Open a 3d printing business

How to Start a 3D Printing Business

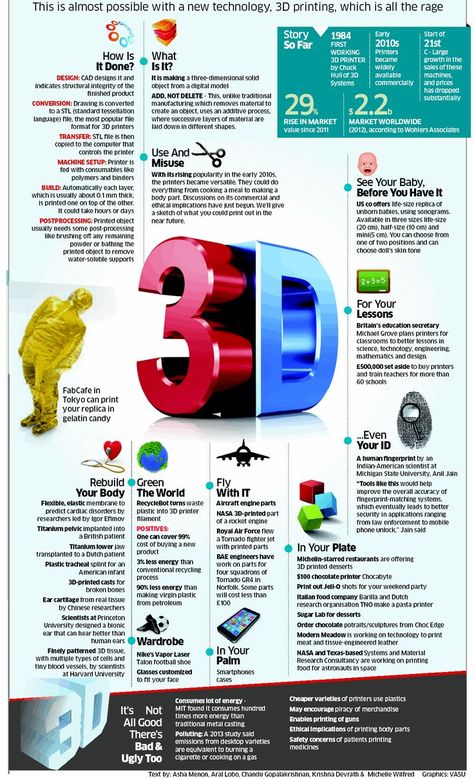

The 3D printing market value increased on average 25% per year over the last five years. Its increased market value generated a boom of interest in setting up a 3D printing business. The 3D printing industry offers different niches in which to develop a business. While each type of 3D printing business will have specific requirements to start, there is general information that can make setting up any form of 3D printing business easier.

Decide Which Kind of 3D Printer You Want to Be

3D printing can be used in a variety of different ways. As such, there are many different niches for profitable 3D printing businesses. Some examples include 3D printing prototypes and manufacturing components, setting up a local 3D printing service, and 3D printing toys.

3D Printing of Prototypes and Models

Roughly 65% of the 3D printing demand comes from engineers developing industrial, electrical, or consumer goods. Also, industries such as architecture, engineering, technology, and medicine require models of devices, manufacturing parts, and chemical compounds. These industries also typically have a section of their research and development process dedicated to testing out prototype designs or finding more efficient ways of creating a needed manufacturing part. 3D printed parts and components not only speeds up production time but also lowers cost. Therefore, dedicating a 3D printing business to helping other businesses with these needs can be quite profitable.

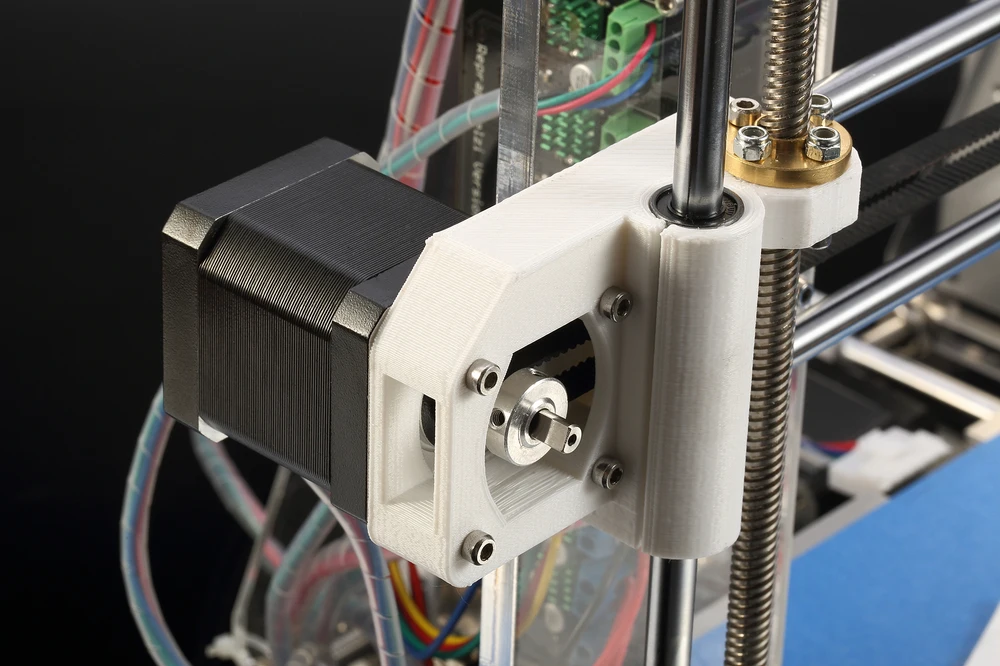

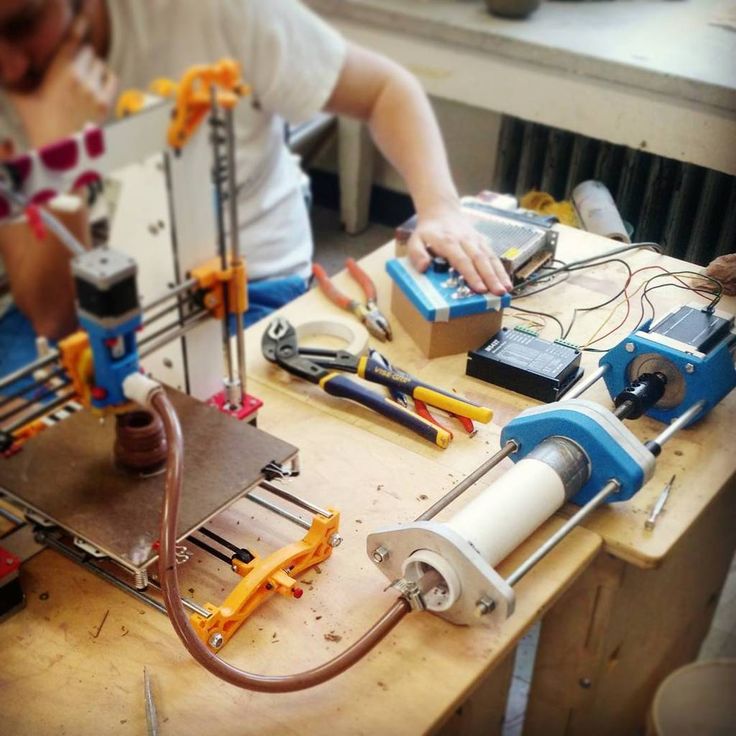

Raise 3D recently interviewed 2050.AT, a 3D printer farm to learn how 3D printing assists manufacturing. 2050.AT created 3D printed components and parts. 2050.AT explained that 3D printing is valuable for producing parts that are hard to find or expensive to produce. 3D printers make prototyping more efficient. To learn more about 2050.AT’s range of work with 3D printing, click here.

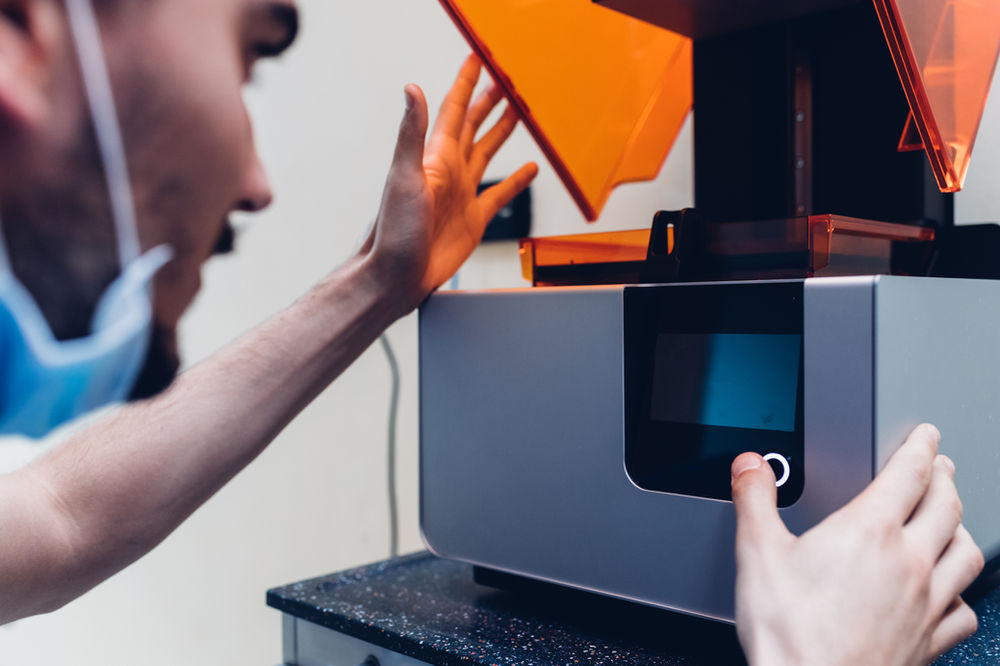

3D Printing Service

A more general idea is to establish a local 3D printing service. As we covered in the previous example, many businesses incorporate 3D printing into their production process. However, not all businesses can afford their 3D printers. In this situation, a local 3D printing service is still more efficient for these businesses than traditional research and manufacturing methods. A 3D printing service also can produce work for individuals that require their own 3d printed products. For example, students may need a 3D printed model for a school project. Or an artist may need 3D printed models or devices for art projects.

As we covered in the previous example, many businesses incorporate 3D printing into their production process. However, not all businesses can afford their 3D printers. In this situation, a local 3D printing service is still more efficient for these businesses than traditional research and manufacturing methods. A 3D printing service also can produce work for individuals that require their own 3d printed products. For example, students may need a 3D printed model for a school project. Or an artist may need 3D printed models or devices for art projects.

3D Printed Toys and Models for Children or Collectors

A third option is to 3D print toys and models of characters or clothing of a character for children, collectors, and cosplayers. For example, a helmet of a well-known character from a tv show or movie will be appealing to all three demographics.

What Kind of 3D Printing Business Can You Set Up?

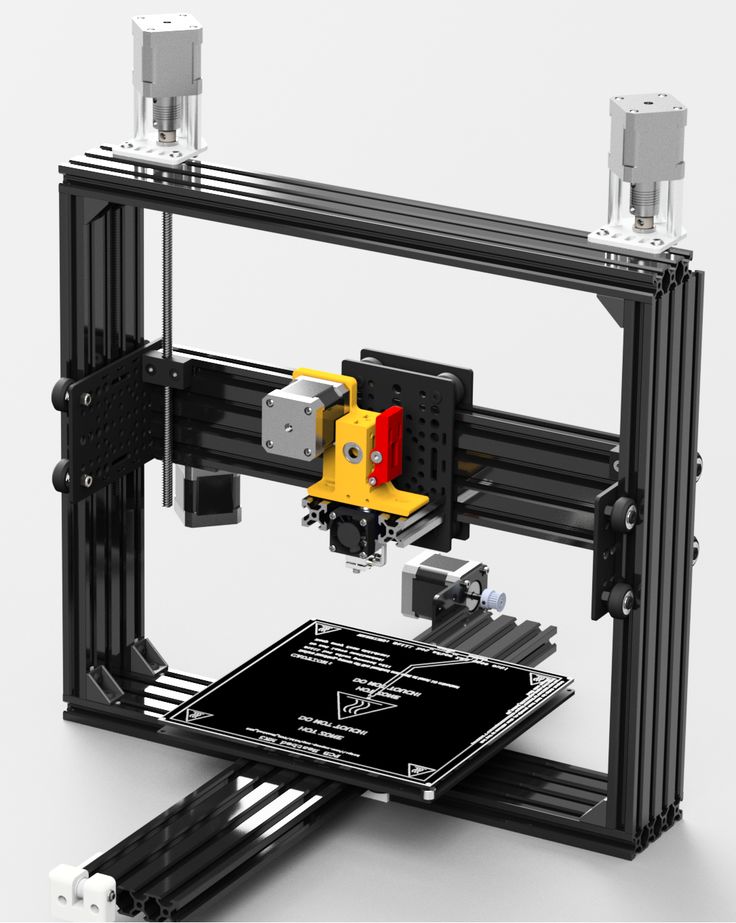

As with any new business, a 3D printing business will take time to get off the ground. Therefore, part of deciding to start a 3D printing business is knowing how much you can handle. This includes knowing your budget, knowing how much physical space you can dedicate to your business, knowing how many people will be working with you, and knowing how much time you can put into each of your projects. Since not every kind of 3D printing business is the same, each niche will have its requirements. For example, 3D printing prototypes and manufacturing parts will require larger printers with more specialized capabilities.

Therefore, part of deciding to start a 3D printing business is knowing how much you can handle. This includes knowing your budget, knowing how much physical space you can dedicate to your business, knowing how many people will be working with you, and knowing how much time you can put into each of your projects. Since not every kind of 3D printing business is the same, each niche will have its requirements. For example, 3D printing prototypes and manufacturing parts will require larger printers with more specialized capabilities.

How Much Does Starting a 3D Printing Business Cost?

The actual cost of starting a 3D printing business depends on the type of focus you choose. However, the cost of setting up a 3D printing business ranges from $1,000 to $10,000. This cost will be affected by the type of 3D printer that you choose, utilities, rent (if you choose to not work from home), software, and marketing. The cost of a 3D printer changes based on the size, capabilities, and quality that you wish to produce.

3D Printing Filaments

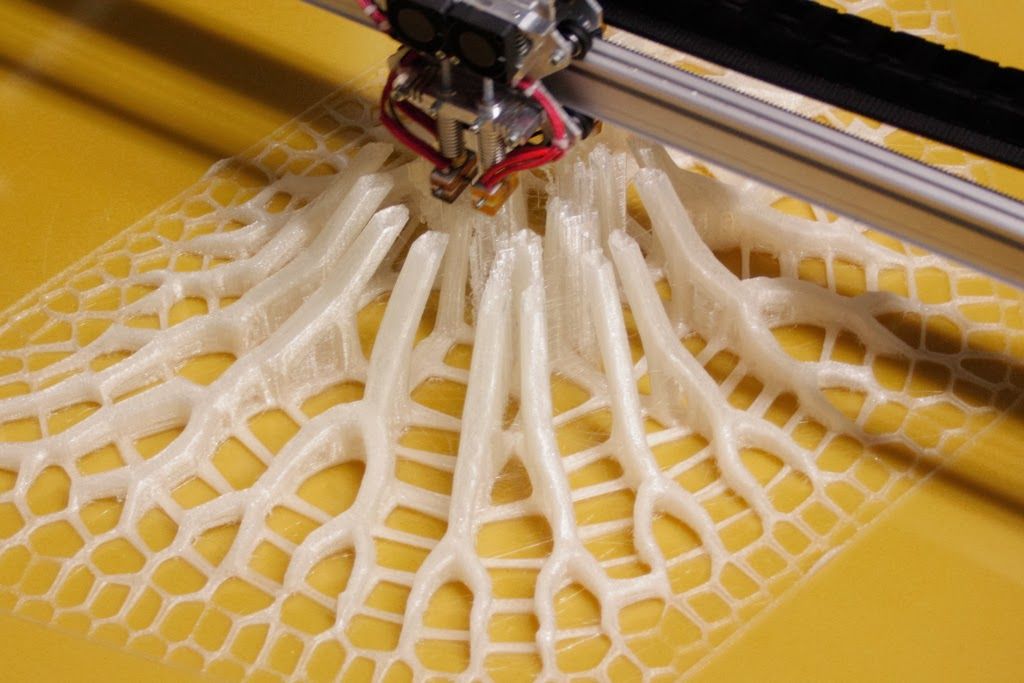

A crucial aspect of establishing a 3D printing business is in understanding the capabilities, characteristics, and differences of each printing material. The different kinds of 3d printing materials are also known as filaments. The most common filaments for 3D printing are plastics. Each plastic has its strengths which make it suitable for different projects and tasks. Sometimes a 3D printed device has many parts to it, and each part may perform better with a different kind of plastic. For example, TPU/TPE filaments are flexible sometimes to the point of being like rubber. And PLA filament is durable and easy to print.

3D Printing Competitors

Each type of 3D printing business will have its market and competitors. For example, a 3D printing service will have a local market with local competitors. Meanwhile, 3d printed toys and models will rely heavily on online sales and social media. A general suggestion for all 3D printing businesses is to find an focus on making yourself visible on the platforms where other businesses like yours appear.

A general suggestion for all 3D printing businesses is to find an focus on making yourself visible on the platforms where other businesses like yours appear.

Making Your 3D Printing Business Stand Out

All forms of 3d printing businesses are competitive, and it can be hard to know how to stand out from competitors. One way of adding value is to know how to do model design. Model design is a necessary procedure to create a 3D printed product. Many businesses contract out the model design process to another business. However, you can learn how the process of turning an image into a digital model which will be used for 3D printing. This will give you more control over your project and keep your work in-house. Another way to stand out from your competition is through post finish. Post finish means smoothing out the final 3D printed device and adding color. Deciding how far you want to go with post finish can also help you stand out from other 3D printing businesses.

3D printing offers a variety of niches to establish a profitable business. Knowing the exact details for setting up the foundations for each niche will require more specific research. However, there are some common factors for establishing any kind of 3D printing business such as learning about filaments and knowing your competitors. Once these factors are known, a strong foundation can be built for a profitable 3D printing business.

Connect with Raise3D:

Have you had a great experience with Raise3D that you would like to share? Please contact us at [email protected]. We look forward to hearing from you.

For more information about Raise3D printers and services, browse our website, or schedule a demo with one of our 3D printing experts.

How to Start a 3D Printing Business

Start » Business Ideas

Advances in 3D, or additive, printing offer endless opportunities for tech enthusiasts.

By: Andrea Forstadt , Contributor

From eyeglasses and jewelry to forensic evidence, there are several ways that your 3D printer can become the catalyst for a new business venture. — Getty Images/vgajic3D printing, also known as additive printing, is an industry that continues to innovate and grow, offering a multitude of opportunities for the aspiring entrepreneur to print designs on demand. This technology-driven discipline utilizes computer aided design (CAD) and a specialty printer to create detailed solid (3D) objects, primarily using thermoplastics and a growing list of materials, through a sophisticated layering method that allows items of any shape or size to be created with precision.

3D printing is environmentally efficient, known for producing zero waste, and it is a lower cost option than traditional manufacturing. It is expected that by 2025, the global 3D printing and services market will reach $50 billion. Starting a small 3D printing business requires a 3D printer, as well as plastic filament reels and design software for beginners. Identifying your niche and allowing for personalization is key. The businesses below are primed for at-home startup and offer something for every interest and expertise.

Starting a small 3D printing business requires a 3D printer, as well as plastic filament reels and design software for beginners. Identifying your niche and allowing for personalization is key. The businesses below are primed for at-home startup and offer something for every interest and expertise.

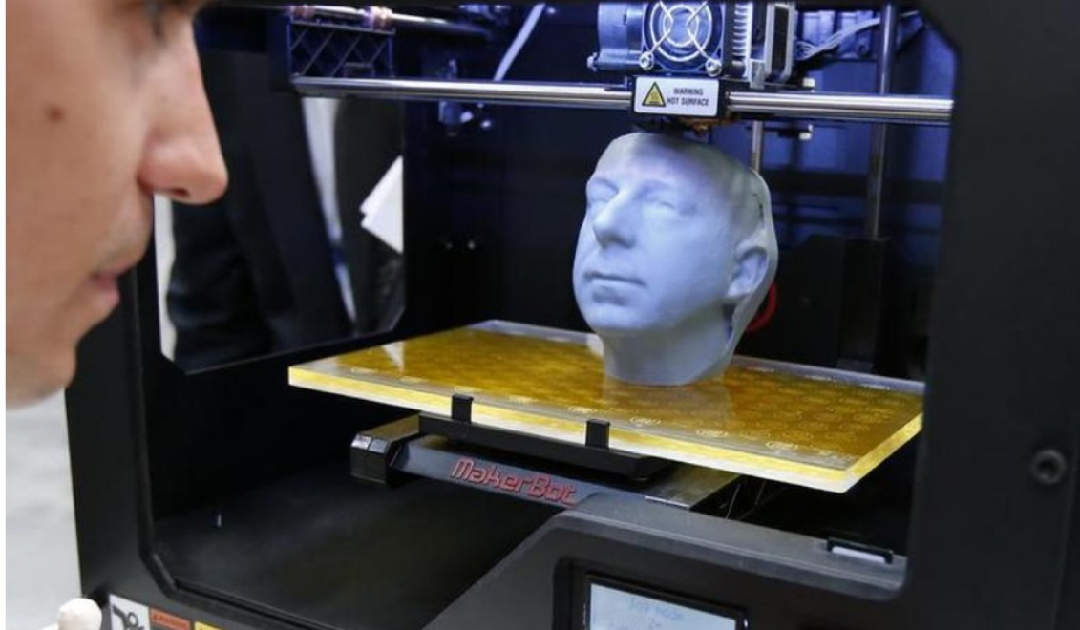

Prototypes

You can build a successful 3D printing business by producing prototypes for others with a quick turnaround time. Entrepreneurs with a vision or design that they hope to bring to life look to 3D printing experts for rapid, lower cost options for product development compared to traditional manufacturing methods. There are a lot of prototype production services, so building an expertise and a solid reputation in a particular niche could be beneficial. You can increase your success if you are an engineer and are adept at retooling, refining and offering ways to improve upon a design.

Eyeglasses

The growth in popularity of customization has had a major impact on the eyeglass market. Eyeglasses wearers can drive the design process for 3D eyeglasses, creating distinctive frames that fit their style and comfort needs through measurements taken by a 3D scanner. The category, from reading glasses to sports goggles, is expected to see significant growth, worth a projected $500 million by the end of 2027. Considering 45% of eyewear goes unsold and is discarded each year, 3D printed eyewear presents a lot of efficiencies for manufacturing and the environment. The nylon powder used to make 3D eyewear can be reused, eliminating waste unlike traditionally made eyewear.

Eyeglasses wearers can drive the design process for 3D eyeglasses, creating distinctive frames that fit their style and comfort needs through measurements taken by a 3D scanner. The category, from reading glasses to sports goggles, is expected to see significant growth, worth a projected $500 million by the end of 2027. Considering 45% of eyewear goes unsold and is discarded each year, 3D printed eyewear presents a lot of efficiencies for manufacturing and the environment. The nylon powder used to make 3D eyewear can be reused, eliminating waste unlike traditionally made eyewear.

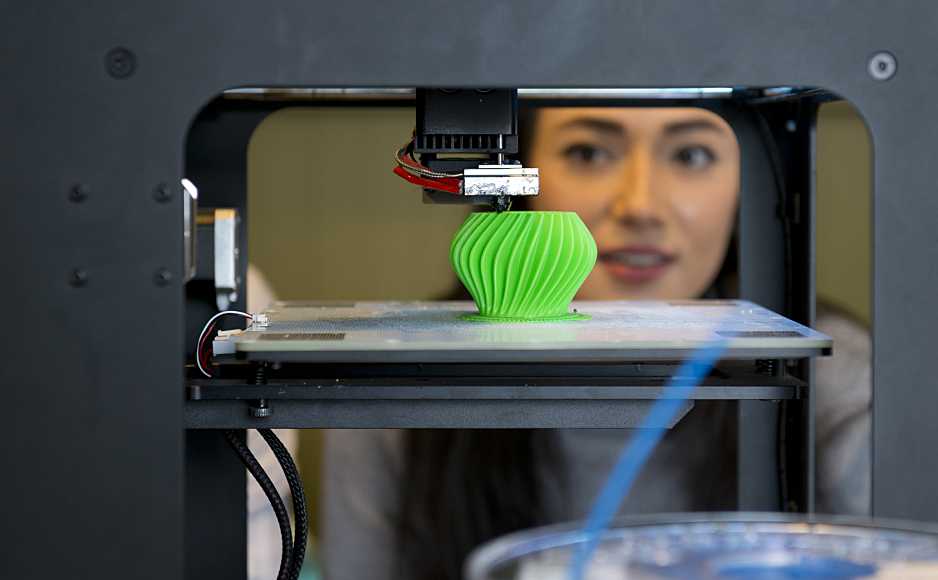

Toys

Toys are among the easiest items to create with 3D printing and are sought-after items among those who are always looking to add to their doll, action figure, fidget spinner, toy car/truck and bath toy collections. Chess or board game pieces are hot 3D printed items that enhance the gaming experience via customization and personalization. Of course, 3D printing also has great implications for toy replacements and replacement parts — after all, who wouldn’t want to be a hero in salvaging a child’s beloved doll or action figure? But there are also safety regulations and copyright laws to consider. While intellectual property laws often consider items produced for private means to be fair trade, copying trademarked or patented proprietary designs can lead to legal action and penalties.

While intellectual property laws often consider items produced for private means to be fair trade, copying trademarked or patented proprietary designs can lead to legal action and penalties.

Jewelry

More and more jewelry designers are using 3D printing to produce their pieces, from rings to bracelets to earrings. Between 2020-2024, the 3D jewelry business is forecasted to grow by $1.95 billion, a 21% compound annual growth rate (CAGR). The popularity can be attributed to the efficiency in creating intricately detailed designs and the significantly quicker production times. There are 3D jewelry printers that allow for casting and are better able to utilize metals, nylons and other materials specific to jewelry making. Oftentimes, designers will start with a plastic model and make adjustments to the design until perfect and then produce the piece in metal. To get started, 3Design, Matrix and JewelCAD all offer design software specifically for jewelry printing. For those who prefer to focus solely on the design process and leave the 3D printing to someone else, there are several services who will take your 3D design model and produce the finished product.

The legal arena has had an increased demand for 3D printing that can help to recreate anything from defective products in liability cases to crime scenes in criminal cases.

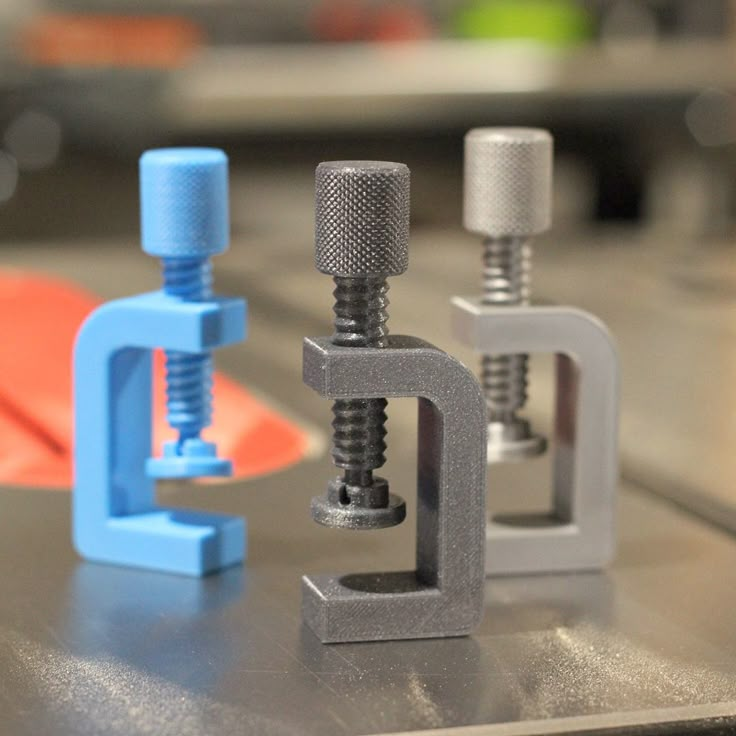

Spare parts

Specializing in 3D printing of spare parts can be very lucrative. Manufacturers are often faced with the challenges producing spare parts present in terms of cost and inventory. Many simply do not have the space to house all the parts that go into assembling their products or the budgets that are required to make and stock them. Add to that the delays in ordering parts from overseas and the impact that has on customer relationships and businesses can find themselves in trouble when repairs or replacements are needed. One solution is for manufacturers to digitize a catalog of parts that can be printed on demand. As a small business specializing in spare parts, you can be the source for local service providers and tradespeople to look to when a replacement or special fitting is required. Decentralizing manufacturing helps to shorten or eliminate the carbon footprint of transporting parts, a major advancement toward greater sustainability.

Decentralizing manufacturing helps to shorten or eliminate the carbon footprint of transporting parts, a major advancement toward greater sustainability.

Promotional products

If you have ever tried to order custom items for promotional purposes or for an event, the minimum quantities required often make it prohibitive and the long lead times mean merchandise takes weeks, if not months, to arrive. Enter 3D printing. With a 3D printer, you can get the word out to local businesses, politicians, families and schools that you have the ability to turn around products that creatively brand their messages, businesses, parties/events and travels in no time, without minimum quantities. Promotional goods are expected to represent over $15 billion in sales in 2021. Eco-friendly products and work-from-home goods are among the hottest trends in promotional items. While most businesses will already have established logos and graphics from which to work from, if you happen to have graphic design skill, you can leverage that for greater profitability.

Printer rental

With the cost of a 3D printer averaging around $1,000, many entrepreneurs who would like to explore implications of the technology on their ideas just don’t have the money to invest and test. There is also a market for those in need of short term access for a small scale project. If you have the resources, you can make considerable money renting or leasing out your 3D printer and materials to commercial and residential customers. Start with a Google Business listing, a website with photos, social media advertising and word-of-mouth brand building. It’s a good idea to differentiate the pricing between private customers and commercial businesses. Weekly rentals could garner a couple hundred per week or $500-$600 monthly, plus cost of supplies and training.

Home decor

For those with a passion for home decor, 3D printing lends itself well to the housewares market. Vases, lamps, planters, photo frames, dishes, drinkware, placemats and cutlery are all easily produced through additive printing. Complex designs with unique textures and finishes can be printed with relative ease. The key is to develop a unique aesthetic and define your niche. Set up an e-commerce site from which to feature your designs and then print on demand to customer specs. At the same time you can leverage existing traffic on sites like Etsy where customers are always looking for interesting and unique home decor that reflects their personal style and a desire for one-of-a kind items.

Complex designs with unique textures and finishes can be printed with relative ease. The key is to develop a unique aesthetic and define your niche. Set up an e-commerce site from which to feature your designs and then print on demand to customer specs. At the same time you can leverage existing traffic on sites like Etsy where customers are always looking for interesting and unique home decor that reflects their personal style and a desire for one-of-a kind items.

Smartphone cases

Smartphone cases are one of those accessories that people often like to reflect their personality or tastes. They are also something people quickly tire of and like to change up often, however valuing protective features remains a constant in their purchasing decisions. If you have a good eye for what’s trending in design, fashion and pop culture and can design to the tastes and interests of customers while offering protective features and materials, a 3D smartphone printing business can be a great small business opportunity. In 2019, the global revenue for protective smartphone cases was $21.67 billion with an expected CAGR of 6.3% between 2019-2027. On average, one large spool of filament makes approximately 200 smartphone cases and there are many variations of filaments, depending on the type of case and durability desired.

In 2019, the global revenue for protective smartphone cases was $21.67 billion with an expected CAGR of 6.3% between 2019-2027. On average, one large spool of filament makes approximately 200 smartphone cases and there are many variations of filaments, depending on the type of case and durability desired.

Forensic evidence

Dream job alert for "CSI" or "Law & Order" fans: The legal arena has had an increased demand for 3D printing that can help recreate anything from defective products in liability cases to crime scenes in criminal cases. Imagine being tasked with 3D printing the fingerprints of a suspect or cars that can be used to simulate an accident. Many medical malpractice suits require anatomically correct body parts and can garner hundreds, if not thousands, of dollars to bring to life.

CO— aims to bring you inspiration from leading respected experts. However, before making any business decision, you should consult a professional who can advise you based on your individual situation.

Follow us on Instagram for more expert tips & business owners stories.

To stay on top of all the news impacting your small business, go here for all of our latest small business news and updates.

CO—is committed to helping you start, run and grow your small business. Learn more about the benefits of small business membership in the U.S. Chamber of Commerce, here.

Subscribe to our newsletter, Midnight Oil

Expert business advice, news, and trends, delivered weekly

By signing up you agree to the CO— Privacy Policy. You can opt out anytime.

Published March 18, 2021

90,000 BUSINESS for 3D printing-How can you earn on a 3D printerContent

- 3D printing

- Small-service production

- 3D-printing medical products

- 3D objects

What successful business can be opened using 3D printers? I will make a reservation right away that so far there are few such examples. I'll tell you about some of them.

I'll tell you about some of them.

3D printing studio

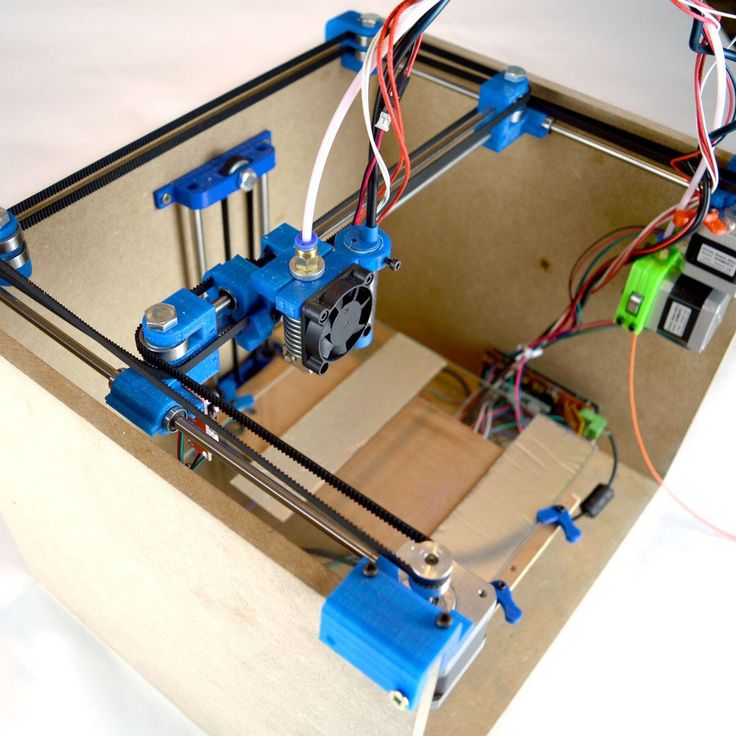

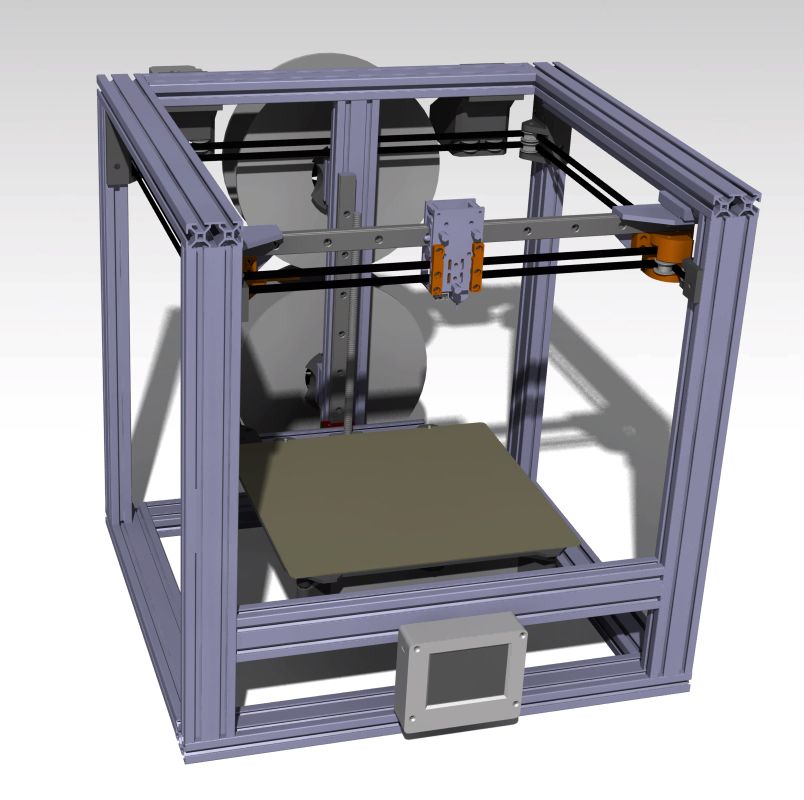

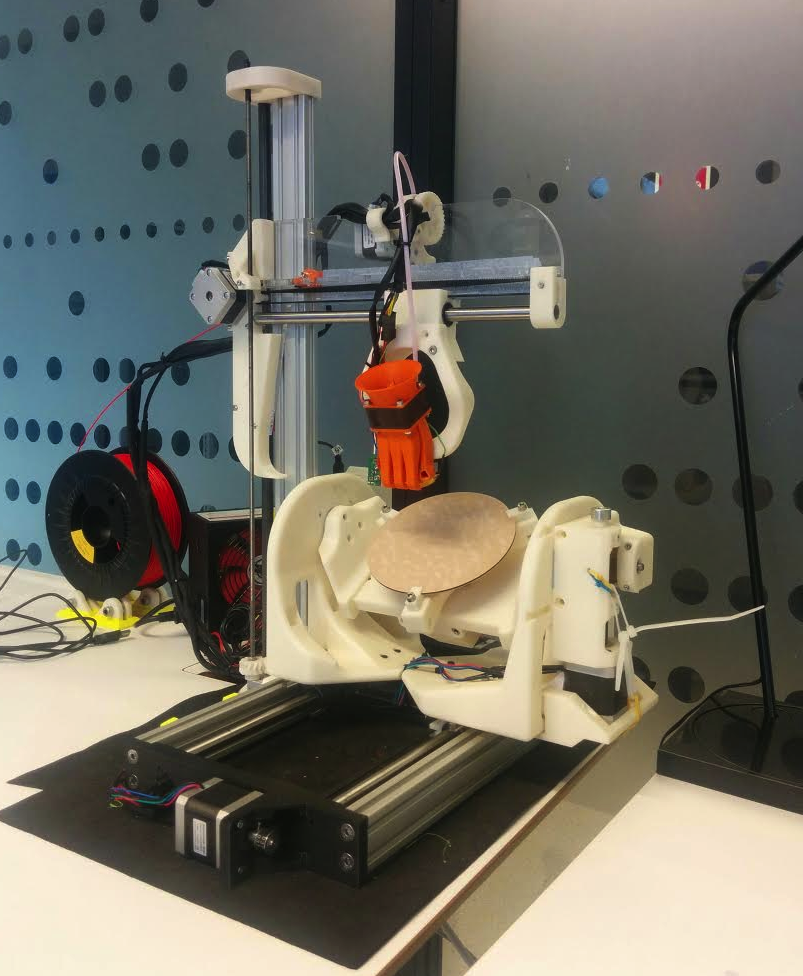

The first thing that comes to mind is the creation of a 3D printing studio. Its business model is based on modeling and printing models for the client. The main success factor is to ensure a consistently high level of equipment utilization. For such a project, it is more important to focus on mass replication than on printing single copies, even in large volumes. The cost of printing a small model should be low, and labor costs large. The main production processes are the high-quality development of printing technology for each specific detail or project, the selection of the right material. The client model is checked for errors, and both the material and the printer are selected. It remains to agree on the price and, in fact, print the model. It is necessary to approve it with the customer, and, if necessary, modify it.

You can build such a studio with almost any level of investment: start with one or two printers, gradually increase the fleet of equipment, or immediately invest in a fleet of 3D printers. You can also purchase industrial equipment for functional prototyping and small-scale production. But in any case, the most important thing is to correctly build the business model of the enterprise.

You can also purchase industrial equipment for functional prototyping and small-scale production. But in any case, the most important thing is to correctly build the business model of the enterprise.

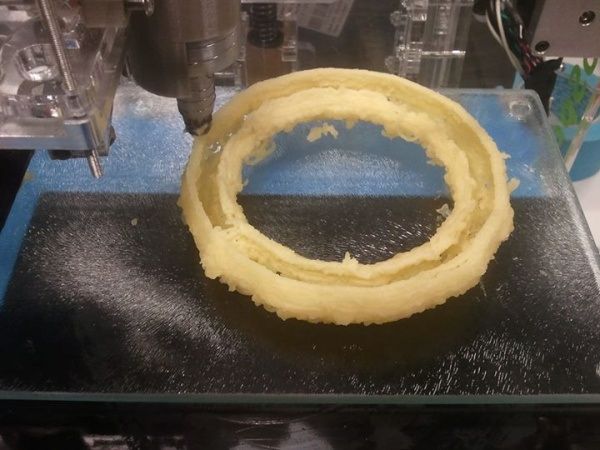

Small batch production

The second most popular business idea is a studio focused on small-scale production. In this case, the main task is not to find a client, but to understand what product will be in demand. There are many examples of such studios, and their success primarily depends on the quality and originality of the products offered. For clarity, consider the production of molds for the manufacture of confectionery. They are easy to model, customize, print and sell. The target audience of this product is clear and stable, the product is easily promoted in social networks, the cost is low, and the most budget 3D printers are suitable for production. The main thing here is the optimal ratio of the number of devices with production volumes. Another popular example: accessories for gamers. Game weapons, masks, costume elements from computer games for cosplayers. The product is not so massive, but consistently in demand, and its price niche is significantly higher. More time will be spent on modeling and printing, but in return you get markets around the world, since the studio is not limited to the location of your region.

Game weapons, masks, costume elements from computer games for cosplayers. The product is not so massive, but consistently in demand, and its price niche is significantly higher. More time will be spent on modeling and printing, but in return you get markets around the world, since the studio is not limited to the location of your region.

Add to compare

Product added to compare Go

| Manufacturer | Creality |

Free shipping

Add to compare

Product added to compare Go

| Manufacturer | FlashForge |

Free shipping

Add to compare

Item added to compare Go

| Manufacturer | Phrozen |

Free shipping

Add to compare

Product added to compare Go

| Manufacturer | PICASO 3D |

Medical 3D printing

The third option for a 3D printing studio is medical. Today it is very much in demand. Prostheses, orthoses, orthopedic insoles, hearing aids, temporary crowns, aligners, spectacle frames are complex in conventional production, but our technologies greatly simplify this process. The equipment here is selected based on the specific task. Usually one company is focused on printing a particular line of models. The accumulated experience allows you to create a product with unique properties as efficiently as possible. In this direction, business goes in tandem with science. The success of the enterprise directly depends on innovative approaches in orthopedics and medicine in general.

Today it is very much in demand. Prostheses, orthoses, orthopedic insoles, hearing aids, temporary crowns, aligners, spectacle frames are complex in conventional production, but our technologies greatly simplify this process. The equipment here is selected based on the specific task. Usually one company is focused on printing a particular line of models. The accumulated experience allows you to create a product with unique properties as efficiently as possible. In this direction, business goes in tandem with science. The success of the enterprise directly depends on innovative approaches in orthopedics and medicine in general.

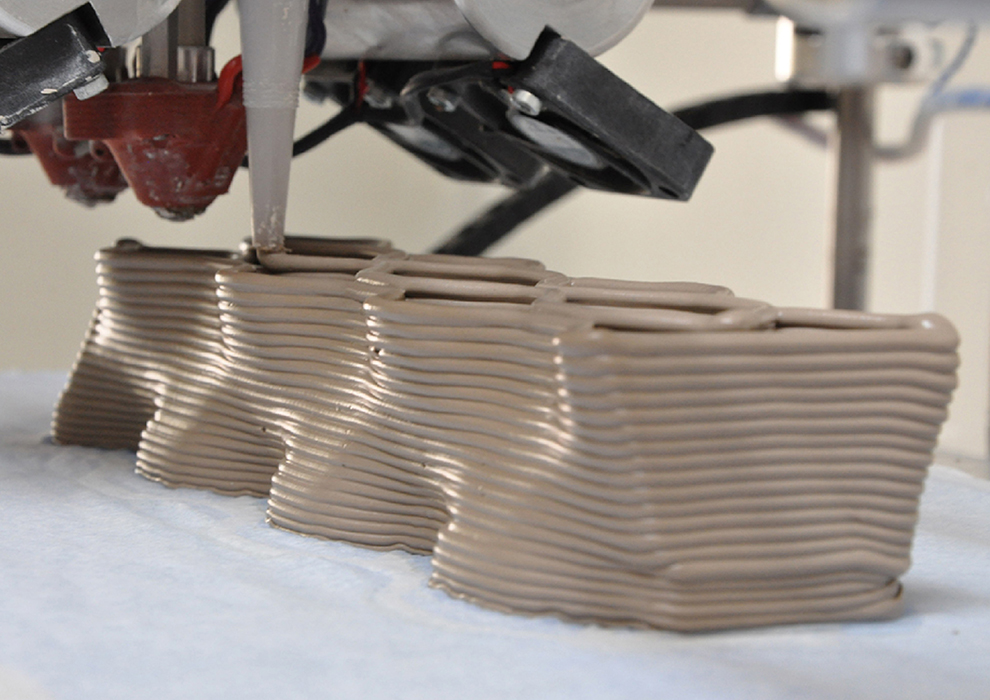

3D printed art objects

Fourth place will be given to art. 3D printing of sculptures is another way to capitalize on this technology. Creating a large art object is not an easy task, and certainly not a cheap one. However, many interiors or public spaces are in need of an aesthetic upgrade. Modern sculptors began to use the new technology in their work precisely to create final products, and not prototypes or layouts, as one might think. To achieve this goal, large-format printers using FDM technology (the model is formed from molten plastic) are needed. Typically, a computer model is divided into parts and printed on several 3D printers, after which it is glued, sanded, primed and painted in the desired colors, sometimes with the addition of texture. This makes the sculpture almost indistinguishable from those made from natural materials.

To achieve this goal, large-format printers using FDM technology (the model is formed from molten plastic) are needed. Typically, a computer model is divided into parts and printed on several 3D printers, after which it is glued, sanded, primed and painted in the desired colors, sometimes with the addition of texture. This makes the sculpture almost indistinguishable from those made from natural materials.

Another option is to show the model in full size, without post-processing, which allows viewers to see the 3D printed model at different stages of its creation.

It is difficult to fit into a short article all the variety of opportunities that 3D printing offers to enthusiasts of this technology, but we see that every day there are more and more new interesting stories of its application. It gives impetus to the development of new technologies and brings innovation to seemingly established areas such as the creation of sculptures or gingerbread. As the American inventor Chuck Hull, who patented the first 3D printer, said: “I don’t have a crystal ball that will tell me what should happen in the future, but one thing I know for sure: when smart people work on a specific task, they gradually move forward. forward".

As the American inventor Chuck Hull, who patented the first 3D printer, said: “I don’t have a crystal ball that will tell me what should happen in the future, but one thing I know for sure: when smart people work on a specific task, they gradually move forward. forward".

Alexander Kornweitz,

Founder and CEO of Tsvetnoy Mir

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Raise3D |

Free Shipping

Add to Compare

Product added to compare Go

| Manufacturer | CreatBot |

Free shipping

Add to compare

Product added to compare Go

| Manufacturer | Raise3D |

Free Shipping

Add to Compare

Product added to compare Go

| Manufacturer | PICASO 3D |

Russian entrepreneur, expert in the field of additive technologies and 3D equipment. Founder and head of the Tsvetnoy Mir company and the Center for Innovative 3D Printing Best3D Print.

Founder and head of the Tsvetnoy Mir company and the Center for Innovative 3D Printing Best3D Print.

3D printing business ideas

Blog navigation

Article search

Categories

Latest articles

Popular articles

-

How to draw with a 3D pen?

12/16/2015

16537 views

Connect the 3D pen and let it warm up for a few seconds. Insert ABS or PLA filament into feed hole...

Read more

-

10 improvements for your Ender-3

Posted in: Basics of 3D printing, 3D Printing Tips and Tricks

22.09.2021

11681 views

10 inexpensive upgrades to improve the stability, performance and security of Ender 3 - the most popular...

Read more

-

Top 20 interesting toys for children on a 3D printer.

Posted in: 3D printing

02/15/2022

11309 views

What kind of toys can be created on a 3d printer? What are the advantages of 3d printing toys at home? In this article you will find...

Read more

-

3D Printing Delamination - 5 Tips and Tricks to Avoid Delamination

Posted in: 3D printing tips and tricks, 3D printing

05/14/2019

11237 views

If you have owned a 3D printer for a while, then you are probably used to solving many problems. Delamination is...

Read more

-

History of 3D pen

Posted in: Basics of 3D printing, Draw 3D

03/21/2019

9695 views

The advent of the 3D pen has led to some areas of art that were previously impossible.

In this article we...

In this article we... Read more

Read all articles

Recommended articles

Article archive

Startup ideas and success stories of 3D printing around the world.

-

Why it's easier to succeed with a 3D printer than you think.

Posted in: 3D Printing Business Ideas

Business case with a 3D printer. Why the first steps in such a business are much easier to take than in any other.

-

3D printed buildings of the future. Killa Design.

Posted in: We print 3D, 3D Printing Business Ideas

Killa Design uses 3D printing to create iconic designs that are quickly becoming landmarks, including one of the most complex structures ever built.

-

You won't believe these dolls are 3D printed.

Posted in: We print 3D, 3D printing business ideas

Articulated dolls are a fairly common hobby not only for children, but also for adults.

A success story about turning a hobby into a business idea with a 3D printer.

A success story about turning a hobby into a business idea with a 3D printer. -

Yves Behar made household items from recycled wood using 3D printing.

Posted in: We print 3D, 3D Printing Business Ideas

Wood sawdust is mixed with natural tree sap, which acts as a binder, and 3D printed into a complex swirling geometry of exclusive and natural home furnishings.

-

How are 3D printers used in light industry?

Posted in: We print 3D, 3D printing business ideas

There is such a thing as functional testing. Before putting any new product into mass production, it is necessary to find out possible flaws in operation. For this purpose, an exact copy of the product is created on a 3D printer, after which it is used for its intended purpose under various conditions.

-

How to make money on 3D printing?

Posted in: 3D printing tips and tricks, 3D printing business ideas

Prospects for using 3D printing in dentistry, limb prosthetics, souvenirs, building construction, etc.

-

The world's first 3D printed settlement in Latin America

Published in: 3D printing news, 3D Printing Business Ideas

Designer Yves Béhart unveiled plans to build 3D printed homes for an impoverished farming community in Latin America.

-

How are 3D printers used in the automotive industry?

Posted in: We print 3D, 3D printing business ideas

Application of 3D printers in the automotive industry, use of 3D printing technology for prototyping and small-scale production

-

Young entrepreneur aspires to send 3D printed rockets into space

Los Angeles-based Relativity Space has already printed nine rocket motors and three second stages for its model rocket, called the Terran 1, with a first test flight scheduled for late 2020 of the year.

-

DePuy Synthes builds €36 million 3D printing center

Johnson & Johnson franchise invests €36 million in research and development to establish a 3D printing development and launch center in Ireland.

Learn more