability of the seller is 89 %

-8

9000 %Parabated data

2 091 ₽

jacket male demisyazon on a zipper with a collar-stand and floral prints

0

1

The reliability of the seller 0%

1 128 ₽

New jacket with a 3d print wolf jacket unisex with animals Spring-stand Sports Clothing Street Clothing Sports suit 9000 9000 1

0

Reliability of the seller 65%

-0.

1

1 %

2042 – 2723 ₽

Men's plus size winter jacket 6xl 7xl 8xl, baseball bomber jacket, men's faux leather jackets and coats

1

2

Reliability of the seller 89%

3 340 ₽

Bomber jacket for men, army, military, with a zipper, with a stand-up collar, with a zipper, color black, green, for spring and autumn

00

The reliability of the seller is 89 %

-10

%

1 593 ₽

Jacket-bomb Menneson, tight-fitting, with a flower print, 5xl-m, size plus

1

22 Reliability of the seller 89%

1 549 – 1 726 ₽

Floral print jackets for men; season spring-autumn; fashionable printed casual sportswear; outdoor baseball jacket; men's bomber jacket; plus size m-6xl

0

0

Reliability of the seller 89%

6xl

0

1

Reliability of the seller 85%

incomplete data

1 676 -1 723 ₽

Men's fashionable cotton jacket with a stic collar, a daily lightning jacket with print, street sports base jacket

9000 26

Reliability of the seller 0%

9000 -3 -3%

1 041 – 1 288 ₽

Mantlconx autumn men's casual jackets, coats solid color men's outerwear with a zipper men's brand clothing collar collar men's bomber jacket

0

1

Reliability of the seller 72%

1 425 – 1 532 ₽

Men's baseball jacket, plain, fitted, with a stand-up collar, with a zipper, designer, outer, bomber jacket, casual, casual Plot jacket plus 8xl

0

0

Seller's reliability 72 %

-3

9000 %Partly data

1 508 -2 033 ₽

Male windbreaker 2021, bomb jacket with embroidery and inscription, military jackets, men's casual army flight jacket, autumn fashion zipper jacket

1

1

The reliability of the seller 0 %

9000 -3%

Equal data

2 038 ₽

Autumn season, with a stand -up collar, single -storage jacket Army clothes of large sizes 2019 Fashionable street clothes with a zipper

0

0

Reliability of the seller 0%

1 626 – 1 876 ₽

Men's windbreaker with a zipper, casual plain simple fitted bomber jacket with a stand-up collar, spring-autumn

0

0

Seller Reliability 68%

1 033 – 1 237 ₽

Men's Bomber Jacket with Zip, Casual Loose Jacket with Stand Collar for Spring and Autumn, Men's Plus Size Jacket 5xl, 2006 2006 1

1

Reliability of the seller 68%

993.

57 – 1 037 ₽

57 – 1 037 ₽ Men's insulated jacket zc1284, casual jacket with stand-up collar, wholesale, autumn-winter9 2019

00003

Seller Reliability 55%

-1

%

2 860 ₽

Street japan style parrot embroidery for men baseball bomber jacket with stand collar 2020 new ankle boots with zipper lace up coat for kids 903

0

1

Seller Reliability 89%

0ratings

0orders

No photos from buyers yet

Product features

- Origin: CN9(rigin) Origin: CN

- Applicable Season: Four Seasons

- Style: Casual

- Material: Polyester

- Applicable Scene: Daily

- Closure Type: zipper

- Item Type: Outerwear & Coats

- Sleeve Style: Regular

- Thickness: STANDARD

- Hooded: No

- Outerwear Type: Jackets

- Detachable Part: NONE

- Lining Material: Polyester

- Type: Regular

- Pattern Type: Print

- Gender: MEN

- Clothing Length: Regular

- Decoration: 3D Print

- Collar: STAND

- Cuff Style: Rib sleeve

Show all

Graffitimarket - Spray paint and markers for graffiti and art

Flame Blue in Russia

120 matt colors

More details

Molotow Artist

Markers and paints for artists

More details

Molotow Acrylic-Twin

One marker for all purposes

Read more

Spray paint

Aerosol paint for any purpose

Markers

A wide range of graffiti and design toolsGas stations

All essentialsCulture

Learn moreAll receipts

New

Allcity marker blank 10mm

More details

New

Allcity marker blank 15mm

Read more

New

Allcity marker blank 30mm

More details

New

Allcity marker blank 50mm

More details

New

Marker Allcity Squeezer Slim empty 10mm

Read more

New

Marker Allcity squeezer blank 10mm

More details

New

Marker Allcity squeezer blank 18mm

More details

New

Graffitimarket x Wekman bag black

Read more

New

Allcity T-Style marker blank 20mm

More details

New

Allcity Round marker blank 8mm

More details

New

Allcity Bullet marker blank 8mm

Read more

New

Spray paint Flame Orange 600ml Thick Black

More details

All news

Molotow and Flame at a new price!

Price reduction

More details

INFINITY - Graffiti cartoon (2022)

by Enderm

More

ALL CITY - a new name in graffiti

Looking for a cost effective and reliable tagging tool?.

..

.. Read more

DOPE - large delivery, price reduction.

We are pleased to announce a large supply and price reduction...

Read more

New FAT INK Oozy Dirt

You've never seen anything like it! New from FAT INK changes the rules...

More

All brands

Arton

Many years of experience in the manufacture of aerosol enamels,...

Go to catalogFat&Skinny

The Fat&Skinny marker is a novelty from the company...

Go to catalogFlame

Flame paints are produced in Germany, where they value high...

Go to catalogGraffiti Market

Our store is not only selling products for...

Go to catalogGrog

GROG is from Italy. Tools of this brand.

Go to catalog ..

.. Molotow

Graffiti products under the Molotow brand are getting more and more every year...

Go to catalogMontana

Montana is the brand of the largest German manufacturer of aerosol...

Go to catalogMtn

First mass production of aerosol...

Go to catalogOn the run

The brand name comes from "On the run", which...

Go to catalogSpray paint Montana Black 400 ml

More details

123

New

Spray paint Arton 400 ml

More details

Cap Montana Level 1

More details

14

New

Aerosol paint Arton 600 ml

More details

Shops

Moscow Graffitimarket on Dmitrovskaya

Address

st. Novodmitrovskaya 1, p. 5 (Bakery Territory No.

9)

9) Phone

8 (800) 707-25-45

Post

Schedule

daily from 10.00 to 22.00:00

Moscow Graffitimarket on Kievskaya

Address

m. Kievskaya (Koltsevaya), Bryanskaya str., 2.

Phone

8 (800) 707-25-45

Post

Schedule

COMPLEMEN st. Upper Radishchevskaya 9a, building 1 (entrance from the courtyard)

Phone

8 (800) 707-25-45

Post office

2 0002 daily from 10.00 to 22.00

St. Petersburg Graffitimarket on Sennaya Square

Address

m. Efimova, 5

Phone

+7 (812) 407-48-94

8 (800) 707-25-45

Post

Work graphic

daily from 10.00 to 22.00

St. Petersburg Graffitimarket on Vosstaniya

Address

Pl. Uprising, st. 1ya Sovietskaya d.

Learn more